Page 1

Vending machine

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

ACCESSORIES AND PAYMENT SYSTEMS

D.A. COMBISNACK

Type: D.A. COMBISNACK

USE AND MAINTENANCE

Page 2

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Contents

1 - DIAGRAM OF CONNECTIONS TO THE KEYPAD BOARD/CPU:. ................................................. 3

2 - PAYMENT SYSTEM INSTALLATION. ............................................................................................. 4

3 - PAYMENT SYSTEM FEEDER KIT. ................................................................................................... 5

4 - INDEPENDENT TANK KIT. ............................................................................................................ 7

5 - FLOAT KIT. .................................................................................................................................. 10

6 - PULSE COUNTER KIT. ................................................................................................................. 12

7 - WATER SOLENOID VALVE KIT. ................................................................................................... 13

8 - SUGAR COIL KIT. ....................................................................................................................... 15

9 - SAECO CARD ASSEMBLY KIT. .................................................................................................. 17

9.1 - Saeco card programming.....................................................................................................19

10 - HANDLING KIT. .......................................................................................................................... 20

11 - BRITA PURIFIER KIT. ................................................................................................................... 21

12 - RS 232 INTERFACE BOX............................................................................................................ 23

13 - SAECO WATER SOFTENER SUPPORT. ........................................................................................ 24

14 - PROGRAMMING KEY. ............................................................................................................... 25

15 - 12V PARALLEL COINER KIT. ...................................................................................................... 25

16 - CLOCK MODULE INSERTION (TIME KEEPER)........................................................................... 26

16.1 - TIME KEEPER functions in the programming menus ..................................................................... 26

16.2 - TIME KEEPER functions in the maintenance menus ...................................................................... 27

2

Page 3

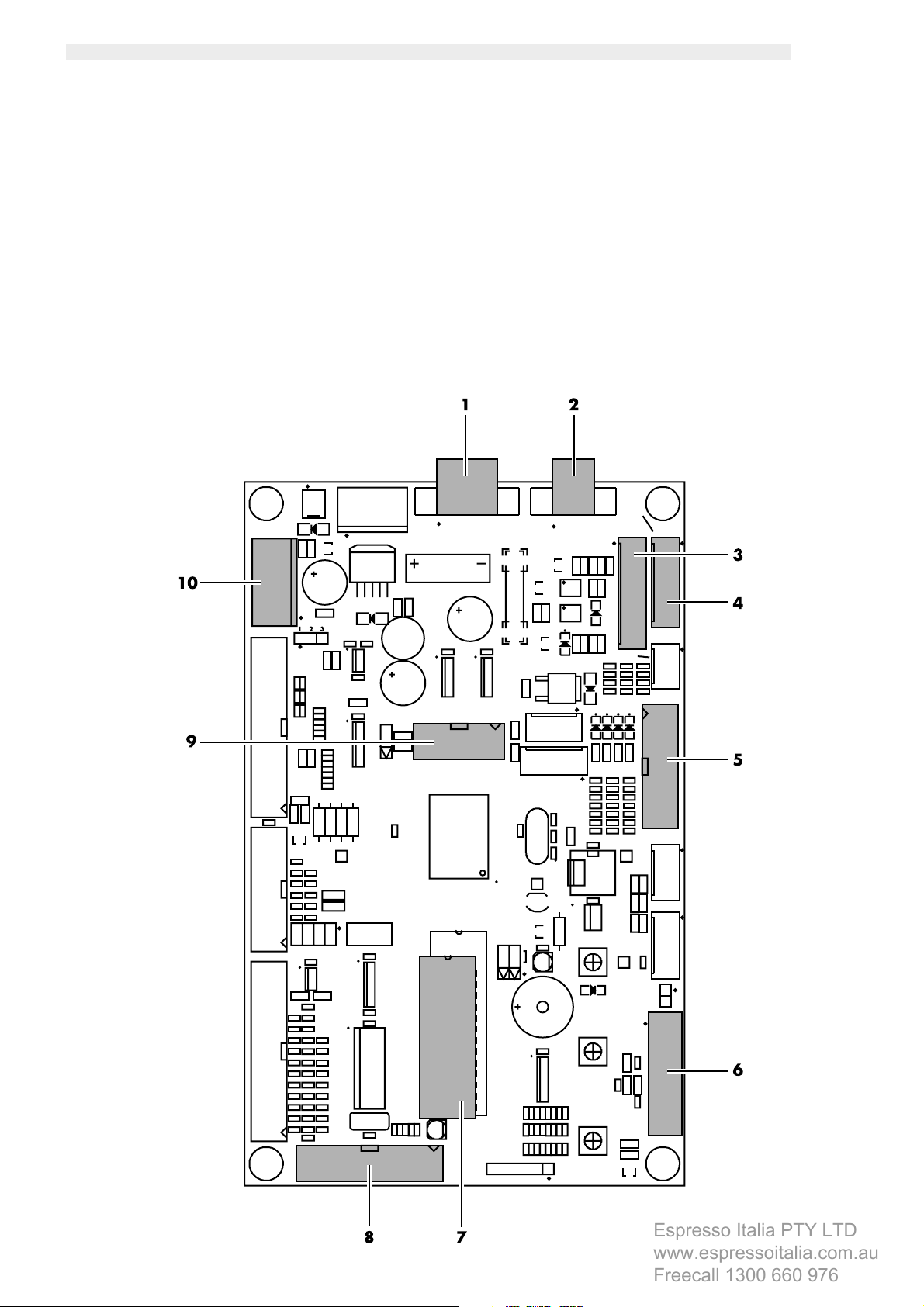

1 - DIAGRAM OF CONNECTIONS TO THE KEYPAD BOARD/CPU:

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

1. MDB systems;

2. BDV, MDB and executive system power supply;

3. 24 V DC / 12 V DC banknote reader;

4. Executive and BDV systems;

5. 24 V DC parallel coiner (non-change giving);

5. 12 V DC parallel coiner (non-change giving) with its suitable kit,

6. Programming key;

7. Clock module;

8. Saeco card;

9. Connector for PC serial interface

10. Feeder kit for payment systems;

English

fig. 1

3

Page 4

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Maintenance technician

It is used to indicate operations to be performed by specialized maintenance technicians only.

He is the only person authorized to keep the KEY TO ACTIVATE THE SAFETY MICROSWITCH which allows disabling the security

system.

2 - PAYMENT SYSTEM

INSTALLATION

A

B

C

D

This vending machine is supplied with panels assembled as shown

in fig. 2. It is possible to change and replace them with those

provided by Saeco according to the customer’s requirements.

- Panel for OTR. and M.IVO banknote readers

- Panel for JCM banknote reader

- Panel for SMILE banknote reader

- Panel for m125 COINCO banknote reader

- Panel for NRI G13 coiner

- Lower Neutra panels (to combine with NRI G 13 panel)

Saeco also supplies the relevant wiring harnesses to connect the

different payment systems.

