Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

PAINT STATION TOOL

STATION DE PEINTURE

ESTACIÓN DE PINTURA

RAP200

Your product has been engineered and manufactured to our high standard for dependability, ease of operation, and operator

safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using this

product. If you do not understand the warnings and instructions in the operator’s manual, do not use this product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette produit a été conçue et fabriquée conformément aux strictes

normes de fiabilité, simplicité d’emploi et sécurité d’utilisation.

Correctement entretenu, cet outil vous donnera des années de

fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su producto ha sido diseñado y fabricado de conformidad con

nuestras estrictas normas para brindar fiabilidad, facilidad de

uso y seguridad para el operador. Con el debido cuidado, le

brindará muchos años de sólido funcionamiento y sin problemas.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

Introduction ..................................................................................................................................................................... 2

Warranty .......................................................................................................................................................................... 2

Important Safety Instructions .......................................................................................................................................... 3

Specific Safety Rules ....................................................................................................................................................... 4

Symbols ........................................................................................................................................................................... 5

Electrical .......................................................................................................................................................................... 6

Features ........................................................................................................................................................................... 7

Assembly ......................................................................................................................................................................7-8

Operation ....................................................................................................................................................................9-12

Maintenance .................................................................................................................................................................. 13

Troubleshooting ........................................................................................................................................................14-15

Figure numbers (illustrations) ...................................................................................................................................16-19

Parts Ordering / Service ................................................................................................................................... Back page

INTRODUCTION

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

WARRANTY

RYOBI® POWER TOOL - LIMITED TWO YEAR WARRANTY AND 30 DAY EXCHANGE POLICY

One World Technologies, Inc., warrants its RYOBI® power tools with the following conditions:

30-DAY EXCHANGE POLICY: During the first 30 days after date of purchase, you may either request service under this

warranty or you may exchange any RYOBI® power tool which does not work properly due to defective workmanship or

materials by returning the power tool to the dealer from which it was purchased. To receive a replacement power tool or requested warranty service, you must present proof of purchase and return all original equipment packaged with the original

product. The replacement power tool will be covered by the limited warranty for the balance of the two year period from

the date of the original purchase.

WHAT THIS WARRANTY COVERS: This warranty covers all defects in workmanship or materials in your RYOBI® power

tool for a period of two years from the date of purchase. With the exception of batteries, power tool accessories are warranted for ninety (90) days. Batteries are warranted for two years.

HOW TO GET SERVICE: Just return the power tool, properly packaged and postage prepaid, to an Authorized Service Center. You can obtain the location of the Service Center nearest you by contacting a service representative at

One World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207, by calling 1-800-525-2579 or by logging on to

www.ryobitools.com. When you request warranty service, you must also present proof of purchase documentation, which

includes the date of purchase (for example, a bill of sale). We will repair any faulty workmanship, and either repair or replace

any defective part, at our option. We will do so without any charge to you. We will complete the work in a reasonable time,

but, in any case, within ninety (90) days or less.

WHAT’S NOT COVERED: This warranty applies only to the original purchaser at retail and may not be transferred. This

warranty only covers defects arising under normal usage and does not cover any malfunction, failure or defects resulting

from misuse, abuse, neglect, alteration, modification or repairs by other than Authorized Service Centers. One World Technologies, Inc. makes no warranties, representations or promises as to the quality or performance of its power tools other

than those specifically stated in this warranty.

ADDITIONAL LIMITATIONS: Any implied warranties granted under state law, including warranties of merchantability or

fitness for a particular purpose, are limited to two years from the date of purchase. One World Technologies, Inc. is not

responsible for direct, indirect, or incidental damages, so the above limitations and exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

2 — English

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

SAVE THESE INSTRUCTIONS. To reduce the risks of

fire or explosion, electric shock, and the injury to persons, read and understand all instructions included in

this manual. Be familiar with the controls and the proper

usage of the equipment.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the operator’s

manual carefully. Learn the machine’s applications and

limitations as well as the specific potential hazards related

to this tool.

WARNING: To reduce the risk of fire or explosion:

Do not spray flammable or combustible materials near

an open flame or sources of ignition such as cigarettes,

motors, and electrical equipment.

For units intended for use with only water-based or

mineral spirit-type materials with a minimum flash point

of 60°C (140°F), do not spray or clean with liquids

having a flash point less than 60°C (140°F).

Paint or solvent flowing through the equipment is able

to result in static electricity. Static electricity creates

a risk of fire or explosion in the presence of paint or

solvent fumes. All parts of the spray system, including

the pump, hose assembly, pistol-grip sprayer, and

objects in and around the spray area shall be properly

grounded to protect against static discharge and

sparks.

Use only conductive or grounded high-pressure airless

paint sprayer hoses specified by the manufacturer.

Verify that all containers and collection systems are

grounded to prevent static discharge.

Connect to a grounded outlet and use grounded

extension cords. Do not use a 3 to 2 adapter.

Do not use a paint or a solvent containing halogenated

hydrocarbons.

Keep spray area well ventilated. Keep a good supply

of fresh air moving through the area. Keep pump

assembly in a well ventilated area.

Do not smoke in the spray area.

Do not operate light switches, engines, or similar spark

producing products in the spray area.

Keep area clean and free of paint or solvent containers,

rags, and other flammable materials.

Know the contents of the paints and solvents being

sprayed. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the paints and

solvents. Follow the paint and solvent manufacturer’s

safety instructions.

Fire extinguisher equipment shall be present and

working.

WARNING: To reduce the risk of skin injection:

Do not aim the nozzle at, or spray any person or

animal.

Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with

any part of the body.

Always use the nozzle tip guard. Do not spray without

nozzle tip guard in place.

Only use a spray tip specified by the manufacturer.

Use caution when cleaning and changing spray tips.

In the case where the spray tip clogs while spraying,

follow the manufacturer’s instructions for turning off

the unit and relieving the pressure before removing

the spray tip to clean.

Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the

unit and relieve the pressure in accordance with the

manufacturer’s instructions.

High pressure spray is able to inject toxins into

the body and cause serious bodily injury. In the

event that injection occurs, seek medical attention

immediately.

Check hoses and parts for signs of damage. Replace

any damaged hoses or parts.

This system is capable of producing 2800 psi. Only use

replacement parts or accessories that are specified by

the manufacturer and are rated a minimum of 3000 psi.

Always engage the trigger lock when not spraying.

Verify the trigger lock is functioning properly.

Verify that all connections are secure before operating

the unit.

Know how to stop the unit and bleed pressure quickly.

Be thoroughly familiar with the controls.

For household use only.

WARNING: To reduce the risk of injury:

Always wear appropriate gloves, eye protection

marked to comply with ANSI Z87.1, and a respirator

or mask when painting.

Do not operate or spray near children. Keep children

away from equipment at all times.

Do not overreach or stand on an unstable support.

Keep effective footing and balance at all times.

Stay alert and watch what you are doing.

Do not operate the unit when fatigued or under the

influence of drugs or alcohol.

Do not kink or overbend the hose.

Do not expose the hoses to temperatures or to

pressur es in ex ce ss of those specified by the

manufacturer.

Do not use the hose as a strength member to pull or

lift the equipment.

3 — English

Page 4

SPECIFIC SAFETY RULES

Keep guards in place and in working order. Never

operate the tool with any guard or cover removed. Make

sure all guards are operating properly before each use.

To reduce the risk of injury, keep children and visitors

away. All visitors should wear safety glasses and be kept

a safe distance from work area.

Keep the area of operation clear of all persons,

particularly small children, and pets.

Use right tool. Don’t force tool or attachment to do a

job it was not designed for. Don’t use it for a purpose not

intended.

Do not operate the equipment while barefoot or when

wearing sandals or similar lightweight footwear. Wear

protective footwear that will protect your feet and improve

your footing on slippery surfaces.

Exercise caution to avoid slipping or falling.

Always wear safety glasses with side shields. Everyday

eyeglasses have only impact-resistant lenses; they are

NOT safety glasses.

Use only recommended accessories. The use of im-

proper accessories may cause risk of injury.

Follow the maintenance instructions specified in this

manual.

Check damaged parts. Before further use of the

or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its

intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard

or other part that is damaged must be properly repaired

or replaced by an authorized service center to avoid risk

of personal injury.

Never leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

Follow manufacturer’s recommendations for safe

loading, unloading, transport, and storage of

machine.

Be thoroughly familiar with controls. Know how to stop

the product and bleed pressure quickly.

Keep tool dry, clean, and free from oil and grease.

Always use a clean cloth when cleaning. Never use brake

fluids, gasoline, petroleum-based products, or any solvents

to clean tool.

Do not use tool if switch does not turn it off. Have defec-

tive switches replaced by an authorized service center.

Before cleaning, repairing, or inspecting, shut off the

motor and make certain all moving parts have stopped.

Avoid dangerous environment. Don’t use in damp or

wet locations or expose to rain. Keep work area well

lit.

tool, a guard

Never direct a paint stream toward people or pets,

or any electrical device.

Never start the machine if ice has formed in any part

of the equipment.

WARNING: High pressure spray can be dangerous

if subject to misuse. The spray must not be directed

at persons, animals, electrical devices, or the machine

itself.

Keep away from hot parts.

Check bolts and nuts for looseness before each use. A

loose bolt or nut may cause serious motor problems.

Before storing, allow the product to cool.

Store in a cool, well-ventilated area, safely away from

spark and/or flame-producing equipment.

