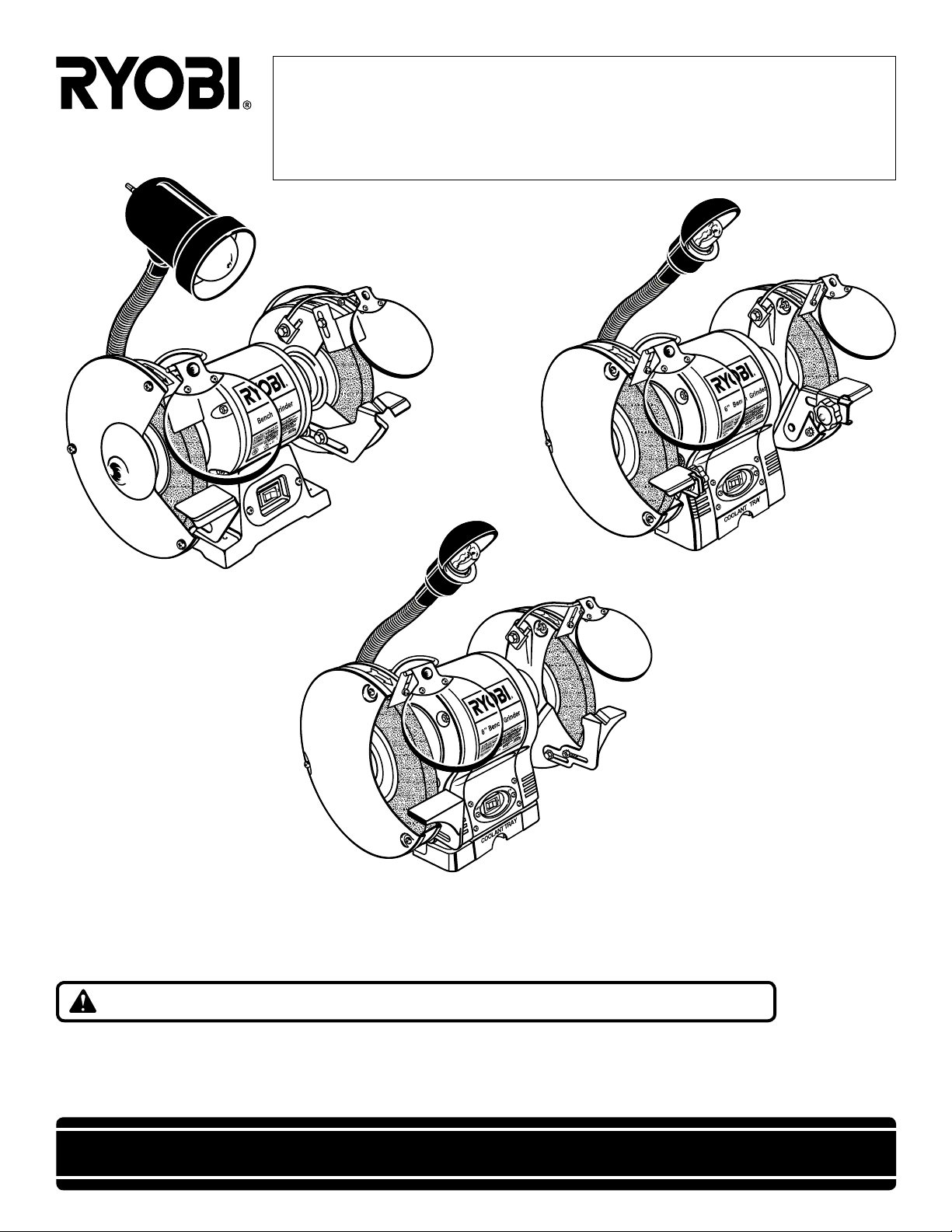

Page 1

OPERATOR'S MANUAL

BENCH GRINDER

MODELS BGH615/BGH625/BGH825

MODEL BGH625

MODEL BGH615

MODEL BGH825

THANK YOU FOR BUYING A RYOBI BENCH GRINDER.

Your new Bench Grinder has been engineered and manufactured to Ryobi's high standards for dependability, ease of

operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

CAUTION: Carefully read through this entire operator's manual before using your new machine.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your grinder properly and only for

what it is intended, you will enjoy years of safe, reliable service.

