Ryobi Drill Press User Manual

Operator´s manual

371K 375K

Please read these instructions carefully and make sure

you understand them before using the machine.

English

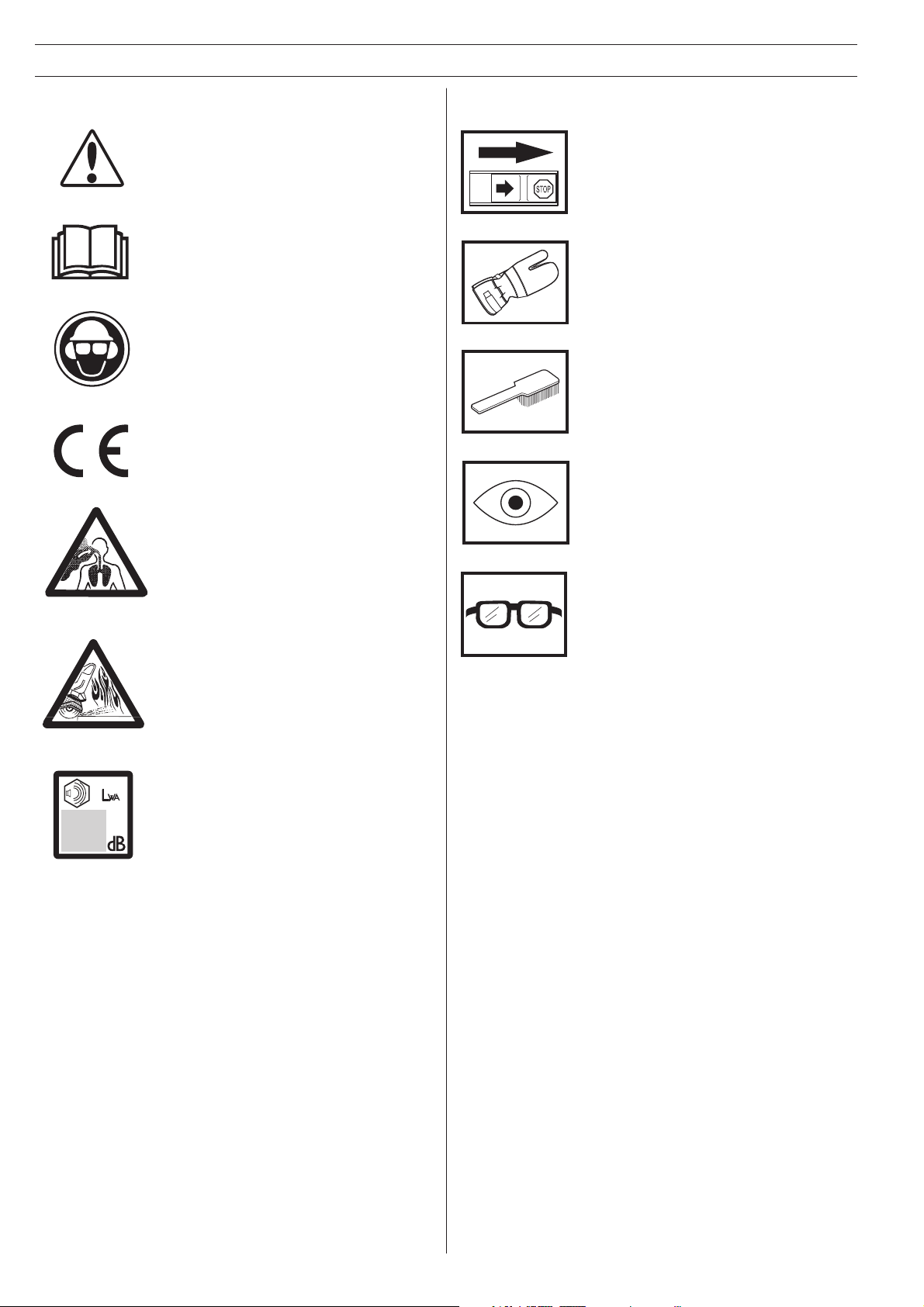

SYMBOL EXPLANATION

Symbols on the power cutter:

WARNING! The power cutter can be

dangerous! Careless and incorrect use can

result in serious or fatal injury to the

operator or others.

Please read the instructions carefully and

make sure you understand them before

using the power cutter.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective glasses or visor

This product is in accordance with

applicable CE directives.

Warning

Cutting creates a lots of dust which can

cause inhalation damages. Use appropriate

dust mask or respirator protection. Avoid

breathing petrol fumes and exhaust gases.

