Page 1

FCC Statement And

Cautions

RUGGEDCOM RX1512

Installation Guide

Product Overview

RUGGEDCOM Modules

Installation

Technical Specifications

EMI And Environmental Type

Tests

Agency Approvals

Warranty

1

2

3

4

5

6

7

6/2013

Page 2

RUGGEDCOM RX1512

Installation Guide

Copyright © 2013 RuggedCom Inc.

All rights reserved. Dissemination or reproduction of this document, or evaluation and communication of its contents, is not authorized

except where expressly permitted. Violations are liable for damages. All rights reserved, particularly for the purposes of patent application or

trademark registration.

This document contains proprietary information, which is protected by copyright. All rights are reserved. No part of this document may be

photocopied, reproduced or translated to another language without the prior written consent of RuggedCom Inc.

Disclaimer Of Liability

Siemens has verified the contents of this manual against the hardware and/or software described. However, deviations between the product

and the documentation may exist.

Siemens shall not be liable for any errors or omissions contained herein or for consequential damages in connection with the furnishing,

performance, or use of this material.

The information given in this document is reviewed regularly and any necessary corrections will be included in subsequent editions. We

appreciate any suggested improvements. We reserve the right to make technical improvements without notice.

Registered Trademarks

ROX™, Rugged Operating System On Linux™, CrossBow™ and eLAN™ are trademarks of Siemens AG. ROS® is a registered trademark of

Siemens AG.

Other designations in this manual might be trademarks whose use by third parties for their own purposes would infringe the rights of the

owner.

Security Information

Siemens provides automation and drive products with industrial security functions that support the secure operation of plants or machines.

They are an important component in a holistic industrial security concept. With this in mind, our products undergo continuous development.

We therefore recommend that you keep yourself informed with respect to our product updates. Please find further information and newsletters

on this subject at: http://support.automation.siemens.com.

To ensure the secure operation of a plant or machine it is also necessary to take suitable preventive action (e.g. cell protection concept) and

to integrate the automation and drive components into a state-of-the-art holistic industrial security concept for the entire plant or machine.

Any third-party products that may be in use must also be taken into account. Please find further information at: http://www.siemens.com/

industrialsecurity.

Warranty

Siemens warrants this product for a period of five (5) years from the date of purchase, conditional upon the return to factory for maintenance

during the warranty term. This product contains no user-serviceable parts. Attempted service by unauthorized personnel shall render all

warranties null and void. The warranties set forth in this article are exclusive and are in lieu of all other warranties, performance guarantees

and conditions whether written or oral, statutory, express or implied (including all warranties and conditions of merchantability and fitness for

a particular purpose, and all warranties and conditions arising from course of dealing or usage or trade). Correction of nonconformities in the

manner and for the period of time provided above shall constitute the Seller’s sole liability and the Customer’s exclusive remedy for defective

or nonconforming goods or services whether claims of the Customer are based in contract (including fundamental breach), in tort (including

negligence and strict liability) or otherwise.

For warranty details, visit www.RuggedCom.com or contact a Siemens customer service representative.

Contacting Siemens

Address

Siemens AG

Industry Sector

300 Applewood Crescent

Concord, Ontario

Canada, L4K 5C7

Telephone

Toll-free: 1 888 264 0006

Tel: +1 905 856 5288

Fax: +1 905 856 1995

E-mail

ruggedcom.info.i-ia@siemens.com

Web

www.RuggedCom.com

ii

Page 3

RUGGEDCOM RX1512

Installation Guide

Table of Contents

Table of Contents

FCC Statement And Cautions ............................................................................. v

Chapter 1

Product Overview ................................................................................................ 1

1.1 Functional Overview ..................................................................................................................... 1

1.2 Feature Highlights ........................................................................................................................ 1

Chapter 2

RUGGEDCOM Modules ...................................................................................... 5

2.1 Installing a Module ....................................................................................................................... 5

2.2 Front Panel .................................................................................................................................. 6

2.2.1 Module Status LEDs .......................................................................................................... 7

2.3 Line Modules (LM) ....................................................................................................................... 7

2.3.1 Ethernet - Copper ............................................................................................................. 7

2.3.2 Ethernet - Fiber ................................................................................................................. 8

2.3.3 SFP Modular ..................................................................................................................... 9

2.3.4 WAN ................................................................................................................................. 9

2.3.5 Serial .............................................................................................................................. 10

2.3.6 Cellular Modem ............................................................................................................... 10

2.3.7 DDS - Digital Data Services ............................................................................................. 10

2.3.8 RuggedAPE™ (Appplication Processing Engine) ............................................................... 11

2.4 Power Supply ............................................................................................................................ 11

Chapter 3

Installation .......................................................................................................... 13

3.1 Mounting .................................................................................................................................... 13

3.1.1 RX1512Dimensions ......................................................................................................... 15

3.2 Power Supply Wiring and Grounding ........................................................................................... 17

3.2.1 RX1512 DC Power Connectors ........................................................................................ 17

3.2.2 Chassis Ground Connection ............................................................................................. 17

3.2.3 DC Power Supply Wiring Example ................................................................................... 18

3.3 Critical Alarm Wiring ................................................................................................................... 18

3.4 Serial Console Port .................................................................................................................... 19

3.5 WAN Ports: RJ45 ....................................................................................................................... 19

3.6 WAN Ports: BNC ........................................................................................................................ 20

iii

Page 4

Table of Contents

3.7 Copper Ethernet Ports ................................................................................................................ 20

3.7.1 RJ45 Twisted-Pair Copper Ports ....................................................................................... 20

3.7.2 M12 Twisted Pair Copper Ports ........................................................................................ 21

3.7.3 Gigabit Ethernet 1000Base-TX Cabling Recommendations ................................................. 21

3.7.4 Transient Suppression ..................................................................................................... 22

3.8 Serial Ports: RJ45 ...................................................................................................................... 22

3.9 DDS Ports: RJ45 ....................................................................................................................... 23

3.10 DDS Rx and Tx LED Indications ............................................................................................... 23

3.11 SFP Optics – Installation, removal, and precautions .................................................................... 24

3.11.1 Module Insertion – SFP .................................................................................................. 25

3.11.2 SFP Module Removal .................................................................................................... 26

3.12 Fiber Ethernet Ports ................................................................................................................. 27

3.13 Cellular Modems ...................................................................................................................... 28

3.13.1 GSM, EDGE, HSPA+ Cellular Modem Card .................................................................... 29

3.13.2 Installing SIM Cards for GSM, EDGE, HSPA+ Cellular Modems ........................................ 30

Chapter 4

RUGGEDCOM RX1512

Installation Guide

Technical Specifications ..................................................................................... 31

4.1 Power Supply Specifications ....................................................................................................... 31

4.2 Critical Alarm Relay Specifications .............................................................................................. 31

4.3 Copper Ethernet Port Specifications ............................................................................................ 31

4.4 Fiber Ethernet Port Specifications ............................................................................................... 32

4.4.1 Fast Ethernet (100Mbps) Optical Specifications ................................................................. 32

4.4.2 Gigabit Ethernet (1Gbps) Optical Specifications ................................................................. 33

4.5 Operating Environment ............................................................................................................... 34

4.6 RuggedAPE™ Specifications ...................................................................................................... 34

4.7 Mechanical Specifications ........................................................................................................... 34

Chapter 5

EMI And Environmental Type Tests .................................................................. 37

Chapter 6

Agency Approvals .............................................................................................. 39

Chapter 7

Warranty ............................................................................................................. 41

iv

Page 5

RUGGEDCOM RX1512

Installation Guide

FCC Statement And Cautions

FCC Statement And Cautions

Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

CAUTION!

This product contains a LASER system and is classified as a CLASS 1 LASER PRODUCT. Use of

controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION!

This product contains no user-serviceable parts. Attempted service by unauthorized personnel shall

render all warranties null and void.

Changes or modifications not expressly approved by RuggedCom Inc. could invalidate specifications,

test results, and agency approvals, and void the user’s authority to operate the equipment.

Should this device require service, refer to Chapter 7, Warranty in this guide.

CAUTION!

This product should be installed in a restricted access location where access can only be gained by

service personnel or users who have been instructed about the reasons for the restrictions applied to

the location and about any precautions that shall be taken; and access is through the use of a tool or

lock and key, or other means of security, and is controlled by the authority responsible for the location.

v

Page 6

RUGGEDCOM RX1512

Installation Guide

FCC Statement And Cautions

vi

Page 7

RUGGEDCOM RX1512

Installation Guide

Product Overview

Product Overview

Section 1.1

Functional Overview

The RUGGEDCOM RX1512 is a cost-efficient, rugged layer 3 switch and router. The RX1512’s modular and field

replaceable platform allows you to select WAN, serial, and Ethernet options, making it ideally suited for electric

power utilities, the industrial plant floor, and traffic control systems. The appliance’s compact form factor makes it

ideal for pole mount applications or installation in restricted spaces.

