EDL/ARF

OPERATION

INFORMATION

EDL/ARF Feature

External Dock Lock (EDL)

Automatic Reset Feature (ARF)

for Trailer Air-Ride Suspensions

XL-AR363-02 Rev. D

TABLE OF CONTENTS

Introduction..................................................................................................2

Warranty........................................................................................................2

Notes, Cautions, and Warnings .................................................................2

Table of Contents .......................................................................................2

xternal Dock Lock (EDL) Installation..................................................3

E

Suspension Ride Height Verification...............................................3

EDL Rod Flipper Plate Installation ................................................4

EDL Actuator Chamber Installation ..............................................4

ir System Connection......................................................................5

A

Operation......................................................................................................6

Automatic Reset Feature (ARF).......................................................6

Purpose:................................................................................................7

Function:..............................................................................................7

INTRODUCTION

This manual provides you information necessary for the installation,

adjustment, inspection, and safe operation of SAF-HOLLAND

External Dock Lock (EDL) Automatic Reset Feature (ARF) for

Trailer Air-Ride Suspensions.

The SAF-HOLLAND EDL is designed and engineered to provide

trouble-free service. In the event of an inoperative EDL, such as a bent

rod assembly or a damaged cam bracket, the vehicle should be driven

CAUTIOUSLY at slow speed, to the nearest service facility for repair

or replacement.

This EDL/ARF uses air drawn from the truck/tractor air system to

operate the EDL actuator. The height control valve regulates the air

pressure required for varying loads. The ARF feature ensures the

flipper plate(s) will not be trapped down (engaged position) while the

trailer is in motion.

WARRANTY

Refer to the complete warranty for the country in which the product

ranty is included with the product

will be used.

as well as in the suspension catalogs and the SAF-HOLLAND Web

Site (www.safholland.us). It may also be ordered by calling

1-888-396-6501.

A copy of

the written w

ar

Parts List ..............................................................................................7

Disengaged Application ....................................................................8

Engaged Application..........................................................................8

ARF Description when Releasing Trapped

Flipper Plates..............................................................................9

aintenance................................................................................................10

M

Auto Reset (Sensor) Valve Performance Check..........................10

EDL Flipper Plate Adjustment......................................................11

Primary Height Control Valve Information ................................12

Pilot Valve Check for EDL/ARF System....................................12

rimary Height Control Valve Adjustment..................................13

P

EDL/ARF System Troubleshooting......................................................14

NOTES, CAUTIONS, AND WARNINGS

You must read and understand all of the safety procedures presented in

this manual before starting any work on the suspension.

Proper tools must be used to perform the maintenance and repair

procedures described in this manual. Many of these procedures require

special tools.

Failure to use the proper equipment could result in

personal injury and/or damage to the suspension.

Safety glasses must be worn at all times when performing the

procedures covered in this manual.

Throughout this manual, you will notice the terms “NOTE,”

“IMPORTANT,” “CAUTION” and “WARNING” followed by

important product information. So that you may better understand the

manual, those terms are as follows:

NOTE: Includes additional information to enable accurate and

easy performance of procedures.

IMPORTANT: Includes additional information that

if not followed could lead to hindered

product performance.

Used without the safety alert symbol,

indicates a potentially hazardous situation

hich, if not avoided, may result in

w

.

e

operty dama

pr

Indicates a potentially hazardous situation

h, if not a

hic

w

moderate injury.

Indica

which, if not avoided, could result in death or

serious injury.

g

oided, may result in minor or

v

tes a potentiall

y hazar

dous situa

XL-AR363-02 Rev. D2

tion

EXTERNAL DOCK LOCK (EDL) INSTALLATION

FIGURE 1

EDL Components

1

3

9

4

3

2

ITEM

NO. DESCRIPTION NS-xxx-16.0* NS-xxx-16.5* NS-xxx-17.0* NS-xxx-18.0* QTY.

1 EDL Rod Assembly 42˝ - 90546178 42˝ - 90546270 42˝ - 90546136 42˝ - 90546138 1

48˝ - 90546177 48˝ - 90546269 48˝ - 90546132 48˝ - 90546134

2 Hex Bolt 38 -16 x 1˝ 93002571 93400471 93400471 93400471 4

3 EDL Rod Support Plate 90034494 90034494 90034494 90034494 2

4 Hex Lock Nut 3/8˝ - 16 93400472 93400472 93400472 93400472 4

5 Hex Nut .50-13 93400136 93400136 93400136 93400136 2

6 Washer .53 93600072 93600072 93600072 93600072 2

7 EDL Actuator Chamber 90546122 90546122 90546122 90546122 1

8 Choke Valve 90054811 90054811 90054811 90054811 1

1

9

/2˝

Clevis Assembly w/1/2˝ Pin

* “xxx” denotes models 400 or 450.

IMPORTANT: Be certain the correct EDL assembly for the

11M018-8 11M018-8 11M018-8 11M018-8 1

NOTE: Example: NS-400/450-4818, last two digits

suspension ride height is being installed. Various

5

6

8

represent 18˝ (457mm) ride height.

