Owner’s Manual

Manual del propietario

FW16 Low Lube Series Fifth Wheels

Operation, Maintenance and Troubleshooting

Procedures; Warranty Information

Quinta ruedas Low Lube Serie FW16

Operación, mantenimiento y procedimientos de

resolución de problemas; información de garantía

EnglishEspañol

XL-FW10055UM-en-US Rev D

Contents

Contents Page

Introduction ..............................................2

Notes, Cautions, and Warnings ..................2

Section 1 – General Safety Instructions .....3

Section 2 – Model Identification................4

Section 3 – Decal Requirements ................4

Section 4 – Fifth Wheel Intended Use ........5

Section 5 – Fifth Wheel Non-Intended Use ...5

Section 6 – Coupling Preparation ..............5

Section 7 – Coupling Procedures ...............8

Section 8 – Uncoupling Procedures .........11

Section 9 – Positioning Sliding Fifth Wheel ...13

Section 10 – Fifth Wheel Maintenance ....14

Introduction

This manual provides the information necessary

for the proper operation and maintenance of the

HOLLAND

®

FW16 XA-161 Series Fifth Wheels.

Read this manual before using or servicing

this product and keep it in a safe location for

future reference. Updates to this manual,

which are published as necessary, are available

on the internet at www.safholland.us.

When replacement parts are required,

SAF-HOLLAND

use of only SAF-HOLLAND

A list of technical support locations that

supply SAF-HOLLAND

®

highly recommends the

®

Original Parts.

®

Original Parts and

an Aftermarket Parts Catalog are available

on the internet at www.safholland.us or

contact Customer Service at 888-396-6501.

Notes, Cautions, and Warnings

Before starting any work on the unit, read

and understand all the safety procedures

presented in this manual. This manual

contains the terms “NOTE”, “IMPORTANT”,

“CAUTION”, and “WARNING” followed by

important product information. These

terms are defined as follows:

Contents Page

Section 11 – Top Plate Removal ..............15

Section 12 – Lube Plate Inspection.......... 16

Section 13 – Fifth Wheel Lubrication .......16

Section 14 – Slide Base Lubrication..........17

Section 15 – Fifth Wheel Adjustment .......18

Section 16 – Slide Base Adjustment .........21

Section 17 – Pocket Insert Inspection ...... 22

Section 18 – Top Plate Installation...........22

Section 19 – Troubleshooting ..................23

Section 20 – Rebuild and Replacement Kits ..25

Warranty and Performance Guarantee .....26

IMPORTANT: Includes additional

information that

if not followed could

lead to hindered

product performance.

Used without the safety

alert symbol, indicates

a potentially hazardous

situation which, if not

avoided, could result in

property damage.

Indicates a potentially

hazardous situation

which, if not avoided,

could result in minor or

moderate injury.

Indicates a potentially

hazardous situation

which, if not avoided,

could result in death or

serious injury.

NOTE: Includes additional information

to enable accurate and easy

performance of procedures.

2

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

1. General Safety Instructions

Read and observe all Warning and Caution

hazard alert messages. The alerts provide

information that can help prevent serious

personal injury, damage to components,

or both.

Failure to follow the instructions

and safety precautions in

this manual could result

in improper servicing or

operation leading to

component failure which,

if not avoided, could result

in death or serious injury.

All fifth wheel installation and maintenance

MUST be performed by a properly

technician using proper/special tools, and

safe procedures.

NOTE: In the United States, workshop

safety requirements are defined by

federal and/or state Occupational

Safety and Health Act (OSHA).

Equivalent laws could exist in

other countries. This manual is

written based on the assumption

that OSHA or other applicable

employee safety regulations are

followed by the location where

work is performed.

IMPORTANT: Prior to operation of the

fifth wheel, verify that

the fifth wheel has been

appropriately installed

on the vehicle.

trained

Model Identification

IMPORTANT: These instructions apply

to the proper operation of

the FW16 XA-161 Series

Fifth Wheel top plates only.

There are other important

checks, inspections, and

procedures not listed here

that are necessary, prudent,

and/or required by law.

For proper installation procedures, refer

to Installation Manual XL-FW10008BM

available on the internet at www.safholland.us.

Failure to follow all the

operating procedures

contained in these

instructions could result

in a hazardous condition

or cause a hazardous

condition to develop

which, if not avoided,

could result in death or

serious injury.

English

Failure to properly install the

fifth wheel could result in

tractor-trailer separation

which, if not avoided,

could result in death or

serious injury.

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

3

General Safety Instructions

2. Model Identification

Fifth wheel serial tags are located on the left

side of the fifth wheel top plate above the

fifth wheel bracket pin, or on the pickup

ramps (Figure 1).

The part number and serial number are

listed on the tag (Figure 2).

3. Decal Requirements

Decal XL-FW20001DC-en-US (Figure 3)

enclosed in plastic bag with the Owner’s

Manual, MUST be installed near the fifth

wheel and easily viewed by the operator.

Position the decal as illustrated (Figure 4).

NOTE: Make sure surface is free of oil

It is the responsibility of the end user to

periodically inspect the decal and ensure

that it is clean and completely legible. If

the label is missing, loose, damaged or

difficult to read, contact SAF-HOLLAND

Customer Service at 888-396-6501 to

order replacements immediately.

and grease before applying decal.

®

Figure 1

Figure 2

Model No. XXXXXXXXXXXXXXXXXX

Serial No. XXXXXXXXXXXXXXXXXX

U.S. AND FOREIGN PATENTS APPLY

MADE IN

FAILURE TO PROPERLY INSTALL, MAINTAIN & OPERATE

THIS PRODUCT COULD RESULT IN TRACTOR TRAILER

SEPARATION CAUSING SERIOUS INJURY OR DEATH.

XXXXXX

Figure 3

WARNING / ADVERTENCIA

ALWAYS inspect fifth wheel after coupling tractor to trailer.

Failure to properly couple the tractor and trailer could result in tractor-trailer separation while in use

which, if not avoided, could result in death or serious injury.

SIEMPRE inspeccione la quinta rueda después de acoplar el tractocamión al remolque.

Si no acopla adecuadamente el tractocamión y el remolque, podría ocasionar la separación del tractocamión

y el remolque durante el uso, lo cual, si no se evita, puede causar muertes o lesiones.

CORRECT COUPLING / ACOPLAMIENTO CORRECTO

1.

Lock notch

behind rib.

Muesca de cierre

detrás del reborde.

2.

Sin separación

No gap

3.

Lock completely closed around kingpin.

Seguro completamente cerrado alrededor

del perno rey.

Copyright © 2014 $SAF-HOLLAND, Inc.

www.safholland.us XL-FW20001DC-en-US

Figure 4

WARNING / ADVERTENCIA

ALWAYS inspect fifth wheel after coupling tractor to trailer.

Failure to properly couple the tractor and trailer could result in tractor-trailer separation while in use

which, if not avoided, could result in death or serious injury.

SIEMPRE inspeccione la quinta rueda después de acoplar el tractocamión al remolque.

Si no acopla adecuadamente el tractocamión y el remolque, podría ocasionar la separación del tractocamión

y el remolque durante el uso, lo cual, si no se evita, puede causar muertes o lesiones.

CORRECT COUPLING / ACOPLAMIENTO CORRECTO

3.

Lock completely closed around kingpin.

1.

Lock notch

2.

No gap

behind rib.

Seguro completamente cerrado alrededor

Sin separación

del perno rey.

Muesca de cierre

detrás del reborde.

Copyright © 2014 $SAF-HOLLAND, Inc.

www.safholland.us XL-FW20001DC-en-US

4

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Instructions

4. Fifth Wheel Intended Use

1. Pulling trailers with standard SAE

kingpins which are in good condition

and securely mounted or locked in

position in the trailer.

2. Transporting loads that are within the

maximum fifth wheel rated capacities:

50,000 lbs. (22,680 kg) Maximum

Vertical Load 150,000 lbs. (68,040 kg)

Maximum Drawbar Pull.

3. In on-road applications.

IMPORTANT: SAF-HOLLAND

®

definition

of off-road refers to

terrain on which a tractortrailer operates which is

unpaved and rough, or

ungraded. Any terrain not

considered part of the

public highway system

falls under this heading.

4. As recommended in SAF-HOLLAND

®

literature available on the Internet at

www.safholland.us.

