Page 1

RuggedBackbone™

RX5000

Hardware Installation Guide

Revision 106 - June 2, 2011

www.RuggedCom.com

Page 2

RuggedBackbone™ RX5000

RuggedBackbone™ RX5000: Hardware Installation Guide

Copyright © 2011 RuggedCom Inc.

All Rights Reserved

Dissemination or reproduction of this document, or evaluation and communication of its contents, is not authorized except where expressly

permitted. Violations are liable for damages. All rights are reserved, particularly for the purposes of patent application or trademark registration.

This document contains proprietary information, which is protected by copyright. All rights are reserved. No part of this document may be

photocopied, reproduced or translated to another language without the prior written consent of RuggedCom Inc.

Disclaimer Of Liability

We have checked the contents of this manual against the hardware and software described. However, deviations from the description cannot

be completely ruled out.

RuggedCom shall not be liable for any errors or omissions contained herein or for consequential damages in connection with the furnishing,

performance, or use of this material.

The information given in this document is reviewed regularly and any necessary corrections will be included in subsequent editions. We appreciate

any suggested improvements. We reserve the right to make technical improvements without notice.

Registered Trademarks

ROX™, RuggedBackbone™, RuggedRated™ and eRSTP™ are trademarks of RuggedCom Inc. Other designations in this manual might be

trademarks whose use by third parties for their own purposes would infringe the rights of the owner.

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.

The registered trademark Linux® is used pursuant to a sublicense from LMI, the exclusive licensee of Linus Torvalds, owner of the mark on

a world-wide basis.

Warranty

Five (5) years from date of purchase, return to factory. For warranty details, visit www.ruggedcom.com or contact your customer service

representative.

Contacting RuggedCom

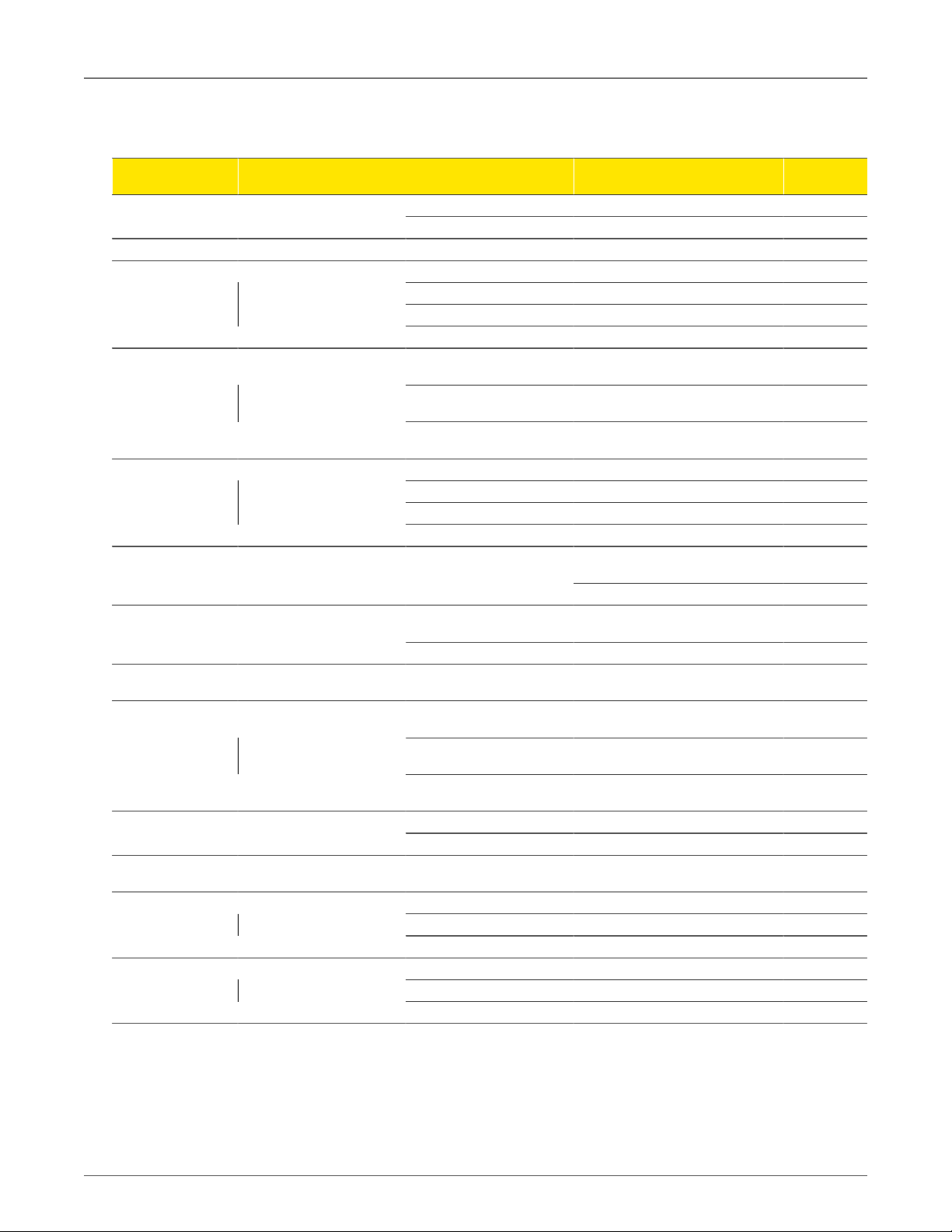

Corporate Headquarters US Headquarters Europe Headquarters

RuggedCom Inc.

300 Applewood Cres., Unit 1,

Concord, Ontario

Canada, L4K 5C7

Tel: +1 905 856 5288

Fax: +1 905 856 1995

Toll-free: 1 888 264 0006

Technical Support

Toll Free (North America): 1 866 922 7975

International: +1 905 856 5288

Email: Support@RuggedCom.com

Web: www.RuggedCom.com

RuggedCom

1930 Harrison St., Suite 209

Hollywood, Florida

USA, 33020

Tel: +1 954 922 7938 ext.103

Fax: +1 954 922 7984

Toll-free: 1 888 264 0006

Email: RuggedSales@RuggedCom.com

RuggedCom

Unit 41, Aztec Centre,

Aztec West, Almondsbury, Bristol

United Kingdom BS32 4TD

Tel: +44 1454 203 404

Fax: +44 1454 203 403

Page 3

RuggedBackbone™ RX5000

Table of Contents

FCC Statement And Cautions ......................................................................................................... 6

1. Product Overview ........................................................................................................................ 7

1.1. Functional Overview .......................................................................................................... 7

1.2. Feature Highlights ............................................................................................................. 7

2. RuggedBackbone™ Modules ...................................................................................................... 9

2.1. Installing A Module In The Chassis .................................................................................. 9

2.2. Control Module ................................................................................................................ 10

2.3. Switch Module ................................................................................................................. 11

2.4. Line Modules ................................................................................................................... 12

2.5. Power Module ................................................................................................................. 13

3. Installation .................................................................................................................................. 14

3.1. Mounting .......................................................................................................................... 14

3.1.1. Rack Mounting ..................................................................................................... 14

3.1.2. Panel Mounting .................................................................................................... 21

3.2. Power Supply Wiring And Grounding ............................................................................. 22

3.2.1. DC Power Supply Wiring ..................................................................................... 23

3.2.2. AC Power Supply Wiring ..................................................................................... 23

3.3. Critical Alarm Relay ........................................................................................................ 25

3.4. Serial Console Ports ....................................................................................................... 26

3.5. Copper Ethernet Ports .................................................................................................... 27

3.5.1. RJ45 Twisted-Pair Copper Ports .......................................................................... 27

3.5.2. Gigabit Ethernet 1000Base-TX Cabling Recommendations ................................. 27

3.5.3. Transient Suppression ......................................................................................... 28

3.6. Fiber Ethernet Ports ........................................................................................................ 28

4. Technical Specifications ............................................................................................................ 29

4.1. Power Supply Specifications ........................................................................................... 29

4.2. Critical Alarm Relay Specifications ................................................................................. 29

4.3. Copper Ethernet Port Specifications ............................................................................... 29

4.4. Fiber Ethernet Port Specifications .................................................................................. 30

4.4.1. Fast Ethernet (100Mbps) Optical Specifications .................................................. 30

4.4.2. Gigabit Ethernet (1Gbps) Optical Specifications .................................................. 30

4.5. Operating Environment ................................................................................................... 31

4.6. Mechanical Specifications ............................................................................................... 31