7

suspension ride heights require different

assemblies with different flip plate heights. If

unsure of ride height, see

FIGURE 3 and Table 1

or call SAF-HOLLAND Customer Service at

1-888-396-6501.

Suspension Ride Height Verification

1. Verify ride height by checking serial number tag located on the rear

crossmember (

If the serial number tag is not legible or unavailable, verify ride height

FIGURE 2).

2. Compare ride height to corresponding Flipper Plate Height from

Table 1 below (FIGURE 3).

TABLE 1.

Model No. Height Height

NS-400/450-16 16˝ (406mm) 6.5˝ (165mm)

NS-400/450-16.5

NS-400/450-17 17˝ (432mm) 7.5˝ (191mm)

NS-400/450-18

Ride Flipper Plate

16.5˝ (419mm) 7.0˝ (178mm)

18˝ (457mm)

“A”

8.5˝ (216mm)

by measuring from the center of the axle to the bottom of the frame

or slider (

FIGURE 2

FIGURE 3).

FIGURE 3

Flipper Plate

Serial Tag Location

Serial Number T

on Rear Crossmember

ag Located

Flipper Plate Height

“A”

Ride

Height

XL-AR363-02 Rev. D 3

5/8˝ (16mm)

Min.

Clearance

EXTERNAL DOCK LOCK (EDL) INSTALLATION continued

EDL Rod Flipper Plate Installation

. Attach one support plate to frame rail above rear axle, and secure

1

with two bolts and nuts.

FIGURE 4

EDL Rod Support Plate

EDL Rod Support Plate

Bolts

2. Slide one end of EDL Rod Assembly into the hole of the attached

support plate. Then slide the other support plate onto the opposite

end of EDL Rod Assembly and secure with two bolts and nuts.

Tighten and torque all four bolts and nuts to 25 ft. lbs. (34 Nm)

FIGURE 5).

(

FIGURE 5

EDL Installation

DO NOT tighten (FIGURE 4).

Nuts

IMPORTANT: EDL Rod/Flipper Plate Assembly should rotate

reely without binding (

f

IGURE 6).

F

FIGURE 6

Flipper Plate Installation

IMPORTANT:

EDL Flipper Plate

Assembly should

otate fully without

r

binding

IMPORTANT:

Flipper Plate must

be completely down

when attaching

actuator push rod

5/8˝ Min. (16mm)

Clearance Gap Required

IMPORTANT: Both flipper plates must rest on equalizing beam

when trailer is loaded.