Please fill out and return the Warranty Registration Card so we can be of future service to you.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

n Table of Contents............................................................................................................................................2

n Product Specifications....................................................................................................................................2

n Rules for Safe Operation ............................................................................................................................ 3-5

n Electrical .........................................................................................................................................................6

n Unpacking.......................................................................................................................................................6

n Loose Parts List ..............................................................................................................................................7

n Tools Needed..................................................................................................................................................7

n Features .................................................................................................................................................... 8-10

n Assembly ................................................................................................................................................ 11-13

n Operation ................................................................................................................................................ 14-15

n Maintenance .................................................................................................................................................16

n Parts Ordering / Service ...............................................................................................................................20

PRODUCT SPECIFICATIONS

BGH615 BGH625 BGH825

Wheels:

- Diameter 6 in. (152 mm) 6 in. (152 mm) 8 in. (203 mm)

- Thickness 3/4 in. (19 mm) 3/4 in. (19 mm) 1 in. (25.4 mm)

- Arbor Hole 1/2 in. (13 mm) 1/2 in. (13 mm) 5/8 in. (16 mm)

No Load Speed 3600 RPM 3600 RPM 3600 RPM

Rating 120 Volts, 60Hz-AC Only 120 Volts, 60Hz-AC Only 120 Volts, 60Hz-AC Only

Input 2.1 Amperes 2.1 Amperes 3.1 Amperes

Tool Weight 25 lbs. (11 kg) 22 lbs. (10 kg) 34 lbs. (15 kg.)

Look for this symbol to point out important safety precautions. It

means attention!!! Your safety is involved.

Page 2

Page 3

RULES FOR SAFE OPERATION

Safe operation of this power tool requires that you read and

understand this operator's manual and all labels affixed to

the tool. Safety is a combination of common sense, staying

alert, and knowing how your bench grinder works.

READ ALL INSTRUCTIONS

n KNOW YOUR POWER TOOL. Read the operator's

manual carefully. Learn the applications and limitations

as well as specific potential hazards related to this tool.

n GUARD AGAINST ELECTRICAL SHOCK by prevent-

ing body contact with grounded surfaces. For example:

pipes, radiators, ranges, refrigerator enclosures.

n KEEP GUARDS IN PLACE and in working order. Never

operate the tool with any guard or cover removed. Make

sure all guards are operating properly before each use.

n REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see keys and adjusting wrenches are

removed from tool before turning it on.

n KEEP THE WORK AREA CLEAN. Cluttered work areas

and work benches invite accidents.

n AVOID DANGEROUS ENVIRONMENTS. Do not use

power tools near gasoline or other flammable liquids,

in damp or wet locations or expose them to rain. Keep

work area well lighted.

n KEEP CHILDREN AND VISITORS AWAY. All visitors

should wear safety glasses and be kept a safe distance

from work area.

n MAKE WORKSHOP CHILDPROOF with padlocks,

master switches, or by removing starter keys.

n DON’T FORCE THE TOOL. It will do the job better and

safer at the rate for which it was designed.

n USE THE RIGHT TOOL. Do not force the tool or attach-

ment to do a job for which it was not designed.

n USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating. A wire gage size (A.W.G.) of at

least 16 is recommended for an extension cord 25 feet

or less in length. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

n INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

n WEAR PROPER APPAREL. Do not wear loose clothing,

neckties, or jewelry that can get caught in the tool’s

moving parts and cause personal injury. Nonslip footwear

is recommended when working outdoors. Wear protective

hair covering to contain long hair.

n ALWAYS W EAR SAF ETY GLAS SES WIT H SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses; they are NOT safety glasses.

n PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

n PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

n DON’T ABUSE CORD. Never carry tool by the cord or

yank it to disconnect from receptacle. Keep cord from

heat, oil, and sharp edges.

n DO NOT OVERREACH. Keep proper footing and balance

at all times.

n MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow instructions

for lubricating and changing accessories.

n NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Disconnect all tools when not in use, before

servicing, or when changing attachments, wheels, etc.

n AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in.

n USE RECOMMENDED ACCESSORIES. The use of

improper accessories may cause risk of injury.

n USE ONLY GRINDING WHEELS that comply with ANSI

B7.1 and rated greater than 3600 RPM.

n DO NOT use wheels with incorrect size holes. NEVER

use wheel washers or wheel screws that are defective

or incorrect and NEVER touch grinding wheel or other

moving parts.

n NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the wheel is unintentionally contacted.

n DIRECTION OF FEED. Be aware of wheel rotation direc-

tion; never grind without the workrest being properly set.

NEVER grind more than one workpiece at a time.

WARNING: Wheel coasts after turn off.

n CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

n KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

n INSPECT TOOL CORDS AND EXTENSION CORDS

PERIODICALLY and, if damaged, have repaired by a

qualified service technician. Stay constantly aware of

cord location and keep it well away from the rotating

wheel.

n NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor or sparking from grinding metal could

ignite fumes.

Page 3

Page 4

RULES FOR SAFE OPERATION

DO N OT EX POS E

TO RAIN OR USE IN

DAMP LOCATIONS

n US E OUTDOOR EXT ENSION CORDS. Use only

extension cords with approved ground connection that

are intended for use outdoors and so marked.

n NEVER reach to pick up a workpiece, a piece of scrap,

or anything else that is in or near the grinding path of the

wheel.

n AVOID AWKWARD OPERATIONS AND HAND POSI-

TIONS where a sudden slip could cause your hand to

move into the wheel. ALWAYS make sure you have good

balance.

n NEVER stand or have any part of your body in line with

the path of the wheel.

n DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorized service center.

n DO NOT TURN THE MOTOR SWITCH ON AND OFF

RAPIDLY. This could cause the wheel to loosen and could

create a hazard. Should this ever occur, stand clear and

allow the wheel to come to a complete stop. Disconnect

your grinder from the power supply and securely retighten

the wheel nut.