5. EMI And Environmental Type Tests .......................................................................................... 32

6. Agency Approvals ...................................................................................................................... 34

7. Warranty ..................................................................................................................................... 35

RuggedCom® RuggedBackbone™ 3 RX5000 Installation Guide Rev106

Page 4

RuggedBackbone™ RX5000

List of Figures

2.1. Chassis Slot Assignment .......................................................................................................... 9

2.2. Control Module ....................................................................................................................... 10

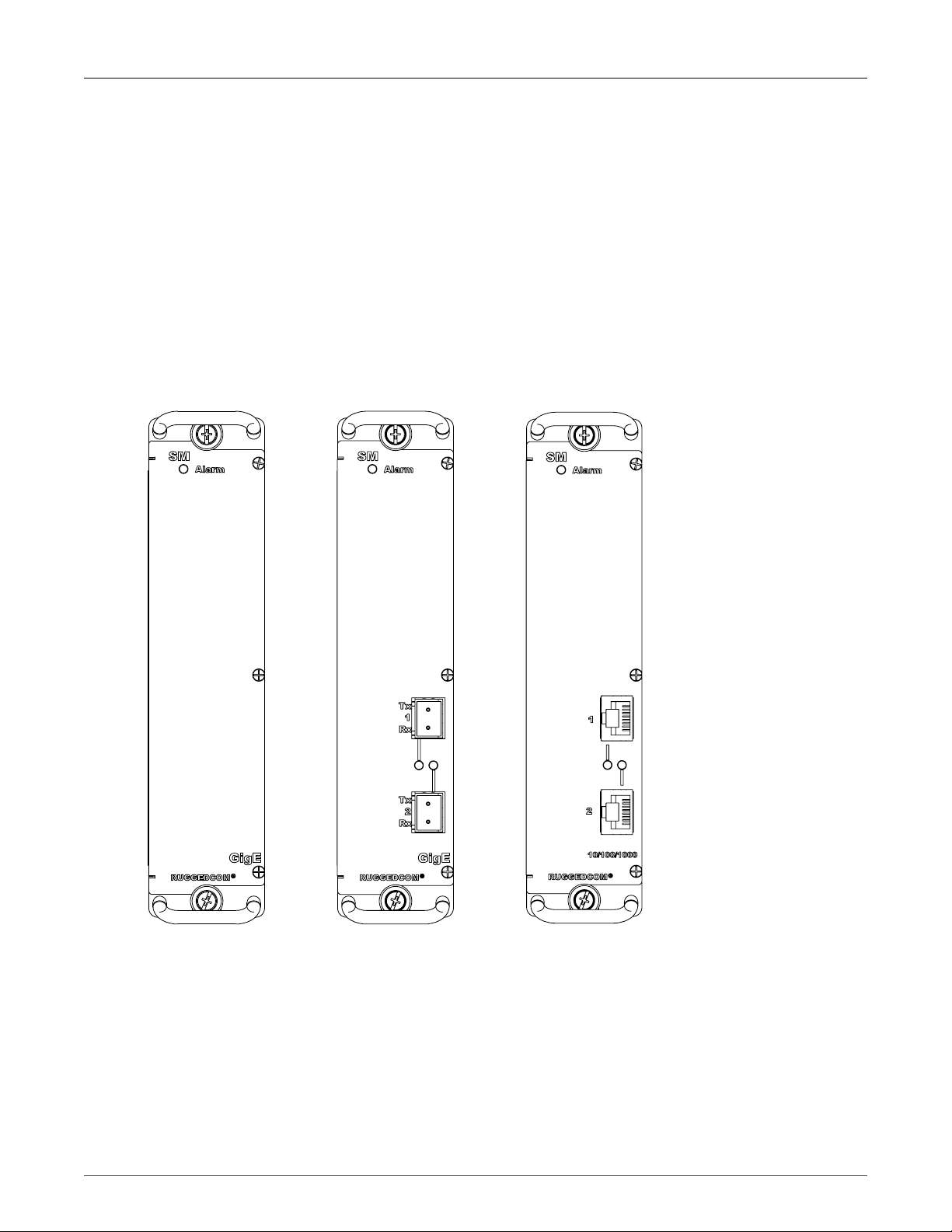

2.3. Switch Module - No Ports ...................................................................................................... 11

2.4. Switch Module - Fiber (LC) .................................................................................................... 11

2.5. Switch Module - Copper ......................................................................................................... 11

2.6. 16TX01 - 16 RJ45 Ports ........................................................................................................ 12

2.7. 8FX11 - 8 LC Fiber Ports ....................................................................................................... 12

2.8. Power Supply Module ............................................................................................................. 13

3.1. Rack Mount Assembly Step 1 ................................................................................................ 14

3.2. Rack Front Mount - Front View .............................................................................................. 15

3.3. Rack Front Mount - Side View ............................................................................................... 15

3.4. Rack Front Mount - Top View ................................................................................................ 16

3.5. Rack Front Mount with Front-Mount Power Supplies - Front View ......................................... 17

3.6. Rack Front Mount with Front-Mount Power Supplies - Side View .......................................... 17

3.7. Rack Front Mount with Front-Mount Power Supplies - Top View ........................................... 18

3.8. Rack Rear Mount - Rear View ............................................................................................... 19

3.9. Rack Rear Mount - Side View ................................................................................................ 19

3.10. Rack Rear Mount - Top View ............................................................................................... 20

3.11. Panel Mount - Side View ...................................................................................................... 21

3.12. RX5000 Power Connector .................................................................................................... 22

3.13. DC Power Connection .......................................................................................................... 23

3.14. AC Power - Integrated Earth Connection ............................................................................. 23

3.15. AC Power - Separate Earth Connection ............................................................................... 24

3.16. Critical Alarm Relay Connection ........................................................................................... 25

3.17. Serial Console Port ............................................................................................................... 26

3.18. RJ45 Ethernet Jack .............................................................................................................. 27

3.19. LC ......................................................................................................................................... 28

3.20. MTRJ ..................................................................................................................................... 28

3.21. SC ......................................................................................................................................... 28

3.22. ST ......................................................................................................................................... 28

RuggedCom® RuggedBackbone™ 4 RX5000 Installation Guide Rev106

Page 5

RuggedBackbone™ RX5000

List of Tables

3.1. RX5000 Power Connector Pinout ........................................................................................... 22

3.2. RX5000 Critical Alarm Relay Connector Pinout ..................................................................... 25

3.3. Serial Console Pinout ............................................................................................................. 26

3.4. RJ45 Ethernet Pinout ............................................................................................................. 27

3.5. Cabling Categories And 1000Base-TX Compliance ............................................................... 27

3.6. Available Fiber Connector Types ........................................................................................... 28

4.1. Power Supply Specifications .................................................................................................. 29

4.2. Critical Alarm Relay Specifications ......................................................................................... 29

4.3. Copper Ethernet Port Specifications ....................................................................................... 29

4.4. Fast Ethernet (100Mbps) Optical Specifications ..................................................................... 30

4.5. Gigabit Ethernet (1Gbps) Optical Specifications ..................................................................... 30

4.6. Operating Environment ........................................................................................................... 31

4.7. Mechanical Specifications ....................................................................................................... 31

5.1. IEC 61850-3 EMI Type Tests ................................................................................................. 32

5.2. IEEE 1613 (C37.90.x) EMI Immunity Type Tests ................................................................... 33

5.3. Environmental Type Tests ...................................................................................................... 33

6.1. Agency Approvals ................................................................................................................... 34

RuggedCom® RuggedBackbone™ 5 RX5000 Installation Guide Rev106

Page 6

FCC Statement And Cautions

FCC Statement And Cautions

Federal Communications Commission Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference on his own expense.

CAUTION: LASER

This product contains a laser system and is classified as a CLASS 1 LASER PRODUCT.

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

CAUTION: Service

This product contains no user-serviceable parts. Attempted service by unauthorized

personnel shall render all warranties null and void.

Changes or modifications not expressly approved by RuggedCom Inc. could invalidate

specifications, test results, and agency approvals, and void the user's authority to operate

the equipment.

Should this device require service, please refer to Chapter 7, Warranty in this guide.

CAUTION: Physical Access

This product should be installed in a restricted access location where access can only

be gained by service personnel or users who have been instructed about the reasons for

the restrictions applied to the location and about any precautions that shall be taken; and

access is through the use of a tool or lock and key, or other means of security, and is

controlled by the authority responsible for the location.

CAUTION: Hot Surface

Avoid contact with the surface of the unit. The metal surface may be hot due to the high

allowable ambient temperature per specification.

