Page 1

OPERATOR'S MANUAL

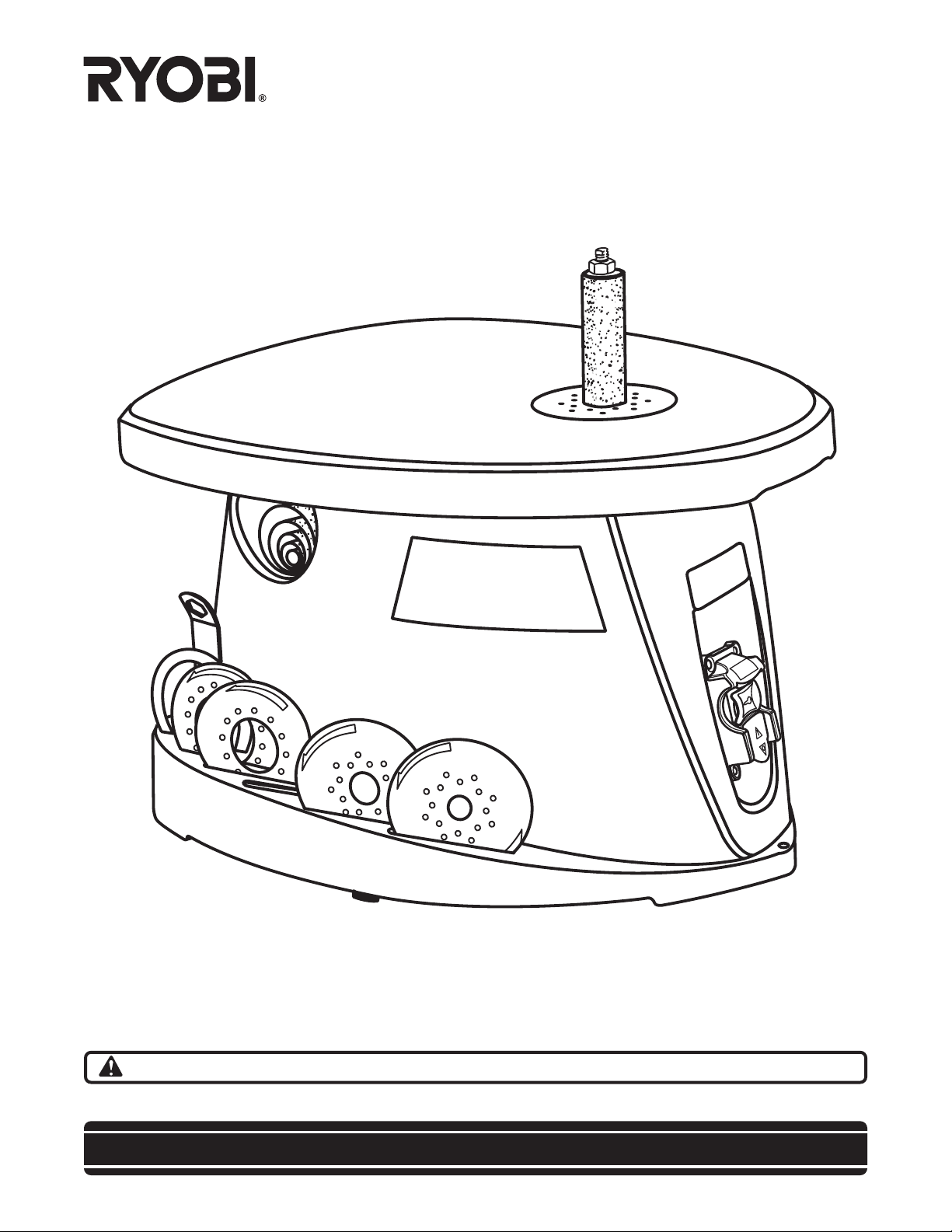

Oscillating Spindle Sander

OSS500 - Double Insulated

Your new oscillating spindle sander has been engineered and manufactured to Ryobi's high standard for dependability,

ease of operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual.

Thank you for buying a Ryobi oscillating spindle sander.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

■ Introduction ........................................................................................................................................................ 2

■ Rules for Safe Operation ................................................................................................................................3-5

■ Specifications .................................................................................................................................................... 6

■ Unpacking ..........................................................................................................................................................6

■ Features .........................................................................................................................................................7-8

■ Adjustments .................................................................................................................................................. 9-11

■ Operation ....................................................................................................................................................12-13

■ Maintenance ....................................................................................................................................................14

■ Parts, Ordering, and Service ........................................................................................................................... 16

INTRODUCTION

Your sander has many features for making sanding

operations more pleasant and enjoyable. Safety,

performance, and dependability have been given top

priority in the design of this tool making it easy to

maintain and operate.

WARNING:

Do not attempt to use this tool until you have read

thoroughly and understand completely the operator’s

manual. Pay close attention to the safety rules, including Dangers, Warnings, and Cautions. If you

use your sander properly and only for what it is

intended, you will enjoy years of safe, reliable service.

