GO THE DISTANCE.

FW83/XA-231

OWNERS MANUAL

FIFTH WHEEL

TECHNOLOGY

XL-FW418-01 Rev C

LowLube

Fifth Wheel

• Operation Instructions

• Maintenance Procedures

QUESTIONS OR COMMENTS?

CALL 1-888-396-6501

www.safholland.us

GENERAL SAFETY INSTRUCTIONS

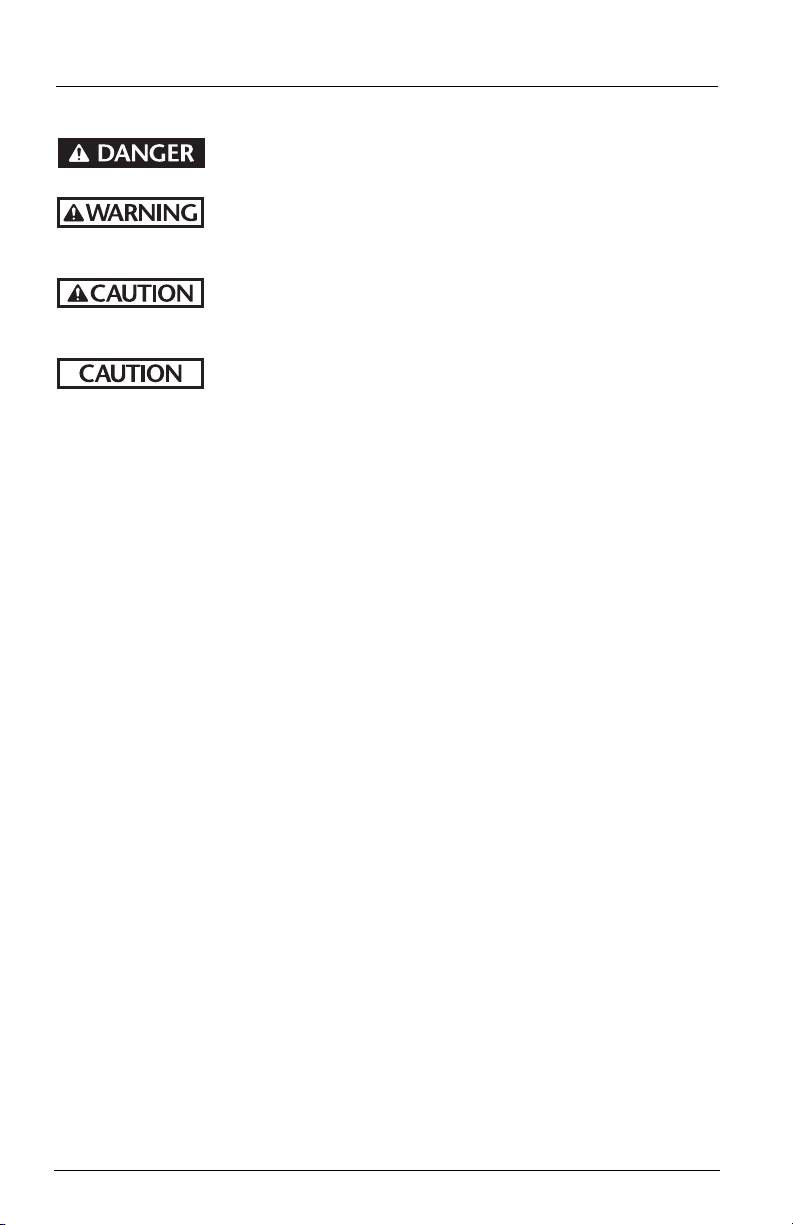

Safety Signal Words

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

h, if not avoided, could result in death or serious

whic

injury.

CAUTION indicates a potentially hazardous situation

whic

h, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which,if not avoided,

may result in property damage.

1. Keep Work Area Clean

Cluttered areas and benches invite accidents.

2. Keep fingers away from all potential pinch points in the fifth wheel.

3. All fifth wheel maintenance m

technician using proper tools and safe procedures.

4. Use only SAF-HOLLAND original parts.

5. Use Safety Goggles

Glasses or goggles not in compliance with ANSI or CSA can cause

ious injury when damaged or broken.

ser

6. Wear Proper Apparel

Do not wear loose clothing, gloves,neckties,jewelry (rings, wristwatches,

etc.) that can get caught in moving parts. Non-slip footw

ust be performed by a qualified service

ear is recommended.

