Page 1

II

I

MODEL BP-325

Belt-pack Inter com S tation

User Manual

9350-5690-00 Rev. M 8/2008

Page 2

PROPRIETARY NOTICE

SHIPPING TO THE MANUFACTURER

The product information and design disclosed herein were originated by

and are the property of Telex Communications, Inc. Telex reserves all

patent, proprietary design, manufacturing, reproduction, use and sales

rights thereto, and to any article disclosed therein, except to the extent

rights are expressly granted to others.

COPYRIGHT NOTICE

Copyright 2007 by Telex Communications, Inc. All rights reserved.

Reproduction, in whole or in part, without prior written permission from

Telex is prohibited.

WARRANTY NOTICE

See the enclosed warranty card for further details.

CUSTOMER SUPPORT

Te chnical questions should be directed to:

Customer Service Department

RTS/Telex Communications, Inc.

12000 Portland Avenue South

Burnsville, MN 55337 USA

Telephone: 800-392-3497

Fax: 800-323-0498

Factory Service: 800-553-5992

RETURN SHIPPING INSTRUCTIONS

Customer Service Department

Telex Communications, Inc. (Lincoln, NE)

Telephone: 402-467-5321

Fax: 402-467-3279

Factory Service: 800-553-5992

Please include a note in the box which supplies the company name,

address, phone number, a person to contact regarding the repair , the type

and quantity of equipment, a description of the problem and the serial

number(s).

All shipments of product should be made via UPS Ground, prepaid (you

may request from Factory Service a different shipment method). Any

shipment upgrades will be paid by the customer. The equipment should

be shipped in the original packing carton. If the original carton is not

available, use any suitable container that is rigid and of adequate size. If

a substitute container is used, the equipment should be wrapped in paper

and surrounded with at least four (4) inches of excelsior or similar

shock-absorbing material. All shipments must be sent to the following

address and must include the Proof of Purchase for warranty repair.

Upon completion of any repair the equipment will be returned via

United Parcel Service or specified shipper, collect.

Factory Service Department

Telex Communications, Inc.

8601 East Cornhusker Hwy.

Lincoln, NE 68507 U.S.A.

Attn: Service

This package should include the following:

Qty Description Part No.

1 Final Assy, BP325, Gray 9010673800

Final Assy, BP325, Rev

2.0

Final Assy, BP325, Black 9010673821

1 User Manual 9350569000

1 W arranty Statement 38110387

1 EMC & LVD Statement 38109675

9010673820

Page 3

Contents

Chapter 1 - Connections And Operation

Connections .................................................................................................................................................1

Headset ........................................................................................................................................................1

Intercom Channels ......................................................................................................................................1

Operation ....................................................................................................................................................2

Programmable Options ...............................................................................................................................3

Factory Settings ..........................................................................................................................................3

Jumpers (W1-w7) ........................................................................................................................................4

Sidetone Adjustment ....................................................................................................................................5

Alternate Powering Methods ......................................................................................................................5

General ........................................................................................................................................................5

Method One: One Channel Operation With A Non-rts Power Supply .......................................................5

Line Input Connector Wiring For 1-channel Operation With Non-rts Power Supply ................................6

Bottom View Of The Main Circuit Board ...................................................................................................6

Line Loop Connector Wiring For 2-channel Operation With Non-rts Power Supply. ...............................6

Line Input Connector Wiring For 2-channel Operation With Non-rts Power Supply ................................6

Method Two: Two Channel Operation With A Non-rts Power Supply .......................................................7

Table

Of

Chapter 2 - Replacement Parts

Where To Obtain Parts ...............................................................................................................................9

Electrical Parts .........................................................................................................................................10

Chapter 3 - Specifications And Drawings

Specifications ............................................................................................................................................15

Drawings ...................................................................................................................................................16

Front Panel Board Assembly, Bp325 ........................................................................................................17

Main Board, Bp325 ...................................................................................................................................18

Rear Panel Assembly, Bp325 ....................................................................................................................19

Rear Panel Assembly, Bp325 ....................................................................................................................20

Final Assembly, Bp325 .............................................................................................................................21

Schematic Diagram, Front Panelcircuit Board ........................................................................................22

Schematic, Main Board Page 1 .................................................................................................................23

Schematic, Main Circuit Board Page 2 ....................................................................................................24

Bp-325 Cable Assemblies ..........................................................................................................................25

Page 4

Page 5

CHAPTER 1

CONNECTIONS AND OPERA TION

This section describes operation of the BP325 as supplied from the factory . Use of an RTS power supply to power the intercom

system is assumed. For options and use of an alternate power source (See “PROGRAMMABLE OPTIONS” on page 3. and

See “ALTERNATE POWERING METHODS” on page 5..

CONNECTIONS

Headset

Connect a headset using one of the three headset connectors on the back panel. The MONO HEADSET and STEREO

HEADSET connectors are for monaural or stereo dynamic-mic headsets. The CARB-MIC HEADSET connector is for a

monaural carbon-mic headset. Refer to the specifications for pin-outs of these connectors if needed.

Intercom Channels

Connect the BP325 to the intercom system using the LINE INPUT connector on the back panel.

If desired, connect an additional intercom station to the intercom system using the LINE LOOP connector on the back panel.