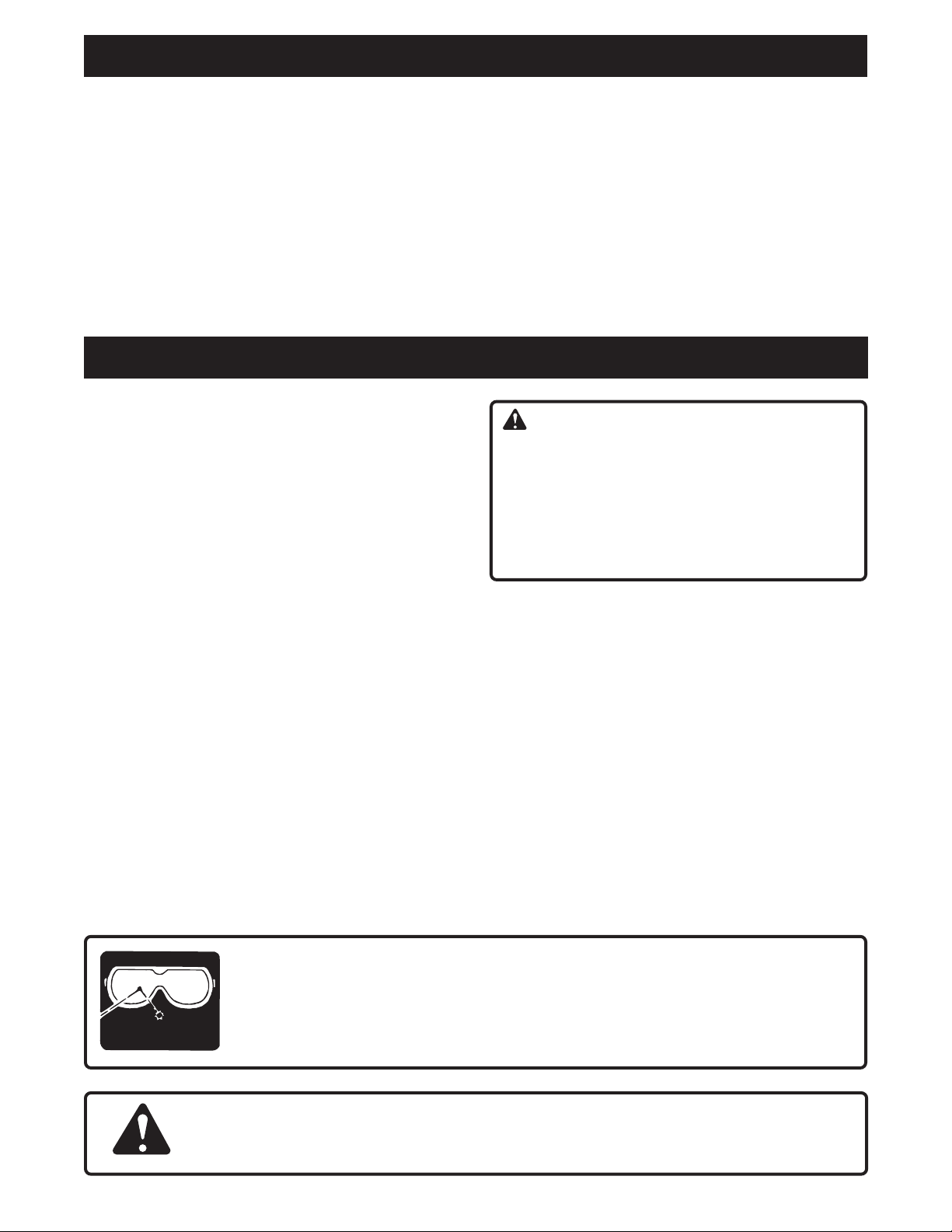

WEAR

YOUR

SAFETY

FORESIGHT IS BETTER

GLASSES

THAN NO SIGHT

Look for this symbol to point out important safety

precautions. It means attention!!! Your safety is involved.

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields. Always wear eye protection which is marked to comply with ANSI Z87.1.

2

Page 3

RULES FOR SAFE OPERATION

Safe operation of this power tool requires that you read

and understand this operator's manual and all labels

affixed to the tool. Safety is a combination of common

sense, staying alert, and knowing how your tool works.

READ ALL INSTRUCTIONS

■ KNOW YOUR POWER TOOL. Read the operator's

manual carefully. Learn the tool's applications and

limitations as well as the specific potential hazards

related to this tool.

■ KEEP THROAT PLATES IN PLACE and in working

order.

■ REMOVE WRENCH. Get in the habit of checking to

see that the wrench is removed from the spindle

before turning on the tool. Return the wrench, upper

spindle washer(s), and throat plates to the storage

area when not in use.

■ KEEP WORK AREA CLEAN. Cluttered work areas

and work benches invite accidents. DO NOT leave

tools or pieces of wood on the tool while it is in

operation.

■ DO NOT USE IN DANGEROUS ENVIRONMENTS.

Work in a well lit area. Do not use power tools near

gasoline or other flammable liquids. Do not expose

power tools to rain or damp or wet conditions.

■ KEEP BYSTANDERS AWAY. Keep bystanders,

children, and pets away while operating a power tool.

Distractions can cause you to lose control.