A specific kit must be used to connect the 12V non-change-giving

parallel coiner.

Open the front doors to replace the panels and remove the CPU

guard to replace the upper door.

Before taking panel B off, it is necessary to remove also the

instruction support steel sheet.

Panel for

OTR. and M.IVO banknote readers

It is inserted in lieu of panels B, C and is preset for OTR. and

M.IVO banknote readers.

- Connect the payment system cable to the suitable connector on the CPU card according to the instructions supplied by the diagram at

page 3.

- If during the payment system installation, the “B” panel instructions are removed, it will be necessary to insert the proper instructions, in

a large, short format, in the “advertising image” area.

4

fig. 2

Panel for JCM banknote reader

It is inserted in lieu of panels B, C and is preset for JCM banknote

reader.

E

Panel for SMILE banknote reader

It is inserted in lieu of panels B, C and is preset for SMILE banknote

reader.

Panel for m125 COINCO banknote reader

It is inserted in lieu of panels B, C and is preset for m125 COINCO

banknote reader.

Panel for NRI G13 coiner and Neutra lower panel

These two panels must be combined.

They are inserted in lieu of panels D, E and are preset for NRI

G13 COINER.

Page 5

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

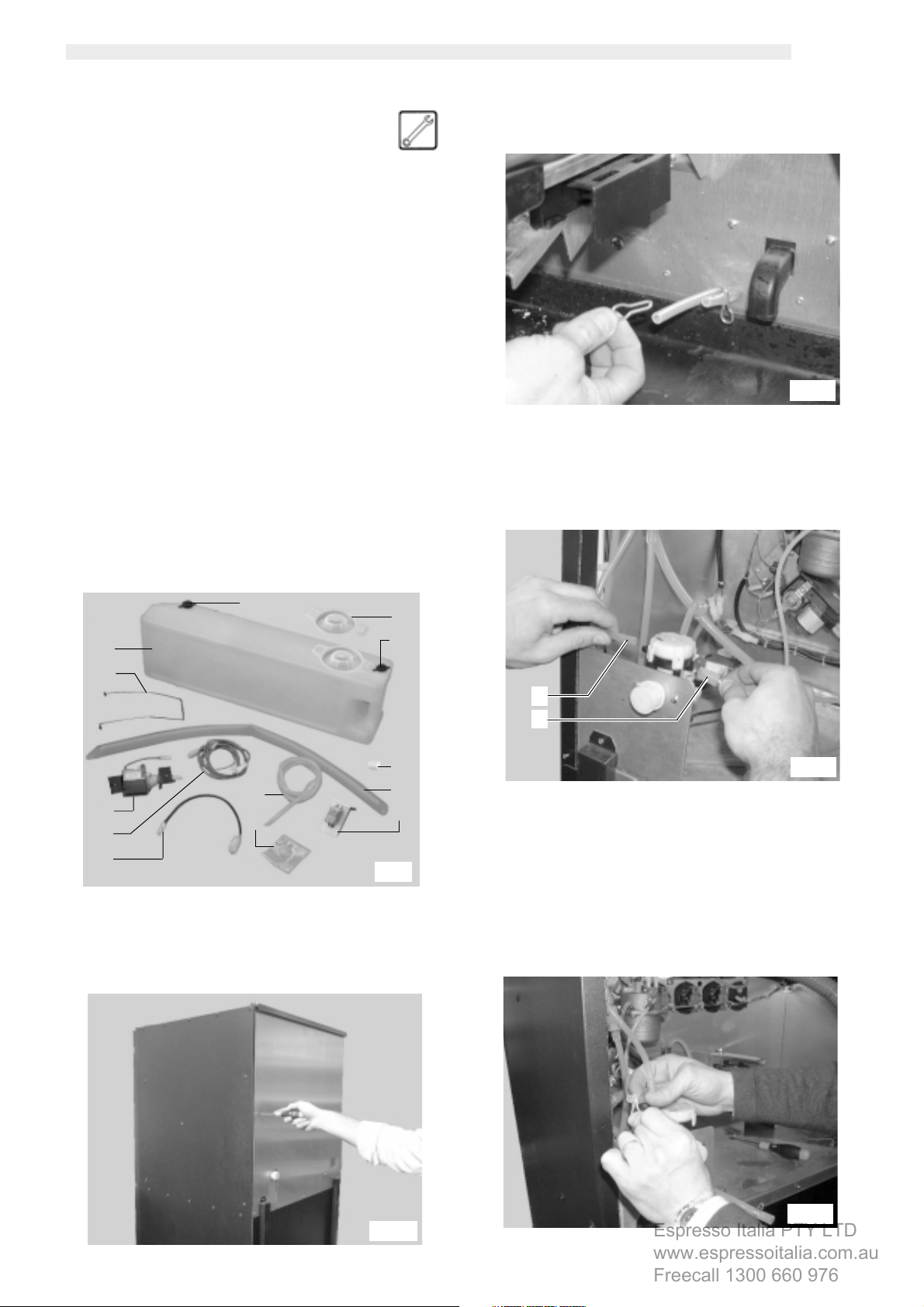

3 - PAYMENT SYSTEM

FEEDER KIT

This kit provides all the necessary power supply for the proper

operation of the payment systems connected to the CPU card of

Combisnack vending machine, which have a mains voltage of

+ 12 Vdc (parallel banknote readers) or + 6 Vdc (1432.0xx

and 1471.0xx models saeco card).

Assembly kit (fig. 3)

a. 1 feeder outlet wiring harness - CPU card

b. 4 screws and spacers

c. 1 feeder inlet wiring harness - CPU card

d. 1 +6Vdc / +12Vdc feeder board

c

d

a

b

- Connect the wiring harness (ref. a, fig. 3) to the payment

system power supply board as well as to the CPU card (fig.

5). See instructions on harness to carry out the connection.

fig. 5

- Unplug the four-pin connector from the CPU card (fig. 6).

fig. 3

Installation

- Open the upper door and fasten (fig. 4) the payment system

power supply board (ref. d, fig. 3) to the same door by using

the four screws and spacers (ref. b, fig. 3).

fig. 4

fig. 6

- Connect the two-pin connector (ref. c, fig. 3) to the payment

system power supply board. Connect the 2 contacts of the

other end to the 2 free slots of the 4-pin connector that was

previously unplugged from the CPU card (fig. 7).

fig. 7

5

Page 6

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

- Connect the four-pin connector to the CPU card (fig. 8).

fig. 8

- Close the vending machine upper door.

The mains voltage values provided by this feeder can also be

found on CN6 (ref. 3, fig. 1) and CN9 (ref. 8, fig. 1) connectors

of CPU card.