FIFTH WHEEL DESIGN AND INTENDED USE:

Holland Fifth Wheels are Designed and Intended to Be Used:

1. For pulling trailers with standard SAE kingpins which are in good

condition and securely mounted or locked in position in the trailer.

2. Within the capacities stated in SAF-HOLLAND literature.

3. As recommended in SAF-HOLLAND literature (available from

.safholland.us).

www

Holland Fifth Wheels are NOT Designed or Intended For:

1. Use with non-SAE kingpins, such as kingpins which are bent, improper

size or dimensions, not securely maintained to SAE configuration, or

which are installed in warped trailer bolster plates.

2. Tow-away operations which damage or interfere with the proper

ation of the fifth wheels.

oper

3. The attachment of lifting devices.

4. The transport of loads in excess of rated capacity.

5. Applications other than recommended.

2

XL-FW418-01 Rev C

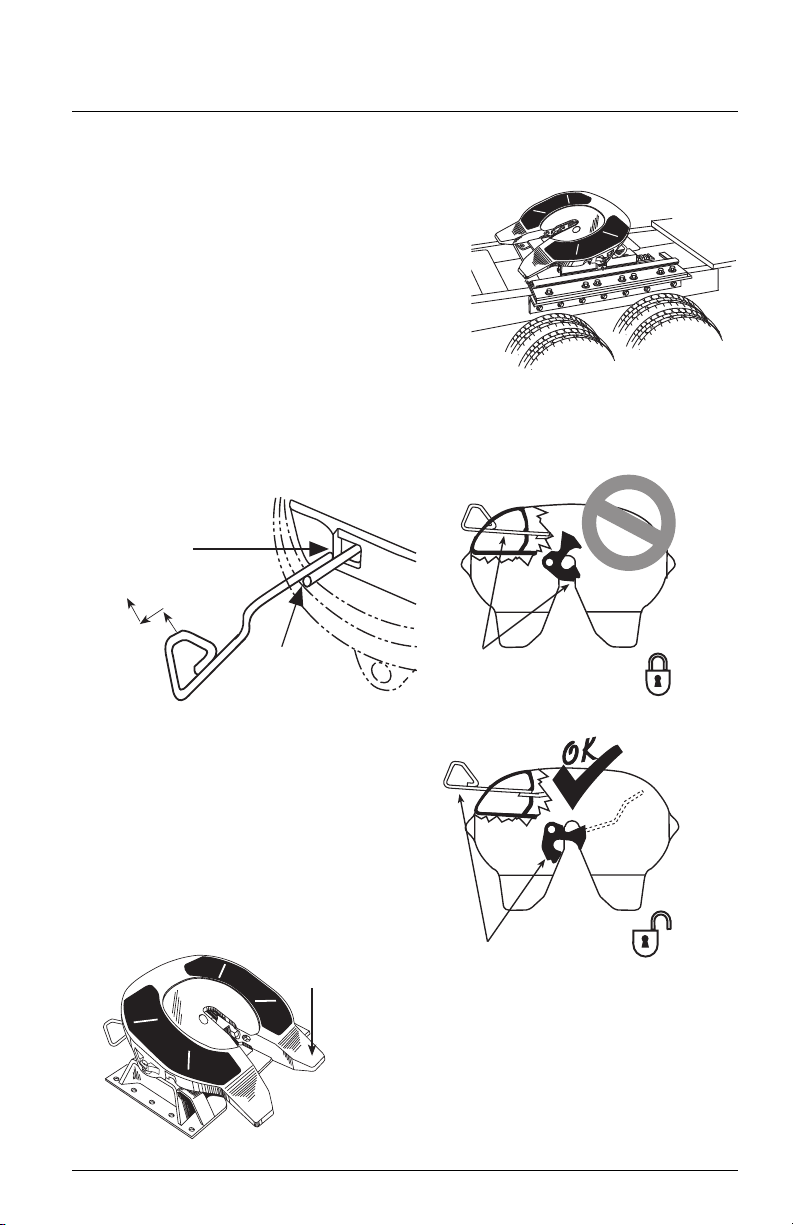

OPERATING

UNLOCK

NOTCH

LOCK NOTCH

1st

2nd

3rd

TILT

DOWNWARD

OPEN

“Ready to Couple”

CLOSED

Wheel is Locked!

DO NOT

Attempt to Couple!