■ MAKE WORKSHOP CHILDPROOF with padlocks

and master switches or by removing starter keys.

■ DO NOT FORCE THE TOOL. It will do the job better

and more safely at the rate for which it was designed.

■ USE THE RIGHT TOOL FOR THE JOB. Do not force

the tool or attachment to do a job for which it was not

designed. Use it only the way it was intended.

■ USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. Use only a

cord heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. A

wire gage size (A.W.G.) of at least 16 is recommended for an extension cord 25 feet or less in

length. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

■ DO NOT ABUSE CORD. Never yank cord to disconnect it from receptacle. Keep cord from heat, oil, and

sharp edges.

■ INSPECT TOOL CORDS AND EXTENSION CORDS

PERIODICALLY and, if damaged, have them re-

paired by a qualified service technician at an authorized service center. Stay constantly aware of cord

location and keep it well away from the moving parts

of the tool.

■ USE OUTDOOR EXTENSION CORDS. When tool is

used outdoors, use only extension cords with approved ground connection that are intended for use

outdoors and so marked.

■ DRESS PROPERLY. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry

that can get caught and draw you into moving parts.

Nonslip footwear is recommended. Also wear protective hair covering to contain long hair.

■ ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses, they are NOT safety glasses.

■ WEAR A DUST MASK to keep from inhaling fine

particles.

■ PROTECT YOUR HEARING. Wear hearing protec-

tion during extended periods of operation.

■ INSPECT WORK. Remove all nails from lumber

before sanding.

■ DIRECTION OF FEED. Feed the workpiece into the

sanding sleeve against the direction of the sanding

sleeve rotation only.

■ DO NOT OVERREACH. Keep proper footing and

balance at all times.

■ MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow

instructions for lubricating and changing accessories.

■ DISCONNECT ALL TOOLS when not in use, before

servicing, or when changing attachments.

■ AVOID ACCIDENTAL STARTING. Be sure switch is

off when plugging in any tool.

■ USE RECOMMENDED ACCESSORIES. Using im-

proper accessories may risk injury.

■ MAINTAIN 1/16 in. (1.6 mm) OR LESS between

sanding drum and throat plate.

■ NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if moving parts are

unintentionally contacted.

■ CHECK DAMAGED PARTS. Check any previously

damaged parts for proper operation and performance.

Check alignment of moving parts, binding of moving

parts, breakage of parts, tool stability, mounting and

any other conditions that may affect its operation. A

damaged part must be properly repaired or replaced

by a qualified service technician at an authorized

service center to avoid risk of personal injury.

■ NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Do not leave tool until it

comes to a complete stop.

■ FIRMLY CLAMP OR BOLT the tool to a work-

bench or table at approximately hip height.

■ KEEP HANDS AWAY FROM SANDING AREA. Keep

hands away from the sanding sleeve. Do not reach

underneath work or around sanding sleeve while

spindle is rotating.

3

Page 4

RULES FOR SAFE OPERATION

■ DO NOT USE TOOL IF SWITCH DOES NOT TURN

IT ON AND OFF. Have defective switches replaced

by a qualified service technician at an authorized

service center.

■ KEEP TOOL DRY, CLEAN, AND FREE FROM OIL

AND GREASE. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline, petroleum-based products, or any solvents to clean tool.

■ REPLACEMENT PARTS. All repairs, whether elec-

trical or mechanical, should be made at your nearest

authorized service center.

■ WHEN SERVICING, use only identical Ryobi replacement parts. Use of any other parts may create

a hazard or cause product damage.

■ NEVER USE THIS TOOL IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor could

ignite fumes.

■ POLARIZED PLUGS. To reduce the risk of electric

shock, this tool has a polarized plug (one blade is

wider than the other). This plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to install the

proper outlet. Do not change the plug in any way.

■ NEVER USE THIS OR ANY POWER SANDER

FOR WET SANDING. Failure to comply can result

in electrical shock causing serious injury.

■ DO NOT OPERATE THIS TOOL WHILE UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

ANY MEDICATION.

■ STAY ALERT AND EXERCISE CONTROL. Watch

what you are doing and use common sense. Do not

operate tool when you are tired. Do not rush.

■ ALWAYS TURN OFF THE TOOL before disconnect-

ing it to avoid accidental starting when reconnecting

to power supply. NEVER leave the tool unattended

while connected to a power source.

■ SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to instruct other users. If you

loan someone this tool, loan them these instructions

also.