Connector Description Voltage Pin

CN6 connector for parallel banknote readers +12Vdc 7

CN9 connector for saeco card universal module +5Vdc or +6Vdc 12,13,14

(see table below)

Pin 12, 13, 14 voltage of CN6 is set according to JP8 jumper

position.

JP8 jumper position Voltage on CN6 12, 13, 14 pins

1-2 +6Vdc

2-3 +5Vdc

JP8 jumper

position

6

Page 7

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

4 - INDEPENDENT TANK KIT

This kit allows the vending machine to be supplied by means of

an internal tank instead of by the water network. To do this, it is

necessary to use the tank inside the machine as drinking water

hopper. If the machine has not been started for the first time, and

the tank has already been used as discharge fluid tank, it shall be

replaced with a new one.

Assembly kit (fig. 9)

a. 1 discharge fluid tank with cap

b. 1 spring for tank

c. 1 pump with supports and pipe fitting

d. 1 pump wiring harness

e. 1 pump feeding wiring

f. 1 cap for spout

g. 1 water inlet pipe

h. 4 screws and washers (two of them measure 4,3x12 and the

other two 4,3x16)

i. 1 perforated cap

m. 1 cap for spout

n. 1 KAPSTO GPN 350 dia 30 cap

p. 1 PVC drain tube

r. 1 relay with support plate

- Open the upper door and take out the retaining spring from

the left hand pipe (fig. 11).

fig. 11

- Disconnect the two pipes from the water inlet solenoid valve

(fig. 12)

f

a

i

m

b

n

c

h

g

p

r

d

e

fig. 9

Installation

- Remove the machine rear panel (fig. 10) by untightening the

screws and disconnecting the ground wiring placed on the

machine.

s

t

fig. 12

- Apply the pipe retaining spring (see fig. 11) on the silicone

pipe (ref. t, fig. 12) fitted on “T” and previously removed from

the inlet solenoid valve (fig. 13).

fig. 13

fig. 10

7

Page 8

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

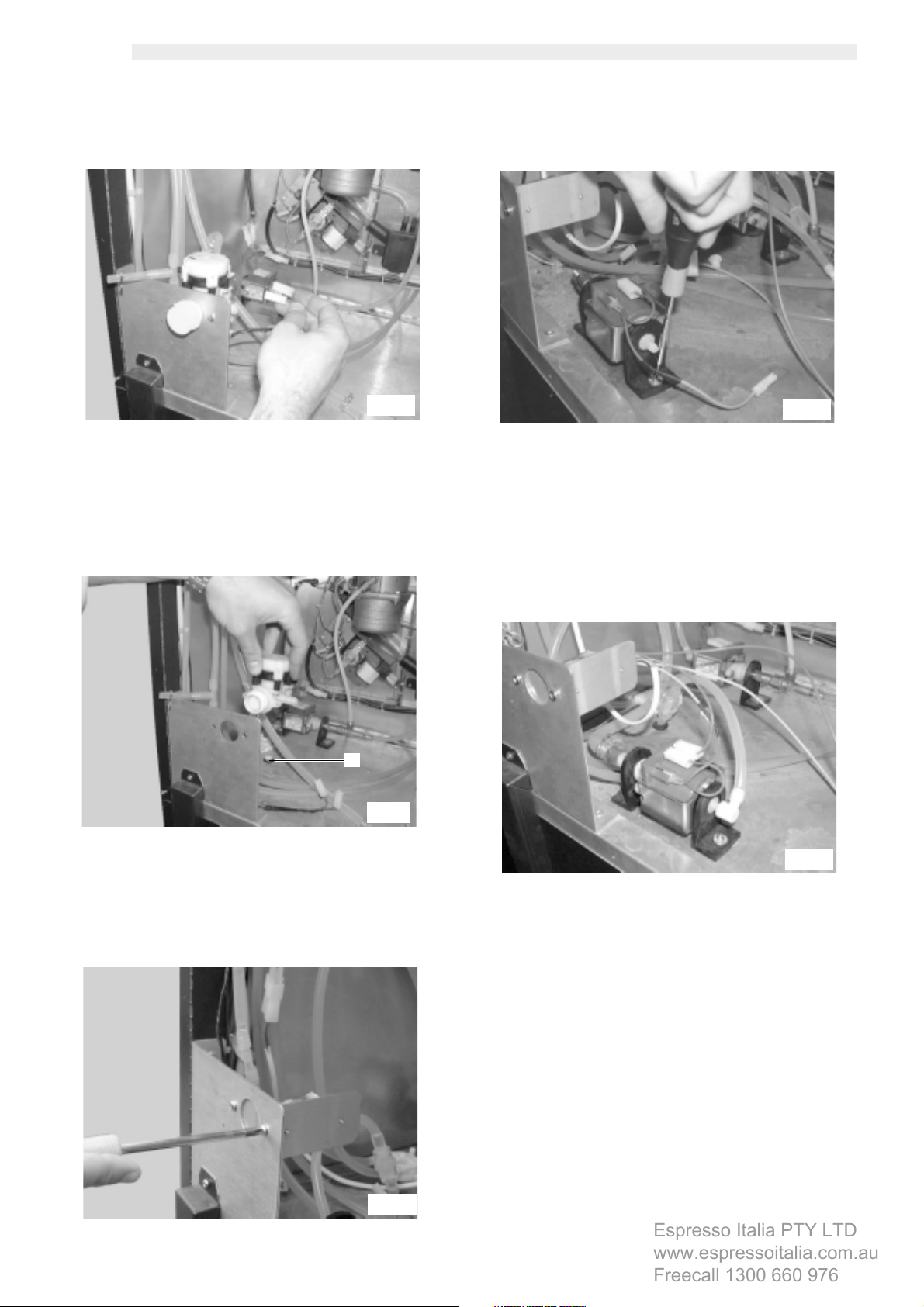

- Disconnect the two power supply wirings from the water inlet

solenoid valve (fig. 14).

fig. 14

- Remove the water inlet solenoid valve (fig. 15).

- Tighten the pump by means of the two screws and two washers

4,3x16 (ref. h, fig. 9) to the bottom (fig. 17).

fig. 17

- Connect the pipe (ref. s, fig. 12), previously extracted from

the water inlet solenoid valve, to the fitting located on the

pump (fig. 18).