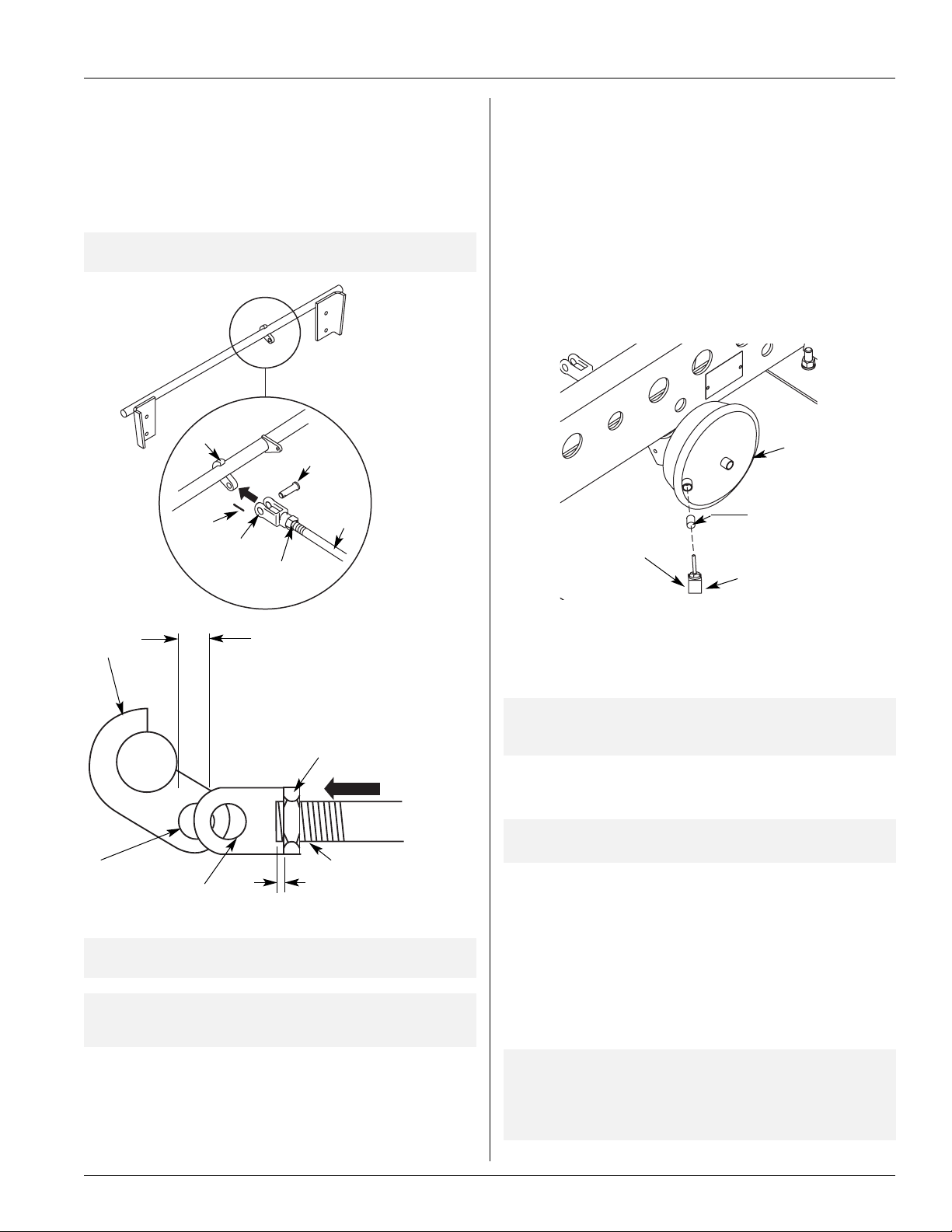

EDL Actuator Chamber Installation

1. Attach actuator chamber to mounting bracket on slider box

crossmember (

Torque nuts to 50-60 ft. lbs. (68-81 Nm).

FIGURE 7

Actuator Chamber Installation

FIGURE 7). Fasten with two lock washers and nuts.

Bolts

Support Plate

Nuts

Flipper Plate

Tab

Cam Bracket

EDL Rod Assembly

Nut

Lockwasher

Actuator

Chamber

To air supply line

Actuator Chamber

Mounting Bracket

Install the adjusting nut and c

2.

vis to the actua

le

tor push rod and

thread adjusting nut and clevis down the push rod. Be sure to leave

clevis 1/2˝ (13mm) short of cam mounting hole (

FIGURE 8).

continued

XL-AR363-02 Rev. D4

EXTERNAL DOCK LOCK (EDL) INSTALLATION continued

3. Pull actuator push rod out (arrow A) so the hole in the cam aligns

ith the clevis hole (this creates tension on the actuator spring to help

w

keep the flipper plate completely down). Install clevis pin and secure

with cotter pin (

FIGURE 8).

FIGURE 8

Clevis Installation

IMPORTANT: Flipper Plate must be completely down when

attaching actuator push rod.

Cam

Cotter

Pin

Clevis

Adjusting

Jam Nut

Clevis

Pin

Push

Rod

Air System Connection

. The control for releasing the EDL is the same for releasing the

1

emergency brakes on the trailer. Locate a trailer supply line (usually

red) at the point it enters the spring brake valve (supply port).

. Replace straight connector fitting with a tee and reconnect the

2

upply line and add a length of plastic line for connection to the

s

actuator chamber (

connects the cylinder port of the pilot valve to the bottom port of

the sensor valve (

FIGURE 9

Connect Air System

To supply line

connection on

sensor valve

FIGURE 9) and the line that you will install which

FIGURE 10).

Actuator

Chamber

Choke Valve

Air Line Fitting

Cam

Bracket

Adjust clevis and jam nut on

push rod so clevis mounting hole

is 1/2˝ (13mm) short of cam

mounting hole to cause tension

on actuator return spring

Adjusting Jam Nut

“A”

Cam Mounting Hole

Clevis Mounting Hole

IMPORT

ANT:

Adjust the push r

is completel

y do

wn (

Actuator Push Rod

3/16˝ (4.76mm)

Maximum actuator

push rod protrusion

od length to assure f

FIGURE 6).

lipper plate

IMPORTANT: EDL Rod/Flipper Plate Assembly should rotate

y without binding after attaching actuator

eel

fr

od (

push r

FIGURE 6).

3. At the threaded end of the 1/4 N.P.T. tube fitting insert the choke

valve (supplied) and install fitting to actuator. Attach the supply line

from the brake valve to a 1/4 N.P.T. tube fitting (FIGURE 9).

NOTE: It may be necessary to use a vise to press choke valve

into tube fitting or use a hammer and gently tap choke

valve into tube fitting.

4. Insert the 1/4 N.P.T. tube fitting into the brake actuator inlet port

FIGURE 9).

(

NOTE: Choke valve should be flush with bottom of

the fitting.

5. From the pressure protection valve, run a line to the bottom port of

the primary height contr

ol valve (

FIGURE 12).

6. Connect the top port of the primary height control valve to the

center port of the sensor valve (

the primary height control valve and sensor

he center por

T

7.

v

alve are connected to the air springs (

ts of

FIGURE 11).

FIGURE 11).

8. The pilot port of the pilot valve is connected to the emergency line

(

FIGURE 12).

Secur

e all suppl

y lines and check for air leaks.

IMPORTANT: It is the responsibility of the air system installer

to secure all air lines and check for any air leaks.

