Page 1

User Manual

MODEL BP-300

Portable Belt Pack User S tation

9350-1786-00 Rev H 09/2006

Page 2

PROPRIETARY NOTICE

SHIPPING TO THE MANUFACTURER

The product information and design disclosed herein were originated by

and are the property of Telex Communications, Inc. Telex reserves all

patent, proprietary design, manufacturing, reproduction, use and sales

rights thereto, and to any article disclosed therein, except to the extent

rights are expressly granted to others.

COPYRIGHT NOTICE

Copyright 2006 by Telex Communications, Inc. All rights reserved.

Reproduction, in whole or in part, without prior written permission from

Telex is prohibited.

WARRANTY NOTICE

See the enclosed warranty card for further details.

CUSTOMER SUPPORT

Te chnical questions should be directed to:

Customer Service Department

RTS/Telex Communications, Inc.

12000 Portland Avenue South

Burnsville, MN 55337 USA

Telephone: 800-392-3497

Fax: 800-323-0498

Factory Service: 800-553-5992

All shipments of product should be made via UPS Ground, prepaid (you

may request from Factory Service a different shipment method). Any

shipment upgrades will be paid by the customer. The equipment should

be shipped in the original packing carton. If the original carton is not

available, use any suitable container that is rigid and of adequate size. If

a substitute container is used, the equipment should be wrapped in paper

and surrounded with at least four (4) inches of excelsior or similar

shock-absorbing material. All shipments must be sent to the following

address and must include the Proof of Purchase for warranty repair.

Upon completion of any repair the equipment will be returned via

United Parcel Service or specified shipper, collect.

Factory Service Department

Telex Communications, Inc.

8601 East Cornhusker Hwy.

Lincoln, NE 68507 U.S.A.

Attn: Service

RETURN SHIPPING INSTRUCTIONS

Customer Service Department

Telex Communications, Inc. (Lincoln, NE)

Telephone: 402-467-5321

Fax: 402-467-3279

Factory Service: 800-553-5992

Please include a note in the box which supplies the company name,

address, phone number, a person to contact regarding the repair , the type

and quantity of equipment, a description of the problem and the serial

number(s).

Page 3

TABLE OF CONTENTS

PROPRIETARYNOTICE

....................................................

.

.

2

COPYRIGHTNOTICE

PATENTNOTICE 2

UNPACKING

WARRANmIWORMATION 2

RETURN

SECTION

1.1DESCRIFTON

1.3 SPECIFICAlIONS 6

SECTION2.INSTALLATION

2.1

POWER

2.2 TYPE OF MOUNTING 7

2.3 CHOOSING HEADSETS

2.4CABLINGREQULREMENTS

2.4.1 WIRE SIZE AND

AND

SHlPPING INSTRUCTIONS 2

1:

DESCRIPTION AND SPECIFICATIONS

REQUlREMENTS. TYPE OF SYSTEM. POWERING METHOD

.....................................................

2

........................................................

INSPECTION 2

...............................................

.................................................

............................................

..................................

.......................................................

5

5

.....................................................

................................................

AND

POWER SUPPLY

(IES)

......

7

7

...................................................

..................................................

...............................................

MAXIMUM

OPERATING DISTANCE

............................

9

9

8

2.5MECHANICAL

2.6SYSTEMCHECK

2.7 STANDARD

SECTION3.OPERATION 13

3.1 OPERATING CONTROLS

3.2 OPERATION

SECTION

4.1

WHERE

4.2 MECHANICAL PARTS

4.3

ELECTRICAL

SECTION

4:

TO OBTAIN

5:

.......................................................

......................................................

USER

STATION CONNECTIONS

.....................................

10

10

10

..................................................

AND

CONNECTORS

........................................................

REPLACEMENT PARTS

PARTS

...................................................

PARTS

DIAGRAMS 1 DRAWINGS

...................................................

...........................................

...............................................

..........................................

....................................

13

13

15

15

15

15

19

Page 4

MICROPHONE

Page

4

Page 5

0

3

()

Ll'

SECTION

1.1

DESCRIPTION

The Model BP300 is a portable, two-channel inter-

com user station. The user station is designed to be

used in a full duplex, conference line intercom sys-

tem.

Conference Line Intercom Svstem (Figure 1-1)

A

of people to talk and listen on a single channel.

On this channel, all users can listen when one or

more other users are talking (conferencing). Up

to

conference bus).

Full duplex operation allows two way conversation

at the same time, that is, one user can interrupt a

second user while the second user is still talking.

