Page 1

FORM NO. G11-501

Supersedes Form No. G11-501

GAS FURNACES

RGRM- SERIES

ECM Equipped

Models with Input Rates of

45,000, 60,000, 75,000,

90,000, 105,000 & 120,000

BTU/HR [13.19, 17.58, 22,

26.38, 30.77 & 35.17 kW]

(45K through 105K Models

Rated at 95% A.F.U.E., 120K

Model Rated at 93.3% A.F.U.E.)

95% A.F.U.E. WITH DUAL

COMFORT CONTROL

TWO-STAGE UPFLOW

GAS FURNACES

The Rheem Classic®Series 95% A.F.U.E. with Dual Comfort Control

line of upflow gas furnaces are designed for utility rooms, closets,

alcoves, or attics. Because of the low-profile 34 inch [864 mm]

height, the upflow model can also be used to satisfy most

applications.

The design is certified by CSA.

Features

■ Two stages of operation to save energy and maintain optimal com-

fort level.

■ Furnace operates at 70% capacity for low-heat and 100% capacity

for high-heat.

■ Compatible with single or two-stage thermostat. (For optimal perfor-

mance a two-stage thermostat is recommended.)

■ Heat exchanger is constructed of all stainless steel for maximum

corrosion resistance and thermal fatigue reliability.

■ Low profile “34 inch” design is lighter and easier to handle and

leaves room for optional accessories.

■ Left or right side gas, electric, and condensate drainage connections.

■ Integrated control board manages all operational functions and pro-

vides hookups for humidifier and electronic air cleaner.

■ An insulated blower compartment, a slow-opening gas valve and a

specially designed inducer system make it one of the quietest furnaces on the market today.

■ Variable speed blower motor technology provides ultimate humidity

control, quieter sound levels and year-round energy savings.

■ Optional indoor or outdoor combustion air. In addition, combustion

air may be piped to either the top or side of the cabinet on all upflow

models. A special molded fitting is provided to ease installation.

■ Solid bottom is standard.

■ Control board diagnostics.

A variety of cooling coils and plenums designed to use with the Rheem

Classic

®

Series 95% A.F.U.E. gas furnaces are available as optional

accessories for air conditioning models.

✝A.F.U.E. (Annual Fuel Utilization Efficiency) calculated in accordance with Department of Energy test

procedures.

“Proper sizing and installation of equipment is critical to achieve optimal performance. Split system air conditioners and heat pumps must be

matched with appropriate coil components to meet ENERGY STAR criteria. Ask your Contractor for details or visit www.energystar.gov.”

“Visit www.RheemAC.com/

taxcredit for complete details.”

