Ryobi RY52504, RY52905 User Manual

OPERATOR’S MANUAL

TP30 GAS PRUNER

RY52504/RY52905

Your pruner has been engineered and manufactured to our high standard for dependability, ease of operation, and operator

safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

TABLE OF CONTENTS

Introduction ..................................................................................................................................................................... 2

General Safety Rules ....................................................................................................................................................... 3

Specific Safety Rules ....................................................................................................................................................... 4

Symbols ........................................................................................................................................................................5-6

Features ........................................................................................................................................................................... 7

Assembly ....................................................................................................................................................................8-10

Operation ..................................................................................................................................................................11-13

Maintenance ............................................................................................................................................................. 14-18

Troubleshooting ............................................................................................................................................................. 19

Warranty ...................................................................................................................................................................20-22

Parts Ordering / Service ................................................................................................................................................ 24

INTRODUCTION

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product, making it easy to maintain and operate.

2

GENERAL SAFETY RULES

WARNING!

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

READ ALL INSTRUCTIONS

For safe operation, read and understand all instructions

before using this product. Follow all safety instructions.

Failure to follow all safety instructions listed below, can result

in serious personal injury.

Do not allow children or untrained individuals to use this

unit.

Never let anyone use the machine who has not received

adequate instructions in the machine’s proper use. This

applies to rentals as well as privately owned units and also

to the power head it is attached to.

Al w a y s wear s a f e t y glasses w i t h side s h i e l d s.

Everyday glasses have only impact resistant lenses. They

are NOT safety glasses. Following this rule will reduce the

risk of eye injury.

Product users on United States Forest Service land, and in

some states, must comply with fire prevention regulations.

This product is equipped with a spark arrestor; however,

other user requirements may apply. Check with your federal,

state, or local authorities.

Wear heavy, long pants, boots, and gloves. Do not wear

loose fitting clothing, short pants, or go barefoot. Do not

wear jewelry of any kind. Wear hearing protection.

Heavy protective clothing may increase operator fatigue,

which could lead to heat stroke. During weather that is hot

and humid, heavy work should be scheduled for early morning

or late afternoon hours when temperatures are cooler.

Never operate this unit on the operator’s left side.

Secure long hair above shoulder level to prevent entangle-

ment in moving parts.

Keep all bystanders, children, and pets at least

50 ft. away. Bystanders should be encouraged to wear

eye protection. If you are approached, stop the engine and

cutting attachment. In the case of bladed units, there is the

added risk of injury to bystanders from being struck with

the moving blade in the event of a blade thrust or other

unexpected reaction of the saw.

Do not operate this unit when you are tired, ill, or under the

influence of alcohol, drugs, or medication.

Do not operate in poor lighting.

Do not operate in rain or use in damp or wet environ-

ments.

Keep firm footing and balance. Do not overreach. Over-

reaching can result in loss of balance or exposure to hot

surfaces.

Keep all parts of your body away from any moving part.

To avoid hot surfaces, never operate the unit with the bottom

of the engine above waist level.

Do not touch area around the muffler or cylinder of the unit.

These parts get hot from operation. Failure to heed this

warning could result in possible serious personal injury.

Carry the chain saw with the engine stopped, the guide bar

and saw chain to the rear, scabbard on the guide bar and

saw chain, and the muffler away from your body.

Always stop the engine and remove the spark plug wire be-

fore making any adjustments or repairs except for carburetor

adjustments.

Inspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace any damaged parts before use.

The chain may rotate during carburetor adjustments.

It has been reported that vibrations from hand-held tools

may contribute to a condition called Raynaud’s Syndrome

in certain individuals. Symptoms may include tingling, numbness and blanching of the fingers, usually apparent upon

exposure to cold. Hereditary factors, exposure to cold and

dampness, diet, smoking and work practices are all thought

to contribute to the development of these symptoms. It is

presently unknown what, if any, vibrations or extent of exposure may contribute to the condition. There are measures

that can be taken by the operator to possibly reduce the

effects of vibration:

a) Keep your body warm in cold weather. When operat

ing the unit wear gloves to keep the hands and wrists

warm. It is reported that cold weather is a major factor

contributing to Raynaud’s Syndrome.

b) After each period of operation, exercise to increase blood

circulation.

c) Take frequent work breaks. Limit the amount of exposure

per day.

d) Keep the tool well maintained, fasteners tightened and

worn parts replaced.

