Page 1

INSTALLATION INSTRUCTIONS

KP98-7 KEYPANEL

VERSION 8.2

WITH EKP98-0 EXPANSION PANEL AND LCP-100A LEVEL CONTROL PANEL

ADAM™, ADAM™ CS, AND ZEUS™ INTERCOM SYSTEMS

NUM

PL

PREFIX

TYPE

E-PNL

DISPLAY

MULT

FUNC

AUTO

3

2

IFB

ISO

5

6

8

9

PGM

0

PUSH

VOLUME

HEADSET

LISTEN1LISTEN2LISTEN3LISTEN4LISTEN5LISTEN6LISTEN7LISTEN8LISTEN9LISTEN10LISTEN11LISTEN12LISTEN13LISTEN14LISTEN

DIR

PROD RACK

TALK

1

KP98-7

TALK2TALK

PL01

3

Page1Page

IFB4

TALK

4

2

TD

NEWS

AD

TALK5TALK6TALK

Page

Page

3

4

7

Level

SAT1

TEL1 TEL2 FLOR

TALK

TALK

8

Phone

TALK10TALK

9

PL

IFB

Scroll

Scroll

CHYR

IS01 IS02

TALK

TALK13TALK14TALK

12

11

Mic

Headset

Enable

KP98-7

CALL

15

CLEAR

AUD1

15

ANSWER

1

SLIST

PHONE

4

RELAY

COPY CW

7

CALL

EX COPY

CLR

TALK2TALK

TALK

1

3

TALK

4

TALK5TALK6TALK

9330-7410-000 V8.2 Rev A2,12/98

TALK

TALK

7

TALK10TALK

9

8

TALK

TALK13TALK14TALK TALK

12

11

15 16

KP98-7

EKP98-0

LCP-100A

LCP-100A

™

Page 2

PROPRIETARY NOTICE

CUSTOMER SUPPORT

The RTS product information and design disclosed herein were

originated by and are the property of Telex Communications, Inc.

Telex reserves all patent, proprietary design, manufacturing, reproduction, use and sales rights thereto, and to any article disclosed

therein, except to the extent rights are expressly granted to others.

COPYRIGHT NOTICE

Copyright 1997 by Telex Communications, Inc. All rights reserved. Reproduction in whole or in part without prior written permission from Telex is prohibited.

UNPACKING AND INSPECTION

Immediately upon receipt of the equipment, inspect the shipping

container and the contents carefully for any discrepancies or damage. Should there be any, notify the freight company and the dealer

at once.

WARRANTY INFORMATION

RTS products are warranted by Telex Communications, Inc. to be

free from defects in materials and workmanship for a period of

three years from the date of sale.

The sole obligation of Telex during the warranty period is to provide, without charge, parts and labor necessary to remedy covered

defects appearing in products returned prepaid to Telex. This warranty does not cover any defect, malfunction or failure caused beyond the control of Telex, including unreasonable or negligent

operation, abuse, accident, failure to follow instructions in the

Service Manual or the User Manual, defective or improper associated equipment, attempts at modification and repair not authorized

by Telex, and shipping damage. Products with their serial numbers

removed or effaced are not covered by this warranty.

To obtain warranty service, follow the procedures entitled "Procedure For Returns" and "Shipping to Manufacturer for Repair or

Adjustment".

This warranty is the sole and exclusive express warranty given with

respect to RTS products. It is the responsibility of the user to determine before purchase that this product is suitable for the user's intended purpose.

ANY AND ALL IMPLIED WARRANTIES, INCLUDING

THE IMPLIED WARRANTY OF MERCHANTABILITY

ARE LIMITED TO THE DURATION OF THIS EXPRESS

LIMITED WARRANTY.

NEITHER TELEX NOR THE DEALER WHO SELLS RTS

PRODUCTS IS LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

Technical questions should be directed to:

Customer Service Department

RTS/Telex,

2550 Hollywood Way, Suite 207

Burbank, CA 91505 U.S.A.

Telephone: (818) 566-6700

Fax: (818) 843-7953

RETURN SHIPPING INSTRUCTIONS

PROCEDURE FOR RETURNS

If a repair is necessary, contact the dealer where this unit was purchased.

If repair through the dealer is not possible, obtain a RETURN

AUTHORIZATION from:

Customer Service Department

Telex Communications, Inc.

Telephone: (800) 828-6107

Fax: (800) 323-0498

DO NOT RETURN ANY EQUIPMENT DIRECTLY TO THE

FACTORY WITHOUT FIRSTOBTAINING A RETURN

AUTHORIZATION.

Be prepared to provide the company name, address, phone number,

a person to contact regarding the repair, the type and quantity of

equipment, a description of the problem and the serial number(s).

SHIPPING TO MANUFACTURER FOR REPAIR OR

ADJUSTMENT

All shipments of RTS products should be made via United Parcel

Service or the best available shipper, prepaid. The equipment

should be shipped in the original packing carton; if that is not

available, use any suitable container that is rigid and of adequate

size. If a substitute container is used, the equipment should be

wrapped in paper and surrounded with at least four inches of excelsior or similar shock-absorbing material. All shipments must be

sent to the following address and must include the Return Authorization.

Factory Service Department

Telex Communications, Incorporated

8601 E. Cornhusker Hwy

Lincoln, NE 68505 U.S.A.

Upon completion of any repair the equipment will be returned via

United Parcel Service or specified shipper collect.

2 Installation Instructions, KP98-7 Keypanel

Page 3

End-User License Agreement for Telex® Software

IMPORTANT - Please read this document carefully before using this

product.

THIS DOCUMENT STATES THE TERMS AND CONDITIONS UPON

WHICH TELEX COMMUNICATIONS, INC. (the “COMPANY”)

OFFERS TO LICENSE THE INSTALLED SOFTWARE OR PROGRAM

(“the SOFTWARE”) FOR USE WITH THE PRODUCT IN WHICH IT

WAS INSTALLED. YOU ARE AGREEING TO BECOME BOUND BY

THE TERMS OF THIS AGREEMENT. IF YOU DO NOT AGREE TO

THE TERMS OF THIS AGREEMENT, DO NOT USE THIS PRODUCT.

PROMPTLY RETURN THE PRODUCT TO THE PLACE WHERE YOU

OBTAINED IT FOR A FULL REFUND.

The installed software as supplied by the Company is licensed, not sold, to

you for use only under the terms of this license, and the Company reserves

all rights not expressly granted to you. You own the product or other media

on or in which the Software is originally or subsequently recorded or fixed,

but the Company retains ownership of all copies of the Software itself.

1. License: This license allows you to use the Software for internal purposes

only on a single product in which it was installed.

2. Restrictions: (a) You may not market, distribute or transfer copies of the

Software to others or electronically transfer or duplicate the Software. YOU

MAY NOT REVERSE ENGINEER, DECOMPILE, DISASSEMBLE,

MODIFY, ADAPT, TRANSLATE, RENT, LEASE OR LOAN THE

SOFTWARE OR CREATE DERIVATIVE WORKS BASED ON THE

SOFTWARE OR ANY ACCOMPANYING WRITTEN MATERIALS. (b)

The Software and the accompanying written materials are copyrighted.