When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

Never use the sprayer without a spray tip in-

stalled.

An injection injury can lead to possible amputation.

See a physician immediately.

Never put your hand in front of the spray tip when in

use. Gloves will not always provide protection against

an injection injury.

Wear protective clothing to keep paint off skin and

hair, along with a mask or respirator during use. Paints,

solvents, and other materials can be harmful if inhaled or

if they come into contact with the body.

Always unplug the paint station, shut the unit off and

release pressure before servicing, cleaning the tip

or guard, changing the tip, or leaving unattended.

Plastic can cause sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths

when spraying flammable materials.

Do not spray outdoors on windy days.

Do not attempt to clean or unclog the spray tip with

your finger.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. A wire

gauge size (A.W.G.) of at least 14 is recommended for an

extension cord 50 feet or less in length. A cord exceeding

100 feet is not recommended. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

Save these instructions. Refer to them frequently and

use them to instruct other users. If you loan someone this

tool, loan them these instructions also.

4 — English

Page 5

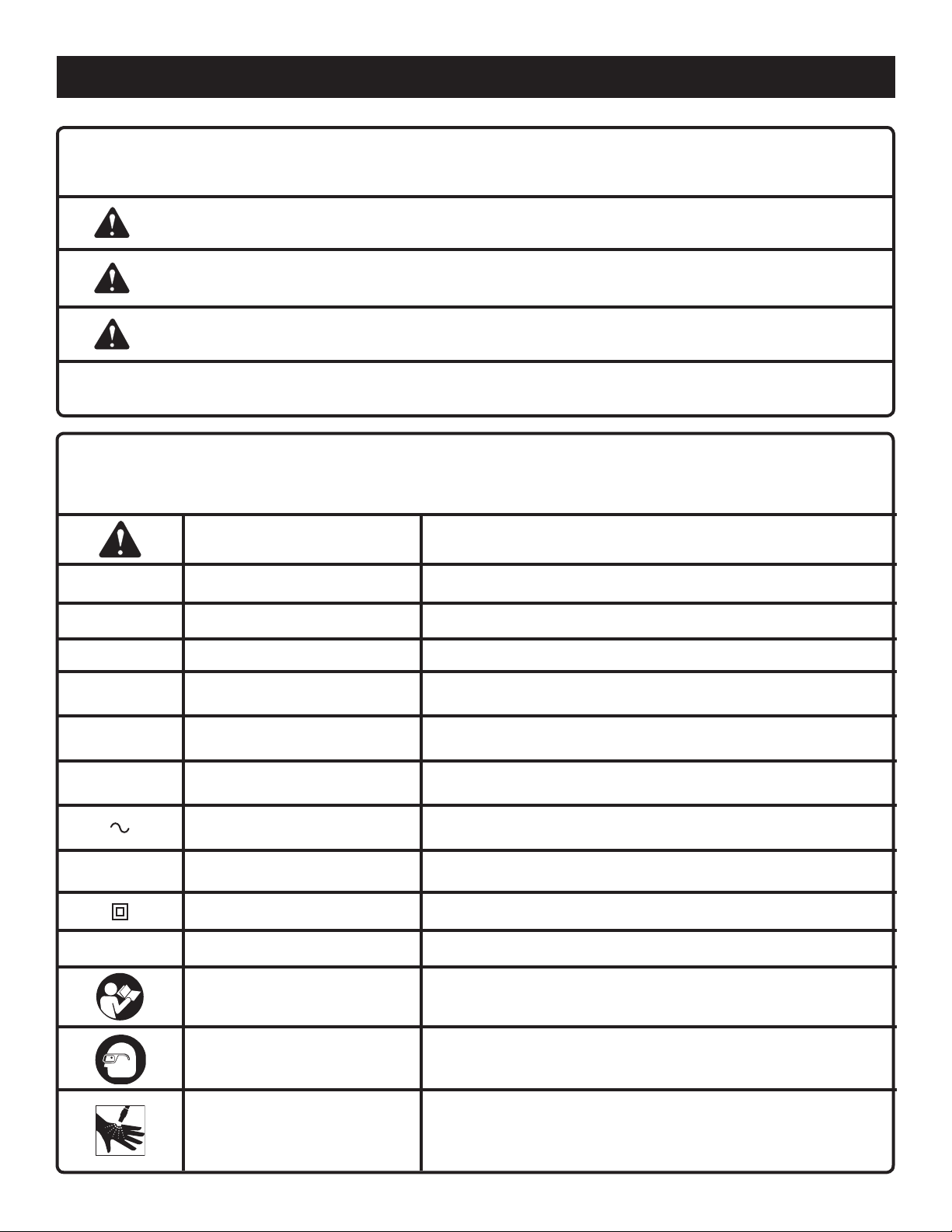

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

V Volts Voltage

PSI Pounds Per Square Inch Fluid Pressure

GPM Gallons Per Minute Amount fluid used per minute of continuous use.

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

Alternating Current Type of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

No Load Speed Rotational speed, at no load

Class II Tool Double-insulated construction

Read Operator’s Manual

Eye Protection

Risk of Injection

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

To reduce the risk of injection or injury, never direct a fluid stream

towards people or pets or place any body part in the stream. Leaking hoses and fittings are also capable of causing injection injury.

Do not hold hoses or fittings.

5 — English

Page 6

ELECTRICAL

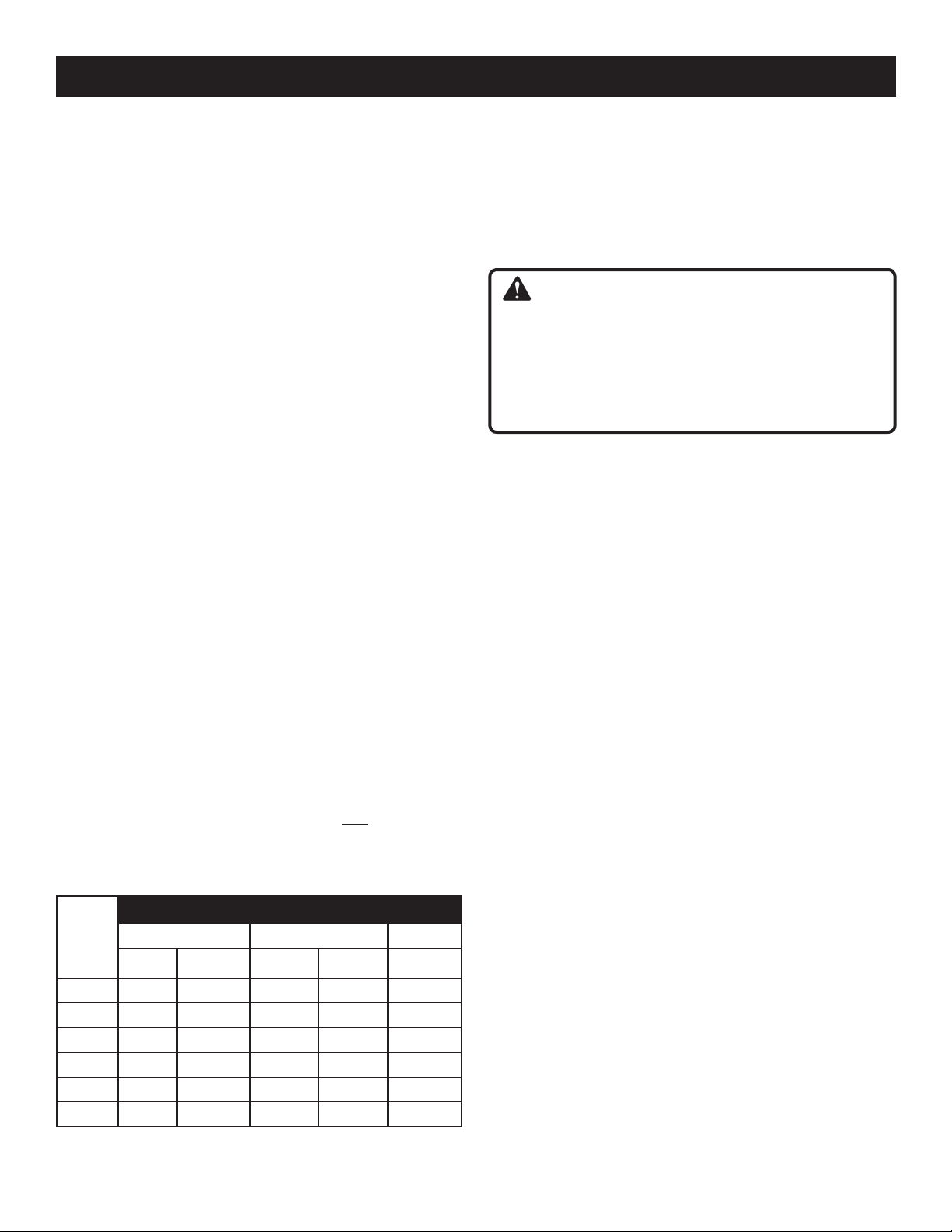

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding

plugs and 3-pole receptacles that accept the product’s plug.

When using a power tool at a considerable distance from

the power source, use an extension cord heavy enough to

carry the current that the product will draw. An undersized

extension cord will cause a drop in line voltage, resulting in

a loss of power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire size

required in an extension cord. Only round jacketed cords

listed by Underwriter’s Laboratories (UL) should be used.

