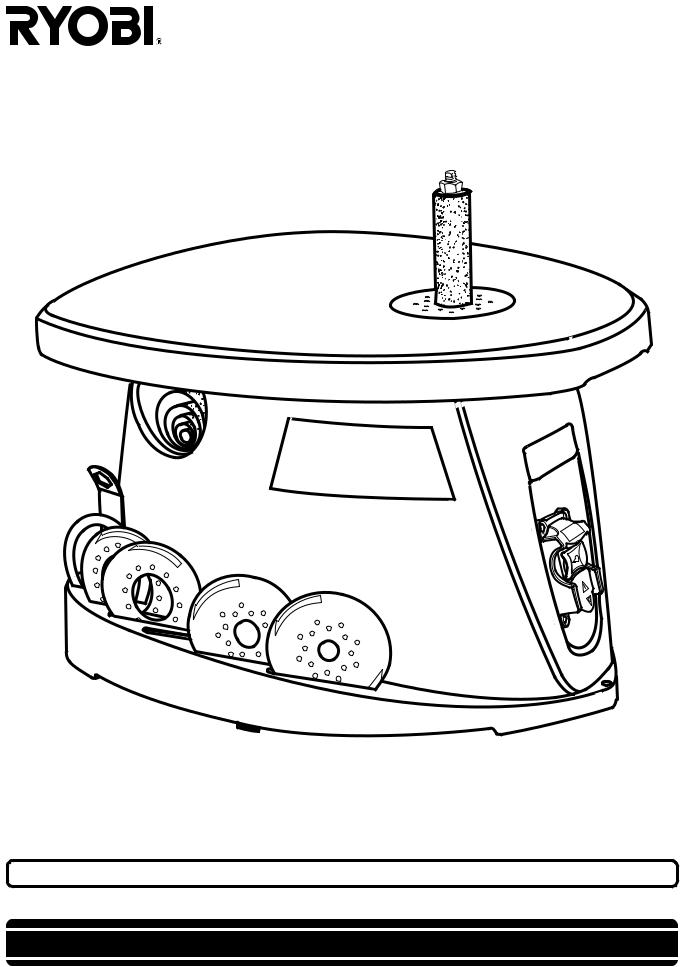

Ryobi OSS500 User Manual

OPERATOR'S MANUAL

Oscillating Spindle Sander

OSS500 - Double Insulated

Your new oscillating spindle sander has been engineered and manufactured to Ryobi's high standard for dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual. Thank you for buying a Ryobi oscillating spindle sander.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual. Thank you for buying a Ryobi oscillating spindle sander.

SAVE THIS MANUAL FOR FUTURE REFERENCE

|

|

TABLE OF CONTENTS |

■ |

Introduction ........................................................................................................................................................ |

2 |

■ Rules for Safe Operation ................................................................................................................................ |

3-5 |

|

■ |

Specifications .................................................................................................................................................... |

6 |

■ |

Unpacking .......................................................................................................................................................... |

6 |

■ |

Features ......................................................................................................................................................... |

7-8 |

■ |

Adjustments .................................................................................................................................................. |

9-11 |

■ |

Operation .................................................................................................................................................... |

12-13 |

■ |

Maintenance .................................................................................................................................................... |

14 |

■ Parts, Ordering, and Service ........................................................................................................................... |

16 |

|

|

|

INTRODUCTION |

Your sander has many features for making sanding operations more pleasant and enjoyable. Safety, performance, and dependability have been given top priority in the design of this tool making it easy to maintain and operate.

WARNING:

WARNING:

Do not attempt to use this tool until you have read thoroughly and understand completely the operator’s manual. Pay close attention to the safety rules, including Dangers, Warnings, and Cautions. If you use your sander properly and only for what it is intended, you will enjoy years of safe, reliable service.

WEAR YOUR

SAFETY GLASSES

SAFETY GLASSES

FORESIGHT IS BETTER

THAN NO SIGHT

The operation of any power tool can result in foreign objects being thrown into your eyes, which can result in severe eye damage. Before beginning tool operation, always wear safety goggles or safety glasses with side shields and a full face shield when needed. We recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields. Always wear eye protection which is marked to comply with ANSI Z87.1.

Look for this symbol to point out important safety precautions. It means attention!!! Your safety is involved.

2

RULES FOR SAFE OPERATION

Safe operation of this power tool requires that you read and understand this operator's manual and all labels affixed to the tool. Safety is a combination of common sense, staying alert, and knowing how your tool works.

READ ALL INSTRUCTIONS

■KNOW YOUR POWER TOOL. Read the operator's manual carefully. Learn the tool's applications and limitations as well as the specific potential hazards related to this tool.

■KEEP THROAT PLATES IN PLACE and in working order.

■REMOVE WRENCH. Get in the habit of checking to see that the wrench is removed from the spindle before turning on the tool. Return the wrench, upper spindle washer(s), and throat plates to the storage area when not in use.

■KEEP WORK AREA CLEAN. Cluttered work areas and work benches invite accidents. DO NOT leave tools or pieces of wood on the tool while it is in operation.

■DO NOT USE IN DANGEROUS ENVIRONMENTS.

Work in a well lit area. Do not use power tools near gasoline or other flammable liquids. Do not expose power tools to rain or damp or wet conditions.

■KEEP BYSTANDERS AWAY. Keep bystanders, children, and pets away while operating a power tool. Distractions can cause you to lose control.

