Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

ELECTRIC POLE SAW

SCIE ÉLECTRIQUE DE MANCHE

ELÉCTRICA SIERRA DE PÉRTIGA

RY43160

ALL VERSIONS

TOUTES LES VERSIONS

TODAS LAS VERSIONES

Your pole saw has been engineered and manufactured to our high standard for dependability, ease of operation, and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette électrique de manche a été conçu et fabriqué conformément

à nos strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenu, cet outil vous donnera des

années de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su eléctrica sierra de pértiga ha sido diseñado y fabricado de

conformidad con nuestras estrictas normas para brindar fiabilidad,

facilidad de uso y seguridad para el operador. Con el debido cuidado,

le brindará muchos años de sólido funcionamiento y sin problemas.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction .......................................................................................................................................2

Introduction / Introducción

Important Safety Instructions ........................................................................................................ 3-4

Instructions importantes concernant la sécurité / Instrucciones de seguridad importantes

Specific Safety Rules .................................................................................................................... 4-5

Règles de sécurité particulières / Reglas de seguridad específicas

Symbols ........................................................................................................................................ 6-7

Symboles / Símbolos

Electrical ............................................................................................................................................ 8

Caractéristiques électriques / Aspectos eléctricos

Features ....................................................................................................................................... 9-10

Caractéristiques / Características

Assembly ................................................................................................................................... 10-11

Assemblage / Armado

Operation ................................................................................................................................... 12-15

Utilisation / Funcionamiento

Maintenance .............................................................................................................................. 16-20

Entretien / Mantenimiento

Troubleshooting ............................................................................................................................... 20

Dépannage / Corrección de problemas

Warranty ..........................................................................................................................................21

Garantie / Garantía

Parts Ordering and Service ............................................................................................... Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ......................................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIÓN

This product has many features for making its use more pleasant and enjoyable. Safety, performance,

and dependability have been given top priority in the design of this product making it easy to maintain

and operate.

* * *

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la conception de ce produit, l’accent a été mis sur la sécurité, les performances et la

fiabilité, afin d’en faire un outil facile à utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el

diseño de este producto se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo

cual se facilita su manejo y mantenimiento.

Page 2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

Read and understand all instructions. Failure

to follow all instructions listed below may result

in electric shock, fire, and/or serious personal

injury.

READ ALL INSTRUCTIONS

For safe operation, read and understand all in-

structions before using this product. Be familiar

with all controls and proper use of the machine.

Follow all safety instructions. Failure to follow

all safety instructions listed below, can result in

serious personal injury.

Do not allow children or untrained individuals

to use this unit.

Thoroughly inspect the area where the equipment

is to be used and remove all foreign objects.

Wear eye protection with side shields, which is

marked to comply with ANSI Z87.1, along with

head protection when operating this equipment.

Dress properly. Wear heavy long pants, long

sleeves, boots, and gloves. Do not wear loose

fitting clothing, short pants, sandals, or go barefoot. Do not wear jewelry of any kind.

Secure long hair above shoulder level to prevent

entanglement in moving parts.

Keep all bystanders, children, and pets at least

50 ft. away.

Stay Alert — Watch what you are doing; use

common sense. Do not operate this unit when

you are tired, ill, or under the influence of alcohol, drugs, or medication.

Do not operate in poor lighting.

Keep firm footing and balance. Do not over-

reach. Overreaching can result in loss of balance

or exposure to hot surfaces.

Keep all parts of your body away from any mov-

ing part.

Inspect the unit before each use for loose fasten-

ers, etc. Replace any damaged parts before use.

When not in use, product should be stored

indoors in a dry, locked up place—out of the

reach of children.

Use only original manufacturer’s replacement

parts. Failure to do so may cause poor performance, possible injury, and will void your warranty.

Do not, under any circumstance, use any at-

tachment or accessory on this product which

was not provided with the product or identified

as appropriate for use with this product in the

operator’s manual.

Avoid dangerous environments. Do not use the

product in damp or wet locations. Do not use

in rain.

Use the right appliance. Do not use the product

for any job except that for which it is intended.

Do not operate from steps, a ladder, rooftop,

tree, or unstable support. Stable footing on a

solid surface enables better control of the product in unexpected situations.

Do not force the product. It will do the job better

and with less likelihood of a risk of injury at the

rate for which it was designed.

DANGER — Keep hands away from cutting

area. Keep both hands on handles when power

is on.

CAUTION — Blade coasts after being turned

off.

To reduce the risk of electric shock, this product

has a polarized plug (one blade is wider than

the other) and will require the use of a polarized

extension cord. The plug will fit into a polarized

extension cord only one way. If the plug does

not fit fully into the extension cord, reverse the

plug. If the plug still does not fit, obtain a correct

polarized extension cord. A polarized extension

cord will require the use of a polarized wall

outlet. This plug will fit into the polarized wall

outlet only one way. If the plug does not fit fully

into the wall outlet, reverse the plug. If the plug

still does not fit, contact a qualified electrician

to install the proper wall outlet. Do not change

the equipment plug, extension cord receptacle,

or extension cord plug in any way.

Do not abuse the cord. Never use the cord to

carry the product or to disconnect the plug from

an outlet. Keep cord away from heat, oil, sharp

Page 3 — English

Page 4

IMPORTANT SAFETY INSTRUCTIONS

edges, or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

Make sure your extension cord is in good condi-

tion. When using an extension cord, be sure to

use one heavy enough to carry the current your

product will draw. A wire gauge size (A.W.G.)

of at least 16 is recommended for an extension

cord 50 feet or less in length. If in doubt, use

the next heavier gauge. The smaller the gauge

number, the heavier the cord. An undersized

SPECIFIC SAFETY RULES

Kickback is a dangerous reaction that can lead

to serious injury. Kickback may occur when the

moving chain contacts an object at the upper

portion of the tip of the guide bar or when the

wood closes in and pinches the chain in the

cut. Contact at the upper portion of the tip of

the guide bar can cause the chain to dig into

the object and stop the chain for an instant.