Page 2

2 Rheem Heating, Cooling and Water Heating

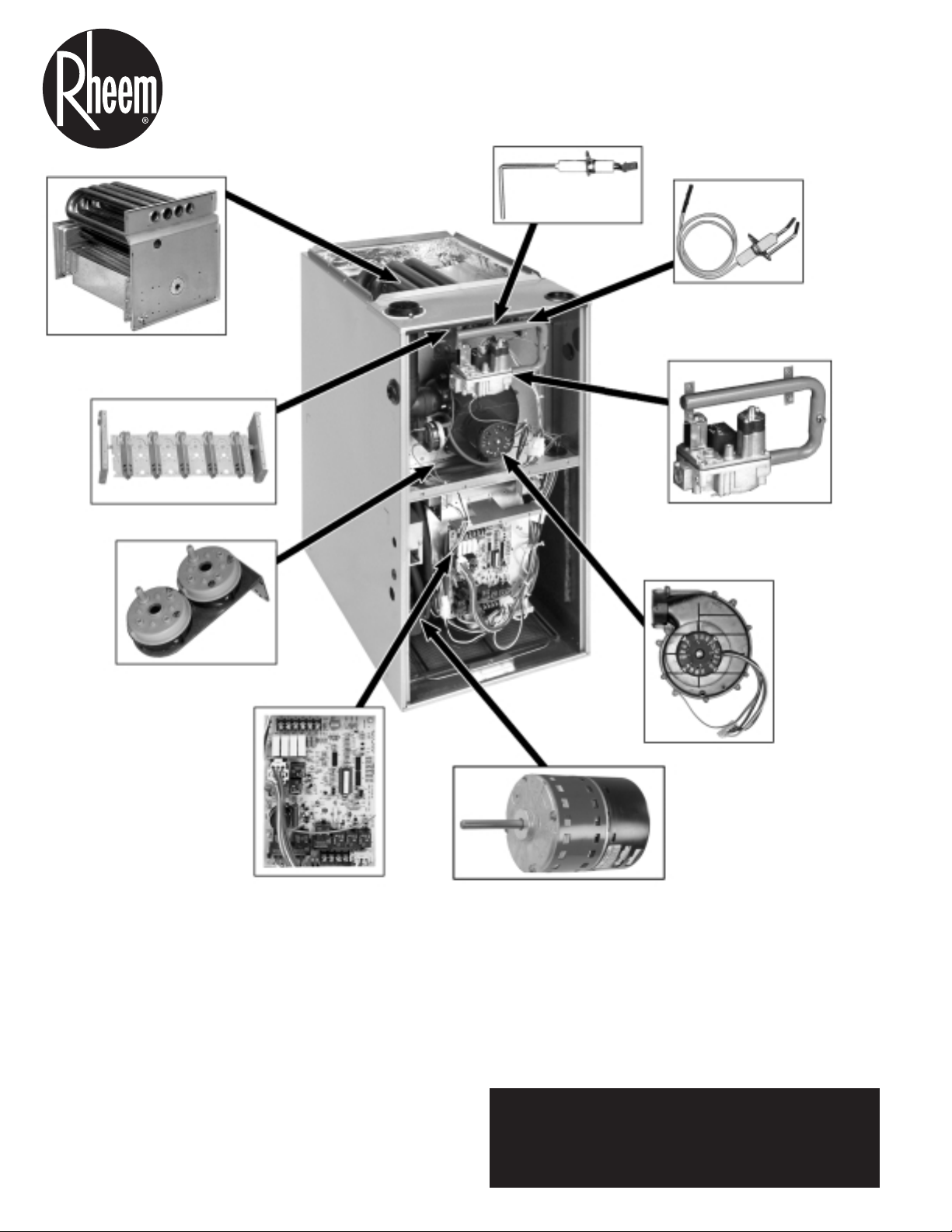

STANDARD EQUIPMENT

Completely assembled and wired; heat exchanger; primary: 409 stainless steel,

secondary: 29-4C stainless steel; induced draft; pressure switches; redundant

main gas control; blower compartment door safety switch; solid state time

on/off blower control; limit controls; manual shut-off valve; 100% safety lock

out; cool fan off delay; field selectable heat fan off delay; one hour automatic

retry; power and self-test diagnostics; flame sense current diagnostics;

electronic air cleaner connections; twinning (built-in) features; humidifier

connections; humidifier on/off delay; low speed continuous fan option; single

speed option for heating and cooling applications; pressure regulator for

natural and L.P. (propane) gasses; transformer; direct drive, multi-speed blower

motor. (Please note: a thermostat is not included as standard equipment.)

OPTIONAL EQUIPMENT

Side and bottom filter racks; return air cabinet for all sizes.

NOTE: Furnace is not listed for use with fuels other than natural or L.P.

(propane) gas.

All models can be converted by a qualified distributor or local service dealer to

use L.P. (propane) gas without changing burners. Factory approved kits must

be used to convert from natural to L.P. (propane) gas and may be ordered as

optional accessories from a parts distributor.

For L.P. (propane) operation, refer to Conversion Kit Index Form.