ATTENTION: Surface Chaude

Éviter tout contact avec la surface. La surface métallique peut être chaude a cause

d'une température ambiante élevée selon les spécifications. S.V.P. se référer à la version

française de ce guide pour les détails.

RuggedCom® RuggedBackbone™ 6 RX5000 Installation Guide Rev106

Page 7

1. Product Overview

1. Product Overview

1.1. Functional Overview

The RuggedBackbone™ RX5000 is a high-port density routing and switching platform, designed

to operate in harsh environments. The RX5000 can withstand high levels of electromagnetic

interference, radio frequency interference, and a wide temperature range of -40°C to +85°C. This

platform is designed to meet the challenging climatic and environmental demands found in utility,

industrial and military network applications.

The RX5000’s superior ruggedized hardware design, coupled with the embedded ROX™ operating

system provides improved system reliability when your network needs it the most. The cyber security

and networking features make it ideally suited for creating secure Ethernet networks for mission

critical, real-time, control applications.

The RX5000 is a scalable, hot-swappable, modular platform which provides its users with the ability

to change the RuggedBackbone™ as their network grows or their needs change.

The RuggedEnclosure™ is rated for IP65 ingress protection, meaning that it is dust tight and can

withstand water from a nozzle in any direction. Constructed with aluminum extrusions with fins on both

sides combined with high reliability internal circulation fans optimizes heat transfer without exchange

of outside air and improves MTBF for the enclosed electronics.

The combination of the RuggedEnclosure™ and the MX5000 RuggedBackbone™ provides an

extremely flexible package that has MIL-STD approvals and continues RuggedCom’s tradition of

pioneering advanced networking solutions specifically for the harsh environments found in military

applications.

1.2. Feature Highlights

Ethernet Ports

• Up to 96 10/100TX + 2 10/100/1000TX copper ports

• Up to 48 100FX optical ports

• Up to 2 Gigabit Ethernet ports

• Long-haul optics allow distances up to 90km

• Multiple connector types (ST, MTRJ, LC, SC)

Cyber Security Features

• Multi-level passwords

• SSH/SSL encryption

• Enable/disable ports, MAC based port security

• Port based network access control (802.1x)

• VLAN (802.1Q) to segregate and secure network traffic

RuggedRated™ for Reliability in Harsh Environments

• Immunity to EMI and high voltage electrical transients:

• Zero-Packet-Loss Technology

RuggedCom® RuggedBackbone™ 7 RX5000 Installation Guide Rev106

Page 8

1. Product Overview

• Meets IEEE 1613 (electric utility substations)

• Exceeds IEC 61850-3 (electric utility substations)

• Exceeds IEC 61800-3 (variable speed drive systems)

• Exceeds IEC 61000-6-2 (generic industrial environment)

• -40°C to +85°C operating temperature (no fans)

• Conformal coated printed circuit boards (optional)

ROX™ Software Features

• Next Generation of ROX™ (Rugged Operating System on LinuX)

• Simple plug and play operation – automatic learning, negotiation, and crossover detection

• MSTP (Multiple Spanning Tree Protocol - 802.1Q-2005 - formerly 802.1s)

• RSTP (Rapid Spanning Tree protocol - 802.1w) and eRSTP™ (Enhanced Rapid Spanning Tree

Protocol) network fault recovery

• QoS (Quality of Service - 802.1p) for real-time traffic

• VLAN (Virtual LAN - 802.1Q) with double tagging and GVRP (GARP VLAN Registration Protocol)

support

• GMRP (GARP Multicast Registration Protocol - 802.1D) and GMVP services

• Link aggregation (802.3ad)

• Traffic prioritization

• Transaction based configuration with rollback

• Telecom-style CLI (Command Line Interface)

Management Tools

• Web-based interface

• Telecom-style CLI

• SNMP v1/v2c

• Rich set of diagnostics with configurable logging

• NETCONF

• RBAC (Role-Based Access Control)