The result is a lightning-fast, reverse reaction

which kicks the guide bar up and back toward

the operator. If the chain is pinched along the

top of the guide bar, the guide bar can be driven

rapidly back toward the operator, which can

cause loss of control and may result in serious

injury. Do not rely exclusively upon the safety

devices built into the product.

With a basic understanding of kickback, you

can reduce or eliminate the element of surprise.

Sudden surprise contributes to accidents.

Use pole saw for cutting wood only. Do not use

for cutting non-wood items.

Make sure that the area in which you are cutting

is free from obstructions. Do not let the nose of

the guide bar contact a log, branch, fence, or

any other obstruction while you are operating

the unit. Have a planned retreat path.

Do not grasp the exposed cutting blades or

cutting edges when picking up or holding the

product.

Cut only when visibility and light are adequate

for you to see clearly.

Page 4 — English

cord will cause a drop in line voltage resulting

in loss of power and overheating.

WARNING: Use outdoor extension cords marked

SW-A, SOW-A, STW-A, STOW-A, SJW-A, SJTWA, or SJTOW-A. These cords are rated for outdoor

use and reduce the risk of electric shock.

Ground Fault Circuit Interrupter (GFCI) protec-

tion should be provided on the circuit(s) or

outlet(s) to be used for the product. Receptacles

are available having built-in GFCI protection and

may be used for this measure of safety.

To protect yourself from electrocution, do not

operate within 50 feet of overhead electrical

lines.

Before starting the motor, make sure the chain

is not contacting any object.

To protect yourself from falling branches, do not

stand directly under the branch or limb being

cut. This unit should not be held at an angle over

60° from ground level.

Turn off the motor and make sure cutting attach-

ment has stopped before setting unit down.

Follow the sharpening and maintenance instruc-

tions for the saw chain.

Use only the replacement guide bars and low

kickback chains specified for the unit.

Do not operate the saw with one hand! Serious

injury to the operator, helpers, bystanders, or

any combination of these persons may results

from one hand operation. This saw intended for

two-handed use.

Use extreme caution when cutting small-sized

brush and saplings because slender material

may catch the saw chain and be whipped toward you or pull you off balance.

When cutting a limb that is under tension, be

alert for spring back so that you will not be struck

when the tension in the wood fibers is released.

To avoid accidental starting, never carry plugged

in product with finger on switch. Be sure switch

is off when plugging in.

Page 5

SPECIFIC SAFETY RULES

SPECIFIC SAFETY RULES

Maintain product with care. Keep cutting edge

sharp and clean for best performance and to

reduce the risk of injury. Follow instructions for

lubricating and changing accessories. Inspect

cord periodically and, if damaged, have it repaired by an authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles dry, clean, and free from

oil and grease.

Check damaged parts. Before further use of the

product, a guard or other part that is damaged

should be carefully checked to determine that

it will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other condition that may

affect its operation. A guard or other part that

is damaged should be properly repaired or replaced by an authorized service center unless

indicated elsewhere in this manual.

Disconnect the plug from power source when

not in use, before servicing, and when changing

accessories.

Service on the product must be performed by

qualified repair personnel only. Service or maintenance performed by unqualified personnel

could result in injury to the user or damage to

the product.

If the power supply cord is damaged, it must

be replaced only by the manufacturer or by an

authorized service center to avoid risk.

Save these instructions. Refer to them frequently

and use them to instruct others who may use

this product. If you loan someone this product,

loan them these instructions also to prevent

misuse of the product and possible injury.