5. Fifth Wheel

Non-Intended Use

1. Operating with a non-SAE compliant

kingpin, such as kingpins which are bent,

improper size or dimensions, not secured

to maintain SAE configuration, or which

are installed in warped trailer bolster

plates, or upper coupler and fifth wheel

lube plates that DO NOT maintain the SAE

kingpin dimensions. Refer to SAF-HOLLAND®

Service Bulletin XL-SB004-01 (available on

the Internet at www.safholland.us) for more

information on fifth wheel lube plates.

Failure to couple with a SAE

compliant kingpin could

result in improper coupling,

allowing tractor-trailer

separation, which if not

avoided, could result in

death or serious injury.

2. Tow-away operations which damage

or interfere with the proper operation

of the fifth wheel.

3. The attachment of lifting devices.

4. The transport of loads in excess of

rated capacity.

5. In off-road applications.

6. Applications other than those

recommended in SAF-HOLLAND

®

literature available on the Internet

at www.safholland.us.

6. Coupling Preparation

1. Prior to coupling, inspect the fifth

wheel and mounting. Perform and

verify the following:

Confirm that lube plates are in place

and firmly fastened.

Tighten loose fasteners.

Replace missing fasteners.

Repair/replace missing, cracked or

otherwise damaged components.

Inspect fifth wheel mechanism.

Lubricate dry or rusty components.

For a sliding fifth wheel, make sure

both plungers are fully engaged.

Inspect air line connections.

Make sure fifth wheel is in appropriate

position for weight distribution on the

tractor. For proper positioning of the

fifth wheel, refer to SAF-HOLLAND

publication XL-FW10008BM available

on the Internet at www.safholland.us.

2. Make sure coupling area is flat, level,

and clear of persons and obstacles.

English

®

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

5

Operation Instructions

3. Tilt ramps of fifth wheel downward

(Figure 5).

4. Make sure locks are open (Figure 6). If

locks are closed, slide release handle to

the left and pull all the way out (Figure

7). Pry locks open with lever bar.

5. Inspect leading edge of trailer bolster/skid

plate. It MUST be free of any square or

sharp edges (Figure 8).

6. Make sure there are no bolts or nuts

extending below bolster/skid plate

within 152 mm (6.0") of the fifth

wheel travel path while coupling.

Figure 5

TILT DOWNWARDTILT DOWNWARD

Figure 6

LOCK IS OPEN LOCK IS CLOSED

Figure 7

LEFT HAND RELEASE RIGHT HAND RELEASE

Figure 8

CHAMFERED (Preferred)

OR LARGE RADIUS

LEADING EDGE

20º

2"

MINIMUM

6

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Instructions

should be free of any large holes or

gouges (Figure 9).

8. Any access holes that the fifth wheel

passes beneath should have chamfered

or radius edges.

9. Check that any splits from the skid

plate to bolster plate are welded

adequately, and that there are no

sharp edges or abrupt changes in

elevation (Figure 10).

10. The upper coupler should extend

adequately rearward to maintain full

contact with the fifth wheel during

tight turning. If it does not, at a

minimum, the rear edges should be

chamfered or radius edges.

11. Make sure that any upper coupler residual

grease is free of heavy course grit.

12. Ensure that the upper coupler fifth

wheel contact surface is free of rust

and is not painted. The area should be

conditioned with a rust inhibitor such

as a light oil.

13. Verify that kingpin is not obstructed by

a kingpin lock or other security device.

Failure to remove kingpin

lock prior to coupling

could result in improper

coupling which, if not

avoided, could result in

death or serious injury.

14. Inspect kingpin for excessive wear

and damage (use HOLLAND

Gage tool TF-0110 ) along with bolster

plate bow (See SAF-HOLLAND

®

Kingpin

®

Service

Bulletins XL-SB020 and XL-SB033).

Figure 97. The area supported by the fifth wheel

KEEP PATH OF FIFTH WHEEL FREE

OF LARGE HOLES AND GOUGES

6" MIN.

40"

6" MIN.

KEEP BOLTS AND

NUTS CLEAR OF

THIS AREA

Figure 10

ACCESS HOLE

MAKE SURE THERE ARE

NO SHARP EDGES

NO ABRUPT TRANSITIONS IN ELEVATION

English

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

7

Operation Instructions

7. Coupling Procedures

IMPORTANT: Following proper coupling

procedures for FW16

Low Lube fifth wheels

is extremely important.

Failure to follow all of the

procedures contained in

these coupling instructions

could result in damage to

the lube plates.

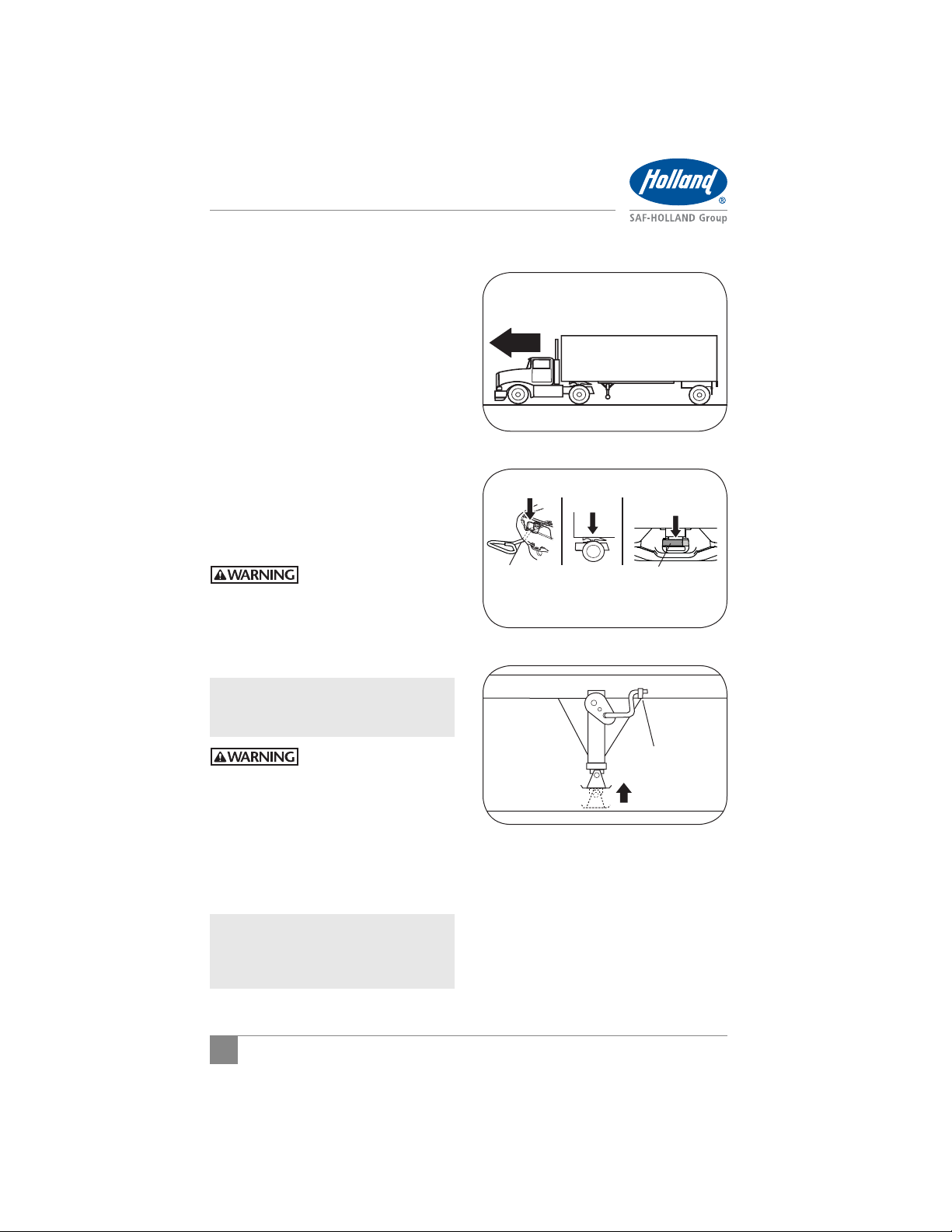

1. Chock trailer wheels.

2. Position the tractor so the center of the

fifth wheel is aligned with the kingpin.

3. Traveling in a straight line, slowly

back tractor to trailer. STOP the tractor

before making contact with the trailer

(Figure 11).