If air leaks are detected, repair as required.

ailure to eliminate the air leaks may compromise

F

.

mance

the suspension perf

or

XL-AR363-02 Rev. D 5

OPERATION

Automatic Reset Feature (ARF)

he Automatic Reset Feature (ARF) is designed to ensure that the

T

External Dock Lock (EDL) flipper plates are not trapped down while

the trailer is being operated. This is accomplished by the use of two

valves. A pilot valve is used to monitor emergency brake pressure to

determine if the trailer is parked or in motion. A sensor valve is used

to monitor the position of the EDL flipper plates (either up or down)

FIGURE 10).

(

FIGURE 10

Sensor Valve Detail

Sensor

Valve

Check Valve

The primary height control valve has full function under two

conditions: (1) parking brakes are engaged or disengaged with flipper

lates up or (2) parking brakes are engaged with flipper plates down.

p

however, parking brakes are disengaged with flipper plates

down, the sensor valve will add air directly to the air springs.

fter the air springs have sufficient air pressure to raise the flipper

A

plates up off the load pads, the flipper plates rotate up and out of the

way. This disengages the sensor valve and allows the primary height

control valve to resume full function (

FIGURE 12).

NOTE: For further ARF information contact SAF-HOLLAND

Customer Service at 1-888-396-6501.

f

I

Emergency

Line

Pilot Valve

FIGURE 12

Automatic Reset Feature

To actuator

chamber

FIGURE 11

Primary Height Control Valve Detail

Primary Height Control Valve

To air springs

Primary Height

Control Valve

To center port

of sensor valve

To PPV

To pilot

valve

To air springs

Sensor Valve

Check Valve

Air Reser

voir Tank

Pressure Protection V

Flipper Plate

alve

Link

Emergency Line

Pilot V

alve

o Actuator

T

Chamber

XL-AR363-02 Rev. D6

OPERATION continued

Purpose:

he ARF (Automatic Reset Feature) is designed to ensure that the

T

External Dock Lock (EDL) flipper plates will not be trapped down

(engaged position) while the trailer is in motion. This is accomplished

by the use of two additional system valves.

OTE:Refer to (FIGURE 13)for component locations in the

N

EDL/ARF system.

FIGURE 13

EDL/ARF System

Piping Diagram

(Numbers correspond

to the Parts List below)

43/4˝±1/8˝

(120.65±

3.18mm)

Tab

8

Must use

Nylok

1/4˝-20 nut

(2 places)

11 Linkage

ssembly

A

Function:

Because both vehicle motion and position of the flipper plates must be

monitored, two additional system valves are used along with the height

control valve. A pilot valve monitors emergency brake pressure to

determine if the vehicle is parked or in motion. An auto reset (sensor)

alve monitors the position of the flipper plates (up or down) on the

v

External Dock Lock (EDL).

IMPORTANT: The sensor valve is not interchangeable with

the HCV.

4

5

From emergency

brake line

10

7 EDL Actuator

2

6

9

EDL Flipper Plate Rod Assembly

shown in engaged (down) position.

Parts List

1. EDL Flipper Plate (Shown in the Engaged Position):

The flipper plates are activated by the vehicle’s emergency parking

brakes. When the parking brakes are engaged, the flipper plates

rotate down to the engaged position. When the parking brakes are

eleased, the f

r

2. Primary Height Control Valve (1/4˝ and 3/8˝ air lines):

he Primar

T

adjusted to suspension design ride height to assure proper air

suspension and EDL function. When the flipper plates are up, the

primar

3. Pilot Valve: A pilot valve is used to monitor emergency brake

pressure to determine if the trailer is parked or in motion.

Auto Reset (Sensor) Valve:

4.

used to monitor the position of

or down). (To distinguish between a sensor valve and an HCV, a

sticker is placed on the sensor valve.) When the flipper plates are

in the up position, the standard height control valve maintains the

predetermined ride height. The auto reset (sensor) valve arm

should only be in the “up” position when the flipper plate is

down, or “down” when the flipper plate is in the up position.

Anytime this valve is in the neutral position it will cause the air

system to malfunction.

5. One-Way Check Valve (1/4˝ and 3/8˝ air lines): Installed

to the middle por

lipper plates rotate up to the disengaged position.

y Height Control Valve must always be properly

y height control v

alve has full function.

the sensor valve.

t of

An auto r

the EDL f

eset (sensor) valv

lipper plates (either up

e is

3

1

6. Pressure Protection Valve: Air pressure protection valve

ensures that safe air brake pressure is always maintained (70

psig—4.8 bars) in the air reservoir.

7. EDL Actuator: Push rod retracts (with emergency brakes on) to

pull flipper plates down (engaged).

8. Air Reservoir: Main vehicle air supply.

9. Air Spring: When the emergency brakes are released, air is

supplied to the air springs, raising the trailer above ride height.

This frees the trapped flipper plates on the trailing arm load pads.

lipper plates will then rotate up and out of the way. The

he f

T

rotation upward of the flipper plates, rotates the arm of the

sensor valve downward. This disengages the sensor valve and

ws the primary height contr

allo

ol v

e to contr

alv

ol all air flow for

ride height.

10. Choke Valve: Can be installed in either side of the air

y line to the actuator. Purpose of choke valve is to slow

suppl

down flipper plate rotation.