If you experience any of the symptoms of this condition,

immediately discontinue use and see your physician about

these symptoms.

Mix and store fuel in a container approved for gasoline.

Mix fuel outdoors where there are no sparks or flames. Wipe

up any fuel spillage. Move 30 ft. away from refueling site

before starting engine.

Stop the engine and allow to cool before refueling or storing

the unit.

Allow the engine to cool, empty the fuel tank, and secure

the unit from moving before transporting in a vehicle.

Check for damaged parts. Before further use of the tool, any

part that is damaged should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced by

an authorized service dealer. Be sure the chain stops moving

when the throttle trigger is released. Following this rule will

reduce the risk of shock, fire, or serious injury.

-

3

SPECIFIC SAFETY RULES

Kickback is a dangerous reaction that can lead to serious

injury. Kickback may occur when the moving chain contacts an object at the upper portion of the tip of the guide

bar or when the wood closes in and pinches the chain

in the cut. Contact at the upper portion of the tip of the

guide bar can cause the chain to dig into the object and

stop the chain for an instant. The result is a lightning-fast,

reverse reaction which kicks the guide bar up and back

toward the operator. If the chain is pinched along the top

of the guide bar, the guide bar can be driven rapidly back

toward the operator, which can cause loss of control and

may result in serious injury. Do not rely exclusively upon

the safety devices built into the product.

With a basic understanding of kickback, you can reduce

or eliminate the element of surprise. Sudden surprise

contributes to accidents.

Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of the guide bar

contact a log, branch, fence, or any other obstruction

while you are operating the unit. Have a planned retreat

path.

Cut only when visibility and light are adequate for you to

see clearly.

Do not use on a ladder or unstable support. Always cut

with both feet on solid ground to prevent being pulled off

balance.

To protect yourself from electrocution, do not operate

within 50 feet of overhead electrical lines.

Before starting the engine, make sure the chain is not

contacting any object.

Always cut with the engine running at full speed. Fully

squeeze the throttle trigger and maintain a steady cutting

speed.

Do not force tool. Use the correct tool for your applica-

tion. The correct tool will do the job better and safer at

the rate for which it is designed.

To protect yourself from falling branches, do not stand di-

rectly under the branch or limb being cut. This unit should

not be held at an angle over 60° from ground level.

Keep the handles dry, clean, and free of lubricant or fuel

mixture.

Shut off the engine and make sure the cutting attachment

has stopped before setting the unit down.

To prevent electrical shock or serious personal injury, do

not use this product with any AC power head.

Follow the sharpening and maintenance instructions for

the saw chain.

Use only the replacement guide bars and low kickback

chains specified for the unit.

Operate saw in well ventilated areas.

Do not operate the saw with one hand! Serious injury to

the operator, helpers, bystanders, or any combination of

these persons may results from one hand operation. This

saw is intended for two-handed use.

Use extreme caution when cutting small sized brush

and saplings because slender material may catch the

saw chain and be whipped toward you or pull you off

balance.

When cutting a limb that is under tension, be alert for

spring back so that you will not be struck when tension

in wood fibers are released.

Keep a good firm grip on the saw with both hands, the

right hand on the rear and the left hand on the front

handle, when the engine is running. Use a firm grip with

thumbs and fingers encircling the chain saw handles. A

firm grip will help you avoid kickback and maintain control

of the saw. Don’t let go.

Do not operate a chain saw in a tree unless you have

been specifically trained to do so.

REFUELING

FUEL IS HIGHLY FLAMMABLE. Take precautions when

using to reduce the chance of serious personal injury.

Store fuel in a cool, well-ventilated area, safely away from

spark and/or flame-producing equipment.

Store fuel in containers specifically designed for this

purpose.

Only refuel outdoors and do not smoke while refueling.

Add fuel before starting the engine. Never remove the cap

of the fuel tank or add fuel while the engine is running or

when the engine is hot.

If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

Replace all fuel tank and container caps securely.

If the fuel tank has to be drained, do this outdoors.

4

SYMBOLS

50' 15m

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Precautions that involve your safety.

Read The Operator’s Manual

Eye, Hearing, and Head Protection

Safety Footwear Wear non-slip safety footwear when using this equipment.

Gloves

Moving Parts Keep hands away from moving parts.

Keep Bystanders Away Keep all bystanders at least 50 ft. away.

Kickback DANGER! Beware of kickback.