Modularity

• Up to 6 slots for line modules

• Up to 96 10/100TX or 48 100FX ports

Universal Power Supply Options

• Fully integrated, dual-redundant (optional) power supplies

• Universal high voltage ranges: 88-300VDC or 85-264VAC

• Terminal blocks for reliable maintenance-free connections

• CSA/UL 60950 safety approved to 85°C

RuggedCom® RuggedBackbone™ 8 RX5000 Installation Guide Rev106

Page 9

2. RuggedBackbone™ Modules

2. RuggedBackbone™ Modules

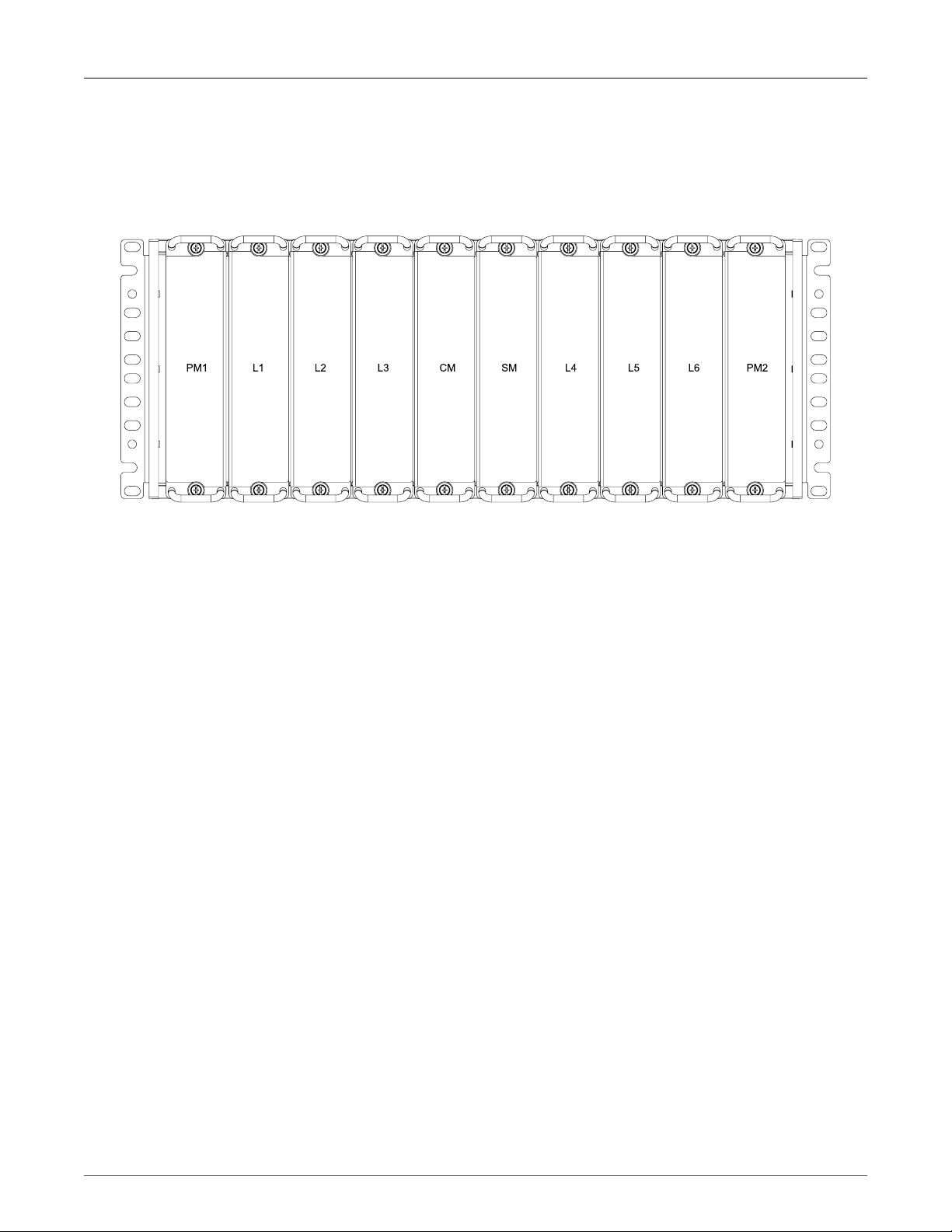

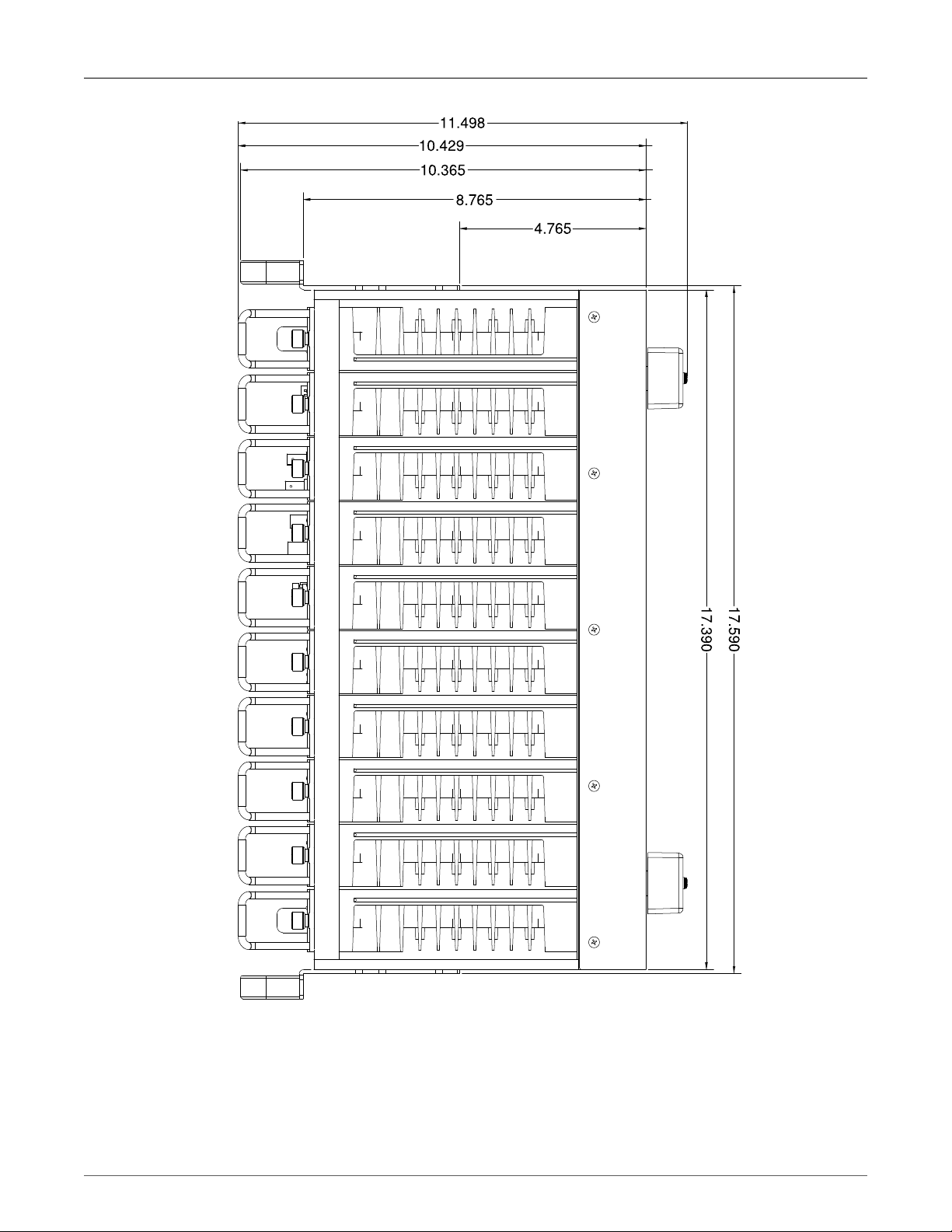

The RX5000 chassis comprises ten slots, each one of which is designed to accommodate a particular

module. Figure 2.1 shows the rear panel view of the RX5000. The slot name at each position (“PM1”,

“L1”, etc.) denotes the type of module that may be installed at that position in the chassis.

Figure 2.1. Chassis Slot Assignment

The slot name markings in the diagram above represent the following RuggedBackbone™ modules:

CM

The Control Module is the central processing unit of the system. Refer to Section 2.2: Control

Module for detail.

SM

The Switch Module contains the chassis-wide Ethernet switch fabric that interconnects Ethernet

ports on all installed line modules. Refer to Section 2.3: Switch Module for detail.

L1..L6

One or more Line Module cards may be installed - refer to Section 2.4: Line Modules for detail.

PM1, PM2

Dual, redundant, power supply modules may be installed - refer to Section 2.5: Power Module

for detail.

All supported modules are built to the RuggedRated™ specifications of the RuggedBackbone™

RX5000. Each of the module types is detailed in the following sections.

2.1. Installing A Module In The Chassis

In order to install a module into the RuggedBackbone™ chassis, align the module guide ribs with the

channels on the chassis, and push the module in as far as it will go. There is a detent position that must

be pushed through to properly seat the connectors - this is the added resistance from the grounding

springs. When properly seated, the module flange will rest on the main chassis frame. Tighten the

thumbscrews using finger strength only.

RuggedCom® RuggedBackbone™ 9 RX5000 Installation Guide Rev106

Page 10

2. RuggedBackbone™ Modules

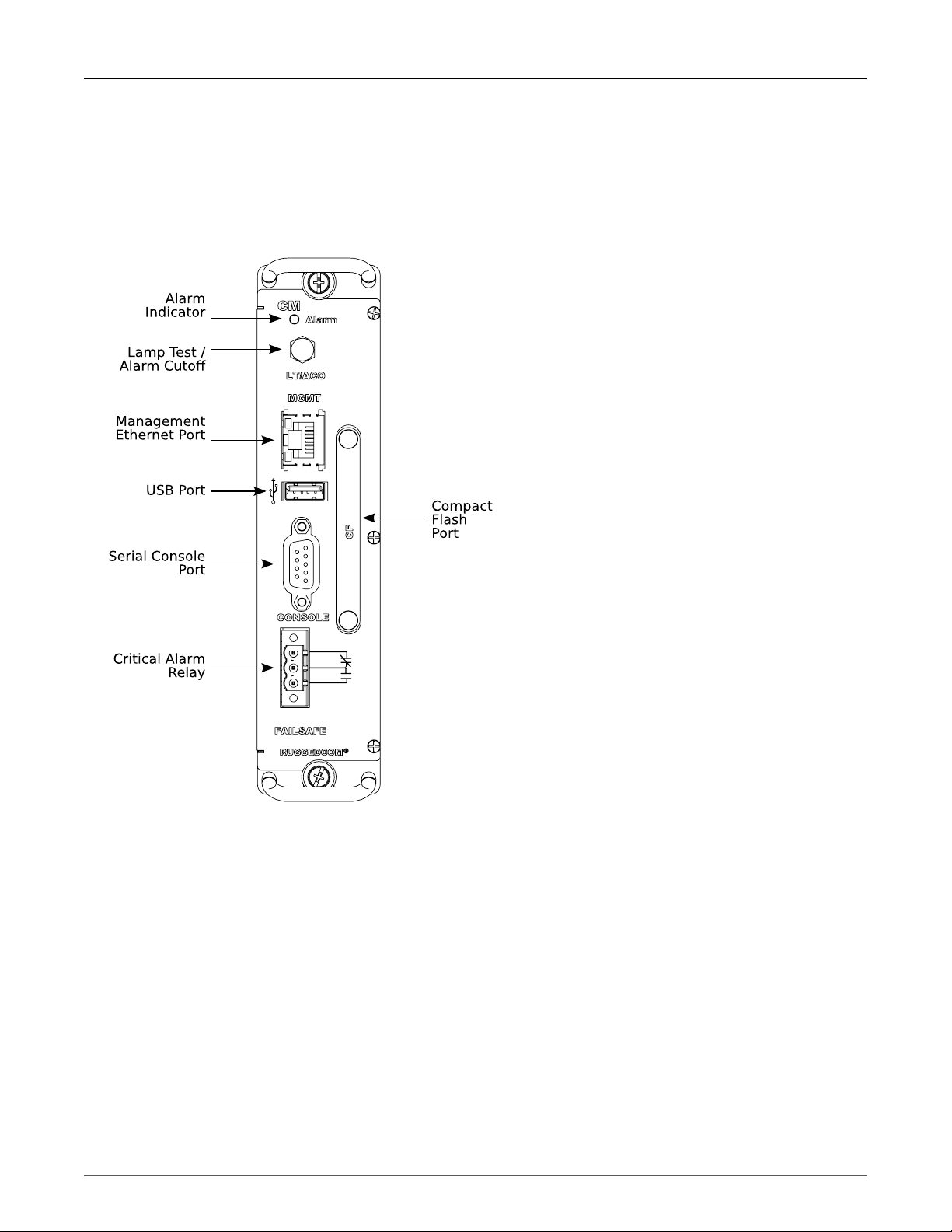

2.2. Control Module

The Control Module (CM) is the central processing unit of the RuggedBackbone™ chassis. The

ROX™ operating system running on the CM controls and coordinates the functions of all modules

installed in the system. The Control Module is installed in the CM slot of the chassis, as shown in

Figure 2.1, “Chassis Slot Assignment”.