WARNING:

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

4

Page 5

RULES FOR SAFE OPERATION

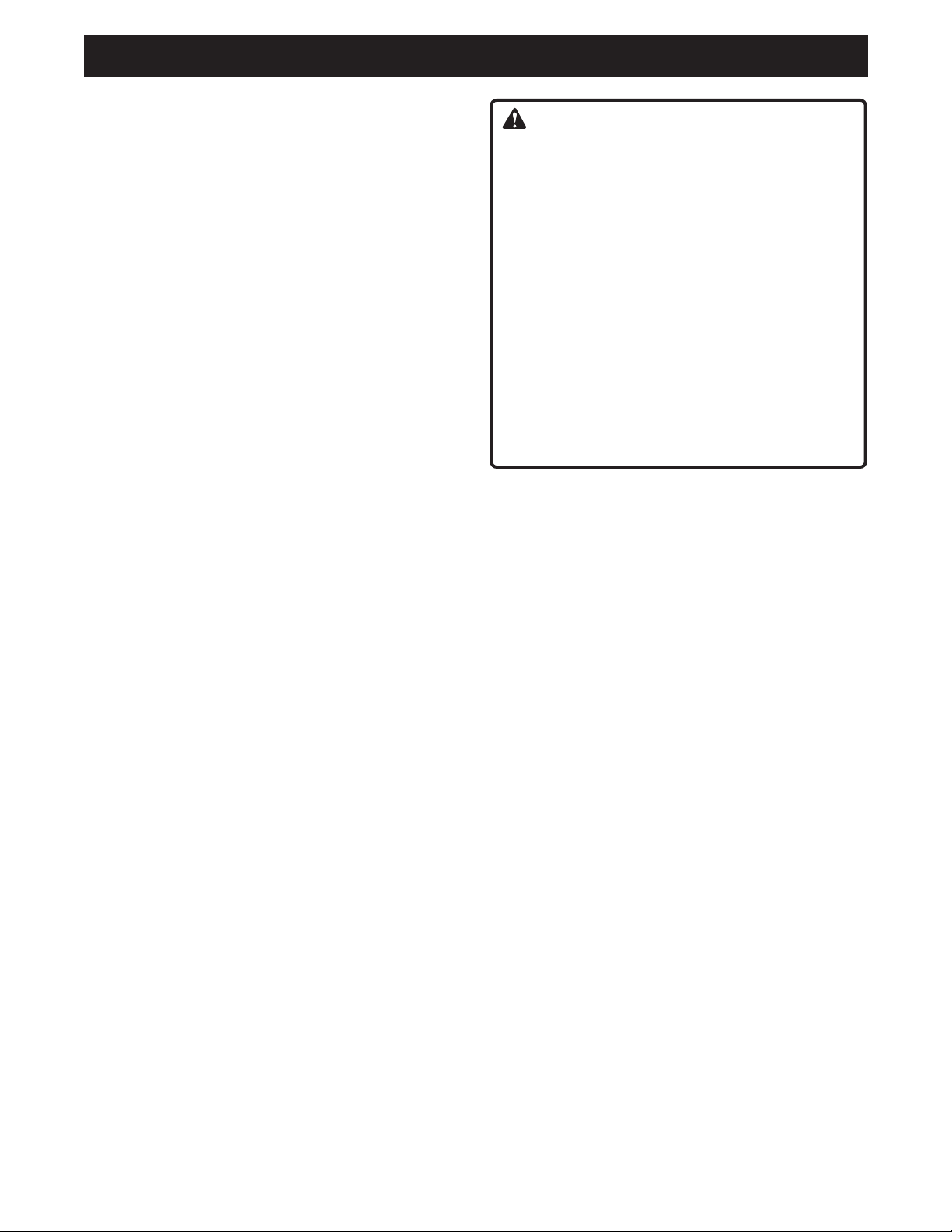

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL MEANING

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

WET CONDITIONS ALERT: Do not expose to rain or use in damp locations.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the

equipment.

SAVE THESE INSTRUCTIONS

DOUBLE INSULATION

Double insulation is a concept in safety in electric power

tools, which eliminates the need for the usual three-wire

grounded power cord. All exposed metal parts are

isolated from the internal metal motor components with

protecting insulation. Double insulated tools do not need

to be grounded.

WARNING:

The double insulated system is intended to protect

the user from shock resulting from a break in the

tool’s internal wiring. Observe all normal safety precautions to avoid electrical shock.

Important: Servicing of a tool with double insulation

requires extreme care and knowledge of the system and

should be performed only by a qualified service

technician. For service, we suggest you return the tool to

your nearest authorized service center for repair. Always

use original factory replacement parts when servicing.

ELECTRICAL CONNECTION

Your tool has a precision built electric motor. It should

be connected to a power supply that is 120 volts, 60

Hz, AC only (normal household current). Do not

operate this tool on direct current (DC). A substantial

voltage drop will cause a loss of power and the motor will

overheat. If your tool does not operate when plugged

into an outlet, double-check the power supply.

5

Page 6

SPECIFICATIONS

Oscillating Range 5/8 in. (15.9 mm)

Oscillations Per Minute 58 OPM

Spindle Size 1/2 in. (12.7 mm)

No Load Speed 2000 RPM

Input 120 Volts, 60 Hz, AC only, 3.5 Amps

Weight 49 lbs. (22.2 kg)

UNPACKING

INFORMATION

We have shipped the oscillating spindle sander

completely assembled and ready to use with a 1 in.

(25.4 mm) rubber spindle, 7/8 in. (22.2 mm) upper

spindle washer, 1 in. (26 mm) throat plate, and 80 grit

1 in. (25.4 mm) sanding sleeve installed on the spindle.

■ Remove the loose parts from the box. Make sure

that all items listed in the loose parts list are included.

■ Remove the packing materials from around the tool.