INSTRUCTIONS

FIFTH WHEEL INSPECTIONS

1. Inspect the fifth wheel and mounting.

• Confirm that the lube plates are

in place and firmly attached.

• Tighten loose fasteners.

• Replace missing fasteners.

• Repair/replace missing, cracked or

otherwise damaged components.

2. Make sure the lock is open. To open lock,pull secondary

k handle and hook on casting if equipped.Then pull

loc

primary release handle as shown.

3. Inspect the lock jaw; if it appears dry,

4. Tilt the ramps down.

XL-FW418-01 Rev C

apply grease to loc

k jaw and front of

throat directly,or through the lube

tube grease fitting located near the

front, left side of the fifth wheel.

LUBE

TUBE

3

OPERATING

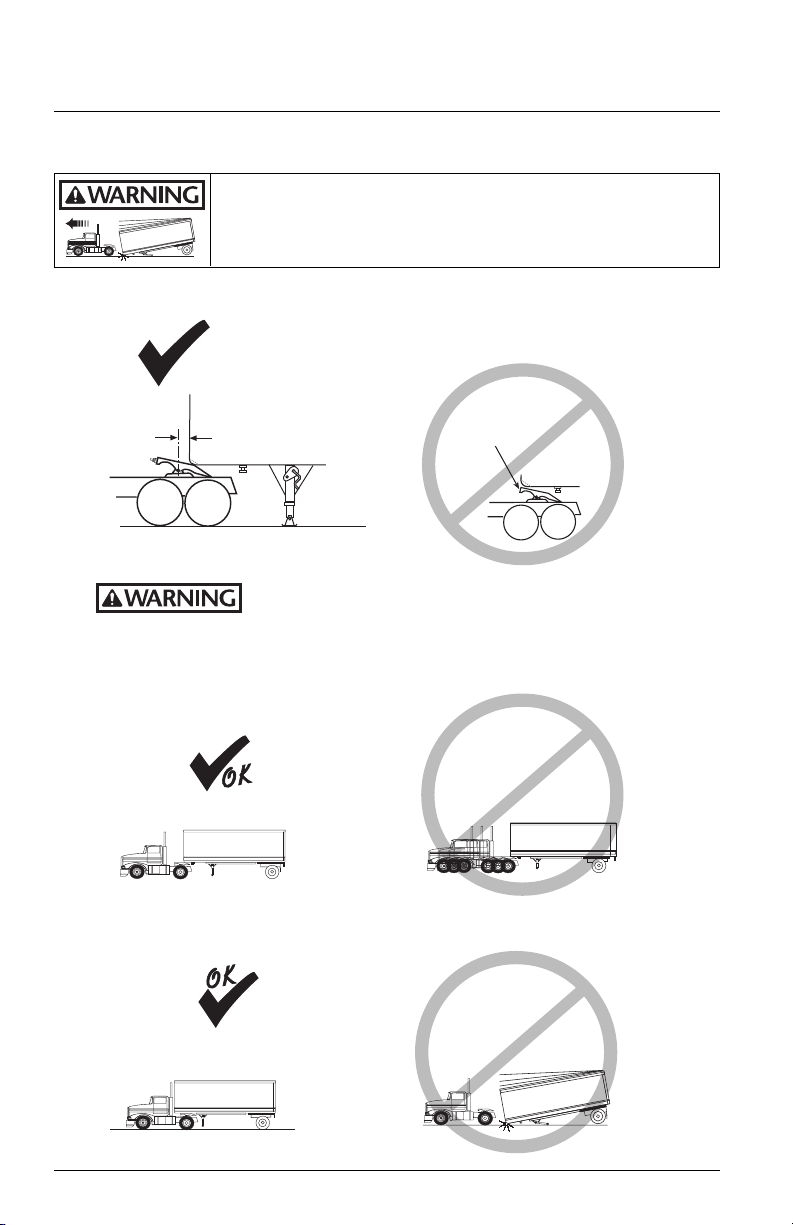

✔

CHAMPHERED (Prefered)

or LARGE RADIUSED

LEADING EDGE

20°

2˝

min.

40˝

6˝min.

6˝min.

Keep bolts and nuts

clear of this ar

ea

Keep path of fifth

wheel free of

large holes

& gouges

✔

MAKE SURE

THERE ARE NO

SHARP EDGES

NO ABRUPT TRANSITIONS

IN ELEVATION

ACCESS

HOLE

✔

NO!