1

Page 6

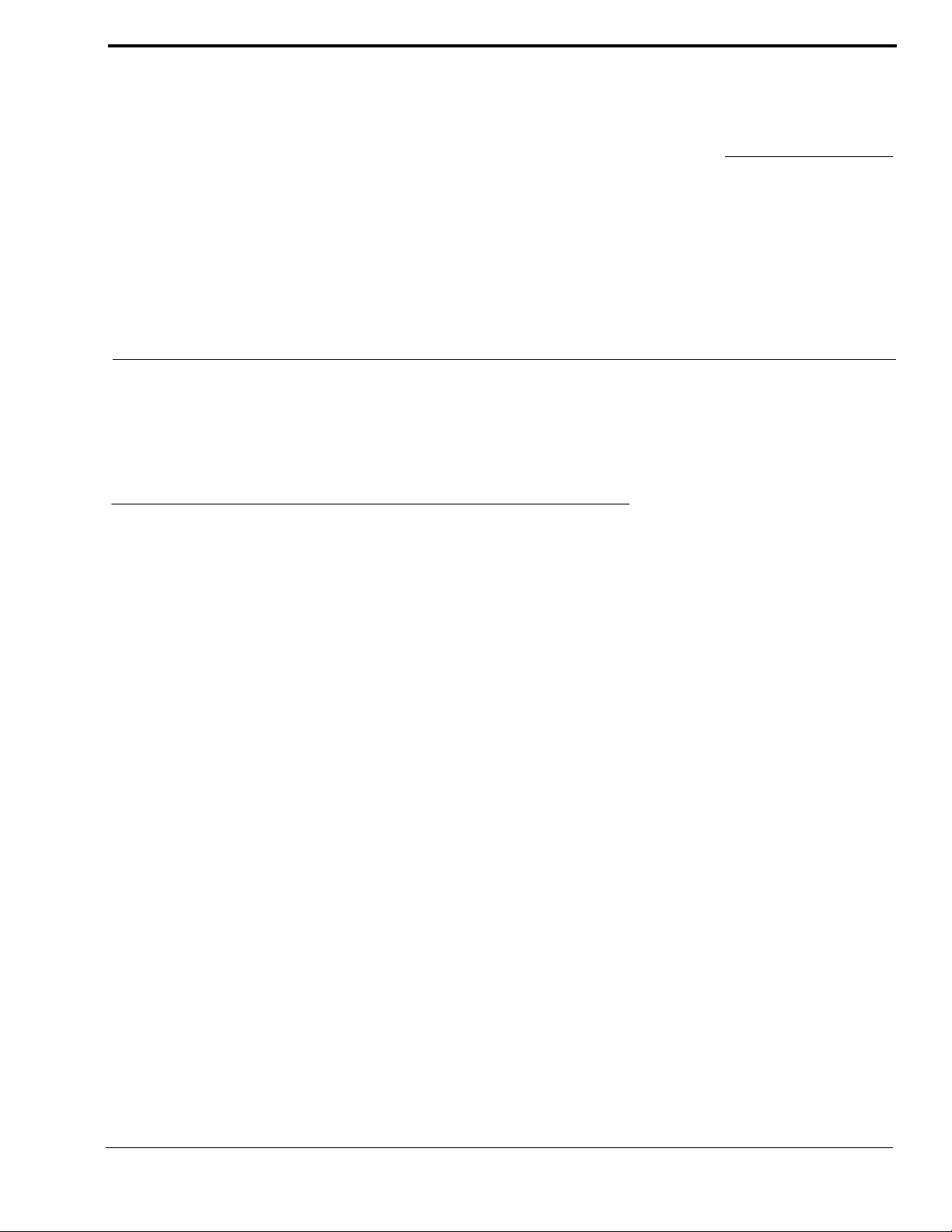

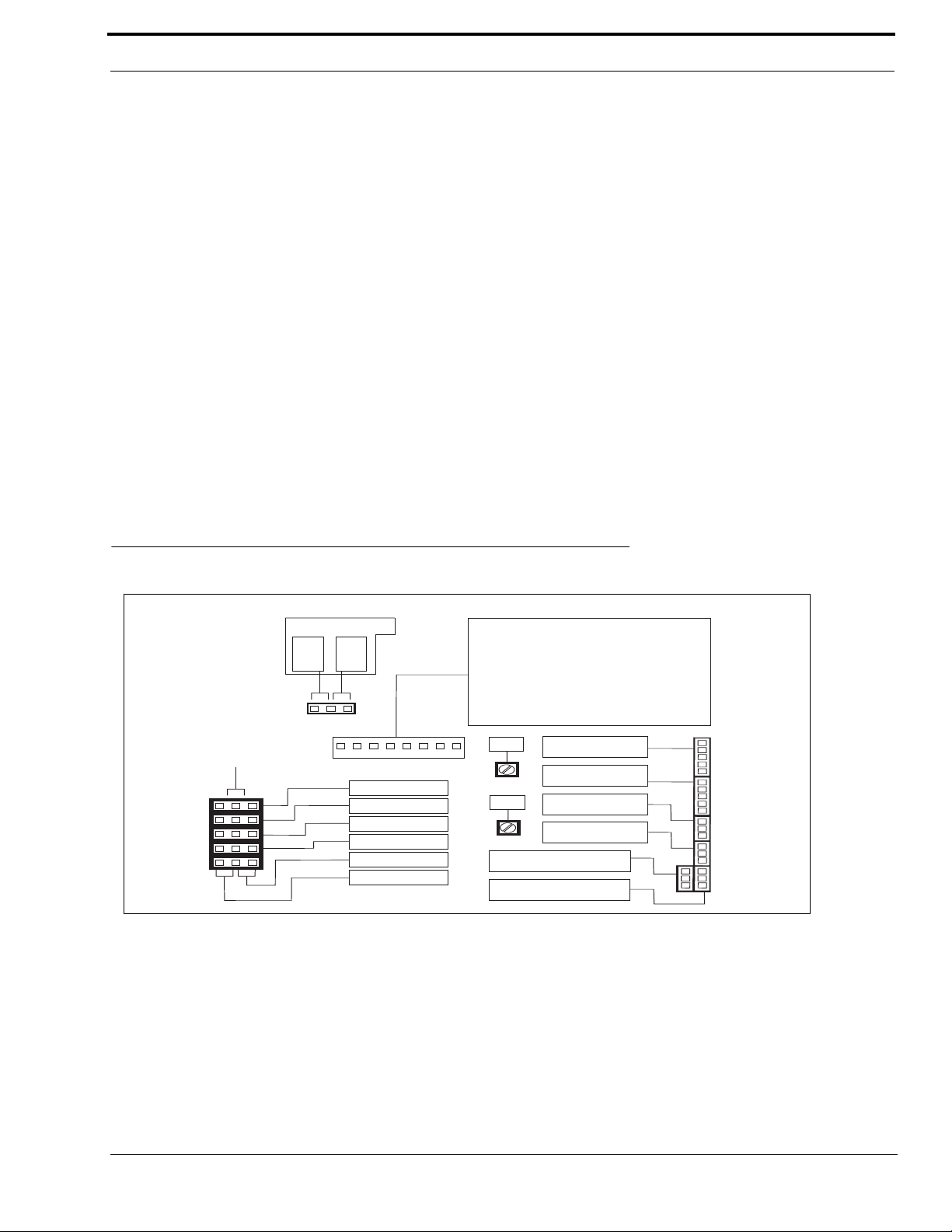

CONNECTIONS AND OPERATION

T

AL

K

T

AL

K

C A L L

RTS SYSTEMS

BP325 PORTABLE HEADSET STATION

MONO

HEADSET

LINE LOOP

AUX I/O

CARB-MIC

HEADSET

LINE

INPUT

PGM

VOL

STEREO

HEADSET

REMOVE

COVER

4 5

1 2

3

6 7 10b 8 9

10a

10a

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Channel 1 talk button, indicator light and listen

volume control.

Channel 2 talk button, indicator light and listen

volume control.

Call button and indicator light.

Carbon-mic headset jack. May also be used

for external mic switch. See "Programable Options".

Program volume control. Active only when using the

line loop connector for optional program input.

See "Programable Options".

Monaural dynamic-mic headset jack.

Intercom line loop connector for connection to

additional intercom stations. May also be used for

external program input, external mic switch, or a

non-standard power source. See "Programable Options"

and "Alternate Powering Methods".

Intercom line connector. For connection to intercom

system.

Stereo dynamic-mic headset jack.

Rear cover removal to set options:

Loosen two screws (10a) and remove

one screw (10b).

OPERATION

1. Attach the BP325 to your belt or other convenient location using the belt clip on the rear panel.

2. Put on the headset and adjust the listen volume controls while listening to the intercom channels.

3. A TALK button may be activated in either of two ways:

Momentary Mode: Press and hold the TALK button, then speak into the microphone. The green talk

LED will remain lit while the TALK button is held. Release the TALK button when finished talking.

The talk LED will turn off.

Latching Mode for Hands-free Conversation: Tap the TALK button (do not press and hold). The

green talk LED will turn on and remain on. When finished talking, tap the TALK button again. The

talk LED will turn off.

4. Calling an intercom channel:

a.Turn on the TALK button for the channel to be called (the green talk LED should be lit).

b.Press and hold the CALL button. The red call LED will light while the button is pressed, indicating

that a call signal is being sent. When a response is heard, release the CALL button and begin your

conversation.

c.Turn off the TALK button when finished with your conversation.