Page 5 — English

Page 6

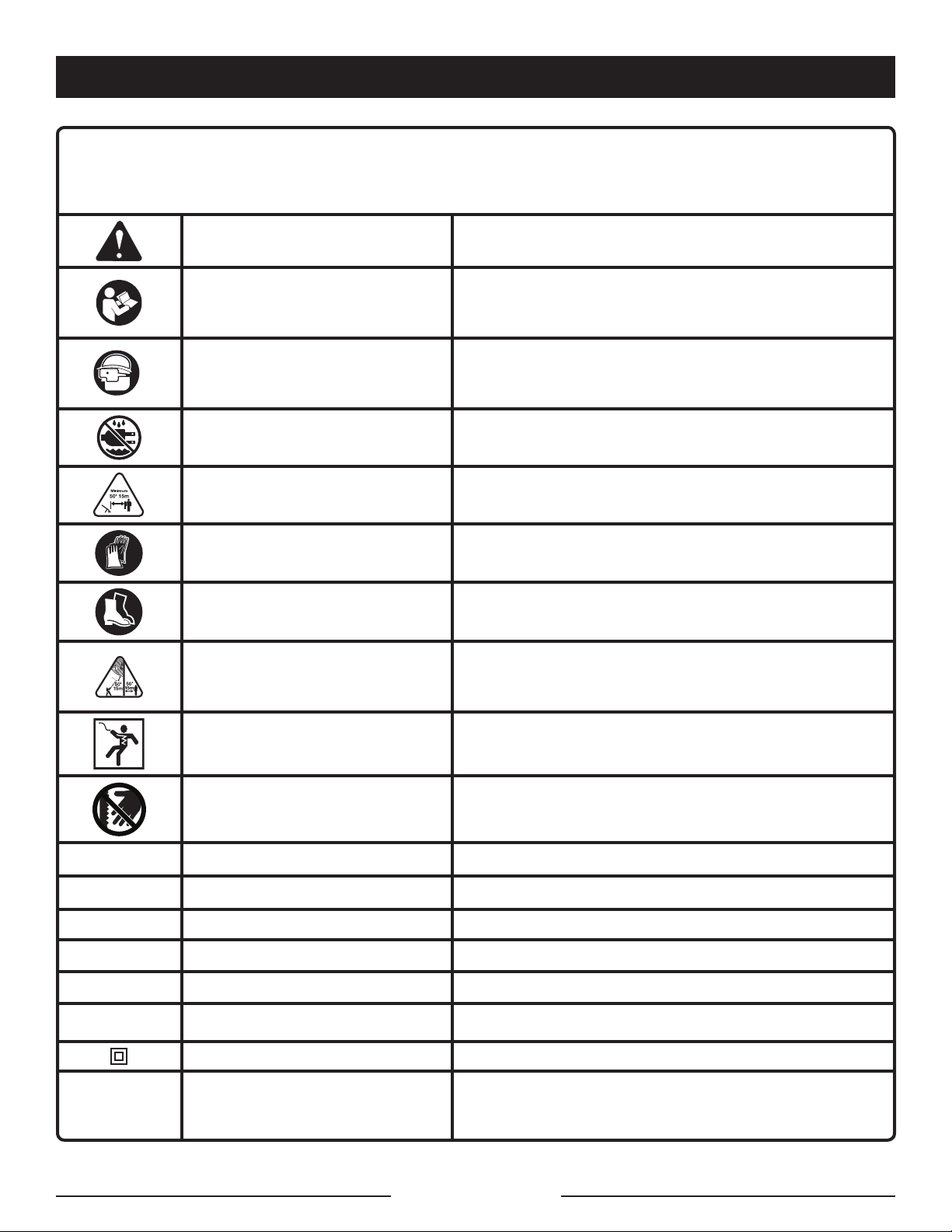

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME EXPLANATION

Safety Alert Symbol Indicates a potential personal injury hazard.

Read the Operator’s

Manual

Wear Eye and Head

Protection

Wet Conditions Alert Do not expose to rain or use in damp locations.

Keep Bystanders Away Keep all bystanders at least 50 ft. away.

Gloves

Safety Footwear

Keep Tool Away from Electrical Lines/Keep Bystanders

Away

To reduce the risk of injury, user must read and

understand operator’s manual before using this

product.

Always wear eye protection with side shields

marked to comply with ANSI Z87.1, along with

head protection.

Wear non-slip, heavy-duty protective gloves when

handling the pole saw and the blade.

Wear non-slip safety footwear when using this

equipment.

DANGER! Risk of electrocution! Keep tool 50 feet

away from electrical lines. Keep all bystanders at

least 50 ft. away.

Electric Shock

No Hands Symbol

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

hrs Hours Time

n

o

.../min Per Minute

No Load Speed Rotational speed, at no load

Class II Construction Double-insulated construction

Failure to use in dry conditions and to observe safe

practices can result in electric shock.

Failure to keep your hands away from the blade will

result in serious personal injury.

Revolutions, strokes, surface speed, orbits etc.,

per minute

Page 6 — English

Page 7

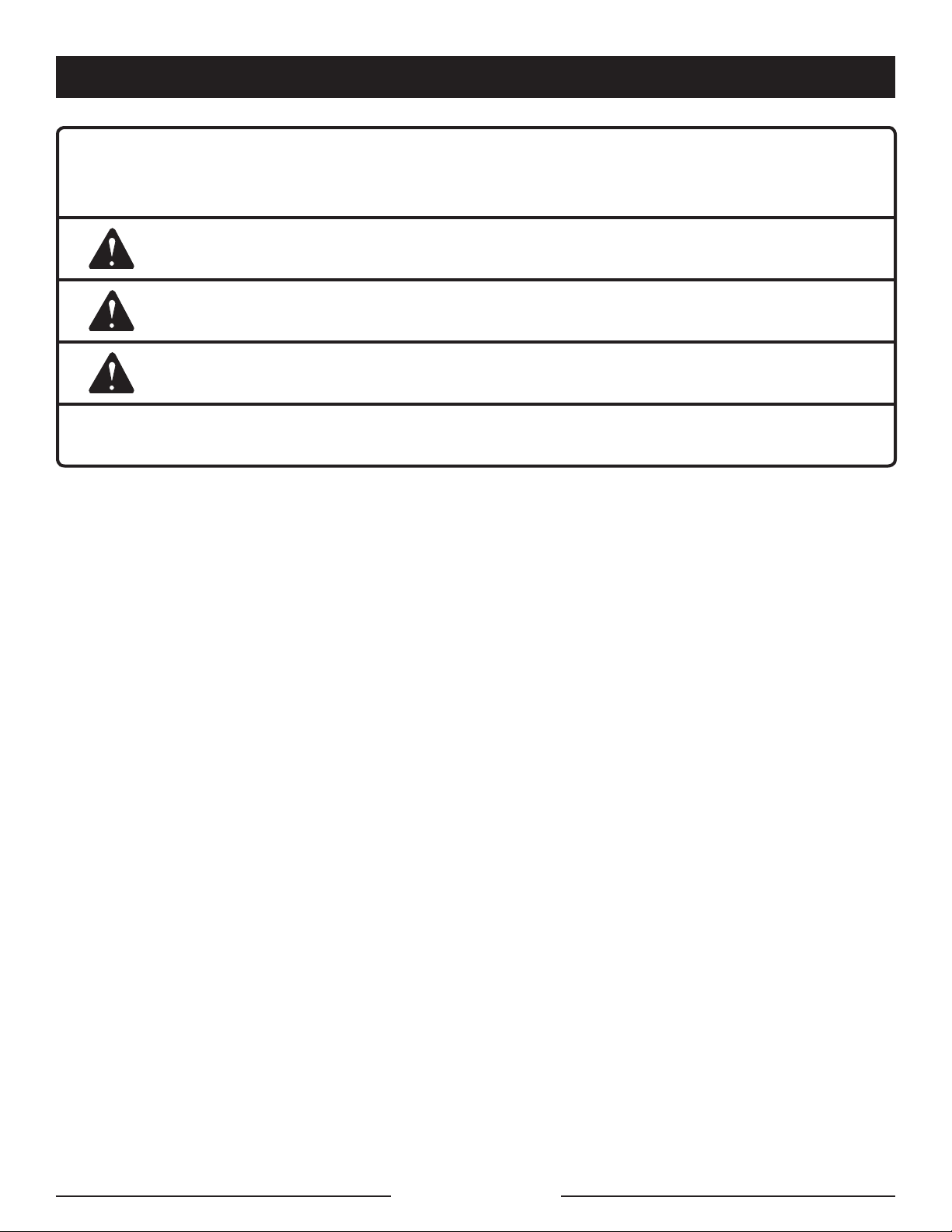

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with

this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result

in property damage.