FULL

CONTACT

INSTRUCTIONS

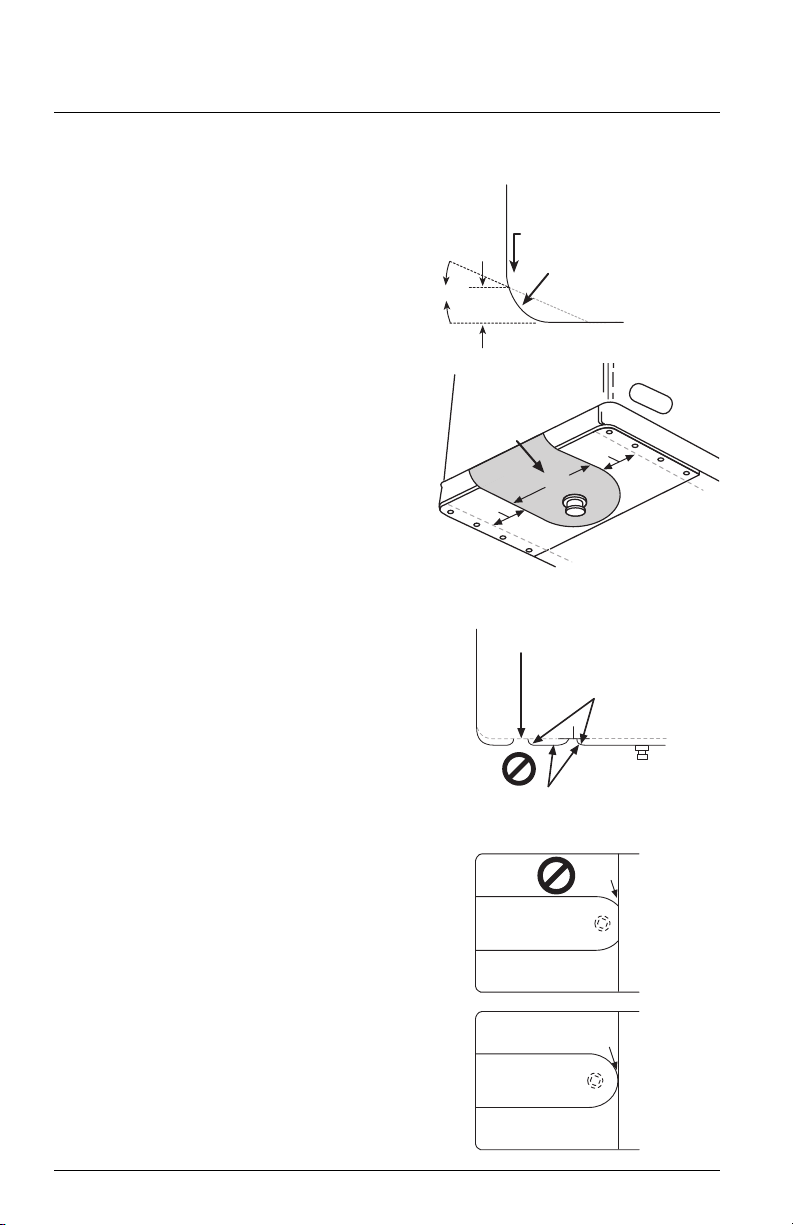

TRAILER UPPER COUPLER INSPECTIONS

1. Inspect the leading edge of the trailer

bolster/skid plate. It must be free of

any square or sharp edges.

2. Make sur

e that there are no bolts or

nuts extending below the bolster/skid

plate within 6˝ of the fifth wheel

travel path while coupling.

3. The area that is supported by the fifth

wheel should be fr

ee of any large holes

or gouges.

4. Any access holes that the fifth wheel

passes belo

w should have chamfered

or radius edges.

5. Check that any splits from the skid

plate to bolster plate ar

e welded

adequately and that there are no sharp

edges or abrupt changes in elevation.

6. The upper coupler should extend

adequatel

y rearward to maintain full

contact with the fifth wheel during

tight turning. If it does not, at a

minimum, the rear edges should be

chamfered or radius edges.

7. Make sure that any upper coupler

esidual grease is free of heavy

r

coarse grit.

8. Ensure that the upper coupler fifth

wheel contact surf

Do not paint contact area! The

ace is free of rust.

area should be conditioned with rust

inhibitor such as a light oil.