■MAKE WORKSHOP CHILDPROOF with padlocks and master switches or by removing starter keys.

■DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which it was designed.

■USE THE RIGHT TOOL FOR THE JOB. Do not force the tool or attachment to do a job for which it was not designed. Use it only the way it was intended.

■USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. Use only a cord heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire gage size (A.W.G.) of at least 16 is recommended for an extension cord 25 feet or less in length. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

■DO NOT ABUSE CORD. Never yank cord to disconnect it from receptacle. Keep cord from heat, oil, and sharp edges.

■INSPECT TOOL CORDS AND EXTENSION CORDS PERIODICALLY and, if damaged, have them repaired by a qualified service technician at an authorized service center. Stay constantly aware of cord location and keep it well away from the moving parts of the tool.

■USE OUTDOOR EXTENSION CORDS. When tool is used outdoors, use only extension cords with approved ground connection that are intended for use outdoors and so marked.

■DRESS PROPERLY. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that can get caught and draw you into moving parts. Nonslip footwear is recommended. Also wear protective hair covering to contain long hair.

■ALWAYS WEAR SAFETY GLASSES WITH SIDE SHIELDS. Everyday eyeglasses have only impactresistant lenses, they are NOT safety glasses.

■WEAR A DUST MASK to keep from inhaling fine particles.

■PROTECT YOUR HEARING. Wear hearing protection during extended periods of operation.

■INSPECT WORK. Remove all nails from lumber before sanding.

■DIRECTION OF FEED. Feed the workpiece into the sanding sleeve against the direction of the sanding sleeve rotation only.

■DO NOT OVERREACH. Keep proper footing and balance at all times.

■MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing accessories.

■DISCONNECT ALL TOOLS when not in use, before servicing, or when changing attachments.

■AVOID ACCIDENTAL STARTING. Be sure switch is off when plugging in any tool.

■USE RECOMMENDED ACCESSORIES. Using improper accessories may risk injury.

■MAINTAIN 1/16 in. (1.6 mm) OR LESS between sanding drum and throat plate.

■NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if moving parts are unintentionally contacted.

■CHECK DAMAGED PARTS. Check any previously damaged parts for proper operation and performance. Check alignment of moving parts, binding of moving parts, breakage of parts, tool stability, mounting and any other conditions that may affect its operation. A damaged part must be properly repaired or replaced by a qualified service technician at an authorized service center to avoid risk of personal injury.

■NEVER LEAVE TOOL RUNNING UNATTENDED. TURN THE POWER OFF. Do not leave tool until it comes to a complete stop.

■FIRMLY CLAMP OR BOLT the tool to a workbench or table at approximately hip height.

■KEEP HANDS AWAY FROM SANDING AREA. Keep hands away from the sanding sleeve. Do not reach underneath work or around sanding sleeve while spindle is rotating.

3

RULES FOR SAFE OPERATION

■DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON AND OFF. Have defective switches replaced by a qualified service technician at an authorized service center.

■KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND GREASE. Always use a clean cloth when cleaning. Never use brake fluids, gasoline, petro- leum-based products, or any solvents to clean tool.

■REPLACEMENT PARTS. All repairs, whether electrical or mechanical, should be made at your nearest authorized service center.

■WHEN SERVICING, use only identical Ryobi replacement parts. Use of any other parts may create a hazard or cause product damage.

■NEVER USE THIS TOOL IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor could ignite fumes.

■POLARIZED PLUGS. To reduce the risk of electric shock, this tool has a polarized plug (one blade is wider than the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not change the plug in any way.

■NEVER USE THIS OR ANY POWER SANDER FOR WET SANDING. Failure to comply can result in electrical shock causing serious injury.

■DO NOT OPERATE THIS TOOL WHILE UNDER THE INFLUENCE OF DRUGS, ALCOHOL, OR ANY MEDICATION.

■STAY ALERT AND EXERCISE CONTROL. Watch what you are doing and use common sense. Do not operate tool when you are tired. Do not rush.

■ALWAYS TURN OFF THE TOOL before disconnecting it to avoid accidental starting when reconnecting to power supply. NEVER leave the tool unattended while connected to a power source.

■SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to instruct other users. If you loan someone this tool, loan them these instructions also.

WARNING:

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

4

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the explanations with them, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WET CONDITIONS ALERT: Do not expose to rain or use in damp locations.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

SAVE THESE INSTRUCTIONS

DOUBLE INSULATION

Double insulation is a concept in safety in electric power tools, which eliminates the need for the usual three-wire grounded power cord. All exposed metal parts are isolated from the internal metal motor components with protecting insulation. Double insulated tools do not need to be grounded.

WARNING:

WARNING:

The double insulated system is intended to protect the user from shock resulting from a break in the tool’s internal wiring. Observe all normal safety precautions to avoid electrical shock.

Important: Servicing of a tool with double insulation requires extreme care and knowledge of the system and should be performed only by a qualified service technician. For service, we suggest you return the tool to your nearest authorized service center for repair. Always use original factory replacement parts when servicing.

ELECTRICAL CONNECTION

Your tool has a precision built electric motor. It should be connected to a power supply that is 120 volts, 60 Hz, AC only (normal household current). Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. If your tool does not operate when plugged into an outlet, double-check the power supply.

5

Loading...

Loading...