■ Lift the tool carefully from the box and place it on a

level work surface.

NOTE: The sander is heavy. Ask for assistance if

necessary.

■ Do not discard the packing material until you have

carefully inspected the tool, identified all loose parts,

and satisfactorily operated the tool.

4

5

■ If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

■ Inspect all parts carefully to make sure no breakage

or damage occurred during shipping.

WARNING:

If any parts are missing do not operate the tool until

the missing parts are replaced. Failure to do so

could result in serious personal injury.

LOOSE PARTS LIST

1. Sanding sleeves, 50, 80, 150 grit (17)

2. Rubber spindles (4)

3. Throat plates (5)

4. Upper spindle washers (2)

5. Wrench

3

1

2

6

Page 7

FEATURES

Before using the oscillating spindle sander, familiarize

yourself with all operating features and safety

requirements. However, do not let familiarity with the tool

make you careless.

WARNING:

Exercise caution when using the oscillating spindle

sander. Careless actions, for even a fraction of a

second, can result in serious personal injury.

SWITCH

The ON/OFF switch has a built-in locking feature that

requires you to insert a key before turning on the sander.

Pushing the switch to the OFF position and removing the

key secures the sander against unintentional use. This

feature is intended to prevent unauthorized and possible

hazardous use by children and others.

WARNING:

Always lock the switch OFF when the sander is not

in use. Remove the key and keep it in a safe place.

In the event of a power failure, turn the switch OFF

and remove the key. This action will prevent the

sander from accidentally starting when power returns.

MOTOR

The sander has a 3.5 amp motor with sufficient power to

handle tough sanding jobs. It develops a no load speed

of 2,000 RPM and 58 OPM.

OSCILLATING MOTION

As the name implies, the most unique feature of this

sander is the fact that it oscillates. This means that the

spindle rises and falls as it rotates. The oscillating range

for the sander is 5/8 in. (15.9 mm).

TABLE SIZE

The sanding table provides ample sanding space for

most workpieces. The table top is 19-1/4 in. (489 mm)

long x 15-3/4 in. (400 mm) wide.

THROAT PLATES

Six throat plates are included with the sander. The throat

plate provides a stable surface around the sanding

sleeve and prevents objects from falling through the

throat and damaging the spindle.

DUST COLLECTION

A standard 2-1/4 in. (57.2 mm) dust exhaust port is

provided to help keep dust to a minimum. It is located

under the table top on the back of the sander. The end

of a standard shop vacuum hose fits tightly inside the

dust exhaust port.

THROAT PLATE/WRENCH STORAGE AREA

A throat plate and wrench storage area is located on the

left side of the cabinet.

SANDING SLEEVE/RUBBER SPINDLE

STORAGE AREA

A sanding sleeve and rubber spindle storage area is

located on the right side of the cabinet. Store unused

sanding sleeves and rubber spindles on their designated

pins. Proper storage of sanding sleeves and rubber

spindles helps protect them from being damaged and

getting lost.

EXTRA SANDING SLEEVE/WASHER

STORAGE AREA

Store extra sanding sleeves and upper spindle washers

under the table in either of the cavities.

SANDING CAPACITIES

The sander accepts sanding sleeves that are 1/2 in.

(12.7 mm) through 3 in. (76.2 mm) in diameter and

4-1/2 in. (114.3 mm) in height.

NOTE: Sanding sleeves are 4-1/2 in. (114.3 mm) tall;

however, you can only sand material up to 3-11/16 in.

(93.7 mm) thick.

The 1/2 in. (12.7 mm) sanding sleeve fits directly on the

1/2 in. (12.7 mm) spindle and requires no rubber spindle.

It is secured in place with a washer and hex nut on top

of the spindle. All other sanding sleeves require a rubber

spindle to secure them in place. These rubber spindles

fit on the spindle and require a throat plate and sanding

sleeve. A washer and hex nut thread on top of the spindle

to hold everything in place.

7

Page 8

FEATURES

TABLE TOP

EXTRA SANDING

SLEEVE/WASHER

STORAGE AREA

WRENCH

STORAGE

AREA

THROAT PLATE

STORAGE AREA

HEX NUT

UPPER

SPINDLE

WASHER

SPINDLE

SANDING SLEEVE

(1 in. (25.4 mm))

THROAT

PLATE

SWITCH

EXTRA SANDING

SLEEVE/WASHER

STORAGE AREA

SANDING SLEEVE/

RUBBER SPINDLE

STORAGE AREA

DUST

EXHAUST

PORT

Fig. 1

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a hazardous condition leading to possible serious

personal injury.

8

Page 9

ADJUSTMENTS

WARNING:

The sander should never be connected to a power

supply when you are assembling parts, making adjustments, cleaning, or when not in use. Disconnecting the tool will prevent accidental starting that could

cause serious personal injury.

SELECTING SANDING SLEEVES

Selecting the correct size diameter, correct size grit, and

correct type sanding sleeve is an extremely important

step in achieving a high quality sanded finish. Aluminum

oxide, silicon carbide, and other synthetic abrasives are

best for power sanding. Natural abrasives, such as flint

and garnet are too soft for power sanding.

