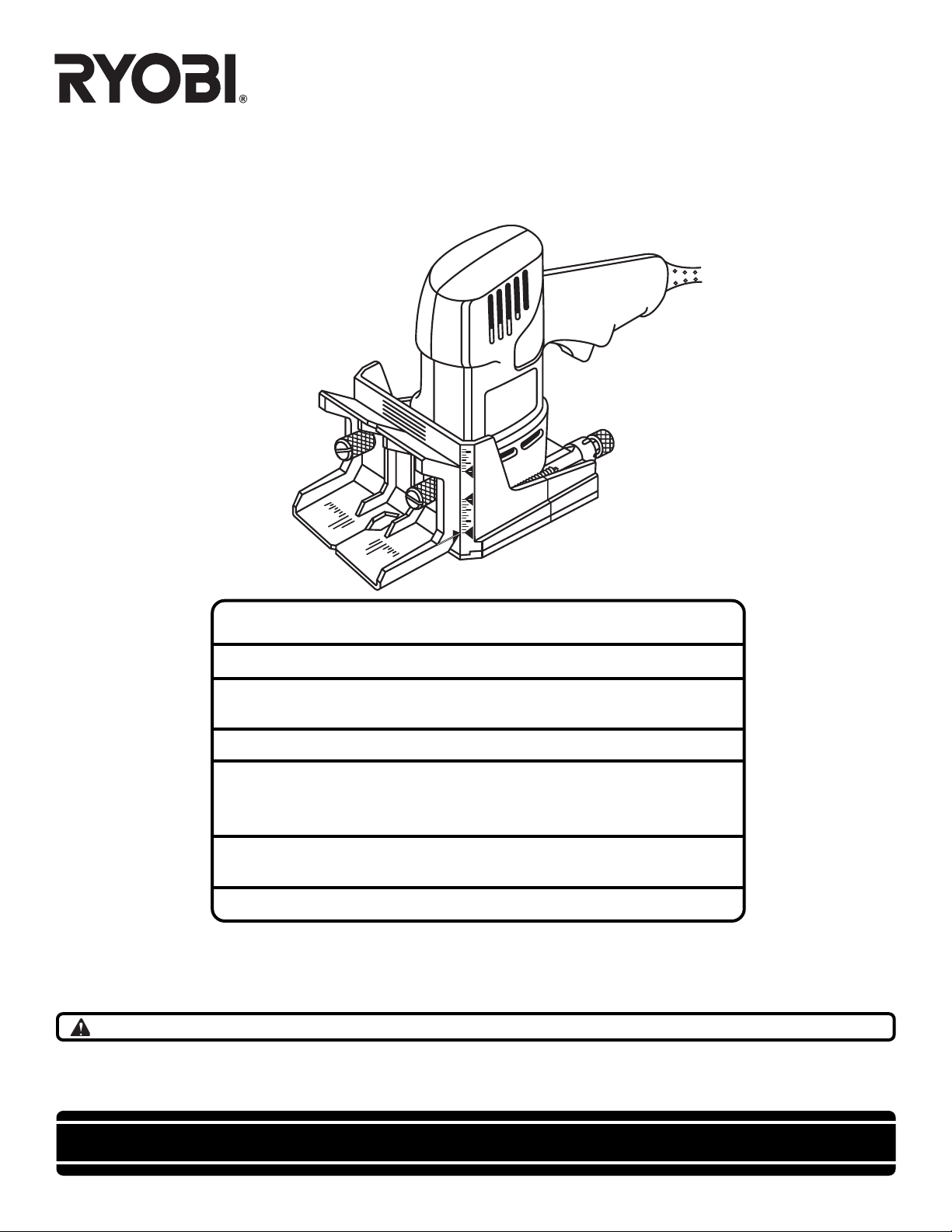

OWNER'S OPERATING MANUAL

DETAIL BISCUIT JOINER / DBJ50

DOUBLE INSULATED

5

16

45°

3

4

3

1

2

1

2

3

0

90°

SPECIFICATIONS:

No Load Speed 19,000 rpm

Rating 120 volts, 60 Hz, AC

3.5 Amperes

Fence Angles 45° and 90°

Fence Height Adjustment

With Fence Angle Set on 90° 0 - 3/4 in.

With Fence Angle Set on 45° 5/16 in. - 13/16 in.

Depth Of Cut

With Micro Depth Of Cut Adjustment 0 - 9/32 in. (0 - 7 mm)

Net Weight 3.625 lbs (1.65 kg.)

THANK YOU FOR BUYING A RYOBI DETAIL BISCUIT JOINER.

Your new detail biscuit joiner has been engineered and manufactured to Ryobi's high standard for dependability, ease of

operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

CAUTION: Carefully read through this entire owner's manual before using your new detail biscuit joiner.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your detail biscuit joiner properly and

only for what it is intended, you will enjoy years of safe, reliable service.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL MEANING

SAFETY ALERT SYMBOL:

Indicates caution or warning. May be used in conjunction with other symbols or pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always

follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others. Always

follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to yourself

or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal

injury.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

DANGER:

To avoid serious personal injury, keep hands out of

blade path.

DOUBLE INSULATION

Double insulation is a concept in safety, in electric power

tools, which eliminates the need for the usual three-wire

grounded power cord. All exposed metal parts are isolated

from the internal metal motor components with protecting

insulation. Double insulated tools do not need to be grounded.

WARNING:

The double insulated system is intended to protect the

user from shock resulting from a break in the tool's

internal wiring. Observe all normal safety precautions

related to avoiding electrical shock.

IMPORTANT

Servicing of a tool with double insulation requires

extreme care and knowledge of the system and should

be performed only by a qualified service technician.

For service we suggest you return the tool to your

nearest RYOBI AUTHORIZED SERVICE CENTER for

repair. When servicing use only identical Ryobi

replacement parts.

WARNING:

Do not attempt to operate this tool until you have read

thoroughly and understand completely all instructions,

safety rules, etc. contained in this manual. Failure to

comply can result in accidents involving fire, electric

shock, or serious personal injury. Save owner's manual

and review frequently for continuing safe operation, and

instructing others who may use this tool.

Page 2

READ ALL INSTRUCTIONS

1. KNOW YOUR POWER TOOL. Read owner's

manual carefully. Learn its applications and

limitations as well as the specific potential

hazards related to this tool.

2. GUARD AGAINST ELECTRICAL SHOCK

BY PREVENTING BODY CONTACT WITH

GROUNDED SURFACES. For example:

Pipes, radiators, ranges, refrigerator

enclosures.

3. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

4. AVOID DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations

or expose to rain. Keep work area well lit.

5. KEEP CHILDREN AND VISITORS AWAY.

All visitors should wear safety glasses and be

kept a safe distance from work area. Do not let

visitors contact tool or extension cord.

6. STORE IDLE TOOLS. When not in use tools

should be stored in a dry, high or locked-up

place – out of the reach of children.

14. SECURE WORK. Use clamps or a vise to

hold work. It's safer than using your hand and

it frees both hands to operate tool.

15. DON'T OVERREACH. Keep proper footing

and balance at all times. Do not use on a

ladder or unstable support.

16. MAINTAIN TOOLS WITH CARE. Keep tools

sharp at all times, and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

17. DISCONNECT TOOLS. When not in use,

before servicing, or when changing

attachments, blades, bits, cutters, etc., all

tools should be disconnected.

18. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed

from tool before turning it on.

19. AVOID ACCIDENTAL STARTING. Don't

carry plugged-in tool with finger on switch. Be

sure switch is off when plugging in.

7. DON'T FORCE TOOL. It will do the job better

and safer at the rate for which it was designed.

8. USE RIGHT TOOL. Don't force small tool or

attachment to do the job of a heavy duty tool.

Don't use tool for purpose not intended – for

example – Don't use a circular saw for cutting

tree limbs or logs.

9. DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught in

moving parts. Rubber gloves and nonskid

footwear are recommended when working

outdoors. Also, wear protective hair covering

to contain long hair and keep it from being

drawn into air vents.

10. ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everyday eyeglasses have

only impact resistant lenses; they are NOT

safety glasses.

11. PROTECT YOUR LUNGS. Wear a face or

dust mask if operation is dusty.

12. PROTECT YOUR HEARING. Wear hearing

protection during extended periods of

operation.

13. DON'T ABUSE CORD. Never carry tool by

cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

20. MAKE SURE YOUR EXTENSION CORD IS

IN GOOD CONDITION. When using an

extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. A wire gage size (A.W.G.) of at

least 16 is recommended for an extension

cord 50 feet or less in length. A cord exceeding

100 feet is not recommended. If in doubt, use

the next heavier gage. The smaller the gage

number, the heavier the cord.

21. OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only extension

cords intended for use outdoors. Outdoor

approved cords are marked with the suffix WA, for example - SJTW-A or SJOW-A.

22. KEEP BLADES CLEAN AND SHARP. Sharp

blades minimize stalling and kickback.

23. KEEP HANDS AWAY FROM CUTTING

AREA. Keep hands away from blades. Do not

reach underneath work while blade is rotating.

WARNING: BLADES COAST AFTER TURN

OFF.

24. NEVER USE IN AN EXPLOSIVE

ATMOSPHERE. Normal sparking of the motor

could ignite flammable liquids, gases, or

fumes.

Page 3

RULES FOR SAFE OPERATION (Continued)

25. INSPECT TOOL CORDS PERIODICALLY

and if damaged, have repaired at your nearest

authorized service center. Stay constantly

aware of cord location and keep it well away

from the rotating blade.

26. INSPECT EXTENSION CORDS PERIODI-

CALLY and replace if damaged.

27. KEEP HANDLES DRY, CLEAN, AND FREE

FROM OIL AND GREASE. Always use a

clean cloth when cleaning. Never use brake

fluids, gasoline, petroleum-based products,

or any strong solvents to clean your tool.

28. STAY ALERT AND EXERCISE CONTROL.

Watch what you are doing and use common

sense. Do not operate tool when you are tired.

Do not rush.

29. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced by an

authorized service center.

30. DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have switches

replaced by an authorized service center.

31. DRUGS, ALCOHOL, MEDICATION. Do not

operate this tool while under the influence of

drugs, alcohol, or any medication.

32. GUARD AGAINST KICKBACK. Kickback

occurs when the blade stalls rapidly and the

biscuit joiner is driven in the direction opposite

blade rotation. Release switch immediately if

blade binds or joiner stalls.

33. USE ONLY 1-1/2 in. (38 mm) DIAMETER

SPECIFIED BLADES. Do not use blades with

incorrect size holes. Never use blade washers

or bolts that are defective, incorrect, or not

specified.

34. AVOID CUTTING NAILS. Inspect for and

remove all nails from lumber before cutting.

35. NEVER touch the blade or other moving parts

during use.

36. NEVER start a tool when the blade is in

contact with the workpiece.

37. NEVER lay a tool down before the blade has

come to a complete stop.

38. POLARIZED PLUGS. To reduce the risk of

electric shock, this equipment has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper

outlet. Do not change the plug in any way.

39. WHEN SERVICING USE ONLY IDENTICAL

RYOBI REPLACEMENT PARTS.

40. SAVE THESE INSTRUCTIONS. Refer to them

frequently and use them to instruct others

who may use this tool. If you loan someone

this tool, loan them these instructions also.

WARNING:

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter

out microscopic particles.

SAVE THESE INSTRUCTIONS

Page 4

TABLE OF CONTENTS

■ Rules For Safe Operation...........................................................2-4

■ Table of Contents / Introduction .....................................................5

■ Typical Applications .......................................................................6

■ Features.....................................................................................7-8

■ Adjustments..............................................................................9-10

■ Operation................................................................................11-16

■ Maintenance...........................................................................17-19

■ Optional Accessories...................................................................19

■ Troubleshooting...........................................................................20

■ Service Information......................................................................22

INTRODUCTION

Spline joinery is one of the strongest methods of joinery

used in woodworking. When glue is properly applied to a

spline and to the joint area of the wood pieces being

connected, a large surface area receives the adhesion

properties of the glue. This forms a very strong joint.

Traditional spline joinery requires cutting slots with a router

or table saw. Small, thin strips of wood must then be cut to

fit inside the slots and act as splines.

Newer methods of spline joinery use a plate or biscuit

joiner to cut precise mating oval slots in adjoining boards.

Your new biscuit joiner is a fast, simple, and accurate

plunge cutting tool that can be used for this purpose. It can

be used to cut slots in hardwood, softwood, plywood, particle board, and other pressed woods.

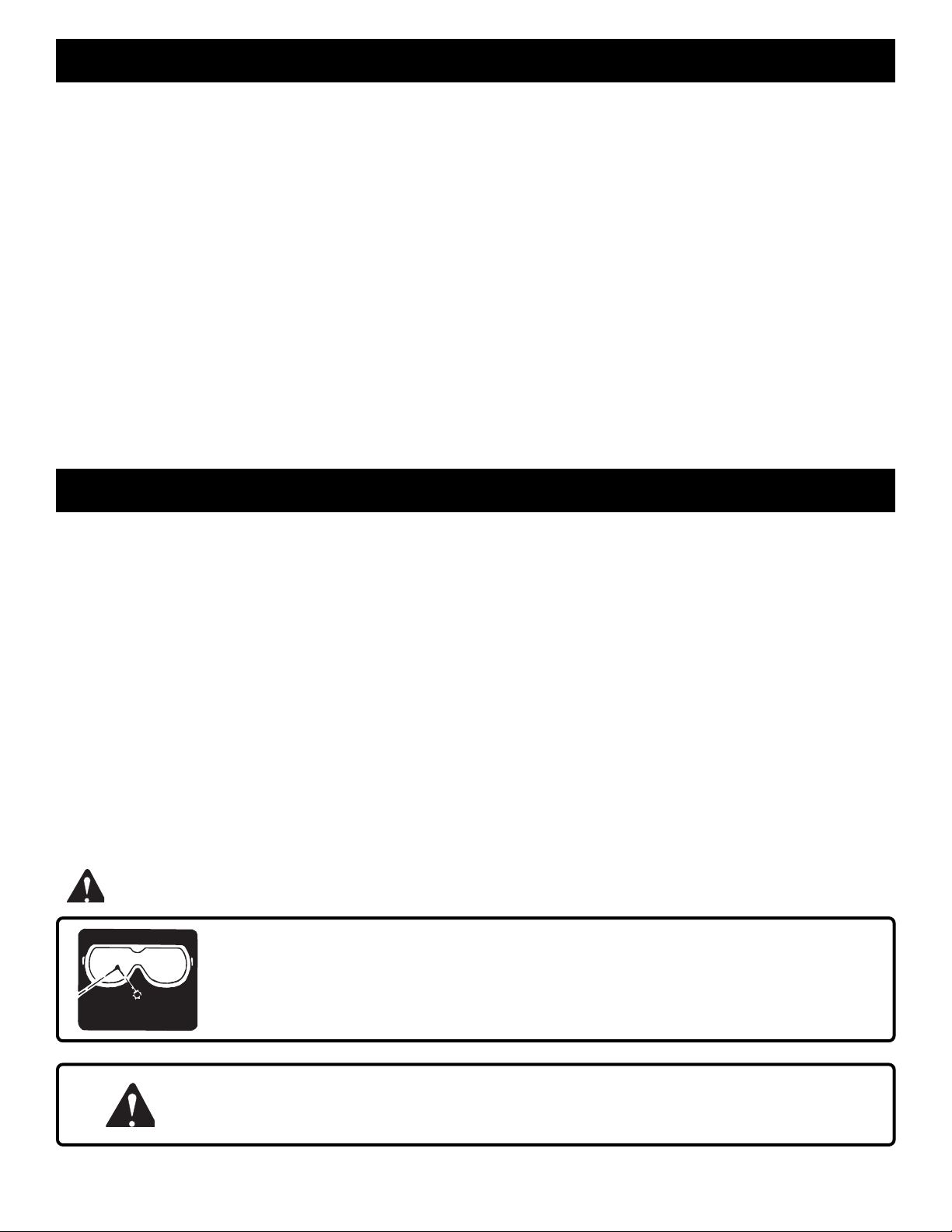

WARNING:

WEAR

YOUR

SAFETY

FORESIGHT IS BETTER

GLASSES

THAN NO SIGHT

The operation of any biscuit joiner can result in foreign objects being thrown into your

eyes, which can result in severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shields and a full face shield

when needed. We recommend Wide Vision Safety Mask for use over eyeglasses or

standard safety glasses with side shields.