WARNING

THIS FURNACE IS NOT APPROVED

OR RECOMMENDED

FOR USE IN MOBILE HOMES

PRIMARY AND SECONDARY

HEAT EXCHANGER

REMOTE

SENSOR

IN-SHOT BURNERS

PRESSURE SWITCHES

DRAFT INDUCER

INTEGRATED

FURNACE

CONTROL

GAS VALVE AND

MANIFOLD

CLASSIC SERIES 90 PLUS HIGH EFFICIENCY

UPFLOW GAS FURNACE

DIRECT SPARK IGNITION &

REMOTE SENSOR

ECM MOTOR

Page 3

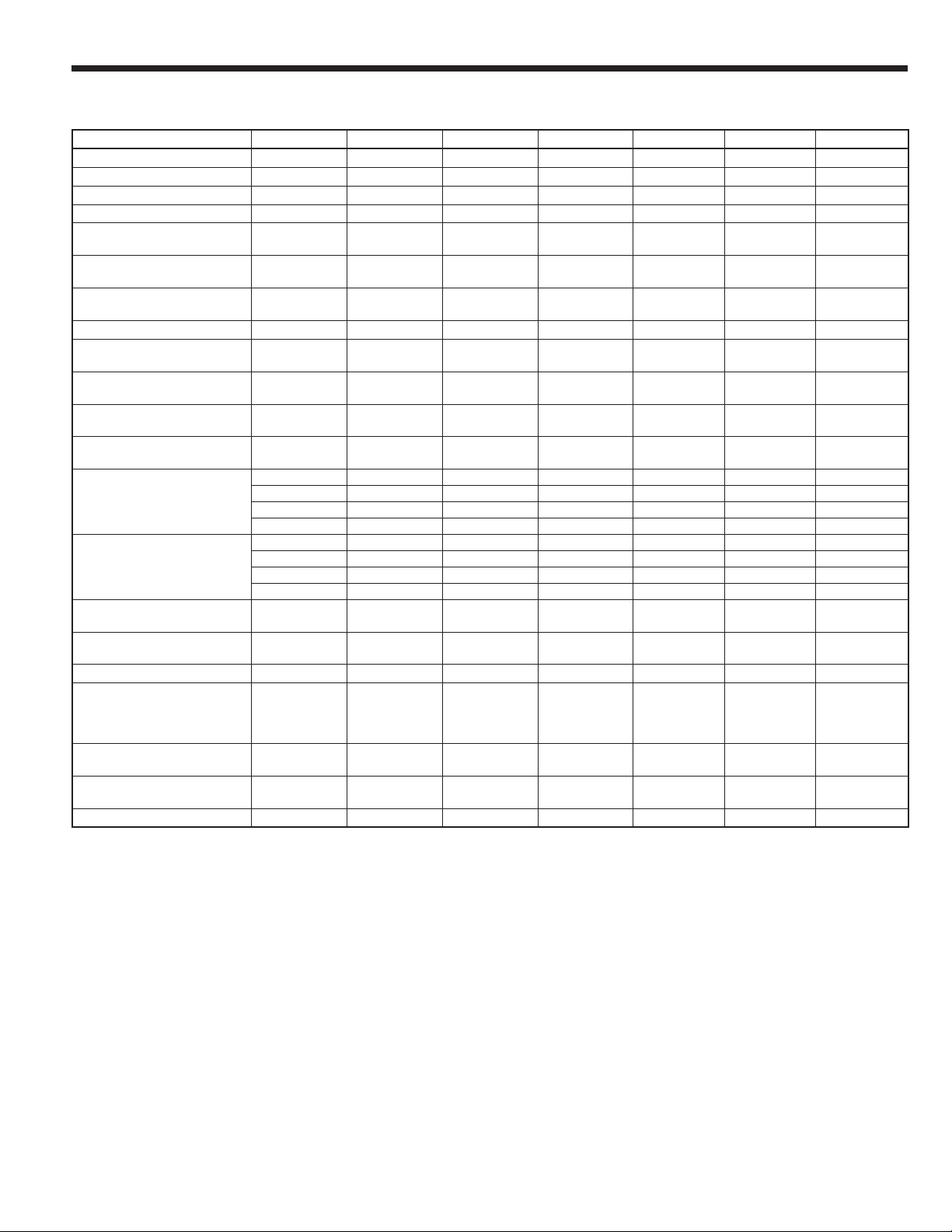

Rheem Heating, Cooling and Water Heating 3

BEFORE PURCHASING THIS APPLIANCE, READ IMPORTANT ENERGY COST AND EFFICIENCY INFORMATION AVAILABLE

FROM YOUR RETAILER.