Unauthorized copying of the Software, including portions thereof or the

written materials, is expressly forbidden. (c) You understand that the

Company may update or revise the Software and in so doing incurs no

obligation to furnish such updates to you.

3. Limited Warranty: The Company does not warrant that the operation of

the Software will meet your requirements or operate free from error. The

Company DISCLAIMS ALL OTHER WARRANTIES AND CONDITIONS

EITHER EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

4. Limited Liability: The liability of the Company for any claims arising out

of this License based upon the Software, regardless of the form of action,

shall not exceed the greater of the license fee for the Software or $50.

38109-709 Rev A 10/97

Installation Instructions, KP98-7 Keypanel 3

Page 4

This page intentionally left blank.

4 Installation Instructions, KP98-7 Keypanel

Page 5

TABLE OF CONTENTS

INTRODUCTION · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

NEW FEATURES FOR VERSION 8.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

UNPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CHECKING THE FACTORY JUMPER AND LEVEL SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DIP SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Talk Key Row Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Expansion Panel In-use Indication for IFB and ISO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LCP Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Logical Keypanel Address Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MOUNTING THE KEYPANEL AND ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

STANDARD CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Gooseneck Microphone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Front Panel Headset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connection To Intercom Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPTIONAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EKP98-0 and LCP-100A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rear Panel Headset Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminal Block Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXT MIC IN Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXT LINE IN Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MIC PRE OUT Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

POWER-UP AND OPERATIONAL CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

KEYPANEL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ELECTRICAL ADJUSTMENTS · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 14

INTERNAL JUMPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

J201 (EXTERNAL INPUT MUTING) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

J202 (SPEAKER/HDST MUTE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

J203 (SIDETONE MUTING). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

J401 (OUTPUT ENABLE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

J402 (BALANCE TEST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

J403 (PREAMP OUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation Instructions, KP98-7 Keypanel 5

Page 6

J404-J406 (PANEL MIC SELECTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AUDIO LEVEL ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MICROPHONE PREAMPLIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SPEAKER/HEADSET AMPLIFIER ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LIST OF FIGURES

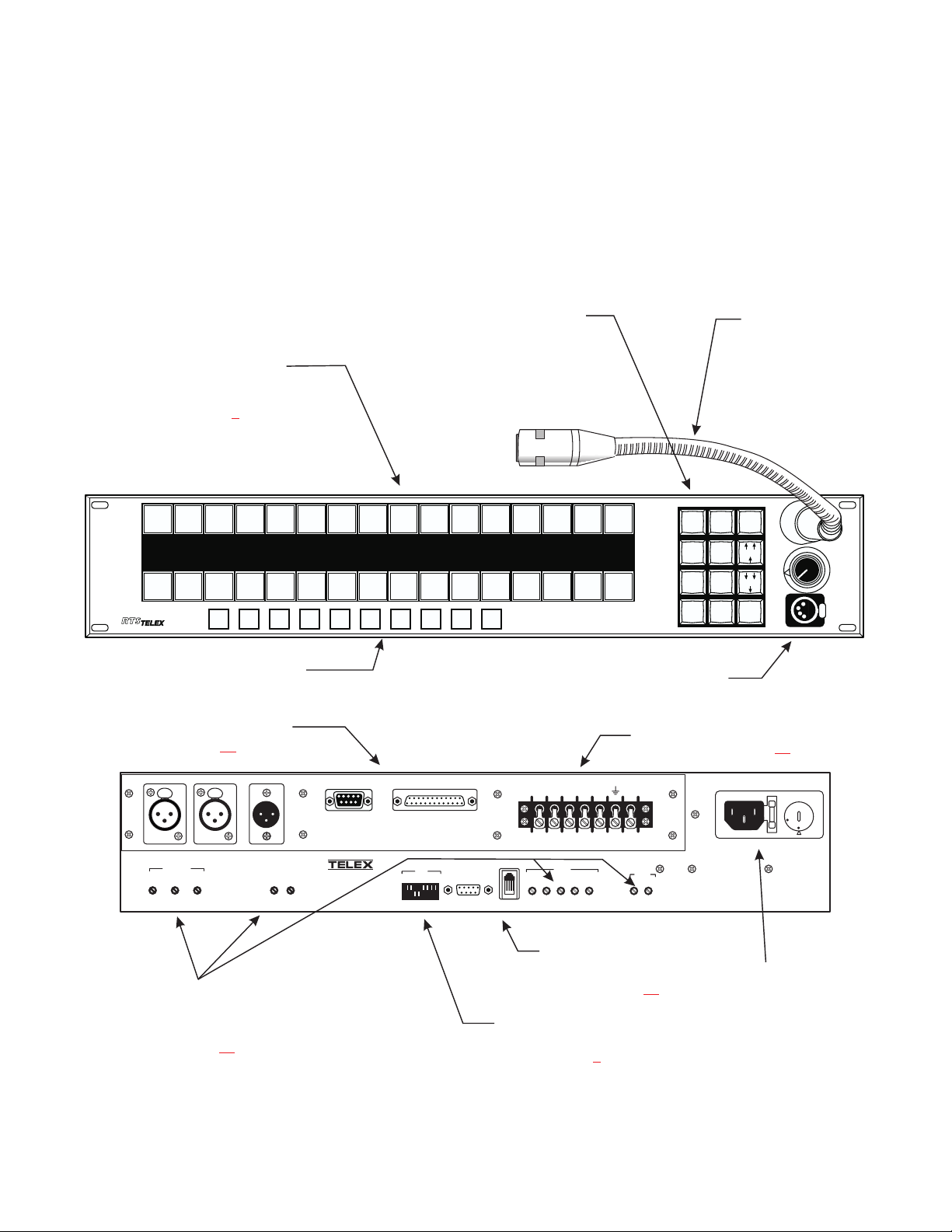

Figure 1. KP98-7 Reference View · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

Figure 2. EKP98-0 Reference View· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

Figure 3. LCP-100A Reference View· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

Figure 4. 9-pin Intercom cable wiring diagram · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 11

Figure 5. RJ-11 Intercom cable wiring diagram· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 11

Figure 6. Typical Interconnections between the KP98-7, EKP98-0, and LCP-100A · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 12

Figure 7. Terminal block wiring diagram for KP-96-RC option · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 12

Figure 8. Locations of internal jumpers and trimmers· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 15

LIST OF TABLES

Table 1. DIP Switch Summary · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

Table 2. 9-pin FRAME Connector Pin-out · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 11

Table 3. RJ-11 FRAME Connector Pin-out · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 11

Table 4. EXT MIC IN Connector Pin-out · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 13

Table 5. EXT LINE IN Connector Pin-out · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 13

Table 6. Rear Panel Headset Connector Pin-out· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 13

Table 7. MIC PRE OUT Connector Pin-out · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 13

Table 8. Correspondence between address numbers and intercom port numbers for ADAM Intercom Systems· · · · · · · · · · · · · · · 20

6 Installation Instructions, KP98-7 Keypanel

Page 7

1 INTRODUCTION

1.1 NEW FEATURES FOR VERSION 8.2

This manual describes the installation of the KP98-7 Keypanel and its accessories, the EKP98-7 Expansion Panel

and the LCP-100A Level Control Panel. The manual is

based on version 8.2 of the keypanel firmware. For operating information, refer to the KP98-7 Operating Instructions Manual, version 8.2.