WARNING:

When servicing use only identical Ryobi replacement

parts. Use of any other parts may create a hazard or

cause product damage.

n USE ONLY FLANGES furnished with this bench

grinder.

n IF ANY PART OF THIS GRINDER IS MISSING or should

break, bend, or fail in any way, or should any electrical

component fail to perform properly, shut off the power

switch, remove the machine plug from the power source

and have damaged, missing, or failed parts replaced before resuming operation.

n MAKE SURE THE GRINDER IS SECURELY MOUNTED

as described in the operating instructions before connecting the tool to a power supply.

n DO NOT OVERTIGHTEN THE WHEEL NUT. Excessive

tightening can cause the wheel to crack during operation.

n INSPECT GRINDING WHEEL for visible defects. Check

the wheel for fissures and cracks, and test for normal

operation prior to use.

n ADJUST distance between wheel and work rest to main-

tain 1/16 in. or less separation as the diameter of the

wheel decreases with use. The value of separation used

in the marking is to be the separation recommended by

the manufacturer but shall not be more than 1/8 in.

n ALWAYS EASE THE WORKPIECE AGAINST THE

ABRASIVE WHEEL when starting to grind. A harsh

impact can break the wheel. Use light pressure when

starting to grind; too much pressure on a cold wheel can

cause the wheel to crack.

Page 4

n RISK OF INJURY DUE TO ACCIDENTAL STARTING.

Do not use in an area where children may be present.

n NEVER START THE GRINDER when the wheel is in

contact with the workpiece.

n SECURE WORK. Always hold workpiece firmly against

the work rest.

n DO NOT USE THE BENCH GRINDER if the flange nut

or clamp nut is missing or if the spindle shaft is bent.

n FREQUENTLY clean grinding dust from beneath grind-

er.

n DO NOT OPERATE THIS TOOL WHILE UNDE R

THE INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION.

n ALWAYS STAY ALERT. Do not allow familiarity (gained

from frequent use of your grinder) to cause a careless

mistake. ALWAYS REMEMBER that a careless fraction

of a second is sufficient to inflict severe injury.

n STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

n SAVE THESE INSTRUCTIONS. Refer to them frequently

and use them to instruct other users. If you loan someone

this tool, loan them these instructions also.

WARNING:

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals

are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Page 5

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the explanations

with them, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate

any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT SYMBOL:

Indicates danger, warning, or caution. May be used in conjunction with other symbols or picto-

graphs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always

follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equip-

ment.

IMPORTANT

Servicing requires extreme care and knowledge and

should be performed only by a qualified service technician.

For service we suggest you return the tool to your nearest

RYOBI AUTHORIZED SERVICE CENTER for repair. When

servicing, use only identical Ryobi replacement parts.

The operation of any grinder can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool operation, always wear safety goggles

or safety glasses with side shields and a full face shield when needed. We recommend Wide

Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields.

WARNING:

Do not attempt to operate this tool until you have read

thoroughly and understand completely all instructions,

safety rules, etc. contained in this manual. Failure to comply can result in accidents involving fire, electric shock,

or serious personal injury. Save this operator's manual

and review frequently for continuing safe operation and

instructing others who may use this tool.

Page 5

Page 6

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool's plug.

When using a power tool at a considerable distance from the

power source, use an extension cord heavy enough to carry

the current that the tool will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the chart

provided below to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed by

Underwriter's Laboratories (UL) should be used.

Length of Extension Cord Wire Size (A.W.G.)