The BP300, with a headset, interfaces a human user

to the intercom system. The user talks

using the headset (or a handset). The headset con-

nects to the BP300 via a four conductor cable and

connector (optionally five or six pin). The BP300

connects to the system using a three conductor

"microphone" type cable. The BP300 contains four

controls: the volume control, the latching micro-

phone switch, the momentary microphone switch,

and the channel select switch. On the Model

BP300L, the momentary microphone switch is re-

placed with the call light button.

Volume Control

The volume control on the

to compensate for: user hearing differences, ambi-

ent noise variation, variations in headset

sensitivity, and variations in voices. The volume

control in the BP300 reduces distortion by driving

the headphone amplifier only

Microphone Switch(es1

In normal system operation, one or more users talk

and the others listen.

station allows the talker's microphone to

and allows the listeners to keep their microphones

disabled. In this condition, speech intelligibility is en-

hanced since background noise from other micro-

phones is not present.

On the Model BP300, a latching switch or momentary

push button turns the microphone on.

1:

DESCRIPTION & SPECIFICATIONS

conference line intercom system allows a group

75

users

can

share the same conference line (or

and

listens

a

BP300 has

as

much as needed.

A

microphone switch on each

wide range

/

handset

be

enabled

The momentaty push button allows quick 'bursts of

communication, especially useful in a high noise envi-

ronment. The latched position allows "hands freen

operation, when the user needs to have two way

conversation while performing another activity.

The Channel Select Switch

A

channel selector switch allows a choice of two

(optionally three) channels.

the

"1"

position the station talks and listens on chan-

nel

1,

on the "2"position, channel 2, and so on. On

larger systems the "1" position may be any system

channel (1 through 12 for example). Similarly, for

position

quirements under these conditions.

Call Light Push Button (BP300L, only)

Pushing this button transmits a call signal to all other

units on the channel selected by the channel selector

switch.

light push button to flash. The flash rate is 2 to

times a second. The call signal itself is a 20 kilohertz

signal.

Options (-DL,

The BP300 and BP3OOL use the CC33 card

indicated below. Codes at the end of each aragraph

indicate the card used. Codes are: *CC33 car$ **CC4O

card, ***CC45 card. (CC33 schematic is SD1464;

CC40/CC45 schematic is SD1427).

-DL: Dual Listen on two channels. The volume control is

changed to

The channel select switch routes the

knob follows the channel selector. The inside knob is the

non-talk, listen only channel.

-E:

the balanced program is fed in instead. Pins 2

input connections.

two knobs provides separate level controls for interwm

program.

-3CII: Three CHannel operation. Line and loop-through

connectors are changed to 4-pin from 3-pin. A 3-position

channel select switch replaces the 2-position switch.

-USMB: UnSwitched Microphone output, Balanced.

Deletes line loop-through. Level: -7dBm to S3dBm. The

USMB

systems such

telephone, radiotelephone, or Stage Announce.

-LP:

power to low volta e to wer the user station,

connector

the interwm line.

"2".

See Section 2.1 for DC powering re-

A

call signal on this channel will cause the call

-E,

-3CH,

-USMB, -LP)

a

dual

concentric potentiometer with two knobs.

Program Input, balanced. Deletes line loop-through,

A

dual

provides a line level microphone signal to other

as

an Interrupted Feedback System

Local

Power source. A small module converts AC line

is

provib;d.