The RX1512 is designed to the RuggedRated™ specification, providing a high level of immunity to

electromagnetic interference (EMI) and heavy electrical surges typical of the harsh environments found in many

industrial applications. An operating temperature range of -40°C to +85°C (-40°F to +185°F) allows the RX1512 to

be placed in almost any location.

Chapter 1

Section 1.2

Feature Highlights

Cyber Security Features

• Multi-level passwords

• SSH/SSL encryption

• Enable/disable ports, MAC-based port security

• Port-based network access control (802.1x)

• VLAN (802.1Q) to segregate and secure network traffic

• RADIUS centralized password management

• SNMPv3 encrypted authentication and access security

RuggedRated™ for Reliability in Harsh Environments

• Immunity to EMI and high voltage electrical transients:

○ Zero-Packet-Loss Technology

○ Meets IEEE 1613 (electric utility substations)

○ Exceeds IEC 61850-3 (electric utility substations)

○ Exceeds IEC 61800-3 (variable speed drive systems)

○ Exceeds IEC 61000-6-2 (generic industrial environment)

• -40°C to +85°C operating temperature (no fans)

• Optional conformal coated printed circuit boards

• Failsafe Output Relay: For critical failure or error alarming

Physical Ports

• Field replaceable line modules

Functional Overview 1

Page 8

Chapter 1

Product Overview

• Up to 12 ports 100FX

• Up to 12 ports 10/100TX

• Up to 4 ports Gigabit Ethernet

WAN Port Options

• Up to 4 T1/E1 ports via RJ45 connectors (channelized/unchannelized)

• Up to 2 E1 ports via BNC connectors (channelized/unchannelized)

• Cellular/DDS

Serial Ports

• Fully compliant EIA/TIA RS485, RS422, RS232 serial ports (software selectable) with RJ45 connectors

• Raw socket mode support allows conversion of any serial protocol

Protocols

WAN

•

○ Frame Relay RFC 1490 or RFC 1294

○ PPP RFC 1661, 1332, 1321, 1334, PAP, CHAP Authentication

○ Multilink PPP RFC 1990

○ GOOSE messaging support

IP

•

○ Routing: OSPF, BGP, RIPv1, RIPv2

○ VRRP Agent

○ Traffic control, NTP Server, IP Multicast Routing

○ DHCP Agent (Option 82 Capable)

RUGGEDCOM RX1512

Installation Guide

Frame Relay Support

• ISO and ITU compliant, network certified.

• ANSI T1.617 Annex D, Q.933 or LMI Local Signaling

Management Tools

• Web-based, SSH, CLI management interfaces

• SNMP v1, v2, and v3

• Remote Syslog

• Rich set of diagnostics with logging and alarms

• Loopback diagnostic tests

• Raw and interpreted real-time line traces

Universal Power Supply Options

• Non-removable power supply integrated with chassis/cm/unit

• Fully integrated power supplies (no external adaptors)

• Input voltage range: 10-72VDC

• TUV/UL 60950 safety approved to 85°C

2 Feature Highlights

Page 9

RUGGEDCOM RX1512

Installation Guide

Warranty

• 5 Year Warranty

Product Overview

Chapter 1

Feature Highlights 3

Page 10

RUGGEDCOM RX1512

Installation Guide

Product Overview

Chapter 1

Feature Highlights 4

Page 11

RUGGEDCOM RX1512

Installation Guide

RUGGEDCOM Modules

RUGGEDCOM Modules

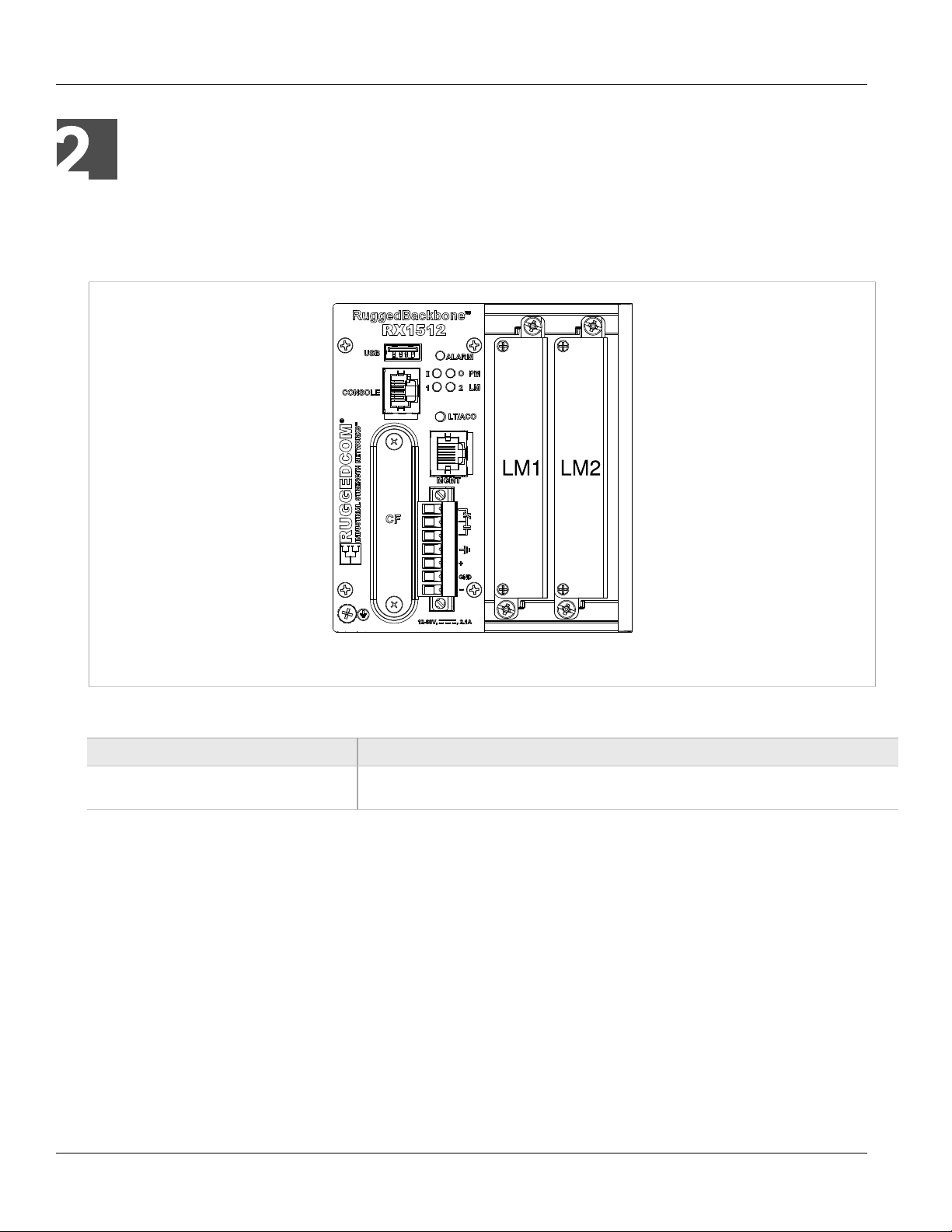

The RX1512 chassis provides two module slots. Each slot accommodates a particular type of RuggedCom

module. Figure 1, “Chassis Slot Assignment” shows the module slots on the RX1512.

Chapter 2

Figure 1: Chassis Slot Assignment

The RX1512 chassis supports the following modules:

Parameter Description

LM1 and LM2 The RX1512 chassis supports up to two line module (LM) cards. For more information on line

The RX1512 features a single 12-60VDC power supply integrated with the Control Module. For instructions on

completing the power supply connections, see Section 2.4, “Power Supply”.

All modules are built to the RuggedRated™ specifications of the RUGGEDCOM RX1512. Each module type is

described in the following sections.

Section 2.1

modules, see Section 2.3, “Line Modules (LM)”.

Installing a Module

To install a module into the RUGGEDCOM chassis, align the module guide ribs with the channels on the chassis.

Push the module in as far as it will go, being sure to push through the resistance provided by the grounding

springs. When properly seated, the module flange will rest on the main chassis frame. Tighten the thumbscrews

using finger strength only.

Installing a Module 5

Page 12

Chapter 2

RUGGEDCOM Modules

RUGGEDCOM RX1512

Installation Guide

NOTE

Serial line modules are hot-swappable, meaning they can be removed and installed while the device is

running.

When installing a serial line module while the device is running, make sure internal VLANs are

enabled. For more information about configuring VLANs, refer to the RX1512 User Guide for the

RX1512.