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

When working with the product outdoors, use an extension

cord that is designed for outside use. This is indicated by the

letters “W-A” or “W” on the cord’s jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber,

tools, or other obstructions while you are working with a

power tool. Failure to do so can result in serious personal

injury.

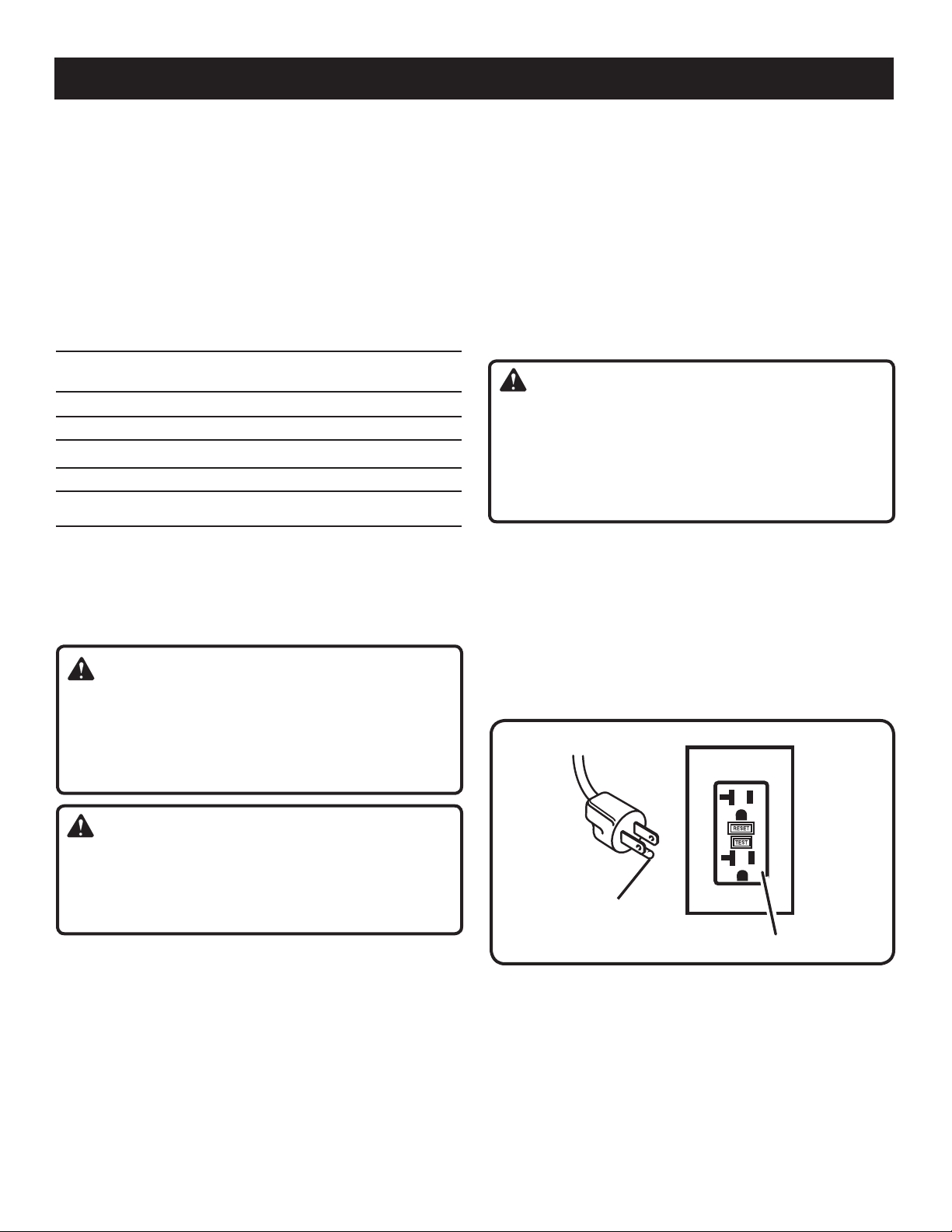

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of a malfunction

or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock.

This product is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

WARNING:

Improper connection of the grounding plug can result in a

risk of electric shock. When repair or replacement of the

cord is required, do not connect the grounding wire to

either flat blade terminal. The wire with insulation having

an outer surface that is green with or without yellow

stripes is the grounding wire.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely understood,

or if in doubt as to whether the product is properly

grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 V circuit and has

a grounding plug similar to the plug illustrated below. Only

connect the product to an outlet having the same configuration

as the plug. Do not use an adapter with this product.

WARNING:

Check extension cords before each use. If damaged

replace immediately. Never use the product with a

damaged cord since touching the damaged area could

cause electrical shock resulting in serious injury.

ELECTRICAL CONNECTION

This product is powered by a precision-built electric motor. It

should be connected to a power supply that is 120 V, AC only

(normal household current), 60 Hz. Do not operate this

product on direct current (DC). A substantial voltage drop

will cause a loss of power and the motor will overheat. If

the product does not operate when plugged into an outlet,

double check the power supply.

6 — English

GroundinG

Pin

GFCi reCePtiCle

Page 7

FEATURES

PRODUCT SPECIFICATIONS

Flow Rate ................................................................................................................................................................0.24 GPM

Pressure .......................................................................................................................................................... 800 - 2800 PSI

Container Size ............................................................................................................................................................. 3.5 gal.

Input ...................................................................................................................................... 120 V, 60 Hz, AC only, 7.0 Amp

Weight .......................................................................................................................................................................... 31 lbs.

KNOW YOUR PAINT STATION

See Figure 1, page 15.

The safe use of this product requires an understanding of

the information on the product and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all

operating features and safety rules.

3.5 GALLON PAINT CONTAINER

The 3.5 gallon paint container can be removed and replaced

with a 5 gallon or 1 gallon paint container for convenience

and minimal clean up.

25 FT. HIGH PRESSURE HOSE

Paint station includes a 25 ft. high pressure hose to reach

longer distances with the pistol-grip spayer or roller without

having to move the paint station.

2800 PSI PISTON PUMP

Maintains pressure as needed for spraying and rolling.

ON-BOARD ACCESSORY STORAGE

Paint station includes on-board accessory storage for

convenient access to pistol-grip sprayer, spray tips, hose

adapter and high pressure hose.

PAINT ROLLER

The paint roller accepts any 9 in. standard rollers up to

3/4 in. nap size.

PISTOL-GRIP SPRAYER

The pistol-grip sprayer provides a smooth finish.

REVERSIBLE SPRAY TIPS

The unit includes two reversible sprays tips that will work for a

wide variety of projects and prevents paint from clogging.

HIGH/LOW PRESSURE DIAL

Variable pressure control to easily match pressure with the

material being applied.

Lower pressure is for priming, cleaning and for thinner

materials or rolling applications.

Higher pressure is ideal for latex and spraying

applications.

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully lift the product from the carton and place on a

level work surface.

WARNING:

Do not use this product if any parts on the Loose Parts

List are already assembled to your product when you

unpack it. Parts on this list are not assembled to the

product by the manufacturer and require customer installation. Use of a product that may have been improperly

assembled could result in serious personal injury.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

LOOSE PARTS LIST

See figure 2, page 15.

Description Qty.

Paint station with 3.5 gallon container and lid ...............1

Pistol-grip sprayer with nozzle tip guard .........................1

Roller head ......................................................................1

Roller handle ...................................................................1

9 in. roller .........................................................................1

Roller cap ........................................................................2

Wheel .............................................................................2

Axle....... ...........................................................................2

Large washer ...................................................................2

Small washer ...................................................................2

Hitch pin ..........................................................................2

25 ft. grounded high pressure hose ................................1

415 Reversible spray tip ..................................................1

515 Reversible spray tip ..................................................1

Garden hose attachment .................................................1

Elastic strap .....................................................................1

Operator's manual (not shown) .......................................1

7 — English

Page 8

ASSEMBLY

WARNING:

If any parts are damaged or missing do not operate this

tool until the parts are replaced. Failure to heed this warning could result in serious personal injury.

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal

injury.

CONNECTING HIGH PRESSURE HOSE/PISTOLGRIP SPRAYER

See Figure 5, page 16.

To connect the high pressure hose to the paint station:

Screw the collar on the high pressure hose onto the spray

hose outlet located on the pump.

Tighten securely with an adjustable wrench.

To connect the pistol-grip sprayer to the high pressure

hose:

Screw the collar on the high pressure hose onto the

pistol-grip sprayer by turning the hose collar clockwise.

Use an adjustable wrench to hold the nut on the pistol-

grip sprayer and another to turn and tighten the nut on

hose end and tighten securely.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

TOOLS NEEDED

Adjustable wrench (2), 2 mm hex key

INSTALLING THE WHEELS

See Figure 3, page 16.

To attach the wheels to the base:

Locate the axle assembly.

Slip the axle into the wheel hole. Slide small washer onto

axle.

Lifting the paint station slightly, slide the axle, wheel, and

small washer into the wheel mounting hole in the machine

base.

Slide large washer onto the axle.

Push the hitch pin into the hole on the end of the axle to

secure assembly.

Repeat with the second wheel assembly.

FOLDING THE HANDLE

See Figures 4, page 16.

To raise the handle: pull the handle up until the handle

release knob snaps through the locking hole to secure

the handle in place.

To lower the handle (for storing): pull the handle release

knob on the right side of handle and lower.