Football shaped wafers, called biscuits, are then placed

inside the slots with glue and used to help line up adjoining

surfaces. When a water based glue is used, the biscuits

swell in the joint, making an extremely strong and firm

bond. White glue, yellow glue, carpenters glue, hide glue,

and aliphatic resin glue are examples of water based glues.

This bonding technique has traditionally been limited to

making edge-to-edge joints. However, with the use of your

new biscuit joiner, biscuits can now be easily used to

connect butt, miter, and T-joints. Biscuit joining can be as

strong as mortise and tenon, tongue and groove, standard

spline, and doweled joints. In most cases the material

around the biscuit will break before the biscuit itself will

break. A greater surface area is exposed to glue in a biscuit

joint, making the seams stronger.

Look for this symbol to point out important safety precautions.

It means attention!!! Your safety is involved.

Page 5

TYPICAL APPLICATIONS

5

1

6

4

5

°

2

1

1

2

3

3

4

0

9

0

°

DETAIL BISCUIT JOINER / DBJ50

EDGE-TO-EDGE JOINTS

BUTT JOINTS

T- JOINTMITER JOINTS

Page 6

FEATURES

Your detail biscuit joiner has been designed for making fast,

accurate, and simple plunge cuts in wood, etc. so that

biscuits can be used to join two or more boards together.

When used properly and only for what it is intended, this

versatile tool will give you years of trouble-free performance.

It is professionally engineered, but its ease of operation

allows the amateur to produce beautiful and precise work.

#R1 = 7/32 in. x 5/8 in.

SWITCH

To turn your biscuit joiner ON, depress the switch trigger.

Release switch trigger to turn your biscuit joiner OFF.

MOTOR

Your biscuit joiner has a powerful motor with sufficient power

to handle tough cutting jobs. It develops a no load speed of

19,000 RPM.

BLADE

Your biscuit joiner has a 1-1/2 in. (38 mm) 6 tooth blade for

cutting biscuit slots.

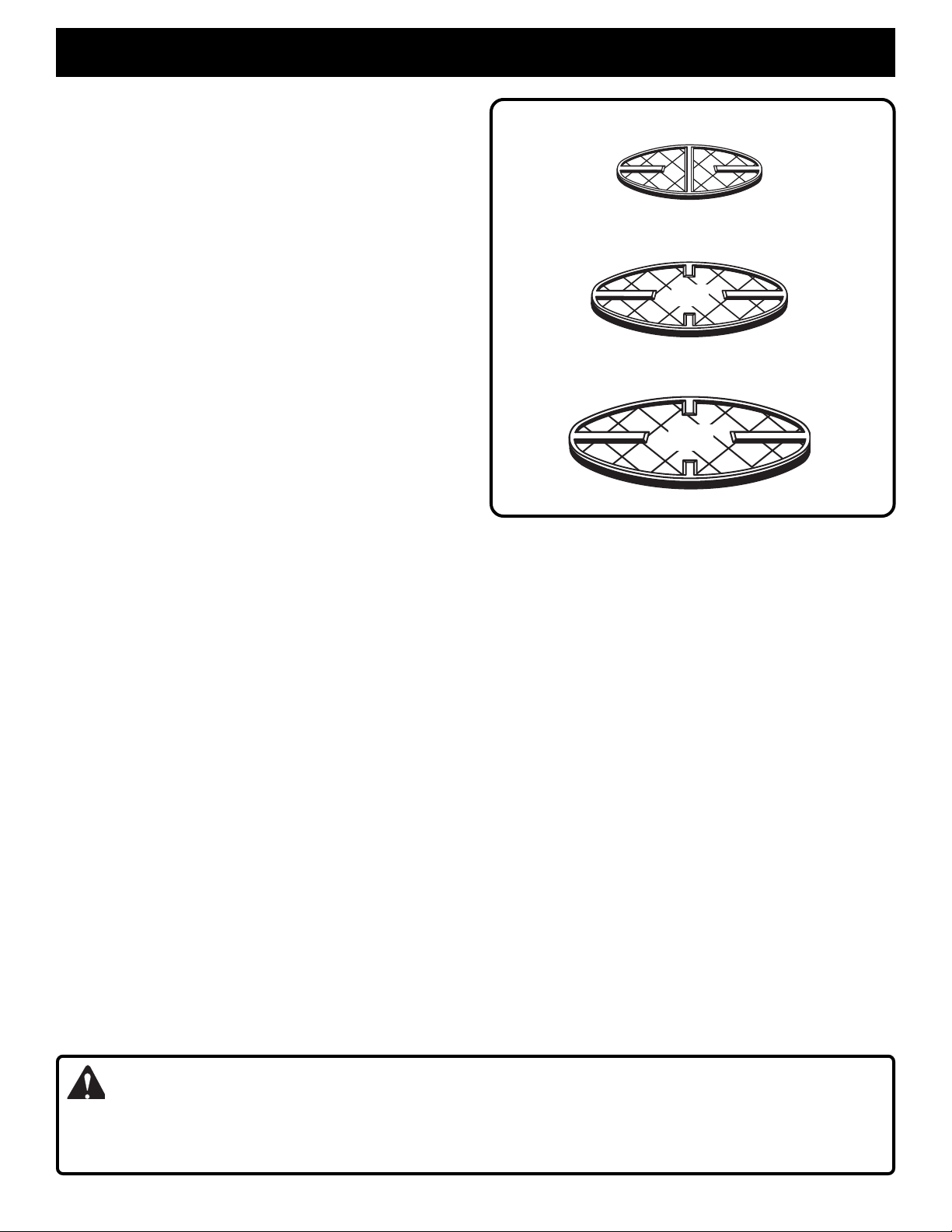

BISCUITS

See Figure 1.

Biscuits are available in three standard sizes:

#R1 (7/32 in. x 5/8 in.)

#R2 (9/32 in. x 3/4 in.)

#R3 (1/2 in. x 1 in.)

NOTE: Store biscuits in a dry place because they swell

rapidly upon contact with water-based woodworking glues.

REVERSIBLE FENCE FOR 45° AND 90° CUTS

Your biscuit joiner has a reversible fence. By loosening the

height adjustment knobs, the fence can be removed through

key hole slots. Once removed, it can be rotated 180° changing

the angle of cut from 90° to 45° or vice versa. The height of

the fence at 90° can be set between 0 to 3/4 in. from the

center of the blade. The height of the fence at 45° can be set

between 5/16 in. to 13/16 in. from the center of the blade.

The fence should always be used to guide and balance your

biscuit joiner, providing ease of operation and maintaining

safe control.

NONSKID BACKING PAD

The fence on your biscuit joiner is padded with a nonskid

backing pad to hold it stationary against the workpiece. It

helps prevent skidding when making cuts. It also prevents

marring of the workpiece from biscuit joiner when cutting.

INDICATOR MARKS

Centerline and line of cut indicator marks have been provided

on your biscuit joiner.

See Figure 2.

#R2 = 9/32 in. x 3/4 in.

2

#R3 = 1/2 in. x 1 in.

3

Fig. 1

APPLICATIONS

(Use only for the purpose listed below)

■ Cutting precise mating oval slots in hardwood, softwood,

plywood, particle board, etc. for spline joinery applications.

ELECTRICAL CONNECTION

Your biscuit joiner has a precision built electric motor. It

should be connected to a power supply that is 120 volts,

60 Hz, AC only (normal household current). Do not

operate this tool on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat.