9. Inspect the kingpin for excessive wear

and damag

Kingpin Gage) along with bolster bow

(see SAE 1700).

4

e (use Holland tool TF-0110

XL-FW418-01 Rev C

OPERATING

OK

TRAILER

(TOP)

KINGPIN

INSTRUCTIONS

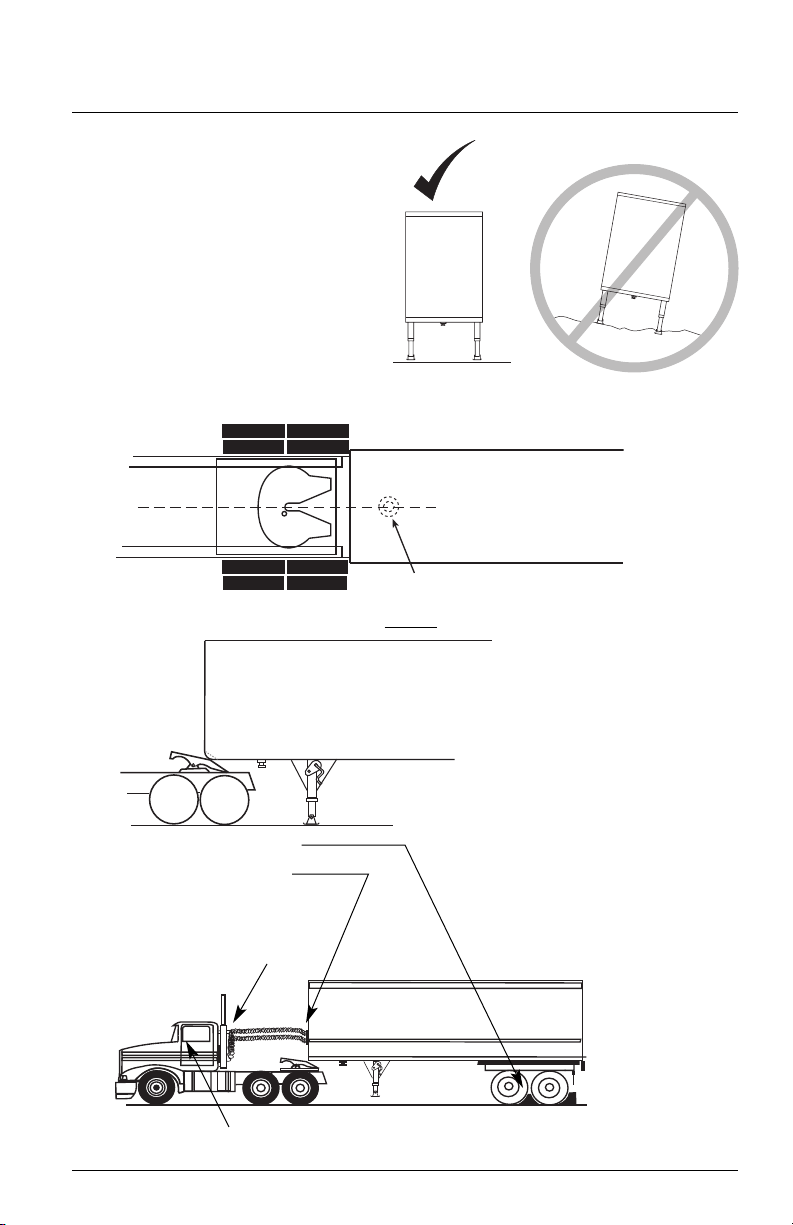

COUPLING PROCEDURES

1. Make sure coupling area is

flat, level and clear of persons

and obstacles.

2. Center fifth wheel with kingpin and back up straight.

3. Back tractor close to trailer and STOP

4. Chock tr

5. Connect brake lines

and light cord.

6. Support slac

to prevent interference.

ailer wheels.

k in lines

7. Set trailer brakes.

XL-FW418-01 Rev C

.