Provide for good ventilation.

Symbols in the Operator's Manual:

Switch off the engine by moving the stop

switch to the STOP position before carrying

out any checks or maintenance.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective glasses or a visor must be worn.

Warning

Sparks from the cutting blade can cause

fire in combustible materials such as: petrol

(gas), wood, dry grass etc.

Noise emission to the environment

according to the European Community’s

Directive. The machine’s emission is

specified in chapter Technical data and on

label.

2 – English

CONTENTS

Before using your new Power cutter

• Read the Operator’s Manual carefully.

• Check the assembly and adjustment of the cutting blade, see

chapter ”

• Start the engine and check the carburettor settings. See

chapter ”

correctly the cutting blade should not rotate when idling.

Setting the idling speed is described in the Operator’s

Manual. Adjust the speed according to these instructions. Do

not use the power cutter if the idling speed is not correctly

adjusted!

• Let your Husqvarna dealer check the power cutter and carry

out essential adjustments and repairs.

!

!

Assembly

Maintenance

WARNING!

Use of products which cut, grind, drill, sand or

shape material can generate dust and vapors

which may contain harmful chemicals. Know

the nature of the material being worked on

and wear appropriate dust mask or respirator

protection.

”.

”, section ”

WARNING!

Under no circumstances should you modify

the original design of the power cutter without

approval from the manufacturer. Always use

genuine spare parts. Unauthorized

modifications or accessories may lead to

serious injury or death.

Carburetor

”. When adjusted

List of Contents

Symbol explanation ..................................................... 2

Safety instructions

Personal protective equipment ....................................... 4

The power cutter’s safety equipment....................... 4

Control, maintenance and service of the machine‘s safety

equipment ............................................................................ 5

General safety instructions .............................................. 6

Transport and storage ......................................................... 6

Fuel safety ........................................................................... 7

General working instructions........................................... 7

Cutting ................................................................................. 7

Kickback .............................................................................. 8

Care and storage ................................................................. 9

Cutting blades .................................................................... 10

Abrasive discs ................................................................... 10

Cutting blades.................................................................... 11

Diamond blades................................................................. 11

What is what?

What is what on a power cutter? ....................................... 12

Assembly

Fitting the cutting head ...................................................... 13

Checking the drive shaft and flanges ................................ 13

Fitting the cutting blade ..................................................... 13

Fuel handling

Fuel mixture ....................................................................... 14

Fuelling .............................................................................. 14

Start and stop

Start and stop .................................................................... 15

Maintenance

Adjusting the drive belt ...................................................... 16

Changing the drive belt ..................................................... 16

Carburettor ........................................................................ 17

Fuel filter ............................................................................ 18

Air filter .............................................................................. 18

Starter ................................................................................ 19

Spark plug ......................................................................... 20

Muffler ............................................................................... 20

Cooling system .................................................................. 20

Daily maintenance ............................................................. 21

Weekly maintenance ......................................................... 21

Monthly maintenance ........................................................ 21

Technical Data

371K .................................................................................. 22

375K .................................................................................. 22

English – 3

SAFETY INSTRUCTIONS

WARNING! Incorrect or careless use of a

!

power cutter can turn it into a dangerous tool

that can cause serious or even fatal injury. It

is extremely important that you read and

understand this manual.

PERSONAL PROTECTIVE EQUIPMENT

WARNING! When using a power cutter,

!

• PROTECTIVE HELMET

• EAR PROTECTION

• PROTECTIVE GLASSES

OR FULL FACE

PROTECTION

• BREATHING MASK

approved protective equipment must be used.

Personal protective equipment does not

eliminate the risk of accidents, however, it can

reduce the effects of an injury in the event of

an accident. Ask your dealer for help when

choosing protective equipment.

THE POWER CUTTER’S SAFETY

EQUIPMENT

This section describes the power cutter’s safety equipment, its

function and how checks and maintenance are carried out to

ensure that it operates correctly. (See the chapter

to locate where this equipment is positioned on your

what“

power cutter.)

WARNING! Never use a power cutter with

!

defective safety equipment. Follow the

control, maintenance and service instructions

described in this manual.