Figure 2.2. Control Module

The CM is equipped with an RS232 serial console port for initial management functions, and a locally

connected 10/100Base-T Ethernet port for system management out of band from the switch fabric.

Other features of the CM include:

• Alarm Indicator LED, which indicates system alarm status.

• Removable 1GB Compact Flash (CF) card, which contains active and fallback installations of the

ROX™ operating system, along with the configuration database and other system data.

• Critical Alarm Relay, activated by the operating system to indicate a critical alarm.

• Lamp Test / Alarm Cutoff button.

• Utility USB port (as yet unused).

Detailed information on connecting to the ports on the CM can be found in this guide as follows:

RuggedCom® RuggedBackbone™ 10 RX5000 Installation Guide Rev106

Page 11

2. RuggedBackbone™ Modules

• Serial Console: Section 3.4, “Serial Console Ports”

• Management Ethernet Interface: Section 3.5, “Copper Ethernet Ports”

• Critical Alarm (Failsafe) Relay Interface: Section 3.3, “Critical Alarm Relay”

2.3. Switch Module

The Switch Module (SM) is the Ethernet switch fabric central to the RuggedBackbone™ RX5000.

It provides one Gbps of bandwidth to each installed Line Module and two 1Gbps ports to (optional)

connectors on its own faceplate. The Switch Module is installed in the SM slot of the chassis, as

shown in Figure 2.1, “Chassis Slot Assignment”.

Switch Modules may be ordered as separate components with copper, LC fiber, or with no Ethernet

ports. Refer to the RuggedBackbone™ RX5000 data sheet for complete ordering details.

Figure 2.3. Switch

Module - No Ports

Figure 2.4. Switch

Module - Fiber (LC)

Figure 2.5. Switch

Module - Copper

RuggedCom® RuggedBackbone™ 11 RX5000 Installation Guide Rev106

Page 12

2. RuggedBackbone™ Modules

2.4. Line Modules

The RuggedBackbone™ RX5000 may be configured with up to six Line Module (LM) cards, in the

LM1 through LM6 slots of the chassis, as shown in Figure 2.1, “Chassis Slot Assignment”. Different

Line Modules are available depending on the required type and number of Ethernet ports:

• Four or eight port 10/100 BaseTX RJ45 (copper)

• Four or eight port 100FX single- or multi-mode fiber

• Four port 10/100/1000 BaseTX RJ45 (copper)

• Four port 1000LX single- or multi-mode fiber

Refer to the RuggedBackbone™ RX5000 datasheet for complete ordering details.

Figure 2.6. 16TX01

- 16 RJ45 Ports

RuggedCom® RuggedBackbone™ 12 RX5000 Installation Guide Rev106

Figure 2.7. 8FX11

- 8 LC Fiber Ports

Page 13

2. RuggedBackbone™ Modules

2.5. Power Module

The RuggedBackbone™ RX5000 may be equipped with either one or two Power Modules (PM). Not

only do two power supplies provide redundancy, but the RX5000 is also able to balance the load it

places on each one.

Each Power Module is capable of delivering a maximum of 100W, and accepts either AC or DC power

at its input. Power Supply Modules are installed in the PM1 or PM2 slots of the chassis, as shown in

the Figure 2.1, “Chassis Slot Assignment” diagram.

Power Supply Modules may be ordered as separate components. Refer to the RuggedBackbone™

RX5000 datasheet for complete ordering details.

Figure 2.8. Power Supply Module

RuggedCom® RuggedBackbone™ 13 RX5000 Installation Guide Rev106

Page 14

3. Installation

3. Installation

3.1. Mounting

The RuggedBackbone™ RX5000 has been designed to provide the greatest possible flexibility in

display configuration and mounting. Hardware is provided to adapt the chassis for mounting to a panel

or to a standard 19" rack.

3.1.1. Rack Mounting

The first step in mounting the RX5000 to a 19" rack is to assemble the handle and rack mount bracket

using two (2) #10-32 × 3/8" flat head steel screws (supplied) as shown. Screws are to be torqued

to 18±1 in-lb.

Figure 3.1. Rack Mount Assembly Step 1

RuggedCom® RuggedBackbone™ 14 RX5000 Installation Guide Rev106

Page 15

3. Installation

3.1.1.1. Rack Front Mounting

Assemble the rack mount brackets to the main chassis using six (6) #10-32 × 3/8" flat head steel

screws (supplied) on each side. Screws are to be torqued to 18±1 in-lb. The brackets may be mounted

either as shown above, or extended by 1".

Figure 3.3. Rack Front Mount - Side View

Figure 3.2. Rack Front Mount - Front View

RuggedCom® RuggedBackbone™ 15 RX5000 Installation Guide Rev106

Page 16

3. Installation

Figure 3.4. Rack Front Mount - Top View

RuggedCom® RuggedBackbone™ 16 RX5000 Installation Guide Rev106

Page 17

3. Installation

3.1.1.2. Rack Front Mounting with Front-Mounted Power Supplies

Figure 3.5. Rack Front Mount with Front-

Mount Power Supplies - Front View

Figure 3.6. Rack Front Mount with Front-

Mount Power Supplies - Side View

RuggedCom® RuggedBackbone™ 17 RX5000 Installation Guide Rev106

Page 18

3. Installation

Figure 3.7. Rack Front Mount with Front-Mount Power Supplies - Top View

RuggedCom® RuggedBackbone™ 18 RX5000 Installation Guide Rev106

Page 19

3. Installation

3.1.1.3. Rack Rear Mounting

Assemble the rack mount brackets to the main chassis using six (6) #10-32 × 3/8" flat head steel

screws (supplied) on each side. Screws are to be torqued to 18±1 in-lb. The brackets may be mounted

either as shown above, or extended by 1".

Figure 3.9. Rack Rear Mount - Side View

Figure 3.8. Rack Rear Mount - Rear View

RuggedCom® RuggedBackbone™ 19 RX5000 Installation Guide Rev106

Page 20

3. Installation

Figure 3.10. Rack Rear Mount - Top View

RuggedCom® RuggedBackbone™ 20 RX5000 Installation Guide Rev106

Page 21

3. Installation

3.1.2. Panel Mounting

Figure 3.11. Panel Mount - Side View

The RX5000 may be fastened to panel mount brackets in one of the two positions shown above.

Assemble the panel mount brackets to the main chassis using six (6) #10-32 × 3/8" flat head steel

screws (supplied) on each side. Screws are to be torqued to 18±1 in-lb.

RuggedCom® RuggedBackbone™ 21 RX5000 Installation Guide Rev106

Page 22

3. Installation

3.2. Power Supply Wiring And Grounding

The RuggedBackbone™ RX5000 may be ordered with dual redundant power supplies, in positions

PM1 and PM2 (see Figure 2.1, “Chassis Slot Assignment”). Power connections are located either on

the PM1 and PM2 module face plates or on the front panel of the RX5000. An optional chassis ground

connection is located on the front panel as pictured in AC Power - Separate Earth Connection.

Each RX5000 Power Module is equipped with a Phillips screw terminal block (Figure 3.12) for main

power connection. The Phillips Screw Terminal Block has Phillips screws with compression plates,

allowing either bare wire connections or crimped terminal lugs. We recommend the use of #6 size

ring lugs to ensure secure, reliable connections under severe shock or vibration. The terminal block

has a safety cover which must be removed via two Phillips screws before connecting any wires. The

safety cover must be reattached after wiring to ensure personnel safety.

A permanently connected RuggedBackbone™ RX5000 must have a readily accessible

disconnect device incorporated external to the equipment.

The RX5000 may have two (2) power supplies installed and be supplied from multiple

power sources. Service personnel must isolate both power supplies prior to servicing.

Pin Function

Live

Ground

Neutral

Table 3.1. RX5000 Power Connector Pinout

Figure 3.12. RX5000 Power Connector

The following sections illustrate methods of connecting power to the RuggedBackbone™ RX5000.