Page 7 — English

Page 8

ELECTRICAL

DOUBLE INSULATION

Double insulation is a concept in safety in electric

power tools, which eliminates the need for the usual

three-wire grounded power cord. All exposed metal

parts are isolated from the internal metal motor components with protecting insulation. Double insulated

tools do not need to be grounded.

WARNING:

The double insulated system is intended to protect

the user from shock resulting from a break in the

tool’s internal insulation. Observe all normal safety

precautions to avoid electrical shock.

NOTE: Servicing of a product with double insulation

requires extreme care and knowledge of the system

and should be performed only by a qualified service

technician. For service, we suggest you return the

product to your nearest authorized service center for

repair. Always use original factory replacement parts

when servicing.

ELECTRICAL CONNECTION

This product has a precision-built electric motor. It

should be connected to a power supply that is 120

volts, AC only (normal household current), 60 Hz.

Do not operate this product on direct current (DC). A

substantial voltage drop will cause a loss of power

and the motor will overheat. If the product does not

operate when plugged into an outlet, double-check

the power supply.

EXTENSION CORDS

See Figure 1.

When using a power tool at a considerable distance

from a power source, be sure to use an extension cord

that has the capacity to handle the current the product

will draw. An undersized cord will cause a drop in line

voltage, resulting in overheating and loss of power. Use

the chart to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed

by Underwriter’s Laboratories (UL) should be used.

When working outdoors with a product, use an

extension cord that is designed for outside use. This

type of cord is designated with “W-A” or “W” on the

cord’s jacket.

Before using any extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

A proper extension cord is available at an authorized

service center.

It is possible to tie the extension cord and power cord

in a knot to prevent them from becoming disconnected

during use. Make the knot as shown in figure 1, then

connect the plug end of the power cord into the receptacle end of the extension cord. This method can also

be used to tie two extension cords together.

Fig. 1

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on

lumber, tools, or other obstructions while you are

working with a power tool. Failure to do so can result

in serious personal injury.

WARNING:

Check extension cords before each use. If damaged replace immediately. Never use the product

with a damaged cord since touching the damaged

area could cause electrical shock resulting in serious injury.

Page 8 — English

Page 9

FEATURES

PRODUCT SPECIFICATIONS

Bar Length ....................................................................................................................................... 8 in.

Chain Pitch ....................................................................................................................................3/8 in.

Chain Type ...................................................................................... Low Profile Skip Tooth Narrow Kerf

Input .......................................................................................................120 V, AC only, 60 Hz, 6 Amps

Weight .........................................................................................................................................8.5 lbs.

OIL CAP

LOCK-OUT

BUTTON

TELESCOPING

POLE

CORD

RETAINER

SCABBARD

Fig. 2

Page 9 — English

Page 10

FEATURES

KNOW YOUR POLE SAW

See Figure 2.

The safe use of this product requires an understanding of the information on the product and

in this operator’s manual as well as a knowledge

of the project you are attempting. Before use of

this product, familiarize yourself with all operating

features and safety rules.

CORD RETAINER

A convenient cord retainer helps keep the extension

cord connection secure during tool operation.

ASSEMBLY

LOCK-OUT BUTTON

To help prevent accidental starting, the lock-out

button must be depressed along with the switch

trigger.

QUICK-VIEW OIL INDICATOR

Semi-transparent bar lube reservoir that allows

user to see when to add lubricant.

SCABBARD

The scabbard keeps the operator from coming in

contact with the sharp blades when the tool is not

in use. It also helps keep the blades from being

nicked or damaged when the tool is in storage.

TELESCOPING POLE

The pole can be adjusted to different lengths for

ease of use.

UNPACKING

This product requires assembly.

Carefully remove the product and any acces-

sories from the box. Make sure that all items

listed in the packing list are included.

WARNING:

Do not use this product if any parts on the Packing List are already assembled to your product

when you unpack it. Parts on this list are not

assembled to the product by the manufacturer

and require customer installation. Use of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the product carefully to make sure

no breakage or damage occurred during

shipping.

Do not discard the packing material until you

have carefully inspected and satisfactorily operated the product.

If any parts are damaged or missing, please call

1-800-860-4050 for assistance.

PACKING LIST

Pole Saw

Scabbard

Operator’s Manual

WARNING:

If any parts are damaged or missing, do not

operate this product until the parts are replaced.

Use of this product with damaged or missing

parts could result in serious personal injury.

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition leading to possible serious personal injury.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in

accidental starting and possible serious personal injury.

Page 10 — English

Page 11

HANDLE POLE

THREADED BASE

ASSEMBLY

BUTTON

LOWER COLLAR

INTERMEDIATE

BUTTON

CORD

UPPER COLLAR

CONNECTING THE POLES

See Figure 3.

Before using the pole saw, a one-time assembly is

required. When removed from the box, the three

poles are connected by an electrical cord as shown

above.

Remove the four (4) rubber cord protectors from

inside the poles. This material protects the cord

during shipping and MUST be discarded immediately.

Unscrew the lower collar from the threaded base

on the intermediate pole and push back over the

cord to the handle pole shaft as shown.

Insert the handle pole into the intermediate pole

and slide together until you hear the button click.

The tubes are egg-shaped and will only install one

way.

THREADED

POLE

BASE

POWERHEAD POLE

Fig. 3

Lower the collar on the handle pole to the threaded

base on the intermediate pole and rotate clockwise to secure.

Repeat this process to attach the intermediate

pole to the powerhead pole.

NOTE: Once assembled correctly, handle pole and

powerhead pole should not be able to separate from

intermediate pole when pulled. Repeat above steps

if poles can be separated from intermediate pole.

WARNING:

Failure to lock powerhead pole as directed above

could result in serious injury or death.

Page 11 — English

Page 12

OPERATION

DANGER:

Never cut near power lines, electric cords, or

other electric sources. If bar and chain jams

on any electrical cord or line, DO NOT TOUCH

THE BAR OR CHAIN, THEY CAN BECOME

ELECTRICALLY LIVE AND VERY DANGEROUS!