11. Auto Reset (Sensor) Valve Linkage Assembly:

Predetermine length of 4 3/4˝±1/8˝ (120.65±3.18mm) ensures

proper function of system. Linkage fasteners must be assembled

e.

v

bo

wn a

as sho

XL-AR363-02 Rev. D 7

OPERATION continued

N.C. Port

Cylinder

Port

N.O.

Port

Exhaust To

Atmosphere

Pilot (Top)

Port to

Emergency

Brake Line

Exhaust

Air Spring

Air

Reservoir

Air Spring

Pressure Protection Valve

Minimum of 75 psig (5.2 bars) to allow

Air to Flow through Valve

Primary

Height

Control

Valve

Auto

Reset

(Sensor)

Valve

Air Spring

Air Spring

One-Way

Check

Valve

EDL Flipper Plate

Disengaged (Up) Position

Pilot

Valve

EDL

Actuator

Disengaged Application

DL Flipper plates up (disengaged) and vehicle is in

E

motion (FIGURE 14).

When the parking brakes are disengaged, the flipper plates will be up

and the primary height control valve (HCV) has full function. The

rimary HCV fills the air springs through its center port and exhausts

p

he air springs through the top port of the auto reset (sensor) valve

t

FIGURE 15).

(

FIGURE 14

EDL

Disengaged

Flipper Plate

Disengaged

(Up Position)

Engaged Application

EDL Flipper plates down (engaged) and vehicle is

parked

1. Releasing air pressure from the trailer brake system or

disconnecting the glad hand engages the parking brakes.

FIGURE 16

EDL Engaged

Flipper Plate

Engaged

(Down

Position)

2. System pressure to the “pilot port” of the pilot valve is cut off.

3. The normally closed (N.C.) port of the pilot valve closes, cutting off

system pressure.

4. The normally open (N.O.) port of the pilot valve opens, providing

an exhaust port for the air between the pilot valve and the EDL

actuator and sensor valve to escape.

5. The HCV maintains the ride height.

6. The EDL actuator push rod retracts, rotating the EDL rod assembly

so the flipper plates are down—in the engaged position.

7. If the suspension is at the correct ride height, the bottom edge of the

flipper plates

down position and the ARF does not function. Trailer and

suspension component damage could result. Refer to

EDL/ARF System Troubleshooting on page 14.

must be 5/8˝ above the beam load pads.

Do not operate vehicle (put in motion)

if flipper plates are trapped in the

FIGURE 15

EDL/ARF Piping Diagram with Flipper Plates Disengaged (up position)

XL-AR363-02 Rev. D8

OPERATION continued

N.C. Port

Cylinder

Port

N.O.

Port

Exhaust To

Atmosphere

Pilot (Top)

Port to

Emergency

Brake Line

Exhaust

Air Spring

Air

Reservoir

Air Spring

Pressure Protection Valve

Minimum of 75 psig (5.2 bars) to allow

Air to Flow through Valve

Primary

Height

Control

Valve

Auto

Reset

(Sensor)

Valve

Air Spring

Air Spring

One-Way

Check

Valve

EDL

Flipper

Plate

Engaged

(Down) Position

Pilot

Valve

EDL

Actuator

ARF Description when Releasing

Trapped Flipper Plates

Trapped flipper plates in the down (engaged)

position (FIGURE 17)

1. With parking brakes disengaged, the air reservoir begins to fill with

air. When air reservoir pressure reaches 85 psig (5.9 bars), the

pressure protection valve opens, supplying air to the

suspension system.

2. System pressure is supplied directly to the height control valve

(HCV) and to the normally closed (N.C.) port of the pilot valve.

. As brake system pressure increases, pressure increases to the top

3

port or “pilot port” of the pilot valve.

4. Increased pressure to the “pilot port” opens the N.C. port of the

pilot valve, applying system pressure through the cylinder port to the

sensor valve and the EDL actuator chamber.

5. System pressure to the EDL actuator chamber in turn pushes the

actuator push rod—which is fastened to the EDL rod assembly by a

clevis and pin—attempting to rotate the

flipper plates up (out of the way).

6. At the same time system pressure is applied to the EDL actuator

hamber, air also flows through the sensor valve and one-way check

c

valve. Air flowing through the check valve into the air springs

temporarily raises the slider box. With the slider box raised—freeing

the “trapped” flipper plates—the actuator push rod rotates the

lipper plates up.

f

7. After quickly releasing the flipper plates, the HCV returns the

suspension to its normal ride height. To return to the normal ride

height, increased air pressure from the air springs exhausts through

he HCV and out through the sensor valve top port.

t

FIGURE 17

Trapped

Flipper Plate

Trapped

Flipper

Plate

FIGURE 18

EDL/ARF Piping Diagram with Flipper Plates Engaged (down position)

XL-AR363-02 Rev. D 9

MAINTENANCE

Auto

Reset

(Sensor)

Valve

Auto Reset (Sensor) Valve Performance Check

To check the Sensor Valve for proper adjustment and

operation, perform the following procedures.

Failure to chock tires prior to beginning

maintenance could allow vehicle rollaway

hich, if not avoided, could result in death or

w

serious injury.