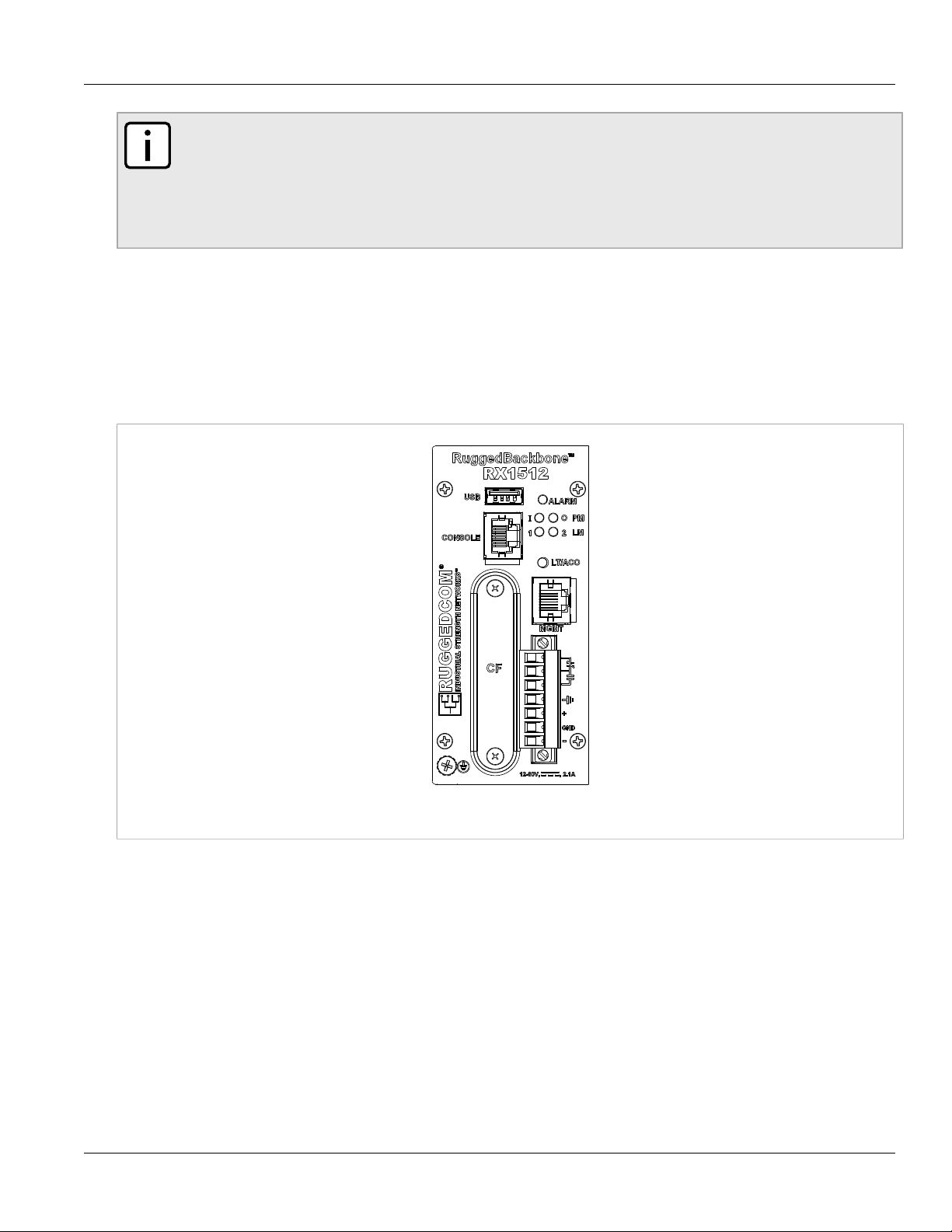

Section 2.2

Front Panel

The RX1512 Front Panel is equipped with an RS232 serial console port for initial management functions, and a

locally connected 10/100Base-T Ethernet port for system management out of band from the switch fabric.

Figure 2: Front View

Other Front Panel features include:

• Utility USB port

• Power module indicator LEDs

• Line module indicator LEDs

• Alarm Indicator LED, which indicates system alarm status.

• Lamp Test / Alarm Cutoff (LT/ACO) button

• Removable 1GB Compact Flash (CF) card, which contains active and fallback installations of the RX1512

operating system, along with the configuration database and other system data

• Chassis ground connection

For more information on connecting to the ports on the front panel, see the following topics:

6 Front Panel

Page 13

RUGGEDCOM RX1512

Installation Guide

• Serial Console: Section 3.4, “Serial Console Port”

• Management Ethernet Interface: Section 3.7, “Copper Ethernet Ports”

• Critical Alarm (Failsafe) Relay Interface: Section 3.3, “Critical Alarm Wiring”

Section 2.2.1

Module Status LEDs

The front panel module status LEDs provide the following information:

Table: Module Status LED Indications

LED Purpose Description

PM Indicates power supply status. I = Power supply is receiving input voltage.

LM 1 through 2 Indicates the line module status. Green = OK

RUGGEDCOM Modules

Chapter 2

O = Power supply is providing

output voltage to the RX1512.

Orange = Warning alert

Red = Configuration error

Section 2.3

Line Modules (LM)

The RUGGEDCOM RX1512 supports two line modules in slots LM1 through LM2. Several types of line modules

may be ordered, depending on the type, speed and number of Ethernet ports required.

The following illustrations show the typical port configurations and connectors available for RX1512 line modules.

For complete information on the available line modules, refer to the RUGGEDCOM RX1512 data sheet.

NOTE

Only one T1/E1 module may be used per router.

Section 2.3.1

Ethernet - Copper

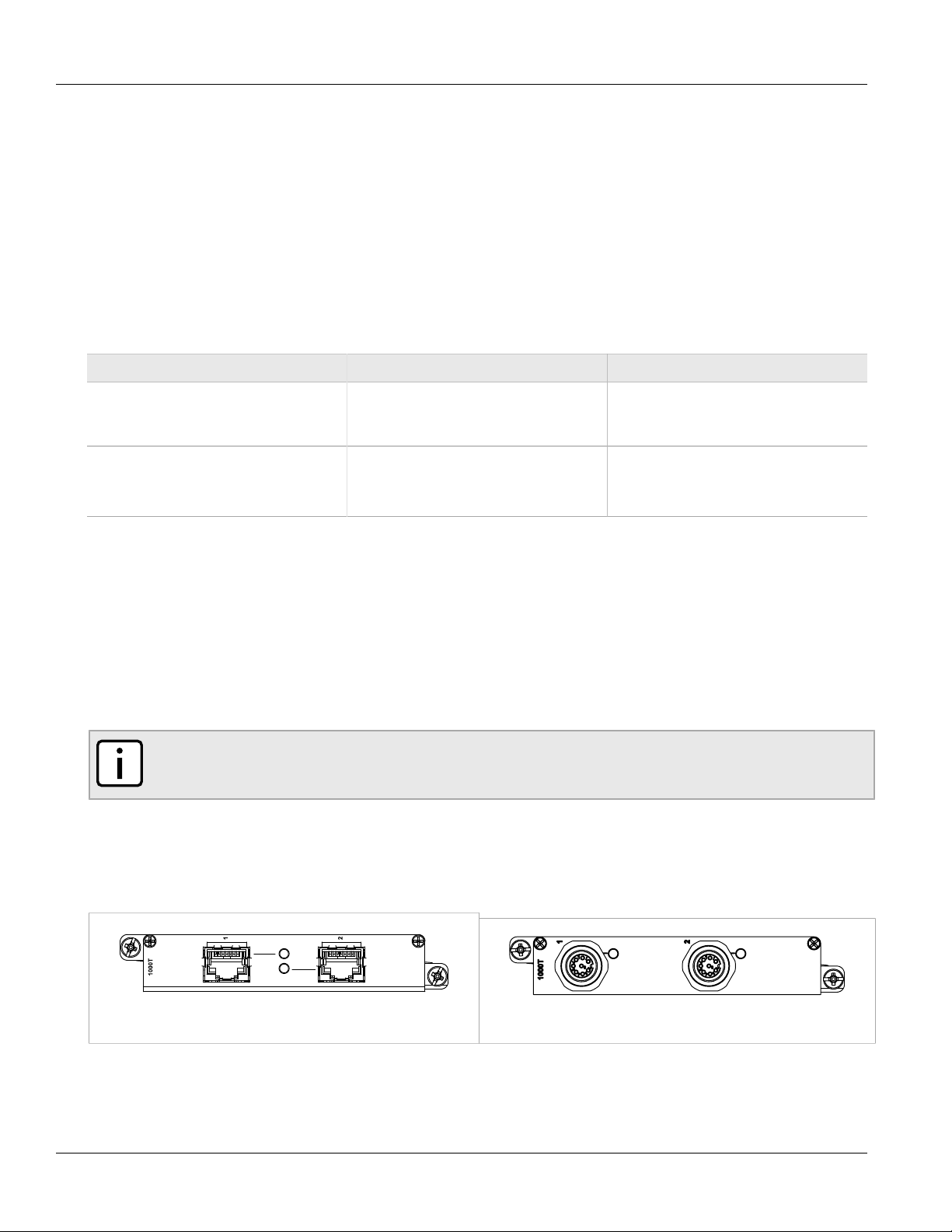

Figure 3: CG01: 2 × 10/100/1000TX RJ45 Figure 4: CG03: 2 x 8-Pin 10/100/1000TX M12