5. Receiving a call:

2

Page 7

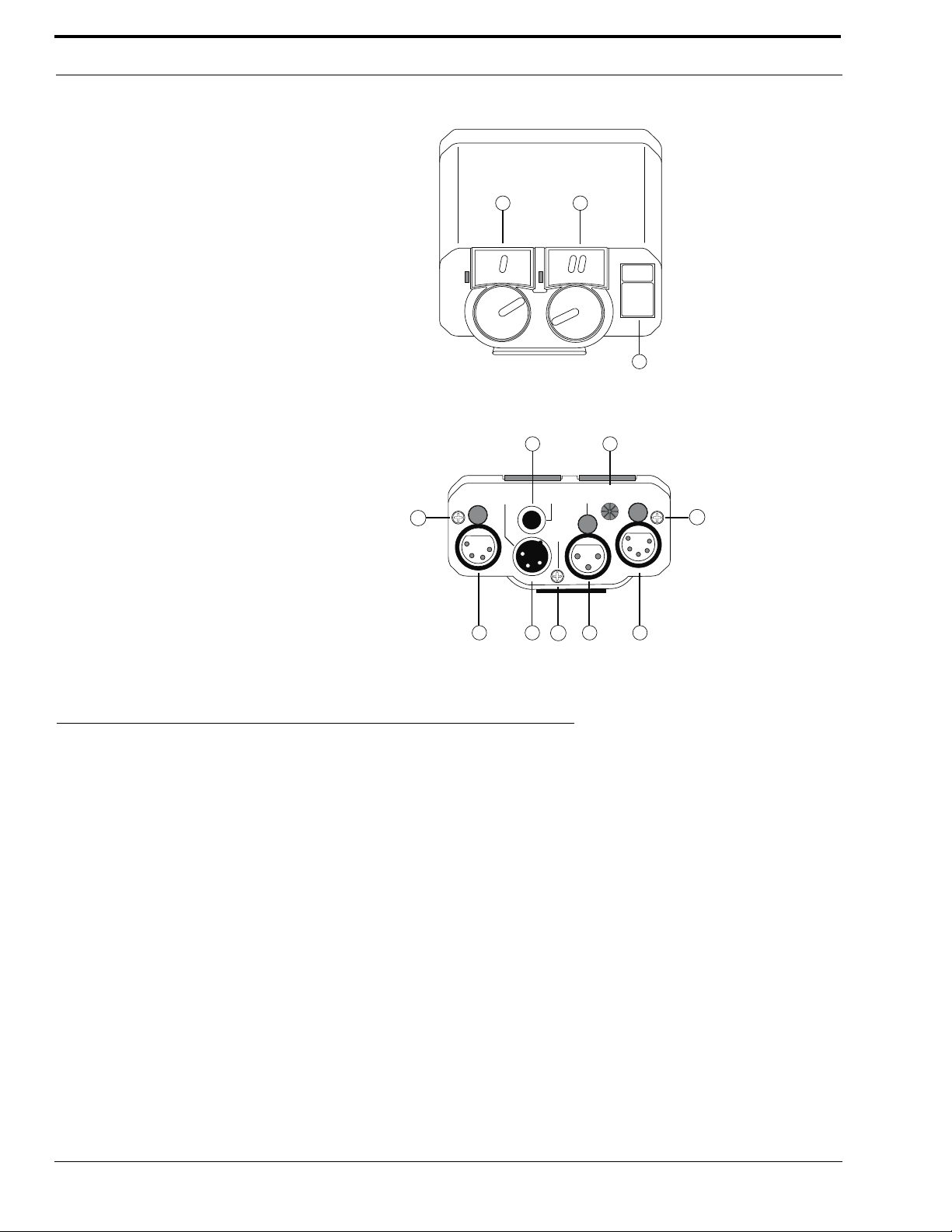

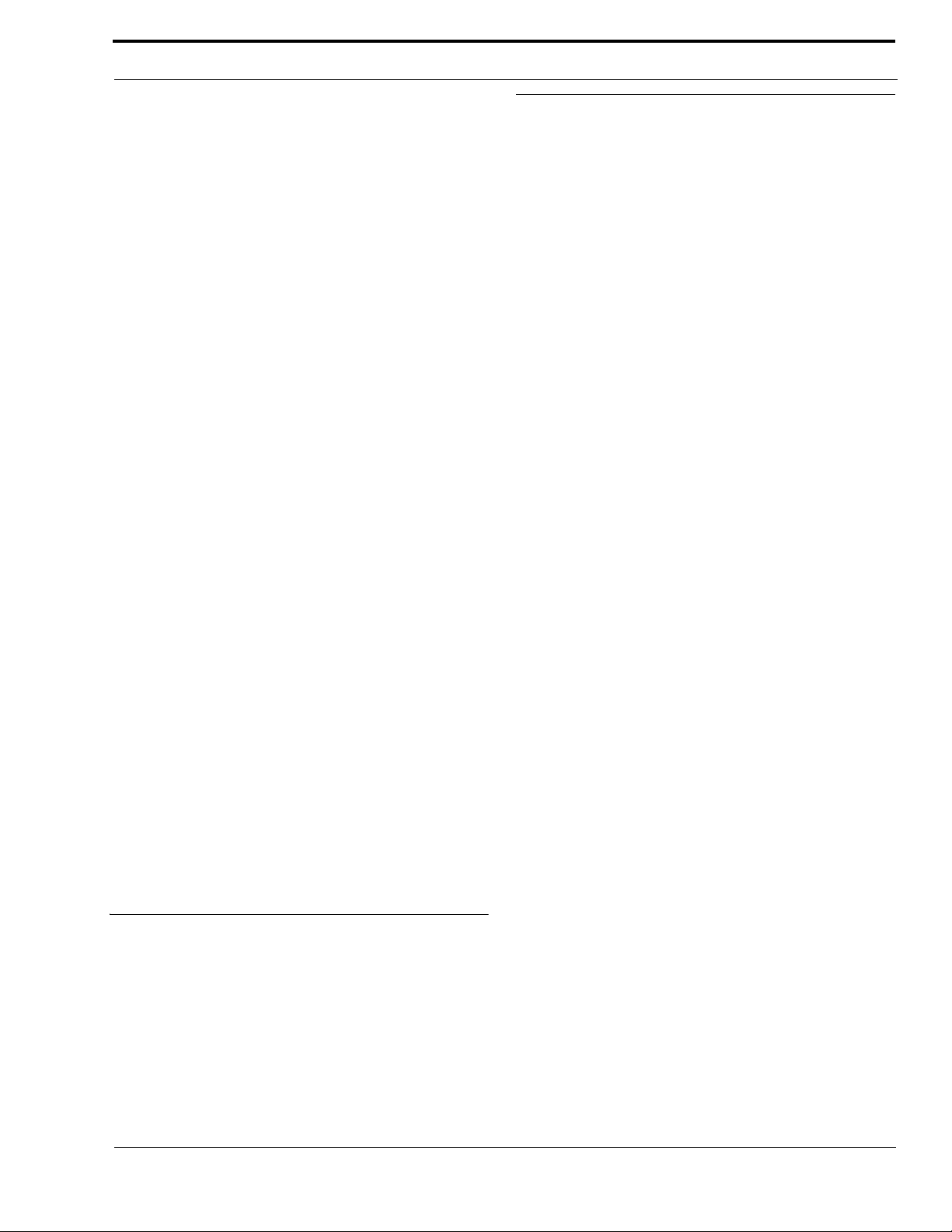

FACTORY SETTINGS

TRS JACK FUNCTION

EXT

MIC

SW

CARB

MIC

HOST

W7

SW 1 CALL SIGNAL DISABLE

SW 2 MOMENTARY ONLY CH 2

SW 3 TALK 2 DISABLE

SW 4 TALK 1 DISABLE

SW 5 MOMENTARY ONLY CH 1

SW 6 TALK OFF TRANSMIT ENABLE

SW 7 NOT USED

SW 8 TALK OFF RECEIVE ENABLE

12345678

ON

S1

W1

THRU

W4

ON

W4

W3

W2

W1

W5

W5

PGM RIGHT

PGM LEFT

CH 2 LISTEN

CH 1 LISTEN

MONO

STEREO

BAL2

R52

BAL1

R39

MONO 4-PIN

HEADSET

STEREO 5-PIN

HEADSET

INTERCOM

INPUT

INTERCOM

LOOP

PGM INPUT

REMOTE MIC SW/

LOCAL POWER

J2

J3

J7

J6

J4

J5

1

1

1

1

1

a.When there is an incoming call on a channel, the red call LED will flash.

b.If a talk LED is also flashing, this indicates that you need to activate that TALK button to begin

your conversation.

c.If no talk LED is flashing, this indicates that the TALK button is already on; simply begin your conversation.

6. Sending a Talk-off Signal: The BP325 can generate an inaudible signal which can be used to deactivate the talk buttons on

other intercom stations connected to an intercom channel. (May be used with models BP325, MCE325 and MRT327). This

feature is useful when an unattended intercom station has its microphone activated and is causing noise on an intercom

channel. To send a talk-off signal:

a.Turn off both TALK buttons on the BP325.

b.Tap the CALL button three quick taps. The red call LED will turn on for about 2 seconds.

c.While the red call LED is on, momentarily press the TALK button for the channel that has the

TALK button to be turned off. This will send the signal and turn off the remote TALK button.

