Page 1

RC40A-G

40L 1.8HP OIL FREE DIRECT DRIVE

UPRIGHT AIR COMPRESSOR

OPERATOR'S MANUAL

ORIGINAL INSTRUCTIONS

1

Important! It is essential you read the instructions in this manual before starting and

Subject to technical modications.

operating this machine.

Page 2

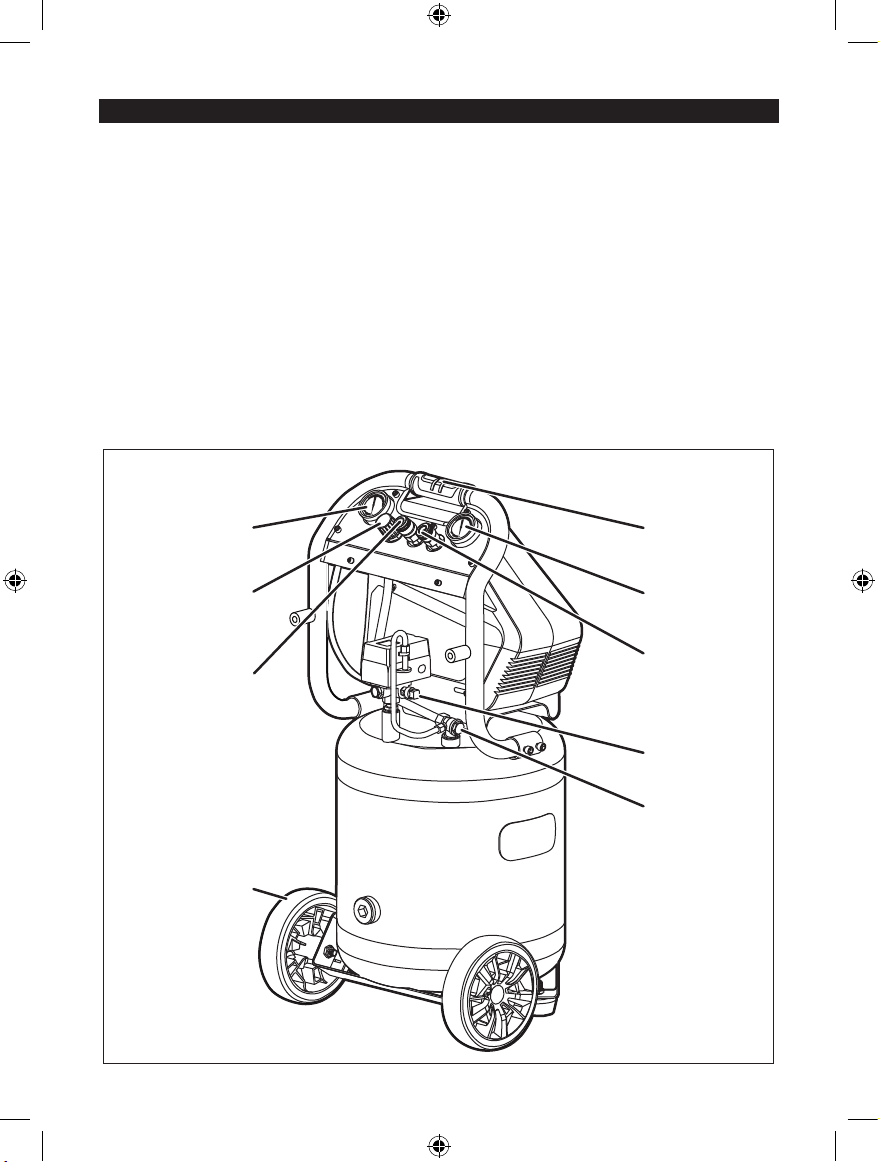

1. Handle

Fig. 2

Fig. 3

12

14

15

13

14

Fig. 3 Fig. 4

Fig. 6

Fig. 5

14

14

13

1716

1

8

9

11

8

12

9

10

2. Regulated pressure gauge

3. Quick connect coupler

4. Pressure relief valve

5. Check valve

6. Tank pressure gauge

7. Pressure regulator knob

8. Wheel

9. Air lter assembly

10. Reset button

11. Air tank

12. Rubber foot

13. Hex nut

14. Flat washer

15. Bolt

16. Axle bolt

17. Wheel axle cover

18. To close

Fig. 1

6 1

DESCRIPTION

19. Quick connect air tting

20. Quick coupler

21. On

22. Off

23. To open

24. Drain valve lever

25. Air lter housing

26. Air lter

27. Air lter cover

28. Wing nut

7

3

8

2

1

3

4

5

Page 3

Fig. 2

8

12

Fig. 3

Fig. 3 Fig. 4

13

14

9

10

11

Fig. 5

9

12

15

14

13

Fig. 6

14

14

8

1716

1

Page 4

Fig. 7

18

19

3

Fig. 8

20

19

Fig. 9 Fig. 10

23

22

21

Fig. 11

10

Fig. 13

Fig. 12

Fig. 14

6 2

24

25

4

28 2714

26

Page 5

GENERAL SAFETY WARNINGS

WARNING

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

re and/or serious personal injury.

Read all instructions.

Know your power tool. Read the operator's manual

carefully. Learn the applications and limitations as well as

the specic potential hazards related to this tool.

WORK AREA SAFETY

■ Keep work area clean. Cluttered areas and benches

invite accidents. Do not leave tools or pieces of wood

on the tool while it is in operation.

■ Do not use in dangerous environments. Do not use

power tools in damp or wet locations or expose to rain.

Keep the work area well lit.

■ Keep children and visitors away. All visitors should

wear safety glasses and be kept a safe distance from

work area. Do not let visitors contact tool or extension

cord while operating.

■ Never use in an explosive atmosphere. Normal

sparking of the motor could ignite fumes.

ELECTRICAL SAFETY

■ Guard against electrical shock by preventing body

contact with grounded surfaces, e.g., pipes, radiators,

ranges, refrigerator enclosures.

■ Do not abuse cord. Never carry tool by the cord or

yank it to disconnect from receptacle. Keep cord from

heat, oil, and sharp edges.

■ Should any electrical component of the tool fail

to perform properly, shut off the power switch,

remove the plug from the power source and

replace before resuming operation.

■ Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

PERSONAL SAFETY

■ Stay alert and exercise control. Watch what you are

doing and use common sense. Do not operate tool

when you are tired. Do not rush.

■ Dress properly. Do not wear loose clothing, neckties,

or jewellery that can get caught and draw you into