IMPORTANT: DO NOT make contact

between fifth wheel and

trailer or damage to lube

plates could occur.

4. Set tractor parking brake and place

into neutral.

5. Completely exhaust air from tractor

suspension, ensuring that the fifth

wheel is below the contact surface

of trailer (Figure 12).

6. Exit the cab and make sure the fifth

wheel is below the upper coupler plate.

Verify proper fifth wheel height. If

trailer is too low, use landing gear to

raise the trailer height.

Figure 11

TRAILER

(TOP)

KINGPIN

Figure 12

EXHAUST SUSPENSION AIR

BEFORE BACKING UP

NOTE: For proper operation of landing

gear, follow the instructions

published by the landing

gear manufacturer.

8

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Instructions

7. Slowly back up, using lowest gear

possible. Stop when fifth wheel is

under the leading edge of the trailer

(Figure 13).

8. Set tractor parking brake. Place in

neutral. Exit cab and verify proper fifth

wheel to kingpin alignment.

9. Adjust tractor suspension to ride height.

The fifth wheel plate face MUST make

contact with the upper coupler plate

(Figure 14). If fifth wheel does not

make contact with the upper coupler

plate, use the landing gear to lower the

trailer until fifth wheel makes contact.

IMPORTANT: If trailer is too high the

kingpin will not properly

connect with the lock jaw.

Failure to couple with the

trailer at the proper height

could result in improper

coupling, allowing tractor

and trailer separation,

which if not avoided,

could result in death or

serious injury.

IMPORTANT: NEVER inflate the tractor

suspension when the

kingpin is above the

throat of the fifth wheel.

Figure 13

BACK UP

AND STOP!

Figure 14

English

Failure to avoid inflating

tractor suspension when

the fifth wheel is not

forward of the king pin,

could result in damage to

the kingpin and fifth wheel.

10. Slowly back into the trailer, engaging

kingpin in the fifth wheel.

11. Connect the air and electrical lines.

12. Raise the landing gear legs until the

pads are just above the ground.

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

9

Operation Instructions

13. Perform a pull test as an INITIAL CHECK

by locking the trailer brakes and pulling

forward with the tractor to make sure

that tractor-trailer separation does not

occur (Figure 15).

14. Set the tractor parking brake.

15. Exit the cab and visually inspect for

the following to ensure that the lock

is closed (Figure 16).

a. Release handle fully retracted with

lock notch behind rib.

b. No gap is permissible between the

trailer upper coupler plate and the

fifth wheel.

c. Lock securely closed behind jaw.

16. If proper coupling has NOT been achieved,

repeat the coupling procedure.

Failure to properly couple

the tractor and trailer could

result in tractor-trailer

separation while in use

which, if not avoided,

could result in death or

serious injury.

IMPORTANT: DO NOT use any fifth

wheel that fails to

operate properly.

Figure 15

LOCK TRAILER BRAKES AND

PULL FORWARD WITH TRAILER

Figure 16

NO GAP!

LOCK NOTCH

BEHIND RIB

Figure 17

LOCKS COMPLETELY

CLOSED AROUND

KINGPIN

Failure to repair a

malfunctioning fifth

wheel before use could

result in tractor-trailer

separation which, if not

avoided, could result in

death or serious injury.

17. Fully retract the landing gear legs

off the ground and secure the crank

handle (Figure 17).

NOTE: For proper operation of landing

gear, follow the instructions

published by the landing

gear manufacturer.

18. Remove the wheel chocks and continue

with the pre-trip inspection.

10

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

SECURE

CRANK

Operation Instructions

8. Uncoupling Procedures

IMPORTANT: Following proper

uncoupling procedures

FW16 Low Lube fifth wheels

is extremely important.

Failure to follow all of the

procedures contained in

these uncoupling instructions

could result in damage to

the lube plates.

1. Position the tractor and trailer, in straight

alignment, on firm, level ground clear

of obstacles and persons.

2. Set the trailer brakes.

3. Slowly back the tractor tightly against

the trailer to relieve pressure on the

fifth wheel locks.

4. Set the tractor parking brake.

IMPORTANT: DO NOT exhaust air

from tractor suspension

before uncoupling.

Failure to avoid exhausting

tractor suspension before

uncoupling could result

in difficulty uncoupling

tractor from trailer which,

if not avoided, could

result in damage to the

fifth wheel and kingpin.

5. Chock the trailer wheels.

6. Lower the landing gear until the pads

just touch the ground (Figure 18).

NOTE: For proper operation and ability

to transfer trailer weight from

the fifth wheel, follow the landing

gear manufacturer’s published

instructions. DO NOT raise

trailer off of the fifth wheel.

Figure 18

LOWER LANDING GEAR

English

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

11

Operation Instructions

7. Disconnect the air and electrical lines

from the trailer and secure to tractor.

8. Slide release handle to the left, pull all

the way out, slide handle left and hook

on casting handle (Figure 19).

9. Release the tractor parking brake and

slowly pull forward 12"-18" (306-457 mm)

to disengage kingpin from fifth wheel.

Fifth wheel should be between the front

edge of trailer and kingpin (Figure 20).

IMPORTANT: DO NOT drive the tractor

free of the trailer.

10. Set the tractor parking brake and place

into neutral. Completely exhaust air

from tractor suspension, ensuring that

the fifth wheel is below the contact

surface of trailer (Figure 21).

11. Visually inspect uncoupling. Make sure

the trailer is completely supported by

the landing gear.

12. Release the tractor parking brake and

slowly pull away from the trailer.

13. Apply air to the tractor air suspension

and allow suspension to return to ride

height (Figure 22).

Figure 19

LEFT HAND RELEASE RIGHT HAND RELEASE

Figure 20

SLOWLY PULL FORWARD

AND STOP

Figure 21

EXHAUST SUSPENSION AIR

BEFORE PULLING FORWARD

12

Figure 22

RETURN TRACTOR SUSPENSION

TO RIDE HEIGHT

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Instructions

9. Positioning Sliding

Fifth Wheels

1. Position the tractor and trailer, in straight

alignment, on firm, level ground clear

of obstacles and persons.

2. Set tractor and trailer parking brakes,

place tractor in neutral.

Failure to stop and properly

lock the tractor and

trailer brakes could cause

uncontrolled sliding of

fifth wheel which, if not

avoided, could result in

component damage to

tractor or trailer.

3. Release slide locking plungers by

moving cab switch to unlock position

(Figure 23). If manual slide release

equipped, pull release lever. If plungers

DO NOT come out, lower the landing

gear to relieve pressure on the fifth

wheel. This will allow fifth wheel to

slide easier.

NOTE: Cab switch style could differ

by OEM.

4. Visually inspect and verify that

plungers are disengaged.

5. Release tractor parking brake while

keeping trailer brakes engaged.

6. Slowly drive the tractor forward or

backward to position fifth wheel. Stop

tractor at desired position.

7. Re-engage slide locking plungers by

moving cab switch to the lock position

(Figure 24). If manual slide release

equipped, pull release arm to allow

plungers to retract.

8. Place tractor in neutral, set tractor

parking brake.

Figure 23

AIR OPERATED

MOVE CAB SWITCH TO

UNLOCK POSITION

Figure 24

AIR OPERATED

MOVE CAB SWITCH

TO LOCK POSITION

English

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

13

Maintenance Procedures

9. Visually inspect plunger lock bars to

ensure proper engagement (Figure 25).

10. Retract landing gear legs, if lowered.

11. Verify that slide locking plungers have

been re-engaged by performing a pull

test (Figure 26).

IMPORTANT: DO NOT operate the

vehicle if the plungers are

not fully engaged (locked).

Failure to properly engage

plungers and slide base

could cause loss of vehicle

control which, if not

avoided, could result in

death or serious injury.

10. Fifth Wheel Maintenance

IMPORTANT: All maintenance MUST be

performed by a properly

trained technician using

proper tools and safe

procedures.

IMPORTANT: All maintenance MUST

be performed while the

tractor is uncoupled

from the trailer.

Failure to properly maintain

the fifth wheel could

result in tractor-trailer

separation which, if not

avoided, could result in

death or serious injury.

Figure 25

LOCKED

(ENGAGED)

RACK

PLUNGER

TRADITIONAL SLIDERS

Figure 26

LOCK TRAILER BRAKES AND

PULL FORWARD WITH TRAILER

NOTE: Removal of the fifth wheel

top plate is not required for

maintenance but could be required

when performing repairs.