Continue to hold the pole saw by the insulated

rear handle or lay it down and away from you in

a safe manner. Disconnect the electrical service

to the damaged line or cord before attempting

to free the bar and chain from the line or cord.

Contact with the bar, chain, other conductive

parts of the pole saw, or live electric cords or

lines will result in death by electrocution or serious injury.

WARNING:

Do not allow familiarity with this product to make

you careless. Remember that a careless fraction

of a second is sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1, along with

head protection. Failure to do so could result in

objects being thrown into your eyes and other

possible serious injuries.

ADDING BAR AND CHAIN LUBRICANT

See Figure 4

Use Bar and Chain Lubricant. It is designed for

chains and chain oilers, and is formulated to

perform over a wide temperature range with no

dilution required.

NOTE: Pole saw comes from the factory with

no bar and chain oil added. Level should also be

checked after every 20 minutes of use and refilled

as needed.

Remove oil cap.

Carefully pour the bar and chain oil into the

tank.

Wipe off excess oil.

Check and fill the oil tank when quick view oil

indicator is below the second to last indicator

line.

Repeat as needed.

NOTE: Do not use dirty, used or otherwise

contaminated oils. Damage may occur to the

bar or chain.

NOTE: It is normal for oil to seep from the saw

when not in use. To prevent seepage, empty the

oil tank after each use then run for one minute.

When storing the unit for a long period of time

(three months or longer) be sure the chain is lightly

lubricated; this will prevent rust on the chain and

bar sprocket.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product.

The use of attachments or accessories not recommended can result in serious personal injury.

APPLICATIONS

You may use this product for the purposes listed

below:

Limbing

Pruning

Page 12 — English

QUICK VIEW

OIL INDICATOR

CHAIN

LUBRICANT

OIL

RESERVOIR

CAP

Fig. 4

Page 13

OPERATION

CONNECTING TO POWER SUPPLY

See Figure 5.

This product is designed with a cord retainer that

prevents the extension cord from being pulled

loose while using.

Form a loop with the end of the extension

cord.

Insert loop portion of extension cord through

opening in the bottom of the rear handle and

place over cord retainer.

Slowly pull loop against cord retainer until the

slack is removed.

Plug product into extension cord.

NOTE: Failure to remove all excess cord slack

from extension cord retainer could result in plug

loosening from receptacle.

LOCK-OUT

BUTTON

SWITCH TRIGGER

CORD RETAINER

Fig. 5

STARTING AND STOPPING

See Figure 5.

To start the motor:

Connect the pole saw to power supply.

Place your thumb on the lock-out button and

pull it completely towards you.

Fully depress the switch trigger.

To stop the motor:

Release the switch trigger.

ADJUSTING TELESCOPING POLE

See Figure 6.

Disconnect the pole saw from the power sup-

ply.

Rotate the collar counterclockwise to loosen.

Push poles towards each other to shorten the

pole or pull away from each other to lengthen

the pole.

NOTE: Extend the pole only to the length

required to reach the limb being cut. Do not

extend the handle above waist height.

When the desired length is achieved, rotate the

collar clockwise to secure.

NOTE: Adjust hand placement on the shaft of the

pole saw to keep proper balance. Do not attempt

to use the pole saw at a length which does not

allow you to achieve proper footing and balance

at all times.

Page 13 — English

Page 14

OPERATION

PREPARATION FOR CUTTING

See Figures 7 - 8.

Wear non-slip gloves for maximum grip and

protection.

Maintain a proper grip on the unit whenever the

motor is running. Use your right hand to firmly

grip the rear handle while your left hand has a

firm grip on the pole shaft.

Hold unit firmly with both hands. Always keep

your left hand on the pole shaft and your right

hand on the rear handle, so your body is to the

left of the chain line. Never use a left-handed

(cross-handed) grip, or any stance that places

your body or arm across the chain line.

Never stand directly under the limb you are cut-

ting.

Be certain the collars are fully tightened before

operating equipment; check them periodically

for tightness during use to avoid serious injury.

BASIC CUTTING PROCEDURE

Follow the steps below to prevent damage to tree

or shrub bark. Do not use a back-and-forth sawing motion.

COLLAR

LOAD

FIRST CUT

1/4 DIAMETER

Fig. 6

SECOND CUT

FINAL

CUT

Fig. 7

Make a shallow first cut (1/4 of limb diameter)

on the underside of the limb close to the main

limb or trunk.

Make a second cut from the top side of the limb

outboard from the first cut. Continue the cut

through the limb until the limb separates from

the tree. Be prepared to balance the weight of

the tool when the limb falls.

Make a final cut close to trunk.

NOTE: For second and final cuts (from top of limb

or branch), hold front cutting guide against the limb

being cut. This will help steady the limb and make

it easier to cut. Allow chain to cut for you; exert

only light downward pressure. If you force the cut,

damage to the bar, chain, or motor can result.

Release the trigger as soon as the cut is com-

pleted.

CUTTING GUIDE

Failure to follow proper cutting procedures will

result in the bar and chain binding and becoming pinched or trapped in the limb. If this should

happen:

Stop the motor and disconnect from power

supply.

If the limb can be reached from the ground,

lift the limb while holding the saw. This should

release the “pinch” and free the saw.

If the saw is still trapped, call a professional for

assistance.

Fig. 8

Page 14 — English

Page 15

OPERATION

LIMBING AND PRUNING

See Figures 9 - 10.

This unit is designed for trimming small branches

and limbs up to 6 in. in diameter. For best results,

observe the following precautions.

Plan the cut carefully. Be aware of the direction

in which the branch will fall.

Branches may fall in unexpected directions. Do

not stand directly under the branch being cut.

The most typical cutting application is to posi-

tion the unit at an angle of 60° or less, depending on the specific situation, as shown. As the

angle of the pole saw shaft to ground increases,

the difficulty of making the first cut (from the

underside of limb) increases.

Remove long branches in several stages.

Cut lower branches first to allow the top branch-

es more room to fall.

60° MAXIMUM

Fig. 9

Work slowly, keeping both hands on the saw

with a firm grip. Maintain secure footing and

balance.

Keep the tree between you and the chain while

limbing. Cut from side of tree opposite branch

you are cutting.