moving parts. Rubber gloves and nonskid footwear

are recommended when working outdoors. Also wear

protective hair covering to contain long hair.

■ Always wear safety glasses with side shields.

Everyday eyeglasses have only impact-resistant

lenses; they are not safety glasses.

■ Protect your lungs. Wear a face or dust mask if the

operation is dusty.

■ Protect your hearing. Wear hearing protection during

extended periods of operation.

■ Do not overreach. Keep proper footing and balance

at all times.

■ Remove adjusting keys and wrenches. Form habit of

checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

AIR COMPRESSOR USE AND CARE

■ Do not exceed the pressure rating of any component

in the system.

■ Protect material lines and air lines from damage or

puncture. Keep hose and power cord away from sharp

objects, chemical spills, oil, solvents, and wet floors.

■ Check hoses for weak or worn condition before each

use, making certain all connections are secure. Do not

use if defect is found. Purchase a new hose or notify

an authorized service center for examination or repair.

■ Release all pressures within the system slowly. Dust

and debris may be harmful.

■ Store idle air compressors out of the reach of children

and other untrained persons. Air compressors are

dangerous in the hands of untrained users.

■ Maintain air compressors with care. Follow

maintenance instructions. Properly maintained

products are easier to control.

■ Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the product’s operation. If damaged, have the

air compressor serviced before using. Many accidents

are caused by poorly maintained products.

■ Keep the exterior of the air compressor dry, clean,

and free from oil and grease. Always use a clean

cloth when cleaning. Never use brake fluids, gasoline,

petroleum-based products, or any strong solvents to

clean the unit. Following this rule will reduce the risk of

deterioration of the enclosure plastic.

SERVICE

■ When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

Save these instructions. Refer to them frequently and

use them to instruct other users. If you loan someone

this tool, loan them these instructions also.

AIR COMPRESSOR SAFETY WARNINGS

■ Know your air compressor. Read operator’s manual

carefully. Learn its applications and limitations, as

well as the specific potential hazards related to this

product. Following this rule will reduce the risk of

electric shock, fire, or serious injury.

■ Use the product on a flat, stable ground surface.

1

Page 6

■ Drain tank of moisture after each day's use. If unit will

not be used for a while, it is best to leave drain valve

open until such time as it is to be used. This will allow

moisture to completely drain out and help prevent

corrosion on the inside of tank.

■ Risk of fire or explosion. Do not spray flammable liquid

in a confined area. Spray area must be well ventilated.