Hot Surface

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Wear eye, hearing, and head protection when operating this

equipment.

Wear non-slip, heavy-duty protective gloves when handling

the pole pruner attachment and the saw chain.

To reduce the risk of injury or damage, avoid contact with

any hot surface.

Risk of Electrocution DANGER! Risk of electrocution!

Use unleaded gasoline intended for motor vehicle use with

Gasoline and Lubricant

an octane rating of 87 [(R + M)/2] or higher. This product is

powered by a 2-cycle engine and requires pre-mixing gasoline

and 2-cycle lubricant.

5

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER: Indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury.

CAUTION: (Without Safety Alert Symbol) Indicates a situation that may result in

property damage.

SERVICE

Servicing requires extreme care and knowledge and should

be performed only by a qualified service technician. For

service we suggest you return the product to your nearest

AUTHORIZED SERVICE CENTER for repair. When servicing, use only identical replacement parts.

WARNING:

To avoid serious personal injury, do not attempt to use this

product until you read thoroughly and understand completely the operator’s manual. If you do not understand

the warnings and instructions in the operator’s manual,

do not use this product. Call Ryobi customer service for

assistance.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool operation, always wear safety goggles or

safety glasses with side shields and, when needed, a full face shield. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety glasses with side shields. Always use eye

protection which is marked to comply with ANSI Z87.1.