PHYSICAL DATA AND SPECIFICATIONS—UPFLOW MODELS

U.S. and Canadian Models

NOTES: All models are 115V, 60HZ, 1 phase. Gas connection size for all models is 1/2" [13 mm] N.P.T.

➀ See Conversion Kit Index Form for high altitude derate.

➁ Canadian installations only.

➂ In accordance with D.O.E. test procedures.

*E=Standard

*N=NOx Models

WARNING: Some heating airflow values may be

higher than those required for cooling. Be sure to size

duct systems for highest possible airflow value.

MODEL NUMBERS RGRM-04*MAES RGRM-06*MAES RGRM-09*ZAJS

HIGH FIRE INPUT BTU/HR [kW] ➀

LOW FIRE INPUT BTU/HR [kW] ➁

HEATING CAPACITY BTU/HR [kW] 42,000 [12.31] 56,000 [16.41] 84,000 [24.62]

HIGH ALTITUDE INPUT 8000' ➁

HIGH ALTITUDE OUTPUT

AT 8000' (HIGH FIRE) [kW] ➁

BLOWER (D x W)

[mm]

MOTOR H.P. [W]–

SPEEDS–TYPE

MOTOR FULL LOAD AMPS 8.7 8.7 12

MINIMUM EXT. STATIC

PRESSURE (IN. W.C.) [kPa]

MAXIMUM EXT. STATIC

PRESSURE (IN. W.C.) [kPa]

LOW HEATING CFM @ .2"

[.049 kPa] W.C. E.S.P. [L/s]

HIGH HEATING CFM @ .2"

[.049 kPa] W.C. E.S.P. [L/s]

HIGH COOLING CFM @ .8"

[.124 kPa] W.C. E.S.P. [L/s]

LOW COOLING CFM @ .8"

[.124 kPa] W.C. E.S.P. [L/s]

TEMPERATURE RISE-HIGH FIRE

RANGE IN DEGREES °F [°C]

TEMPERATURE RISE-LOW FIRE

RANGE IN DEGREES °F [°C]

RETURN AIR CABINETS (OPT.)

RXGRFILTER SIZE

[mm]

STANDARD, HIGH VELOCITY

PERMANENT FILTER (IN.)

APPROX. SHIPPING WEIGHT

(LBS.) [kg]

AFUE ➂

45,000 [13.19] 60,000 [17.58] 90,000 [26.38]

31,500 [9.23] 42,000 [12.31] 63,000 [18.46]

30,600 [8.97] 40,800 [11.96] 61,200 [17.94]

28,458 [8.34] 37,944 [11.12] 56,916 [16.69]

11 x 7

[279 x 178]

1

/2 [373] VAR.

SPEED

.10 [0.25] .12 [.029] .15 [.037]

.80 [0.2] .80 [0.2] .80 [0.2]

850 725 1275

780 900 1450

A = 1200 A = 1200 A = 2000

C = 800 C = 800 C = 1400

A = 900 A = 900

C = 600 C = 600 C = 1050

30-60

[16.7-33.3]

15-45

[8.3-25]

C17B

(2) 12" x 16"

[305 x 406]

4 x 25 x 1

153/

117

[53.2]

95.0% 95.0% 95.0%

11 x 7

[279 x 178]

1

/2 [373] VAR.

SPEED

40-70

[22.2-38.9]

35-65

[19.4-36.1]

C17B

(2) 12" x 16"

[305 x 406]

4 x 25 x 1

153/

123

[56.0]

RGRM-07*MAES

75,000 [21.98]

52,500 [15.39]

70,000 [20.51]

51,000 [14.95]

47,430 [13.90]

11 x 7

[279 x 178]

1

/2 [373] VAR.