Do not smoke while spraying or spray where spark or

flame is present. Keep compressors as far from the

spraying area as possible, at least 10 m (33 feet) from

the spraying area and all explosive vapors.

■ Risk of bursting. Do not adjust regulator to result

in output pressure greater than marked maximum

pressure of attachment. Do not use at pressure

greater than 8 bar.

■ If connected to a circuit protected by fuses, use time

delay fuses with this product.

■ To reduce the risk of electric shock, do not expose to

rain. Store indoors.

■ Inspect tank yearly for rust, pin holes, or other

imperfections that could cause it to become unsafe.

■ Never weld or drill holes in the air tank.

■ Make sure the hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of balance

or footing and may become damaged.

■ Use the air compressor only for its intended use. Do

not alter or modify the unit from the original design or

function.

■ Always be aware that misuse and improper handling

of this product can cause injury to yourself and others.

■ Never leave a tool unattended with the air hose

attached.

■ Never point any air tool toward yourself or others.

■ Do not operate this air compressor if it does not

contain a legible warning label.

■ Do not continue to use a tool or hose that leaks air or

does not function properly.

■ Always disconnect the air supply and power supply

before making adjustments, servicing a product, or

when a product is not in use.

■ Do not attempt to pull or carry the air compressor by

the hose.

■ Your tool may require more air consumption than this

air compressor is capable of providing.

■ Always follow all safety rules recommended by the

manufacturer of your air tool, in addition to all safety

rules for the air compressor. Following this rule will

reduce the risk of serious personal injury.

■ Never direct a jet of compressed air toward people or

animals. Take care not to blow dust and dirt towards

yourself or others. Following this rule will reduce the

risk of serious injury.

■ Do not use this air compressor to spray chemicals.

Your lungs can be damaged by inhaling toxic fumes.

A respirator may be necessary in dusty environments

or when spraying paint. Do not carry while painting.

■ Inspect product cords and hoses periodically and,

if damaged, have them repaired at your nearest

authorised service center. Constantly stay aware of

cord location. Following this rule will reduce the risk of

electric shock or fire.

■ Never use an electrical adaptor with this grounded

plug.

■ Check for damaged parts. Before further use of the

air compressor or air tool, a guard or other part that

is damaged should be carefully checked to determine

that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A

guard or other part that is damaged should be properly

repaired or replaced by an authorized service center.

Following this rule will reduce the risk of serious injury.

■ Never store a tool with an air line connected. Storing

the tool while connected to an air supply can result

in unexpected operation, firing or movement and

possible serious personal injury.

■ Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the

risk of serious personal injury.

■ If the power supply cord is damaged, it must be

replaced only by the manufacturer or by an authorised

service centre to avoid risk.

■ Save these instructions. Refer to them frequently and

use them to instruct others who may use this product.

If you loan someone this product, loan them these

instructions also.

■ The machine shall be connected to a circuit

protection device (fuse or circuit breaker).

■ Operate the machine from the front of the control

panel.

■ When the machine is in operation, many parts

of machine may cause a high temperature. Use

necessary personal protection equipment such

as gloves to avoid injuries resulting from a high

temperature.

■ This machine is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge. Children should be supervised to

ensure that they do not play with the machine.

2

Page 7

PRODUCT SPECIFICATIONS

Rated motor power 1350 W

Rated current 6 A

Air outlets 2 pcs, 6.35mm (1/4”)

Quick connector tting size 6.35 mm (1/4")

Weight 32.3 kg

Input 220 - 240 V AC, 50 Hz

Power cord length 2.0 m

Air tank capacity 40 L

Free air delivery 105 L/min (3.7 cfm)

Maximum air delivery 175 L/min (6.2 cfm)

Maximum air pressure 8 bar (115 psi)

Working pressure range 6 - 8 bar (87 - 115 psi)

Pressure gauge 2 pcs, 50.8 mm (2 in.)

Maximum rotational shaft

speed

Short-circuit rating 3 kA

Operating temperature 0 - 45°C

Measured sound pressure

level (the reference

number of the noise test

code: EN ISO 2151:2008)

Measured sound power

level (the reference

number of the noise test

code: EN ISO 2151:2008)

NITTO-style quick

connector (coupler)

at 0 bar tank pressure

diameter

2,900 rpm

LpA=72.3 dB(A),

KpA=2 dB

LwA=92.3 dB(A),

KwA=2 dB

INTENDED USE

This compressor is designed to supply pressurised air

only. It must not be used to compress any other gas. It is

designed to operate air powered tools. The compressor

should be operated indoors only.