Up to 25 feet 16

26-50 feet 16

51-100 feet 16

When working with the tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the

letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

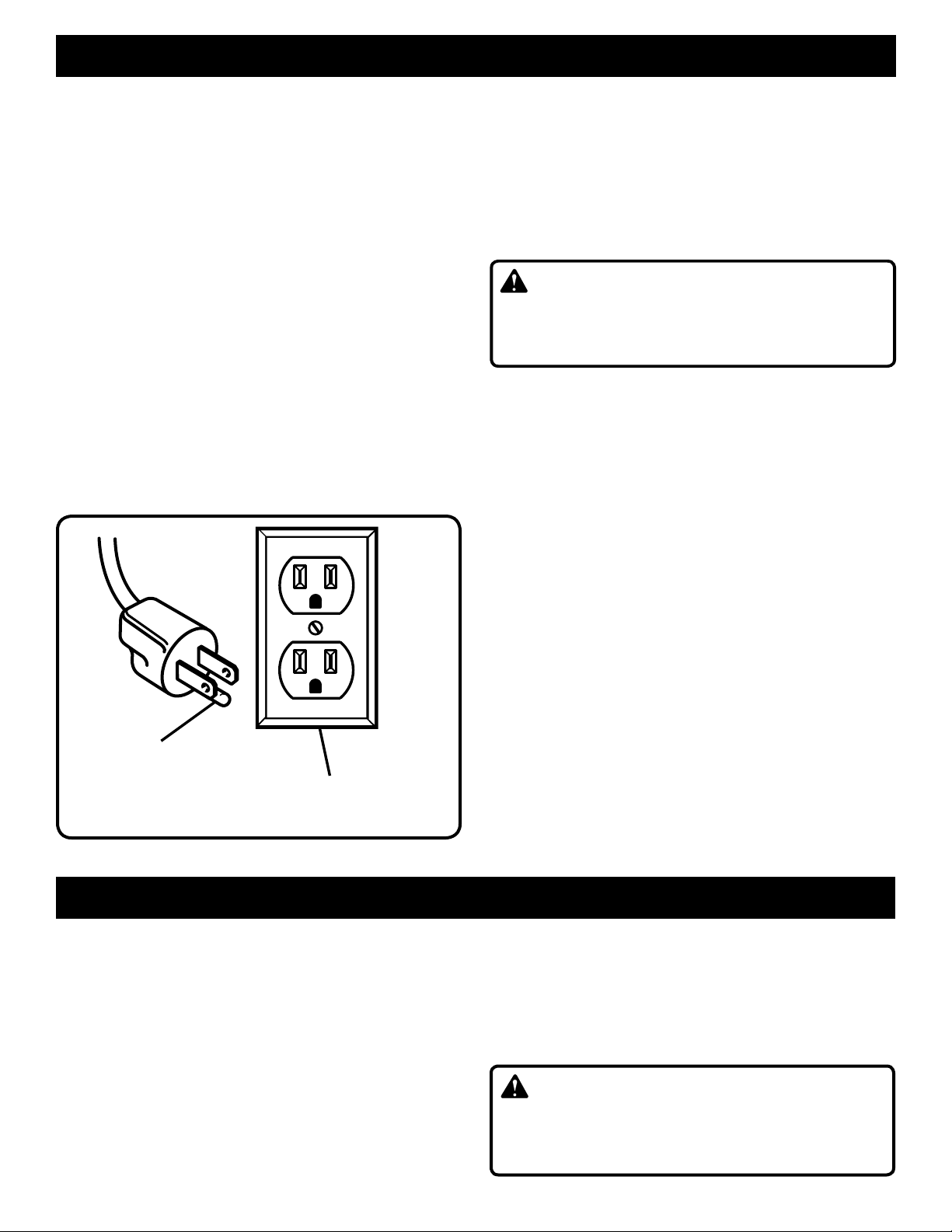

GROUNDING

PIN

COVER OF GROUNDED

OUTLET BOX

Fig. 1

ELECTRICAL CONNECTION

Your Ryobi Bench Grinder is powered by a precision built

electric motor. It should be connected to a power supply

that is 120 volts, 60Hz, AC only (normal household current).

Do not operate this tool on direct current (DC). A substantial

voltage drop will cause a loss of power and the motor will

overheat. If the machine does not operate when plugged

into an outlet, double check the power supply.

CAUTION:

Keep the cord away from the grinding area and position

the cord so that it will not be caught on material, tools,

or other objects.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor

can result in electrical shock. The conductor with insulation

having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary, do

not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet

like the one shown in figure 1. It also has a grounding pin

like the one shown.

UNPACKING

n Carefully remove all parts from the shipping carton.

n Lift the bench grinder from the carton and place it on a

level work surface.

n Do not discard the packing materials until you have care-

fully inspected the machine, identified all loose parts, and

satisfactorily operated your bench grinder.

n Examine all parts to make sure no breakage or damage

has occurred during shipping.

n If all parts have been included, proceed to assembly.

Page 6

n If any parts are damaged or missing, do not attempt to

plug in this tool or turn it on until the damaged or missing

parts are obtained and installed correctly.

n Contact your nearest Ryobi dealer or call 1-800-525-2579

in the United States or 1-800-265-6778 in Canada for

assistance if any parts are missing or damaged.

WARNING:

If any parts are missing do not operate this machine until

the missing parts are replaced. Failure to do so could

result in possible serious injury.

Page 7

LOOSE PARTS LIST

LOOSE PARTS LIST – BGH615

The following items are included with your Bench Grinder:

n Shield Rods – one left, one right ................................. 2

n Shield Rod Brackets with Hardware............................ 2

n Safety Shields.............................................................. 2

n Spark Deflectors – one left, one right.......................... 2

n Work Rests – one left, one right .................................. 2

LOOSE PARTS LIST – BGH625

The following items are included with your Bench Grinder:

n Shield Rods – one left, one right ................................. 2

n Shield Rod Brackets with Hardware............................ 2

n Safety Shields ............................................................. 2

n Spark Deflectors.......................................................... 2

n Work Rests – one left, one right .................................. 2

n Lock Washers (5 mm).................................................. 2

n Washers (5 mm)........................................................... 2

n Washers (6 mm)........................................................... 2

n Washers (8 mm)........................................................... 6

n Hex Bolts (6 mm x 6) ................................................... 2

n Hex Bolts (8 mm x 8) ................................................... 4

n Hex Bolts (8 mm x 14) ................................................. 2

n Operator's Manual

n Washers (8 mm)........................................................... 2

n Phillips Screws (5 mm x 8) .......................................... 2

n Hex Bolts (8 mm x 14) ................................................. 2

n Adjustment Knobs....................................................... 2

n Hex Nuts (5 mm).......................................................... 2

n Washers (5 mm)........................................................... 2

n Operator's Manual

LOOSE PARTS LIST – BGH825

The following items are included with your Bench Grinder:

n Shield Rods – one left, one right ................................. 2

n Shield Rod Brackets with Hardware............................ 2

n Safety Shields.............................................................. 2

n Spark Deflectors.......................................................... 2

n Work Rests – one left, one right .................................. 2

n Lock Washers (5 mm).................................................. 2

n Washers (5 mm)........................................................... 2

n Washers (8 mm)........................................................... 2

n Phillips Screws (5 mm x 8) .......................................... 2

n Hex Bolts (8 mm x 14) ................................................. 2

n Hex Bolts (5 mm x 10) ................................................. 2

n Operator's Manual

TOOLS NEEDED

The following tools (not included) are needed for assembly and alignment:

7 MM, 10 MM, AND 12 MM

COMBINATION WRENCH

PHILLIPS SCREWDRIVER

ADJUSTABLE WRENCH

Page 7

Fig. 2

Page 8

FEATURES – BGH615

KNOW YOUR BENCH GRINDER

See Figure 3a.

Before attempting to use your new tool, familiarize yourself with all operating features and safety requirements.

Carefully read this operator’s manual before using your

grinder.

ON/OFF SWITCH

Your BGH615 Bench Grinder features a front access On/

Off switch for convenience and safety.

MOTOR

Powered by a precision-built electric induction motor, your

bench grinder has sufficient power to handle tough grinding jobs.

GRINDING WHEEL

Equipped with course and fine grinding wheels to suit

most applications.

Note: New wheels sometimes require dressing to true up

the face of the wheel.

WORKLIGHT

SWITCH

WORKLIGHT

SAFETY SHIELD AND SPARK DEFLECTOR

The safety shields and spark deflectors are adjustable for

operator convenience. Operating the grinder without these

features attached could result in serious injury. Do not grind

with the safety shield raised; always wear safety glasses for

personal protection.

WORK REST

The work rests are independently adjustable to compensate for wheel wear. Before grinding, make certain

the work rests are adjusted properly. Generally the object

being ground is done slightly above center of the grinding

wheel.

Adjust the distance between the wheel and the work rest

to maintain 1/16 in. or less separation as the diameter of

the wheel decreases with use.

WORKLIGHT

Your BGH615 Bench Grinder comes equipped with a permanently mounted worklight that lights the work area for

safer, more accurate grinding and sharpening. (Requires a

40 watt bulb – not included.)

SPARK

DEFLECTOR

(LEFT)

WHEEL

GUARD

SAFETY

SHIELD(S)

SHIELD RODS

(RIGHT AND LEFT)

SPARK

DEFLECTOR

(RIGHT)

WORK REST

(RIGHT)

OFF

ON

SWITCH

WORK REST

(LEFT)

MODEL BGH615

Fig. 3a

Page 8

Page 9

FEATURES – BGH625

KNOW YOUR BENCH GRINDER

See Figure 3b.

Before attempting to use your new tool, familiarize yourself

with all operating features and safety requirements. Carefully

read this operator’s manual before using your grinder.

ON/OFF SWITCH

Your BGH625 Bench Grinder features a front access On/Off

switch for convenience and safety.

MOTOR

Powered by a precision-built electric induction motor, your

bench grinder has sufficient power to handle tough grinding jobs.

GRINDING WHEEL

Equipped with course and fine grinding wheels to suit most

applications.

Note: New wheels sometimes require dressing to true up

the face of the wheel.

SAFETY SHIELD AND SPARK DEFLECTOR

The safety shields and spark deflectors are adjustable for

operator convenience. Operating the grinder without these

features attached could result in serious injury. Do not grind

with the safety shield raised; always wear safety glasses for

personal protection.

WORK REST

The work rests are independently adjustable to compensate

for wheel wear. Before grinding, make certain the work rests

are adjusted properly. Generally the object being ground is

done slightly above center of the grinding wheel.

Adjust the distance between the wheel and the work rest to

maintain 1/16 in. or less separation as the diameter of the

wheel decreases with use.

WHEEL DRESSING TOOL

A buildup of metals, dirt, rust, etc. will become embedded

in the grinding wheel as it wears. Using the Wheel Dressing

Tool to clean the wheel of these ground-in particles will help

improve the grinder’s performance.

AUTO-ON WORKLIGHT

Your BGH625 Bench Grinder comes equipped with a

permanently mounted worklight that automatically lights

the work area for safer, more accurate grinding and

sharpening.