INSTALLING REVERSABLE SPRAY TIP AND

NOZZLE TIP GUARD ON PISTOL-GRIP

SPRAYER

See Figure 6, page 16.

See operator's instructions for flushing, priming and cleaning

before installing nozzle tip guard and spray tip. Note all

warnings regarding use of pistol-grip sprayer and the

possibility of injection.

Turn lock-off thumbscrew counterclockwise to lock

sprayer trigger.

Install nozzle seat and cap into nozzle tip guard.

Thread nozzle tip guard assembly onto sprayer and tighten

securely.

Select spray tip and push securely into nozzle tip

guard.

Keep pistol-grip sprayer trigger locked when not in use.

INSTALLING PAINT ROLLER

See Figure 7, page 16.

Place roller caps in each end of the paint roller.

Align pins in the end of each roller cap to the holes inside

the roller head. Push out on the side of the roller head

until the roller snaps into place.

WARNING:

Never use the handle to lift the paint sprayer. Failure

to heed this warning could result in serious personal

injury.

8 — English

Page 9

OPERATION

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection marked to comply with ANSI

Z87.1. Failure to do so could result in objects being thrown

into your eyes resulting in possible serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

ACCESSORIES

All accessories used with this product must be rated greater

than 3000 psi. Ensure compatibility and fit before using any

accessory with this product.

WARNING:

Risk of fire or explosion - spray area must be well

ventilated and away from spark of flames. Failure to heed

this warning could result in serious personal injury.

APPLICATIONS

You may use this product for the purposes listed below:

Exterior painting and staining of decks, outdoor furniture,

fences, and interior/exterior rolling of walls.

WARNING:

To reduce the risk of injection NEVER change spray tip

without locking the lock-out thumbscrew on the sprayer

and NEVER point sprayer at any part of the body,

persons, or unit itself. In case of skin injection, seek

medical attention immediately. Failure to heed this may

cause serious personal injury.

LOCKING THE PISTOL-GRIP SPRAYER

See Figure 8, page 16.

Always lock the pistol-grip sprayer trigger when you have

stopped spraying to prevent the sprayer from being bumped

or triggered accidentally and causing injection.

Turn lock-off thumbscrew counterclockwise to lock

sprayer trigger.

Turn lock-off thumbscrew clockwise to unlock sprayer

trigger.

RELEASE PRESSURE PROCEDURE

Always follow this procedure when shutting paint station

OFF for any reason. This procedure releases pressure in the

high pressure hose.

On pistol-grip sprayer, turn lock-off thumbscrew coun-

terclockwise to lock sprayer trigger.

Turn ON/OFF switch OFF.

Turn prime/spray lever to PRIME, as shown in figure 10.

This releases pump pressure.

Unlock sprayer trigger and point to inside wall of paint

container releasing unused paint or stain back into container. This releases pressure in the hose and pistol-grip

sprayer.

Turn lock-off thumbscrew counterclockwise to lock

sprayer trigger.

Leave prime/spray lever in the PRIME position until ready

to spray again.

FLUSHING THE PAINT STATION

Before using your new paint station or before beginning a

new project or changing colors, it is important to thoroughly

flush the paint station of any storage fluid, previous cleaning

fluid, or material left in the system. Follow instructions for

Cleaning the Paint Station before beginning any project.

SET UP AND PRIMING

See Figure 9-11, pages 16-17.

User must prime the pump and sprayer before beginning

any spraying or rolling.

Fill the 3.5 gallon container with desired paint or stain.

Place lid on container.

NOTE: Paint container may also be removed and replaced

with 5 gallon paint container, 1 gallon square container

or 1 gallon container. Secure container with elastic strap.

Place lid on container.

Remove nozzle tip guard and spray tip from pistol-grip

sprayer.

Place intake tube in paint container.

Set return tube over waste container to flush out waste

material.

Turn prime/spray lever to PRIME.

Turn HIGH/LOW pressure control to LOW pressure.

Plug in the paint station.

Turn ON/OFF switch ON.

When material begins to flow through return tube set

return tube into paint container and clip to intake tube.

Point pistol-grip sprayer (without guard and spray tip in

place) into waste container.

Turn prime/spray lever to SPRAY.

Unlock sprayer trigger.

Turn HIGH/LOW pressure control from LOW to HIGH until

pump starts.

9 — English

Page 10

OPERATION

Spray into waste container until all air, water, cleaning

fluid is expelled and only paint comes out.

NOTE: When the motor stops, this indicates that the

pump and hoses are under pressure. If the motor continues to run, re-prime by turning the prime/spray lever

to PRIME.

Turn lock-off thumbscrew counterclockwise to lock

sprayer trigger.

Turn ON/OFF switch OFF.

Replace nozzle tip guard and reversible spray tip onto

pistol-grip sprayer.

Unit is ready to spray.

SELECTING A SPRAY TIP

See Figure 12, page 17.

Spray tips come in a variety of hole sizes and fan widths.

Your unit includes two reversible spray tips with a hole size

of .015 in. that will work for a wide variety of applications.

The 415 spray tip has a fan width of 8-10 in. The 515 spray

tip has a fan width of 10-12 in.

HOLE SIZE: Spray tip hole size determines the flow rate,

that is the amount of paint that is discharged from sprayer.

A larger hole size is best for thicker materials. A smaller hole

size is best for thinner materials.

FAN SIZE: Fan width determines the size of the spray pattern

when sprayer is held approximately 12 in. from surface to

be painted.

A narrow fan width will provide thicker coverage of material

and is better suited for small, tight areas.

A wide fan width will give thinner coverage of material and

provide better coverage on large, broad areas.

SPRAY TIP NUMBERS: When selecting a spray tip, the last

three numbers of the spray tip number contains information

on hole size and fan width.

For example if the spray tip number is 1415, the 4, when

doubled is the approximate fan width of paint when applied

12 inches from surface. The last two numbers, 15, refer to

the hole size in inches. In this case .015 in.

Tip

hole

size

0.011

0.013

0.015

0.017

0.019

0.021

SPRAY TIP WEAR: It is important to replace or spray tips

when they become worn. A worn spray tip will cause uneven

Light Medium Heavy

Stains Enamels Primers

•

• •

Coatings

Interior

Paints

• • •

• • •

• • •

Exterior

Paints

•

application and finish of material. Over time the spray tip hole

size increases and the width of the fan spray decreases.

When using latex paint, spray tips need to be replaced

between 15 and 40 gallons. For oil based materials, replace

spray tips after 35 to 60 gallons of use.

To increase the life of your spray tips, use the lowest pressure

setting needed to apply an even coating of material.

WARNING:

This is a high pressure device. To reduce the risk of injury,

user must read and understand operator's manual. To

reduce the risk of injection do not point sprayer at any

part of the body, persons, or unit itself. In case of skin

injection, seek medical attention immediately. Failure to

heed this may cause serious personal injury.

SPRAYING

See Figure 13, page 17.

Ensure surface to be painted is free of dust, dirt, and

grease.

Mask or cover any areas not intended to be painted or

stained. Be aware of wind that may cause your paint or

stain to spray into areas not desired. Always use drop

cloths or other cover to protect areas that are not intended

to be painted or stained.

Select spray tip and seat securely into nozzle tip guard.

Arrow on spray tip should face direction of spray.

Plug in the paint station.

Prime unit. Follow Set Up and Priming instructions.

Turn ON/OFF switch ON.

Turn prime/spray lever to SPRAY.

Turn HIGH/LOW pressure control clockwise to SPRAY

icon (HIGH pressure). Pressure can be adjusted to reach

desired spray pattern and coverage.

Unlock pistol-grip sprayer trigger. Begin spraying.

NOTE: If spray tip becomes clogged, turn 180° and spray

into waste container to clear clog. Return spray tip to

spray position and continue spraying.

Lock pistol-grip sprayer trigger and follow release

pressure procedure when finished or stopping for any

reason.

PAINTING TIPS

See Figures 14-15, page 17.

Practice spraying on a piece of scrap material to test your

spray pattern before beginning. If you cannot get a good

spray pattern see Troubleshooting section.

To create an even coating over the entire surface:

• Keep the sprayer an even distance from the area be-

ing sprayed, about 12 inches from the spray tip of the

sprayer to the surface being sprayed.

• Operate the sprayer in straight horizontal strokes. Do

10 — English

Page 11

OPERATION

not hold the sprayer at an angle. This will result in

uneven coverage.

• Depress the trigger to start the spray at the beginning

of the stroke and release the trigger as you end the

stroke. To prevent material build-up, do not keep the

trigger depressed as you proceed to the next stroke.

• Make one pass for each stroke. Overlap strokes in

halves for full coverage.

When finished, return any unused paint or stain to its

original container and thoroughly clean the sprayer.

PAINTING WITH THE ROLLER ATTACHMENT

See Figures 16-17, pages 17 - 18.

NOTE: The pistol-grip sprayer is used to control the flow of

paint into the roller attachment. Pull the trigger only when

more paint is needed on the roller.

Turn lock-off thumbscrew counterclockwise to lock pistol-

grip sprayer trigger.

Turn off paint station and release pressure from spraying.

Assemble the 9 in. roller into the roller head according to

the Installing Paint Roller.

Remove nozzle tip guard and spray tip from pistol-grip

sprayer.

Thread roller handle onto sprayer (make sure rubber

washer is in the roller handle before assembling).

Tighten securely with an adjustable wrench.