Programming keypad.See

operating instruction manual

Talk and listen keys, with 4character alpha-numeric displays.Talk and listen keys

are reversible. See “Talk Key

Row Selection”, page 9

LISTEN1LISTEN2LISTEN3LISTEN4LISTEN5LISTEN6LISTEN7LISTEN8LISTEN9LISTEN10LISTEN11LISTEN12LISTEN13LISTEN14LISTEN

PL01

PROD RACK

TALK

1

TM

KP98-7

TALK2TALK

IFB4

TALK

3

4

Page2Page

Page

1

TD

TALK5TALK6TALK

3

NEWS

AD

Page

Level

4

7

for details.Internal speaker is

behind keypad.

SAT1

TEL1 TEL2 FLOR

TALK10TALK

TALK

9

PL

IFB

Scroll

Scroll

Phone

TALK

8

Headset

Version 8.2 adds support for the LCP-100A Level Control

Panel. Version 8.2 also changes the positions of some of

the function buttons at the bottom of the front panel and

replaces the P-P function button with a Mic Enable function button. Note: usage of some of the DIP switches has

also changed.

Optional panel

microphone for

use with internal

speaker.

CALL

15

CLEAR

DIR

CHYR

IS01 IS02

TALK13TALK14TALK

TALK

11

12

Mic

Enable

AUD1

CALL

15

ANSWER

NUM

1

SLIST

PHONE

4

RELAY

COPY CW

7

EX COPY

CLR

PREFIX

TYPE

E-PNL

DISPLAY

MULT

FUNC

PL

AUTO

2

3

IFB

ISO

5

6

8

9

0

PGM

PUSH

VOLUME

HEADSET

Function buttons.See operating

instruction manual for details.

Optional KP96-RC Rear Connector Module.See “Optional

Connections”, page 11

MIC LEVEL

CARBON

HDSTPNL

HDST

DYN

PUSH

EXT LINE IN

MIC PRE OUT

COMPR.

PUSH

EXT MIC IN

Level trimmers provide adjustment for non-standard levels.See “Electrical

Adjustments”, page 14

.

LEVEL

TO

MATRIX

HEADSET

TELEX COMMUNICATIONS,INC.

MADE IN U.S.A.

KP98-7

®

EXPANSION

SW1

1 OPEN 8

CLOSED

P11

P10

MIN

I/C

Configuration switches.

See “DIP Switch Settings”, page 9.

Figure 1. KP98-7 Reference View

Headset connector.May be

used instead of speaker and

panel microphone.

Terminal strip. See “Optional

Connections”, page 11.

+

-

+

AMP

OUT

-

AMP

GROUP

IN

MUTE

HDST

CALL

EXT

MUTE

LEVEL

SPKR HDST

SPKR

SPKR

OUT

IN

LEVEL

SIDE

MIN

SPKR

TONE

EXT

MUTE

Choice of DE9S or RJ11

intercom connector.See

“Connection to Intercom

Matrix”, page 10

.

CAUTION

DISCONNECT POWER

BEFORE OPENING

Fused power

entry module with

110/220 voltage

selector switch.

220

SERIAL No.

110

Installation Instructions, KP98-7 Keypanel 7

Page 8

TALK2TALK

TALK

1

3

TALK

4

TALK5TALK6TALK

7

TALK

9

TALK10TALK

TALK

8

TALK

TALK13TALK14TALK TALK

12

11

15 16

™

EKP98-0

TELEX COMMUNICATIONS,INC.

MADE IN U.S.A.

®

CONTROL

EKP98-0

SERIAL No.

CAUTION

DISCONNECT POWER

BEFORE OPENING

110 /220VAC,50/60 Hz

220

110

Figure 2. EKP98-0 Reference View

®

LCP-100A

EXP. DATA IN

EXP. DATA OUT

TELEX COMMUNICATIONS, INC.

Minneapolis, MN.

®

Figure 3. LCP-100A Reference View

2 INSTALLATION

2.1 GENERAL

Installation consists of the following general steps:

1. Unpack and inspect the equipment.

2. Check that the factory default jumper positions and

level settings are appropriate for your application and

make any required changes. (The defaults are

virtually always acceptable.)

3. Set the back panel DIP switches.

4. Mount the keypanel and any accessories in an

equipment rack or bay.

8 Installation Instructions, KP98-7 Keypanel

5. Connect the keypanel and any accessories.

6. Power up the equipment and check operation.

7. Program the keypanel using the intercom system

configuration software (ADAMedit or ZEUSedit).

Some aspects of keypanel setup, such as key

assignment, may also be performed from the

keypanel using the programming keypad. Refer to the

“Advanced Operation” information in the KP98-7

Operating Instructions Manual.

8. Place the keypanel in service. If the keypanel keys

have been assigned prior to placing the keypanel in

service, the station operator should only need to refer

to the “Basic Operation” information in the KP98-7

Operating Instructions Manual.

Page 9

2.2 UNPACKING AND INSPECTION

Table 1. DIP Switch Summary

As soon as possible after receipt, inspect the container(s)

and contents for physical damage that may have occurred

in shipping. If damage has occurred, immediately (within

24 hours of receipt of equipment) contact the carrier involved and file a claim. Save all packing materials, and

request an immediate inspection by the carrier’s insurance

claims agent.

There should be one power cord for each KP98-7 and one

gooseneck microphone for each KP98-7 ordered with a

microphone. There should be one power cord and one interconnect cable for each EKP98-0 Expansion Panel and

LCP-100A Level Control Panel.

For information about returns to RTS, refer to the

☞

front of this manual.

2.3 CHECKING THE FACTORY JUMPER AND

LEVEL SETTINGS

There are several internal jumpers and level adjustments

which can be changed to modify the keypanel operation

and audio input/output levels. These have been set to meet

the requirements of most typical situations. However, if

you wish to review these settings prior to installation, refer to “Electrical Adjustments”, page 14.

2.4 DIP SWITCH SETTINGS

The DIP switches are located on the back of the KP98-7

keypanel. The switch settings are summarized in Table 1

and are described in the following paragraphs.

DIP

Switch

1 Talk key row

2 Expansion Panel

3 LCP select Open: No LCP connected

4

5 3 Close Close Open Open

6 5 Close Open Close Open

7 7 Close Close Close Open

8 Baud rate select Open: 9600 baud

Description Settings

select

In-use Indication

Logical keypanel

address select.