- Withdraw the cap (ref. u, fig. 15). Connect the water inlet

pipe to the pump. Move the other end of the pipe to the

lower part of the vending machine passing through the hole

(ref. u, fig. 15)

u

fig. 15

- Tighten the relay and support plate (ref. r, fig. 9) by using the

screws previously taken from the inlet solenoid valve (fig. 16)

fig. 16

fig. 18

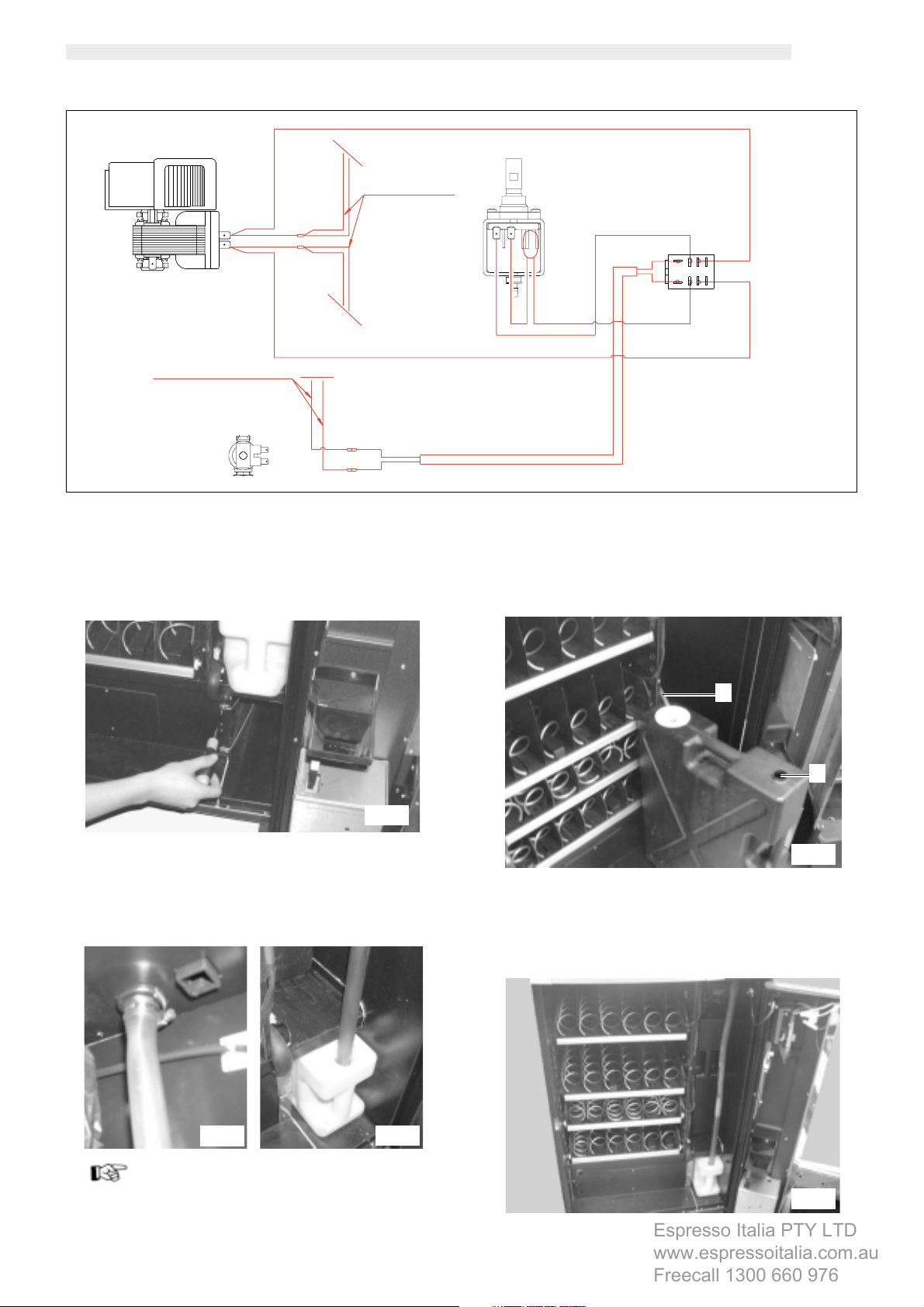

- Carry out all the electric connections as indicated by the

diagram below.

8

Page 9

230V 50Hz

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

FAN

Power supply wirings inlet solenoid valve

INLET SOLENOID VALVE

PINK

DARK BLUE

PINK

DARK BLUE

PINK

DARK BLUE

DARK BLUE

Power supply wirings

BLUE

PINK

fan motor

PUMP 1

DARK BLUE

BLUE

RED

English

RELAY

PINK

DARK BLUE

RED

24 V D.C.

RED

- Reassemble the machine rear panel taking care to reconnect

the earth cable.

- Open the V.M. lower door.

-

Tighten the spring (ref. b, fig. 9) in the position shown in fig. 29

by using the two screws and two washers 4,3x12 (ref. h, fig. 9).

fig. 20

- Replace the pipe fastened to the drain channel (fig. 21) with

the drain tube (ref. p, fig.9). Remove the cap (ref. m, fig. 9)

from the tank. Insert the other end of the pipe in the discharge

fluid tank (fig. 22). Make sure that the other tank holes are

properly capped.

fig. 19

- Insert the pipe (ref. g, fig. 23) in the perforated cap of the

drinking water tank.

- Fill the drinking water tank.

g

v

fig. 23

- Fit the cap on the tank. Place the tank inside the V.M. (fig. 24)

by sliding the pipe inside the tank itself. Close the hole (ref. v,

fig. 23) by means of the cap (ref. n, fig. 9).

fig. 21

Important

Before removing the tank to empty it, close the pipe hole

using the relevant cap (ref. m, fig. 9). This will help preventing

any liquid spillage due to the surge effect.

fig. 22

fig. 24

- Close the vending machine lower door.

9

Page 10

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

5 - FLOAT KIT

It allows the display to read the discharge fluid maximum level. In

this condition, no hot beverage is available and the display will

read “ERROR 09”.

The float can be installed in different positions according to whether

the machine is connected to a water network (22 L tank) or uses

an independent tank (7L tank).

Assembly kit (fig. 25)

a. 1 basket set for discharge fluid level

b. 2 screws

c. 1 reed wiring

a

b

c

- Slide the other end of the reed

wiring inside the hole (ref. d,

fig. 26) and couple it to the

connector (ref. f, fig. 27).

- Remove the tank cap (fig. 28) and replace it with the discharge

level basket set (fig. 29).

f

fig. 27

g

fig. 28

fig. 29

fig. 25

Important

When assembling the lower level sensor (fig. 26) disconnect

the higher sensor (fig. 30). The drain level control system

doesn’t work if two sensors are connected.

Installation

- Open the front lower door.

- If it is applied on the independent tank version, it is necessary

to remove the 7 L tank (ref. g, fig. 28) and to assemble the

reed wiring (ref. c, fig. 25) by means of the two screws (ref.

b, fig. 25) according to the position shown in the figure (ref.

e, fig. 26).

d

e

- Reinstall the tank.