ASSEMBLY

UNPACKING

This product requires assembly. Carefully remove the

product and any accessories from the box.

WARNING

Do not use this product if any parts on the packing

list are already assembled to your product when you

unpack it. Parts on this list are not assembled to the

product by the manufacturer and require customer

installation. Use of a product that may have been

improperly assembled could result in serious personal

injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

WARNING

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modication is misuse

and could result in a hazardous condition leading to

possible serious personal injury.

WARNING

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

Packing list

– Air compressor

– Air filter

– Wheel x 2

– Rubber foot x 2

– Bolt x 2

– Nut x 4

– Flat washer x 8

– Wheel axle cover x 2

– Axle bolt x 2

– Operator's manual

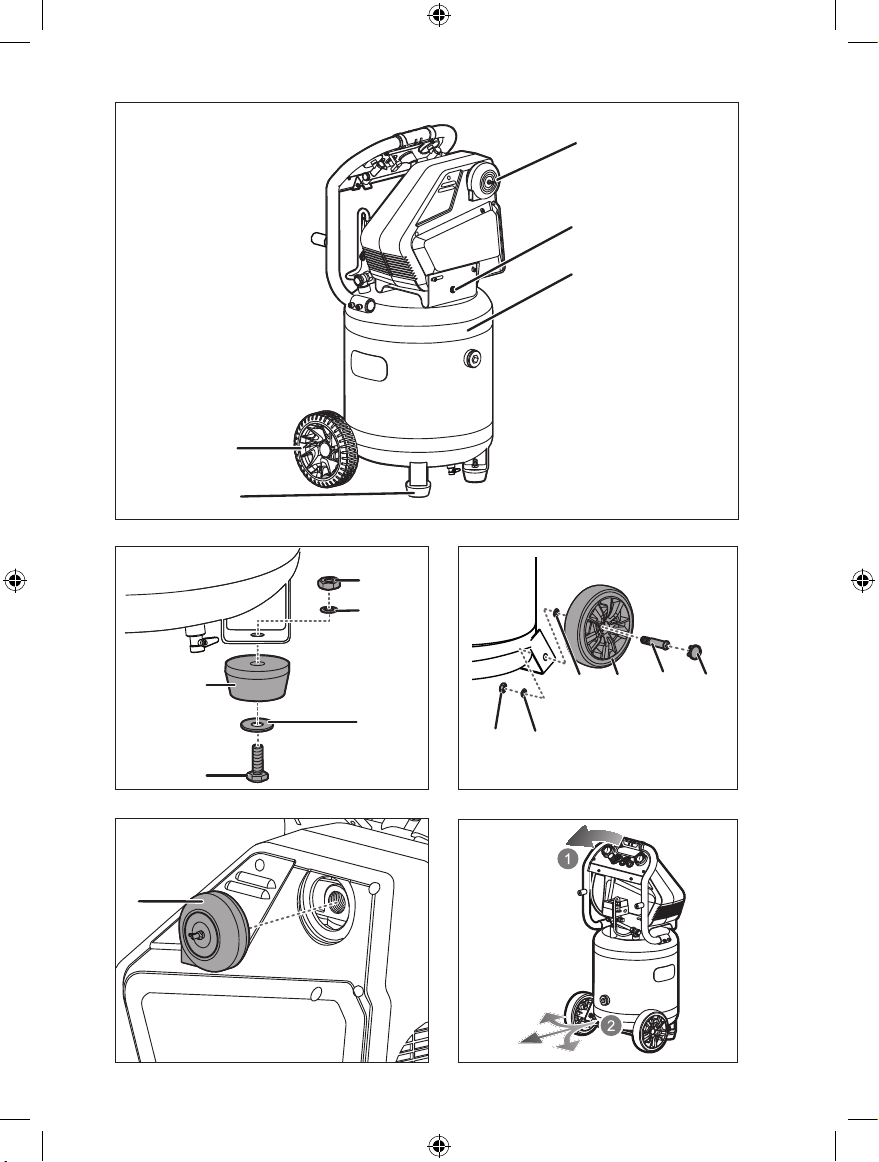

INSTALLING FEET

See gure 3.

1. Place a rubber foot under the left supporting frame at

the rear. Align the screw holes.

2. Insert a screw and washer in the holes in the rubber

foot and the supporting frame from the bottom.