PROGRAMMABLE OPTIONS

Several internal option switches and jumpers can modify the belt pack’s operation. The factory settings are summarized

below. To change any of the factory settings, remove the rear cover screws as shown in Figure 1. Jumper and switch locations

are shown on the label inside the rear cover.

FACTORY SETTINGS

TABLE 1. BP-325 Unit Jumper Settings - This equipment complies with the requirements in Part 15 of the FCC Rules for a

Class A computing device. Operation of this equipment in a residential area may cause unacceptable interference to radio

and TV reception requiring the operator to take whatever steps are necessary to correct the interference.

3

Page 8

CONNECTIONS AND OPERATION

Jumpers (W1-W7)

No.

Setting Description

W1

W2

W3

W4

W5

W6 Not Used

W7

DIP Switches (S1)

1 Call Signal Transmit Disable OFF

2

3

4

5

6

7Not Used OFF

8

CH 1 Intercom Audio Listen

CH 2 Intercom Audio Listen

Program input to left headphone

Program input to right

headphone

Stereo/Mono operation

CARB/MIC Jack Function

Momentary Only Talk Button,

CH2

CH2 Talk Disable

CH1 Talk Disable

Momentary Only Talk Button,

CH1

Talk-off Transmit enable

Talk-off Receive Enable

i

b

e

f

f

e

a

a

c

d

g

h

a. Listen is factory set to be ON all the time on both

channels. Setting W1 to the OFF position will disable intercom listen audio on channel 1 (usually

the left headphone of a stereo headset). Setting W2

to the OFF position will disable intercom listen

audio on channel 2 (usually the right headphone of

a stereo headset). Listen disable could be used, for

example, when you want to use the left side of a

stereo headphone exclusively for program audio

input and the right side for a single channel of

intercom audio. In this case you would:

1. Set W1 to OFF to disable channel 1 intercom

audio listen to the left headphone.

2. Set DIP switch 4 to ON to disable channel 1

talk.

3. Setup the left channel for program input.

b

Factory

Default

ON

ON

OFF

OFF

Stereo

Headset

OFF

OFF

OFF

OFF

ON

ON

b. To use program audio input:

1. Unplug the LINE LOOP connector from J6, and

plug it into J5.

2. If you are using a stereo headset, set W3 and/or

W4 to ON to route the program audio to the left

headphone, right headphone or both headphones.

If you are using a mono headset, set both W3 and

W4 to ON.

3. Connect the program source to the LINE LOOP

connector using an XLR-3-32 female receptacle

wired as follows

Pin 1 - Common

Pin 2 - Program input high

Pin 3 - Program input low

4. Adjust program input volume using the PGM

VOL control on the back panel.

c. W5 applies to a stereo dynamic-mic headset con-

nected to the STEREO HEADSET jack. With W5

set in the stereo position, intercom channel 1 will

be heard in the left headphone only, and channel 2

will be heard only in the right. In the mono position, both intercom channels (and program audio if

connected) will be heard in both headphones. If

you are using monaural headphones connected to

the MONO HEADSET jack, W5 may be left in the

stereo position.

d. The CARB-MIC connector may be used to con-

nect either a headset or an external mic ON/OFF

switch. (If you are using a carbon-mic headset, but

still wish to use an external mic switch, the LINE

LOOP connector may alternatively be used for the

mic switch. See note X, below.) To use the CARBMIC connector for an external mic ON/OFF

switch:

1. Place jumper W7 in the “EXT MIC SW” position.

2. Use a stereo phone plug to connect the external

switch to the CARB-MIC HEADSET jack:

Tip: Remote Mic Switch Normal-open

Contact

Ring: No connection

Sleeve: Remote Mic Switch Common

3. To use the external mic switch, first set one or

both T A LK buttons to the latched-on position.

Then, press the external mic switched turn th e

TALK button(s) ON. Release the mic switch to

turn the TALK button(s) OFF. Note, the TALK

buttons may still be turned ON or OFF from the

BP-325; however, the external mic switch will not

work unless the TALK buttons are first turned ON

at the BP-325

4

Page 9

CONNECTIONS AND OPERATION

e. As supplied, the TA LK buttons feature a dual-

action momentary/latching operation: press and

hold for momentary talk, then release when finished; or tap to latch ON for hands-free talk, and

tap again to turn OFF when finished talking. If

desired, the latching operation may be defeated,

and the TALK buttons may be operated in momentary mode only.

f. Setting DIP switch 3 to the ON position will dis-

able the channel 2 TALK button. Setting DIP

switch 4 to the ON position will disable the channel 1 TALK button.

g. As supplied, the BP-325 can generate an inaudible

talk-off signal which can be used to deactivate the

talk buttons on other intercom stations connected

to an intercom channel. To turn this feature OFF,

set DIP switch 6 to the OFF position.

h. As supplied, other intercom stations can deactivate

the TALK buttons on the BP-325 using the TalkOff feature from their intercom stations. T o disable

this feature, set DIP switch 8 in the OFF position.

i. Using the LINE LOOP connector for an external

mic ON/OFF switch:

1. Unplug the LINE LOOP connector from J6 on

the circuit board, and plug it into J4.

2. Connect the external mic switch to the LINE

LOOP connector using an SLR-3-32 female receptacle wired as follows:

Pin 1: Remote Mic Switch Common

Pin 2: No Connection

Pin 3: Remote Mic Switch

Normal-open Contact

3. To use the external mic switch, first set one or

both TALK buttons to the latched-ON position.

Then, press the external mic switch to turn ON the

T ALK button(s). Release the mic switch to turn o ff

the T A LK button(s). Note, the TALK buttons may

still be turned ON or OFF from the BP-325; however, the external mic s wi tc h will not work unle ss

the TALK buttons are first turned on at the BP-

325.

ALTERNAT E POW ERING METHODS

GENERAL

When using an RTS power supply to power the intercom

system, power is carried to the BP325 on pin 2 of the LINE

INPUT connector along with the channel 1 audio. Pin 1 is

the DC return. The unique design of RTS power supplies

permits power to be carried on an audio channel. RTS power

supplies also provide the proper terminating impedance for

each intercom channel. If a non-RTS power supply is used,

there are two alternatives for connecting power and intercom

audio.