- If it is applied to the water network version, it is necessary to

remove the 22L tank (ref. i, fig. 31) and to fit the reed wiring

(ref. c, fig. 25) by means of the two screws (ref. b, fig. 25)

on the square (ref. h, fig. 30). Then, couple the other end to

the connector (fig. 30).

h

fig. 30

- Remove the tank cap (fig. 31) and replace it with the discharge

level basket set (fig. 32).

10

fig. 26

i

- Reinstall the tank.

fig. 31

fig. 32

Page 11

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Access the machine programming menu and set “YES” in the

“TANK” menu (fig. 34) to enable the display reading of the

discharge fluid maximum level.

In order to properly carry out this operation, disable the safety

device and press key 1 (fig. 33) to access the programming

menu.

If no password has been assigned you enter the programming

menu directly.

Important

If vending machine was assigned a password to enable the

programming menu, “PASSWORD 0000” will appear on

display with a flashing cursor on the first digit.

Now digit the password using UP and DOWN keys. Confirm

the entered digit by means of ENTER key.

To exit the programming menu and return to the normal operation

of the vending machine:

- press key 1 again;

- remove the key from the safety switch to turn off the vending

machine;

- close the door and wait for the self-configuration process to

end.

Important

When the tank maximum level is reached, the display will

read “HOT BEVERAGES NOT AVAILABLE” (ERROR 09 code).

In this condition, the V.M. cannot brew hot beverages. It is

therefore necessary to empty the tank. After emptying the

tank, the error message will automatically disappear at the

machine switching on.

SISTEM MANAGEMENT

VM CODE

0000

STOP

MIN. TEMPERATURE

098

MAX. TEMPERATURE

108

COLD TEMPERATURE

6

1

fig. 33

Entries selectable

only with complete

menus

COMPRESSOR

YES

DRAINAGE TANK

NO

DRAINAGE TANK

>Y< N

fig. 34

11

Page 12

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

6 - PULSE COUNTER KIT

The vending machine can be fitted with an electromechanical

pulse counter (24V DC) which will count the number of coffees or

the total beverages brewed by the machine.

Assembly kit (fig. 35)

a. 1 pulse counter with support

b. 2 screws

a

b

fig. 35

Installation

- Open the upper door and fasten the pulse counter (ref. a, fig.

35) to it (fig. 36) by means of the two screws (ref. b, fig. 35).

To enable the counting of coffees or beverages brewed, access

the machine programming menu and set “COFFEE” or

“BEVERAGES” in the “PULSE COUNTER” menu (fig. 38).

In order to properly carry out this operation, disable the safety

device and press key 1 (fig. 33) to access the programming

menu.

If no password has been assigned you enter the programming

menu directly.

Important

If vending machine was assigned a password to enable the

programming menu, “PASSWORD 0000” will appear on

display with a flashing cursor on the first digit.

Now digit the password using UP and DOWN keys. Confirm

the entered digit by means of ENTER key.

To exit the programming menu and return to the normal operation

of the vending machine:

- press key 1 again;

- remove the key from the safety switch to turn off the vending

machine;

- close the door and wait for the self-configuration process to

end.

fig. 36

- Couple the pulse counter wiring with the “CN14” connector

of the board (fig. 37).

fig. 37

SISTEM MANAGEMENT

VM CODE

0000

STOP

MIN. TEMPERATURE

098

MAX. TEMPERATURE

108

COLD TEMPERATURE

6

COMPRESSOR

YES

DRAINAGE TANK

NO

MECH. COUNTER

COFFEE

Entries selectable

only with complete

menus

MECH. COUNTER

COFFEE

MECH. COUNTER

BEVERAGES

12

fig. 38

Page 13

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

7 - WATER SOLENOID

VALVE KIT

It is possible to brew hot water alone by installing the required kit

Assembly kit (fig. 39)

a. 1 water pipe set

b. 1 OR, pipe clamp and 1/8" H4,5 nut

c. 1 two-way solenoid valve

c

a

b

fig. 39

- Open the upper door and loosen the screw (fig. 42) fixing

the block support plate.

fig. 42

- Remove the hopper (Fig. 43).

Installation

- Remove the machine rear panel (fig. 40) by untightening the

screws and disconnecting the ground wiring placed on the

machine.

fig. 40

- Unscrew the cap inserted on the solenoid valve block (fig.

41) and hold the latter to avoid any excessive stress to the

block support plate.

fig. 43

- Loosen the two screws fixing the block support plate (fig. 44).

fig. 44

fig. 41

13

Page 14

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

- Screw the nut and fix the OR (ref. b, fig. 39) on the 2-way

solenoid valve (ref. c, fig. 39). Remove the block support

from its seat and screw the solenoid valve in the hole (fig. 45)

previously cleared from its cap (fig. 41). The solenoid valve

must be placed with fastons upwards

Reinstall the block support in their seat and tighten the screws.

fig. 45

- Insert the pipe clamp (ref. b, fig. 39) on pipe (ref. a, fig. 39).

Then, fasten the pipe (fig. 48) at the solenoid valve outlet and

position the pipe retaining spring.

Slide the other end of the pipe inside the assembly plate

passage hole (ref. d, fig. 48).

- Reassemble the machine rear panel.

d

fig. 48

- Remove the clamp (fig. 46) that fastens the two unused cables.

fig. 46

- Connect the 2 free cables to the solenoid valve taking care to

insert the red cable on the left and the white cable on the

right.

- Fasten the pipe end with fitting to the spout (fig. 49).

fig. 49

To brew hot water alone, it is necessary to set the beverage

associated with the required key according to the following

parameters:

Parameter Value

Sequence 0001

Soluble product quantity 1 0

14

fig. 47

H2O soluble product quantity 1

% soluble 1 100

sugar 0

- Close the vending machine upper door.

Set the required water quantity

Page 15

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

8 - SUGAR COIL KIT

This kit allows the sugar door opening only when required, since

an electromagnet controls it. This prevents any sugar grain from

accidentally falling when the “without sugar” option has been

selected.

Assembly kit (fig. 50)

a. 1 two-pin connector

b. 1 connecting rod

c. 2 M3x6 screws, 1 M3x8 screw and 1 M3 nut

d. 1 relay electromagnet

e. 1 spring

f. 1 sticker

c

d

- Disassemble the sugar-dispensing channel (Fig. 52).

fig. 52

- Install the connecting rod (ref. b, fig. 50) on the electromagnet

piston (ref. d, fig. 50) by means of the spring (ref. e, fig. 50)

to obtain the unit shown in fig. 53.

- Apply the sticker (ref. f, fig. 50) to the electromagnet (fig. 54)

in order to seal the hole located on the machine housing.

a

b

e

f

fig. 50

Installation

- Open the upper front door.