If your biscuit joiner does not operate when plugged into an

outlet, double-check the power supply.

DEPTH ADJUSTMENT KNOB

A spring loaded depth adjustment knob makes it possible to

make proper settings for three standard size biscuits. Fine

adjustments to the cutting depth can be made with a knurled

adjustment knob and jam nut located behind the depth

adjustment knob. Once the correct depth setting has been

made for one biscuit size, the other two depth settings will be

automatically set.

O

A

b

p

WARNING:

Your detail biscuit joiner should never be connected to power supply when you are assembling parts, making

adjustments, assembling or removing blades, cleaning or when not in use. Disconnecting your detail biscuit joiner will

prevent accidental starting that could cause serious personal injury.

Page 7

0

5

16

3

4

45°

90°

FEATURES

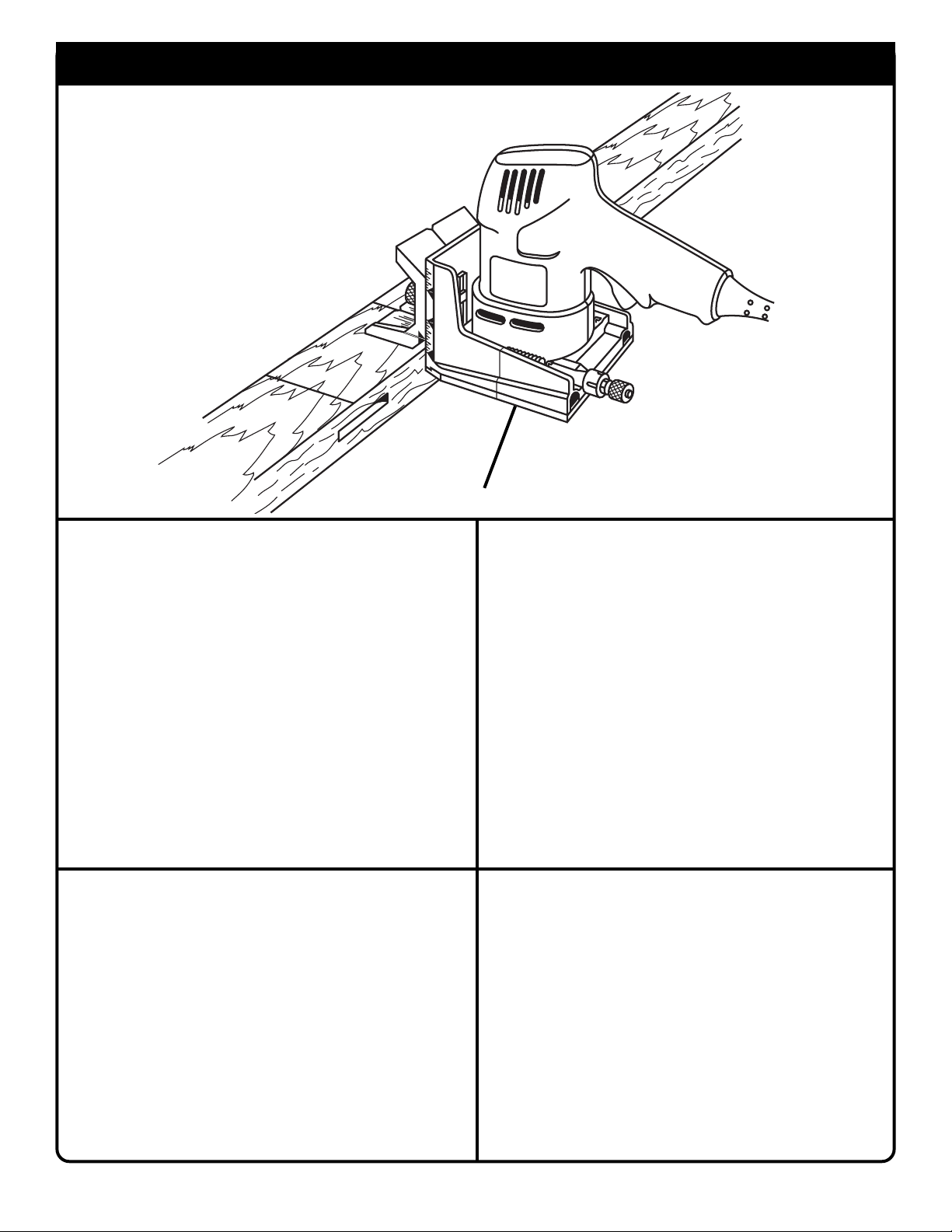

KNOW YOUR DETAIL BISCUIT JOINER

See Figure 2.

Your biscuit joiner has been shipped completely assembled

and ready for use. An owner's manual and warranty

registration are also included. Inspect your new biscuit joiner

carefully to make sure no breakage or damage has occurred

during shipping. If any parts are damaged or missing, contact

your local Ryobi factory or authorized service center to

obtain replacement parts before attempting to operate your

biscuit joiner.

Before attempting to use any tool familiarize yourself with all

operating features and safety requirements.

LINE OF

CUT WINDOW

CENTERLINE / LINE

OF CUT INDICATOR

MARK(S)

WARNING:

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal

injury.

WARNING:

Do not allow familiarity with tools to make you careless.

Remember that a careless fraction of a second is

sufficient to inflict severe injury.

REAR HANDLE

WIDTH OF

CUT SCALE

DEPTH

SWITCH

TRIGGER

ADJUSTMENT

KNOB

KNURLED

ADJUSTMENT

KNOB

JAM

FENCE

5

16

45°

3

4

3

1

2

1

2

3

HEIGHT

ADJUSTMENT

KNOBS (2)

NONSKID

BACKING PAD

0

90°

REAR

BASE

FRONT

BASE

BOTTOM

SHOE

NUT

HEIGHT

INDICATOR MARK

HEIGHT

SETTING SCALE

Fig. 2

Page 8

3

2

ADJUSTMENTS

WARNING:

If any parts are missing, do not operate tool until the

missing parts are replaced. Failure to do so could result

in possible serious personal injury.

DEPTH OF CUT ADJUSTMENTS

Your biscuit joiner can be adjusted to three standard

cutting depths to accommodate three standard size biscuits

— #R1, #R2, and #R3. Adjustments are made by engaging

slots on depth adjustment knob with tabs on rear base. For

example, when using a #R1 size biscuit, rotate the depth

adjustment knob until the slot marked 1 aligns with the

depth indicator mark on the rear base. When using a #R2

size biscuit, rotate the depth adjustment knob until the slot

marked 2 aligns with the depth indicator mark on the rear

base, and when using a #R3 size biscuit rotate the depth

adjustment knob until the slot marked 3 aligns with the

depth indicator mark on the rear base.

See Figure 3.

TO SET DEPTH ADJUSTMENT KNOB

■ Unplug your detail biscuit joiner.

WARNING:

Failure to unplug biscuit joiner could result in accidental

starting causing possible serious personal injury.

3

2

REAR

BASE

RELEASE TO APPLY

PRESSURE AGAINST DEPTH

ADJUSTMENT KNOB

TABS

SLOT

DEPTH

INDICATOR

MARK

ROTATE TO

DESIRED SETTING

1, 2, OR 3

PULL AND HOLD TO

ROTATE DEPTH

ADJUSTMENT KNOB

KNURLED

ADJUSTMENT

KNOB

JAM

NUT

DEPTH

ADJUSTMENT

KNOB

■ Pull knurled adjustment knob and jam nut in the direction

of the arrow shown in figure 3.

NOTE: Knob and jam nut are spring loaded, therefore

pulling them in the direction of the arrow shown puts

pressure on the spring and releases pressure from the

depth adjustment knob.

■ Rotate depth adjustment knob until desired slot setting

aligns with tabs on rear base — 1, 2, or 3.

■ Next release knurled adjustment knob and jam nut applying

pressure from spring on depth adjustment knob.