Snap roller head onto roller handle (make sure latches

are completely engaged).

Turn ON/OFF switch ON.

Turn HIGH/LOW pressure control to ROLLING icon (LOW

pressure).

Turn prime/spray lever to SPRAY.

Squeeze the trigger. Once the roller has paint, release

the trigger and squeeze again only when more paint is

needed.

NOTE: Do not continuously squeeze the trigger. For best

results, after every third stroke, pull trigger for 1 second,

release, then continue to paint.

To create an even coating over the entire surface:

• Apply paint or stain in an area several feet wide in a

zig-zag direction.

• Roll back and forth repeatedly over the same area

until the entire area is covered and the roller marks

are smoothed out.

• If additional coats are necessary, let paint or stain dry

completely between coats.

When finished, lock pistol-grip sprayer trigger and follow

Release Pressure Procedure.

Unplug the paint station.

WARNING:

To reduce the risk of fire or explosion: Do not use with

flammable liquids (i.e., paint stripper, paint remover,

brush cleaner, mineral spirits, lacquer thinner, turpentine,

acetone, gasoline, kerosene, etc.). Use only water (for

water based paints) or Klean Strip® Revolutionary White

Formula Paint Thinner (for oil-based paints or varnish).

OVERNIGHT STORAGE (UP TO 12 HOURS)

NOTE: These instructions are for latex paint and water based

materials only. If you are using oil-based material, refer to

Cleaning the Paint Station and Long Term Storage for

instructions. Stains and oil based materials do not keep for

any extended period of time.

Lock pistol-grip sprayer and follow Release Pressure

Procedure.

Turn ON/OFF switch OFF.

Unplug the paint station.

Leave intake tube and return tube in paint.

Gently pour 1/2 cup water over top of paint to prevent

drying.

Close lid on 3.5 gallon container. Wrap damp cloth around

tubes and over opening of container. If using 5 gallon or

other container, wrap tubes and container with plastic

to seal out air.

Wrap pistol-grip sprayer with damp cloth and place in

plastic bag. Seal bag.

Store for short time out of sunlight. For longer storage,

follow instructions for Cleaning the Piant Station.

CLEANING THE PAINT STATION

See Figures 18-19, page 18.

The solution used to clean the sprayer is determined by the

type of material that has been sprayed. For anything other

than latex material use Klean Strip® Revolutionary White

Formula Paint Thinner (for oil-based paints or varnish).

CAUTION:

It is important to thoroughly clean paint station and

pistol-grip sprayer after each use or when changing paint

color. Allowing paint or stain to remain in an idle tool for

an extended period of time can cause its hoses to clog

and its moving parts to seize.

Always use drop cloths or other cover to protect areas

from possible spills.

Lock pistol-grip sprayer and follow Release Pressure

Procedure.

Unplug the paint station.

Remove the spray tip and nozzle tip guard from

sprayer.

11 — English

Page 12

OPERATION

Use spray tip cleaning brush to clean material from spray

tip holes.

Soak spray tip(s) and nozzle tip guard in water (for water

based paints) or Klean Strip® Revolutionary White

Formula Paint Thinner (for oil-based paints or varnish),

rinse.

Return any unused paint or stain to its original container.

If using paint station container, rinse clean with water (for

water based paints) or Klean Strip® White Formula Paint

Thinner (for oil-based paints or varnish). Empty into waste

container.

Remove filter from intake tube, soak in cleaning fluid and

rinse.

Fill paint station container with water (for water based

paints) or Klean Strip® Revolutionary White Formula Paint

Thinner (for oil-based paints or varnish).

NOTE: If flushing or cleaning using water for water based

materials, It may be easier to use a garden hose and the

garden hose attachment (included). Remove filter from

intake tube and attach intake tube to garden hose with

attachment.

Place intake tube to paint station container.

Place return tube in original paint container.

Place original paint container right next to waste con-

tainer.

Turn prime/spray lever to PRIME.

Turn HIGH/LOW pressure control counterclockwise to

LOW pressure.

Turn ON/OFF switch ON.

The paint station will draw cleaning fluid up the intake tube

through the pump and out the return tube into the paint

container. Move the return tube from the paint container to

the waste container as soon as the cleaning fluid starts to

come out of the return tube.

Turn prime/spray lever to SPRAY.

Unlock pistol-grip sprayer.

Point pistol-grip sprayer at the interior side of original

paint container to run out paint in system so as not to

waste paint.

Move the pistol-grip sprayer from the paint container to

the waste container as soon as the cleaning fluid starts

to come out sprayer.

Let fluid run through system for at least 1 minute (until

clean fluid is noticed).

NOTE: If using the garden hose adapter, turn on garden

hose and run water through system until water runs clear.

Leave system running for approximately one minute or

until cleaning fluid runs clear.

Turn prime/spray lever to PRIME.

Turn ON/OFF switch OFF.

Unplug the paint station

Dispose of dirty water (or Klean Strip® Revolutionary

White Formula Paint Thinner) in accordance with federal,

state, and local ordinances.

TO CLEAN THE PAINT ROLLER:

Always use drop cloths or other cover to protect areas

from possible spills.

Disconnect the roller head from the roller handle and pour

the remaining paint or stain from the roller head and roller

handle into the original container.

Thoroughly clean the roller and accessories by soaking

and rinsing in water (for water based paints) or Klean

Strip® Revolutionary White Formula Paint Thinner (for

oil-based paints or varnish).

CLEANING THE PISTOL-GRIP SPRAYER

FILTER

See Figure 20, page 18.

Shut down the paint station using Release Pressure

Procedure.

Unplug the paint station.

Check that pistol-grip sprayer trigger is locked off.

Remove pistol-grip sprayer from the high pressure hose

using two adjustable wrenches.

Unscrew hex socket screw and lock nut to release trigger

guard from plate on the base of sprayer.

Using wrench, turn handle counterclockwise to re-

move.

Remove filter from handle, noting direction of filter.

Thoroughly clean filter container with water (for water

based paints) or Klean Strip® Revolutionary White Formula Paint Thinner (for oil-based paints or varnish).

If filter has any holes, replace with new filter. NEVER

puncture filter with any object.

Replace filter in handle, tapered end down facing back of

sprayer. Sprayer will not work if filter is improperly inserted

in handle.

Reassemble pistol-grip sprayer in reverse order, tighten

securely.

12 — English

Page 13

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result

in fluids entering your eyes resulting in possible serious

injury.

MAINTENANCE PROCEDURES

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

LONG-TERM STORAGE

See Figure 22, page 18.

When storing the paint station for 16 hours or more, a thorough

cleaning is recommended.

Shutdown paint station.

Thoroughly clean paint station and sprayer according to

instructions.

Be sure that machine and tubes are clear any water or

fluid as these may freeze.

Coil 25 ft. high pressure hose and store on back of tool

with hook and loop straps.

Keep intake tube and prime tube in 3.5 gallon paint

container. Store filter and sprayer in plastic bag and seal.

Fold handle over front of tool.

Do not at any time let brake fluids, gasoline, petroleum

based products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken, or

destroy plastic which may result in serious personal

injury.