1. Thoroughly clean the locking mechanism

every six (6) months or 60,000 miles.

2. Prior to coupling, inspect the fifth

wheel and mounting. Perform and

verify the following:

Confirm that lube plates are in place

and firmly fastened.

14

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Maintenance Procedures

Tighten loose fasteners.

Replace missing fasteners.

Repair/replace missing, cracked or

otherwise damaged components.

Inspect fifth wheel mechanism.

Lubricate dry or rusty components.

For a sliding fifth wheel, make sure

both plungers are fully engaged.

Inspect air line connections.

Make sure fifth wheel is in appropriate

position for weight distribution on the

tractor. For proper positioning of the

fifth wheel, refer to SAF-HOLLAND

®

publication XL-FW10008BM available

on the Internet at www.safholland.us.

11. Top Plate Removal

IMPORTANT: Fifth wheel assembly

1. Remove bracket pin retention nuts and

bolts from both sides of fifth wheel top

plate (Figure 27).

2. Using a pry bar, pull bracket retention pins

out of fifth wheel top plate (Figure 27).

3. Using a lifting device capable of lifting

500 lbs. (227 kg), remove the top plate

from the mounting base. Place fifth

wheel on a flat, clean working area.

has replaceable pocket

inserts installed between

the fifth wheel top plate

and mounting base.

When removing top

plate, be careful not

to lose pocket inserts.

Failure to prevent pocket

inserts from falling out of

the top plate could cause

a potentially hazardous

situation which, if not

avoided, could result in

minor or moderate injury.

Figure 27

TOP PLATE

RETENTION BOLT

BRACKET PIN

RETENTION NUT

English

NOTE: Follow instructions published by

lifting device manufacturer for

proper operation of lifting device.

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

15

Maintenance Procedures

12. Lube Plate Inspection

Thoroughly steam clean top surface of fifth

wheel for visual inspection. Replace lube

plates if:

One or both lube plates is missing.

A straight edge laid across the lube

plate contacts any metal portion of the

fifth wheel surrounding the lube plates

(Figure 28).

Lube plates are severely chipped, worn,

cracked, gouged or bent

20% (40 sq. in.) or more of lube plate

coating is missing from one or both

plates due to normal wear or damage.

13. Fifth Wheel Lubrication

IMPORTANT: Fifth wheel lubrication

is necessary to get the

maximum service life

from the FW16 series

fifth wheel. Perform the

following procedures at

the intervals listed.

Figure 28

LOOK FOR

STRAIGHT EDGE

CONTACT HERE

FW16 series fifth wheels are equipped with

NoLube plate inserts that eliminate the

need to lubricate the fifth wheel-to-trailer

contact surfaces.

FW16 series fifth wheels are equipped

with a lube tube that provides grease to the

locking mechanism using a grease fitting.

Lubricate locking mechanism every three

(3) months or 30,000 miles.

Thoroughly clean the locking mechanism

every six (6) months or 60,000 miles.

16

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Maintenance Procedures

IMPORTANT:

Fifth wheels that operate

in snowy or icy winter

conditions, lubrication

should be performed

every spring in addition

to routine lubrication

(as noted on the previous

page) to ensure

optimum operation.

13.A Proper Lubrication Method

Using water-resistant lithium-based

1.

grease,

lubricate (A) swing lock-to-hook

contact areas directly or through the lube

tube grease fitting, and (B) camtrack

(Figure 29).

2. Using a light oil, lubricate (C) hook pin,

and (D) release handle pivot (Figure 29).

13.B As-Needed Lubrication

Clean and lubricate locking mechanism

if operational difficulties (i.e. problems

with coupling, uncoupling, or pulling the

release handle) arise during the service

life of the fifth wheel (Figure 29).

14. Slide Base Lubrication

NOTE: Slide base should be moved fore

IMPORTANT: If equipped with air

1. With the piston shaft in the exposed

ILS Sliders: Spray spring covered piston

and aft at least once a year to

maintain optimum performance.

release, lubricate air

cylinder every three (3)

months or 30,000 miles

whichever comes first.

position, clean with penetrating oil

and a clean shop towel (Figure 30).

shaft thoroughly with penetrating oil

(Figure 31).

Figure 29

D

B

C

Figure 30

Figure 31

ILS SLIDER

PISTON

SHAFT

LUBE TUBE GREASE FITTING

A

PISTON

SHAFT

TRADITIONAL SLIDERS

English

IMPORTANT: DO NOT use any abrasives

on the exposed shaft as

they could damage the

piston shaft.

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

17

Maintenance Procedures

2. Remove supply air line and add 2-4 drops

of air tool oil to cylinder through the

supply fitting. Re-install supply air line

(Figures 32 and 33 - Traditional

Sliders, Figure 34- ILS Sliders).

3. Activate and de-activate air cylinder

2-3 times to work air tool oil into

cylinder and onto piston and verify

proper operation.

15. Fifth Wheel Adjustment

Fifth wheel adjustment should be performed

at a minimum of every 60,000 miles or if

excessive movement between kingpin and

fifth wheel is noticed when driving the vehicle.

IMPORTANT: Excessive movement

between the tractor

and trailer can effect

vehicle handling.

Failure to maintain proper

fifth wheel adjustment

could result in loss of

vehicle control which, if

not avoided, could result

in death or serious injury.

Figure 32

TRADITIONAL SLIDER

SUPPLY FITTING

Figure 33

SUPPLY FITTING

TRADITIONAL SLIDER

Figure 34

ILS SLIDER

NOTE: To obtain proper adjustment

SAF-HOLLAND

use of HOLLAND

Part No. TF-TLN-5001, available

from a local HOLLAND

®

recommends

®

lock tester

®

distributor.

1. If fifth wheel is locked, slide release

handle to the left and pull all the way

out (Figure 35). Pry locks open with

lever bar.

2.

Set lock tester on fifth wheel top plate .

18

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

PISTON

SHAFT

Figure 35

LEFT HAND RELEASE RIGHT HAND RELEASE

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Maintenance Procedures

3. To lock fifth wheel, rotate handle on

lock tester clockwise until the locks

close around the kingpin (Figure 36).

4. Slide the lock tester forward and

backward in the closed lock to check

for play between lock and kingpin.

Ensure that the tool remains flat with

full contact on the fifth wheel top plate.

Use pin gage to measure free play. If

free play exceeds 0.080" (2.03 mm).

adjust lock mechanism (Figure 37).

5. To adjust lock, remove the low head

socket cap screw. Rotate adjusting pin

counter-clockwise (left hand release), or

clockwise (right hand release), until the

next notch lines up with the low head

socket cap screw tapped hole. Replace

the low head socket cap screw. Adjust

only one notch at a time (Figure 38).

6. Verify the proper adjustment by locking

and unlocking fifth wheel several times

with lock tester. Check that fifth wheel

is properly locked (Figure 39).

NOTE: To unlock fifth wheel, push

down on lock tester, and rotate

“J” hook under the fifth wheel,

then pull handle back.

Figure 36

Figure 37

Figure 38

FIRST NOTCH

FIRST NOTCH

English

LOW HEAD

SOCKET

CAP SCREW

LEFT HAND RIGHT HAND

Figure 39

LOCK NOTCH

BEHIND RIB

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

LOW HEAD

SOCKET

CAP SCREW

LOCK COMPLETELY

CLOSED AROUND

KINGPIN

19

Maintenance Procedures

7. Rotate lock tester from side-to-side to

ensure that lock is not overtightened.

Lock should not grip kingpin and the

tool should rotate freely (Figure 40).

8. Disengage lock tester J-Hook from

front skirt of casting and re-check for

free play in lock by sliding lock tester

forward and backward using pin gage

to measure free play (Figure 40).

Free play should be 0.040" (1.02 mm)

minimum. If free play still exceeds

0.080" (2.03 mm) repeat procedure

and adjust one more notch.

NOTE: If there is still excessive free

play in the locks with the

adjusting pin on the last (third)

notch, then the fifth wheel

should be rebuilt using the

appropriate SAF-HOLLAND

®

service kit.