3

Page 8

3. Insert a washer at the other end.

4. Secure the rubber foot with a hex nut.

5. Repeat the above steps to install the other foot on the

right.

6. Ensure the compressor is stable by lightly applying

lateral force on it.

INSTALLING WHEELS

See gure 4.

1. Insert an axle bolt and washer in the centre hole of

the wheel.

2. Insert the threaded part of the axle bolt in the hole in

the front supporting frame on the left side. Insert a

washer on both sides of the frame.

3. Secure the axle bolt with a hex nut.

4. Attach the wheel axle cover to the centre of the wheel.

5. Repeat the above steps to install the other wheel on

the right.

6. Ensure the compressor is stable by lightly applying

lateral force on it.

INSTALLING AIR FILTER

See gure 5.

Attach the air lter to the motor cover. Screw in a clockwise

direction to fasten securely.

OPERATION

DANGER

Do not disassemble check valve, tank drain valves or

pressure relief valve with air in tank — bleed tank.

WARNING

Always wear eye protection with side shields. Failure

to do so could result in objects being thrown into your

eyes resulting in possible serious injury.

WARNING

Do not attach any tools to the open end of the hose until

start-up has been completed.

CAUTION

Do not use in an environment that is dusty or otherwise

contaminated. Using the air compressor in this type of

environment may cause damage to the unit.

This will help you to avoid damaging the wheel or the air

compressor by rolling it over items in its path.

Ensure the air compressor is unplugged, make sure the

power cord is secured in the cord wrap.

To move the air compressor:

1. Grasp the handle rmly.

2. Tilt the air compressor toward you. Make sure the

compressor is balanced on the wheels.

3. Pull the compressor along to the desired location.

4. Recover the air compressor to its upright position until

it sits securely on a at surface.