SPEED

8.7

.12 [.029]

.80 [0.2]

765

1080

A = 1200

B = 1000 B = 1400 B = 1600B = 1000 B = 1000 B = 1600 B = 1600

C = 800

D = 600 D = 1000 D = 1200D = 600 D = 600 D = 1200 D = 1200

A = 900

B = 750 B = 1050 B = 1200B = 750 B = 750 B = 1200 B = 1200

C = 600

D = 450 D = 750 D = 900D = 450 D = 450 D = 900 D = 900

40-70

[22.2-38.9]

35-65

[19.4-36.1]

180MAX. OUTLET AIR TEMPERATURE 160 170 170 165 180 180

C17B

(2) 12" x 16"

[305 x 406]

4 x 25 x 1

153/

128

[58.2]

95.0%

RGRM-07*YBGS

75,000 [21.98]

52,500 [15.39]

70,000 [20.51]

51,000 [14.95]

47,430 [13.90]

12 x 7

[305 x 178]

1 [746] VAR.

SPEED

12

.12 [.029]

.80 [0.2]

1180

1180

A = 1600

C = 1200

A = 1200

C = 900

35-65

[19.4-36.1]

20-50

[11.1-27.8]

C21B

(2) 12" x 20"

[305 x 508]

4 x 25 x 1

153/

139

[63.2]

95.0%

RGRM-10*ZAJS

105,000 [30.77]

73,500 [21.54]

97,000 [28.43]

71,400 [20.93]

66,402 [19.46]

12 x 11

[305 x 279]

1 [746] VAR.

SPEED

A = 1500

35-65

[19.4-36.1]

25-55

[13.9-30.6]

C21B

(2) 12" x 20"

[305 x 508]

4 x 25 x 1

191/

148

[67.3]

12 x 11

[305 x 279]

1 [746] VAR.

SPEED

12

.20 [.049]

.80 [0.2]

1400

1604

A = 2000

C = 1400

A = 1500

C = 1050

40-70

[22.2-38.9]

30-60

[16.7-33.3]

C21B

(2) 12" x 20"

[305 x 508]

4 x 25 x 1

191/

150

[68.2]

95.0%

RGRM-12*RAJS

120,000 [35.17]

84,000 [24.62]

113,000 [33.12]

81,600 [23.91]

75,888 [22.24]

[279 x 254]

1 [746] VAR.

[22.2 – 38.9]

(2) 14" x 16"

[609 x 406]

223/

11 x 10

SPEED

12

.20 [.049]

.80 [0.2]

1250

1450

A = 2000

C = 1400

A = 1500

C = 1050

50-80

[27.8-4.4]

40-70

C24B

4 x 25 x 1

159

[72.3]

93.3%

Page 4

4 Rheem Heating, Cooling and Water Heating

MODEL IDENTIFICATION

R G R M 07E* BY G S

Rheem Gas

Furnace

Upflow

Condensing

Gas Furnace

Design

Series

Heating Input

Designation

Variations

A = Std.

B = Wide

Blower Size

M = 11 x 7

[279 x 178 mm]

R = 11 x 10

[279 x 254 mm]

Z = 12 x 11

[305 x 279 mm]

Y = 12 x 7

[305 x 178 mm]

Heat/Cool

Designation

E = 1100-1300 CFM

[519-613.5 L/s]

G = 1500-1700 CFM

[707.9-802.3 L/s]

J = 1900-2100 CFM

[896.7-991.1 L/s]

Fuel Code

S = U.S. and

Canadian

Electric

Ignition

04

*

06

*

07

*

09

*

10*

12*

Input

BTU/HR

45,000 [13.19 kW]

60,000 [17.58 kW]

75,000 [22 kW]

90,000 [26.38 kW]

105,000 [30.77 kW]

120,000 [35.17 kW]

278

Option Code

for

High Altitude

—

Available Models:

RGRM-04EMAES RGRM-07EMAES RGRM-09EZAJS278

RGRM-04NMAES RGRM-07NMAES RGRM-10EZAJS

RGRM-04EMAES278 RGRM-07EYBGS RGRM-10NZAJS

RGRM-06EMAES RGRM-07NYBGS RGRM-12ERAJS

RGRM-06NMAES RGRM-09EZAJS RGRM-12NRAJS

RGRM-06EMAES278 RGRM-09NZAJS RGRM-12ERAJS78

[ ] Designates Metric Conversions

NOTES: *E = Standard

*N = NO

x

Models

Page 5

MODEL

RGRM-

A B C D E F

LEFT

SIDE

MINIMUM CLEARANCE (IN.) [mm]