Module Status LEDs 7

Page 14

Chapter 2

RUGGEDCOM Modules

RUGGEDCOM RX1512

Installation Guide

Figure 5: 6TX01: 6 × 10/100TX RJ45

Figure 7: 4TX04: 4 x 4-Pin 10/100TX M12

Figure 6: 4TX03: 4 x 8-Pin 10/100TX M12

Section 2.3.2

Ethernet - Fiber

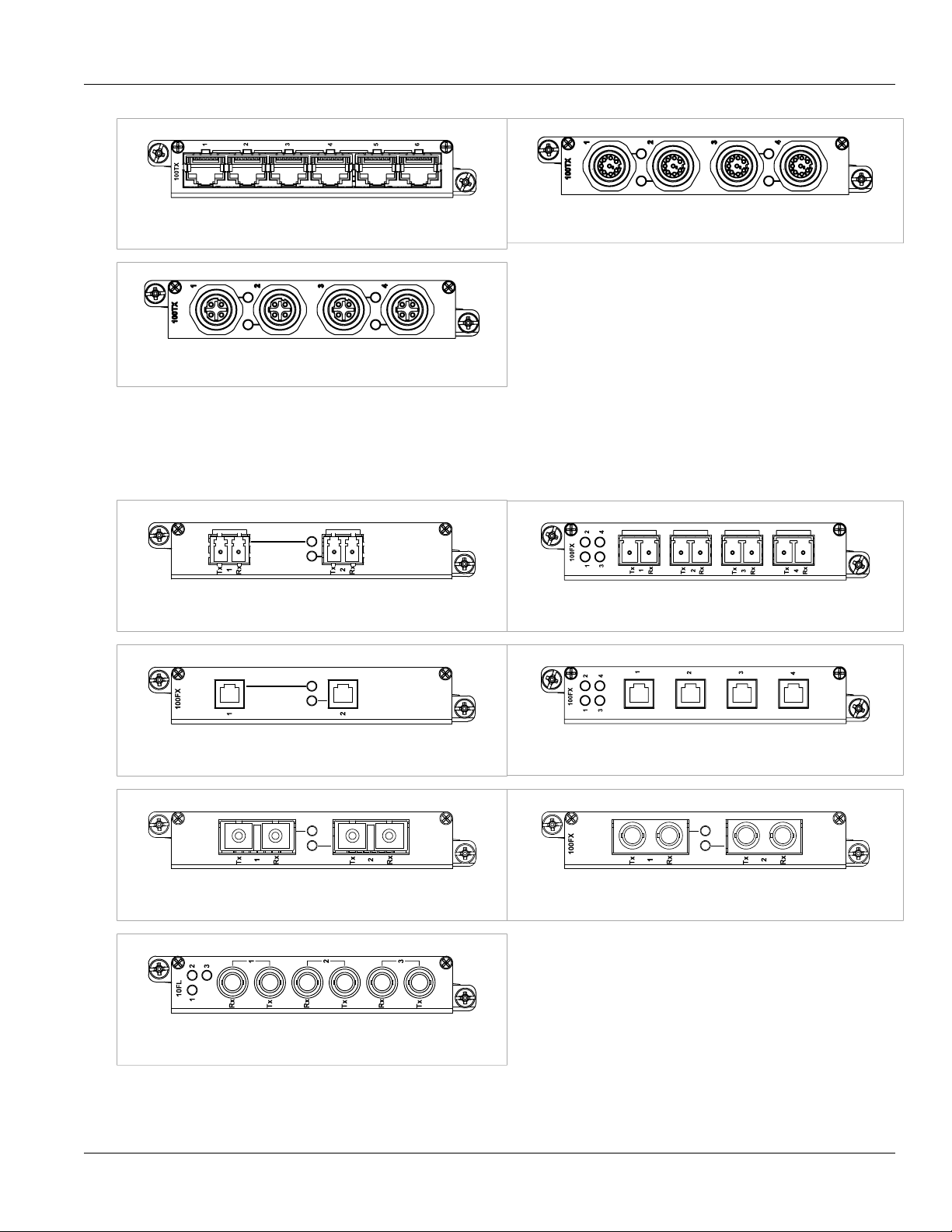

Figure 8: FX**/FG**: 2 × 100FX/1000SX/1000LX LC Figure 9: 4FX**: 4 × 100FC LC

Figure 10: FX03: 2 × 100 FX MTRJ

Figure 12: FX**: 2 × 100FX SC

Figure 11: 4FX03: 4 × 100FX MTRJ

Figure 13: FX**: 2 × 100FX ST

Figure 14: FL01: 3 × 10FL/100SX

8 Ethernet - Fiber

Page 15

RUGGEDCOM RX1512

Installation Guide

Section 2.3.3

SFP Modular

Figure 15: FG5*: 2 × 1000LX/1000SX SFP Figure 16: FX5*: 4 × 100FX/100LX/100SX SFP

Figure 17: 6FX50: 6 × 100FX SFP

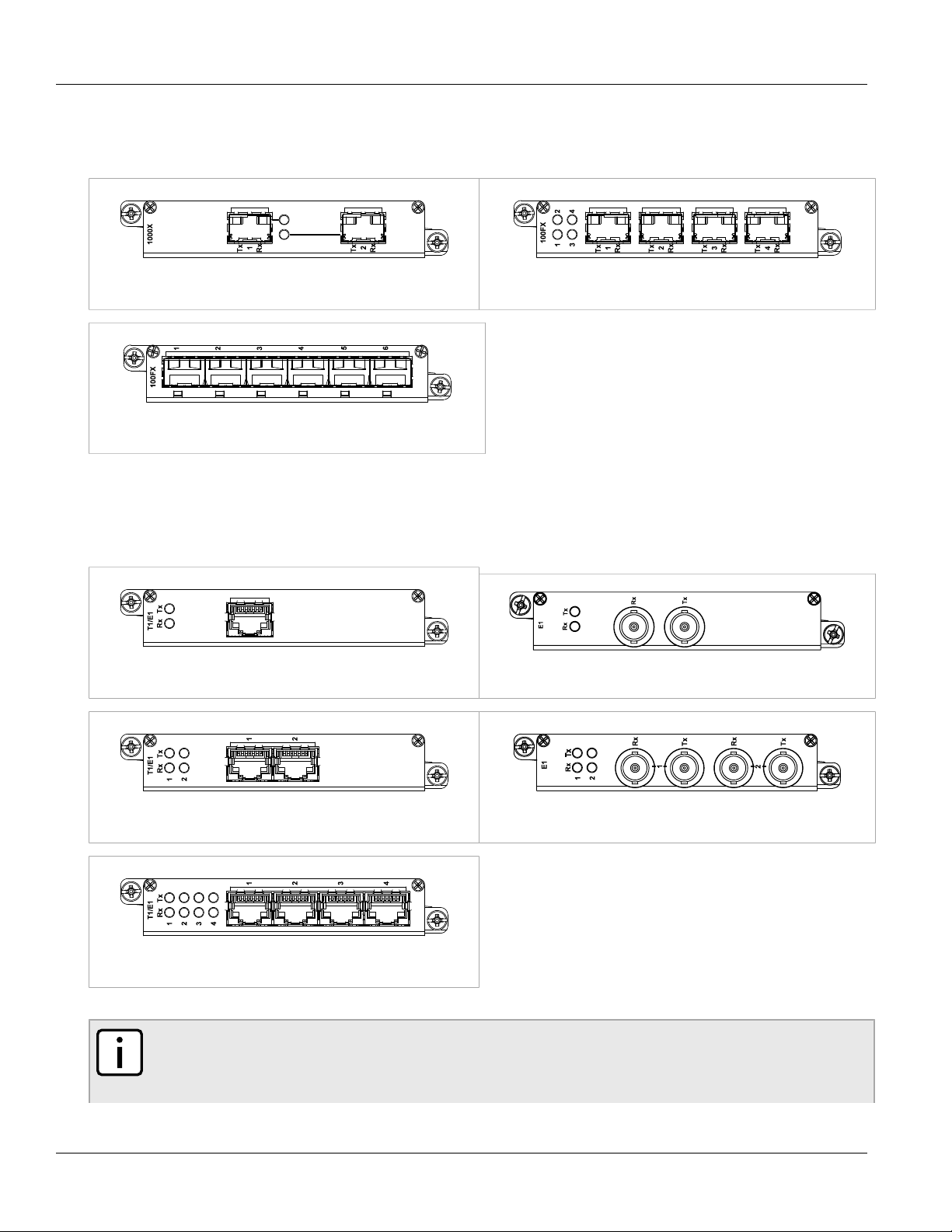

Section 2.3.4

RUGGEDCOM Modules

Chapter 2

WAN

Figure 18: TC1: 1 × T1/E1 RJ45 Figure 19: E01: 1 × E1 BNC

Figure 20: TC2: 2 × T1/E1 RJ45

Figure 22: TC4: 4 × T1/E1 RJ45

Figure 21: E02: 2 × E1 BNC

NOTE

The TC1, TC2 and TC4 WAN modules comply with Part 68 of the FCC rules and requirements

adopted by ACTA. The product identifier is provided on a label on top of the modules. If requested, this

information must be provided to the telephone company.