5

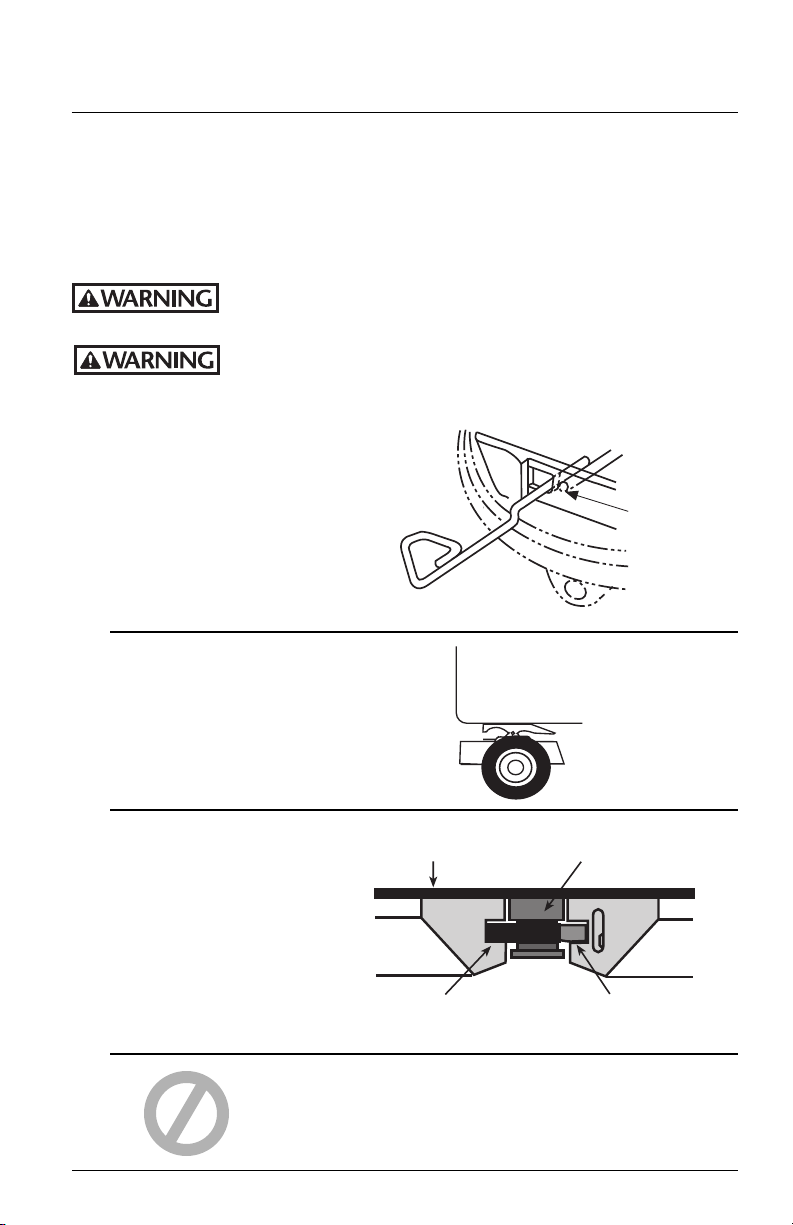

OPERATING

Wrong

FIFTH WHEEL

WILL NOT

LIFT TRAILER

BACK INTO TRAILER

SLOWLY

➠➠

OK

FIFTH WHEEL

MUST LIFT

TRAILER

➠

➠

FIFTH WHEEL

TILTED DOWN

4˝- 6˝

DO NOT

BACK INTO

TRAILER FAST

➠➠ ➠➠ ➠➠ ➠➠

➠

PULL TEST

➠

➠

PULL FORWARD WITH TRACTOR

➠

WITHOUT

PULL TEST

INSTRUCTIONS

COUPLING PROCEDURES

FAILURE TO PROPERLY INSTALL, OPERATE, OR MAINTAIN THIS FIFTH

WHEEL MAY RESULT IN TRACTOR AND TRAILER SEPARATION WHICH, IF

NOT AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

8. Adjust trailer height so fifth wheel will lift trailer. Trailer should

contact fifth wheel 4˝ – 6˝ behind fifth wheel bracket pin.

Attempting to couple with the trailer at an improper

allowing tractor and trailer separation which, if not avoided, could result

in death or serious injury.

9. Slowly back into trailer.

height may result in a false or improper coupling,

10. Do a pull test as an INITIAL CHECK.

6

XL-FW418-01 Rev C

OPERATING

LOCK

NOTCH

BEHIND

RIB

CHECK

RELEASE

HANDLE

➠

➠

CLOSED POSITION

➠

NO GAP!