Make a test cut in a scrap piece of wood. Fit the correct size

biscuit into biscuit slot. If biscuit slot is too deep or too

shallow, fine adjustments to the depth setting can be made

by loosening knurled adjustment knob and making fine

adjustments with the jam nut. Turning jam nut forward will cut

shallow biscuit slots. Turning jam nut backwards will cut

deeper biscuit slots. The biscuit slot should be deep enough

to allow slightly more than one-half of the biscuit into the slot.

This extra room allows for proper alignment of the wood

being joined.

TO MAKE FINE ADJUSTMENTS

See Figure 4.

■ Unplug your detail biscuit joiner.

■ Loosen knurled adjustment knob. This knob is used as a

lock nut only. Loosen by twisting it in the opposite direction away from jam nut.

TURN FORWARD

FOR SHALLOW

BISCUIT SLOTS

KNURLED ADJUSTMENT KNOB USED AS A LOCK NUT.

JAM NUT USED TO MAKE FINE ADJUSTMENTS.

■ Turn jam nut forward for a more shallow cut, or

backwards for a deeper cut.

■ Once desired depth of cut is reached, hold jam nut so that

it will not move out of adjustment. Next, tighten knurled

adjustment knob against jam nut.

■ Recheck depth setting by making a test cut in a scrap

piece of wood. Also periodically check depth setting for

accuracy.

Page 9

See Figure 4.

TURN BACKWARDS FOR

DEEPER BISCUIT SLOTS

Fig. 3

Fig. 4

ADJUSTMENTS

FENCE HEIGHT ADJUSTMENT

See Figure 5.

The fence on your biscuit joiner can be moved up and down

to adjust the position of the blade in relation to the top of the

workpiece. A scale on both sides of the front base indicates

height settings for both 45° and 90° angles. The fence and

height indicator mark can be positioned from 5/16 in. to 13/16

in. from the center of the blade for 45° angles. It can be

positioned from 0 to 3/4 in. from the center of the blade for 90°

angles. Scale marks are in increments of 1/16 in.

TO ADJUST HEIGHT SETTING

See Figure 5.

■ Unplug your detail biscuit joiner.

WARNING:

Failure to unplug your detail biscuit joiner could result in

accidental starting causing possible serious personal

injury.

■ Loosen the two height adjustment knobs.

■ Pull the fence forward and slide it up or down until the

height indicator mark is aligned with the desired dimension on the scale.

NOTE: Slots in the front base align with a tab on the

backside of the fence.

keeps the fence square at each height setting.

■ Tighten height adjustment knobs securely.

FENCE ROTATION / ANGLE ADJUSTMENT

See Figure 6.

The fence on your biscuit joiner can be rotated 180° and set

at either 45° or 90° angles.

TO ROTATE FENCE / CHANGE ANGLE SETTING

See Figure 6.

■ Unplug your detail biscuit joiner.

See Figure 6.

This alignment

HEIGHT

ADJUSTMENT

KNOB(S)

TO LOWER

FENCE

HEIGHT

ADJUSTMENT

KNOBS

(1) PULL

FORWARD

5

16

45°

3

4

0

90°

3

1

2

1

2

3

(2) SLIDE

DOWN

FENCE ORIENTATION

FOR 45° ANGLES

FENCE

SETTING SCALE

5

16

45°

3

4

0

90°

FENCE

HEIGHT

Fig. 5

FRONT

BASE

WARNING:

Failure to unplug your detail biscuit joiner could result in

accidental starting causing possible serious personal

injury.

■ Loosen the two height adjustment knobs.

■ Pull the fence forward and slide it down the front base until

it can be removed through the key hole slots.

■ Rotate the fence 180°.

■ Reinstall the fence on the front base. Place height adjust-

ment knob bolts in key hole slots and align bolt heads with

the slots on back of front base.

■ Slide fence up the front base to desired depth of cut.

■ Tighten height adjustment knobs securely.

See Figure 6.

Page 10

ADJUSTMENT

KNOB BOLT(S)

FENCE ORIENTATION

FOR 90° ANGLES

HEIGHT

SLOTS

TABS

KEY

HOLE

SLOTS

SLOT(S)

FRONT

BASE

Fig. 6

OPERATION

WARNING:

Always wear safety goggles or safety glasses with side

shields when operating tools. Failure to do so could

result in objects being thrown into your eyes, resulting in

possible serious injury.

A variety of spline joints can be made using your biscuit

joiner. The number and size biscuits needed for each joint

depends on the thickness of the wood and the length of the

joint. In general, the small #R1 biscuits should be used for

miter cuts in small, thin materials. The larger biscuits should

be used for edge-to-edge joinery.

When joining thick materials, stack two biscuits, one above

the other. For example, joining 2 in. x 4 in. dressed lumber.

See Figure 9.

additional biscuits, stacked above each other.

When making edge-to-edge joints the more biscuits you use,

the stronger the joint will be.

The following sections illustrate how to make various spline

joints using your biscuit joiner.

EDGE-TO-EDGE JOINTS

See Figures 7 and 8.

Edge-to-edge joinery is one of the most basic and easiest

joints to construct. In general, two basic adjustments have

to be made for all biscuit joinery applications. One is the

depth of cut and the other is the location of the cut.

When joining even thicker materials, use

INDICATOR

MARK(S)

1

1

2

2

3

CENTERLINE

MARK(S)

TOP VIEW OF DETAIL BISCUIT JOINER

3

LINE OF

CUT WINDOW

Fig. 7

CENTERLINE

MARKS

BISCUIT(S)

HOW TO MAKE EDGE-TO-EDGE JOINTS

■ Unplug your detail biscuit joiner.

■ Prepare the workpieces by laying them side by side on a

workbench in the order in which they will be assembled.

■ Using a square, determine the location of each biscuit

spline joint and mark the center of each joint by drawing

a line across each workpiece. Mark the edges 1 in. from

the ends of workpieces. The joint will be stronger if you

use multiple biscuits placed close together.

■ Set fence angle at 90°.

■ Loosen height adjustment knobs, then pull and slide the

fence up or down until the indicator point is aligned with

the desired dimension on the scale. REMEMBER: The

scale indicates the height of the fence from the center of

blade.

■ Tighten height adjustment knobs securely.

■ Select the correct depth of cut setting to match the biscuit

size you are planning to use. We suggest that you make

a test cut in a scrap piece of wood from the same

workpiece if possible.

■ Clamp workpiece securely so that it will not move during

the cut.

■ Plug your biscuit joiner into power supply and prepare to

make your first cut. Grasp and hold your biscuit joiner

securely with both hands.

BISCUIT SLOT(S)

EDGE-TO-EDGE JOINTS

Fig. 8

■ Place the fence against the board and align the indicator

marks on the fence with the centerline mark(s) on the

board.

See Figure 7.

■ Depress the switch trigger and let the motor build to its

maximum speed, then gradually push biscuit joiner forward

to extend the blade into the wood.

■ When the base assembly bottoms out against the depth

of cut adjustment knob setting, pull back releasing pressure

on the spring. Blade will retract from biscuit slot.

■ Repeat this procedure for all desired biscuit slots.

■ Once all biscuit slots have been cut, place a biscuit in

each joint and dry assemble the workpieces. Make sure

each joint lines up and fits.

■ Finally, disassemble the workpieces and place a bead of

glue in each slot. Also, spread a bead of glue over the

entire surface of the joint. Reinsert the biscuits and

assemble the workpieces.

See Figure 8.

■ Clamp workpieces together until the glue sets up.

Page 11

OPERATION

BUTT JOINTS

See Figure 9.

A butt joint is one of the weakest joints in woodworking.

This type of joint is mating the end grain of one board with

the edge grain of another. The bonding of glue on this type

of surface is poor. However, by using biscuits you can

create a very strong joint that gives a mortise-and-tenon

effect.

HOW TO MAKE BUTT JOINTS

■ Unplug your detail biscuit joiner.

■ Place the two pieces of wood to be joined on a level

workbench. Align them against each other in the

arrangement in which they will be assembled.

■ Using a square, determine the location of each biscuit

spline joint and mark the center of each joint by drawing

a line across the edges of the two boards.