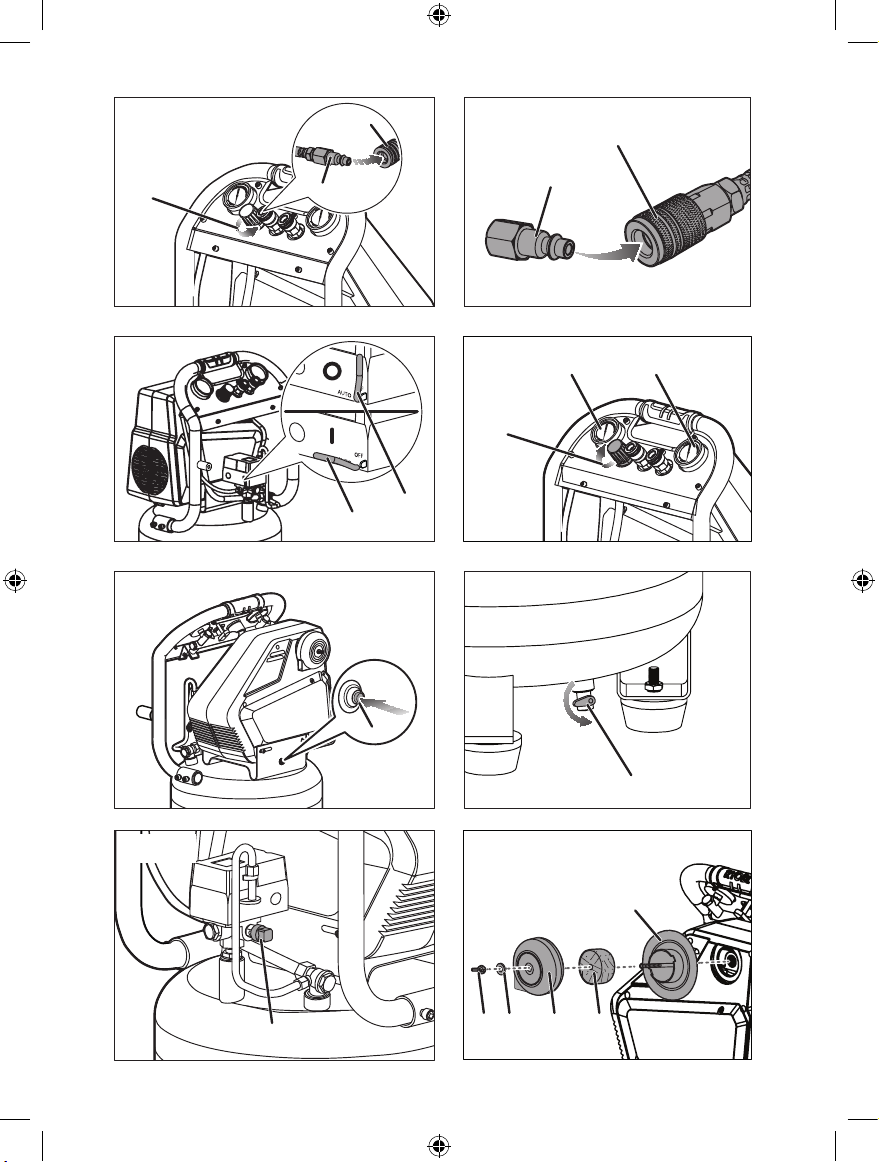

ATTACHING/DISCONNECTING AIR HOSE

See gure 7.

NOTE: For operation using pressures above 7 bar,

(102 psi) delivery hoses should be tted with a safety cord,

e.g., wire rope.

1. Make sure the air compressor is off and unplugged.

2. Rotate pressure regulator knob fully counterclockwise.

3. Conrm that the outlet pressure is at zero (0) bar.

4. Attach hose with quick connect air tting to 6.35 mm

(1/4 in.) quick connect coupler (regulated pressure) on

air compressor. Make sure to push the hose adapter

end fully into the coupler until the sleeve springs

forward to lock it in place.

To disconnect an air hose or an air tool:

1. Rotate pressure regulator knob fully counterclockwise.

2. Conrm that the outlet pressure is at zero (0) bar.

3. When disconnecting a hose from 6.35 mm (1/4 in.)

quick coupler, always rmly hold release end of hose.

4. Pull back on the release sleeve on the 6.35 mm

(1/4 in.) quick coupler.

5. With a rm grip, pull out the quick connect air tting

that is attached to the quick coupler.

TURNING THE AIR COMPRESSOR ON/OFF

See gure 9.

1. With the air compressor plugged in, move the power

switch to the AUTO position to power the compressor

on.

2. To turn the air compressor off, move the power switch

to the OFF position.

NOTE: When the compressor is in the AUTO position,

the air compressor will automatically turn on when the

designated tank air pressure drops below the preset

pressure limit. It will also shut off again when the

desired pressure is reached.

TRANSPORTING THE AIR COMPRESSOR

See gure 6.

The air compressor should be moved as instructed.

4

Page 9

WARNING

Never exceed the air tool’s pressure rating as

recommended by the manufacturer. When using

this air compressor as an ination device, always

follow the maximum ination guidelines stated by the

manufacturer of the item being inated.

WARNING

Always ensure the switch is in the OFF position and the

regulator pressure gauge reads zero before changing

air tools or disconnecting the hose from the air outlet.

Failure to do so could result in possible serious

personal injury.

USING THE AIR COMPRESSOR

See gure 8 - 10.

1. Ensure power switch is in the OFF position and air

compressor is unplugged.

2. If not already installed, attach hose to compressor as

previously instructed.

3. Attach 6.35 mm (1/4 in.) quick connect air tting to

accessory or tool you intend to use.

4. Insert the other end of the quick connect air tting to

the quick coupler (regulated pressure) on the open

end of hose.

5. Connect the power cord to the power supply.

6. Turn the power switch to the AUTO position.

7. Rotate pressure regulator knob to desired line

pressure. Turning the knob clockwise increases

air pressure at the outlet; turning counterclockwise

reduces air pressure at the outlet.

8. Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

WARNING

Air powered tools may require more air consumption

than this air compressor is capable of providing. Check

the tool manual to avoid damage to the tool or risk of

personal injury.

9. Control the amount of air ow with the pressure

regulator knob. Turning the knob fully counterclockwise

will completely stop the ow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher

pressure than needed will drain air from the tank more

rapidly and cause the unit to cycle on more frequently.

10. When nished, always drain the tank and unplug the

unit. Never leave the unit plugged in and/or running

unattended.

11. It is recommended to use a residual current device

with a rated residual current of 30 mA or less.

DRAINING THE TANK

See gure 12-13.

To prevent tank corrosion and keep moisture out of the

air used, the air tank of the compressor should be drained

daily.

To drain:

1. Turn the air compressor off.

2. Rotate drain valve lever counterclockwise to open and

relieve the air pressure in the tank.

3. Drain the moisture in the tank.

NOTE: Condensate is a polluting material and should

be disposed of in compliance with local regulations.

4. If drain valve is clogged, release all air pressure.

Remove and clean the valve, then reinstall.

DANGER

Unplug the air compressor and release all air from

the tank before servicing. Failure to depressurize tank

before attempting to remove valve may cause serious

personal injury.