In general, when sanding, coarse grit removes the most

material and fine grit produces the best finish. The

condition of the surface to be sanded determines which

grit will do the best job. If the surface is rough, start with

a coarse grit and sand until the surface is uniform. Then

use medium grit to remove scratches left by the coarser

grit. Finally, use finer grit for finishing the surface. Always

continue sanding with each grit until the surface is

uniform.

NOTE: Do not use the sander without a sanding sleeve.

Doing so will damage the rubber spindle.

Select and install the desired sanding sleeve for your

particular application. As mentioned previously, you can

use sanding sleeves from 1/2 in. (12.7 mm) to 3 in.

(76.2 mm) in diameter with this sander. Choose one that

is close in size to the workpiece you are sanding.

SELECTING THROAT PLATES/UPPER

SPINDLE WASHERS

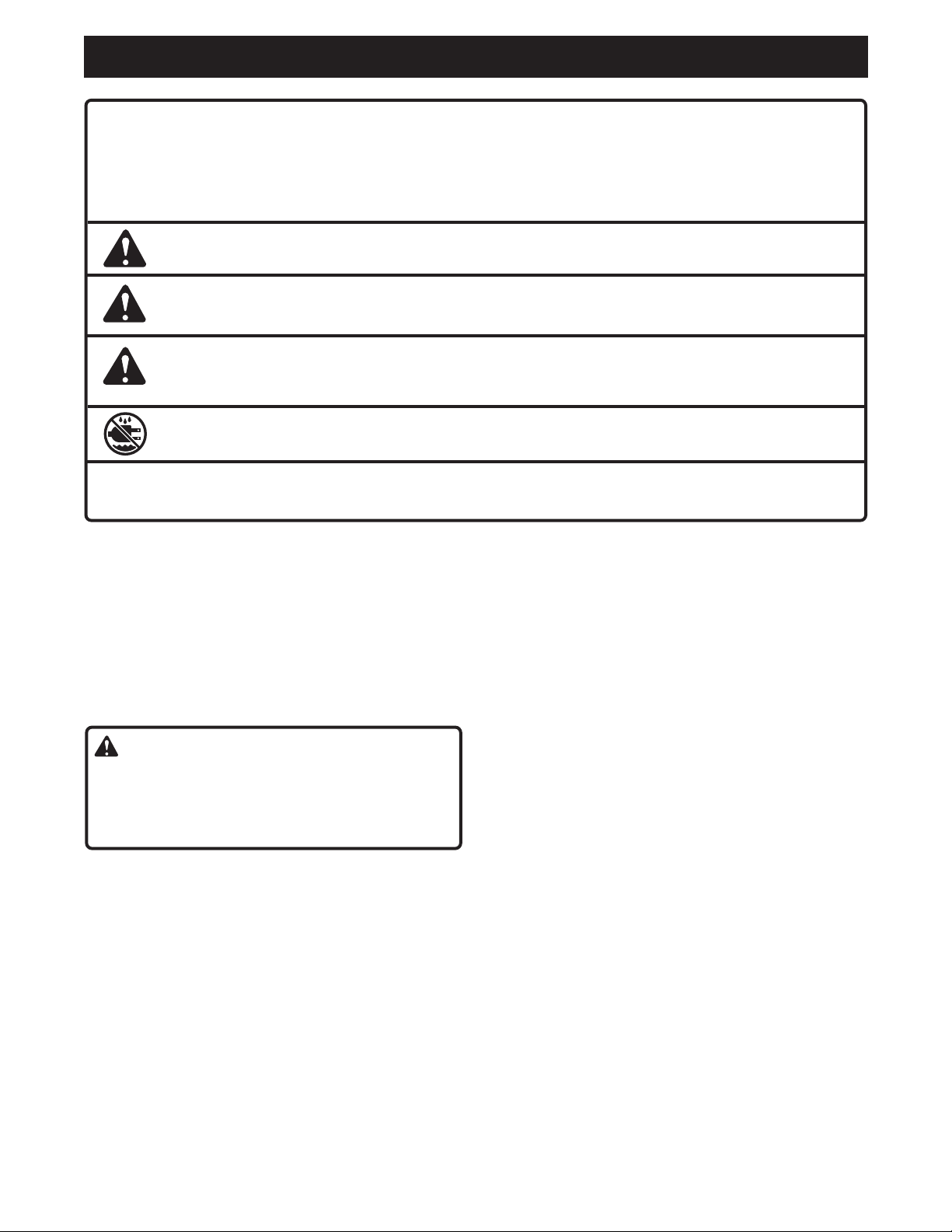

See Figure 2.

Six throat plates are provided with this sander. Each

throat plate indicates the correct sanding sleeve/rubber

spindle size to use.

The chart below identifies the relationship between

sanding sleeves/rubber spindles, throat plates, and upper

spindle washers.

WARNING:

Failure to use the correct size throat plate with its

matching sanding sleeve could result in fingers being

pinched or the workpiece being pulled down between

the throat plate and the sanding sleeve.