Open: Use bottom row

Closed: Use top row

Open: Flash

Closed: No flash

Closed: LCP connected

Address Sw 4 Sw 5 Sw 6 Sw 7

1 Close Open Open Open

2 Open Close Open Open

4 Open Open Close Open

6 Open Close Close Open

8 Open Open Open Close

Closed: 76.8 kbaud (DO NOT USE!)

keypanel operator is able to conclude that the flashing indication is not an incoming call.

EKP98-0 expansion panels connected to the KP98-7 are a

different matter, however, since they use illuminated buttons without alphanumeric displays and cannot display

names. In this case the keypanel operator can only distinguish between an in-use indication and an incoming call

indication by the speed of the button flash. If this creates

confusion, disable the flashing in-use indication by setting

DIP switch 2 to the “closed” position.

Important: Any time you change the DIP switch

☞

settings you must turn the power off-then-on to reset.

2.4.1 Talk Key Row Selection

You can select whether you want the talk keys to use the

top row (above the displays) or the bottom row. See DIP

switch 1 settings.

2.4.2 Expansion Panel In-use Indication for IFB

and ISO

The KP98-7 provides a flashing display indication when

an IFB or ISO is in-use by another keypanel. Generally,

the keypanel operator can distinguish this from an incoming call for two reasons: first, the flashing indication is

slower than an incoming call indication; second, an IFB

or ISO will generally have a distinctive name, and since

calls are not normally received from an IFB or ISO, the

2.4.3 LCP Selection

If a level control panel will be connected for use with the

KP98-7, set DIP switch 3 to the “Closed” position. Otherwise, leave this switch in the “Open” position.

2.4.4 Logical Keypanel Address Selection

DIP switches 4-7 set the logical keypanel address, which

uniquely identifies the keypanel in the intercom system.

Zeus Intercom Systems: The logical keypanel addresses

are the numbers 1 through 8 printed on the back panel of

the Zeus frame next to the keypanel connectors. (The

number s repeat for every group of 8 connectors.) As you

connect each keypanel to a connector, use the number

printed next to that connector to set the address. For example, if you connect a keypanel to a connector numbered

1, refer to Table 1

and set DIP switches 4 through 7 to se-

lect address 1.

Installation Instructions, KP98-7 Keypanel 9

Page 10

ADAM CS Intercom Systems: Use the appropriate planning worksheet in the ADAM CS Installation Manual.

(Refer to the List of Tables in the front of the manual. The

planning worksheets are listed at the bottom of the List of

Tables.)

ADAM CS with RJ-11 or DB-9 back panel: You

•

can determine the correct logical keypanel address

from the worksheet in either of two ways: 1) If you

know the port number that a keypanel will be

connected to, look up the port number in the

worksheet, then read across to the appropriate logical

keypanel number for that port number. 2) If you

know the connector number (on the back of the

ADAM CS frame) that the keypanel will be

connected to, look up that connector number in the

worksheet, then read across to the appropriate logical

keypanel number.

2.5 MOUNTING THE KEYPANEL AND

ACCESSORIES

Keypanels, expansion panels and level control panels may

be mounted in any industry standard 483 mm (19") wide

equipment rack or equipment bay. For all panels, allow an

additional 2 to 3 inches in back for cables and connectors.

No special tools other than those found in a typical tool

kit are required for mounting. The panels have no special

ventilation requirements.

For ease of use, when positioning the panels it may help

to locate each level control panel directly above or below

the keypanel or expansion panel that it will be used with.

Otherwise, you will have to label each LCP control knob

according to the key assignment alphas on the keypanel or

expansion panel.

2.6 STANDARD CONNECTIONS

Once you have determined the correct logical

keypanel number, refer to Table 1

switches 4 through 7 to set this as the address.

ADAM CS frame with 50-pin Telco back panel:

•

You can determine the correct logical keypanel

address from the worksheet in either of two ways: 1)

If you know the port number that a keypanel will be

connected to, look up the port number in the

worksheet, then read across to the appropriate logical

keypanel number for that port number. 2) If you

know the connector numbers and pin numbers that

the keypanel will be connected to, look up these

numbers in the worksheet, then read across to the

appropriate logical keypanel number.

Once you have determined the correct logical

keypanel number, refer to Table 1

switches 4 through 7 to set this as the address.

ADAM Intercom Systems: To set the address, first refer

to Table 8, page 20, and locate the intercom port number

to which the keypanel will be connected. Then, read

across to the “Address” column to find the logical keypanel address (it will always be a number between 1 and

8). Finally, refer to Table 1 and set the DIP switches to

this address number.

2.4.5 Baud Rate

and position DIP

and position DIP

2.6.1 Gooseneck Microphone

If you ordered the KP98-7 with a gooseneck microphone,

screw the microphone into the panel microphone jack on

the front panel.

2.6.2 Front Panel Headset

The front panel headset jack accepts a monaural,

dynamic-microphone headset. Headphone impedance

should be 8 to 400 ohms. Nominal microphone output

should be -60 dBm, 150 ohms.

Connector Type: D4F (Mates with A4M)

Pin 1: Microphone Pin 2: Microphone +

Pin 3: Headphone Pin 4: Headphone +

2.6.3 Connection To Intercom Matrix

Use either a 9-pin or RJ-11 intercom cable (but not both)

to connect to the intercom system. You can use a prefabricated cable, or construct a cable using the wiring diagram

in Figure 4

P11 connector on the back panel of the KP98-7. Plug the

other end into the appropriate port of the intercom system.

(This will be the port number that you designated previously when setting the address DIP switches.)

or 5. Plug one end of the cable into the P10 or

SW1-8 selects the baud rate for communication with the

intercom system’s configuration computer. For all

ADAM, ADAM CS, and Zeus intercom systems this

switch must be set to the open position (9600 baud). Do

not use the 76.8 kbaud setting.

10 Installation Instructions, KP98-7 Keypanel

Keypanels may be connected while the intercom

☞

system is running.

Page 11

DE-9P (MALE)

TO KEYPANEL

1

2

6

4

5

9

7

8

3

DATA

AUDIOTO MATRIX

AUDIO FROM MATRIX

CABLE TYPE:

BELDEN 8777

DE-9S (FEMALE)

TO INTERCOM SYSTEM*

+

-

+

-

-

+

IMPORTANT!

When connecting to an ADAM CS back panel, use

*

only low-profile cable connectors such as AMP

Part No.747516-3 (Telex Part No. 59926-678)

CONTACTS

RJ 11 MOD PLUG

AMP 55550423 or equivalent

1

2

6

4

5

9

7

8

3

(View from cable entrance)

3 TWISTED PAIR TELEPHONE CABLE

PAIR 1: AUDIOTO MATRIX

PAIR 2: AUDIO FROM MATRIX

PAIR 3: DATA

1

2

3

4

5

6

DATA -

AUDIO FROM MATRIX +

AUDIOTO MATRIX +

AUDIOTO MATRIX -

AUDIO FROM MATRIX -

DATA +

123456

Use AMP Crimp Tool

12316661

LATCH

1

2

3

4

5

6

Figure 4. 9-pin Intercom cable wiring diagram

Table 2. 9-pin FRAME Connector Pin-out

Pin Function

1 RS422 Data “+”

2 RS 422 Data “-”

3 Ground , Shield

4 Audio Output “+”

5 Audio Output “-”

6 Ground, Shield

7 Audio Input “-”

8 Audio Input “+”

9 Ground

Note that 9-pin intercom cables for use with an

☞

ADAM CS frame must use special connectors at the

intercom matrix end as shown in Figure 4.