■ Set fence angle at 90°.

■ Loosen height adjustment knobs, then pull and slide the

fence up or down until the indicator point is aligned with

the desired dimension on the scale. REMEMBER: The

scale indicates the height of the fence from the center of

the blade.

■ Tighten height adjustment knobs securely.

■ Select the correct depth of cut setting to match the biscuit

size you are planning to use. We suggest that you make

a test cut in a scrap piece of wood from the same

workpiece if possible.

■ Clamp workpiece securely so that it will not move during

the cut.

■ Plug your biscuit joiner into power supply and prepare to

make your first cut. Grasp and hold your biscuit joiner

securely with both hands.

■ Place the fence against the board and align the indicator

marks on the fence with the centerline mark(s) on the

board.

■ Depress the switch trigger and let the motor build to its

maximum speed, then gradually push biscuit joiner forward

to extend the blade into the wood.

■ When the base assembly bottoms out against the depth

of cut adjustment knob setting, pull back releasing pressure

on the spring. Blade will retract from biscuit slot.

■ Repeat this procedure for cutting the slot in the mating

workpiece.

■ Once all biscuit slots have been cut, place a biscuit in

each joint and dry assemble the workpieces. Make sure

each joint lines up and fits.

■ Finally, disassemble the workpieces and place a bead of

glue in each slot. Also, spread a bead of glue over the

entire surface of the joint. Reinsert the biscuits and

assemble the workpieces.

■ Clamp workpieces together until the glue sets up.

See Figure 9.

BISCUIT(S)

BISCUIT

SLOT(S)

CENTERLINE

MARK(S)

MULTIPLE

BISCUITS STACKED

BUTT JOINTS

OFFSET BUTT JOINT

BISCUIT

SLOT

CENTERLINE

MARK(S)

Fig. 9

BISCUIT

Fig. 10

OFFSET BUTT JOINTS

See Figure 10.

The rails of a table or workbench are often offset from the

front of the table legs. When offsets are required, it is

necessary to cut the slots in the rails first, then re-adjust the

fence to cut the slots in the legs.

Keeping this one exception in mind, the procedure for cutting

offset butt joints is identical to the procedure for cutting butt

joints.

For example — If a 1/4 in. offset is desired, you would mark

the centerlines for cutting a butt joint as mentioned in the

procedures for cutting butt joints, and cut the slots in the ends

of the rails. Next you would raise the fence 1/4 in. to the

desired offset and cut the slots in the legs.

Page 12

OPERATION

T- JOINTS

See Figures 11-15.

A T-joint is used when the end of a board is joined to the

face of another board as shown in figure 11. Attaching

shelves to bookcases and inner support braces to frames

are typical applications. Actual cutting of a T-joint is as

simple as any other cut. However, it is critical that you mark

the centerlines, mark the intersection points for each slot,

and cut each slot correctly.

HOW TO MAKE T- JOINTS

■ Unplug your detail biscuit joiner.

■ Place the two pieces of wood to be joined on a level

workbench as shown in figure 12. The inside face of the

vertical board should be facing up.

■ Determine the location of each biscuit joint and mark the

centerlines on each board as shown. The centerlines for

both boards must line-up with each other. Measure

carefully, these measurements must be accurate and

precise. TIP: Measure twice and cut once. In addition to

the centerlines lining up, the spacing of the biscuit slots

from side-to-side must also match.

■ Plug your biscuit joiner into power supply and cut slots in

all boards that require end slots.

procedures explained in "Edge-To-Edge Joints". Rotate

fence angle to 90°, set fence height at desired dimension

on the scale, select the correct depth of cut setting for the

biscuit size you plan to use, clamp workpiece securely,

then cut each slot at the marked centerline intersection.

■ Next, you must remove the fence from your biscuit joiner

in order to cut slots into the face of the vertical board.

TO REMOVE FENCE:

■ Unplug your detail biscuit joiner.

■ Loosen height adjustment knobs, pull fence forward and

slide it down the front base until it can be removed through

the key hole slots.

depth of cut setting for the biscuit size you plan to use,

clamp workpiece securely, and cut each slot at the marked

centerline intersection.

See Figure 11.

See Figure 14.

See Figure 13.

Follow

Next, select the correct

BISCUIT SLOT(S)

HORIZONTAL BOARD

HORIZONTAL BOARD

T- JOINT

BISCUIT SLOT

CENTERLINE MARK(S)

CENTERLINES

VERTICAL BOARD

CENTERLINE

MARK(S)

BISCUIT(S)

Fig. 11

BOARD

Fig. 12

WARNING:

When the fence is removed, the cutter may be exposed.

Use extreme caution to avoid serious personal injury.

■ Place your biscuit joiner on vertical board as shown in

figure 15 and align indicator marks on bottom shoe with

centerline on vertical board.

■ Place a straight piece of wood on the vertical board and

securely clamp it flush against the bottom shoe. This piece

of wood is used for a fence or guide. It must be square with

the sides of the vertical board and parallel with the

centerline.

■ Align centerline on bottom of shoe with marked intersection

for biscuit slot.

Page 13

5

1

6

1

4

2

5°

3

3

4

0

90

°

CLAMP

TO CUT END SLOTS IN

HORIZONTAL BOARDS

Fig. 13

OPERATION

T-JOINTS (Continued)

■ Plug your biscuit joiner into power supply and prepare to

cut slot.

■ Depress the switch trigger and let the motor build to its

maximum speed, then gradually push biscuit joiner forward

to extend the blade into the wood.

■ When the base assembly bottoms out against the depth of

cut adjustment knob setting, pull back releasing pressure

on the spring. Blade will retract from biscuit slot.

■ Repeat this procedure for cutting all required slots in

vertical boards.

■ Once all slots have been cut, place a biscuit in each joint

and dry assemble the workpieces. Make sure each joint

lines up and fits.

■ Finally, disassemble the workpieces and place a bead of

glue in each slot. Also, spread a bead of glue over the

entire surface of the joint. Reinsert the biscuits and

assemble the workpieces.

■ Clamp workpieces together until the glue sets up.

Upon completion of a T-joint cutting operation, reinstall

the fence on the front base by reversing "TO REMOVE

FENCE" procedure. Place height adjustment knob bolts in

key hole slots and align bolt heads with the slots on back of

front base. Slide fence up the front base to desired depth of

cut. Tighten height adjustment knobs securely.

See Figure 11.

FACE CUTS IN VERTICAL BOARDS

BOTTOM SIDE OF BOTTOM SHOE

CENTERLINE MARK

ON WORKPIECE

HORIZONTAL

BOARD

5

16

45°

3

4

0

90°

REMOVE FENCE TO MAKE

Fig. 14

INDICATOR

MARK

MITER JOINTS

See Figures16-18.

There are two types of miter joints that can be made using

biscuits: flat miters and edge miters. Flat miters are used

when making picture frames. Edge miters are used when

making boxes or things where you don't want to show the

end grain of the wood. Butt joints show the end grain in

wood.

HOW TO MAKE FLAT MITER JOINTS

■ Unplug your detail biscuit joiner.

WARNING:

Failure to unplug your detail biscuit joiner could result in

accidental starting causing possible serious personal injury.

■ Place the pieces of wood to be joined on a level

workbench as shown in figure 16.

■ Using a combination square, draw a line through the

center of each joint perpendicular to the mitered edges.

■ Set fence angle at 90°, set fence height at desired dimension

on the scale, select the correct depth of cut setting for the

biscuit size you plan to use, and clamp workpiece securely.

■ Align indicator mark on fence with the centerline on the

workpiece.

■ Plug your biscuit joiner into power supply and prepare to

cut slot.

CLAMP

TO CUT SLOTS IN VERTICAL BOARDS

CENTERLINE

BISCUIT

SLOT

FLAT MITER JOINTS

VERTICAL

BOARD

Fig. 15

MARK(S)

BISCUIT

Fig. 16

Page 14

OPERATION

FLAT MITER JOINTS (Continued)

■ Depress the switch trigger and let the motor build to its

maximum speed, then gradually push biscuit joiner forward

to extend the blade into the wood.