RIGHT

SIDE

BACK TOP FRONT VENT

04*M 17.5 [445] 1611/32 [415] 155/8 [397] 2 [51] 151/2 [422] 1325/32 [352] 0 0 0 1 [25] 2 [51] 0

06*M 17.5 [445] 1611/32 [415] 155/8 [397] 2 [51] 151/2 [422] 1325/32 [352] 0 0 0 1 [25] 2 [51] 0

07*Y 21 [533] 1927/32 [504] 191/8 [487] 2 [51] 181/2 [511] 179/322 [441] 0 0 0 1 [25] 2 [51] 0

09*Z 21 [533] 1927/32 [504] 191/8 [487] 2 [51] 181/2 [511] 179/322 [441] 0 0 0 1 [25] 2 [51] 0

07*M 17.5 [445] 1611/32 [415] 155/8 [397] 2 [51] 151/2 [422] 1325/32 [352] 0 0 0 1 [25] 2 [51] 0

10*Z 21 [533] 1927/32 [504] 191/8 [487] 2 [51] 181/2 [511] 179/322 [441] 0 0 0 1 [25] 2 [51] 0

12*R 24.5 [622]

2311/32 [593] 225/8 [575]

2 [51]

221/2 [600] 2025/32 [530]

0 0 0 1 [25] 2 [51] 0

UPFLOW MODELS

*

E=Standard

*

N=NO

x

[ ] Designates Metric Conversions

Rheem Heating, Cooling and Water Heating 5

Page 6

6 Rheem Heating, Cooling and Water Heating

BLOWER PERFORMANCE DATA**—RGRM MODELS

GENERAL TERMS OF LIMITED WARRANTY

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

period stated, in accordance with the terms of the limited

warranty.

For Complete Details of the Limited Warranty, Including Applicable Terms

and Conditions, See Your Local Installer or Contact the Manufacturer for

a Copy.

Primary and Secondary Heat Exchanger.......Limited Lifetime

Conditional Parts Warranty

(Registration Required)..............................Ten (10) Years

Conditional Unit Replacement Warranty

(Registration Required)..............................Ten (10) Years

*

E=Standard

*

N=NO

x

Models

[ ] Designates Metric Conversions

MODEL

RGRM-

RGRM-04*M

RGRM-06*M

RGRM-07*M

RGRM-07*Y

RGRM-09*Z

RGRM-10*Z

RGRM-12*R

BLOWER

SIZE (D x W)

IN. [mm]

11 x 7

[279 x 178]

11 x 7

[279 x 178]

11 x 7

[279 x 178]

12 x 7

[305 x 279]

12 x 11

[305 x 279]

12 x 11

[305 x 279]

11x 10

[279 x 254]

ECM

MOTOR

H.P. [W]

1/2

[373]

1/2

[373]

1/2

[373]

1

[746]

1

[746]

1

[746]

1

[746]

BLOWER

SPEED

HIGH

MED-HI

MED

LOW

HIGH

MED-HI

MED

LOW

HIGH

MED-HI

MED

LOW

HIGH

MED-HI

MED

LOW

HIGH

MED-HI

MED

LOW

HIGH

MED-HI

MED

LOW

HIGH

MED-HI

MED

LOW

CFM [L/s] AIR DELIVERY

EXTERNAL STATIC PRESSURE

INCHES WATER COLUMN [kPa]

0.1 [.02] – 0.8 [.20]

1200 [566]

1000 [472]

800 [378]

600 [283]

1200 [566]

1000 [472]

800 [378]

600 [283]

1200 [566]

1000 [472]

800 [378]

600 [283]

1600 [755]

1400 [661]

1200 [566]

1000 [472]

2000 [944]

1600 [755]

1400 [661]

1200 [566]

2000 [944]

1600 [755]

1400 [661]

1200 [566]

2000 [944]

1600 [755]

1400 [661]

1200 [566]

Page 7

Rheem Heating, Cooling and Water Heating 7

ACCESSORIES—UPFLOW

VENT TERMINATION KITS CONCENTRIC: HORIZONTAL/

VERTICAL =

RXGY-E03A (US & Canadian Installations)

HORIZONTAL TWO PIPE: RXGY-D02, RXGY-D03, RXGY-D04

(US Installations)

RXGY-D02A, RXGY-D03A, RXGY-D04A (Canadian Installations)

RXGY-G02 (US Only)

CONDENSATE PUMP KIT: RXGY-B01

NEUTRALIZER KIT: RXGY-A01

FOSSIL FUEL KIT: RXPF-F01, RXPF-F02 (TVA)

RETURN AIR PLENUM: RXGR-C17B, RXGR-C21B, RXGR-C24B

*Filter racks are shipped without filters.