SFP Modular 9

Page 16

Chapter 2

RUGGEDCOM Modules

The TC1, TC2 and TC4 WAN modules meet the Industry Canada's CS-03 Part II, Issue 9 technical

specifications. The industry Canada registration number and model number is provided on a label on

top of the modules.

The WAN modules TC1, TC2 and TC4 use only RJ48C connectors.

The modules have no user serviceable parts and equipment must only be repaired by authorized

RuggedCom personnel only.

Section 2.3.5

Serial

Figure 23: S01: 6 × Serial RJ45

RUGGEDCOM RX1512

Installation Guide

Section 2.3.6

Cellular Modem

Figure 24: W11, W21 Cellular Modem Figure 25: W12, W22, W32 Cellular Modem

Section 2.3.7

DDS - Digital Data Services

Figure 26: D02: 1 × DDS RJ45

10 Serial

Page 17

RUGGEDCOM RX1512

Installation Guide

Section 2.3.8

RuggedAPE™ (Appplication Processing Engine)

Figure 27: RuggedAPE™ Module

NOTE

For more information about the RuggedAPE module, including installation and setup instructions, refer

to the APE Installation and User Guide.

Section 2.4

Power Supply

RUGGEDCOM Modules

Chapter 2

The RX1512 power supply is integrated with the Control Module. The power supply and fail-safe relay

connections are made on a pluggable terminal block located on the front panel of the Control Module. The

RX1512 power supply input is 11VDC to 72VDC, and consumes a maximum of 25W.

Figure 28: Pluggable terminal block power module and fail-safe relay connections

RuggedAPE™ (Appplication Processing Engine) 11

Page 18

RUGGEDCOM RX1512

Installation Guide

RUGGEDCOM Modules

Chapter 2

Power Supply 12

Page 19

RUGGEDCOM RX1512

Installation Guide

Installation

Section 3.1

Mounting

The RUGGEDCOM RX1512 features optional mounting brackets for panel and DIN rail mounting. The optional

brackets attach to both sides of the appliance at the rear of the chassis. For panel mounting, the mounting

bracket provides four mounting holes. For DIN rail mounting, the DIN adaptor mounts to a standard 1" DIN rail

and is secured with a lock screw on each adaptor.

To attach the mounting brackets, align the brackets with the threaded holes on the sides of the appliance. Secure

the mounting brackets to the appliance with the screws included in the mounting bracket kit.

Chapter 3

Installation

Figure 29: Installing Mounting Brackets

Mounting 13

Page 20

Chapter 3

Installation

Figure 30: DIN Rail Mounting: Front View

RUGGEDCOM RX1512

Installation Guide

Figure 31: DIN Rail Mounting: Side View

14 Mounting

Page 21

RUGGEDCOM RX1512

Installation Guide

Section 3.1.1

RX1512Dimensions

Chapter 3

Installation

Figure 32: RX1512 Dimensions – Front View

RX1512Dimensions 15

Page 22

Chapter 3

Installation

RUGGEDCOM RX1512

Installation Guide

Figure 33: RX1512Dimensions – Top View

Figure 34: RX1512 Dimensions – Side View

16 RX1512Dimensions

Page 23

RUGGEDCOM RX1512

Installation Guide

Section 3.2

Power Supply Wiring and Grounding

The RX1512 features a Phoenix Plug Terminal Block. Both DC power supply and fail-safe relay connections are

made on the same terminal block.

For DC power supply wiring examples, refer to Section 3.2.3, “DC Power Supply Wiring Example”.

For fail-safe relay wiring, refer to DC power supply wiring examples, refer to Section 3.3, “Critical Alarm Wiring”.

WARNING!

The RX1512 has one (1) power supply installed. Service personnel must isolate all power supplies

prior to servicing.

Section 3.2.1

RX1512 DC Power Connectors

Chapter 3

Installation

Figure 35: RX1512 DC Power Connectors

Section 3.2.2

Chassis Ground Connection

The RX1512 chassis ground connection, shown in Figure 36, “Chassis Ground Connection”, uses a #10-32

screw. It is recommended to terminate the ground connection in a #10 ring lug. Torque on the chassis ground

connection should not exceed 30 in-lbs (3.4 Nm).

Figure 36: Chassis Ground Connection

Power Supply Wiring and Grounding 17

Page 24

Chapter 3

+

Installation

Section 3.2.3

DC Power Supply Wiring Example

RUGGEDCOM RX1512

Installation Guide

Figure 37: Wiring for RX1512 DC Power Supply

NOTE

• It is recommended to provide a separate circuit breaker for the power supply.

• Equipment must be installed according to applicable local wiring codes.

Section 3.3

Critical Alarm Wiring

The Critical Alarm output relay signals critical error conditions that may occur on the RUGGEDCOM RX1512.

The contacts are energized upon power-up of the unit and remain energized unless a critical alarm condition is

detected. Relay connections are shown in the Critical Alarm Relay Connector diagram. You can configure control

of the relay output through the RX1512 user interface.

A common application for this output is to signal an alarm in case of a power failure.

Figure 38: Critical Alarm Relay Connector

18 DC Power Supply Wiring Example

Page 25

RUGGEDCOM RX1512

Installation Guide

Section 3.4

Serial Console Port

The serial console port on the front panel provides access to the boot-time control and configuration menu

interface, and a console interface to the RX1512 operating system.

The serial ports implement RS232 DCE on a RJ45 connector. Serial settings are: 57600 bps, 8 bits, No parity, 1

stop bit. See the illustration and table below for pin configuration and assignment.

Table: RJ45 Serial Console Pinout

RJ45 Pin Signal Function

1 DSR/RI

2 RLSD

3 DTR

4 GND

5 RD

6 TD

Chapter 3

Installation

Figure 39: RJ45 Serial Console Port

7 CTS

8 RTS

NOTE

The RX1512 connects the DSR/RI, RLSD, and DTR pins internally and does not drive or require these

pins.

The RX1512 connects the CTS and RTS pins internally and does not drive or require these pins.

Section 3.5

WAN Ports: RJ45

The RX1512 supports T1/E1 WAN ports, to interface to standard T1 or E1 telecommunication infrastructure.

Carefully note the orientation of the RJ45 receptacle when inserting or removing cabling. See the illustration and

table below for pin configuration and assignment.

Table: RJ45 T1/E1 Pin Assignment

T1/E1 pinout

Pin Description

1 RRING

2 RTIP

3 NC

4 TRING

5 TTIP

6 NC

Figure 40: RJ45 T1/E1 Pin Configuration

Serial Console Port 19

7 NC

Page 26

Chapter 3

Rx Tx

Chassis

RTIP

Chassis

TTIP

Installation

T1/E1 pinout

Pin Description

8 NC

Section 3.6

RUGGEDCOM RX1512

Installation Guide

WAN Ports: BNC

The RX1512 supports optional E1 WAN ports with BNC connectors. The Tx and Rx connections are labelled on

the line module. See the illustration below for the connection configuration.

Figure 41: RJ45 T1/E1 Pin Configuration

Section 3.7

Copper Ethernet Ports

The RUGGEDCOM RX1512 can be ordered with up to 10/100Base-TX ports that allow connection to standard

CAT-5 UTP cable with RJ45 male connectors. All copper Ethernet ports feature auto-negotiation, auto-polarity,

and auto-crossover functions. The female RJ45 connector can accept and take advantage of screened

(commonly known as “shielded”) cabling.

Section 3.7.1

RJ45 Twisted-Pair Copper Ports

Female RJ45 connectors are available on LMs that support 10/100Base-T and on LMs and SMs that support

10/100/1000Base-T Ethernet. See the illustration and table below for pin configuration and assignment.

Table: RJ45 Ethernet Pin Assignment

RJ45 Pin 10/100Base-Tx 10/100/1000Base-Tx

1 RX+ A+

2 RX- A-

3 TX+ B+

4 NC C+

5 NC C-

6 TX- B-

Figure 42: RJ45 Ethernet Pin Configuration

7 NC D+

20 WAN Ports: BNC

Page 27

RUGGEDCOM RX1512

Installation Guide

RJ45 Pin 10/100Base-Tx 10/100/1000Base-Tx

8 NC D-

Section 3.7.2

M12 Twisted Pair Copper Ports

M12 ports are available on LMs that support 10/100Base-TX and 10/100/1000Base-TX. See the illustrations and

tables below for pin configuration and assignmnt.