The first method uses channel 1 only to connect the non-RTS

power supply. Audio on channel 1 will be unusable as the

power supply will look like a short circuit at audio

frequencies. Channel 2, however, will still be operational.

Also, channel 2 will require a terminating impedance, since

this is not supplied by the non-RTS power supply.

The second method allows the use of a non-RTS power

supply while still maintaining two audio channels. This

method requires an additional wire to the belt pack, and the

LINE LOOP connector will not be usable for connecting

another intercom station. Also, each intercom channel must

be properly terminated. The two methods are discussed

below.

METHOD ONE: ONE CHANNEL OPERATION WITH A NON-RTS POWER SUPPLY

Using an XLR-3-32 female connector, connect the external

power source and the channel terminating components to the

LINE INPUT connector as

shown in Figure 2.

SIDETONE ADJUSTMENT

You can change the level of your own voice heard in your

headphones while talking on an intercom channel. Adjust

R39 to change your voice level when talking on channel 1.

Adjust R52 to change your voice level when talking on

channel 2.

If desired, the LINE LOOP connector may be

used to connect power and audio to an additional

intercom station.

5

Page 10

CONNECTIONS AND OPERATION

200 Ohms

+

Pin 1, Common

10mF/50V

Pin3,Ch2+Audio

Pin 2, +18 TO +2 4 VDC

TO BP325

LINE INPUT

TO INTERCOM

CHANNELS AND

POWER SUPPLY

CUT

TRACE

Pin 1

Pin 2

Pin 3

+18to+24VDC

Common

No Connection

200 Ohms

+

Pin 1, Common

200 Ohms

+

10mF/50V

10mF/50V

Pin3,Ch2+Audio

Pin2,Ch1+Audio

TO BP325

LINE INPUT

TO INTERCOM

CHANNELS

OPTIONAL CONNECTOR

TO ADDITIONAL

INTERCOM STATION

LINE INPUT

FIGURE 1. LINE INPUT Connector Wiring for 1-Channel

Operation with Non-RTS Power Supply

FIGURE 2. Bottom View of the Main Circuit Board

FIGURE 3. LINE LOOP Connector Wiring for 2-Channel

Operation with Non-RTS Power Supply.

FIGURE 4. LINE INPUT Connector Wiring for 2-Channel Operation with Non-RTS Power Supply

6

Page 11

CONNECTIONS AND OPERATION

METHOD TWO: TWO CHANNEL OPERATION WITH A NON-RTS POWER SUPPLY

1. Referring to Figure 1, remove all three screws (10a and

10b) on the back connector panel of the BP325. Remove

the rear cover/belt clip assembly.

2. There are two connectors that connect the main circuit

board to the front panel circuit board. Pry the tabs on

these two connectors to disconnect them. Remove the

back connector panel and main circuit board from the belt

pack.

3. On the bottom side of the main circuit board, cut the trace

as shown in Figure 3.

4. Reassemble the main circuit board and rear connector

panel to the belt pack.

Note: If the rear connector panel becomes separated from

the main circuit board at any time, make sure that

the shaft of the program volume control knob inserts

into the program volume control potentiometer on

the main circuit board during reassembly.

5. Referring to the label on the inside of the rear cover,

unplug the LINE LOOP connector from J6 and plug it

into J4.

6. Reassemble the rear cover.

7. Using an XLR-3-32 female receptacle, connect the

external power source to the LINE LOOP connector as

shown in Figure 4. Connect +DC to pin 2 and connect

power supply common to pin 1.

Using an XLR-3-32 male plug, connect intercom channels

and termination components as shown in Figure 5. Plug this

connector into the LINE INPUT jack of the BP325.

7

Page 12

CONNECTIONS AND OPERATION

8

Page 13

WHERE TO OBTAIN PARTS

Parts may be obtained directly from RTS at:

TELEX/RTS SYSTEMS

Attn: Factory Service

8601 East Cornhusker Hwy.

Lincoln, NE 68507 U.S.A.