Figure 40

20

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Maintenance Procedures

16. Slide Base Adjustment

NOTE: ILS slider locking plungers

Some HOLLAND

adjustable locking plungers. Adjustment should

be performed at a minimum of every 60,000

miles or if excessive movement is noticed

when driving the vehicle. To obtain proper

adjustment, follow the following procedures:

1. Loosen lock nut and turn adjustment

2. Disengage and engage locking plungers.

3. Tighten adjustment bolt until it contacts

4. Turn adjustment bolt clockwise an

If locking plungers DO NOT release fully to

allow fifth wheel to slide:

a. Check the air cylinder for proper

b. Check locking plunger adjustment as

c. If a locking plunger is binding in the

NOTE: If problems persists, contact

DO NOT require adjustment.

®

slide bases are equipped with

bolt counterclockwise (Figure 41).

Verify that locking plungers have engaged

properly (Figures 42 and 43).

the rack.

additional 1/2 turn, then tighten lock

nut securely.

operation. Replace if necessary.

explained above.

plunger pocket, remove the locking

plunger using a HOLLAND

®

TF-TLN-2500

spring compressor. Grind the top edges

of the locking plunger 1/16" (1.5 mm)

(Figure 44). Re-install and adjust the

locking plungers as explained above.

SAF-HOLLAND

®

Customer Service

at 888-396-6501.

Figure 41

LOCK NUT

ADJUSTMENT BOLT

Figure 42

UNLOCKED

(RELEASED)

RACK

PLUNGER

Figure 43

LOCKED

(ENGAGED)

RACK

PLUNGER

Figure 44

CHECK FOR POSSIBLE INTERFERENCE

PLUNGER

English

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

1/16"

(1.5 mm)

21

Maintenance Procedures

17. Pocket Insert Inspection

Replace pocket inserts if:

The pocket insert thickness is 1/16"

(1.5 mm) or less.

The free vertical movement of top plate

on the bracket is 1/2" (12.7 mm) or

greater, without compressing rubber

bushings (Figure 45).

The pocket inserts are severely

chipped, cracked or gouged.

18. Top Plate Installation

1. If pocket inserts are dislodged from fifth

wheel casting, clean pocket area of

casting and apply a strip of double-face

tape in bottom of pockets. Install pocket

inserts by pressing down into pockets

(Figure 46).

2. Using a lifting device capable of lifting

500 lbs. (227 kg), install the fifth wheel

top plate onto its mounting base.

NOTE: Follow instructions published by

lifting device manufacturer for

proper operation of lifting device.

3. Install bracket pins through fifth wheel

casting and mounting base and secure

by installing the bracket pin retention

bolts and nuts (Figure 47). Torque

retention fasteners to 50-60 ft.-lbs.

/tN

Figure 45

REPLACE IF

1/16" (1.5 mm)

OR LESS

1/2" (12.7 mm) MAX. (MEASURED AT EAR)

PUSH DOWN

Figure 46

DOUBLE-FACE TAPE

POCKET

INSERT

POCKET

AREA

Figure 47

TOP PLATE

RETENTION BOLT

RETENTION NUT

BRACKET PIN

22

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Troubleshooting

19. Troubleshooting

Difficult to Couple to Trailer:

9

POSSIBLE CAUSE

Attempting to couple too fast. Couple in accordance with the procedure in Section 7.

The trailer could be too high; the kingpin

is not entering the locks properly.

Lower the trailer in accordance with manufacturer's

instructions.

Lock is closed. Manually pull the release handle out as far as possible. Lock

will swing open.

Accumulated rust or grime interfering with

the lock operation.

Thoroughly clean the fifth wheel and re-lubricate in

accordance with the procedure in Section 13.

The locks are adjusted too tightly. Check lock adjustments in accordance with the procedure

in Section 15.

The locks could be damaged. The fifth wheel MUST be rebuilt using the appropriate

service kit.

Damaged, bent release handle. Replace release handle using the appropriate service kit.

Bent kingpin, damaged upper coupler, or

improper use of “lube plate” could be

interfering with lock movement.

Check the kingpin and upper coupler plate as detailed in

®

HOLLAND

required. Remove any improperly installed or improperly

specified lube plates. Refer to HOLLAND

XL-SB004-01 for lube plate warnings.

Service Bulletin XL-SB020. Repair/replace as

Difficult to Uncouple from Trailer:

9

The tractor could be putting pressure

against locks.

Tractor too low. Raise tractor suspension to proper ride height.

The release handle is not pulled out

completely and hooked on the notch in the

casting.

Accumulated rust or grime interfering with

the lock operation.

The locks are adjusted too tightly. Check lock adjustments in accordance with the procedure

The release handle will not stay out or MUST

be held out when unlocking.

Missing or damaged release system parts. The fifth wheel MUST be rebuilt using the

Casting bent/damaged at throat area,

restricting movement.

Bent kingpin, damaged upper coupler, or

improper use of “lube plate” could be

interfering with lock movement.

POSSIBLE CAUSE REMEDY

Lock the trailer brakes and back the tractor tightly

against the kingpin to relieve the pressure on the fifth

wheel lock, set the brakes, then pull the release handle.

Slide the release handle forward, then pull out the

handle, slide it forward, and hook it on the notch of the

top plate casting.

Thoroughly clean the fifth wheel and re-lubricate in

accordance with the procedure in Section 13.

in Section 15.

The fifth wheel MUST be rebuilt using the

appropriate SAF-HOLLAND

appropriate SAF-HOLLAND

The entire fifth wheel top plate MUST be replaced.

Check the kingpin and upper coupler plate as detailed in

®

HOLLAND

required. Remove any improperly installed or improperly

specified lube plates. Refer to HOLLAND

XL-SB004-01 for lube plate warnings.

Service Bulletin XL-SB020. Repair/replace as

REMEDY

®

service kit.

®

service kit.

®

®

Service Bulletin

English

Service Bulletin

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

23

Troubleshooting

Excessive Movement between Fifth Wheel and Kingpin:

9

Fifth wheel lock requires adjustment. Follow the procedures contained in Section 15.

Fifth wheel cannot be adjusted further. The fifth wheel MUST be rebuilt using the appropriate service kit.

Kingpin is loose. Repair trailer.

Kingpin is worn. Check kingpin for acceptable wear with HOLLAND

POSSIBLE CAUSE REMEDY

Replace kingpin, if necessary.

Hard Steering or Binding:

9

Warped trailer upper coupler plate. Check upper coupler plate for flatness and replace, if

POSSIBLE CAUSE REMEDY

®

necessary. Refer to HOLLAND

Service Bulletin XL-SB020.

®

TF-0110.

24

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Rebuild and Replacement Kits

20. Rebuild and Replacement Kits

REBUILD AND REPLACEMENT KITS PART NUMBER

Rebuild Kit-Manual Release RK-161-A

Lock and Hook Replacement Kit RK-161-11078

Release Handle Replacement Kit-Manual Release RK-161-11493

Lube Plate Inserts-Pair RK-161-1

Pocket Inserts-Pair RK-PKT-2

Lube Tube Replacement Kit RK-161-11774

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

English

25

Warranty and Performance Guarantee

within rated capabilities.

fifth wheels and for using the product in the approved application

(including lubrication) as specified in our publications on “FW Series”

Your Responsibilities

You are responsible for proper installation, operation, and maintenance

FW83 SERIES FIFTH WHEELS

SAF-HOLLAND’s Commitment

HOLLAND FW17, FW16, FWAL, FWS1, FWS2, FW8 and

We warrant each FW17, FW16, FWAL, FWS1, FWS2, FW8 and FW83

5-Year North American Commercial Warranty

and operated in accordance with our requirements, as follows:

March 1, 2013, when properly installed on your vehicle and maintained

fifth wheel (herein referred to as “FW Series”) manufactured after

returning any part. You are required to retain the product or part

SAF-HOLLAND customer service representative before replacing or

Claims

You are required to obtain prior authorization from an authorized

after the in-service date or 500,000 miles (whichever comes

free from defects in material and workmanship for five years

SAF-HOLLAND warrants our “FW Series” fifth wheels will be

I. Materials and Workmanship:

by calling 888-396-6501.

under the Service Section of our website at www.safholland.us or

warranty request considered. The Service Report form is available

upon request. You must submit a valid Service Report to have your

claimed to be covered by this warranty and return it to SAF-HOLLAND

(FW16, FWAL, and FW83) are warranted for two years after

the in-service or 200,000 miles (whichever comes first).