13 — English

Page 14

TROUBLESHOOTING

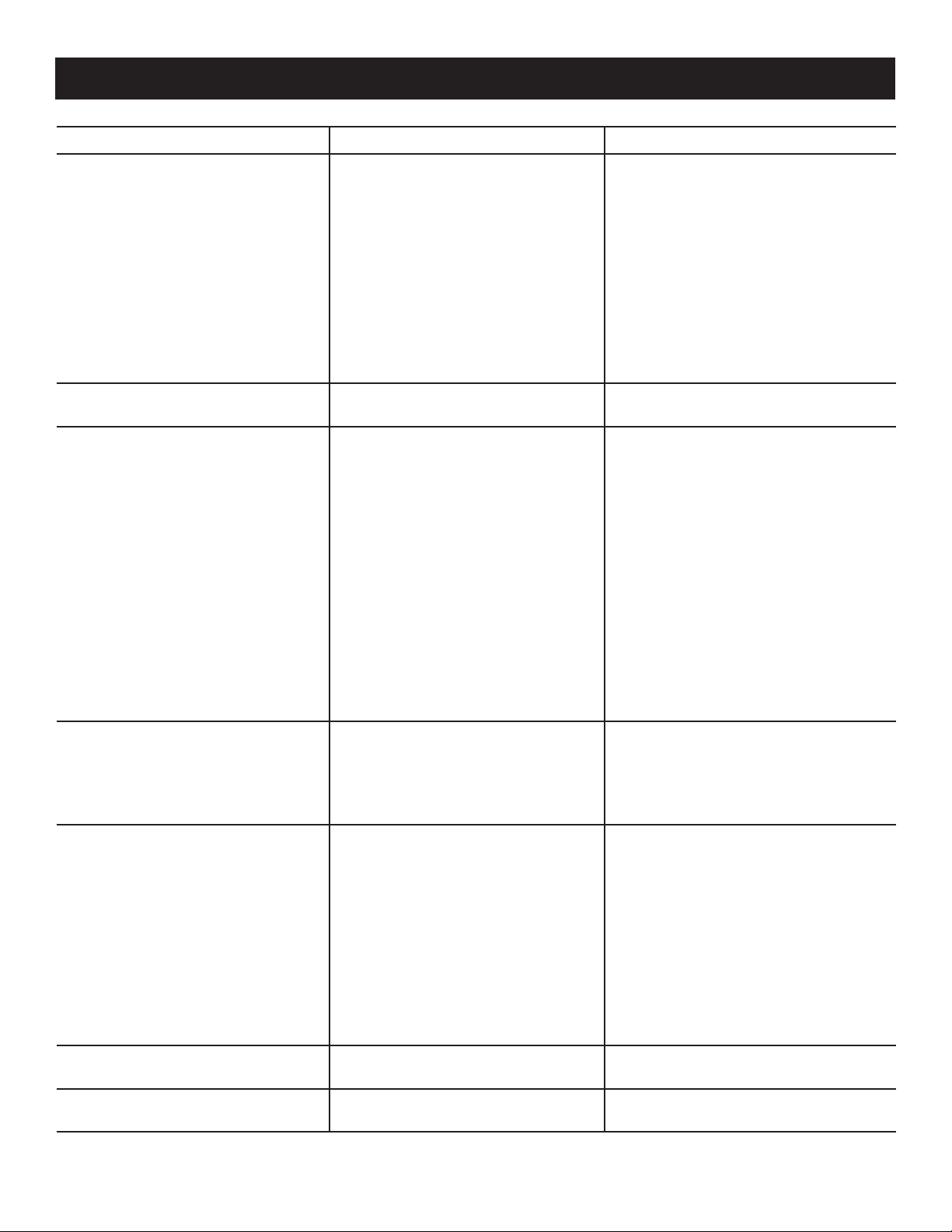

PROBLEM CAUSE POSSIBLE SOLUTION

Motor does not run. Paint station is not plugged in

On/Off switch in OFF position

Paint station has shut off while under

pressure

No current coming from outlet

Extension cord is damaged or has low

voltage

A fuse has blown on paint station

Motor is not working properly

Pressure setting is too low HIGH/LOW pressure control set too

high.

Pump does not prime Prime/Spray valve is in Spray position

Make sure unit is plugged in

Turn On/Off switch to ON

Turn the high/low pressure knob to

maximum pressure or release pressure by

turning Prime/Spray lever to Prime

Test the power supply voltage

Replace extension cord

Contact Authorized Service center

Contact Authorized Service Center

Turn HIGH/L OW pres sure con trol

clockwise

Turn Prime/Spray lever to Prime

Paint station starts but does not

circulate paint when Prime/Spray

lever is turned to Prime

Motor seems to be running properly

but pressure drops when pistol-grip

is triggered

Inlet screen is clogged or intake tube

is not immersed

Inlet valve check ball is stuck

Intake tube is loose

Paint container is empty or intake tube

is not fully submerged in fluid

Suction filter is clogged

Prime/Spray valve is clogged

Reversible spray tip is worn

Spray tip is clogged

Suction tube and filter are loose or

damaged

Pistol-grip sprayer filter is clogged

Material being sprayed is too thick

Inlet valve is damaged or worn

Clean debris off inlet screen and make

sure intake tube is at bottom of paint

bucket

Tap firmly on the outside of the inlet valve

with a small wrench, allowing pump to

prime properly

Remove intake tube and place a pencil

into the inlet section to dislodge the ball,

allowing pump to prime properly.

Tighten intake tube with flat-head

screwdriver

Fill paint container with material and

submerge intake tube into material

Clean suction filter

Contact Authorized Service Center

Replace spray tip

Turn spray tip 180° and spray to clean

Reinstall or replace suction tube and filter

as needed

Clean or replace pistol-grip sprayer filter

Follow material manufacturer’s directions

and thin material as needed

Replace inlet valve

Intake tube is loose

Prime/spray lever is set to spray but

there is flow through the prime tube

Pistol-grip sprayer leaks Internal sprayer parts are worn or

Prime/spray lever is dirty or damaged Contact Authorized Service Center

damaged

14 — English

Tighten intake tube

Contact Authorized Service Center

Page 15

TROUBLESHOOTING

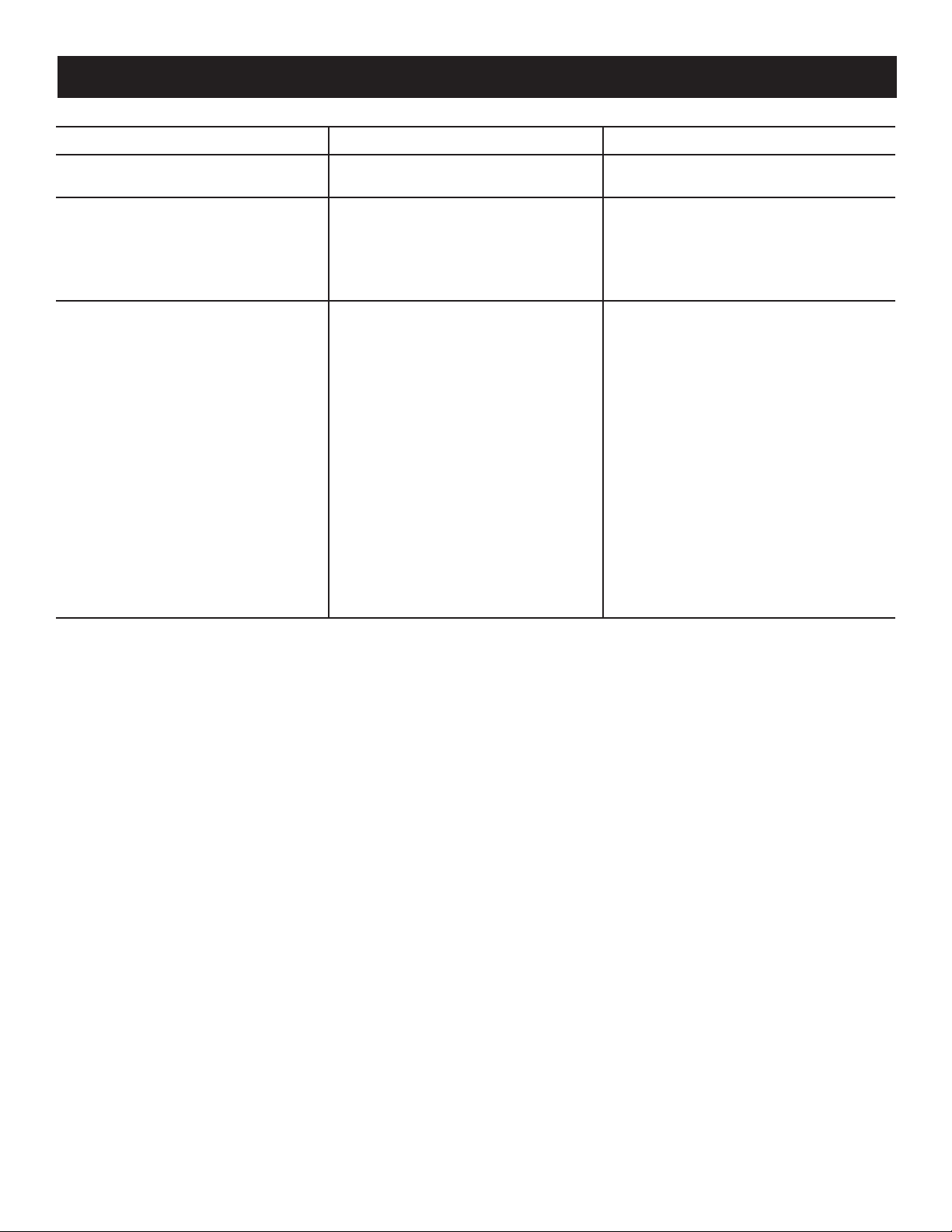

PROBLEM CAUSE POSSIBLE SOLUTION

Nozzle tip guard leaks Nozzle tip guard or spray tip where

assembled improperly

Pistol-grip sprayer will not spray Spray tip is clogged

Reassemble according to nozzle tip guard

and Spray tip assembly instructions.

Turn spray tip 180° and spray to clean

Pistol-grip sprayer filter is clogged

Spray tip is not fully seated into nozzle

tip guard

Paint pattern is weak or uneven Pressure is set to low

Pistol-grip sprayer or intake tube filter

is clogged

Intake tube is loose at inlet valve

Spray tip is worn

Material being sprayed is too thick

Loss of pressure

Clean or replace pistol-grip sprayer filter

Reassemble according to nozzle tip guard

and Spray tip assembly instructions.

Turn High-low pressure knob clockwise

to increase pressure

Clean or replace filters

Tighten tube fitting

Replace spray tip

Follow material manufacturer’s directions

and thin material as needed

See Cause/Possible solutions for

"Pressure setting is too low," and

"Motor seems to be running properly

but pressure drops when pistol-grip is

triggered"

NOTE: FIGURES (ILLUSTRATIONS) START ON PAGE 16 AFTER

SPANISH LANGUAGE SECTION.