5. Rotate drain valve lever clockwise until tightly closed.

PRESSURE RELIEF VALVE

See gure 13.

WARNING

Do not attempt to tamper with the pressure relief valve.

Anything loosened from this device could y up and hit

you. Failure to heed this warning could result in death

or serious personal injury.

The pressure relief valve will automatically release air if

the air tank pressure exceeds the preset maximum, and

will stop releasing air once the tank pressure drops to

within the preset minimum.

Keep the pressure relief valve clean and do not cover it

with any object.

RESET BUTTON

See gure 11.

When current into the air compressor motor exceeds the

specied limit, the air compressor will automatically shut

off.

To reset the air compressor:

1. Unplug the air compressor.

2. Turn the air compressor off.

3. Wait three minutes for the motor to cool.

4. Press the reset button.

5. Plug the air compressor into an approved outlet.

6. Turn the air compressor on.

5

Page 10

STORAGE

1. Move the power switch to the OFF position to turn off

the compressor.

2. Unplug the compressor.

3. Run the air tool to relieve the air pressure in the hose,

then remove the air hose and the tool, or release the

air by the drain valve.

4. Drain water from the tank as instructed in Draining

the Tank section. Leave the valve open until the next

usage.

5. Store the air compressor in its normal operating

position in a dry and protected area.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING

Do not at any time let brake uids, gasoline, petroleum-

based products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

WARNING

Water will condense in the air compressor tank when

the compressor is in operation. Water left in the tank

can cause the tank to weaken and corrode, increasing

the risk of tank rupture.

WARNING

Always disconnect the air hose from tools whenever

not in use or while servicing. During maintenance, a

tool connected to air hose may operate accidentally,

causing serious personal injury!

WARNING

Failure to unplug the air compressor before storage

may result in the compressor running continuously,

causing overheating, damage to the compressor, and

possibly a re.

MAINTENANCE

WARNING

When servicing use only original replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING

Always wear eye protection with side shields. Failure

to do so could result in objects being thrown into your

eyes resulting in possible serious injury.

Bearing lubrication

All of the bearings in this product are lubricated with a

sufcient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore, no

further lubrication is required.

REPLACING AIR FILTER

See gure 14.

1. Loosen the wing nut and washer on the air lter cover.

2. Remove the cover.

3. Remove the air lter.

4. Install new air lter.

5. Replace the air lter cover and secure it with the wing

nut and washer.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing

of as waste. The machine, accessories

and packaging should be sorted for

environmental-friendly recycling.

SYMBOLS

Safety Alert

Please read the instructions carefully

before starting the machine.

Wear ear protection

WARNING

Always release all pressure, disconnect from power

supply, and allow unit to cool before cleaning or making

repairs on the air compressor.

Wear eye protection

6

Page 11

Waste electrical products should not

be disposed of with household waste.

Please recycle where facilities exist.

Check with your local authority or

retailer for recycling advice.

Regulatory Compliance Mark (RCM).

Product meets applicable regulatory

requirements.

Caution, risk of electric shock

Wet condition alert. Do not expose to

rain. Store indoors.

Risk of bursting. Do not adjust regulator

to result in output pressure greater

than marked maximum pressure of

attachment. Do not use at pressure

greater than 8 bar.

Risk of fire or explosion. Spray area

must be well ventilated. Do not smoke

while spraying or spray where spark or

ame is present. Keep compressors as

far from the spraying area as possible.

Keep compressor, at least 10 m from

the spraying area and all explosive

vapours.

Hot surface: To reduce the risk of injury

or damage, avoid contact with any

surface.

Risk of breathing. Air obtained directly

from the air compressor should never

be used to supply air for human

consumption.

This compressor may start without

warning.

7

Page 12

TROUBLESHOOTING

Current protector

Pressure switch

Main winding

Aux. winding

Capacitor

Motor

bracket

GND

L

~

N

PROBLEM CAUSE POSSIBLE SOLUTION

Compressor will not run Loss of power or overheating Check for proper use of extension cord

No electrical power Check to be sure unit is plugged in

Check fuse/breaker

Blown shop/house fuse Replace shop/house blown fuse

Shop/house breaker open Reset shop/house breaker, determining

why problem happened

Current limiting protector open Reset motor overload to restart after motor

has cooled.