COOLANT TRAY

When grinding, metal objects become heated quickly. It is

important to keep moving the object back and forth across

the grinding wheel and to cool the object frequently using

the grinder’s Coolant Tray.

SPARK

DEFLECTOR

(LEFT)

SAFETY

SHIELD(S)

WHEEL

GUARD

AUTO-ON

WORKLIGHT

WORK REST

(LEFT)

SHIELD RODS

(RIGHT AND LEFT)

ADJUSTMENT

KNOB(S)

COOLANT

TRAY

SPARK

DEFLECTOR

(RIGHT)

WORK REST

(RIGHT)

ON

OFF

SWITCH

MODEL BGH625

Page 9

Fig. 3b

Page 10

FEATURES – BGH825

KNOW YOUR BENCH GRINDER

See Figure 3c.

Before attempting to use your new tool, familiarize yourself

with all operating features and safety requirements. Carefully

read this operator’s manual before using your grinder.

ON/OFF SWITCH

Your BGH825 Bench Grinder features a front access On/Off

switch for convenience and safety.

MOTOR

Powered by a precision-built electric induction motor, your

bench grinder has sufficient power to handle tough grinding jobs.

GRINDING WHEEL

Equipped with course and fine grinding wheels to suit most

applications.

Note: New wheels sometimes require dressing to true up

the face of the wheel.

SAFETY SHIELD AND SPARK DEFLECTOR

The safety shields and spark deflectors are adjustable for

operator convenience. Operating the grinder without these

features attached could result in serious injury. Do not grind

with the safety shield raised; always wear safety glasses for

personal protection.

WORK REST

The work rests are independently adjustable to compensate

for wheel wear. Before grinding, make certain the work rests

are adjusted properly. Generally the object being ground is

done slightly above center of the grinding wheel.

Adjust the distance between the wheel and the work rest to

maintain 1/16 in. or less separation as the diameter of the

wheel decreases with use.

WHEEL DRESSING TOOL

A buildup of metals, dirt, rust, etc. will become embedded

in the grinding wheel as it wears. Using the Wheel Dressing

Tool to clean the wheel of these ground-in particles will help

improve the grinder’s performance.

AUTO-ON WORKLIGHT

Your BGH825 Bench Grinder comes equipped with a

permanently mounted worklight that automatically lights

the work area for safer, more accurate grinding and

sharpening.

COOLANT TRAY

When grinding, metal objects become heated quickly. It is

important to keep moving the object back and forth across

the grinding wheel and to cool the object frequently using

the grinder’s Coolant Tray.

WHEEL

GUARD

SPARK

DEFLECTOR

(LEFT)

SAFETY

SHIELD(S)

AUTO-ON

WORKLIGHT

WORK REST

(LEFT)

SHIELD RODS

(RIGHT AND LEFT)

COOLANT TRAY

MODEL BGH825

SPARK

DEFLECTOR

(RIGHT)

WORK REST

(RIGHT)

ON

OFF

SWITCH

Fig. 3c

Page 10

Page 11

ASSEMBLY

WARNING:

Always disconnect the bench grinder from the power

source before performing any assembly or adjustment.

Failure to do so could result in accidental starting resulting in possible serious personal injury.

SPARK DEFLECTOR – BGH615

See Figure 4a.

Using two 6 mm hex bolts and washers, attach the spark

deflector to the inside of the wheel guard.

Adjust the spark deflectors to within 1/16 in. of the grinding

wheel. Tighten the hex bolts securely.

SPARK DEFLECTOR – BGH625 AND BGH825

See Figures 4b and 4c.

Using the two phillips head screws, washers, and lock

washers, attach the spark deflector to the top of the wheel

guard.

Adjust the spark deflectors to within 1/16 in. of the grinding

wheel. Tighten the hex bolts securely.

WARNING:

Always spin the wheel by hand before turning on the

grinder to make sure the spark deflector doesn’t hit the

grinding wheel.

HEX BOLT

BGH615

WASHER

SPARK

DEFLECTOR

Fig. 4a

SPARK DEFLECTOR

WASHER

SCREW

LOCK

WASHER

WARNING:

Always make sure your bench grinder is securely mounted

to a workbench or an approved workstand. Failure to do

so could result in an accident resulting in possible serious personal injury.

BGH625

SPARK DEFLECTOR

Fig. 4b

WASHER

SCREW

LOCK

WASHER

Page 11

BGH825

Fig. 4c

Page 12

ASSEMBLY

SHIELD BRACKET ASSEMBLY

See Figure 5.

Note: The hardware used for assembling the safety

shields to the shield brackets has been preassembled and

prepackaged.

Remove the two phillips head screws, washers, and hex

nuts from the shield bracket. Fit the shield bracket to the

top of the safety shield. Reattach the screws, washers, and

hex nuts taking care not to tighten the screws so tight as to

crack the plastic. Repeat for the other shield bracket and

safety shield.

WARNING:

To prevent personal injury, never operate the bench

grinder unless the safety shields and spark deflectors

are properly installed and in place.

MOUNTING SAFETY SHIELDS

See Figures 6a - 6c.