Filters shipped with furnace may be used or a suitable 1" [25.4 mm] filter.

[ ] Designates Metric Conversions

Option – 278 furnaces are shipped with #51 DMS orifices installed.

This is one drill size smaller than standard furnaces to account for

expected average elevations and heating values typically seen in

these areas.

CAUTION: Always follow National Fuel Gas Code (NFGC) guidelines

when converting for high altitudes.

For all installations above 2000 ft. (including all option – 278

models), the burner orifice size needs to be recalculated and

verified. A burner orifice change may still be required. See

Installation Instructions for more information.

NOTE: For Canadian installations only, an optional derate (manifold

gas pressure reduction) method may be used to adjust the

furnace for altitude. See Installation Instructions for more

information. This optional method may NOT be used for

U.S. installations.

(U.S. Models—Kit packaged with furnace.

Requires field installation).

LP CONVERSION KITS:

U.S./Canadian RXGJ-FP19 or RXGJ-FP21

EXTERNAL BOTTOM FILTER RACK: RXGF-CB

EXTERNAL SIDE FILTER RACK: RXGF-CA

FOR HIGH ALTITUDES:

HIGH ALTITUDE KIT:

PLENUM DATA FOR “A” COILS

Plenum adapters are required in some instances for use on upflow

applications when plenum and furnace size do not match.

Note: See Form Number C11-206 for MultiFlex®coil data.

Note: See Form Number C11-206 for MultiFlex®coil data.

FURNACE

WIDTH

IN. [mm]

141/2 [356] 161/4 [413]

141/2 [356] 201/4 [514] RXAA-C172 RXAL-B20BU

171/2 [445] 161/4 [413] RXAA-C185 RXAL-B16BU

171/2 [445] 201/4 [514] RXAA-C173 RXAL-B20BU

171/2 [445] 215/8 [549]

171/2 [445] 251/4 [641]

21 [533] 251/4 [641]

21 [533] 221/4 [565]

21 [533] 215/8 [549] RXAA-C188 RXAL-B21BU

241/2 [622] 251/4 [641]

241/2 [622] 215/8 [549] RXAA-C187 RXAL-B21BU

PLENUM

WIDTH

IN. [mm]

PLENUM ADAPTER

UPFLOW

RXAA-C171 RXAL-B16BU

RXAA-C187 RXAL-B21BU

RXAA-C174 RXAL-B25BU

RXAA-C175 RXAL-B25BU

RXAA-C176 RXAL-B22BU

RXAA-C177 RXAL-B25BU

PLENUM

COIL

INPUT BTU/HR [kW] HIGH ALTITUDE KIT NO.

RGRM-04*M RXGY-F18

RGRM-06*M

RGRM-07*M Not Required

RGRM-07*Y Not Required

RGRM-09*Z RXGY-F20

RGRM-10*Z Not Required

RGRM-12*R RXGY-F21

RXGY-F18

FILTER RACK FILTER SIZES* INCHES [mm]

MODEL

RGRM-

04

06

07EM

07NM

07EY

07NY

09

10

12

RXGF-CB

(BOTTOM)

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

191/4 x 25

[489 x 635]

191/4 x 25

[489 x 635]

191/4 x 25

[489 x 635]

223/4 x 25

[578 x 635]

RXGF-CA

(SIDE)

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

153/4 x 25

[400 x 635]

Page 8

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

Rheem Heating,

Cooling and

Water Heating

P.O. Box 17010, For t Smith, AR 72917

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 5-09 DC FORM NO. G11-501

Supersedes Form No. G11-501 Rev. 5

Loading...

Loading...