SANDING

SLEEVE

THROAT

PLATE

THROAT

PLATE

OPENING

Sanding Sleeve/Rubber Spindle Throat Plate Upper Spindle Washer

1/2 in. (12.7 mm) .5” (13 mm) 5/8 in. (15.9 mm)

3/4 in. (19.1 mm) .75” (19 mm) 7/8 in. (22.2 mm)

1 in. (25.4 mm) 1” (26 mm) 7/8 in. (22.2 mm)

1-1/2 in. (38.1 mm) 1.5” (38 mm) 7/8 in. (22.2 mm)

2 in. (50.8 mm) 2” (51 mm) 1-13/16 in. (46 mm)

3 in. (76.2 mm) 3” (76 mm) 1-13/16 in. (46 mm)

Fig. 2

9

Page 10

ADJUSTMENTS

REMOVING SANDING SLEEVES

See Figure 3.

Follow these directions to remove sanding sleeves.

■ Unplug the sander.

WARNING:

Failure to unplug the tool could result in accidental

starting causing serious injury.

■ Grasp and hold the sanding sleeve on the spindle.

■ Loosen the hex nut using the wrench provided.

NOTE: If the hex nut is too tight and the spindle shaft

spins inside the sanding sleeve, grasp the flats on

top of the spindle shaft with a 1/4 in. wrench (not

provided) and loosen the hex nut.

■ Remove the hex nut, upper spindle washer, sanding

sleeve, rubber spindle, and throat plate.

NOTE: It is recommended that you clean dust

accumulations from the throat plate, throat plate nest,

and under the lower spindle washer after each use.

Remove the lower spindle washer and clean dust

accumulations.

INSTALLING SANDING SLEEVES

(All except 1/2 in. (12.7 mm))

See Figure 4.

Follow these directions to install sanding sleeves.

■ Unplug the sander.

SANDING

SLEEVE

THROAT

PLATE

HEX NUT

UPPER

SPINDLE

WASHER

RUBBER

SPINDLE

LOWER

SPINDLE

WASHER

WRENCH

TO LOOSEN

TO TIGHTEN

Fig. 3

THROAT

PLATE

SANDING

SLEEVE

WRENCH

SPINDLE

WARNING:

Failure to unplug the tool could result in accidental

starting causing serious injury.

■ Place the lower spindle washer over the spindle, fin

side down.

NOTE: Always install the fin side of the washer

down. The fins help push dust through the dust

exhaust port opening, preventing buildup of dust.

Dust in this area may cause the oscillating motion to

stop. Always use the lower spindle washer with all

sanding sleeves.

■ Select and install the correct throat plate. Refer to

SELECTING THROAT PLATES/UPPER SPINDLE

WASHERS earlier in this manual.

■ Select and install the correct rubber spindle.

■ Install the appropriate sanding sleeve on the rubber

spindle.

NOTE: If the sanding sleeve becomes difficult to

remove or install, apply talcum powder on the rubber

spindle or inside the sanding sleeve before installing

the sanding sleeve on the rubber spindle.

Fig. 4

■ Install the upper spindle washer and hex nut.

NOTE: Use the 7/8 in. (22.2 mm) washer for the 3/4

in. (19.1 mm), 1 in. (25.4 mm), and 1-1/2 in.

(38.1 mm) rubber spindles. Use the 1-13/16 in.

(46 mm) washer for the 2 in. (50.8 mm) and 3 in.

(76.2 mm) rubber spindles.

■ Grasp and hold the sanding sleeve on the spindle.

■ Tighten the hex nut using the wrench provided.

NOTE: Tighten the hex nut only enough to expand

the rubber spindle against the inner wall of the

sanding sleeve. Do not overtighten.

■ Return the wrench to the storage area.

10

Page 11

ADJUSTMENTS

INSTALLING 1/2 INCH (12.7 mm) SANDING

SLEEVES

See Figure 5.

Follow these directions to install 1/2 inch (12.7 mm)

sanding sleeves.

■ Unplug the sander.

WARNING:

Failure to unplug the tool could result in accidental

starting causing serious injury.

■ Place the lower spindle washer over the spindle, fin

side down.

NOTE: Always install the fin side of the washer

down. The fins help push dust through the dust

exhaust port opening, preventing buildup of dust.

Dust in this area may cause the oscillating motion to

stop. Always use the lower spindle washer with all

sanding sleeves.

■ Install the throat plate with the .5 in. (13 mm) opening.

■ Install the 1/2 in. (12.7 mm) sanding sleeve on the

spindle shaft.

UPPER

SPINDLE

WASHER

THROAT

PLATE

LOWER

SPINDLE

WASHER

HEX NUT

SANDING

SLEEVE

WRENCH

SPINDLE

Fig. 5

NOTE: Mount the sanding sleeve directly onto the

spindle shaft. A rubber spindle is not required.

■ Install the 5/8 in. (15.9 mm) upper spindle washer

and hex nut.

■ Grasp and hold the sanding sleeve on the spindle.

■ Tighten the hex nut using the wrench provided.

NOTE: Tighten the hex nut securely. Do not

overtighten.

■ Return the wrench to the storage area.

11

Page 12

OPERATION

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating this tool. Failure to do

so could result in dust, shavings, or loose particles

being thrown into your eyes, resulting in possible

serious injury.