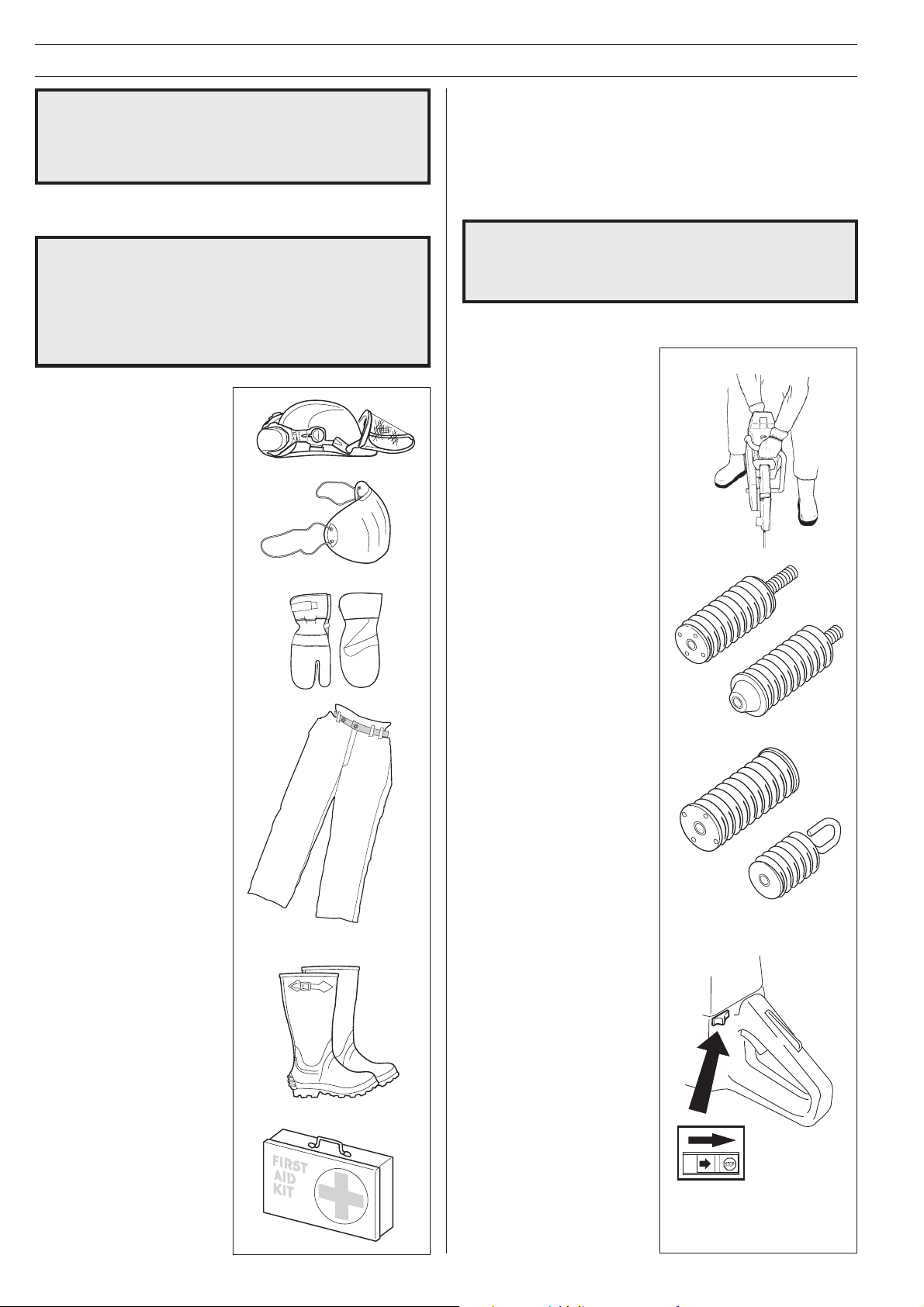

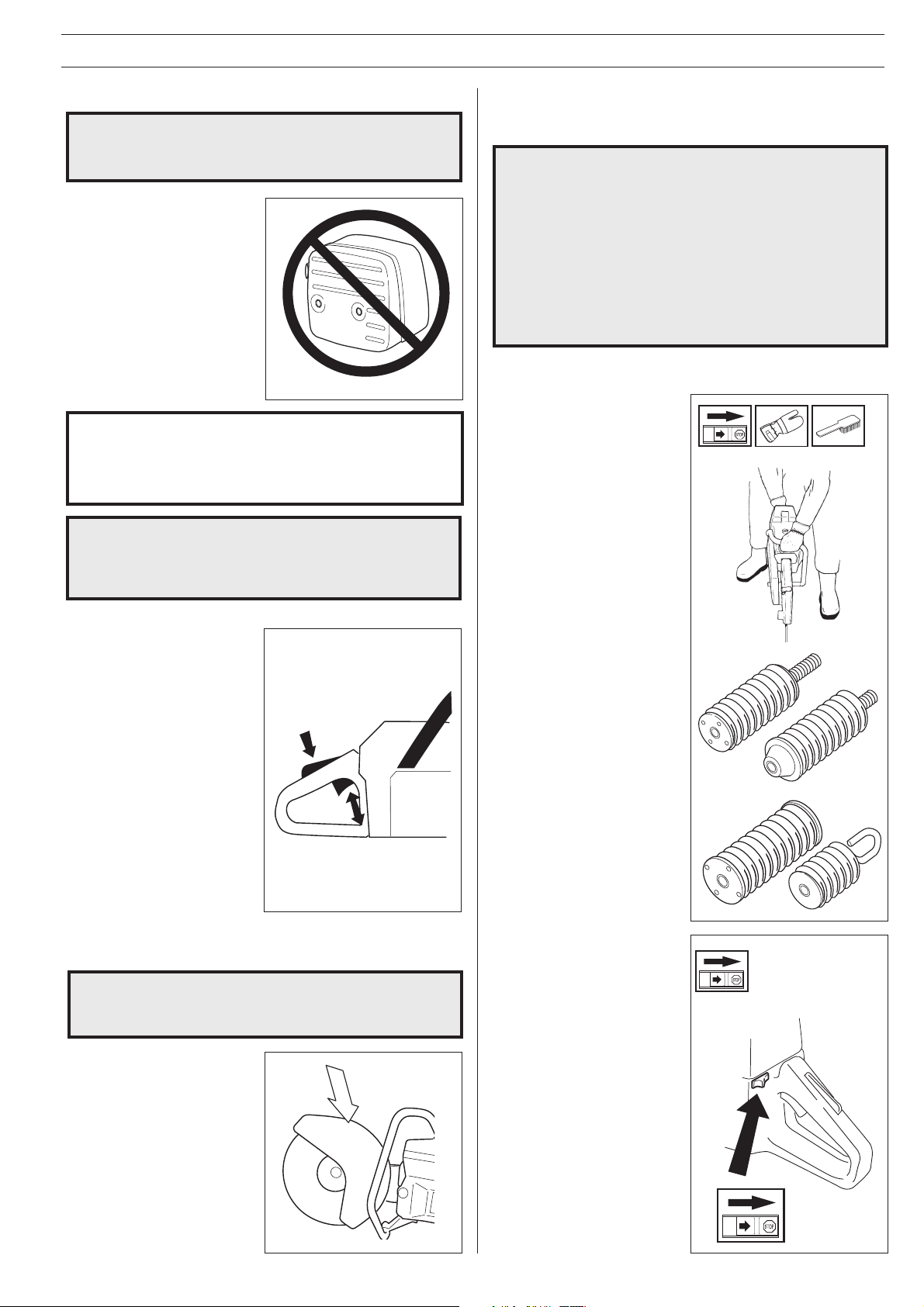

1 Anti-vibration

system

Your power cutter is equipped

with an anti-vibration system.

This is designed to give as low

vibration levels and

comfortable usage as possible.

“What is

• HEAVY-DUTY, FIRM GRIP

GLOVES

• SNUG-FITTING, HEAVYDUTY, COMFORTABLE

CLOTHING THAT ALLOWS

FULL FREEDOM OF

MOVEMENT

• LEG PROTECTION (TO

PROTECT AGAINST

SPARKS AND CUTTING

FRAGMENTS)

• ANTI-SLIP BOOTS WITH

STEEL TOE CAPS

The power cutter’s antivibration system reduces the

transfer of vibration between

the engine/cutting equipment

and the cutting trolley. The

engine body including the

cutting equipment is

suspended in a handle system

via anti-vibration elements.

2 Stop switch

The stop switch should be

used to stop the engine.

• FIRST AID KIT SHOULD

ALWAYS BE ON HAND

4 – English

SAFETY INSTRUCTIONS

3 Muffler

WARNING! During use and for some time

!

The muffler is designed to

give the lowest possible noise

level and to direct the engine‘s

exhaust fumes away from the

user. The engine‘s exhaust

fumes are hot and can contain

sparks, which can lead to the

outbreak of fire.

MPORTANT INFORMATION! It is extremely important that

the instructions for checking, maintaining and servicing

the muffler are followed. (see the section

maintenance and service of the machine’s safety

equipment“

!

after the muffler is very hot. Do not touch the

muffler if it is hot!