■ When the base assembly bottoms out against the depth of

cut adjustment knob setting, pull back releasing pressure

on the spring. Blade will retract from biscuit slot.

■ Repeat this procedure for cutting mating slot and all

required miter joint slots.

■ Once all slots have been cut, place a biscuit in each joint

and dry assemble the workpieces. Make sure each joint

lines up and fits.

■ Finally, disassemble the workpieces and place a bead of

glue in each slot. Also, spread a bead of glue over the

entire surface of the joint. Reinsert the biscuits and

assemble the workpieces.

■ Clamp workpieces together until the glue sets up.

HOW TO MAKE EDGE MITER JOINTS

■ Unplug your detail biscuit joiner.

■ Place the pieces of wood to be joined on a level workbench

as shown in figure 17.

■ Mark centerline of the joint on each board.

■ When making edge miter joints with workpieces that have

different thicknesses, clamp securely to a workbench

with the long sides up. This will assure that the outside

surfaces will match.

■ Set fence angle at 45°.

■ Slide the fence up or down until fence height is at desired

setting.

■ Tighten height adjustment knobs securely.

■ Place your biscuit joiner on workpiece with the fence

resting on the long side of workpiece as shown in figure

18. The front base should be against the mitered edge of

the workpiece.

■ Recheck fence height setting to make sure it will not cut

through the workpiece.

■ Align indicator mark on fence with the centerline on the

workpiece. Make sure the front base is pressed flat

against the mitered edge of the workpiece.

■ Plug your biscuit joiner into power supply and prepare to

cut slot.

■ Depress the switch trigger and let the motor build to its

maximum speed, then gradually push biscuit joiner forward

to extend the blade into the wood.

■ When the base assembly bottoms out against the depth

of cut adjustment knob setting, pull back releasing pressure on the spring. Blade will retract from biscuit slot.

See Figure 16.

See Figure 18.

BISCUIT

SLOT

CENTERLINE

MARK(S)

EDGE MITER JOINTS

BISCUIT

Fig. 17

CUTTING EDGE MITER SLOT

FROM LONG SIDE OF WORKPIECE

5

16

45°

3

4

0

90°

Fig. 18

■ Repeat this procedure for cutting mating slot and all

required miter joint slots.

■ Once all slots have been cut, place a biscuit in each joint

and dry assemble the workpieces. Make sure each joint

lines up and fits.

■ Finally, disassemble workpieces and place a bead of glue

in each slot. Also, spread a bead of glue over the entire

surface of the joint. Reinsert the biscuits and assemble

workpieces.

See Figure 17.

■ Clamp workpieces together until the glue sets up.

Page 15

OPERATION

HINGE JOINTS

See Figure 19.

Hinge joints are used when joining two boards using hinges

supplied in one of Ryobi's optional hinge kits. Jewelry boxes,

doors on clocks, recipe boxes, etc. are typical applications.

HOW TO MAKE HINGE JOINTS

■ Unplug your detail biscuit joiner.

■ Prepare the workpieces to be joined by laying them side

by side on a workbench in the order in which they will be

hinged.

■ Determine the location of each hinge joint and mark the

center of each joint by drawing a line across each workpiece.

■ Set fence angle at 90°.

■ Loosen height adjustment knobs, then pull and slide the

fence down the scale until the height indicator mark is set

at zero depth of cut. REMEMBER: The scale indicates the

height of the fence from the center of the blade, which is

approximately .050 of an inch.

■ Tighten height adjustment knobs securely.

■ Select the #3 depth of cut setting. We suggest that you

make a test cut in a scrap piece of wood from the same

workpiece if possible.

■ Clamp workpiece securely so that it will not move during

the cut.

■ Plug your biscuit joiner into power supply and prepare to

make your first cut. Grasp and hold your biscuit joiner

securely with both hands.

■ Place the fence against the board and align the indicator

marks on the fence with the centerline mark(s) on the

board.

■ Depress the switch trigger and let the motor build to its

maximum speed, then gradually push biscuit joiner forward

to extend the blade into the wood.

■ When the base assembly bottoms out against the depth

of cut adjustment knob setting, pull back releasing pressure

on the spring. Blade will retract from hinge slot.

■ Repeat this procedure for all desired hinge slots.

■ Once all hinge slots have been cut, place a hinge in each

slot and dry assemble the workpieces. Make sure each

slot lines up and fits.

■ Finally, assemble the hinges to the workpieces and

secure with the fasteners supplied.

See Figure 19.

HINGE

SLOT(S)

HINGE

FASTENERS

HINGE

Fig. 19

EXTENSION CORDS

The use of any extension cord will cause some loss of power.

To keep the loss to a minimum and to prevent tool overheating,

use an extension cord that is heavy enough to carry the

current the tool will draw.

A wire gage size (A.W.G.) of at least 16 is recommended for

an extension cord 50 feet or less in length. When working

outdoors, use an extension cord that is suitable for outdoor

use. The cord's jacket will be marked WA.

WARNING:

Check extension cords before each use. If damaged,

replace immediately. Never use tool with a damaged

cord since touching the damaged area could cause

electrical shock resulting in serious injury.

CAUTION:

Keep extension cords away from the cutting area and

position the cord so that it will not get caught on lumber,

tools, etc. during cutting operations.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication

is required.

Page 16

MAINTENANCE

BLADE REPLACEMENT

See Figures 20– 22.

After extended use, the blade on your biscuit joiner may

become dull. If you accidentally hit a nail or other blunt

object, it will dull or break the blade. These situations

require replacing the blade.

HOW TO REPLACE THE BLADE

■ Unplug your detail biscuit joiner.

WARNING:

Failure to unplug your detail biscuit joiner could result in

accidental starting causing possible serious personal injury.

■ Place your biscuit joiner upside down on a workbench and

remove the bottom shoe screws (4) and bottom shoe.

Figure 20.

■ Place a #1 Phillips screwdriver or 3/16 in. diameter pin

between the blade and front base.

See Figure 21.

■ Place one of the blade teeth against the screwdriver or pin

and lock blade preventing it from rotating.

■ Using a 9/64 in. hex key, remove blade screw.

NOTE: Turn blade screw counterclockwise to remove.

See Figure 22.

■ Remove outer blade washer and blade.

■ Clean wood particles and resin from blade washer and all

surrounding parts.

See

2

3

#1 PHILLIPS SCREWDRIVER

OR 3/16 in. DIAMETER PIN

BLADE

SCREWS (4)

BOTTOM

SHOE

Fig. 20

FRONT BASE

WARNING:

If inner blade washer has been removed, replace it

before installing new blade. Failure to do so could cause

an accident since blade screw will not tighten properly.

■ Place inner blade washer on gear spindle.

■ Place new blade onto gear spindle and align flats on blade

with flats on gear spindle.

■ Secure with outer blade washer and blade screw.

■ Place a #1 Phillips screwdriver or 3/16 in. diameter pin

between the blade and front base.

■ Place one of the blade teeth against the screwdriver or pin

and lock blade preventing it from rotating.

NOTE: Blade teeth point toward the right of your biscuit

joiner when held in normal operating position. An arrow

on the bottom shoe also indicates direction of blade

rotation.

See Figure 20.

■ Tighten blade screw securely.

NOTE: Turn blade screw clockwise to tighten.

■ Reassemble bottom shoe.

■ Replace screws (4) and tighten securely.

See Figure 22.

See Figure 21.

OUTER

BLADE WASHER

BLADE

BLADE

FLATS

INNER

BLADE

WASHER

2

3

2

3

Fig. 21

BLADE SCREW

GEAR

SPINDLE

FLATS

GEAR

SPINDLE

Page 17

Fig. 22

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi replacement

parts. Use of any other part may create a hazard or

cause product damage.

CLEANING BASE ASSEMBLY

See Figures 23-25.

After extended use, wood particles and resin may build up

inside the base assembly of your biscuit joiner and clog the

path for wood particles going through dust exhaust opening.