- Remove the sugar-dispensing channel by opening the screw

(ref. g, fig. 51).

g

fig. 53

- Assemble this unit (see fig. 54) on the sugar channel (fig. 55)

by means of two M3x6 screws (ref. c, fig. 50).

fig. 54

fig. 51

fig. 55

15

Page 16

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

- Fasten the connecting rod on the sugar door (fig. 56) by

means of an M3x8 screw and an M3 nut (ref. c, fig. 50).

fig. 56

- Assemble the whole unit on the sugar stirrer dispenser (fig.

57)

- Reinstall the sugar channel and fix it with the spring (fig. 59).

fig. 59

- Close the vending machine upper door.

fig. 57

- Couple the connector (ref. a, fig. 50) with the electromagnet

by means of the fastons. Insert the other end in the connection

located on the mounting plate (fig. 58).

fig. 58

16

Page 17

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

9 - SAECO CARD ASSEMBLY

KIT

Assembly kit (fig. 60)

a. 1 adhesive sheet for drilling

b. 1 guard for universal module

c. 1 flat cable

d. 4 screws and 4 spacers for card

e. 1 Saeco card external antenna

a

b

c

d

e

f

fig. 60

- Open the upper front door.

- Loosen the guard fastening screws and remove it (fig. 62).

fig. 62

- Remove the two screws (fig. 63) of the external antenna; they

will be subsequently used to fasten the antenna to the tile.

Important

To use the Saeco card, the machine must be equipped with a

Time keeper.

Important

If the universal module to be mounted has a 1432.0xx or

1471.0xx code, it will be necessary to use a payment system

feeder kit.

Installation

- Place the adhesive sheet (ref. a, fig. 60) on the lower tile (fig.

61). Drill according to the diagram on sheet using a 3 dia.

point for the two small holes and a 10 dia. point for the other

hole.

fig. 63

- Fasten the antenna on the tile (fig. 64) by sliding the cable

through the 3 dia. hole.

fig. 61

fig. 64

17

Page 18

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

- Tighten the two screws (fig. 65).

fig. 65

- Fasten the universal module by means of the 4 screws and

spacers (ref. d, fig. 60) on the door (fig. 66).

- Connect the antenna cable to the universal module (fig. 68).

fig. 68

- Assemble the guard (ref. b, fig. 60) on the universal module

(fig. 69).

fig. 66

- Connect the universal module to the I/O card (fig. 67) by

means of the flat cable (ref. c, fig. 60).

fig. 69

18

fig. 67

Page 19

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

9.1 - Saeco card programming

The Saeco card module presence (automatically detected by the

V.M.) adds the following entries to the PAYMENT SYSTEM

programming menu

SAECO CARD

RECHARGE

YES

PRICE DIFFERENTIAL

YES

MAX CARD LOAD

60000

MAX VALUE ACCEPTED

70000

FREE CARD

YES

RECHARGE

>Y< N

PRICE DIFFERENTIAL

>Y< N

MAX CARD LOAD

65000

MAX VALUE ACCEPTED

65000

FREE CARD

>Y< N

Card maximum recharge

- This function allows setting the credit maximum level, beyond

which all recharge operation (if enabled) is ineffective.

By setting MAX CARD LOAD = 20.00, the credit on the V.M.

will pass to the card if their sum does not exceed 20.00.

Reject card

- This function allows setting the credit maximum level, beyond

which the card is rejected by the system.

By setting MAX VALUE ACCEPTED = 25.00, the V.M. will

reject all cards having a credit exceeding this amount. In

case this card is detected, the display will not read the credit

but an “

----------

“ message and will not carry

out any dispensing.

Free Card

- It allows enabling or disabling the use of free service cards.

By setting FREE CARD = NO, no free service card will be

accepted by the vending machine.

Entry description:

Recharge

- It allows disabling or enabling any saeco card recharge

operations.

By setting RECHARGE = NO the V.M. will only deduct the

cost from saeco cards

Card prices

- This function allows applying differentiated prices in case of

card use for the beverage payment.

By setting PRICE DIFFERENTIAL = YES a new menu entry will

appear in PRICE MANAGEMENT, which will allow setting

the price level to be applied to the product (beverage or

snack) in case of saeco card use.

BEVERAGE PRICES

BEVERAGE PRICES

NORMAL

BEVERAGE PRICES

DIFF. 1

PREZZI BEVANDE

DIFF. 2

BEVERAGE PRICES

CARD

19

Page 20

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

10 - HANDLING KIT

This kit allows easy handling of the vending machine in order to

carry out any maintenance operations and to place it in narrow

spaces.

Warning

During handling operations be extremely careful in order to

avoid any limb crushing. The handling operations can

exclusively be carried out by skilled personnel.

Assembly kit (fig. 70)

a. 2 carriage sets

b. 1 lever

a

b

- Insert the carriage set under the V.M. (fig. 73), move the lever

back to its initial position, then remove it from under the

machine (fig. 74).

fig. 73

- Repeat the same operations for the other side of the vending

machine (fig. 75, 76, 77, 78). By inserting the second

carriage, it is possible to handle the machine.

fig. 74

fig. 70

Installation

- Insert the lever under the vending machine. Rotate the lever to

lift the machine (fig. 71 and 72). The lever position shall

allow the carriage set to be subsequently inserted.

fig. 75

fig. 77

fig. 76

fig. 78

fig. 71

20

fig. 72

Page 21

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

11 - BRITA PURIFIER KIT

It is possible to install a filter, manufactured by Brita Company, on

the vending machine, in order to decalcify water and eliminate

all unpleasant smells.

Assembly kit (fig. 79)

a. 2 fittings

b. 1 cover for filter cartridge support

c. 1 filter cartridge support

d. 4 screws for filter cartridge support cover

e. 4 screws for cartridge head

f. cartridge head (not supplied)

g. Brita Aquaquell cartridge (not supplied)

h. 1 air break pipe

i. 2 pipe clamps

l. 2 pipe retaining springs

m. 1 pump pipe

g

a

b

h

i

- Assemble the cover (ref. b, fig. 79) on the support (ref. c, fig.

79) and tighten it by using the 4 screws (ref. d, fig. 79). Then

screw the 2 fittings (ref. a, fig. 79) inside the holes following

the right orientation, as shown in fig. 81.

fig. 81

- Remove the machine rear panel and open the upper front

door.

- Remove the hole-closing panel.

- Assemble the cartridge support set (fig. 81) and fasten it by

means of the 4 screws (fig. 82 e 83)

l

m

fig. 79

d

e

c

f

Installation

- Insert the head (ref. f, fig. 79) into the support (ref. c, fig. 79)

carefully following the required sense (fig. 80). Fasten the

head to the support by means of the 4 screws (ref. e, fig.

79).

fig. 82

fig. 80

fig. 83

21

Page 22

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

The following operation differs according to whether the machine

is connected to a water network or if it uses an independent tank

- Independent tank

Insert the clamp (ref. i, fig. 79) into the pipe (ref. m, fig. 79)

and the latter into the pump fitting. Tighten the clamp screw

(fig. 84).