RuggedCom® RuggedBackbone™ 22 RX5000 Installation Guide Rev106

Page 23

3. Installation

3.2.1. DC Power Supply Wiring

Figure 3.13. DC Power Connection

3.2.2. AC Power Supply Wiring

Figure 3.14. AC Power - Integrated Earth Connection

RuggedCom® RuggedBackbone™ 23 RX5000 Installation Guide Rev106

Page 24

3. Installation

Figure 3.15. AC Power - Separate Earth Connection

If the ground terminal on the Figure 3.12, “RX5000 Power Connector” is not connected

to safety earth, a connection must be provided from the chassis ground terminal, shown

above.

RuggedCom® RuggedBackbone™ 24 RX5000 Installation Guide Rev106

Page 25

3. Installation

Normally

Open

Normally

Closed

Common

3.3. Critical Alarm Relay

The Critical Alarm output relay signals critical error conditions that may occur on the

RuggedBackbone™ RX5000. The contacts are energized upon power-up of the unit and remain

energized unless a critical alarm condition is detected. Relay connections are shown in the Critical

Alarm Relay Connection diagram. Control of the relay output may be configured via the ROX™ user

interface.

Pin Function

NC Normally Closed

Common Ground

NO Normally Open

Table 3.2. RX5000 Critical Alarm Relay Connector

Pinout

Figure 3.16. Critical Alarm Relay Connection

A common application for this output is to signal an alarm in case of a power failure.

RuggedCom® RuggedBackbone™ 25 RX5000 Installation Guide Rev106

Page 26

3. Installation

Pin 1

Pin 5

Pin 6

Pin 9

3.4. Serial Console Ports

The serial console port on the CM provides access to the boot-time control and configuration menu

interface. Both the CM serial console port and the one on the front panel of the RX5000 chassis

provide a console interface to the ROX™ operating system.

The serial ports implement RS232 DCE on a female DB9 connector. Serial settings are: 57600 bps,

8 bits, No parity, 1 stop bit. The pin assignment of both console ports is given in the Table 3.3, “Serial

Console Pinout” table.

Figure 3.17. Serial Console Port

Pin Function

1 DCD

2 RX

3 TX

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

1

2

9 NC

DCD, DTR, and DSR are looped back internally.

RTS and CTS are looped back internally.

1

1

1

2

2

Table 3.3. Serial Console Pinout

RuggedCom® RuggedBackbone™ 26 RX5000 Installation Guide Rev106

Page 27

3. Installation

3.5. Copper Ethernet Ports

The RuggedBackbone™ RX5000 can be ordered with up to 96 10/100Base-TX ports that allow

connection to standard CAT-5 UTP cable with RJ45 male connectors. All copper Ethernet ports feature

auto-negotiation, auto-polarity, and auto-crossover functions. The female RJ45 connector can accept

and take advantage of screened (commonly known as "shielded") cabling.

3.5.1. RJ45 Twisted-Pair Copper Ports

Female RJ45 connectors are available on LMs that support 10/100Base-T and on LMs and SMs that

support 10/100/1000Base-T Ethernet. Their pin assignments are described below.

RJ45 Pin 10/100Base-Tx 10/100/1000Base-Tx

1 RX+ A+

2 RX- A3 TX+ B+

4 NC C+

5 NC C6 TX- B7 NC D+

8 NC D-

Figure 3.18. RJ45 Ethernet Jack

Table 3.4. RJ45 Ethernet Pinout

3.5.2. Gigabit Ethernet 1000Base-TX Cabling Recommendations

The IEEE 802.3ab Gigabit Ethernet standard defines 1000 Mbit/s Ethernet communications over

distances of up to 100 meters using 4 pairs of category 5 (or higher) balanced, unshielded

twisted-pair cabling. For wiring guidelines, system designers and integrators should refer to the

Telecommunications Industry Association (TIA) TIA/EIA-568-A wiring standard that characterizes

minimum cabling performance specifications required for proper Gigabit Ethernet operation. To

ensure reliable, error-free data communications, new and preexisting communication paths should be

verified for TIA/EIA-568-A compliance. The table: Cabling Categories And 1000Base-TX Compliance

summarizes the relevant cabling standards as they apply to 100Base-TX connections.

Cabling Category

< 5 No New wiring infrastructure required.

5 Yes Verify TIA/EIA-568-A compliance.

5e Yes No action required. New installations should be designed with Category 5e or higher.

6 Yes No action required.

> 6 Yes Connector and wiring standards to be determined.

Table 3.5. Cabling Categories And 1000Base-TX Compliance

Follow these recommendations for copper data cabling in high electrical noise environments:

• Data cable lengths should be as short as possible - ideally limited to 3m (10') in length. Copper data

cables should not be used for inter-building communications.

1000Base-

TX Compliant

Required Action

• Power and data cables should not be run in parallel for long distances, and should be installed in

separate conduits. Power and data cables should intersect at 90° angles when necessary to reduce

inductive coupling.

RuggedCom® RuggedBackbone™ 27 RX5000 Installation Guide Rev106

Page 28

3. Installation

• Shielded/screened cabling can optionally be used. The cable shield should be grounded at one

single point to avoid the generation of ground loops.

3.5.3. Transient Suppression

All copper Ethernet ports on RuggedCom products include transient suppression circuitry to protect

against damage from electrical transients and to ensure conformance to IEC 61850-3 and IEEE 1613

Class 1. This means that during a transient electrical event, it is possible for communications errors

or interruptions to occur, but recovery is automatic.

RuggedCom does not recommend the use of copper cabling of any length for critical, realtime, substation automation applications.

RuggedCom also recommends against the use of copper Ethernet connections to interface to devices

in the field across distances which could produce high levels of ground potential rise, i.e. greater than

2500V, during line-to-ground fault conditions.

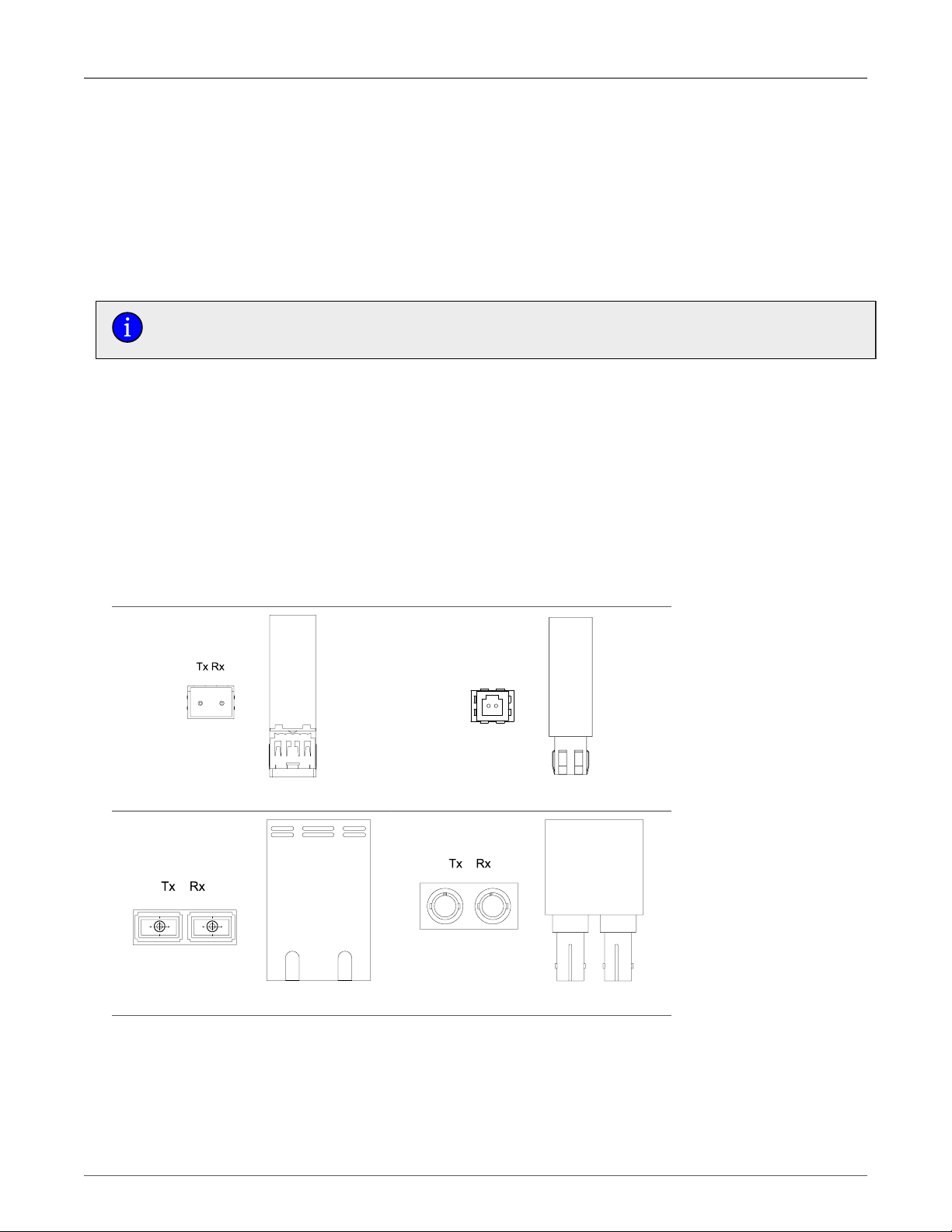

3.6. Fiber Ethernet Ports

Depending on the order code of the product, the RuggedBackbone™ RX5000 can be equipped with

LMs and SMs with several different types of fiber optic ports. The Transmit (TX) and Receive (RX)

connections of each port must be properly connected and matched for proper link establishment and

operation. The drawings in the following figures show a side and top view of each supported fiber

optic connector type to assist in identifying the proper cable connection orientation.