15 — English

Page 16

TABLE DES MATIÈRES

Introduction .......................................................................................................................................................................2

Garantie .............................................................................................................................................................................2

Instructions importantes concernant la sécurité ...............................................................................................................3

Règles de sécurité particulières ........................................................................................................................................4

Symboles ...........................................................................................................................................................................5

Caractéristiques électriques ..............................................................................................................................................6

Caractéristiques ................................................................................................................................................................7

Assemblage ...................................................................................................................................................................7-8

Utilisation ..................................................................................................................................................................... 9-12

Entretien ..........................................................................................................................................................................13

Dépannage ................................................................................................................................................................14-15

Figure numéros (illustrations) ..................................................................................................................................... 16-19

Commande de pièces / réparation ..................................................................................................................Page arrière

INTRODUCTION

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

GARANTIE

OUTILS ÉLECTRIQUES RYOBI® – GARANTIE LIMITÉE DE DEUX ANS ET POLITIQUE D’ÉCHANGE DE 30 JOURS

One World Technologies, Inc., garantit ses outils électriques dans les conditions suivantes :

POLITIQUE D’ÉCHANGE DE 30 JOURS : En cas de défaillance due à des vices de matériaux ou de fabrication au cours

des 30 jours suivant la date d’achat, l’acheteur pourra faire réparer tout outil électrique RYOBI® au titre de cette garantie

ou le retourner l’établissement où il a été acheté. Pour obtenir un outil en échange ou demander la réparation en garantie,

l’équipement complet devra être retourné, dans son emballage d’origine, accompagné d’une preuve d’achat. L’outil fourni en

échange sera couvert par la garantie limitée pour le restant de la période de validité de deux ans à compter de la date d’achat.

CE QUI EST COUVERT PAR LA GARANTIE : Cette garantie couvre tous les vices de matériaux et de fabrication de cet

outil électrique RYOBI®, pour une période de deux ans, à compter de la date d’achat. À l’exception des batteries, les

accessoires sont garantis pour une période de quatre-vingt-dix (90) jours. Les batteries sont garanties deux ans.

RÉPARATIONS SOUS GARANTIE : Il suffit de retourner l’outil, correctement emballé, en port payé, à un centre de

réparations agréé. L’adresse du centre de réparations agréé le plus proche peut être obtenue en contactant un représentant

du service après-vente par courrier, à l’adresse One World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207,

par téléphone au 1-800-525-2579 ou par courriel, à l’adresse Internet www.ryobitools.com. Lors de toute demande de

réparation sous garantie, une preuve d’achat datée (par exemple un reçu de vente) doit être fournie. Nous nous engageons

à réparer tous les défauts de fabrication et à réparer ou remplacer, à notre choix, toutes les pièces défectueuses. Les

réparations et remplacements seront gratuits. Les réparations sous garantie seront effectuées dans un délai raisonnable,

ne dépassant en aucun cas quatre-vingt-dix (90) jours.

CE QUI N’EST PAS COUVERT : La garantie ne couvre que l’acheteur au détail original et n’est pas transférable. Cette

garantie ne couvre que les défauts résultant d’une utilisation normale. Elle ne couvre pas les problèmes de fonctionnement,

défaillances ou autres défauts résultant d’un usage incorrect ou abusif, de la négligence, de la modification, de l’altération

ou de réparations effectuées par quiconque autre qu’un centre de réparations agréé. One World Technologies, Inc. ne fait

aucune autre garantie, représentation ou promesse concernant la qualité et les performances de cet outil électrique, autres

que celles expressément indiquées dans le présent document.

AUTRES LIMITATIONS : Toutes les garanties implicites accordées par les lois en vigueur, y compris les garanties de valeur

marchande ou d’adéquation à un usage particulier, sont limitées à une durée de deux ans, à compter de la date d’achat.

One World Technologies, Inc. déclinant toute responsabilité pour les dommages directs ou indirects, les limitations et

exclusions peuvent ne pas s’appliquer à chaque acheteur. Cette garantie donne au consommateur des droits spécifiques,

et celui-ci peut bénéficier d’autres droits, qui varient selon les états ou provinces.

2 — Français

Page 17

INSTRUCTIONS IMPORTANTES CONCERNANT LA SÉCURITÉ

On doit retrouver un extincteur sur le lieu de travail et celui-ci

AVERTISSEMENT :

CONSERVER CES INSTRUCTIONS. Pour réduire les

risques d’incendie ou d’explosion, choc électrique, et la

blessure aux personnes lire et veiller à bien comprendre

toutes instructions incluses le manuel. Familarisez-vous

avec toutes les commandes et l’utilisation correcte de

l’équipement.

LIRE TOUTES LES INSTRUCTIONS

APPRENDRE À CONNAÎTRE L’OUTIL. Lire attentivement le

manuel d’utilisation. Apprendre les applications et les limites

de l’outil, ainsi que les risques spécifiques relatifs à son utilisation.

AVERTISSEMENT : Pour réduire les risques d’incendie ou

d’explosion :

Ne pas pulvériser de substances inflammables ou combustibles

à proximité des flammes vives ou des sources d’inflammation

comme les cigarettes, les moteurs et l’équipement électrique.

Dans le cas des unités uniquement compatibles avec des

substances à base d’eau ou avec des essences minérale ayant

un point d’éclair de 60 °C (140 °F), ne pulvériser aucun liquide

ayant un point d’éclair inférieur à 60 °C (140 °F) et n’effectuer

aucune opération de nettoyage avec ce type de liquide.

La peinture ou le solvant qui circule dans l’équipement peut

créer de l’électricité statique. L’électricité statique crée un risque

d’incendie ou d’explosion en présence de vapeurs de peinture

ou de solvant. Toutes les pièces du système de pulvérisation, y

compris la pompe, le tuyau, le pulvérisateur ainsi que les objets

se trouvant dans la zone de pulvérisation ou autour de celle-ci,

doivent être correctement mises à la terre afin d’assurer une

protection contre les décharges statiques et les étincelles.

Utiliser uniquement les tuyaux flexibles haute pression

conducteurs ou mis à la terre pour pulvérisateur de peinture

sans air recommandés par le fabricant

S’assurer que tous les contenants et les systèmes de

captage sont mis à la terre afin d’empêcher les décharges

statiques.

Brancher l’outil dans une prise de courant mise à la terre et

utiliser des cordons prolongateurs avec mise à la terre. Ne

pas utiliser un adaptateur 3 voies vers 2 voies.

Ne pas utiliser une peinture ou un solvant qui contient des

hydrocarbures halogénés.

L’aire de pulvérisation doit être bien ventilée. S’assurer que le

lieu de travail comprend une bonne alimentation en air frais.

Garder l’ensemble de pompe dans un endroit bien ventilé. Ne

pas pulvériser la pompe elle-même.

Ne pas fumer à proximité du l’aire de pulvérisation.

Ne pas faire fonctionner les interrupteurs d’éclairage, les

moteurs ou d’autres dispositifs produisant des étincelles à

proximité du l’aire de pulvérisation.

Garder le lieu de travail propre et exempt de contenants de

peinture ou de solvant, de chiffons et d’autres matériaux

inflammables.

Bien connaître le contenu des peintures et des solvants qui sont

pulvérisés. Lire toutes les fiches signalétiques et les étiquettes

du contenant fournies avec les peintures et les solvants. Suivre

les instructions de sécurité du fabricant concernant les peintures

et les solvants.

doit fonctionner.

AVERTISSEMENT : Pour réduire les risques d’injection:

Ne pas orienter la buse ou pulvériser en direction des personnes

ou des animaux.

Garder les mains et les autres parties du corps à l’écart de la

décharge. Par exemple, ne pas tenter de bloquer une fuite avec

une partie du corps.

Toujours utiliser le protecteur d’embout. Ne pas utiliser l’outil

si le protecteur d’embout n’est pas en place.

Utiliser seulement un embout de pulvérisation recommandé par

le fabricant.

Faire preuve de prudence au moment de nettoyer et de

changer les embouts de pulvérisation. Si l’embout de

pulvérisation s’encrasse pendant l’opération, suivre les

instructions du fabricant pour éteindre l’unité et relâcher la

pression avant de retirer l’embout pour le nettoyer.

Ne pas laisser l’unité sans surveillance lorsque celle-ci

est en marche ou sous pression. Lorsque l’unité n’est pas

utilisée, l’éteindre et relâcher la pression conformément aux

instructions du fabricant.

Le pulvérisateur haute pression peut injecter des substances

toxiques dans le corps et entraîner des blessures graves. Au cas

où ce genre d’injection surviendrait, consulter immédiatement

un médecin.

Vérifier les tuyaux flexibles et les pièces afin de s’assurer

qu’ils ne sont pas endommagés. Remplacer tout tuyau flexible

endommagé ou toute pièce endommagée.

Ce système peut produire une pression de 17 236,89 kPa

(2 800 psi). Utiliser uniquement des pièces de remplacement

ou des accessoires recommandés par le fabricant et

qui tolèrent une pression nominale de 17236,89 kPa

(3 000 psi).

Toujours enclencher le verrou de la gâchette lorsqu’aucune

opération de pulvérisation n’est requise. S’assurer que le

verrou de la gâchette fonctionne correctement.

S’assurer que tous les raccords sont solides avant d’utiliser

cette unité.

Savoir comment arrêter rapidement l’unité. Se familiariser avec

toutes les commandes.

Pour l’usage de ménage seulement.

AVERTISSEMENT : Pour réduire les risques de blessure :

Toujours porter une protection oculaire certifiée conforme

à la norme ANSI Z87.1, ainsi qu’un appareil respiratoire ou

un masque approprié au moment de peinturer.

Ne pas utiliser ou pulvériser le produit à proximité des enfants.

Garder les enfants à l’écart de l’équipement en tout temps.

Ne pas travailler hors de portée ou se tenir sur un support

instable. Se tenir bien campé et en équilibre en tout

temps.

Rester attentif et prêter attention au travail.

Ne pas utiliser cet appareil en cas de fatigue ou sous l’influence

de l’alcool ou de drogues.