“Control,

).

WARNING! The inside of muffler contain

chemicals that may be carcinogenic. Avoid

contact with these elements in the event of a

damaged muffler.

Control, maintenance and service of

the machine‘s safety equipment

WARNING! All service and repairs to the

power cutter require special training. This

!

1 Anti-vibration system

Check the anti-vibration

elements regularly for material

cracks and deformation.

applies especially to the power cutter’s safety

equipment. If the power cutter does not meet

any of the controls listed below you should

contact your service workshop.

The purchase of one of our products

guarantees that professional repair and

servicing will be carried out on it. If the point

of purchase is not one of our servicing

dealers, please ask for details of the closest

service workshop.

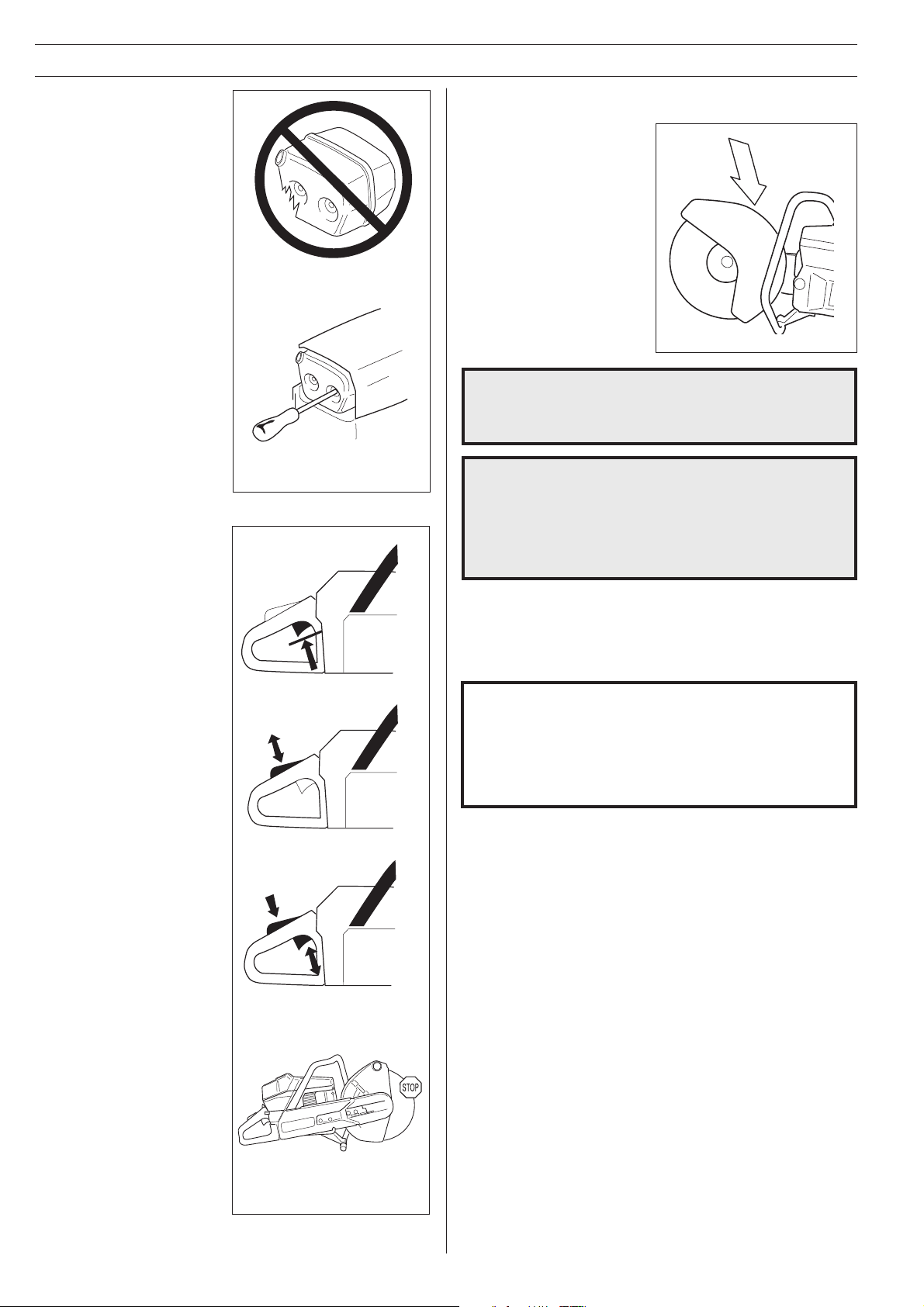

4 Throttle lock

The throttle lock is designed

to prevent accidental operation of the throttle control.