MOUNTING THE SANDER TO A WORK

SURFACE

See Figures 6 and 7.

Follow these directions to mount the sander to a work

surface.

■ Place the sander on a sturdy work surface, e.g.,

work stand, workbench, counter top.

■ Mark the holes in the sander base with a pencil.

■ Remove the sander from the work surface.

■ Drill three holes through the work surface.

■ Place the sander back on the work surface, aligning

the holes in the base with the holes in the work

surface.

NOTE: If the sander does not appear to be stable,

make sure the rubber stabilizers are intact on the

sander bottom.

■ Insert three bolts (not included, 1/4 in. (6.4 mm)

machine bolts recommended) and tighten securely

with lock washers and hex nuts (not included).

■ Check the work surface carefully after you mount

the sander to make sure that no movement can

occur during use. If you notice any tipping, sliding,

or walking, secure the work surface to the floor

before operating the tool.

NOTE: If you plan to transport the sander to different

locations, we recommend that you attach it

permanently to a mounting board that you can easily

clamp to a work surface.

Fig. 6

Fig. 7

12

Page 13

OPERATION

OPERATING THE SANDER

See Figures 8 and 9.

Follow these directions to operate the sander.

■ Insert the switch key.

■ Turn on the sander by lifting the switch.

■ Let the motor build to its full speed.

■ Feed the workpiece gradually against the sanding

sleeve from right to left.

WARNING:

Do not let the workpiece contact the sanding sleeve

before you turn on the sander and allow it to develop

full speed.

WARNING:

When you feed the workpiece from right to left, the

rotation of the sanding sleeve sands against the

workpiece. If you feed the workpiece in the opposite

direction, the rotation forces of the spinning sanding

sleeve tends to bounce the workpiece away from the

sanding sleeve. This action could cause you to lose

control of the workpiece.

SWITCH KEY

SWITCH

Fig. 8

COLLECTING DUST

See Figure 10.

A dust exhaust port is provided to help keep dust to a

minimum. It is located under the table top on the back of

the sander. The end of a standard shop vacuum hose fits

tightly inside the dust exhaust port.

Even with a dust collection system, it is important to

periodically clean sanding dust from the throat plate

area. After extended use, sanding dust builds up under

the throat plate and forces its way into the throat plate

nest. Sanding dust build up in this area may cause the

throat plate surface to rise above the table surface.

TRANSPORTING THE SANDER

In a portable application, you can lift and carry the

sander by the table top. When carrying the sander, be

careful not to dislodge the throat plates, wrench, and

upper spindle washers from their respective storage

areas. Also, be careful not to lose any parts when

transporting.

Fig. 9

13

Fig. 10

Page 14

MAINTENANCE

WARNING:

When servicing use only identical Ryobi replacement parts. Use of any other parts may create a hazard or cause

product damage.

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc. come in

contact with plastic parts. They contain chemicals

that can damage, weaken, or destroy plastic.

Electric tools used on fiberglass material, wallboard,

spackling compounds, or plaster are subject to

accelerated wear and possible premature failure, as the

fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommend that this tool be used for extended

work on these types of materials. If, however, you do

work with any of these materials, it is extremely important

that you clean the tool frequently by blowing it with an air

jet.

NOTE: Only use this sander for sanding wood and

plastics.

LUBRICATION

All the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further

lubrication is required.

WARNING:

Always wear safety goggles or safety glasses with

side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a dust

mask.

14

Page 15

NOTES

15

Page 16

OPERATOR'S MANUAL

Oscillating Spindle Sander

OSS500 - Double Insulated

EXTENSION CORD CAUTION

When using a power tool at a considerable distance from a

power source, be sure to use an extension cord that has the

capacity to handle the current the tool will draw. An undersized cord will cause a drop in line voltage, resulting in overheating and loss of power. Use the chart to determine the minimum wire size required in an extension cord. Only round jacketed cords should be used.

When working with a tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the letters

"WA" on the cord's jacket.

Before using any extension cord, inspect it for loose or exposed wires and cut or worn insulation.

**Ampere rating

(on tool faceplate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

CAUTION: Keep the extension cord clear of the working

area. Position the cord so that it will not get caught on

lumber, tools or other obstructions while you are working

with a power tool.

**Used on 12 gauge - 20 amp circuit.

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or

service, simply contact your nearest Ryobi Authorized Service Center. Be sure to

provide all pertinent facts when you call or visit. Please call 1-800-525-2579 for your

nearest Ryobi Authorized Service Center. You can also check our Web site at

www.ryobitools.com for a complete list of Authorized Service Centers.

• MODEL NO. AND SERIAL NO.

The model number and serial number of this product are found on the label attached to the

rear of the cabinet. Please record the serial number in the space provided below.

• HOW TO ORDER REPAIR PARTS

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFORMATION:

• MODEL NUMBER

• SERIAL NUMBER

RYOBI TECHNOLOGIES INC.

1428 Pearman Dairy Road Anderson, SC 29625

Post Office Box 1207 Anderson, SC 29622

983000-146

9-02

OSS500

www.ryobitools.com

Phone 1-800-525-2579

Loading...

Loading...