SAVE THESE INSTRUCTIONS

6

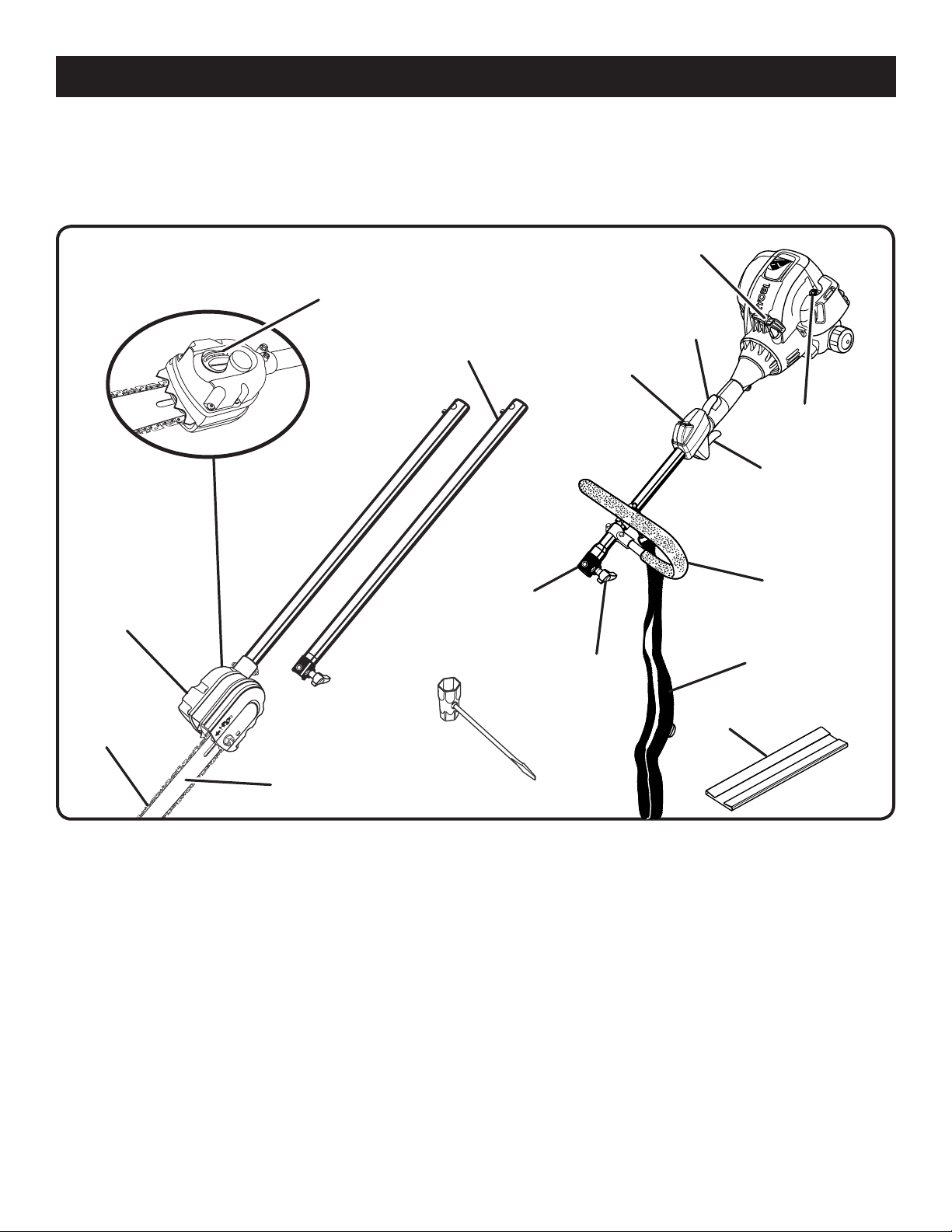

FEATURES

PRODUCT SPECIFICATIONS

Engine Displacement.......................................................................................................................................................30cc

Bar length .......................................................................................................................................................................10 in.

Weight ..........................................................................................................................................................................16 lbs.

PRUNER

ATTACHMENT

CHAIN OILER

TANK CAP

EXTENSION

SHAfT

COUPLER

ENGINE

SwITCH

KNOB

STARTER GRIP

TRIGGER

LOCK

PRIMER BULB

THROTTLE

TRIGGER

“j”

HANDLE

SHOULDER

STRAP

CHAIN

COMBINATION

BAR

wRENCH

KNOW YOUR PRUNER

See Figure 1.

Before attempting to use this product, familiarize yourself

with all operating features and safety rules.

ENGINE SWITCH

The engine switch controls the ignition system. The switch

must be in the ON (I) position for the engine to start and

run.

“J” HANDLE

Using the “J” handle allows better control of the pruner to

maximize operator safety.

PRIMER BULB

The priming bulb pumps fuel from the fuel tank to the carburetor. This is necessary only when starting a cold engine

or after refueling an engine that has run out of fuel.

SCABBARD

Fig. 1

SHOULDER STRAP

The shoulder strap helps support the weight of the pruner

during use.

START LEVER

The start lever opens and closes the choke valve in the

carburetor.

STARTER GRIP

The starter grip is used for starting the engine.

THROTTLE TRIGGER

The throttle trigger is used for starting the pruner, and also

for controlling blade rotation.

7

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the tool and any accessories from the

box. Make sure that all items listed in the packing list are

included.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-860-4050 for assistance.

PACKING LIST

Power Head Assembly

Pruner Attachment

Extension Shaft

Scabbard

Combination Wrench (5/8 in. x 3/4 in.)

8 oz. Bar and Chain Lubricant

Bottle of 2-cycle Lubricant

Shoulder Strap Hanger (with mounting hardware)

Shoulder Strap

“J” Handle Assembly:

“J” Handle

Top and Bottom Clamp

Short Bolt

Long Bolt

Flat Washers (2)

Lock Washers (2)

Nuts (2)

Hanger Cap

Operator’s Manual

ATTACHING THE “J” HANDLE

See Figure 2.

Hold the top and bottom clamp snugly in position on the

shaft housing so that the handle will be located to the

operator’s left.

Insert the end of the handle between the clamps.

Align the bolt holes and push the long bolt (1/4-20 x

1-1/2 in.) through the handle side.

Place short bolt (1/4-20 x 1 in.) through opposite side of

the clamp. Install the flat washer, lock washers, and hex

nuts to hold the assembly in place.

After assembly is complete, adjust the position of the

handle for best balance and comfort.

Tighten the long bolt first and then the short bolt.

SHORT

BOLT

LONG

BOLT

CLAMP

“j”

HANDLE

WARNING:

If any parts are damaged or missing do not operate this

tool until the parts are replaced. Failure to heed this warning could result in serious personal injury.

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal

injury.

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug when assembling parts.

CLAMP

fLAT wASHER

HEX NUT

LOCK

wASHER

Fig. 2

INSTALLING THE SHOULDER STRAP AND

HANGER

See Figure 3.

When operating this unit, you must wear a shoulder strap

to support the unit.

To install the shoulder strap hanger:

Remove the hex nut, lock washer, and bolt from the

shoulder strap hanger.

Pull apart the ends of the hanger to expand slightly.

Slide the hanger over the power head shaft immediately

behind the “J” handle.

Squeeze hanger ends together to retighten.

8

Loading...

Loading...