When you press the lock (A)

(i.e. when you grasp the

handle) it releases the throttle

trigger (B). When you release

the handle the throttle trigger

and the throttle lock both

move back to their original

positions. This movement is

controlled by two independent

return springs. This arrangement means that the throttle

control is automatically locked

at the idle setting when you

release the handle.

A

B

5 Blade guard for the cutting blade

WARNING! Always check that the blade guard

!

The blade guard is mounted

above the cutting blade and

prevents cutting fragments

from being thrown towards the

user.

is correctly fitted before starting the machine.

Check that the anti-vibration

elements are securely

mounted between the engine

unit and the handle system.

2 Stop switch

Start the engine and make

sure that the engine stops

when the stop switch is

moved to the stop position.

English – 5

SAFETY INSTRUCTIONS

3 Muffler

Never use a machine that

has a defective muffler.

Check regularly that the

muffler is secured to the

engine body.

4 Throttle lock

1 Make sure the throttle

control is locked at the

idle setting when you

release the throttle lock.

5 Blade guard for the cutting blade

Never use a defective blade

guard or a blade guard that is

not fitted correctly.

WARNING! Check that the cutting blade is

fitted correctly and does not show signs of

!

!

damage. A damaged cutting blade can cause

personal injury.

WARNING! Never use a power cutter with

defective safety equipment. The power

cutter’s safety equipment should be checked

and maintained as described in this

Operator’s Manual. If your power cutter does

not meet any of these controls you should

contact your service workshop.

2 Press the throttle lock and

make sure it returns to its

original position when you

release it.

3 Check that the throttle

control and throttle lock

move freely and that the

return springs work

properly.

4 Start the power cutter and

apply full throttle. Release

the throttle control and

check that the blade stops

and remains stationary. If

the blade rotates when

the throttle is on idle

setting you should check

the carburettor idle

adjustment. See the

section on

”Maintenance”

GENERAL SAFETY INSTRUCTIONS

IMPORTANT INFORMATION!

Do not use the power cutter until you have read the

entire contents of this Operator’s Manual.

All servicing, in addition to the points listed in the

section ”

power cutter’s safety equipment”

out by trained service specialists.

• Use the equipment recommended in the chapter

safety equipment”.

• Never use the machine when you are tired, under the

influence of medicines/drugs or alcohol.

• Do not lend the power cutter to anyone without providing this

Operator’s Manual. Ensure the person using the power cutter

understands the information in this Operator’s Manual.

Control, maintenance and service of the

, should be carried

”Personal

Transport and storage

• Store the power cutter under lock and key so that it’s out of

reach for children and unauthorised persons.

• Do not store or transport the power cutter with the cutting

blade fitted.

.

6 – English

SAFETY INSTRUCTIONS

Fuel safety

(Filling/Fuel mixture/Storage)

WARNING! Exercise great care when handling

!

• Never fill the machine while

the engine is running.

• Provide good ventilation

when filling or mixing fuel

(petrol and 2-stroke oil).

• Move the machine at least 3

m from the filling position

before starting.

• Never start the machine:

• Store the power cutter and fuel so that any leakage or fumes

do not risk coming into contact with sparks or naked flames.

For example, electric machines, electric motors, electrical

switches/power switches, heaters or the like.

• When storing fuel, approved containers intended for this

purpose must be used.

• When storing the power cutter for long periods the fuel tank

must be emptied. Contact your local petrol station to find out

how to dispose of excess fuel.

fuel. Bear in mind the risk of fire, explosions

and inhaling fumes.

Min 3 m

(10ft)

a) If you have spilt fuel

on it. Wipe up all

spillage.

b) If you have spilt fuel

on yourself or your

clothes. Change your

clothes.

c) If there is a fuel leak.

Make regular checks for

leakage from the fuel

cap and the fuel supply

pipes.

GENERAL WORKING INSTRUCTIONS

This section takes up the basic safety precautions for working

with the power cutter. Follow these general working instructions,

but never use a machine without the possibility of calling for

help in the event of an accident.