NOTE: Apply air system pressure in excess of 85 psig (5.9 bars)

before doing performance check.

. Disconnect the auto reset (sensor) valve lower linkage connection to

1

the EDL rod assembly. Rotate valve arm up approximately 20˚ and

FIGURE 19). Air should flow through one-way check valve

hold (

ports to air springs (

2. Move valve arm down 20˚ (

primary height control valve upper linkage connection. Rotate

primary height control valve arm down approximately 45˚ and hold

for 5-10 seconds. Air should flow (exhaust) out top port of auto

reset (sensor) valve (

3. Reconnect sensor valve and primary height control valve linkages.

sensor valve ONLY. Use of primary height control valve

(1/4˝ [6.35mm] or 3/8˝ [9.53mm] air lines) in place of

sensor valve will result in malfunction of the auto reset

feature and possible damage to suspension and/or trailer.

NOTE: To prevent side loading on sensor valve linkage

connection—fastening hardware

shown in (

assembled as shown, disconnect linkage assembly and

refasten as shown.

FIGURE 21

Auto Reset Sensor V

FIG. 19).

FIGURE 20) and hold. Disconnect the

FIGURE 20).

In the event replacement of the

sensor valve is necessary, replace with

MUST be assembled as

FIGURE 21) for proper function. If not

alve Linkage Assembly

FIGURE 19

Auto Reset (Sensor) Valve (EDL Engaged) Air Flow

Check

Valve Arm in up position

(above horizontal)

Bottom Port

EDL Rod Assembly

Air should be

flowing out of

both check

valve ports

To Air

Springs

Disconnect

Lower

Linkage

Tab

FIGURE 20

Auto Reset (Sensor) Valve Air Flow Check

Air should exhaust

out top port of

sensor valve

Auto

Reset

(Sensor)

Valve

Sensor Valve

Arm down 20˚

below horizontal

Sensor

alve

V

Arm

ab

T

Link - Must

be vertical

to prevent

side loading

43/4˝±1/8˝

(120.65±

3.18mm)

Must use Nylok

1/4˝-20 nut (2

places)

Flat Washers

Nylok Nut

Shoulder

Bolt

Tab

Flat

Washers

Sensor

Valve Arm

Nut Slot

Nylok

Nut

Sensor

Valve

Shoulder

Bolt

EDL Rod

Assembly

Primary

Height

Control

Valve

Hold Primar

45˚ below horizontal for

10-15 seconds

y HCV Arm down

Disconnect upper

linkage connection

Air

Spring

XL-AR363-02 Rev. D10

MAINTENANCE continued

Auto

Reset

(Sensor)

Valve

EDL

Flipper

Plate

Disengaged (Up) Position

EDL

Actuator

Auto

Reset

(Sensor)

Valve

EDL

Flipper

Plate

Engaged

(Completely Down) Position

EDL

Actuator

EDL Flipper Plate Adjustment

Proper EDL Flipper Plate/Auto Reset (Sensor) Valve

Arm Adjustment

ailure to chock tires prior to beginning

F

aintenance could allow vehicle

m

rollaway which, if not avoided, could result in death or

serious injury.

. With the emergency brakes applied visually check the EDL Flipper

1

Plates and valve arm for correct positioning (

positioning is found move ahead to Step 4.

ORRECT Flipper Plates Engaged (Down) Position

C

mergency Brakes APPLIED:

E

When the EDL is engaged and properly installed/adjusted the valve

arm will be approximately 20˚ above the horizontal position, and

the flipper plates will be in the completely down

position (

FIGURE 22).

EDL/ARF System could malfunction if

the flipper plates and sensor valve arm

are not in the correct alignment to each other. If operated

under incorrect alignment—trailer and/or property

damage could result.

2. If upon inspection the flipper plates do not rotate to the complete

down position and the sensor valve arm is not approximately 20˚

above horizontal position, the actuator push rod must be adjusted.

Remove clevis pin, loosen jam nut, and thread the clevis in until the

push rod will pull the EDL flipper plates to the straight down

position and push the valve arm approximately 20˚ above

horizontal position.

IMPORTANT: When adjusting flipper plates to the straight

down position, clevis must be threaded in 1/2˝

(13mm) short of cam mounting hole (

24

). This creates tension on the actuator return

spring to pull the flipper plates completely down

during the engaged application.

3. Pull actuator push rod out so the hole in the cam aligns with the

clevis hole. Install clevis pin and secure with cotter pin

FIGURE 24). Tighten jam nut against clevis.

(

NOTE: Maximum push rod protrusion is 3/16˝ (4.76mm)

FIGURE 24).

(

4. With the emergency brakes OFF visually check the EDL flipper

plates and sensor valve arm for correct positioning (

FIGURE 22). If correct

FIGURE

FIGURE 23).