Mount the left and right shield rods to the inside of the wheel

guards using the clamp brackets, hex bolts (8 mm x 14 mm),

and washers (8 mm).

Locate your grinder in figures 6a, 6b, or 6c. Use the illustration as a guide to determine which shield rod is mounted

on the left and which shield rod is mounted on the right of

the grinder.

Once shield rods are firmly in place, slide the shield bracket

onto the shield rod. Tighten the carriage bolt leaving it loose

enough to allow the safety shield to be raised and lowered

easily.

SHIELD ROD

CLAMP BRACKET

WASHER

HEX BOLT

SHIELD ROD

CLAMP BRACKET

WASHER

HEX BOLT

BGH615

Fig. 6a

SHIELD ROD

WASHER

HEX NUT

WASHER

LOCK

WASHER

HEX NUT

CARRIAGE

LOCK

WASHER

SAFETY

SHIELD

BOLT

PHILLIPS SCREW

SHIELD

BRACKET

Fig. 5

Page 12

SHIELD ROD

CLAMP BRACKET

WASHER

HEX BOLT

BGH625

BGH825

Fig. 6b

Fig. 6c

Page 13

ASSEMBLY

WORK REST – BGH615

See Figure 7a.

Mount the work rests to the inside of each wheel guard using two hex bolts (8 mm x 8) and two washers (8 mm) on

each side.

Before tightening the bolts, adjust the gap between the

grinding wheel and the work rest to a maximum of 1/16 in.

Tighten securely.

WORK REST – BGH625

See Figure 7b.

Mount the work rests to the work rest bracket using the

knob, washer, and one hex nut.

Before tightening the bolts, adjust the gap between the

grinding wheel and the work rest to a maximum of 1/16 in.

Tighten securely.

WORK REST – BGH825

See Figure 7c.

Before attempting to mount the work rest, remove the hex

nut and star washer from the phillips screw. See Figure 7c.

Place the work rest over the phillips screw before replacing the

hex nut and star washer. Using the hex bolt (5 mm x 10 mm)

and washer (5 mm), secure the work rest against the inside

of the wheel guard.

Before tightening the bolts, adjust the gap between the

grinding wheel and the work rest to a maximum of 1/16 in.

Tighten securely.

HEX BOLTS

BGH615

WORK

REST

WASHERS

Fig. 7a

HEX

NUT

WASHER

KNOB

BGH625

WORK REST

BRACKET

WORK

REST

Fig. 7b

PHILLIPS

SCREW

WORK

REST

STAR

WASHER

Page 13

HEX BOLT

WASHER

BGH825

HEX NUT

Fig. 7c

Page 14

OPERATION

BASIC OPERATION

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing dust.

If operation is dusty, wear a dust mask.

To be efficient and work as designed, your tools should be

kept sharp. Dull tools can and will cause accidents.

Bench Grinders are ideal for sharpening tools such as

chisels, planer blades, scissors, etc., and for removing rust

or corrosion.

WARNING:

Never sharpen or grind anything made of aluminum.

Grinders remove material rapidly so pressure is the key to

efficient grinding.

The proper way to sharpen a tool and avoid overheating

is:

n Keep the object in constant motion, moving it at an even

pace.

n Never force a tool against the grinding wheel.

n Keep the tool cool by using either a cooling tray or a pan

of water.

n The grinding wheel should rotate “into” the object being

sharpened.

Note: Excessive pressure may damage the tool, cause the

motor to overheat, and prematurely wear down the grinding

wheel.

BIT SHARPENING

SCREWDRIVER

V-GROOVE

Fig. 8

LAWN MOWER BLADE

VISE

WARNING:

Excessive pressure on a cold wheel may cause the wheel

to crack.

The following recommendations will help you sharpen

specific tools:

TWIST DRILL BITS

See Figure 8.

Drill bits are best sharpened on a sharpening jig (available

at most hardware stores). Begin on one side of the point

at the existing angle, then twist the bit while maintaining

contact with the grinding surface. Sharpen only the tip.

This technique requires considerable practice, so take your

time and make a few “dry runs” first with the grinder off. Be

sure to maintain the original cutting edge angle as this is

important to the efficiency of your bits. One work rest has

a V-groove (models BGH615 and BGH825 only) angled to

fit most drill bits.

Fig. 9

LAWN MOWER BLADES

See Figure 9.

Lawn mower blades are usually sharpened on only one

edge and dressed up slightly on the other. Perform this

sharpening process on both cutting ends of the blade.

After sharpening, be sure to balance the blade by removing

additional material.

CAUTION:

An unbalanced lawn mower blade may cause excessive

vibration which will damage the lawn mower.

Page 14

Page 15

OPERATION

CHISELS AND SCREWDRIVER BLADES

See Figure 10.

When sharpening chisels and screwdrivers, work rest

should support the chisel at the correct angle against the

wheel.

WARNING:

Always disconnect the bench grinder from the power

source before performing any assembly or adjustment.

Failure to do so could result in accidental starting resulting in possible serious personal injury.