INDEPENDENT TANK

fig. 84

- Insert the other clamp (ref. i, fig. 79) into the pipe free end

(ref. m, fig. 79) and the latter into the lower fitting of the

cartridge support set (ref. a, fig. 79). Tighten the clamp screw

(fig. 86).

fig. 86

- Insert the spring (ref. i, fig. 79) into the pipe (ref. m, fig. 79)

and the latter into the air break fitting (fig. 87).

- Water network

Insert the clamp (ref. i, fig. 79) into the pipe (ref. m, fig. 79)

and the latter into the water inlet solenoid valve fitting. Tighten

the clamp screw (fig. 85).

WATER NETWORK

fig. 85

fig. 87

- Insert the other spring (ref. l, fig. 79) into the pipe free end

(ref. h, fig. 79) and the latter (fig. 88) into the upper fitting of

the cartridge support set (ref. a, fig. 79).

22

fig. 88

Page 23

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

- The pipe connection logic is clearer in fig. 89, since some

plates have been removed.

fig. 89

- Insert the cartridge and tighten it (ref. g, fig. 79) clockwise

(fig. 90).

12 - RS 232 INTERFACE BOX

The RS232 interface box allows connecting the automatic vending

machine to a PC, in order to transfer statistic data.

Assembly kit (fig. 91)

a. 1 TTL-RS232 level adapter

a

b

c

fig. 91

fig. 90

- Reassemble the rear panel and close the upper front door.

Installation

- Insert the flat cable (ref. b., fig. 91) on the machine CPU

relevant connector to carry out the connection. Then insert the

other flat cable (ref. c, fig. 91) into the PC serial cable.

- The interface box is supplied with 2 LEDs. When they

alternatively blink, this means that the V.M. and the P.C. are

communicating.

- It is advisable to carry out all the electrical connections while

the V.M. and the PC are both switched off.

23

Page 24

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

13 - SAECO WATER SOFTENER

SUPPORT

This support allows fixing the water softener supplied by Saeco

in a proper way.

Assembly kit (fig. 92)

a. 1 water softener support

b. 1 water softener

c. 4 screws

a

b

- Insert the water softener (ref. b, fig. 92) into the support (fig.

94).

fig. 94

c

fig. 92

Installation

- Remove the machine rear panel and assemble the water

softener support (ref. a, fig. 92) by using the 4 screws (fig.

93).

24

fig. 93

Page 25

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

14 - PROGRAMMING KEY

The programming key allows the set data transfer in the following

programming menu entries:

- PRICE MANAGEMENT. All data can be transferred;

- TIME MANAGEMENT. All data can be transferred;

- PAYMENT SYSTEMS. All data can be transferred;

- SYSTEM MANAGEMENT. All data can be transferred,

expect the PASSWORD.

To properly use the programming key, do as follows:

- open the vending machine front door;

- insert the programming key into the connector (ref. 6, fig. 1).

- switch on the vending machine.

The copy key presence enables the following menu display:

DATA TRANSFER

->->

COPY VMC

- > KEY

->->

DATA TRANSFER

->->

COPY KEY

- > VMC

->->

DATA TRANSFER

0..50..99%

DATA TRANSFER

0..50..99%

DATA TRANSFER

DATA TRANSFERRED

DATA TRANSFER

DATA TRANSFERRED

15 - 12V PARALLEL COINER KIT

Allows to use 12Vdc parallel coin selectors.

Assembly kit (fig. 95)

a. 16-pole flat cable

b. 3 adhesive spacers

c. 10-pole flat cable

d. Interface card

c

a

b

Installation

- Open the upper door and slide the keypad carter up. Insert

the 3 adhesive spacers (fig. 95, b) into the special holes of the

interface card (fig. 95, d) and remove their protective paper

(fig. 96). Fasten the card in the most convenient position for

the user.

d

fig. 95

This is only displayed if the data on

the key comes from a vending

machine of the same type.

The allowable operations are the following:

Display message

DATA TRANSFER

COPY VMC ==> KEY

copy of vending

machine data on the

key

DATA TRANSFER

COPY KEY ==> VMC

copy of key data on

the vending machine

Any possible data transfer error is shown on the display through

the “TRANSFER KEY - ERROR IN KEY DATA” message. Should

this message appear, repeat the transfer procedure, and if the

error is not removed, please contact the AUTHORIZED

CUSTOMER SERVICE CENTER.

Operation

Notes

This operation is

always possible.

This operation is

only possible if the

data on the key

comes from a

vending machine

of the same type.

fig.96

- Insert the 16-pole flat cable (fig. 95, a) into the special seats

of the CPU card and interface card (see fig. 97, e).

- Insert the 10-pole flat cable (fig. 95, c) into the interface card

seat (see fig. 97, f), then connect the other end of the 10-pole

flat cable to the 12V parallel selector.

e

f

fig.97

25

Page 26

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

16 - CLOCK MODULE

INSERTION

(TIME KEEPER)

To insert the clock module, do as follows:

- open the vending machine front door;

- insert the clock module into the CPU card connector (7 - Fig.

1).

Warning

Insert the clock module A from the lower part of connector B.

B

A

Important

The functions managed by the TIME KEEPER are described

later on at 16.1 and 16.2 manual sections.

16.1 - TIME KEEPER functions in the

programming menus

Price management

This menu allows setting 2 different differentiated prices

(DIFFERENTIATED PRICES 1, DIFFERENTIATED PRICES 2), which

are only enabled at a certain time.

Timetable management

Besides the ALWAYS FREE and NEVER FREE functions, this menu

allows setting the time for FREE beverages/selections (i.e. FREE Monday - ON=20,00 - OFF=24,00. The beverages/selections

will be free each Monday from 8 to 12 pm).

The DIFFERENTIATED PRICES 1 and 2 associated to any beverage

or selection can be equally set.

It is also possible to set:

the time for the machine switching on and off;

the time for the pregrinding enabling;

the rinsing time.

System management

This menu allows accessing the CLOCK function in order to set

hour, minutes, month and year.