2.7 OPTIONAL CONNECTIONS

The following connections require an optional

☞

KP96-RC Rear Connector Panel on the back of the

KP98-7 Keypanel.

2.7.1 EKP98-0 and LCP-100A

Figure 6

shows optional connections when using an

Expansion Panel and/or Level Control Panel with the

KP98-7. Use the cables supplied with the panels. A maxi-

Figure 5. RJ-11 Intercom cable wiring diagram

Table 3. RJ-11 FRAME Connector Pin-out

Pin Function

1 RS422 Data “-”

2 Audio Input “+”

3 Audio Output “+”

4 Audio Output “-”

5 Audio Input “-”

6 RS422 Data “+”

mum of one EKP98-0 and one LCP-100A may be connected. The LCP-100A can only be used to adjust levels

for the KP98-7. To adjust listen levels for keys on the

EKP98-0, use the Crosspoint Gain feature of ADAMedit

or Zeus-edit.

To use the Crosspoint Gain feature with a key on the

☞

EKP98-0, you will first have to assign one of the

special functions to the key. To do this, run

ADAMedit or Zeus-edit. Press the KP button on the

toolbar at the bottom of the screen to open the

“Keypanels / Ports” edit screen. Right-click on the

box next to the listen key that you want to assign. A

dialog window titled “Key Assignment Select” will

open. Select “Special Function” and click ok. Select

“AL”, “AM”, or “AR”. “AL” assigns auto-listen;

listen will automatically activate whenever the talk

Installation Instructions, KP98-7 Keypanel 11

Page 12

KP98-7 Keypanel with LCP-100A Level Control Panel Only

KP98-7

EXPANSION

EXP.DATA IN

EXP.DATA OUT

LCP-100A

KP98-7 Keypanel with EKP98-0 Expansion Panel Only

KP98-7

EXPANSION

EKP98-0

CONTROL

KP98-7 Keypanel with LCP-100A Level Control Panel and EKP98-0 Expansion Panel

(The LCP-100A adjusts levels only for the KP98-7 Keypanel.)

KP98-7

LCP-100A

EKP98-0

EXTERNAL

SPEAKER

EXPANSION

EXP.DATA IN

EXP.DATA OUT

CONTROL

Figure 6. Typical Interconnections between the KP98-7, EKP98-0, and LCP-100A

INTERNAL

SPEAKER

+

+

–

–

AMP

OUT

SPKR

IN

AMP

OUT

SPKR

IN

NOT

USED

EXT.

MUTE

TS1

TERMINAL

BLOCK

1234567

JUMPER

JUMPER

EXTERNAL DRIVER

DEVICE CIRCUIT

DRIVER

Figure 7. Terminal block wiring diagram for KP-96-RC option

12 Installation Instructions, KP98-7 Keypanel

Page 13

key is activated. “AM” assigns auto-mute; listen will

be on when the key is off and will automatically mute

when the key is turned on. “AR” assigns

auto-reciprocal; listen will remain on all the time.

Once you’ve selected one of these options, you can

then adjust the crosspoint gain. Click the Gain button

on the toolbar, select Crosspoint Gains and click OK,

then press the F1 key on the computer keyboard to

get help with this feature if desired.

2.7.4 EXT MIC IN Connector

An external microphone can be connected. The external

microphone may be used with or without a front panel

gooseneck microphone of the same type. (Internal keypanel jumpers J404-J406 must be set for the type of microphone (see "Internal Jumpers", page 14

).

Table 4. EXT MIC IN Connector Pin-out

2.7.2 Rear Panel Headset Connection

Table 6

lists the HEADSET connector pin functions. A

variety of headset types can be connected. Headset/speaker switching can also be accomplished from this

connector. When the front panel HDST switch is in the off

position, shorting pins 7 and 8 on the rear panel headset

connector will cause the headset to activate, and the front

panel speaker and microphone will turn off.

Table 6. Rear Panel Headset Connector Pin-out

Pin Function

1 Dynamic mic “+” input

2 Dynamic mic common (shield)

3 Carbon mic “+” input

4 Carbon mic common

5 Headphone “+”

6 Dynamic mic “-” input

7 HDST switch control

8 HDST switch common

9 Headphone common

2.7.3 Terminal Block Connections

(Reference Figure 7

)

Pin Function

1 Shield

2 Mic in “+”

3 Mic in “-”

2.7.5 EXT LINE IN Connector

An external balanced audio source, such as program

sound, can be connected. The input is calibrated for a

nominal line level of +8dBu. This level can be changed if

required. See "Line Input to Speaker Level Adjustment",

page 18

, for further information.

Table 5. EXT LINE IN Connector Pin-out

Pin Function

1 Shield

2 Line in “+”

3 Line in “-”

2.7.6 MIC PRE OUT Connector

This connector provides a balanced mic output signal of

+8 dBu at 60 ohms. As supplied, the MIC PRE OUT signal is activated only when any Talk key is on. If you want

this output to be on continuously, you must reset internal

jumper J403 (see "Internal Jumpers", page 14

).

AMP OUT + and - : These terminals provide the keypanel audio amplifier output signal to drive an 8-ohm, 3watt speaker. As supplied from the factory, jumpers connect these terminals to the SPKR IN + and - terminals.

Remove these jumpers only if the keypanel audio output

is to be redirected to an external speaker.

SPKR IN + and - : These terminals connect to the internal speaker.

EXT MUTE: This terminal may be used to drive an external device at no greater than 2 mA sinking current. Its

normal logic state is low (0 Vdc). It shifts to logic high

(+5Vdc) when any Talk key is pressed. This signal may

be used, for example, to mute a monitor speaker when the

keypanel operator is talking on the intercom system.

Table 7. MIC PRE OUT Connector Pin-out

Pin Function

1 Shield

2 Mic out “+”

3 Mic out “-”

Installation Instructions, KP98-7 Keypanel 13

Page 14

2.8 POWER-UP AND OPERATIONAL CHECK

3 ELECTRICAL ADJUSTMENTS

Plug in the ac power cords on the keypanel and any connected expansion panels. When power is applied, all alphanumeric displays will first display asterisks (****)

then dashes (----). After a few moments, the Talk key assignments will display. If no Talk key assignments have

yet been programmed, the displays will continue to show

dashes (----).

If the keypanel cannot establish data communications

with the intercom system, the alphanumeric displays will

continue to show asterisks (****). Check the data line

connections.

Several symptoms may occur if the logical keypanel

number is incorrectly set: 1) the keypanel may not display

the expected key assignments; 2) there may be no indication when there is an incoming call; 3) when a key is

pressed to talk, the destination may not hear the audio, or

may hear audio from a different intercom station; 4) the

displays may behave erratically. If any of these symptoms

occur, recheck the logical keypanel number DIP switches.