Basic safety precautions

IMPORTANT INFORMATION! Never work with a power

cutter that is defective or incorrectly adjusted. Do not

work with a power cutter that is incomplete or where

assembly has not been carried out in a satisfactory

manner. Check that the cutting blade stops rotating

when the throttle is released. If you encounter a situation

where you are uncertain how to proceed you should ask

an expert.

Avoid all usage which you consider to be beyond your

capability.

• Check that no one is in the immediate vicinity when the

machine is started or while working with the machine to

ensure that people, animals or other things cannot affect your

control of the power cutter.

• Avoid usage in unfavourable weather conditions, for example,

thick fog, heavy rain, strong winds or extreme cold, etc. To

work in bad weather conditions is tiring and can create

dangerous circumstances, e.g. slippery surfaces.

• Never start to work with the power cutter before the working

area is clear and you have a firm foothold. Look out for any

obstacles with unexpected movement. Ensure when cutting

that no material can become loose and fall, causing operating

injury.Take great care when working on sloping ground.

• Make sure clothing and parts of the body do not come into

contact with the cutting blade when the engine is started.

• Maintain a safe distance from the cutting blade when the

engine is running.

• The blade guard should always be fitted when the engine is

running.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Check the cutting area for buried cables and wires.

• Use a Husqvarna fuel can with an anti-spill device.

WARNING! Fuel and fuel fumes are highly

flammable. Think of the risks of fire, explo-

!

sion and breathing in fumes. Stop the engine

before refuelling. Do not overfill with fuel.

Mop up any spills on the ground or the

machine. If you spill fuel on yourself or your

clothes, change your clothes. Move the

machine at least 3 metres from the refuelling

site before starting.

Only use the machine in areas with good

ventilation. Neglect can result in serious

!

injury or death.

Cutting

WARNING! A safe distance from the power

!

• Start cutting with the engine at full throttle.

• Always hold the power cutter firmly, with both hands. Hold

the machine so that the thumb and fingers grip around the

handle.

cutter is 15 metres. You are responsible that

animals and onlookers are not in the working

area. Do not start to work with the power

cutter before the working area is clear and

you have a firm foothold.

English – 7

SAFETY INSTRUCTIONS

WARNING! Over exposure to vibrations can

!

Cutting technique

The technique described below is of a general character. Check

information for each blade regarding individual cutting characteristics. (For example, a diamond blade requires less feeding

pressure than a abrasive blade).

1.Support the work piece in

such away that you can

predict what will happen

and so it will not pinch.

2.Always cut at full throttle.

3.Start cutting gently, do

not force or squeeze the

blade in.

result in blood-vessel or nerve injury to

persons suffering with blood circulation

problems. Seek medical attention if you

experience physical symptoms that can be

related to over exposure to vibrations.

Examples of such symptoms are numbness,

lack of feeling, “tickling“, “pricking“, pain lack

of or a reduction in normal strength, changes

in the colour of the skin or its surfaces. These

symptoms normally appear in the fingers,

hands or wrists.

Water cooling

WARNING! Water cooling, which is only used

for petrol-driven power cutters and when

!

Sharpening diamond blades

Blades can become dull when the wrong feeding pressure is

used or when cutting some materials such as heavily reinforced

concrete. To force a dull blade results in overheating and finally

the loss of segments (part of the blade).

Sharpen against a soft material such as sandstone or haydite

brick.

Blade vibration

The blade can become out of shape (not round) and vibrate if a

too high feeding pressure is used or if the blade is pressed into

the work piece.

A lower feeding pressure ought to stop the vibration. Otherwise

replace the cutting blade.

cutting concrete, cools the cutting blade and

increases its service life as well as reduce

dust formation (see the section ”

”). Among the disadvantages are

blades

difficulties at very low temperatures, the risk

of damaging the floor and other sections of

the building and risk for slippage.