CHAPTER 2

REPLACEMENT PARTS

9

Page 14

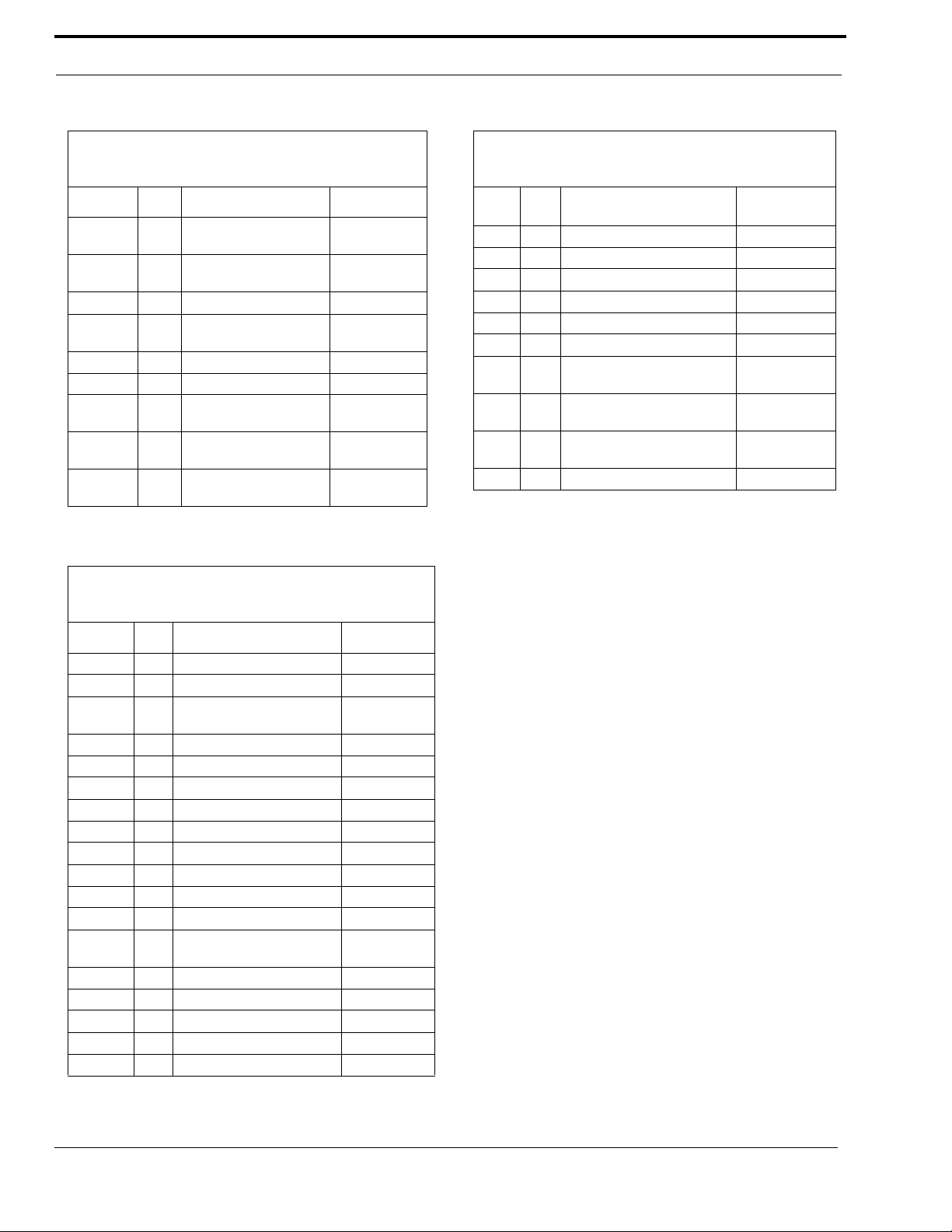

REPLACEMENT PARTS

MECHANICAL PARTS

Final Assembly

(Refer to Figure 5, “Final Assembly, BP325,” on page21

drawing for Item No. locations)

Item No. Qty Description RTS Part No.

11

21

3 1 Back Panel Assy., BP325 9020673600

41

5 3 Screw, 4-40 X 3/4” LG 1008407600

6 1 Label, Serial, GM035260 3101001700

71

81

91

Front/Top Panel Assy

(Refer to Figure 1, “Front Panel Board Assembly, BP325,” on

page 17 drawing for Item No. locations)

Front/Top Panel Assy,

BP325

Front/Top Panel Assy,

BP325

Bottom Case w/ Belt

Clip, BP325

Front/Top Panel Assy.,

BP325, Black

Back Panel Assy., BP325.

Black

Bottm Case w/ belt clip,

BP325, Black

9020673700

9020673720

9020563500

9020673721

9020673621

9020563521

Rear Panel Assy

(Refer to Figure 3, “Rear Panel Assembly, BP325,” on page 19

drawing for Item No. locations)

Item

No. Qty Description RTS Part No.

1 1 Back Panel, Gray 9080563700

2 1 Back Panel, Black 9080563701

3 3 Release Lever, Blue 9160563701

4 3 Release Lever, Dark Gray 9160563711

5 1 Knob, Program Volume 9160677500

6 1 Connector Assy, Line Input 25026736000

71

81

91

10 1 Screw, M2.5 X 0.45 X 8MM FST000023000

Connector Assy, Line Loop

Aux I/O

Connector Assy, Mono

Headset

Connector Assy, Stereo

Headset

25026736001

25026736002

25026736003

Item No. Qty Description RTS Part No.