PLUNGER

LOCK JAW

AROUND

KINGPIN

PLUNGER

VISIBLE AS

SHOWN

TRAILER BOLSTER

PLATE

KINGPIN

INSTRUCTIONS

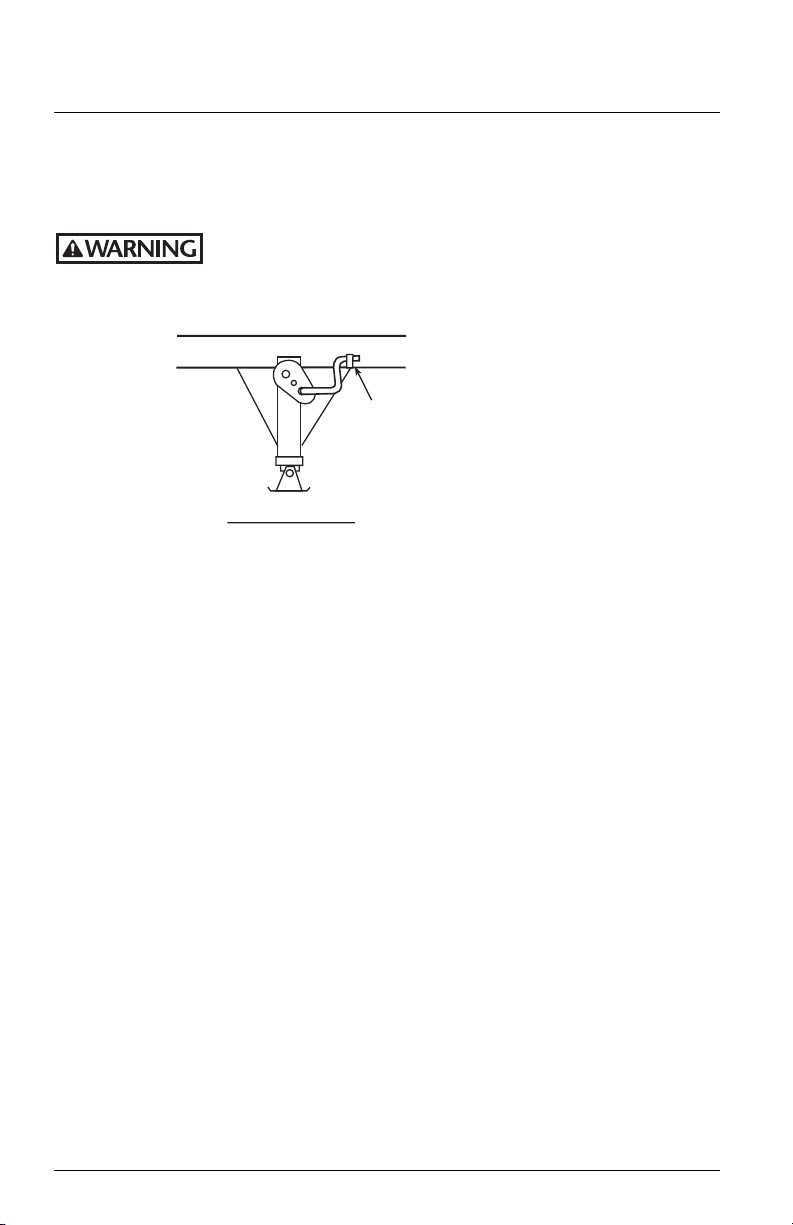

COUPLING PROCEDURES

11. Visual Inspection.

GET OUT OF THE TRACTOR!

VISUALLY check that the lock is CLOSED!

An improperly coupled tractor and trailer may separate while

serious injur

while in use which, if not avoided, could result in death or serious injury.

If you do not obtain a proper couple, repeat the coupling sequence.

in use which, if not avoided, could result in death or

y.

Do not use any fifth wheel that fails to operate properly. Failure

to properly couple tractor and trailer may allow separation

1

✓

XL-FW418-01 Rev C

2

✓

3

✓

DO NOT

RELY ON

SOUND

7

OPERATING

SECURE

CRANK

INSTRUCTIONS

COUPLING PROCEDURES

12. Follow instructions published separately for safe operation of the trailer to fully

retract landing gear and secure crank handle.

DO NOT operate the vehicle without fully retracting the

landing gear

sufficient ground clearance for transit may result in damage to the landing gear

or components which, if not avoided, could result in death or serious injury.

. Failure to fully retract the landing gear to attain

13. Re-check brake lines and light cord.Remove wheel chocks,

continue with pre-trip inspection.

8

XL-FW418-01 Rev C

Loading...

Loading...