Wood particles packing up in this area makes cutting biscuit

slots more difficult.

HOW TO CLEAN BASE ASSEMBLY

■ Unplug your detail biscuit joiner.

WARNING:

Failure to unplug your detail biscuit joiner could result in

accidental starting causing possible serious personal injury.

■ Place your biscuit joiner upside down on a workbench and

remove the bottom shoe screws (4) and bottom shoe.

■ Remove the blade. See "Blade Replacement" section.

■ With your biscuit joiner still upside down on a workbench,

remove front base screws (2).

■ Pull front base in the direction shown by the arrow in figure

23 and remove.

■ Using a pair of needle nose pliers, stretch and release

springs from tabs on bearing plate.

■ Lift adjustment rod away from bearing plate and remove

rear base.

■ With front and rear base assemblies removed, place your

biscuit joiner upside down on a workbench and clean

wood particles and resin from bearing plate and surrounding

areas. NOTE: Also clean the blade, blade washers, etc.

See Figure 23.

See Figure 24.

SCREWDRIVER

TAB(S)

BEARING

PLATE

REAR

BASE SLOT

SCREW

HOLE

FRONT BASE

2

SPRING(S)

TO

REMOVE

3

Fig. 23

NOTCH(ES)

REAR BASE

Fig. 24

ADJUSTMENT

ROD

CAUTION:

Blade tips are sharp. Be carefull not to cut yourself

when cleaning.

■ Clean wood particles and resin from slots and surrounding

areas on front and rear base.

coat of general purpose grease in slots or on bearing plate

where base slides.

■ Replace rear base. Position adjustment rod in its proper

place as shown in figure 24.

■ Secure rear base in place with the two springs. Hook one

end of each spring in notch on each side of rear base.

Using needle nose pliers, stretch each spring and hook it

over tabs on bearing plate.

■ Reassemble front base. Replace screws and tighten securely.

See Figure 25.

Apply a thin

Page 18

REAR

BASE SLOT

FRONT

BASE SLOT

FRONT

BASE SLOT

■ Reinstall blade. Tighten blade screw securely.

■ Reassemble bottom shoe. Tighten screws (4) securely.

Fig. 25

MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating oils, etc. come in contact

with plastic parts. They contain chemicals that can

damage, weaken or destroy plastic.

When electric tools are used on fiberglass it has been

found that they are subject to accelerated wear and possible

premature failure, as the fiberglass chips and grindings are

highly abrasive to bearings, brushes, commutator, etc.

Consequently it is not recommended that this tool be used

for extended work on any fiberglass material. During any

use on fiberglass it is extremely important that the tool is

cleaned frequently by blowing with an air jet.

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing

dust. If operation is dusty, also wear a dust mask.

OPTIONAL ACCESSORIES

The following recommended accessories are current and were available at the time this manual was printed:

Item No. Description Quantity

4600411 Size #R1 Accu Biscuits™, Canister Pack 110 Pcs.

4600412 Size #R2 Accu Biscuits™, Canister Pack 100 Pcs.

4600413 Size #R3 Accu Biscuits™, Canister Pack 90 Pcs.

4600415 Size #R3 Value Pack Total 1000 Pcs.

4600435 High Speed Steel Blade 1

4600450 Brass Hinge Kit 6 Pcs.

4600451 Chrome Hinge Kit 6 Pcs.

HELPFUL HINTS

✓ Always clamp workpiece securely before cutting.

✓ A safe operator is one who thinks ahead.

✓ Always wear eye protection when cutting slots.

✓ Make set-up adjustments carefully. Then double check.

Measure twice and cut once.

✓ Always dry assemble your project before gluing it

together.

✓ For loose fit situations, wet biscuits to make them swell.

✓ The more biscuits used, the stronger the joint will be.

✓ Keep blade clean. When the blade becomes dull,

replace it.

✓ Don’t let familiarity make you careless.

✓ Study all safety rules and do the job safely.

✓ NEVER place your hands in jeopardy.

✓ Make certain clamps can’t loosen while in use.

✓ Test difficult set-ups on scrap—Don’t waste lumber.

✓ Plan each operation before you begin.

✓ Provide for smoother operation by cleaning your bis-

cuit joiner frequently. Shake biscuit joiner or blow with

an air jet to remove wood particle build-up.

✓ DO NOT ABUSE POWER TOOLS. Abusive practices

can damage tool as well as workpiece.

✓ THINK SAFETY BY THINKING AHEAD.

Page 19

TROUBLESHOOTING

PROBLEM SOLUTION

1. Biscuits do not fit slots. Biscuits not fitting slots may

also cause misalignment of boards being joined.

2. Wood particles begin to backup on front of unit. A. Dust exhaust may be clogged preventing wood

A. Biscuit slots are too deep or too shallow. Make fine

adjustments to depth setting. See "TO MAKE FINE

ADJUSTMENTS" section on page 9.

B. Biscuit thickness may be out of tolerance. Compress

biscuits in a vise if they are too thick.

C. Check to see if biscuits are the correct size for the

size slots that have been cut: #1, #2, or #3.

D. Check to see if biscuits have gotten wet and swollen.

E. If biscuits fit loose in slots, wet them to take up the

loose fit.

particles from going through dust exhaust opening.

Remove bottom shoe and clean blade, bearing

plate, base assembly slots, and surrounding areas.

See "CLEANING BASE ASSEMBLY" section on

page 18.

3. Blade becomes difficult to push in when cutting

slots. Blade does not retract properly when cutting

slots.

4. Cutting performance is poor and there is a loss of

power or stalling of motor when cutting slots.

A. Wood particles and resin have built up on base

assembly slots and surrounding areas. Remove

front and rear base assemblies and clean blade,

bearing plate, base assembly slots and surrounding

areas. Apply a thin coat of general purpose grease

in slots or on bearing plate where base slides. See

"CLEANING BASE ASSEMBLY" section on page

18.

A. Blade is dull. Replace blade. See "BLADE

REPLACEMENT" section on page 17.

B. Resin has built up on blade. Remove blade and

clean it with gum and pitch remover. See "BLADE

REPLACEMENT" section on page 17 for blade

removing instructions. Once clean, follow "BLADE

REPLACEMENT" instructions to replace the blade.

Page 20

NOTES

Page 21

OWNER'S OPERATING MANUAL

DETAIL BISCUIT JOINER / DBJ50

DOUBLE INSULATED

EXTENSION CORD CAUTION

When using a power tool at a considerable distance from a power

source, be sure to use an extension cord that has the capacity to

handle the current the tool will draw. An undersized cord will cause

a drop in line voltage, resulting in overheating and loss of power.

Use the chart to determine the minimum wire size required in an

extension cord. Only round jacketed cords should be used.

When working with a tool outdoors, use an extension cord that is

designed for outside use. This is indicated by the letters "WA" on

the cord's jacket.

Before using any extension cord, inspect it for loose or exposed

wires and cut or worn insulation.

**Ampere rating

(on tool data plate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

CAUTION: Keep the extension cord clear of the working

area. Position the cord so that it will not get caught on lumber,

tools or other obstructions while you are working with a power

tool.

**Used on 12 gauge - 20 amp circuit.

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or service,

simply contact your nearest Ryobi Authorized Service Center. Be sure to provide all pertinent

facts when you call or visit. Please refer to the Service Center insert or call 1-800-525-2579

in the United States or 1-800-265-6778 in Canada for your nearest Authorized Service

Center.

• MODEL NO.

The model number of your tool will be found on a plate attached to the motor housing. Please

record the model number and serial number in the space provided below.

•MODEL NUMBER DBJ50

• SERIAL NUMBER

RYOBI TECHNOLOGIES INC.

1428 Pearman Dairy Road Anderson SC 29625

Post Office Box 1207 Anderson SC 29622-1207

Phone 1-800-525-2579

972000-311

10-00 Printed in U.S.A.

RYOBI TECHNOLOGIES INC.

P.O. Box 910

Cambridge, Ontario N1R 6K2

Phone 1-800-265-6778

Loading...

Loading...