Table: 8-Pin A-coded M12 Ethernet Port Pin Assignment

Pin

1 NC (terminated

10/100Base-Tx

Signal (On 4TX03)

at GND)

10/100/1000Base-

Tx Signal (on CG03)

Chapter 3

Installation

C+

Figure 43: 8-Pin A-coded M12

Ethernet Port Pin Configuration

2 NC (terminated

at GND)

3 NC (terminated

at GND)

4 TX- A-

5 RX+ B+

6 TX+ A+

7 NC (terminated

at GND)

8 RX- B-

D+

D-

C-

Table: 4-Pin D-coded M12 Ethernet Port Pin Assignment

Pin 10/100Base-Tx Signal

1 TX+

2 RX+

3 TX-

4 RX-

Figure 44: 4-Pin D-coded M12

Ethernet Port Pin Configuration

Section 3.7.3

Gigabit Ethernet 1000Base-TX Cabling Recommendations

The IEEE 802.3ab Gigabit Ethernet standard defines 1000 Mbit/s Ethernet communications over distances of up

to 100 meters using 4 pairs of CAT-5 (or higher) balanced, unshielded twisted-pair cabling. For wiring guidelines,

system designers and integrators should refer to the Telecommunications Industry Association (TIA) TIA/EIA-568A wiring standard for minimum cabling performance specifications required for proper Gigabit Ethernet operation.

M12 Twisted Pair Copper Ports 21

Page 28

Chapter 3

Installation

RUGGEDCOM RX1512

Installation Guide

To ensure reliable, error-free data communications, new and pre-existing communication paths should be verified

for TIA/EIA-568-A compliance. The table: Cabling Categories and 1000Base-TX Compliance summarizes the

relevant cabling standards as they apply to 100Base-TX connections.

Table: Cabling Categories and 1000Base-TX Compliance

Cabling Category

< 5 No New wiring infrastructure required.

5 Yes Verify TIA/EIA-568-A compliance.

5e Yes No action required. New installations should be designed with Category 5e or higher.

6 Yes No action required.

> 6 Yes Connector and wiring standards to be determined.

1000Base-

TX Compliant

Required Action

Follow these recommendations for copper data cabling in high electrical noise environments:

• Data cable lengths should be as short as possible, ideally limited to 10' (3 m) in length. Copper data cables

should not be used for inter-building communications.

• Power and data cables should not be run in parallel for long distances, and should be installed in separate

conduits. Power and data cables should intersect at 90° angles when necessary to reduce inductive coupling.

• Optionally, shielded/screened cabling can be used. The cable shield should be grounded at one single point to

avoid the generation of ground loops.

Section 3.7.4

Transient Suppression

All copper Ethernet ports on RuggedCom products include transient suppression circuitry to protect against

damage from electrical transients and to ensure conformance to IEC 61850-3 and IEEE 1613 Class 1. This

means that during a transient electrical event, it is possible for communications errors or interruptions to occur,

but recovery is automatic.

NOTE

RuggedCom does not recommend the use of copper cabling of any length for critical, real-time,

substation automation applications.

RuggedCom also recommends against the use of copper Ethernet connections to interface to devices in the field

across distances which could produce high levels of ground potential rise (that is, greater than 2500V), during

line-to-ground fault conditions.

Section 3.8

Serial Ports: RJ45

The RX1512 supports serial port line modules with RJ45 connections. On power-up, all serial ports default to

RS485 mode. Each port can be individually set to RS232, RS485, or RS422 mode via software.

22 Transient Suppression

Page 29

RUGGEDCOM RX1512

Installation Guide

Figure 45: RJ45 Serial Pin Configuration

Chapter 3

Installation

Table: RJ45 RS232/RS485/RS422 Serial Pin Assignment

Pin RS232 Mode RS485 Mode RS422 Mode

1 — — RX-

2 Reserved

3 COM (Isolated GND)

4 COM (Isolated GND)

5 RX — RX+

6 TX TX/RX + TX +

7 CTS — —

8 RTS TX/RX - TX -

Shield Chassis GND

NOTE

Pin 2 is reserved for future IRIG-B output. Do not connect Pin 2 at this time; doing so may cause

hardware damage. Pins 7 and 8 are connected internally. No internal termination is provided. In RS232

mode, these pins enter a high impedance state. A DTE that asserts RTS will see CTS asserted, but

hardware flow control is not performed on the port.

Section 3.9

DDS Ports: RJ45

The RX1512 supports DDS port line modules with RJ45 connections. The 56 kbps DDS port is compatible with

Bellcore standards. Each DDS module features a single 56/64 kbps DDS line interface with a standard RJ45

receptacle.

Table: RJ45 DDS Pin Assignment

RJ45 Pin Description

1 R1: Transmit data to network (Ring 1)

2 T1: Transmit data to network (Tip 1)

3 NC

4 NC

5 NC

6 NC

Figure 46: RJ45 DDS Pin Configuration

7 T: Receive data from network (Tip)

8 R: Receive data from network (Ring)

Section 3.10

DDS Rx and Tx LED Indications

The DDS module features Rx and Tx LED indicators that display transmit and receive status.

DDS Ports: RJ45 23

Page 30

Chapter 3

Installation

Figure 47: DDS Module Rx and Tx LED Indicators

The following tables describe the DDS module Rx and Tx LED status indications:

Table: DDS Rx LED Indications

Rx LED Color Status

GREEN Frame sync detected and signal OK.

YELLOW Signal OK, but no frame sync.

RED Loss of signal.

RUGGEDCOM RX1512

Installation Guide

OFF The interface is not enabled.

Table: DDS Tx LED Indications

Tx LED Color Status

GREEN The interface is enabled and remote device has no errors.

YELLOW The interface is in loopback mode.

RED Loss of signal or receiving any of OOS, UNM, or UMC codes: the remote device is out of service or has

OFF The interface is not enabled.

Section 3.11

problems with the signal.

SFP Optics – Installation, removal, and precautions

The RX1512 can be ordered with SFP (Small Form-factor Pluggable) pluggable optics modules. SFP modules

can be safely inserted and removed while the chassis is powered and operating. When inserting or removing

optics, observe the following precautions:

• Ensure that dust caps are mounted on SFP cages at all times, unless you are in the process of inserting or

removing an SFP module. The dust caps prevent the accumulation of residue or particles that might inhibit

proper operation.

• Ensure that you have properly discharged any possible electrostatic build-up to prevent electrostatic

discharges (ESD). This can be accomplished by proper grounding through an ESD wrist strap, or by touching

earth or chassis ground before installing or removing optical modules. ESD can damage or shorten the life of

optical modules when they are not plugged into a chassis.

24 SFP Optics – Installation, removal, and precautions

Page 31

RUGGEDCOM RX1512

Installation Guide

• Ensure that SFP optical modules are always stored in an ESD-safe bag or other suitable ESD-safe

environment. Keep SFP modules free from moisture and store them at the proper temperature (-40°C to

+85°C).

• Disconnect all cables from the SFP module before inserting or removing the module.

• Use only components certified by RuggedCom Inc. with RuggedCom products. Damage can occur to optics

and product if compatibility and reliability have not been properly assessed.

Section 3.11.1

Module Insertion – SFP

Special attention must be paid to the orientation of SFP modules upon installation in the RX1512 chassis. The

figure below shows the proper orientation of SFP modules installed in both upper and lower line modules. SFP

modules on the upper row must be inserted top-side up. SFP modules on the lower row must be inserted top-side

down. SFP modules should be inserted with the bail-latch in the locked position.

Chapter 3

Installation

Figure 48: SFP module orientation

Module Insertion – SFP 25

Page 32

Chapter 3

Installation

Figure 49: SFP module insertion

RUGGEDCOM RX1512

Installation Guide

SFP modules should slide gently into their ports and should lock in place when fully inserted. Dust covers should

be in place when installing the modules, and should always be in place when cables are not connected.

Section 3.11.2

SFP Module Removal

To remove the SFP module, disconnect any cables and replace the dust cover to protect the optics. Extend the

bail latch found on the top of the module. Grasp the bail latch and gently pull outwards to unlock and remove the

module.

Immediately after removal, store the SFP module in an ESD-safe environment.

26 SFP Module Removal

Page 33

RUGGEDCOM RX1512

Tx Rx

Installation Guide

Figure 50: SFP module removal

Chapter 3

Installation

Section 3.12

Fiber Ethernet Ports

Depending on the order code of the product, the RUGGEDCOM RX1512 can be equipped with several different

types of fiber optic ports. The Transmit (TX) and Receive (RX) connections of each port must be properly

connected and matched for proper link establishment and operation. The drawings in the following figures show a

side and top view of each supported fiber optic connector type to assist in identifying the proper cable connection

orientation.

Table: Available Fiber Connector Types

Figure 51: LC

Figure 52: MTRJ

Fiber Ethernet Ports 27

Page 34

Chapter 3

Tx Rx

Tx Rx

Installation

RUGGEDCOM RX1512

Installation Guide

Figure 53: SC

Figure 54: ST

Section 3.13

Cellular Modems

The RX1512 can be equipped with cellular modem modules for operation on GSM, EDGE, HSPA+, or CDMA

networks. The cellular modems feature 50 Ω SMA antenna connectors on the front plate of each module. The

following cellular modem modules are available:

Table: Cellular Modem Modules

Module Order Code Description

W11 1 Port Cell Modem GSM,EDGE,HSPA+

W12 2 Port Cell Modem GSM,EDGE,HSPA+

W21 1 Port Cell Modem EVDO Rev.A Verizon Wireless

W22 2 Port Cell Modem EVDO Rev.A Verizon Wireless

W32 1 Port Cell Modem GSM,EDGE,HSPA+, 1 Port Cell Modem EVDO Rev.A Verizon Wireless

Figure 55: Single Port Cellular Modem: Antenna Connections

28 Cellular Modems

Page 35

RUGGEDCOM RX1512

Installation Guide

Figure 56: Dual Port Cellular Modem: Antenna Connections

NOTE

If two or more antennas are to be installed, the antennas must be separated by a minimum distance of

20 cm (7.9").