FIGURE 22

CORRECT Flipper Plate Engaged Position

Valve Arm up 20˚

(above horizontal)

Tab

Adjusting

Cam

Clevis

Jam Nut

Actuator

Push Rod

FIGURE 23

CORRECT Flipper Plate Disengaged Position

Valve Arm down 20˚

(below horizontal)

Cam

43/4˝±1/8˝

(120.65±3.18mm)

Actuator

Tab

Push Rod

FIGURE 24

EDL Cam to Actuator Push Rod Adjustment

Cam

Bracket

1/2˝

(13mm)

Leave clevis 1/2˝ (13mm) short of

cam mounting hole to preload

spring in chamber assembly

CORRECT Flipper Plates Disengaged (UP) Position

gency Brakes OFF:

Emer

Adjusting Jam Nut

When the EDL is disengaged and properly installed/adjusted the

sensor valve arm will be down approximately 20˚ below horizontal

position and the f

(

FIGURE 23).

lipper pla

IMPORTANT: If

Engaged or Disengaged positioning, by adjusting

the actua

SAF-HOLLAND Customer Service.

XL-AR363-02 Rev. D 11

tes will be in the up position

e unable to obtain either the correct

ou ar

y

tor push r

od (

FIGURE 22),

contact

Cam

Mounting

Hole

Clevis Mounting Hole

3/16˝ (4.76mm)

Maximum actuator

push rod protrusion

IMPORTANT: Flipper plate must be completely down

(engaged position).

MAINTENANCE continued

Primary Height Control Valve Information

Height Control Valve Performance Check

IMPORTANT: Proper inspection can eliminate unnecessary

replacement of height control valve.

FIGURE 25

Height Control Valve Performance Check

NOTE: Apply air system pressure in excess of 85 psig

5.9 bars) before doing performance check.

(

1. Disconnect the link assembly from height control valve arm.

. Move control arm up 45˚ for 10-15 seconds – air should flow to air

2

springs (

3. Move control arm to center (neutral) position – valve should shut

off air flow to air springs.

4. Move control arm down 45˚ for 10-15 seconds (

should f

and exhaust out the top port of the auto reset (sensor) valve.

5. Move control arm to center (neutral) position – valve should shut

off air flow.

6. Valve is good if performance is as noted.

7. Reconnect upper link assembly to control arm.

FIGURE 25).

FIGURE 25) - air

low from air springs into center port of height control valve

Pilot Valve Check for EDL/ARF System

Pilot Valve Performance Check

NOTE: Apply air system pressure in excess of 85 psig (5.9 bars)

before doing performance check.

Central

(Neutral)

Position

Intake

Up 45˚

Exhaust

Down 45˚

NOTE: If valve does not perform correctly, refer to the

adjustment procedures on page 13.

FIGURE 26

Pilot Valve Check

1. When air from emergency brakes is present on top port of pilot

valve air should flow from N.C. port to cylinder port (

2. When emergency spring brakes are released (no air to top port of

pilot valve, air should exhaust (quickly) from EDL actuator out of

t (

por

.

.O

N

FIGURE 26).

FIGURE 26).

Pilot Port to

Emergency

Brake Line

Pilot Valve

Cylinder Port

N.O. Port

Exhaust to

Atmosphere

N.C. Port

XL-AR363-02 Rev. D12

MAINTENANCE continued

Primary Height Control Valve Adjustment

Height Control Valve Adjustment Procedures

IMPORTANT: This adjustment procedure is for ONE Height

Control Valve system with an External Dock

Lock Device

. Prior to adjustment, the vehicle must be in an unladen condition on

1

a level floor and supported on a king pin stand or coupled to a

tractor (

FIGURE 27).

Failure to properly support suspension

during maintenance may allow

suspension to fall which, if not avoided, could result in

eath or serious injury.

d

IMPORTANT: DO NOT use flipper plate height plus 5/8˝

(16mm) clearance spacing to determine ride

height setting.

2. Verify ride height by checking serial number tag located on the frame

bracket or crossmember (FIGURE 28).

Example: NS400/450-4816, last two digits

represent 16˝ (406mm) ride height.

3. Confirm proper EDL flipper plate rod assembly by comparing

predetermined ride height to corresponding EDL flipper plate

FIGURE 29, see chart).

height (

4. Disconnect primary height control valve linkage to lower mounting

bracket, and move control arm up 45˚ and hold for 10-15 seconds to

raise vehicle. Return control arm to center (neutral) position.

5. Move control arm down 45˚ and hold until system air exhausts

completely, lowering flipper plates. Return control arm to center

(neutral) position, and check for proper ride height (determined in

step 2—

FIGURE 29).

FIGURE 27

Trailer Supported at Fifth Wheel Height

Operating

Height

Support at King Pin

FIGURE 28

Serial Tag

FIGURE 29

Obtaining Proper Ride Height

Flipper Plate

“A”

Ride

Height

Ride

Height

C

L

Axle

Serial Number Tag

Located on Rear

Crossmember

5/8˝ MIN.

(16mm)

Clearance must

be maintained

between

bottom of

flipper plates

and beam pads.

6. Insert the locating pin into the adjusting block and bracket on the

height control valve (

nut located on the adjusting block (

FIGURE 30). Loosen the 1/4˝ adjusting lock

FIGURE 30), allowing the

control arm to move up and down approximately 1˝ (25mm).

Replace lower link bolt back into lower link and mounting bracket.