Abrasive

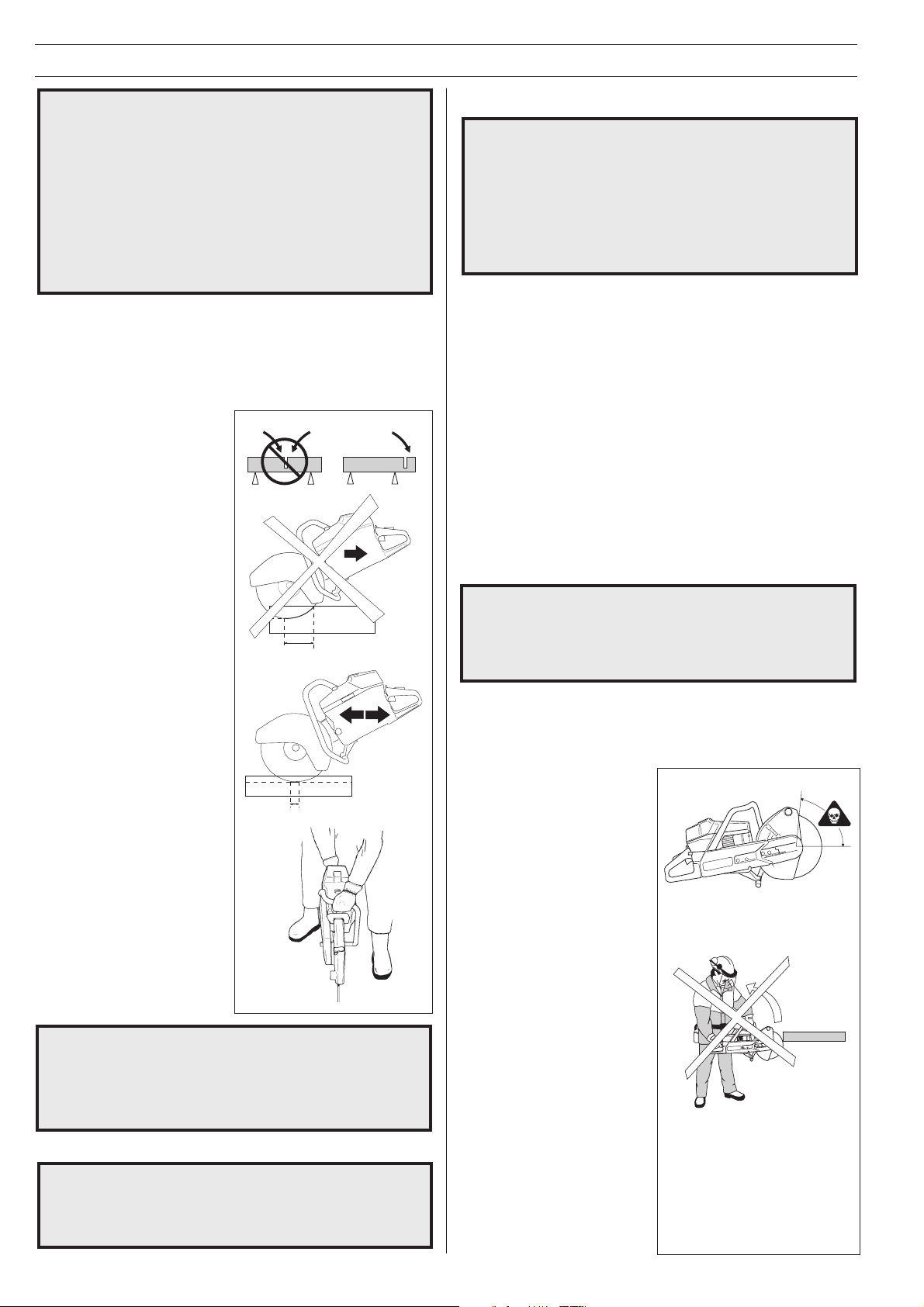

Kickback

4.Use a high blade speed.

5.Move the blade slowly

backwards and forwards.

6.Use a small part of the

blade’s cutting edge.

7.Only use the blade’s

cutting edge when

cutting.

8.Cut with the blade fully

vertical – at right angles

to the work piece.

WARNING!

Under all circumstances avoid cutting using

!

the side of the blade; it will almost certainly

be damaged, break and can cause immense

damage. Only use the cutting section.

WARNING!

Kickback can occur very suddenly and with

!

If the sector of the blade illustrated below is used for cutting the

blade can start to climbing and kickback the power cutter

upwards and backwards towards the user with immense force.

How to avoid kickback

1.Never cut with the

segment illustrated in the

diagram.

2.Keep a good balance and

a firm foothold.

3.Use both hands and take

a firm grip with the thumb

and fingers around the

handle.

4.Keep the work piece at a

comfortable distance.

5.Use the cutter at full

throttle.

6.Take care when inserting

the blade in an existing

cut.

great force. If the following directives are not

followed, it can result in serious or even fatal

injury.

!

8 – English

WARNING!

Do not lean the blade to the side, this can

cause the blade to jam or break with personal

injury as a consequence.

7.Never cut above shoulder

height.

8.Be alert to movement of

the work piece or anything

else that can occur, which

could cause the cut to

close and pinch the blade.

Loading...

Loading...