Chapter 3

Installation

Section 3.13.1

GSM, EDGE, HSPA+ Cellular Modem Card

The HSPA option is available for use on various GSM based networks. This option supports GSM, GPRS, EDGE,

UMTS and WCDMA/HSDPA/HSUPA. The Main antenna and Receive Diversity antenna connections are made to

the 50 Ω SMA connectors located on either side of the front faceplate.

Supported frequency bands are given in the following table. For safe operation of the device, ensure that the

maximum antenna gain is not exceeded.

Table: HSPA Antenna Requirements

Band

Band I

WCDMA 2100

Band II

WCDMA 1900

Band VIII

WCDMA 900

Band V

WCDMA 850

Band VI

WCDMA 800

Frequency Range

Tx (MHz) VSWR Rx (MHz) VSWR

1920-1980 <2.5:1 2110-2170 <3.5:1 Y 4

1850-1910 <2.5:1 1930-1990 <2.5:1 Y 4

880-915 <2.5:1 925-960 <3.5:1 Y 5

824-849 <2.5:1 869-894 <3.5:1 Y 5

830-840 <2.5:1 875-885 <3.5:1 Y 5

RX Diversity

Support

Maximum

Allowable

Gain (dBi)

GSM 850 824-849 <2.5:1 869-894 <3.5:1 — 5

EGSM 900 880-915 <2.5:1 925-960 <3.5:1 — 5

GSM 1800 1710-1785 <2.5:1 1805-1880 <3.5:1 — 4

GSM 1900 1850-1910 <2.5:1 1930-1990 <2.5:1 — 4

GSM, EDGE, HSPA+ Cellular Modem Card 29

Page 36

Chapter 3

Installation

Section 3.13.2

Installing SIM Cards for GSM, EDGE, HSPA+ Cellular Modems

NOTE

Be sure to take appropriate anti-static precautions before opening the cellular modem module.

1. Remove the module from the RX1512.

2. On the smooth side of the module, remove the four screws and remove the back of the module.

RUGGEDCOM RX1512

Installation Guide

Figure 57: Cellular Modem Module Assembly:

W11 and W32 Single Antenna Modules

Figure 58: Cellular Modem Module

Assembly: W12 Dual Antenna Modules

3. Note the location of the SIM card cages. For modules W11 and W32, install the SIM card in SIM 1. For

module W22, install a SIM card in both SIM 1 and SIM 2.

4. Top open a SIM card cage, slide the silver catch down towards the antenna connector end of the module and

flip the cage open.

5. Hold the SIM card at its notched end, with its connectors facing down, and insert the SIM card into the cage.

6. Flip the cage down and slide the silver catch up away from the antenna connector end of the module.

7. Replace the back of the module and secure the back of the module with the four screws removed earlier.

8. Re-install the module in the RX1512.

30

Installing SIM Cards for GSM, EDGE, HSPA+ Cellular

Modems

Page 37

RUGGEDCOM RX1512

Installation Guide

Technical Specifications

Section 4.1

Power Supply Specifications

Table: Power Supply Specifications

Technical Specifications

Chapter 4

Power

Supply Type

Internal 10 VDC 72 VDC 6.3A 27W Max (TBD) 20W (TBD)

a

Power consumption varies based on configuration.

Section 4.2

Input Range

Min Max

Internal

Fuse Rating

Max. Power

Consumption

a

Max Power

Output

Connections

terminal block

Critical Alarm Relay Specifications

Table: Form C Contact Relay Specifications

Voltage Current

30VDC 2A

Section 4.3

Copper Ethernet Port Specifications

The RX1512 can be ordered with several different modules which contain 10/100Tx or 10/100/1000Tx Ethernet

ports. All copper Ethernet ports have the following specifications:

Pluggable

Table: Copper Ethernet Port Specifications

Parameter Specification Notes

Speed 10/100 or 10/100/1000 Mbps Auto-negotiating

Duplex FDX / HDX Auto-negotiating

Cable-Type > Category 5 Shielded/Unshielded

Wiring Standard TIA/EIA T568A/B Auto-Crossover, Auto-Polarity

Max Distance 100 m

Connector RJ45

M12 8-Pin A-Coded

M12 4-Pin D-Coded

Isolation 1.5kV RMS 1-minute

Power Supply Specifications 31

Page 38

Chapter 4

Technical Specifications

RUGGEDCOM RX1512

Installation Guide

Section 4.4

Fiber Ethernet Port Specifications

The following sections detail fiber optic specifications for ports that can be ordered with the modules on a

RUGGEDCOM RX1512. The user determines the type of optics at time of ordering, and can determine the

modules installed on a particular unit by reading the factory data file via the RX1512 user interface. Section 4.4.1,

“Fast Ethernet (100Mbps) Optical Specifications” and Section 4.4.2, “Gigabit Ethernet (1Gbps) Optical

Specifications” list the specifications of the optical transceivers used in the fiber Ethernet modules available for

the RX1512. The specifications are organized by order code. Module order codes are contained within each

unit when it is assembled and configured at the factory. Consult the RuggedCom RX1512 User Guide for help in

obtaining the factory configuration data.

Section 4.4.1

Fast Ethernet (100Mbps) Optical Specifications

Fixed Fast Ethernet Transceivers

Table: Fast Ethernet (100Mbps) Optical Specifications

Order

Code

FX01 MM ST

FX02 MM SC

FX11 and

4FX11

FX03 and

4FX03

FX04 SM ST 9/125 1300 -15 -8 -32 -3 20 17

FX05 SM SC 9/125 1300 -15 -8 -31 -7 20 16

FX06 and

4FX06

FX07 SM SC 9/125 1300 -5 0 -34 -3 50 29

FX08 and

4FX08

Mode

MM

MM MTRJ

SM LC 9/125 1300 -15 -8 -34 -7 20 19

SM LC 9/125 1300 -5 0 -35 3 50 30

Connector

Type

MTRJ 62.5/125 -19 12

LC 50/125

Cable

Type

(μm)

62.5/125 -19 12

50/125

62.5/125 -19 12

50/125

62.5/125 -19 12

50/125

Tx λ

(typ.)

(nm)

1300

1300

1300

1300

Tx min.

(dBm)

-22.5

-22.5

-22.5

-22.5

Tx max.

(dBm)

-14 -31 -14 2

-14 -31 -14 2

-14 -31 -14 2

-14 -31 -14 2

Rx

Sensitivity

(dBm)

Rx

Saturation

(dBm)

Distance

(typ.)

(km)

Power

Budget

(dB)

8.5

8.5

8.5

8.5

FX09 SM SC 9/125 1300 0 5 -37 0 90 37

FX10 and

4FX10

SM LC 9/125 1300 0 5 -37 0 90 37

32 Fiber Ethernet Port Specifications

Page 39

RUGGEDCOM RX1512

Installation Guide

SFP Fast Ethernet Transceivers

Table: SFP Fast Ethernet Transceivers

Technical Specifications

Chapter 4

Order

Code

FX51 MM LC

FX52 SM LC 9/125 1300 -15 -8 -31 -8 20 16

FX53 SM LC 9/125 1300 -5 0 -34 0 50 29

FX54 SM LC 9/125 1550 -5 0 -34 -10 90 29

Mode

Connector

Type

Cable

Type

(μm)

62.5/125 -20 11

50/125

Tx λ

(typ.)

(nm)

1310

Tx min

(dBm)

-23.5

Tx max

(dBm)

-14 -31 -14 2

Rx

Sensitivity

(dBm)

Saturation

(dBm)

Section 4.4.2

Gigabit Ethernet (1Gbps) Optical Specifications

Fixed Gigabit Transceivers

Table: Fixed Gigabit Transceivers

Order

Code

FG01 MM LC 50/125 850 -9 -2.5 -20 0 0.5 11

Mode

Connector

Type

Cable

Type

(μm)

Tx λ

(typ.)

(nm)

Tx min

(dBm)

Tx max

(dBm)

Rx

Sensitivity

(dBm)

Saturation

(dBm)

Rx

Rx

Distance

(typ.)

(km)

Distance

(typ.)

(km)

Power

Budget

(dB)

7.5

Power

Budget

(dB)

FG02 SM SC 9/125 1310 -10 -3 -20 -3 10 10

FG03 SM LC 9/125 1310 -9.5 -3 -21 -3 10 11.5

FG04 SM SC 9/125 1310 -5 0 -20 -3 25 15

FG05 SM LC 9/125 1310 -7 -3 -24 -3 25 17

SFP Gigabit Transceivers

Table: SFP Gigabit Transceivers

Order

Code

FG51 MM LC

FG52 SM LC 9/125 1310 -9.5 -3 -19 -3 10 9.5

FG53 SM LC 9/125 1310 -7 -3 -23 -3 25 16

FG54 SM LC 9/125 1550 0 5 -23 -3 70 23

Mode

Connector

Type

Cable

Type

(μm)

50/125 0.5

62.5/125

Notes:

1. Maximum segment length is greatly dependent on factors such as fiber quality, and the number of patches

and splices. Please consult RuggedCom sales associates when determining maximum segment distances.