Figure 3.19. LC Figure 3.20. MTRJ

Figure 3.21. SC Figure 3.22. ST

Table 3.6. Available Fiber Connector Types

RuggedCom® RuggedBackbone™ 28 RX5000 Installation Guide Rev106

Page 29

4. Technical Specifications

4. Technical Specifications

4.1. Power Supply Specifications

Power Supply Type

HI (125/250 VDC)

HI (110/230 VAC)

a

Power consumption varies based on configuration, i.e. the number and type of ports. Each 10/100Base-TX port consumes

roughly 1W less than a fiber optic port.

b

The “HI” power supply is the same power supply for both AC and DC.

c

(T) denotes time-delay fuse. Internal fuse is not user-replaceable.

d

Rating at 85°C ambient temperature at worst-case load.

b

b

Min Max

88 VDC 300 VDC 6.3A, 250V(T)

85 VAC 264 VAC 6.3A, 250V(T)

Input Range

Internal Fuse Rating

c

c

Max. Power

Consumption

84 W

84 W

Table 4.1. Power Supply Specifications

4.2. Critical Alarm Relay Specifications

Parameter Value (Resistive Load)

Max Switching Voltage 250 VAC, 125 VDC

Rated Switching Current 2A@250VAC, 2A@30VDC

Table 4.2. Critical Alarm Relay Specifications

4.3. Copper Ethernet Port Specifications

The RX5000 can be ordered with several different modules which contain 10/100Tx or 10/100/1000Tx

Ethernet ports. All copper Ethernet ports have the following specifications:

a

d

d

Parameter Specification Notes

Speed 10/100 or 10/100/1000 Mbps Auto-negotiating

Duplex FDX / HDX Auto-negotiating

Cable-Type > Category 5 Shielded/Unshielded

Wiring Standard TIA/EIA T568A/B Auto-Crossover, Auto-Polarity

Max Distance 100 m

Connector RJ45

Isolation 1.5kV RMS 1-minute

Table 4.3. Copper Ethernet Port Specifications

RuggedCom® RuggedBackbone™ 29 RX5000 Installation Guide Rev106

Page 30

4. Technical Specifications

4.4. Fiber Ethernet Port Specifications

The following sections detail fiber optic specifications of ports that can be ordered with the modules

on a RuggedBackbone™ RX5000. The user determines the type of optics at time of ordering, and can

determine the modules installed on a particular unit by reading the factory data file via the ROX™ user

interface. Section 4.4.1, “Fast Ethernet (100Mbps) Optical Specifications” and Section 4.4.2, “Gigabit

Ethernet (1Gbps) Optical Specifications” list the specifications of the optical transceivers used in the

fiber Ethernet modules available for the RX5000. The specifications are organized by signaling speed

and then by order code. Module order codes are contained within each unit when it is assembled

and configured at the factory. Consult the RuggedCom ROX™ User Guide for help in obtaining the

factory configuration data.

4.4.1. Fast Ethernet (100Mbps) Optical Specifications

Order

Code

FX01 MM ST

FX02 MM SC

FX11 MM LC 62.5/125 1300 -19 -14 -32 -14 2 13

FX03 MM MTRJ

FX04 SM ST 9/125 1310 -15 -8 -32 -3 20 17

FX05 SM SC 9/125 1310 -15 -8 -31 -7 20 16

FX06 SM LC 9/125 1310 -15 -8 -34 -7 20 19

FX07 SM SC 9/125 1310 -5 0 -34 -3 50 29

FX08 SM LC 9/125 1310 -5 0 -35 3 50 30

FX09 SM SC 9/125 1310 0 5 -37 0 90 37

FX10 SM LC 9/125 1310 0 5 -37 0 90 37

Mode

Connector

Type

Cable

Type (µm)

62.5/125 -19 12

50/125

62.5/125 -19 12

50/125

62.5/125 -19 12

50/125

Tx λ (typ.)

(nm)

1300

1300

1300

Tx min.

(dBm)

-22.5

-22.5

-22.5

Tx max.

(dBm)

-14 -31 -14 2

-14 -31 -14 2

-14 -31 -14 2

Rx

Sensitivity

(dBm)

Table 4.4. Fast Ethernet (100Mbps) Optical Specifications

4.4.2. Gigabit Ethernet (1Gbps) Optical Specifications

Rx

Saturation

(dBm)

Distance

(typ.) (km)

Power

Budget

(dB)

8.5

8.5

8.5

Order

Code

SM04 MM LC

SM05 SM SC 9/125 1310 -10 -3 -20 -3 10 10

SM06 SM LC 9/125 1310 -9.5 -3 -21 -3 10 11.5

SM07 SM SC 9/125 1310 -5 0 -20 -3 25 15

SM08 SM LC 9/125 1310 -7 -3 -24 -3 25 17

Mode

Connector

Type

Cable

Type (µm)

50/125

62.5/125

Tx λ (typ.)

(nm)

850 -9 -2.5 -20 0 0.5 11

Tx min.

(dBm)

Tx max.

(dBm)

Rx

Sensitivity

(dBm)

Rx

Saturation

(dBm)

Distance

(typ.) (km)

Power

Budget

(dB)