Ne pas entortiller ou courber excessivement le tuyau flexible.

Ne pas exposer le tuyau flexible à des températures ou à

des pressions qui dépassent celles recommandées par le

fabricant.

Ne pas utiliser le tuyau fl e x i b l e comme élément de

renforcement pour tirer ou soulever l’équipement.

3 — Français

Page 18

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Maintenir tous les dispositifs de protection en place et en

bon état de fonctionnement. Ne jamais utiliser l’outil avec des

couvercles ou dispositifs de protection retirés. S’assurer que

tous les dispositifs de protection fonctionnent correctement

avant chaque utilisation.

Pour réduire les risques de blessures, garder les enfants

et visiteurs à l’écart. Tous les visiteurs doivent porter des

lunettes de sécurité et se tenir à bonne distance de la zone

de travail.

Ne laisser personne approcher la zone de travail,

particulièrement le s petits enfants et le s animaux

domestiques.

Utiliser l’outil approprié. Ne pas utiliser l’outil ou un accessoire

pour effectuer un travail pour lequel il n’est pas conçu. Ne ne

pas utiliser l’outil pour une application non prévue.

Ne pas faire fonctionner l’équipement pied-nu ou en

portant des sandales ou des chaussures légères similaires.

Porter des chaussures de sécurité protégeant les pieds et

améliorant l’équilibre sur des surfaces glissantes.

Faire preuve de prudence pour éviter de glisser ou

tomber.

Toujours porter des lunettes de sécurité avec écrans

latéraux. Les lunettes de vue ordinaires sont munies seulement

de verres résistants aux impacts ; ce ne sont PAS des lunettes

de sécurité.

N’utiliser que les accessoires recommandés. L’emploi

de tout accessoire inadapté peut présenter un risque de

blessure.

Suivre les instructions d’entretien spécifiées dans ce

manuel.

Vérifier l’état des pièces. Avant d’utiliser l’outil de nouveau

examiner soigneusement les pièces et dispositifs de protection

qui semblent endommagés afin de déterminer s’ils fonctionnent

correctement et s’ils remplissent les fonctions prévues. Vérifier

l’alignement des pièces mobiles, s’assurer qu’aucune pièce

n’est bloquée ou cassée, vérifier la fixation de chaque pièce et

s’assurer qu’aucun autre problème ne risque d’affecter le bon

fonctionnement de l’outil. Pour éviter les risques de blessures,

toute protection ou pièce endommagée doit être correctement

réparée ou remplacée dans un centre de réparations agréé.

Ne jamais laisser un outil en fonctionnement sans

surveillance. Ne pas s’éloigner de l’outil avant qu’il soit

parvenu à un arrêt complet.

Suivre les recommandations du fabricant pour charger,

décharger, transporter et entreposer l’unité en toute sécurité.

Se familiariser complètement avec les commandes. Veiller à

savoir arrêter la machine et relâcher la pression rapidement.

Garder l’outil sec, propre et exempt d’huile ou de graisse.

Toujours utiliser un chiffon propre pour le nettoyage. Ne jamais

utiliser de liquide de freins, d’essence ou de produits à base

de pétrole pour nettoyer l’outil.

Ne pas utiliser l’outil si le commutateur ne permet pas de

l’arrêter. Faire remplacer les commutateurs défectueux dans

un centre de réparations agréé.

Avant de nettoyer, réparer ou inspecter, couper le moteur et

vérifier que toutes les pièces en mouvement sont arrêtées.

Éviter les environnements dangereux. Ne pas utiliser dans

des endroits mouillés ou humides, ne pas exposer à la pluie.

Garder le lieu de travail bien éclairé.

4 — Français

Ne jamais diriger un jet de peinture vers des personnes,

des animaux et des appareils électriques.

Ne jamais mettre la machine en marche si de la glace s’est

formée sur quelque partie que ce soit.

AVERTISSEMENT : Les pulvérisateur à haute pression

peuvent être dangereux s’ils sont utilisés incorrectement.

Le pulvérisateur ne doit pas être dirigé vers des personnes,

animaux, dispositifs électriques ou l’équipement lui-même.

Rester à l’écart des pièces brûlantes.

Vérifier le serrage de la boulonnerie avant chaque utilisation.

Un boulon ou écrou desserré peut causer de sérieux problèmes

de moteur.

Laisser le produit refroidir avant de remiser l’outil.

Remiser dans un endroit frais, bien aéré, à l’écart d’étincelle

et/ou d’appareils produisant des flammes.

Utiliser exclusivement des pièces identiques à celles

d’origine pour les réparations. L’usage de toute autre pièce

pourrait créer une situation dangereuse ou endommager

l’outil.

Ne pas utiliser l’outil si l’embout de pulvérisation n’est pas

en place.

Les conséquences d’une blessure par injection peuvent

aller jusqu’à l’amputation. Consulter immédiatement un

médecin.

Ne jamais mettre les mains devant l’embout de pulvérisation

pendant l’utilisation. Le fait de porter des gants ne protège

pas toujours l’utilisateur des blessures par injection.

Porter des vêtements protégeant la peau et les cheveux

de la peinture, ainsi qu’un masque ou un respirateur

pendant l’utilisation. Les peintures, les solvants et les autres

substances peuvent être dangereux s’ils sont inhalés ou s’ils

entrent en contact avec le corps.

Toujours débrancher le pulvérisateur, éteindre l’unité et

relâcher la pression avant de procéder à l’entretien ou au

nettoyage de l’embout ou du dispositif de protection de

l’embout, de changer d’embout, ou de laisser l’unité sans

surveillance.

Le plastique peut provoquer des étincelles. Ne jamais

suspendre du plastique pour clôturer une aire de

pulvérisation. Ne pas utiliser de toiles de peintre en plastique

au moment de pulvériser des substances inflammables.

Ne pas pulvériser à l’extérieur lors de journées

venteuses.

Ne pas tenter de nettoyer ou de décrasser l’embout de

pulvérisation avec son doigt.

S’assurer que le cordon prolongateur est en bon état. Si un

cordon prolongateur est utilisé, s’assurer que sa capacité

est suffisante pour supporter le courant de fonctionnement

de l’outil. Un calibre de fil (A.W.G) d’au minimum 14 est

recommandé pour un cordon prolongateur de 15 m (50 pi)

ou moins. L’usage d’un cordon de plus de 30 m (100 pi) est

déconseillé. En cas de doute, utiliser un cordon du calibre

immédiatement supérieur. Moins le numéro de calibre

est élevé, plus la capacité du fil est grande. Un cordon de

capacité insuffisante causerait une baisse de la tension de

ligne, entraînant une perte de puissance et une surchauffe.

Conserver ces instructions. Les consulter fréquemment et

les utiliser pour instruire d’autres utilisateurs. Si cet outil est

prêté, il doit être accompagné de ces instructions.

Page 19

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à l’utilisation

de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

ATTENTION :

Certains des symboles ci-dessous peuvent être présents sur le produit. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser le produit plus efficacement et de réduire les risques.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

V Volts Tension

PSI Livres par pouce carré Pression des fluides

GPM Gallons par minute

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée,

aura pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une situation pouvant entraîner

des dommages matériels.

Quantité de liquide utilisée par minute lors d’une utilisation

continue.

A Ampères Intensité

Hz Hertz Fréquence (cycles par seconde)

min Minutes Temps

Courant alternatif Type de courant

n

o

.../min Par minute Tours, coups, vitesse périphérique, orbites, etc., par minute

Vitesse à vide Vitesse de rotation à vide

Outil de la classe II Construction à double isolation

Pour réduire les risques de blessures, l’utilisateur doit lire et

Lire le manuel d’utilisation

Protection oculaire

Risque d’injection

veiller à bien comprendre le manuel d’utilisation avant d’utiliser

ce produit.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Pour réduire les risques d’injection ou de blessures, ne jamais diriger

un jet de liquide vers des personnes ou des animaux, ou placer

l’une ou l’autre des parties du corps devant le jet. Les fuites sur les

tuyaux et les raccords peuvent également causer des blessures

par injection. Ne pas tenir les tuyaux ou les raccords.

5 — Français

Page 20

CARACTÉRISTIQUES ÉLECTRIQUES

CORDONS PROLONGATEURS

Utiliser exclusivement des cordons prolongateurs à trois fils doté

d’une fiche à prise de terre brabchés sur une prise triphasée

compatible avec la fiche de l’outil. Lors de l’utilisation d’un

outil électrique à grande distance d’une prise secteur, veiller à

utiliser un cordon prolongateur d’une capacité suffisante pour

supporter l’appel de courant de l’outil. Un cordon de capacité

insuffisante causerait une baisse de la tension de ligne, entraînant

une perte de puissance et une surchauffe. Se reporter au tableau

ci-dessous pour déterminer le calibre minimum de fil requis pour

un cordon donné. Utiliser exclusivement des cordons à gaine

ronde homologués par Underwriter’s Laboratories (UL).

**Intensité nominale (sur la plaquette signalétique de l’outil)

0-2,0 2,1-3,4 3,5-5,0 5,1-7,0 7,1-12,0 12,1-16,0

Longueur Calibre de fil

du cordon (A.W.G.)

25’ 16 16 16 16 14 14

50’ 16 16 16 14 14 12

100’ 16 16 14 12 10 —

**Utilisé sur circuit de calibre 12 – 20 A.