Bad pressure switch Replace pressure switch

Tank is full of air Compressor will turn on when tank

pressure drops to cut-in pressure

Motor hums but cannot run or

runs slowly

Low voltage Check with voltmeter

Wrong gauge wire or length of

extension cord

Check for proper gauge wire and cord

length

Shorted or open motor winding Take compressor to service centre

Defective check valve or unloader Take compressor to service centre

Current limiting protector cuts

out repeatedly

Low voltage Check with voltmeter

Lack of proper ventilation/room

Move compressor to well-ventilated area

temperature too high

Air tank pressure drops when

compressor shuts off

Wrong gauge wire or length of

extension cord

Loose connections (ttings, tubing,

etc.)

Loose drain valve Tighten drain valve

Check valve leaking Take compressor to service centre

Check for proper gauge wire and cord

length

Check all connections with soap and water

solution and tighten

DANGER

Excessive moisture in

discharge air

Excessive water in air tank Drain tank

Do not disassemble check valve, tank drain

valve or pressure relief valve with air in

tank — bleed tank.

High humidity Move to area of less humidity; use air line

lter

8

Page 13

PROBLEM CAUSE POSSIBLE SOLUTION

Compressor runs continuously Defective pressure switch Take compressor to service centre

Excessive air usage Take compressor to service centre

Decrease air usage; compressor not large

enough for tool’s requirement

Piston rings are worn Replace piston rings; air inlet lter

is blocked, call customer service for

assistance

Air output lower than normal Broken inlet valves Take compressor to service centre

Connections leaking Tighten connections

CIRCUIT DIAGRAM

Current protector

L

~

N

Main winding

Aux. winding

Capacitor

GND

Motor

bracket

9

Pressure switch

Page 14

PARTS LIST

20

19

18

17

16

15

14

13

12

11

10

61

22

5

6

7

8

3

9

60

59

57

58

57

2

3

23

2

3

4

66

56

55

21

31

25

24

1

64

62

50

32

29

30

33

34

28

27

26

35

65

38

39

63

69

68

42

41

43

67

36

37

40

52

51

54

53

49

48

44

45

46

45

47

10

Page 15

No. Description No. Description No. Description No. Description

01 Crankcase - ZL108 21 Air lter 41 Thermal cutout 61 Bolt M6 x 40

02 Bolt M6 x 35 22 Nut 5 42 Exhaust pipe 62 Φ28 Handle

03 Spring washer 6 23 30UF Capacitor 43 Tank 63 Bolt M8 x 10

04 Crank shaft - QT500-7 24 Bearing 6204-2RZ 44 Nut M8 64 Handle sleeve

05 Bolt M6 x 18 25 Rotor 45 Washer 8 65 Rubber tube

06 Bearing 6203-2RZ 26 Bearing 6202-2RZ 46 Cushion foot 66 Bumper

07 Fan-PA 27 Stator 47 Bolt M8 x 25 67 Self tapping screw

08 Washer 6 28 Rear cap - HT200 48 Drain cock 68 Heat shrink tube

09 Bolt M6 x 15 LH 29 Bolt M5 x 140 49 Nut M10 69 Heat shrink tube

10 Piston pin - YL104 30 Spring washer 5 50 Washer 10

11 Leather bowl 31 Washer 5 51 Wheel

12 Connecting rod cover

- YL104

13 Bolt M6 x 16 33 Bolt M5 x 20 53 Bolt M5 x 18

14 Cylinder 63 34 Motor right housing

15 Gasket - XB150 35 Pressure switch 55 Panel Support

16 Valve 36 Unloading tube 56 Adjusting holder

17 Gasket - NYX350 37 Safety valve 57 Dia. 50mm pressure gauge

18 Valve plate - PH15-7Mo 38 Tightening nut on

19 Gasket - XB350 39 Elbow 59 Tightening nut

20 Cylinder head -ZL108 40 Check Valve 60 Power cable with plug

32 Motor left housing

- PP

- PP

pressure switch

52 Bolt M10 x 75

54 Panel

58 Quick valve

M4 x 10

Φ6 x 270 mm

Φ30 x 80 mm

11

Page 16

RYOBI is a trade mark of Ryobi Limited, and is used under license.

© 2019 Techtronic Cordless GP.

NITTO is a registered trade mark owned by Nitto Kohki Co., Ltd.

Techtronic Industries Australia Pty Ltd

31 Gilby Road, Mount Waverley

VIC, 3149, Australia

Techtronic Industries N.Z. Limited

Unit C, 70 Business Parade South

Highbrook, Auckland 2013, New Zealand

20200527v3

Loading...

Loading...