Table 4.5. Gigabit Ethernet (1Gbps) Optical Specifications

RuggedCom® RuggedBackbone™ 30 RX5000 Installation Guide Rev106

Page 31

4. Technical Specifications

4.5. Operating Environment

Parameter Range Comments

Ambient Operating Temperature -40 to 85°C

Ambient Relative Humidity 5% to 95% Non-condensing

Ambient Storage Temperature -40 to 85°C

Table 4.6. Operating Environment

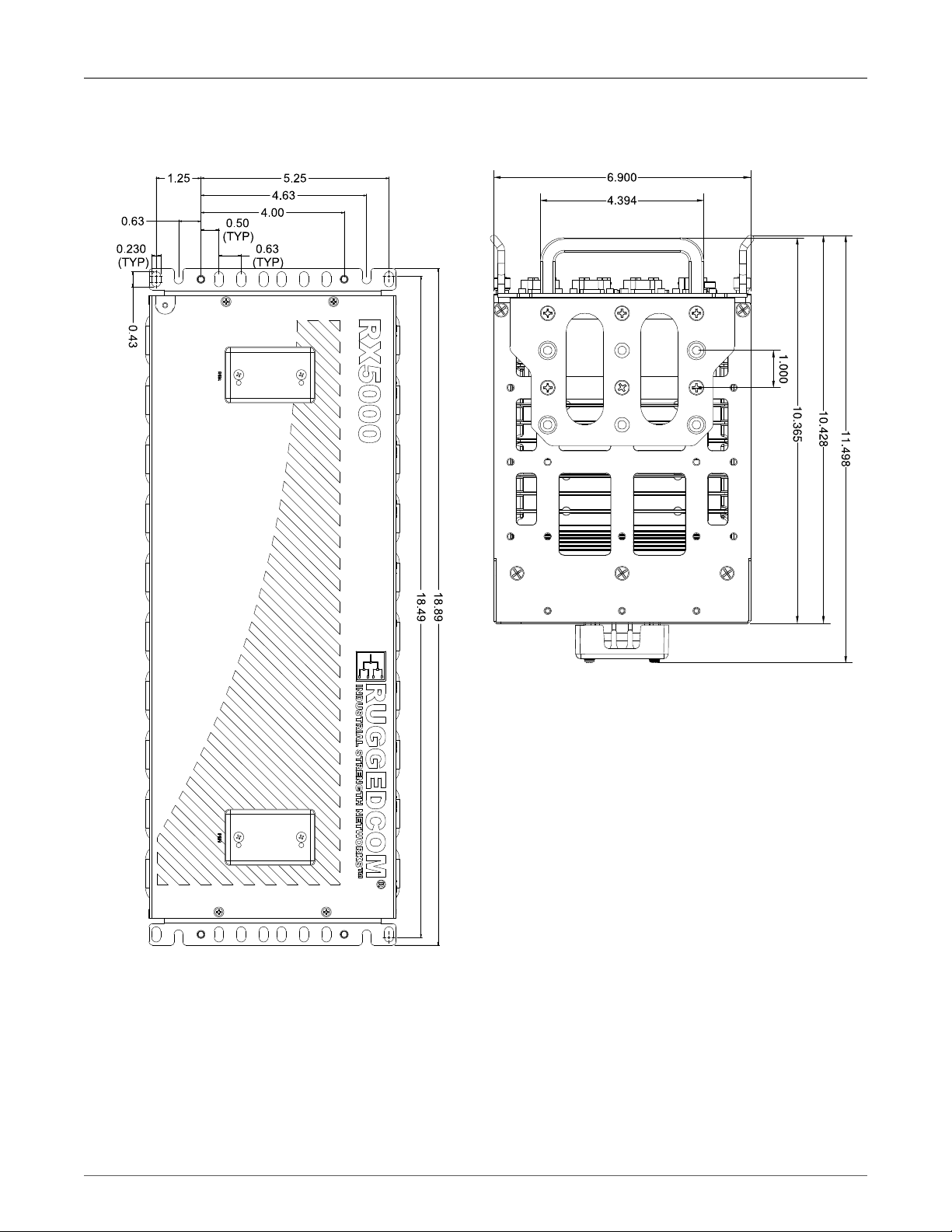

4.6. Mechanical Specifications

Parameter Value Comments

Dimensions

Weight Variable Weight dependent on module complement.

Ingress Protection IP40 (1 mm objects)

Enclosure Aluminum

Table 4.7. Mechanical Specifications

6.9 x 17.9 x 11.89 inches

(175.26 x 454.66 x 302.01 mm)

Ambient Temperature as measured from a 30cm

radius surrounding the center of the enclosure.

(Height x Width x Depth)

RuggedCom® RuggedBackbone™ 31 RX5000 Installation Guide Rev106

Page 32

5. EMI And Environmental Type Tests

5. EMI And Environmental Type Tests

Test Description Test Levels

IEC 61000-4-2 ESD

IEC 61000-4-3 Radiated RFI Enclosure Ports 20 V/m Note

IEC 61000-4-4 Burst (Fast Transient)

IEC 61000-4-6 Induced (Conducted) RFI

IEC 61000-4-8 Magnetic Field Enclosure Ports

IEC 61000-4-29 Voltage Dips & Interrupts

IEC 61000-4-11 Voltage Dips & Interrupts A.C. Power ports

IEC 61000-4-16 Mains Frequency Voltage

IEC 61000-4-17

a

RuggedCom-specified severity levels

Ripple on D.C.

Power Supply

Enclosure Contact +/- 8 kV 4

Enclosure Air +/- 15 kV 4

Signal ports +/- 4kV @ 2.5kHz Note

D.C. Power ports +/- 4kV 4

A.C. Power ports +/- 4kV 4

Earth ground ports +/- 4kV 4

Signal ports

D.C. Power ports

A.C. Power ports

Signal ports 10V 3

D.C Power ports 10V 3

A.C. Power ports 10V 3

Earth ground ports 10V 3

D.C. Power ports

A.C. Power ports 30% for 1 period, 60% for 50 periods N/A

Signal ports

D.C. Power ports

A.C. Power ports

Signal ports 30V Continuous, 300V for 1s 4

D.C. Power ports 30V Continuous, 300V for 1s 4

D.C. Power ports 10% 3

Signal ports 2kVAC (Fail-Safe Relay output) N/A

D.C. Power ports 1.5kVDC N/AIEC 60255-5 Dielectric Strength

A.C. Power ports 2kVAC N/A

Signal ports 5kV (Fail-Safe Relay output) N/A

D.C. Power ports 5kV N/AIEC 60255-5 H.V. Impulse

A.C. Power ports 5kV N/A

+/- 4kV line-to-earth,

+/- 2kV line-to-line

+/- 2kV line-to-earth,

+/- 1kV line-to-line

+/- 4kV line-to-earth,

+/- 2kV line-to-line

40 A/m, continuous,

1000 A/m for 1 s

1000 A/m for 1 s 5

30% for 0.1s, 60% for

0.1s, 100% for 0.05s

100% for 5 periods,

100% for 50 periods

2.5kV common, 1kV

diff. mode@1MHz

2.5kV common, 1kV

diff. mode@1MHz

2.5kV common, 1kV

diff. mode@1MHz

Table 5.1. IEC 61850-3 EMI Type Tests

Severity

Levels

a

a

4

3IEC 61000-4-5 Surge

4

a

Note

N/A

N/A

3

3IEC 61000-4-12 Damped Oscillatory

3

RuggedCom® RuggedBackbone™ 32 RX5000 Installation Guide Rev106

Page 33

5. EMI And Environmental Type Tests

Test Description Test Levels

IEEE C37.90.3 ESD

IEEE C37.90.2 Radiated RFI Enclosure ports 35 V/m

IEEE C37.90.1 Fast Transient

Table 5.2. IEEE 1613 (C37.90.x) EMI Immunity Type Tests

Enclosure Contact +/-2kV, +/-4kV, +/- 8kV

D.C. Power ports +/- 4kV

A.C. Power ports +/- 4kV

Earth ground ports +/- 4kV

D.C. Power ports 2.5kV common, 1kV diff. mode@1MHzIEEE C37.90.1 Oscillatory

A.C. Power ports 2.5kV common, 1kV diff. mode@1MHz

D.C. Power ports 5kVIEEE C37.90 H.V. Impulse

A.C. Power ports 5kV

D.C. Power ports 2kVDCIEEE C37.90 Dielectric Strength

A.C. Power ports 2kVAC

Enclosure Air +/-4kV, +/-8kV, +/-15kV

Signal ports +/- 4kV @ 2.5kHz

Signal ports 2.5kV common mode @1MHz

Signal ports 5kV (Fail-Safe Relay output)

Signal ports 2kVAC

a

Test Description Test Levels

IEC 60068-2-1 Cold Temperature Test Ad -40°C, 16 Hours

IEC 60068-2-2 Dry Heat Test Bd +85°C, 16 Hours

IEC 60068-2-30 Humidity (Damp Heat, Cyclic) Test Db 95% (non-condensing), 55°C , 6 cycles

IEC 60255-21-1 Vibration 2g @ (10 - 150) Hz

IEC 60255-21-2 Shock 30g @ 11mS

Table 5.3. Environmental Type Tests

RuggedCom® RuggedBackbone™ 33 RX5000 Installation Guide Rev106

Page 34

6. Agency Approvals

6. Agency Approvals

Agency Standards Comments

Canada (cTUVus) CAN/CSA C22.2 No. 60950-1-07 Pending

USA (NRTL - cTUVus) UL 60950-1:2007 Pending

CE EN 60950, EN 61000-6-2

FCC FCC Part 15, Class A Pending

CISPR EN55022, Class A Pending

FDA/CDRH 21 CFR Chapter 1, Subchapter J Pending

ISO ISO9001:2000

Table 6.1. Agency Approvals

CE Compliance is claimed via

Declaration of Self Conformity Route

Designed and manufactured using a

ISO9001: 2000 certified quality program

RuggedCom® RuggedBackbone™ 34 RX5000 Installation Guide Rev106

Page 35

7. Warranty

7. Warranty

RuggedCom warrants this product for a period of five (5) years from the date of purchase. This product

contains no user-serviceable parts. Attempted service by unauthorized personnel shall render all

warranties null and void. For warranty details, visit www.RuggedCom.com or contact your customer

service representative.

Should this product require service, contact the factory at:

RuggedCom Inc.

300 Applewood Crescent

Concord, Ontario

Canada L4K 5C7

Phone: +1 905 856 5288

Fax: +1 905 856 1995

RuggedCom® RuggedBackbone™ 35 RX5000 Installation Guide Rev106

Loading...

Loading...