(as defined in our Fifth Wheel Application Guide), lube plates

Catalog and Specification Guide). In approved applications

Fifth Wheel Application Guide found in our Holland Fifth Wheel

first) when used for approved applications (as defined in our

or normal wear not covered under the performance guarantee.

THIS WARRANTY IS OUR SOLE WARRANTY IN REGARD TO THE FIFTH

WHEELS LISTED ABOVE. WE MAKE NO OTHER WARRANTIES, EXPRESS

OR IMPLIED, OR OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL WE BE RESPONSIBLE FOR SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND.

modification, corrosion, failure to provide reasonable maintenance,

accident, abuse, improper use, improper installation, intentional

component that fails, malfunctions or is damaged as a result of

Exclusions and Limitations

This warranty does not cover any “FW Series” fifth wheel or

operation and maintenance literature;

your purchase or 500,000 miles (whichever comes first):

Application Guide) it will, for five years after the date of

Standard Duty Applications (as defined in our Fifth Wheel

Application Specific 5-Year Performance Guarantee:

II.

1. Operate as described in our applicable “FW Series”

In addition, when your “FW Series” fifth wheel is used in

CONSEQUENTIAL DAMAGES OF ANY KIND.

wheel locks and a new SAE J700b kingpin when adjusted

in accordance with our applicable “FW Series”

maintenance literature.

a published labor schedule in conjunction with local labor rates.

exceed the suggested list price. Labor reimbursement is based on

replacement under the above warranty.

Parts reimbursement is limited to the parts acquisition cost, not to

replace any “FW Series” fifth wheel or component needing

SAF-HOLLAND will, at its option, cover the cost to repair or

2. Maintain an acceptable wear limit between the fifth

XL-FW10039WC-en-US Rev A · 2013-03-01 · Amendments and Errors Reserved © SAF-HOLLAND, Inc.

26

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Notes

XL-FW10055UM-en-US Rev D · 2014-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

English

27

Manual del propietario

Quinta ruedas Low Lube Serie FW16

Operación, mantenimiento y procedimientos de

resolución de problemas; información de garantía

XL-FW10055UM-es-US Rev D

Español

Índice

Índice Página

Introducción ......................................................... 30

Notas, precauciones y advertencias ..................... 30

Sec. 1 – Instrucciones generales de seguridad ... 31

Sec. 2 – Identificación del modelo ................... 32

Sec. 3 – Requisitos de la calcomanía ............... 32

Sec. 4 – Uso esperado para la quinta rueda ......... 33

Sec. 5 – Uso no esperado para la quinta rueda .... 33

Sec. 6 – Preparación para el acople ..................... 33

Sec. 7 – Procedimientos de acople ....................... 36

Sec. 8 – Procedimientos de desacople .................39

Sec. 9 – Ubicación de quintas ruedas deslizantes ...41

Sec. 10 – Mantenimiento de la quinta rueda ...... 42

Introducción

Este manual provee la información necesaria

para la operación y mantenimiento

adecuados de quintas ruedas de HOLLAND

®

series FW16 XA-161.

Lea este manual antes de utilizar o dar

mantenimiento a este producto y guárdelo en

un lugar seguro para consultas posteriores.

Las actualizaciones de este manual, que

se publican cuando sea necesario, están

disponibles en la red en www.safholland.us.

Cuando se requieran refacciones,

SAF-HOLLAND

usar sólo partes originales SAF-HOLLAND

®

recomienda encarecidamente

®

.

Una lista de locales de apoyo técnico que

proveen refacciones originales SAF-HOLLAND

y un catálogo del mercado de repuestos, están

disponibles en la red en www.safholland.us

o llame al Servicio al Cliente al 888-396-6501.

Notas, precauciones

y advertencias

Antes de comenzar a trabajar en la unidad,

lea y entienda todos los procedimientos

de seguridad presentados en este manual.

Este manual contiene los términos “NOTA”,

“IMPORTANTE”, “PRECAUCIÓN” y

“ADVERTENCIA” seguidos de información

importante sobre el producto. Estos términos

se definen como sigue:

Índice Página

Sec. 11 – Remoción de la placa superior ............. 43

Sec. 12 – Inspección de la placa lubricante .......... 44

Sec. 13 – Lubricación de la quinta rueda ............. 44

Sec. 14 – Lubricación de la base de deslizamiento .. 45

Sec. 15 – Ajuste de la quinta rueda ...................... 46

Sec. 16 – Ajuste de la base de deslizamiento ....... 49

Sec. 17 – Inspección del interior de los incertos .... 50

Sec. 18 – Instalación de la placa superior ............ 50

Sec. 19 – Resolución de problemas ...................... 51

Sec. 20 – Equipos de reconstrucción y reemplazo.. 53

Garantía y garantía de rendimiento ..................... 54

IMPORTANTE: Incluye información

adicional que, de

no atenderse podría

ocasionar una

disminución en el

rendimiento del producto.

PRECAUCIÓN

Sin el símbolo de alerta

de seguridad indica una

situación con riesgo

potencial que, si no se

evita, puede provocar

daños materiales.

®

PRECAUCIÓN

Indica una situación

con riesgo potencial que,

si no se evita, puede

provocar lesiones menores

o moderadas.

ADVERTENCIA

Indica una situación

con riesgo potencial que,

si no se evita, puede

provocar la muerte

o lesiones graves.

NOTA: Incluye información adicional

para permitir la realización de

procedimientos exactos

y fáciles.

30

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

1. Instrucciones generales

de seguridad

Lea y preste atención a todos los mensajes de

alerta de advertencia y precaución de riesgos.

Las alertas proporcionan información que

puede ayudar a evitar lesiones personales

graves, daños a los componentes o ambos.

Si no se siguen las

instrucciones y las

precauciones de seguridad de

este manual, podría ser causa

de mantenimiento inadecuado

o mal funcionamiento con

daño de los componentes que,

si no se evita, podría provocar

muertes o lesiones graves.

Toda instalación y mantenimiento de la

quinta rueda debe realizarlos un técnico

debidamente capacitado con las herramientas

y los procedimientos de seguridad adecuados.

NOTA: En Estados Unidos, los requisitos

IMPORTANTE: Antes de comenzar la

de seguridad en el taller están

definidos por la Ley de seguridad

y salud laboral federal o estatal

(OSHA). En otros países pueden

existir leyes equivalentes. Este

manual está escrito basándose

en la suposición de que se

siguen los reglamentos de OSHA

u otros reglamentos aplicables

de seguridad del empleado en el

lugar donde se realiza el trabajo.

operación de la quinta

rueda, asegúrese que la

quinta rueda haya sido

instalada adecuadamente

en el vehículo.

ADVERTENCIA

Si no se instala

adecuadamente la quinta

rueda podría ocasionar la

separación del tractocamión

y el remolque lo cual, si no

se evita, podría causar la

muerte o lesiones graves.

Identificación del modelo

IMPORTANTE:

Para procedimientos de instalación

adecuados, consulte el manual de

instalación XL-FW10008BM disponible en

la red en www.safholland.us.

ADVERTENCIA

Estas instrucciones

son para la operación

adecuada

de las placas

superiores de quinta

rueda series

FW16 XA-161

solamente. Existen

otras verificaciones,

inspecciones y

procedimientos que no

aparecen aquí y que son

necesarios, prudentes y/o

exigidos por la ley.

Si no se siguen todos

los procedimientos de

operación contenidos en

estas instrucciones, podría

ocasionar una situación

de riesgo o causar el

desarrollo de una situación

de riesgo que, si no se

evita, podría causar la

muerte o lesiones graves.

Español

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

31

Instrucciones generales de seguridad

3.

Lock completely closed around kingpin.

Seguro completamente cerrado alrededor

del perno rey.

CORRECT COUPLING / ACOPLAMIENTO CORRECTO

1.

Lock notch

behind rib.

Muesca de cierre

detrás del reborde.

2.

No gap

Sin separación

WARNING / ADVERTENCIA

Copyright © 2014 $SAF-HOLLAND, Inc.

www.safholland.us XL-FW20001DC-en-US

SIEMPRE inspeccione la quinta rueda después de acoplar el tractocamión al remolque.

Si no acopla adecuadamente el tractocamión y el remolque, podría ocasionar la separación del tractocamión

y el remolque durante el uso, lo cual, si no se evita, puede causar muertes o lesiones.

ALWAYS inspect fifth wheel after coupling tractor to trailer.

Failure to properly couple the tractor and trailer could result in tractor-trailer separation while in use

which, if not avoided, could result in death or serious injury.