26

fig. 98

PASSWORD

PRICE MANAGEMENT

TIME MANAGEMENT

SYSTEM MANAGEMENT

PRICE VALUE

BEVERAGE PRICES

SNACK PRICES

CUP PRICE

50

DISCOUNTS/SURCHARGES

50

FREE

NEVER

ON/OFF TIME

YES

DIFF 1

NO

DIFF 2

NO

PREGRINDINGNOPREGRINDING

RINSING TIMENORINSING TIME

PRICE VALUE

PREZZO 001: 50

PRICE VALUE

PRICE 002: 250

PRICE VALUE

PRICE n: 550

BEVERAGE PRICES

NORMAL

BEVERAGE PRICES

DIFF 1

BEVERAGE PRICES

DIFF 2

BEVERAGE PRICES

CARD

SNACK PRICES

NORMAL

SNACK PRICES

DIFF 1

SNACK PRICES

DIFF 2

SNACK PRICES

CARD

CUP PRICE

001: 200

DISCOUNTS/SURCHARGES

FREE

NEVER

FREE

ALWAYS

FREE

TIME RANGE

ON/OFF TIME

>Y< N

DIFF 1

>Y< N

DIFF 2

>Y< N

>Y< N

>Y< N

SET

GLOBAL

SET

SINGLE

SET

GLOBAL

SET

SINGLE

SET

GLOBAL

SET

SINGLE

only with Card

Prices enabled

40

FREE

ON1:LMMgvsd 00:15

FREE

OFF1:LMMgvsd 07:15

FREE

ON2:lmmGVsd 19:15

FREE

OFF2:lmmGVsd 20:15

ON/OFF TIME

ON1:LMMgvsd 00:15

ON/OFF TIME

OFF1:LMMgvsd 07:15

ON/OFF TIME

ON2:lmmGVsd 19:15

ON/OFF TIME

OFF2:lmmGVsd 20:15

DIFF 1

ON1:LMMgvsd 00:15

DIFF 1

OFF1:LMMgvsd 07:15

DIFF 1

ON2:lmmGVsd 19:15

DIFF 1

OFF2:lmmGVsd 20:15

DIFF 2

ON1:LMMgvsd 00:15

DIFF 2

OFF1:LMMgvsd 07:15

DIFF 2

ON2:lmmGVsd 19:15

DIFF 2

OFF2:lmmGVsd 20:15

PREGRINDING

ON1:LMMgvsd 00:15

PREGRINDING

OFF1:LMMgvsd 07:15

PREGRINDING

ON2:lmmGVsd 19:15

PREGRINDING

OFF2:lmmGVsd 20:15

RINSING TIME

ON1:LMMgvsd 00:15

RINSING TIME

ON2:lmmGVsd 19:15

GLOBAL

001:200 ABCDEFGHI

GLOBAL

nnn:500 ABCDEFGHI

SINGLE

001:200 ABCDefghi

SINGLE

nnn:500 abcdEFGHI

GLOBAL

001:200 ABCDEFGHI

GLOBAL

nnn:500 ABCDEFGHI

SINGLE

001:200 ABCDefghi

SINGLE

nnn:500 abcdEFGHI

GLOBAL

001:200 .

GLOBAL

nnn:500 .

SINGLE

S11 001:200

SINGLE

Smm nnn:1200

Page 27

English

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

16.2 - TIME KEEPER functions in the

maintenance menus

STATISTIC

With this function you can display all sales statistics accounted

by the vending machine.

VM CODE

assigned by the operator.

COINS TOTAL

the total value of the inserted coins is displayed.

BANKNOTE TOTAL

the total value of the inserted banknotes is displayed.

By pressing [ENTER] it is possible to display the number of inserted

banknotes according to their denomination.

CARD IN

the amount of credit collected from cards is displayed

CARD OUT

the amount of credit charged on cards is displayed

OVERPAY:

the amount of credit kept at the OVERPAY time elapsing.

FREE BEVERAGES

the total number of free selections dispensed is displayed.

BEVERAGE TEST

the total number of test beverages brewed is displayed.

FREE SELECTIONS

the total number of free selections dispensed is displayed.

TOTAL SALES:

the total gain from the sales of all selection and beverage is

displayed

By pressing [ENTER] it is possible to get detailed information of

this gain for:

beverages (further divided according to price level, if required),

snack selections (also divided according to price level)

cups sold

discounts granted

COUNTERS

The presence of the Time keeper in this menu allows the displayed

information extension.

Therefore, it is possible to display the total and partial number of

beverages and snack selections divided by price brackets.

STATISTICS

TOTAL COINS

TOTAL BANKNOTES

BEVERAGE 0013

BEVERAGE 0067

SNACK 0005

TOTAL SALES

COUNTER

RESET RESET

COFFEE COUNTER

TT:008000 PP:005000

BEVERAGE COUNTER

TT:004500 PP:002500

SOLUBLE COUNTER

TT:000800 PP:000800

SNACK COUNT

TT:004500 PP:002500

WATER LEVEL COUNT

TT:000500 PP:000500

CUP COUNTER

TT:000500 PP:000500

SUGAR COUNT

TT:000500 PP:000500

CODE D.A.

12345

00

00

CARD IN

00

CARD OUT

00

OVERPAY

15980

FREE

TEST

FREE

00

>Y< N

TOTAL BANKNOTES

BANKNOTE 01 35000

TOTAL BANKNOTES

BANKNOTE 02 90000

TOTAL BANKNOTES

BANKNOTE 02 90000

BEVERAGE

SNACK

CUP COUNTER

0000

DISCOUNTS/SURCHARGES

0000

BEVERAGE A

TT:000800 PP:000500

BEVERAGE B

TT:000800 PP:000500

Saeco Card

BEVERAGE I

TT:000800 PP:000500

SOLUBLE COUNTER 1

TT:000175 PP:000175

SOLUBLE COUNTER 2

TT:000270 PP:000270

SOLUBLE COUNTER 3

TT:000225 PP:000225

SOLUBLE COUNTER 4

TT:000130 PP:000130

SNACK 11

TT:004500 PP:002500

SNACK 13

TT:000800 PP:000500

only with

Saeco Card

SNACK nn

TT:000800 PP:000500

Appears only where reset

PRICE 01

00023

PRICE 02

0015

PRICE nn

0005

PRICE 01

00023

PRICE 02

0015

PRICE nn

0005

NORMAL

TT:000300 PP:000200

DIFF. 1

TT:000050 PP:000050

DIFF. 2

TT:000000 PP:000000

CARD

TT:000450 PP:000250

TEST

TT:000005 PP:000005

NORMAL

TT:000300 PP:000200

DIFF. 1

TT:000050 PP:000050

DIFF. 2

TT:000000 PP:000000

CARD

TT:000450 PP:000250

FREE

TT:000015 PP:000012

is enabled in SYSTEM

MANAGEMENT. It resets

both statistics and

counters

NORMAL

TT:000300 PP:000200

DIFF. 1

TT:000050 PP:000050

DIFF. 2

TT:000000 PP:000000

CARD

TT:000450 PP:000250

FREE

TT:000015 PP:000002

TEST

TT:00015 PP:000005

NORMAL

TT:000300 PP:000200

DIFF. 1

TT:000050 PP:000050

DIFF. 2

TT:000000 PP:000000

CARD

TT:000450 PP:000250

FREE

TT:000025 PP:000015

27

Page 28

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Cod. 0875.978 - Ed° 01 02/03

Loading...

Loading...