WHEEL REPLACEMENT

See Figure 11.

If you must replace a grinding wheel, be sure to obtain one

with a safe rated speed at least as high as the “no load

speed” RPM marked on the data plate of the grinder and

which is marked to comply with ANSI B7.1.

To replace the grinding wheel, remove the wheel cover by

loosening the screws. Loosen the wheel nut in a clockwise

direction for the left side and a counterclockwise direction

for the right side. Remove the outer flange and grinding

wheel. To install a new grinding wheel, reverse the above

procedure. Be sure the grinding wheel and outer flange are

properly seated on the spindle shaft.

CHISEL SHARPENING

Fig. 10

SCREW(S)

WHEEL

GUARD COVER

OUTER

FLANGE

STAR

WASHER(S)

SPINDLE

WHEEL

NUT

SHAFT

GRINDING

WHEEL

HEX NUT(S)

INNER

FLANGE

Fig. 11

Page 15

Page 16

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi replacement

parts. Use of any other part may create a hazard or cause

product damage.

GENERAL

Keep the bench grinder clean. Remove dust from working

parts and beneath the grinder frequently.

Make sure the bench grinder operates properly. Check

screws, nuts, and bolts for tightness.

EXTENSION CORDS

The use of any extension cord will cause some loss of

power. To keep the loss to a minimum and to prevent tool

overheating, use an extension cord that is heavy enough to

carry the current the tool will draw.

A wire gage size (A.W.G.) of at least 16 is recommended for

an extension cord 25 feet or less in length. When working

outdoors, use an extension cord that is suitable for outdoor

use. The cord's jacket will be marked WA.

WARNING:

Check extension cords before each use. If damaged,

replace immediately. Never use tool with a damaged cord

since touching the damaged area could cause electrical

shock resulting in serious injury.

10 WATT, 120 VOLT

WORKLIGHT BULB

SLOT

BGH625/BGH825

TO REMOVE BULB

TAB

TO INSTALL BULB

10 WATT, 120 VOLT

WORKLIGHT BULB

Fig. 12

WORKLIGHT BULB REPLACEMENT

For models BGH625 and BGH825, Figure 12.

To remove worklight bulb, gently push the bulb into the

socket and turn counterclockwise. To install the new bulb,

gently push the bulb into the socket and turn clockwise.

For model BGH615, Figure 13.

To remove bulb, turn counterclockwise. To install new bulb,

turn clockwise.

Note: To avoid the risk of fire, never use a bulb with a wattage

higher than 40.

WHEEL DRESSER

For models BGH625 and BGH825 ONLY.

Dressing a wheel is done to renew sharpness or to true up

the face of the wheel.

Set the work rest of the bench grinder at a slight angle and

brace the wheel dresser against it. Do not make contact with

the grinding wheel until after you have turned on the motor

and the wheel is rotating at full speed. Press the dresser

slightly against the rotating wheel until you get a bite, then

move slowly from side to side across the wheel. A small bite

and many passes is better than a big bite and one pass.

Work cautiously, hold the dresser with force on the work rest.

Do not use excessive pressure against the grinding wheel.

Proceed slowly until you master the technique.

40 WATT

WORKLIGHT

BULB

REMOVE BULB

BGH615

TO

INSTALL BULB

TO

Fig. 13

Page 16

Page 17

NOTES

NOTES

Page 17

Page 18

OPERATOR'S MANUAL

Bench Grinder

Models BGH615/BGH625/BGH825

EXTENSION CORD CAUTION

When using a power tool at a considerable distance from a power

source, be sure to use an extension cord that has the capacity to

handle the current the tool will draw. An undersized cord will cause

a drop in line voltage, resulting in overheating and loss of power.

Use the chart to determine the minimum wire size required in an

extension cord. Only round jacketed cords should be used.

When working with a tool outdoors, use an extension cord that

is designed for outside use. This is indicated by the letters "WA"

on the cord's jacket.

Before using any extension cord, inspect it for loose or exposed

wires and cut or worn insulation.

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or service, simply contact your nearest Ryobi Authorized Service Center. Be sure to provide all

pertinent facts when you call or visit. Please call 1-800-525-2579 for your nearest Ryobi

Authorized Service Center. You can also check our web site at www.ryobitools.com for

a complete list of Authorized Service Centers.

**Ampere rating

(on tool data plate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

CAUTION: Keep the extension cord clear of the working

area. Position the cord so that it will not get caught on workpiece,

tools, or other obstructions while you are working with a power

tool.

**Used on 12 gauge - 20 amp circuit.

• MODEL NO.

The model and serial numbers of your tool will be found on a plate attached to the motor

housing. Please record the serial number in the space provided below.

• MODEL NUMBER BGH615/BGH625/BGH825

• SERIAL NUMBER

972000-880

7-04

RYOBI TECHNOLOGIES INC.

1428 Pearman Dairy Road Anderson, SC 29625

Post Office Box 1207 Anderson SC 29622-1207

Phone 1-800-525-2579

Loading...

Loading...