2. All optical power numbers are listed as dBm averages.

Tx λ

(typ.)

(nm)

850 -9 -2.5 -20 0

Tx min

(dBm)

Tx max

(dBm)

Rx

Sensitivity

(dBm)

Saturation

Rx

(dBm)

Distance

(typ.)

(km)

0.3

Power

Budget

(dB)

11

Gigabit Ethernet (1Gbps) Optical Specifications 33

Page 40

Chapter 4

Technical Specifications

3. F51 transceivers are rated for -40°C to +85°C.

Section 4.5

Operating Environment

Table: Operating Environment

Parameter Range Comments

RUGGEDCOM RX1512

Installation Guide

Ambient Operating Temperature -40°C to 85°C Ambient Temperature as measured from a 30cm

Section 4.6

radius surrounding the center of the enclosure.

RuggedAPE™ Specifications

Table: RuggedAPE™ Specifications

Feature APE1402 APE1402W7 APE1404 APE1404W7 APE1404CPK

Processor Intel Atom E660 1.3 GHz, 512KB L2 Cache Intel Atom E660T 1.3 GHz, 512KB L2 Cache

RAM 2 GB DDR2, 800 MHz, 32-bit

Disk 8 GB SATA, solid state 16 GB SATA, solid state

Networking Realtek RTL8111, RJ45 Gigabit Ethernet interface

USB 2 x USB 2.0, maximum combined USB device power consumption 500 mA at 5 V

Video Intel 4108 Grpahics Processor, DVI-D

LED Indications Power and Disk

Contols Momentary contact reset button

Temperature Range -40C to 70C

Power Requirements 12W with no USB load, 14.5W with full USB load

Software Platform Debian Linux® Windows®

Embedded Standard

7

Section 4.7

Debian Linux® Windows®

Embedded Standard

7

Check Point GAiA™

OS

Mechanical Specifications

Table: Mechanical Specifications

Parameter Value Comments

Dimensions 4.83 × 4.40 × 7.00 REF (6.86) inches

122.68 × 111.76 × 177.80 REF (174.24) mm

Weight Approximately 5 lbs (2.3 kg) Weight dependent on module selection.

34 Operating Environment

(Height × Width × Depth)

Page 41

RUGGEDCOM RX1512

Installation Guide

Ingress Protection IP40

Technical Specifications

Chapter 4

Parameter Value Comments

Enclosure Aluminum

Mechanical Specifications 35

Page 42

RUGGEDCOM RX1512

Installation Guide

Technical Specifications

Chapter 4

Mechanical Specifications 36

Page 43

RUGGEDCOM RX1512

Installation Guide

EMI And Environmental Type Tests

Table: IEC 61850-3 EMI Type Tests

EMI And Environmental Type Tests

Chapter 5

Test Description Test Levels

Enclosure Contact +/- 8 kV 4IEC 61000-4-2 ESD

Enclosure Air +/- 15 kV 4

IEC 61000-4-3 Radiated RFI Enclosure Ports 20 V/m Note

IEC 61000-4-4 Burst (Fast Transient)

IEC 61000-4-6 Induced (Conducted) RFI

IEC 61000-4-8 Magnetic Field Enclosure Ports

Signal ports +/- 4kV @ 2.5kHz Note

D.C. Power ports +/- 4kV 4

Earth ground ports +/- 4kV 4

Signal ports +/- 4kV line-to-earth,

+/- 2kV line-to-line

D.C. Power ports +/- 2kV line-to-earth,

+/- 1kV line-to-line

Signal ports 10V 3

D.C Power ports 10V 3

Earth ground ports 10V 3

40 A/m, continuous,

1000 A/m for 1 s

1000 A/m for 1 s 5

Severity

Levels

4IEC 61000-4-5 Surge

3

Note

a

a

a

IEC 61000-4-29 Voltage Dips & Interrupts D.C. Power ports 30% for 0.1s, 60% for

Signal ports 2.5kV common, 1kV

D.C. Power ports 2.5kV common, 1kV

Signal ports 30V Continuous, 300V for 1s 4IEC 61000-4-16 Mains Frequency Voltage

D.C. Power ports 30V Continuous, 300V for 1s 4

IEC 61000-4-17 Ripple on D.C.

a

RuggedCom-specified severity levels

Power Supply

D.C. Power ports 10% 3

Signal ports 2kVAC (Fail-Safe Relay output) N/AIEC 60255-5 Dielectric Strength

D.C. Power ports 2kVDC N/A

Signal ports 5kV (Fail-Safe Relay output) N/AIEC 60255-5 H.V. Impulse

D.C. Power ports 5kV N/A

0.1s, 100% for 0.05s

diff. mode@1MHz

diff. mode@1MHz

N/A

3IEC 61000-4-12 Damped Oscillatory

3

37

Page 44

Chapter 5

EMI And Environmental Type Tests

RUGGEDCOM RX1512

Installation Guide

Table: IEEE 1613 (C37.90.x) EMI Immunity Type Tests

b

Test Description Test Levels

Enclosure Contact +/-2kV, +/-4kV, +/- 8kVIEEE C37.90.3 ESD

Enclosure Air +/-4kV, +/-8kV, +/-15kV

IEEE C37.90.2 Radiated RFI Enclosure ports 35 V/m

IEEE C37.90.1 Fast Transient

Signal ports +/- 4kV @ 2.5kHz

D.C. Power ports +/- 4kV

Earth ground ports +/- 4kV

Signal ports 2.5kV common mode @1MHzIEEE C37.90.1 Oscillatory

D.C. Power ports 2.5kV common, 1kV diff. mode@1MHz

Signal ports 5kV (Fail-Safe Relay output)IEEE C37.90 H.V. Impulse

D.C. Power ports 5kV

Signal ports 2kVACIEEE C37.90 Dielectric Strength

D.C. Power ports 2kVDC

b

Meets Class 2 requirements for an all-fiber configuration. Meets Class 1 requirements for copper ports.

Table: Environmental Type Tests

Test Description Test Levels

IEC 60068-2-1 Cold Temperature Test Ad -40°C, 16 Hours

IEC 60068-2-2 Dry Heat Test Bd +85°C, 16 Hours

IEC 60068-2-30 Humidity (Damp Heat, Cyclic) Test Db 95% (non-condensing), 55°C , 6 cycles

IEC 60255-21-1 Vibration 2g @ (10 - 150) Hz

IEC 60255-21-2 Shock 30g @ 11mS

38

Page 45

RUGGEDCOM RX1512

Installation Guide

Agency Approvals

Table: Agency Approvals

Agency Approvals

Chapter 6

Agency Standards Comments

TUV

CE EN 60950, EN 61000-6-2

FCC FCC Part 15, Class A

CISPR EN55022, Class A

FDA/CDRH 21 CFR Chapter 1, Subchapter J Laser Eye Safety

ISO ISO9001:2008

ACTA FCC Part 68 TC1, TC2 and TC4 line modules

Industry Canada IC CS-03 Part II, Issue 9 TC1, TC2 and TC4 line modules

GSM: 850/900/1800/1900, UMTS FDD:

Band I/Band II/Band V/Band VIII [http://

PTCRB

view_complete_request_guest.cfm?

Cellco Partnership d/b/a Verizon Wireless MA-00203-2009

UL 60950-1:2007,

CAN/CSA-C22.2 No. 60950-1-07

www.ptcrb.com/vendor/complete/

modelid=19987]

CE Compliance is claimed via

Declaration of Self Conformity Route

Designed and manufactured using an

ISO9001: 2008 certified quality program

Cellular LM Models RX1500PN-W11-XX

RX1500PN-W12-XX RX1500PN-W32-XX

Carrier Certification for Cellular

LM Models RX1500PN-W21-XX

RX1500PN-W22-XX RX1500PN-W32-XX

39

Page 46

RUGGEDCOM RX1512

Installation Guide

Agency Approvals

Chapter 6

40

Page 47

RUGGEDCOM RX1512

Installation Guide

Warranty

RuggedCom warrants this product for a period of five (5) years from the date of purchase. This product contains

no user-serviceable parts. Attempted service by unauthorized personnel shall render all warranties null and void.

For warranty details, visit www.RuggedCom.com or contact your customer service representative.

Should this product require service, contact the factory at:

RuggedCom Inc.

300 Applewood Crescent

Concord, Ontario

Canada L4K 5C7

Phone: +1 905 856 5288

Fax: +1 905 856 1995

Chapter 7

Warranty

41

Page 48

RUGGEDCOM RX1512

Installation Guide

Chapter 7

Warranty

42

Loading...

Loading...