Do not cut from a ladder; this is extremely

dangerous. Leave this operation for professionals.

Do not make the flush cut next to the main limb

or trunk until you have cut off the limb further out

to reduce the weight. Following proper cutting

procedures will prevent stripping the bark from

the main member.

Do not use the pole saw for felling or bucking.

To prevent electrocution, do not operate within

50 ft. of overhead electrical lines.

Keep bystanders at least 50 ft. away.

Fig. 10

Page 15 — English

Page 16

MAINTENANCE

WARNING:

When servicing, use only identical replacement

parts. Use of any other parts could create a

hazard or cause product damage.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1, along with

head protection. Failure to do so could result in

objects being thrown into your eyes and other

possible serious injuries.

WARNING:

Before inspecting, cleaning or servicing the unit,

stop the motor, wait for all moving parts to stop,

and disconnect from power supply. Failure to

follow these instructions can result in serious

personal injury or property damage.

FLATS

APPROX .050 in.

CHAIN TENSION

See Figures 11 - 12.

Fig. 11

Fig. 12

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from

various types of commercial solvents and may be

damaged by their use. Use clean cloths to remove

dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken, or destroy plastic, which could

result in serious personal injury.

All chain saw service, other than the items listed in

the instruction manual maintenance instructions,

should be performed by competent chain saw

service personnel. (For example, if improper tool

is used to hold the flywheel in order to remove

the clutch, structural damage to the flywheel could

occur and subsequently could cause the flywheel

to burst).

WARNING:

To avoid possible serious injury, never touch or

adjust the chain while the motor is running. The

saw chain is very sharp; always wear protective gloves when performing maintenance to

the chain.

Stop the motor and disconnect from power

supply before setting the chain tension. Make

sure the guide bar nut is loose to finger tight,

turn the chain tensioning screw clockwise to

tension the chain. Refer to Replacing the Bar

and Chain for additional information.

NOTE: A cold chain is correctly tensioned when

there is no slack on the underside of the guide

bar, the chain is snug, but it can be turned by

hand without binding.

Chain must be re-tensioned whenever the flats on

the drive links hang out of the bar groove as

shown in fig. 11.

During normal operation, the temperature of the

chain will increase. The drive links of a correctly

tensioned warm chain will hang approximately

.050 in. out of the bar groove, as shown in

fig. 12.

Page 16 — English

Page 17

MAINTENANCE

NOTE: New chain tends to stretch; check chain

tension frequently and tension as required.

CAUTION:

Chain tensioned while warm, can be too tight

upon cooling. Check the “cold tension” before

next use.

REPLACING THE BAR AND CHAIN

See Figures 13 - 16.

WARNING:

To avoid possible serious injury, stop the motor and disconnect from power supply before

replacing the bar, chain, or performing any

maintenance operation.

Remove the bar nut (7/16 in.) and drivecase

cover.

The bar contains a bar stud slot that fits over the

bar stud. The bar also contains a chain tensioning pin hole which fits over the chain tensioning

pin.

Place the bar onto the bar stud so that the chain

tensioning pin fits into the chain tensioning pin

hole.

Fit the chain over the sprocket and into the bar

groove. The cutters on the top of the bar should

face toward the bar tip, in the direction of the

chain rotation.

Replace the drivecase cover and install the bar

nut. Tighten the bar nut finger tight only. The bar

must be free to move for tension adjustment.

DRIVECASE

COVER

SPROCKET

DRIVECASE

COVER

BAR

NUT

SPROCKET

CHAIN

TENSIONING

PIN HOLE

CHAIN

BAR NUT

TENSIONING PIN

BAR STUD

CHAIN

ROTATION

BAR

Fig. 13

CHAIN

BAR

STUD

BAR

SLOT

Fig. 14

CHAIN

Remove all slack from chain by turning the chain

tensioning screw clockwise, assuring that the

chain seats into the bar groove during tensioning.

Lift the tip of the bar up to check for sag. Re-

lease the tip of the bar, and turn the chain tensioning screw 1/2 turn clockwise. Repeat this

process until sag does not exist.

Hold the tip of the bar up and tighten the bar

nut securely.

Chain is correctly tensioned when there is no slack

on the underside of the bar, the chain is snug, but

it can be turned by hand without binding.

Page 17 — English

CHAIN

TENSIONING SCREW

Fig. 15

NOTE: If chain is too tight, it will not rotate. Loos-

en the bar nut slightly and turn adjusting screw

1/4 turn counterclockwise. Lift the tip of the bar

up and retighten bar nut.

Page 18

MAINTENANCE

CHAIN OILER

See Figure 17.

Use Premium Bar and Chain Lubricant. It is

designed for chains and chain oilers and is

formulated to perform over a wide temperature

range with no dilution required.

Remove the cap and carefully pour approxi-

mately 2 oz. of bar and chain lubricant into the

bar lube reservoir.

Replace the cap and tighten securely.

Check and refill the bar lube reservoir every time

the pole saw is used.

NOTE: Do not use dirty, used, or otherwise contaminated lubricants. Damage may occur to the

oil pump, bar, or chain.

CHAIN MAINTENANCE

See Figure 18.

For smooth and fast cutting, the chain needs to

be maintained properly. The following conditions

indicate that the chain requires sharpening:

Wood chips are small and powdery

Chain must be forced through the wood during

cutting

Chain cuts to one side

During maintenance of the chain, consider the

following:

Improper filing angle of the side plate can in-

crease the risk of a severe kickback.

Depth gauge (or raker clearance) setting de-

termines the height the cutter enters the wood

and the size of the wood chip that is removed.

Too much clearance increases the potential for

kickback. Too little clearance decreases the size

of the wood chip thus decreasing the chain's

cutting ability.

If cutter teeth have hit hard objects such as nails

and stones, or have been abraded by mud or

sand on the wood, have service dealer sharpen

chain.

BAR

NUT

Fig. 16

REMOVE

CAP

BAR LUBE

RESERVOIR

Fig. 17

RAKER (DEPTH GAUGE)

CLEARANCE

.025 in.