2. Identificación del modelo

Las etiquetas de número de serie de la quinta

rueda están colocadas en la placa superior de

la quinta rueda encima del perno de soporte,

o en las rampas de acoplamiento (Figura 1).

El número de parte y el número de serie

aparecen en la etiqueta (Figura 2).

3. Requisitos de calcomanía

La calcomanía XL-FW20001DC-en-US

(Figura 3) adjunta en una bolsa de plástico

con el manual del propietario, debe instalarse

cerca de la quinta rueda y para que el

operador la pueda ver fácilmente. Ubique la

calcomanía como se muestra (Figura 4).

NOTA: Asegúrese de que la superficie

Es responsabilidad del usuario final

inspeccionar periódicamente la calcomanía

y asegurarse de que esté limpia y

completamente legible. Si no está la etiqueta,

se suelta, daña o resulta difícil de leer,

comuníquese con el Servicio de atención al

cliente de SAF-HOLLAND

para pedir un reemplazo de inmediato.

esté libre de aceite y grasa antes

de pegar la calcomanía.

®

al 888-396-6501

Figura 1

Figura 2

Model No. XXXXXXXXXXXXXXXXXX

Serial No. XXXXXXXXXXXXXXXXXX

U.S. AND FOREIGN PATENTS APPLY

FAILURE TO PROPERLY INSTALL, MAINTAIN & OPERATE

THIS PRODUCT COULD RESULT IN TRACTOR TRAILER

SEPARATION CAUSING SERIOUS INJURY OR DEATH.

Figura 3

MADE IN

XXXXXX

32

Figura 4

WARNING / ADVERTENCIA

ALWAYS inspect fifth wheel after coupling tractor to trailer.

Failure to properly couple the tractor and trailer could result in tractor-trailer separation while in use

which, if not avoided, could result in death or serious injury.

SIEMPRE inspeccione la quinta rueda después de acoplar el tractocamión al remolque.

Si no acopla adecuadamente el tractocamión y el remolque, podría ocasionar la separación del tractocamión

y el remolque durante el uso, lo cual, si no se evita, puede causar muertes o lesiones.

CORRECT COUPLING / ACOPLAMIENTO CORRECTO

3.

Lock completely closed around kingpin.

1.

Lock notch

2.

No gap

behind rib.

Seguro completamente cerrado alrededor

Sin separación

del perno rey.

Muesca de cierre

detrás del reborde.

Copyright © 2014 $SAF-HOLLAND, Inc.

www.safholland.us XL-FW20001DC-en-US

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Instrucciones de operación

4. Uso esperado para

la quinta rueda

1. Para jalar remolques con pernos

rey estándar de la SAE en buenas

condiciones y colocados firmemente o

asegurados en su lugar en el remolque.

2. Para transportar cargas por debajo de

la capacidad máxima estipulada de la

quinta rueda: Carga vertical máxima

55,000 lb (22,680 kg) Arrastre máximo

de la barra de tracción 150,000 lb.

(68,040 kg).

3. En aplicaciones en la carretera.

IMPORTANTE: La definición de

SAF-HOLLAND

®

de fuera de la carretera se

refiere al terreno en el cual el tractocamiónremolque funciona, que no está pavimentado,

es irregular y no está aplanado. Cualquier

terreno que no se considere parte del sistema

público de carreteras cae en esta categoría.

4. Como recomiendan las publicaciones

SAF-HOLLAND

®

disponibles en la red en

www.safholland.us.

5. Uso no esperado para

la quinta rueda

1. Uso con pernos rey que no cumplan con la

SAE, como pernos rey que estén torcidos,

de tamaño o dimensiones inadecuadas, no

asegurados para mantener la configuración

de la SAE o instalados en placas de soporte

para remolque torcidas o con placas

lubricantes de acoplador superior y quinta

rueda que no mantengan las dimensiones

del perno rey de la SAE. Consulte en

el boletín de servicio SAF-HOLLAND

XL-SB004-01 (disponible en internet en

www.safholland.us) para obtener más

información sobre las placas lubricantes de

la quinta rueda.

ADVERTENCIA

Si no acopla con un perno

rey que cumpla con la SAE,

podría ocasionar un acoplamiento incorrecto,

permitir la separación del tractocamión y el

remolque que, si no se evita, podría causar

muertes o lesiones graves.

®

2. Las operaciones de remolque que dañen

o interfieran con el funcionamiento

adecuado de la quinta rueda.

3. El acople de dispositivos de elevación.

4. El transporte de cargas que superen la

capacidad estipulada.

5. En aplicaciones fuera de la carretera.

6. Aplicaciones diferentes a las que se

recomiendan en las publicaciones

SAF-HOLLAND

®

disponibles en

www.safholland.us.

6. Preparación para el acople

1. Antes de acoplar usted deberá inspeccionar

la quinta rueda y el montaje. Haga y verifique

lo siguiente:

Confirme que las los platos lubricantes

estén colocadas y firmemente sujetas.

Ajuste los tornillos flojos.

Reemplace los tornillos faltantes.

Repare o reemplace los componentes

faltantes, agrietados o dañados.

Inspeccione el mecanismo de

la quinta rueda. Lubrique los

componentes secos u oxidados.

Si tiene una quinta rueda deslizante,

asegúrese de que los dos vástagos

estén completamente enganchados.

Inspeccione las conexiones de la

línea neumática.

Asegúrese de que la quinta rueda esté

en la posición correcta para la

distribución del peso sobre el

tractocamión. Consulte el documento

de SAF-HOLLAND

(disponible en internet en www.

safholland.us) acerca de la ubicación

correcta de la quinta rueda.

2. Asegúrese de que el lugar de

acoplamiento sea plano, horizontal

libre de personas y obstáculos.

®

XL-FW10008BM

Español

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

33

Instrucciones de operación

3. Incline hacia abajo las rampas de la

quinta rueda (Figura 5).

4. Asegúrese que los seguros estén abiertos

(Figura 6). Si los seguros están cerrados,

deslice la manija de liberación hacia la

izquierda y jálela totalmente hacia afuera

(Figura 7). Abra los seguros con una

barra de palanca.

5. Inspeccione el borde delantero de la

placa de soporte/deslizamiento del

remolque. Debe estar libre de cualquier

borde cuadrado

o afilado (Figura 8).

6. Asegúrese de que no haya tornillos o

tuercas que sobresalgan por debajo de

la placa de soporte/deslizamiento dentro

de 152 mm (6 pulg.) de la trayectoria

de desplazamiento de la quinta rueda

durante el acople.

Figura 5

INCLINAR HACIA ABAJO

Figura 6

SEGURO ABIERTO SEGURO CERRADO

Figura 7

34

LIBERACIÓN

A LA IZQUIERDA

LIBERACIÓN

A LA DERECHA

Figura 8

BORDE ANTERIOR

BISELADO (preferido)

O MUY REDONDEADO

20º

2"

MÍNIMO

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

7. El área apoyada por la quinta rueda debe

estar libre de agujeros o surcos grandes

(Figura 9).

8. Cualquier orificio de acceso que pase por

debajo de la quinta rueda deberá tener

bordes biselados o redondeados.

9. Verifique que cualquier parte separada

de la placa de deslizamiento a la placa

de soporte esté adecuadamente soldada

y que no haya bordes afilados o cambios

abruptos en la elevación (Figura 10).

10. El acoplador superior se deberá extender

adecuadamente hacia atrás para mantener

el contacto total con la quinta rueda

duante una vuelta cerrada. Si no lo hace,

al menos, los bordes traseros deberán

tener bordes biselados o redondeados.

11. Asegúrese de que la grasa residual

del acoplador superior esté libre de

arena gruesa.

12. Asegúrese de que la superficie de contacto

del acoplador superior con la quinta

rueda esté libre de óxido. El área deberá

estar acondicionada con un inhibidor de

corrosión tal como aceite ligero.

13. Verifique que el perno rey no esté

obstruido por un seguro de perno

rey u otro dispositivo de seguridad.

ADVERTENCIA

Si no retira el seguro del perno

rey antes de acoplar podría

ocasionar un acoplamiento

incorrecto que, si no se evita,

podría causar muertes o

lesiones graves.

Instrucciones de operación

MANTENGA LA TRAYECTORIA DE LA QUINTA

RUEDA LIBRE DE ORIFICIOS Y SURCOS GRANDES

6˝ MÍN.