Important! Always reset the keypanel after changing

☞

the DIP switch settings. Do this by briefly removing

power to the keypanel.

2.9 KEYPANEL PROGRAMMING

If you previously configured the keypanel using the intercom system configuration software, it should be ready for

operation. Refer the station operator to the “Basic Operation” instructions in the KP98-7 Operating Instructions

Manual.

3.1 INTERNAL JUMPERS

There are several internal jumpers which modify keypanel

operation. The jumpers are set for the following default

operations:

J201: The EXT LINE IN signal (KP-96-RC option only)

is muted when any Talk key is pressed. May be optionally

set for no mute.

J202: The speaker (or headphones) are muted by 15 dB

when any Talk key is pressed. May be optionally set to

full mute.

J203: Continuous sidetone. When using a headset, the

keypanel operators own voice will be heard at all times in

the headphones. May be optionally set for sidetone only

during talk.

J401: The microphone activates when any Talk key is

pressed. May be optionally set for continuous microphone.

J402: Normal/test switch set for normal operation.

J403: The MIC PRE OUT signal (KP-96-RC option only)

is activated only when any Talk key is pressed. May be

optionally set for continuous operation.

J404-J406: The keypanel is configured for operation with

the standard dynamic, -70dB, 150-ohm gooseneck microphone. May be optionally configured for other microphone types.

If the keypanel has not yet been configured you can do so

now. Run the ADAMedit or Zeus-edit configuration software. By default, the configuration software starts up in

the “Keypanels / Ports” setup screen. For assistance with

keypanel setup, press the F1 key on the computer while

viewing that screen. Once you have configured the keypanel as instructed and sent the changes to the intercom

system, the keypanel should be ready for operation. Refer

the station operator to the “Basic Operation” instructions

in the KP98-7 Operating Instructions Manual.

This completes the standard installation procedures.

14 Installation Instructions, KP98-7 Keypanel

To reset any of the jumpers, remove the top cover from

the keypanel. Locations of the jumpers are shown in Fig-

. The following paragraphs describe the alternative

ure 8

settings for the jumpers.

3.1.1 J201 (EXTERNAL INPUT MUTING)

This jumper is only significant in keypanels that have the

KP-96-RC Rear Connector Plate option installed. When

pins 2 and 3 are shorted, a signal input at the EXT LINE

IN connector is muted when any Talk key is pressed.

When pins 1 and 2 are shorted, the signal is not muted

during Talk key activation.

3.1.2 J202 (SPEAKER/HDST MUTE)

When pins 1 and 2 are shorted, the speaker/headset signal

is fully muted when any Talk keys are pressed. When pins

Page 15

P1

RV208

RV207

U203

J203

U309

Y301

U305

U302

RV204

J202

P2

J201

P6

U314

RV201

RV206

RV209

RV203

RV205

RV202

P11

P10

SW1

18

Q402

J402

RV408

J401

J406

J403

RV406

RV405

P5

RV404

RV403

J405

RV407

RV401

J404

P4

RV409

TP 407

Figure 8. Locations of internal jumpers and trimmers

Installation Instructions, KP98-7 Keypanel 15

RV402

Page 16

2 and 3 are shorted, the signal is muted by 15 dB when

any Talk keys are pressed.

3.1.3 J203 (SIDETONE MUTING)

When pins 1 and 2 are shorted, the sidetone signal is always on. When pins 2 and 3 are shorted, the sidetone signal is on only when a Talk key is pressed.

3.2 AUDIO LEVEL ADJUSTMENTS

3.2.1 GENERAL

The following paragraphs describe the procedures to calibrate the output level to the factory standard of +8 dBu. If

a different level is required, substitute that level for +8

dBu.

3.1.4 J401 (OUTPUT ENABLE)

When the jumper is installed, the microphone is on only

when any Talk key is pressed. When the jumper is removed, the microphone will always be on.

3.1.5 J402 (BALANCE TEST)

For normal operation, there should be no jumper installed.

This jumper is used when adjusting the keypanel audio

levels. See “Balance Adjustment”, page 17

3.1.6 J403 (PREAMP OUT)

This jumper is only significant in keypanels that have the

KP-96-RC Rear Connector Plate option installed. When

pins 1 and 2 are shorted, the mic signal at the MIC PRE

OUT connector is switched on and off by the Talk keys.

When pins 2 and 3 are shorted, the mic signal at the MIC

PRE OUT connector is always on.

3.1.7 J404-J406 (PANEL MIC SELECTION)

These jumpers work together to configure the panel microphone preamp for various types of microphones as follows:

2-Wire Electret:

J404 Pins 1 and 2 shorted

J405 No jumper

J406 No jumper

.

Most audio level trimmers are accessible through access

holes on the back of the keypanel. Each trimmer access

hole is labeled with its function. Some trimmers are internal, and can only be accessed with the top cover removed.

Locations of trimmers are shown in Figure .8

Audio levels may be adjusted with the panel disconnected

from the intercom system. However, proper operation

should be confirmed when the panel is reconnected. If

levels change after reconnection, check the intercom system wiring for one-sided shorts to ground, wiring errors,

or unintended terminations.

The following procedures make use of the additional connectors available on the KP-96-RC Rear Connector Plate

option. Connector pin-outs for these connectors were presented earlier in this section. If the keypanel under adjustment does not have these connectors, refer to drawing

number IKP-950/2-5 (in the Keypanel Drawings and Parts

Manual). The IKP-950/2-5 drawing shows equivalent locations where test equipment may be connected.

Required test equipment:

Audio Signal Generator with balanced output

Audio Signal Analyzer with balanced input

DC Millivoltmeter

Oscilloscope - any commercially available type

3-Wire Electret:

J404 No jumper

J405 No jumper

J406 No jumper

Balanced Dynamic (-70 dB, 150 ohms):

J404 Pins 2 and 3 shorted

J405 Pins 1 and 2 shorted

J406 Pins 1 and 2 shorted

16 Installation Instructions, KP98-7 Keypanel

3.2.2 MICROPHONE PREAMPLIFIER

1. Set the HDST switch to off.

2. Remove the gooseneck microphone, and insert a -70

dBm signal (1KHz at 150 ohms) into the microphone

connector. Or use the EXT MIC IN connector with

the front panel microphone removed (ref Table 4

page 13

3. Activate the microphone by setting a Talk key to the

latched-up position.

for pin-out).

,

Page 17

4. Check the level at the MIC PRE OUT connector (ref

Table 7 for pin-out). It should measure +8 dBu.

2-3; J405 short pins 1-2; J406 short pins 1-2. (This is

the default microphone configuration.)

5. If the reading is not +8 dBu, but within a 3dB range,

adjust the LEVEL TO MATRIX trimmer (RV406)

for +8dBu.

6. If the reading is more than 3 dB from +8 dBu, or

another output level is used by your facility, proceed

to paragraph to begin the mic preamp calibration

procedures.