1 1 Front Case, Gray 9020563601

2 1 PCB Assembly, BP325 90306634000

31

4 3 Screw, # 3-24 x 3/8” Pan Head 51856-035

5 1 Button Talk CH1 (FAM) 9160563603

6 1 Button Talk CH2 (FAM) 9160563604

7 1 Lens Call 9150563606

8 1 Button Call (FAM) 9160563605

9 2 Knob Boot 9160563602

10 2 Knob Body Nylon 9160563601

11

12 2 Pushnut Fastener 1005021100

13 1

14 1 Front Case, Black 9020563602

15 1 Button, Talk, CH1, Dark Gray 9160563613

16 1 Button, Talk, CH2, Dark Gray 9160563614

17 1 Button, Call, Dark Gray 9160563615

18 Loctite BE753

PC Board Assembly, BP325

6*90406635000

PC Board Assy, BP325 Rev

2.0

90306635000

90306635001

10

Page 15

REPLACEMENT PARTS

ELECTRICAL PARTS

ITEM QTY REF PART NUMBER VALUE

19

2 1 C41 1502R2284E 2200UF

3 1 U11 53266124

4 2 U13,U14 53281100

5 1 U8 53290000

6 4 J4,J5,J6,J7 59958103

7 1 U10 59631000

8 2 J2,J3 59958106

9 4 Q2,Q3,Q11,Q15 102210000

10 13

11 2 R4,R6 102404146 301

12 2 R62,R64 102404300 10K

13 4 R42,R43,R55,R56 102404329 20K

14 6 R40,R41,R53,R54,R61,R63 102404375 60.4K

15 3 R69,R128,R130 1025132R7 2.7

16 3 R27,R44,R57 102513101 100

17 6 R3,R8,R29,R31,R33,R49 102513102 1K

19 5 R25,R30,R66,R68,R70 102513103 10K

20 17

21 1 R71 102513112 1_1K

22 1 R24 102513153 15K

23 3 R18,R26,R77 102513201 200

24 9

25 34

27 1 R112 102513225 2.2M

28 6

29 2 R72,R81 102513300 30

30 1 R122 102513302 3K

31 5 R119,R120,R121,R125,R127 102513473 47K

32 3 R116,R117,R118 102513474 470K

33 3 R15,R16,R17 102513515 5.1M

34 2 R9,R10 102513621 620

35 2 R35,R47 102513683 68K

36 1 R123 102513390 39

C12,C22,C23,C24,C26,

C30,C31,C32,C46

D1,D2,D3,D7,D8,D9,D10,

D11,D12,D13,D101,D102,D103102252000

R11,R19,R21,R23,R28,R45,

R58,R59,R60,R67,R78,R79,

R85,R101,R102,R103,R104

R12,R13,R80,RR1,RR2,

RR3,RR4,RR5,RR6

R1,R2,R14,R20,R22,R34,

R36,R37,R38,R46,R48,R50,

R51,R73,R74,R75,R76,R82,

R83,R84,R106,R108,R109,

R110,R111,R124,R126,R129,

R131,R132,R133,R134,R135,

R136

R32,R105,R107,R113,R114,R

115

1099R2263GT 22UF

102513104 100K

102513220 22

102513223 22K

102513274 270K

39 7

40 10

41 6

42 25

43 1 C13 102881339 .01UF

45 8

46 8

47 1 U12 90157491010

48 1 U2 53266123

49 1 R65 1412100601 50K

50 2 FB1,FB2 59180303

51 2 R39,R52 14090065SMT 10K

53 1 D6 16010004SMT

54 2 D4,D5 16016481SMT

55 4 Q10,Q12,Q13,Q14 16025087SMT

56 1 Q1 16025484SMT

57 1 U15 16030008SMS

58 4 U3,U4,U6,U7 16030131SMT

59 1 U5 16030140SMS

60 1 U1 16030833SMT

61 1 SS1 19090002SMS

62 6 2007009900

63 2 J8,J9 20070143SM

64 4 TP1,TP2,TP3,TP4 2017001400

65 1 Y100 33010009SM

66 1 4502001600

67 1 90406635000

68 2 RP1,RP2 1411220200 22K

69 1 J1 2013004900

70

71 1 W8 102513000

73 6 W1,W2,W3,W4,W5,W7 2515001500

74 1 1006004100

75 1 1007000700

76 1 1008402300

77 1 2703002900

78 AR 51741000

79 2 R5,R7 102404246 3.01K

C4,C5,C14,C36,C37,C107,C1

12

C2,C18,C19,C20,C25,

C27,C28,C33,C39,C104

C15,C21,C29,C102,C103,C10

5

C6,C7,C8,C11,C17,C44,C45,

C106,C108,C109,C111,C113,

C114,CC1,CC2,CC3,CC4,

CC5,CC6,CC7,CC10,CC11,

CC12,CC13,CC14

C1,C3,C110,C9,C115,C40,C4

2,C43

C16,C34,C35,C38,C100,C101

,C116,C117

102879216 1000PF

102879204 100PF

102879271 10PF

102880226 .1UF

102884215 47UF

102884606

1.0UF_3

5V

19.6608

MHZ

38 1 C10 102879212 470PF

11

Page 16

REPLACEMENT PARTS

12

Page 17

CHAPTER 3

Specifications and Drawings

Specifications

Dimensions

5.00” High x 3.75” Wide x 2.05” Deep

(127mm x 96.3mm x 52.1mm)

Weight

0.5 pounds (225 grams)

Exterior

Polystyrene and polycarbonate mix; gray textured main body

Power Requirements

Input DC Voltage

=18 to +35 volts DC, operating; -200 to +36 volts DC

without damage

DC Current

mA

Average talk + call light: 6 No Signal: 27 milliamperes.

Average talk (25 ohm headphones, 10dB below clipping): 43

0mA

Impedance Across Intercom Line

10,000 ohms typical

Ambient Temperature Range

Operating: 0°C to 50°C (32°F - 122°F)

Storage: -40°C to 125°C (-40°F to 257°F)

Noise Contribution to 200-Ohm Intercom Line

-75 dBu

Headphone Amplifier

Maximum Voltage Gain: 30dB

Frequency Response: 100 Hz to 8 kHz,

+/-3 dB

Headphone Impedance: 50 to 600 ohms

Output Power: 150 mW/50 ohms

Output Voltage Level: 8 volt peak-to-peak

Microphone Preamplifier

Maximum Voltage Gain: 54 dB

Frequency Response: 100 Hz to 8 kHz,

+/-3 dB

Input Impedance: 1,000 ohms, balanced

Limiter Range: 30 dB

Program Input

Maximum Input Level: +20 dBu

Nominal Input Level: -10 to +8 dBu

Frequency Response: 100 Hz to 12 kHz,

+/-3 dB

Monaural Dynamic-mic Headset Connector

XLR-4-31 receptacle (J13)

Pin 1 - Microphone low

Pin 2 - Microphone high

Pin 3 - Common

Pin 4 - Headphone high

Stereo Dynamic-mic Headset Connector

XLR-5-31 receptacle (J14)

Pin 1 - Microphone low

Pin 2 - Microphone high

Pin 3 - Common

Pin 4 - Headphone left high

Pin 5 - Headphone right high

Carbon-mic Headset Connector (J1) - 1/4 inch, 3-conductor

Phone Jack

Used for Headset

Tip - Carbon microphone

Ring - Headphone

15

Page 18

Specifications and Drawings

Drawings

Drawing Number Title

9030-6634-000 Front Panel Circuit Board Assemblyt

9030-6635-000 Main Board Layout

9020-6736-000 Rear Panel Assembly

9020-6737-000 Front/Top Panel Assembly

9010-6738-000 Final Assembly

9027-6635-000 Schematic Diagram, Main Circuit Board (pages 1 & 2)

2502-6736-000 Cable Assemblies

16

Page 19

Figure 1: Front Panel Board Assembly, BP325

17

Page 20

Figure 2: Main Board, BP325

18

Page 21

Figure 3: Rear Panel Assembly, BP325

19

Page 22

Figure 4: Front/Top Panel Assembly, BP325

20

Page 23

Figure 5: Final Assembly, BP325

21

Page 24

Figure 6: Schematic, Main Board page 1

22

Page 25

Figure 7: Schematic, Main Circuit Board page 2

23

Page 26

Figure 8: BP-325 Cable Assemblies

24

Page 27

Page 28

Loading...

Loading...