DO NOT fasten.

7. Tighten adjusting loc

ut at the adjusting b

k n

lock to 30-40 in. lbs.

(3.75-5 Nm), and remove locating pin inserted in Step 6.

8. Remove lower link bolt, and raise control arm 45˚ and hold for

10-15 seconds (

FIGURE 30). T

his will raise the vehicle. Bring the

control arm back to center (neutral) position.

9. Reconnect linkage to lower mounting bracket and fasten connection.

NOTE: If the suspension returns to a dimension less than

design ride height,

adjust (up) so suspension will al

ride height.

loosen the 1/4˝ adjusting nut and

n to its cor

etur

ys r

a

w

r

NEVER LESS THAN DESIGN HEIGHT.

ect

RIDE “A”

HEIGHT

16.0˝ (406mm) 6.5˝ (165mm)

16.5˝ (419mm) 7.0˝ (178mm)

17.0˝ (432mm) 7.5˝ (191mm)

18.0˝ (457mm) 8.5˝ (216mm)

FIGURE 30

Primary Height Control Valve

45˚ Intake

(Up)

Control

Arm

45˚ Exhaust

(down)

Exhaust (Top Port)

For EDL/ARF applications,

line is run to Sensor V

top port

To Air Springs

(Always Center Port)

alve

Supply (Always Bottom Port)

FLIPPER PLATE HEIGHT

1/4˝ Adjusting

Lock Nut

Adjusting

Block

Locating Pin

(Remove After

Adjustments)

XL-AR363-02 Rev. D 13

EDL/ARF SYSTEM TROUBLESHOOTING

Failure to chock tires prior to beginning

maintenance could allow vehicle rollaway

which, if not avoided, could result in death or

erious injury.

s

IMPORTANT: Apply air system pressure in excess of 85 psig

(5.9 bars) before doing any performance checks.

PROBLEM POSSIBLE CAUSE and REMEDY

Incorrect plumbing of the sensor valve. Check and repair as required.

(See pages 7 and 10.)

One-way check valve malfunction. Check and repair or replace as required.

(See page 8.)

Air is continually leaking

out the exhaust port of the

sensor valve.

Trailer is at full extension

and suspension is pulling

on shock absorber.

Flipper plates are trapped

in the down position.

Flipper plates will not Cam bracket that connects to EDL actuator Repair or replace as required.

swing down completely. is damaged or weld is broken.

EDL actuator or sensor valve malfunctioning. Check and repair or replace as required.

(See pages 7 to 11.)

Primary HCV mis-adjusted or malfunctioning. Check and repair or replace as required.

(See pages 12 and 13.)

Pilot valve malfunctioning. Check and repair or replace as required.

(See page 12.)

Diaphragm on EDL actuator ruptured. Replace as required. (See pages 4 and 5.)

Sensor valve linkage is the wrong length. Replace linkage with Linkage Ass’y.

(See FIGURE 21, page 10.) (See pages 7 and 10.)

No air flow out of pressure protection Check specified air pressure. Minimum

valve from the air reservoir. 70 psig (4.8 bars) required in air reservoir.

EDL actuator or sensor valve mis-adjusted Check and adjust or replace as required.

or malfunctioning. (See pages 7 to 11.)

Pilot valve malfunctioning. Check and repair or replace as required.

(See pages 8 and 12.)

Push rod of EDL actuator is bent. Replace as required. (See pages 4 and 5.)

Cam bracket that connects to EDL actuator Repair or replace as required.

is damaged or weld is broken.

Diaphragm on EDL actuator ruptured. Replace as required. (See pages 4 and 5.)

Sensor v

(See FIGURE 21, page 10.) (See pages 7 and 10.)

No air f

valve from the air reservoir. Minimum70 psig (4.8 bars) required

No air flo

Vehicle overloaded or unevenly loaded. Check wheel loads and correct as needed.

Primary HCV mis-adjusted or malfunctioning. Check and repair or replace as required.

Trailer not at proper ride height. Check and adjust if needed.

alve linkage is the wrong length. Replace linkage with Linkage Ass’y.

e protection Check specified air pressure.

low out of

w to

pressur

ARF system pilot v

in air reservoir.

alve. Check for breech in air supply line and

repair/replace as required. (Pgs 6, 7, & 12.)

es 12 and 13.)

g

(See pa

(See pages 12 and 13.)

Ride height set improperly (too low). See pages 12 and 13.

Actua

tor push r

od needs adjustment.

Need 5/8˝ (25mm) g

ap.

XL-AR363-02 Rev. D14

NOTES

XL-AR363-02 Rev. D 15

Engineering Your Road to Success

SAF-HOLLAND USA,

888.396.6501

800.356.3929

ax

F

Inc

.

SAF-HOLLAND Canada Limited

519.537.3494

Western Canada

604.574.7491

800.565.7753

ax

F

Fax 604.574.0244

Copyright © J

anuary 2008-SAF-HOLLAND

, Inc. All information contained in this document was correct at time of copyright, and is subject to change without notice. All rights reserved.

www.safholland.us

XL-AR363-02 Rev. D16

Loading...

Loading...