7. Check the frequency response from 200 Hz to 15

KHz. It should be within 1 dB.

8. Check the input noise. It should be at least -70 dB

below +8 dBu.

9. Check the Total Harmonic Distortion (THD) from

200 Hz to 15KHz at +18 dBu output. It should be less

than or equal to 0.15 percent.

Balance Adjustment

1. Turn the COMPR trimmer (RV405) fully

counterclockwise. This sets the compressor circuit to

minimum (compressor ratio of 1:1).

2. Measure and record the dc voltage at test point

TP407.

3. Install a shorting plug across J402.

4. Measure the dc voltage at TP407, and adjust RV408

(internal) to match (within 5 mV) the previously

recorded voltage.

5. Remove the shorting plug at J402.

Tone Generator Level Adjustment

1. Activate the 400 Hz tone generator in the keypanel

(enter 0-8-7 on the keypad).

2. Adjust the LEVEL TO MATRIX trimmer (RV406)

for a +8dBu tone output level at the MIC PRE OUT

connector.

3. Turn off the tone generator (press CLR on the

keypad).

2. Insert a -70dBm signal (1 KHz at 150 ohms) into the

gooseneck microphone connector. Or use the EXT

MIC IN connector (with the front panel microphone

removed).

3. Adjust the PNL trimmer (RV401) for +8dBu at the

MIC PRE OUT connector.

4. Insert a common mode signal (120 Hz, -70 dBm) into

the gooseneck microphone connector, or into the

EXT MIC IN connector.

5. Adjust RV402 (internal) for a minimum common

mode signal at the MIC PRE OUT connector.

6. Re-insert a -70dBm signal.

7. Remove the shorting plug across J401 (causes

continuous mic activation).

8. Monitor the level at the audio output pins of the

FRAME connector, P10 (reference Table - for

pin-out). The output level should be +8dBu.

9. Remove the signal from the mic input, and reinstall

the shorting plug across J401.

Headset Dynamic-Mic Level

1. Insert a -60dBm signal (1 KHz at 150 ohms) into the

dynamic mic input of the HEADSET connector

(reference Table 6

2. Activate the HDST key on the front of the keypanel.

3. Monitor the signal level at the MIC PRE OUT

connector. It should be +8 dBu. If not, adjust the

DYN HDST trimmer (RV403) to achieve an output

reading of +8 dBu.

4. Insert a common mode signal into the dynamic mic

input of the HEADSET connector.

5. Adjust RV404 (internal) for a minimum common

mode signal at the MIC PRE OUT connector.

6. Remove the signal at the dynamic mic input.

, page 13 for pin-out).

Panel Mic Level Adjustment

1. Configure the J404-J406 jumper blocks for a

balanced dynamic panel microphone: J404 short pins

Installation Instructions, KP98-7 Keypanel 17

Page 18

Headset Carbon-Mic Level

1. Insert a -25dBm signal (1 KHz at 50 ohms) into the

carbon mic input of the HEADSET connector

(reference Table 6 for pin-out).

A +12 vdc bias voltage is supplied at pin 3 (carbon

☞

mic + input) of the HEADSET connector. The signal

generator should be isolated from this dc bias

voltage.

2. Activate the HDST key on the front of the keypanel.

3. Monitor the signal level at the MIC PRE OUT

connector. It should be +8 dBu. If not, adjust the

CARBON HDST trimmer (RV407) to achieve an

output reading of +8 dBu.

4. Remove the signal from the carbon mic input.

Compressor/AGC Setup

1. Insert a -60 dBm signal (1 KHz at 150 ohms) into the

front panel microphone connector. Or use the EXT

MIC IN connector (with the front panel microphone

removed).

3. Remove the keypanel audio connection from the

intercom matrix.

4. Insert a +8dBu (1 KHz) signal into the audio input +

and - pins of the FRAME connector, P10 (Table 2

page 11).

5. Turn the front panel HDST switch off.

6. Turn the front panel intercom audio level control

(outer knob) fully clockwise (maximum volume).

7. Adjust the SPKR trimmer (RV207) to measure

4.9VRMS (3 watts) at the audio analyzer. There

should be no clipping of the output signal.

8. Turn the front panel intercom audio level control

fully counterclockwise (minimum volume). Adjust

the MIN I/C trimmer (RV202) to measure -30 dB

below the 4.9VAC reference level.

9. Readjust the front panel intercom audio level control

to again measure 4.9VAC at the audio analyzer.

10. Insert a 1 KHz common mode signal into the audio

input + and - pins of the FRAME connector.

,

2. Adjust the COMPR trimmer (RV405) to measure

+13dBu at the audio output of the FRAME

connector, P10.

3. Reduce the input signal level to -80 dBm.

4. Adjust RV409 (internal) for a +4 dBu audio output

level at the FRAME connector.

5. Perform this procedure several times to optimize the

compression ratio accuracy. This will test

compression at a 2:1 ratio (0.5dBu). Confirm correct

operation of the compression circuit by increasing

and reducing input levels and measuring output ratio

accordingly.

3.2.3 SPEAKER/HEADSET AMPLIFIER

ADJUSTMENTS

Matrix-to-Speaker Gain

1. Disconnect the loudspeaker (either internal or

external) from the + AMP OUT and - AMP OUT

terminals on the back of the keypanel.

2. Terminate the + AMP OUT and - AMP OUT

terminals with an 8-ohm, 10-watt resistive load.

Connect an audio analyzer across the load.

11. Adjust RV201 (internal) for a minimum common

mode signal.

12. Remove the signal from the FRAME connector.

Line Input-to-Speaker Gain Adjustment

1. Install a shorting plug across J201, pins 2 and 3.

2. Insert a +8dBu (1 KHz) signal into the EXT LINE IN

connector (reference Table 5

3. The HDST switch should be off.

4. Turn the line input level control (inner knob on the

front panel) fully counterclockwise.

5. Adjust the MIN EXT trimmer (RV205) to measure

-30 dB below a reference level of 4.9VAC level at

the audio analyzer connected to the amplifier output.

6. Readjust the line input level control to measure

4.9VAC output at the audio analyzer.

7. Insert a 1KHz common mode signal into the EXT

LINE IN connector.

, page 13, for pin-out).

18 Installation Instructions, KP98-7 Keypanel

Page 19

8. Adjust RV204 (internal) for a minimum common

mode signal.

9. Insert a +8dBu (1 KHz) signal into the EXT LINE IN

connector and record the output reading.

10. Remove the signal from the EXT LINE IN connector,

and insert it into the audio input + and - pins of the

FRAME connector, P10.

11. Remove the shorting plug from jumper block J201.

The output reading should be the same as in step 9.

Speaker Muting Setup

Sidetone Level Adjust

1. Install a shorting plug across pins 1-2 of J203.

2. Insert a -70dBm signal (1KHz at 150 ohms) into the

dynamic mic input of the HEADSET connector .

3. Turn on the HDST switch, and monitor the signal

level across the 8-ohm load at the headphone output

of the HEADSET connector.