40"

6˝ MÍN.

ORIFICIO DE ACCESO

ASEGÚRESE DE QUE NO HAYA

BORDES AFILADOS

SIN TRANSICIONES ABRUPTAS DE ELEVACIÓN

MANTENGA LOS

TORNILLOS Y TUERCAS

LIBRANDO ESTA ÁREA

Español

14. Inspeccione el perno rey en busca

de desgaste y daño excesivo (use la

herramienta TF-0110 Kingpin Gage de

HOLLAND

®

) junto con el arco de soporte

(ver los boletines de servicio SAF-HOLLAND®

XL-SB020 y XL-SB033).

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

35

Instrucciones de operación

7. Procedimientos de acople

IMPORTANTE: Seguir los procedimientos

PRECAUCIÓN

1. Bloquee las ruedas del remolque.

2. Ubique el tractocamión de manera que el

centro de la quinta rueda esté alineado

con el perno rey.

3. Desplazándose en línea recta, haga

retroceder lentamente el tractocamión

hacia el remolque. DETENGA el

tractocamión antes de hacer contacto

con el remolque (Figura 11).

IMPORTANTE: NO ponga en contacto

de acople de las quintas

ruedas FW16 Low Lube

es extremadamente

importante.

Si no sigue todos los

procedimientos contenidos

en estas instrucciones de

acople puede ocasionar

daño a las placas lubricantes.

la quinta rueda y el

remolque o podría dañar

las placas lubricantes.

Figura 11

REMOLQUE

(ARRIBA)

PERNO

REY

Figura 12

VACÍE LA SUSPENSIÓN NEUMÁTICA

ANTES DE RETROCEDER

4. Ponga el freno de estacionamiento del

tractocamión y colóquelo en neutral.

5. Vacíe completamente el aire de la

suspensión del tractocamión, asegúrese

de que la quinta rueda está por debajo

de la superficie de contacto del remolque

(Figura 12).

6. Salga de la cabina y asegúrese de que

la quinta rueda esté por debajo de la

placa del acoplador superior. Verifique la

altura adecuada de la quinta rueda. Si

el remolque está demasiado bajo, use el

patín para elevar la altura del remolque.

NOTA: Para operar correctamente el patín,

siga las instrucciones publicadas

por el fabricante del patín.

36

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Instrucciones de operación

7. Retroceda lentamente, usando la menor

velocidad posible. Pare cuando la quinta

rueda esté debajo del borde anterior del

remolque (Figura 13).

8. Ponga el freno de estacionamiento del

tractocamión. Colóquelo en neutral. Salga

de la cabina y verifique la alineación

correcta entre la quinta rueda y el perno rey.

9. Ajuste la suspensión del tractocamión

hasta la altura de viaje. La placa de la

quinta rueda debe hacer contacto con la

placa del acoplador superior (Figura 14).

Si la quinta rueda no está en contacto con

la placa del acoplador superior, use el patín

para bajar el remolque hasta que lla quinta

rueda haga contacto.

IMPORTANTE: Si el remolque está

demasiado alto, el perno

rey no se conectará

correctamente con las

mordazas del seguro.

ADVERTENCIA

Si no acopla con el remolque

a la altura adecuada, podría

ocasionar un acoplamiento

incorrecto, permitir la

separación del tractocamión

y el remolque que, si no se

evita, podría causar muertes

o lesiones graves.

Figura 13

RETROCEDA

Y ¡PARE!

Figura 14

IMPORTANTE: Nunca infle la suspensión

del tractocamión cuando

el perno rey esté por

encima del la garganta

de la quinta rueda.

PRECAUCIÓN

Si no evita inflar la suspensión

del tractocamión cuando

la quinta rueda no está por

delante del perno rey, podría

ocasionar daños en el perno

rey y la quinta rueda.

10. Retroceda lentamente hacia el remolque,

enganchando el perno rey en la quinta rueda.

11. Conecte las líneas eléctricas y neumáticas.

12. Levante el apoyo del patín hasta que los

pies apenas toquen el suelo.

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Español

37

Instrucciones de operación

13. Realice una prueba de arrastre como

VERIFICACIÓN INICIAL poniendo los

frenos del remolque y arrastrando hacia

adelante con el tractocamión para

asegurarse de que no se separen el

tractocamión del remolque (Figura 15).

14. Ponga el freno de estacionamiento

del tractocamión.

15. Salga de la cabina e inspeccione

visualmente lo siguiente para asegurar

que el seguro esté cerrado (Figure 16).

a. Manija de liberación totalmente

retraida con la muesca de cierre

detrás del reborde.

b. No se permite una separación entre

la placa del acoplador superior del

remolque y la quinta rueda.

c. Seguro bien cerrado detrás de la mordaza.

16. Si no se ha logrado un acople correcto,

repita el procedimiento de acople.

ADVERTENCIA

Si no acopla adecuadamente

el tractocamión y el remolque,

podría ocasionar la separación

del tractocamión y el remolque

durante el uso, lo cual, si

no se evita, podría causar

muertes o lesiones graves.

Figura 15

PONGA LOS FRENOS DEL REMOLQUE

Y ARRASTRE HACIA ADELANTE

CON EL REMOLQUE

Figura 16

¡SIN

SEPARACIÓN!

MUESCA DE

CIERRE DETRÁS

DEL REBORDE

Figura 17

SEGUROS

COMPLETAMENTE

CERRADOS ALREDEDOR

DEL PERNO REY

IMPORTANTE: NO utilice una quinta

rueda que no funcione

correctamente.

ADVERTENCIA

Si no repara una quinta

rueda que no funciona

correctamente antes de

usarla, podría ocasionar la

separación del tractocamión

y el remolque que, si no se

evita, podría causar muertes

o lesiones graves.

17. Suba por completo el apoyo del patín del

y fije la manivela (Figura 17).

NOTA: Para operar correctamente el patín,

siga las instrucciones publicadas

por el fabricante del patín.

18. Retire el bloqueo de las ruedas y continúe

con la inspección previa al viaje.

38

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

FIJE LA MANIVELA

Instrucciones de operación

8.

Procedimientos de desacople

IMPORTANTE: Seguir los procedimientos

de desacople adecuados

de las quintas ruedas

FW16 Low Lube es

extremadamente importante.

PRECAUCIÓN

Si no sigue todos los

procedimientos contenidos

en estas instrucciones de

desacople puede ocasionar

daño a las placas.

1. Ubique el tractocamión y el remolque

en una línea recta, en un lugar firme,

horizontal y sin personas ni obstáculos.

2. Ponga los frenos del remolque.

3. Haga retroceder lentamente el

tractocamión hasta apretarlo contra

el remolque para aliviar la presión del

seguro de la quinta rueda.

4. Ponga el freno de estacionamiento del

tractocamión.

IMPORTANTE: NO vacíe la suspensión

neumática del tractocamión

antes de desacoplar.

PRECAUCIÓN

Si no evita vaciar

la suspensión del

tractocamión antes

de desacoplar, podría

ocasionar dificultades para

desacoplar el tractocamión

del remolque, lo cual, si no

se evita podría dañar la

quinta rueda y el perno rey.

5. Bloquee las ruedas del remolque.

6. Baje el patín hasta que los pies apenas

toquen el suelo (Figura 18).

Figura 18

BAJE EL PATÍN

Español

NOTA: Siga las instrucciones publicadas

por el fabricante para la

operación adecuada del patín y

la capacidad de transferir el peso

del remolque desde la quinta

rueda. NO levante el remolque

de la quinta rueda.

XL-FW10055UM-es-US Rev D · 2014-01-29 · Correcciones y errores reservados · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

y logos son marcas registradas de SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

39

Instrucciones de operación

7. Desconecte las líneas eléctrica y

neumática del remolque y asegure

el tractocamión.

8. Deslice la manija de liberación hacia

la izquieda, jale completamente hacia

afuera, deslice la manija a la izquierda

y enganche el en molde de la manija

(Figura 19).

9. Libere los frenos de estacionamiento

del tractocamión y avance lentamente

12 a 18 pulgadas (306-457 mm) para

desenganchar el perno rey de la quinta

rueda. La quinta rueda debe quedar

entre el borde delantero del remolque

y el perno rey (Figura 20).

IMPORTANTE: NO avance el

tractocamión para

liberarlo del remolque.