Fig. 18

Page 18 — English

Page 19

MAINTENANCE

HOW TO SHARPEN THE CUTTERS

See Figures 19 - 22.

Be careful to file all cutters to the specified angles

and to the same length, as fast cutting can be

obtained only when all cutters are uniform.

Tighten the chain tension enough that the chain

does not wobble. Do all of your filing at the mid-

point of the bar. Wear gloves for protection.

Use a 5/32 in. diameter round file and holder.

Keep the file level with the top plate of the tooth.

Do not let the file dip or rock.

Using light but firm pressure, stroke towards

the front corner of the tooth. Lift file away from

the steel on each return stroke.

Put a few firm strokes on every tooth. File all left

hand cutters in one direction. Then move to the

other side and file the right hand cutters in the

opposite direction. Occasionally remove filings

from the file with a wire brush.

TOP

PLATE

RIVET HOLE

HEEL

PARTS OF A CUTTER

CUTTING

CORNER

SIDE PLATE

GULLET

DEPTH GAUGE

TOE

Fig. 19

Fig. 20

CAUTION:

Dull or improperly sharpened chain can cause

excessive motor speed during cutting which

may result in severe motor damage.

WARNING:

Improper chain sharpening increases the potential of kickback. Failure to replace or repair

damaged chain can cause serious injury.

Fig. 21

LEFT HAND

CUTTERS

RIGHT HAND

CUTTERS

Page 19 — English

Fig. 22

Page 20

MAINTENANCE

STORING THE PRODUCT

See Figure 23.

Clean all foreign material from the product. Store

idle unit indoors in a dry, well-ventilated area

that is inaccessible to children. Keep away from

corrosive agents such as garden chemicals and

de-icing salts.

Always place the scabbard on the saw bar

when transporting or storing the pole saw. The

scabbard is a snug fit and must be attached

very carefully due to the sharp teeth on the

saw chain. This is best done by grasping the

scabbard at one end, in the center portion of

the scabbard, and carefully sliding it over the

chain as shown. Use caution to avoid the sharp

teeth of the chain.

SCABBARD

Fig. 23

NOTE: The saw chain is very sharp. Always

wear protective gloves when handling the

chain.

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Bar and chain

running hot and

smoking.

Motor runs,

but chain is not

rotating.

Check chain tension

for overtightened

condition

Bar lube reservoir

empty

Chain tension too

tight.

Check guide bar and

chain assembly.

Check guide bar and

chain for damage.

Tension chain. Refer to Chain Tension earlier in this manual.

Check bar lube reservoir.

Retention chain. Refer to Chain Tension earlier in this

manual.

Refer to Replacing the Bar and Chain earlier in this

manual.

Inspect guide bar and chain for damage.

CALL US FIRST

For any questions about operating or maintaining your product,

call the Ryobi® Help Line!

Your product has been fully tested prior to shipment to ensure

your complete satisfaction.

Page 20 — English

Page 21

WARRANTY

LIMITED WARRANTY STATEMENT

Techtronic Industries North America, Inc., warrants to the

original retail purchaser that this RYOBI® brand outdoor

product is free from defect in material and workmanship

and agrees to repair or replace, at Techtronic Industries

North America, Inc.’s, discretion, any defective product

free of charge within these time periods from the date of

purchase.

Three years if the product is used for personal, family

or household use;

90 days, if used for any other purpose, such as

commercial or rental.

This warranty extends to the original retail purchaser only

and commences on the date of the original retail purchase.

Any part of this product found in the reasonable judgment

of Techtronic Industries North America, Inc. to be defective

in material or workmanship will be repaired or replaced

without charge for parts and labor by an authorized service

center for RYOBI® brand outdoor products (Authorized

Ryobi Service Center).

The product, including any defective part, must be returned

to an authorized Ryobi service center within the warranty

period. The expense of delivering the product to the service

center for warranty work and the expense of returning it

back to the owner after repair or replacement will be paid

by the owner. Techtronic Industries North America, Inc.’s,

responsibility in respect to claims is limited to making the

required repairs or replacements and no claim of breach of

warranty shall be cause for cancellation or rescission of the

contract of sale of any RYOBI® brand outdoor product. Proof

of purchase will be required by the dealer to substantiate

any warranty claim. All warranty work must be performed

by an authorized service dealer.

This warranty is limited to ninety (90) days from the date

of original retail purchase for any RYOBI® brand outdoor

product that is used for rental or commercial purposes, or

any other income-producing purpose.

This warranty does not cover any product that has been

subject to misuse, neglect, negligence, or accident, or that

has been operated in any way contrary to the operating

instructions as specified in this operator’s manual. This

warranty does not apply to any damage to the product that

is the result of improper maintenance or to any product

that has been altered or modified. The warranty does not

extend to repairs made necessary by normal wear or by the

use of parts or accessories which are either incompatible

with the RYOBI® brand outdoor product or adversely affect

its operation, performance, or durability. In addition, this

warranty does not cover:

A. Tune-ups – Spark Plugs, Carburetor, Carburetor

Adjustments, Ignition, Filters

B. Wear items – Bump Knobs, Outer Spools, Cutting

Lines, Inner Reels, Starter Pulleys, Starter Ropes, Drive

Belts, Tines, Felt Washers, Hitch Pins, Mulching Blades,

Blower Fans, Blower and Vacuum Tubes, Vacuum Bag

and Straps, Guide Bars, Saw Chains

Techtronic Industries North America, Inc., reserves the

right to change or improve the design of any RYOBI® brand

outdoor product without assuming any obligation to modify

any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION

TO THE STATED WARRANTY PERIOD. ACCORDINGLY,

ANY SUCH IMPLIED WARRANTIES INCLUDING

MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ARE DISCLAIMED

IN THEIR ENTIRETY AFTER THE EXPIRATION OF

THE APPROPRIATE THREE-YEAR OR NINETY-DAY

WARRANTY PERIOD. TECHTRONIC INDUSTRIES

NORTH AMERICA, INC.’S, OBLIGATION UNDER THIS

WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED TO

THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS

AND TECHTRONIC INDUSTRIES NORTH AMERICA,

INC., DOES NOT ASSUME OR AUTHORIZE ANYONE

TO ASSUME FOR THEM ANY OTHER OBLIGATION.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. TECHTRONIC

INDUSTRIES NORTH AMERICA, INC., ASSUMES NO

RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL,

OR OTHER DAMAGES INCLUDING, BUT NOT LIMITED

TO, EXPENSE OF RETURNING THE PRODUCT TO AN

AUTHORIZED RYOBI SERVICE CENTER AND EXPENSE

OF DELIVERING IT BACK TO THE OWNER, MECHANIC’S

TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES,

RENTAL OF A LIKE PRODUCT DURING THE TIME

WARRANTY SERVICE IS BEING PERFORMED, TRAVEL,

LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS

OF REVENUE, LOSS OF USE OF THE PRODUCT, LOSS

OF TIME, OR INCONVENIENCE. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

This warranty applies to all RYOBI® brand outdoor products

manufactured by or for Techtronic Industries North America,

Inc., and sold in the United States and Canada.

To locate your nearest Authorized Ryobi Service Center,

dial 1-800-860-4050.

Page 21 — English

Page 22

OPERATOR’S MANUAL / ELECTRIC POLE SAW

MANUEL D’UTILISATION / SCIE ÉLECTRIQUE DE MANCHE

MANUAL DEL OPERADOR / ELÉCTRICA SIERRA DE PÉRTIGA

RY43160

WARNING:

This product and substances that

may become airborne from its use

may contain chemicals, including

lead, known to the State of California to cause cancer, birth defects,

or other reproductive harm. Wash

hands after handling.

CALIFORNIA PROPOSITION 65

AVERTISSEMENT :

Ce produit ainsi que les substances

rejetées dans l’air à la suite de son utilisation peuvent contenir des produits

chimiques, notamment du plomb qui,

selon l’État de la Californie, peuvent

causer le cancer, des anomalies congénitales et d’autres dommages au

système reproducteur. Bien se laver

les mains après toute manipulation.

PROPOSITION 65 DE L’ÉTAT DE

CALIFORNIE

ADVERTENCIA:

Este producto y sustancias que

puedan llegar a ser aerotransportadas por su uso pueden contener

sustancias químicas (por ejemplo,

plomo) consideradas por el estado

de California como causantes de

cáncer, defectos de nacimiento u otras

alteraciones reproductivas. Lávese las

manos después de utilizar el aparato.

CALIFORNIA - PROPUESTA DE LEY

NÚM. 65

RYOBI is a registered trademark of Ryobi

Limited and is used pursuant to a license

granted by Ryobi Limited.

RYOBI est une marque déposée de RYOBI

Limited et est utilisée en vertu d’une licence

accordée par Ryobi Limited.

RYOBI es una marca registrada de Ryobi

Limited y se utiliza conforme a una licencia

otorgada por Ryobi Limited.

• PARTS AND SERVICE

Prior to requesting service or purchasing replacement parts, please obtain your model

and serial number from the product data plate.

• MODEL NO. ______________________SERIAL NO. __________________________

• HOW TO OBTAIN REPLACEMENT PARTS:

Replacement parts can be purchased online at www.ryobitools.com or by calling

1-800-860-4050. Replacement parts can also be obtained at one of our Authorized

Service Centers.

• HOW TO LOCATE AN AUTHORIZED SERVICE CENTER:

Authorized Service Centers can be located online at www.ryobitools.com or by calling 1-800-860-4050.

• HOW TO OBTAIN CUSTOMER OR TECHNICAL SUPPORT:

To obtain Customer or Technical Support please contact us at 1-800-860-4050.

• PIÈCES ET SERVICE

Avant de faire la demande de service ou l’achat de pièces de remplacement, veuillez

obtenir le numéro de série du modèle à partir de la plaque de données du produit.

• NUMÉRO DE MODÈLE ____________NUMÉRO DE SÉRIE ___________________

• COMMENT OBTENIR LES PIÈCES DE REMPLACEMENT :

Les pièces de remplacement peuvent être achetées en ligne sur le site

www.ryobitools.com ou par téléphone au 1-800-860-4050. Les pièces de remplacement

peuvent être obtenues à un de nos centres de service autorisés.

• COMMENT TROUVER UN CENTRE DE SERVICE AUTORISÉ :

Les centres de service autorisés peuvent être localisés en ligne au www.ryobitools.

com ou en téléphonant au 1-800-860-4050.

• COMMENT OBTENIR DE L’AIDE EN CONTACTANT LE SERVICE À LA CLIENTÈLE :

Pour contacter le service à la clientèle pour une question technique ou pour tout autre

renseignement, veuillez nous téléphoner au 1-800-860-4050.

• PIEZAS DE REPUESTO Y SERVICIO

Antes de solicitar servicio técnico o comprar piezas de repuesto, obtenga su modelo

y número de serie de la placa de datos del producto.

• NÚMERO DE MODELO ____________NÚMERO DE SERIE ___________________

• CÓMO OBTENER PIEZAS DE REPUESTO:

Las piezas de repuesto se pueden comprar en nuestro sitio en la red mundial, en la

dirección www.ryobitools.com o llamando al 1-800-860-4050. Las piezas de repuesto

también se pueden obtener en uno de nuestros Centros de Servicio Autorizados.

• CÓMO LOCALIZAR UN CENTRO DE SERVICIO AUTORIZADO:

Puede encontrar los Centros de Servicio Autorizados visitando nuestro sitio en la red

mundial, en la dirección www.ryobitools.com or by calling 1-800-860-4050.

• CÓMO OBTENER SERVICIO O ASISTENCIA TÉCNICA AL CONSUMIDOR:

Para obtener Servicio o Asistencia Técnica al Consumidor, sírvase comunicarse con

nosotros llamando al 1-800-860-4050.

RY43160

RY43160

RY43160

TECHTRONIC INDUSTRIES NORTH AMERICA, INC.

1428 Pearman Dairy Road, Anderson, SC 29625 USA

1-800-860-4050 • www.ryobitools.com

988000-750

10-1-11 (REV:01)

Loading...

Loading...