4. Adjust the SIDETONE trimmer (RV209) to 35 dB

below a 2V AC reference level. (The level may be

varied according to user preference.)

1. Short pins 2 and 3 of jumper block J202.

2. Insert a +8dBu signal (1 KHz) into the audio input

pins of the FRAME connector, P10.

3. Alternately activate and deactivate a front panel Talk

key while adjusting the SPKR MUTE trimmer

(RV203) to provide 15dB muting at the + AMP OUT

and - AMP OUT terminals during Talk switch

activation.

4. Short pins 1 and 2 of J202. Insert a +8dBu signal (1

KHz) into the audio input of the FRAME connector.

5. Activate a front panel Talk key, and check that the

amplifier output is fully muted. Restore the J202

shorting plug to pins 2-3.

6. Remove the 8-ohm load from the amplifier output,

and reconnect the speaker.

Headphone Level Adjust

1. Terminate the headphone output of the HEADSET

connector (pins 5 and 9) with an 8-ohm, 10-watt

resistive load. Connect an audio analyzer across the

load.

5. Remove the test equipment.

2. Set the front panel HDST switch to on.

3. Insert a +8dBu signal (1 KHz) into the audio input of

the FRAME connector.

4. Adjust the HDST trimmer (RV208) for 2VRMS (500

milliwatts) at the headphone output.

5. Set the front panel HDST switch to off.

6. Adjust the HDST MUTE trimmer (RV206) for 6dB

muting below the 2V AC reference level.

Installation Instructions, KP98-7 Keypanel 19

Page 20

Table 8. Correspondence between address numbers and intercom port numbers for ADAM Intercom Systems

Address Intercom Port Numbers (8 Ports per Audio I/O Card)

1 1 9 17 25 33 41 49 57 65 73 81 89 97 105 113 121 129 137 145 153 161 169 177 185 193

2 2 10 18 26 34 42 50 58 66 74 82 90 98 106 114 122 130 138 146 154 162 170 178 186 194

3 3 11 19 27 35 43 51 59 67 75 83 91 99 107 115 123 131 139 147 155 163 171 179 187 195

4 4 12 20 28 36 44 52 60 68 76 84 92 100 108 116 124 132 140 148 156 164 172 180 188 196

5 5 13 21 29 37 45 53 61 69 77 85 93 101 109 117 125 133 141 149 157 165 173 181 189 197

6 6 14 22 30 38 46 54 62 70 78 86 94 102 110 118 126 134 142 150 158 166 174 182 190 198

7 7 15 23 31 39 47 55 63 71 79 87 95 103 111 119 127 135 143 151 159 167 175 183 191 199

8 8 16 24 32 40 48 56 64 72 80 88 96 104 112 120 128 136 144 152 160 168 176 184 192 200

1 201 209 217 225 233 241 249 257 265 273 281 289 297 305 313 321 329 337 345 353 361 369 377 385 393

2 202 210 218 226 234 242 250 258 266 274 282 290 298 306 314 322 330 338 346 354 362 370 378 386 394

3 203 211 219 227 235 243 251 259 267 275 283 291 299 307 315 323 331 339 347 355 363 371 379 387 395

4 204 212 220 228 236 244 252 260 268 276 284 292 300 308 316 324 332 340 348 356 364 372 380 388 396

5 205 213 221 229 237 245 253 261 269 277 285 293 301 309 317 325 333 341 349 357 365 373 381 389 397

6 206 214 222 230 238 246 254 262 270 278 286 294 302 310 318 326 334 342 350 358 366 374 382 390 398

7 207 215 223 231 239 247 255 263 271 279 287 295 303 311 319 327 335 343 351 359 367 375 383 391 399

8 208 216 224 232 240 248 256 264 272 280 288 296 304 312 320 328 336 344 352 360 368 376 384 392 400

1 401 409 417 425 433 441 449 457 465 473 481 489 497 505 513 521 529 537 545 553 561 569 577 585 593

2 402 410 418 426 434 442 450 458 466 474 482 490 498 506 514 522 530 538 546 554 562 570 578 586 594

3 403 411 419 427 435 443 451 459 467 475 483 491 499 507 515 523 531 539 547 555 563 571 579 587 595

4 404 412 420 428 436 444 452 460 468 476 484 492 500 508 516 524 532 540 548 556 564 572 580 588 596

5 405 413 421 429 437 445 453 461 469 477 485 493 501 509 517 525 533 541 549 557 565 573 581 589 597

6 406 414 422 430 438 446 454 462 470 478 486 494 502 510 518 526 534 542 550 558 566 574 582 590 598

7 407 415 423 431 439 447 455 463 471 479 487 495 503 511 519 527 535 543 551 559 567 575 583 591 599

8 408 416 424 432 440 448 456 464 472 480 488 496 504 512 520 528 536 544 552 560 568 576 584 592 600

1 601 609 617 625 633 641 649 657 665 673 681 689 697 705 713 721 729 737 745 753 761 769 777 785 793

2 602 610 618 626 634 642 650 658 666 674 682 690 698 706 714 722 730 738 746 754 762 770 778 786 794

3 603 611 619 627 635 643 651 659 667 675 683 691 699 707 715 723 731 739 747 755 763 771 779 787 795

4 604 612 620 628 636 644 652 660 668 676 684 692 700 708 716 724 732 740 748 756 764 772 780 788 796

5 605 613 621 629 637 645 653 661 669 677 685 693 701 709 717 725 733 741 749 757 765 773 781 789 797

6 606 614 622 630 638 646 654 662 670 678 686 694 702 710 718 726 734 742 750 758 766 774 782 790 798

7 607 615 623 631 639 647 655 663 671 679 687 695 703 711 719 727 735 743 751 759 767 775 783 791 799

8 608 616 624 632 640 648 656 664 672 680 688 696 704 712 720 728 736 744 752 760 768 776 784 792 800

1 801 809 817 825 833 841 849 857 865 873 881 889 897 905 913 921 929 937 945 953 961 969 977 985 993

2 802 810 818 826 834 842 850 858 866 874 882 890 898 906 914 922 930 938 946 954 962 970 978 986 994

3 803 811 819 827 835 843 851 859 867 875 883 891 899 907 915 923 931 939 947 955 963 971 979 987 995

4 804 812 820 828 836 844 852 860 868 876 884 892 900 908 916 924 932 940 948 956 964 972 980 988 996

5 805 813 821 829 837 845 853 861 869 877 885 893 901 909 917 925 933 941 949 957 965 973 981 989 997

6 806 814 822 830 838 846 854 862 870 878 886 894 902 910 918 926 934 942 950 958 966 974 982 990 998

7 807 815 823 831 839 847 855 863 871 879 887 895 903 911 919 927 935 943 951 959 967 975 983 991 999

8 808 816 824 832 840 848 856 864 872 880 888 896 904 912 920 928 936 944 952 960 968 976 984 992 1000

20 Installation Instructions, KP98-7 Keypanel

Page 21

NOTES

Installation Instructions, KP98-7 Keypanel 21

Page 22

™

Loading...

Loading...