#e unit does not use power from

When the switch is on

except

as

talk

signal. The outside

and

concentric potentiometer with

3 are the

(IFB),

a

separate

and

5

Page

5

Page 6

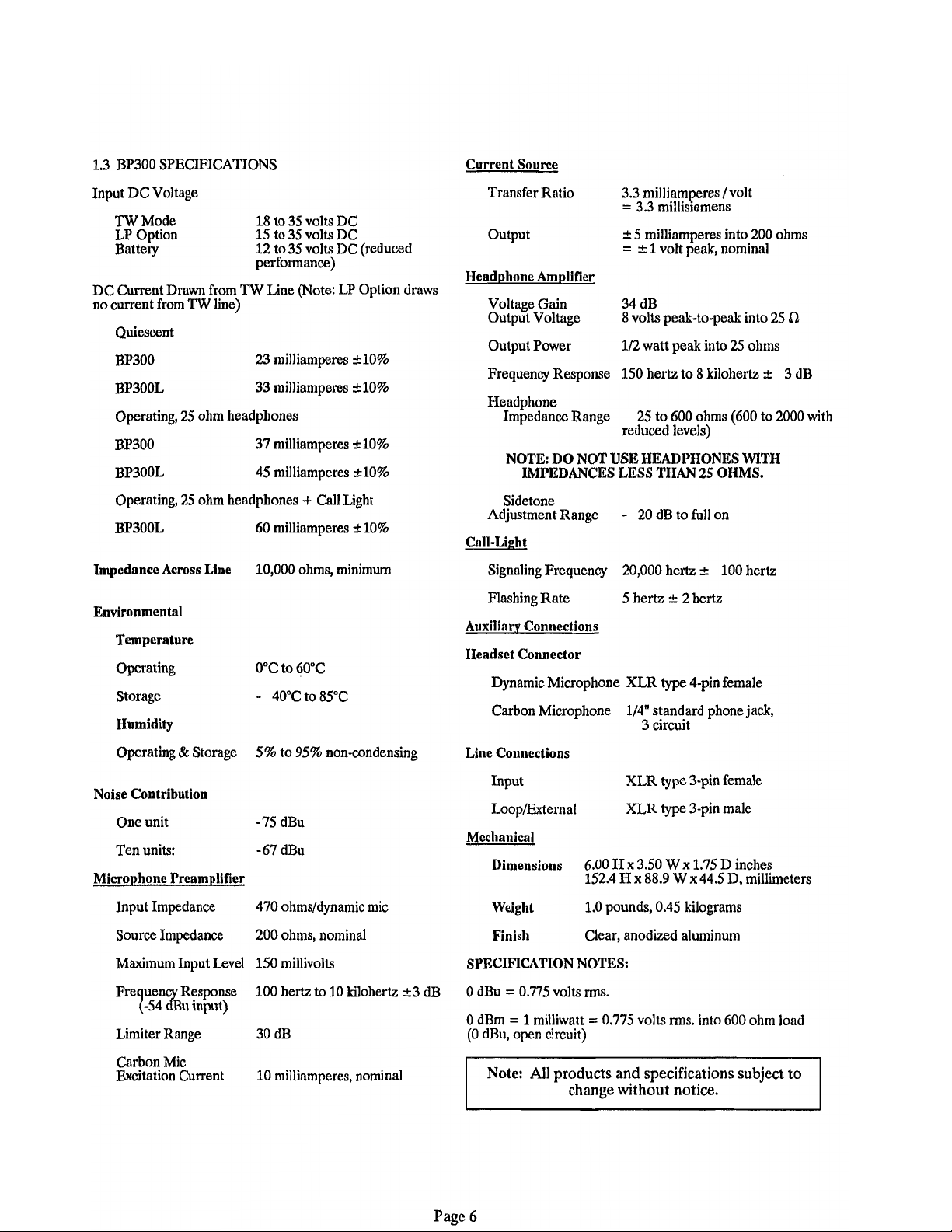

1.3 BP300 SPECIFICATIONS

Current Source

Input DC Voltage

18

TW Mode

LP Option

Battery

DC Current Drawn from

no current from

Quiescent

BP300 23 milliamperes 210%

BP3OOL 33 milliamperes 210%

Operating, 25 ohm headphones

BP300 37 milliamperes

BP3OOL 45 milliamperes 210%

Operating, 25 ohm headphones

BP300L 60 milliamperes

Impedance Across Line 10,000 ohms, minimum

Environmental

Temperature

Operating 0.C to 60°C

Storage

Humidity

TW

line)

to 35 volts DC

15 to 35 volts DC

12 to 35 volts DC (reduced

performance)

TW

Line (Note: LP Option draws

2

10%

+

Call Light

f

10%

-

40°C to 85°C

Transfer Ratio

Output

I-leadphone Amplifier

Voltage Gain 34 dB

Output Voltage 8 volts peak-to-peak into 25

Output Power 112 watt peak into 25 ohms

Frequency Response 150 hertz to 8 kilohertz

Headphone

Impedance Range

NOTE: DO NOT USE HEADPHONES

IMPEDANCES LESS THAN

Sidetone

Adjustment Range

Call-Light

Signaling Frequency 20,000 hertz

Flashing Rate

Auxiliarv Connections

Headset Connector

Dynamic Microphone XLR

Carbon Microphone 114" standard phone jack,

3.3 milliamperes

=

3.3 millislemens

A

5 milliamperes into 200 ohms

=

-c

1

volt peak, nominal

25 to 600 ohms (600 to 2000 with

reduced levels)

-

20 dB to full on

A

5 hertz

type

3 circuit

/

volt

25

OHMS.

f

100 hertz

2 hertz

4-pin female

-t

WITH

Cl

3 dB

&

Operating

Noise Contribution

One unit -75 dBu

Ten units: -67 dBu

Microphone Preamplifier

Input Impedance 470 ohmsldynamic mic

Source Impedance 200 ohms, nominal

Maximum Input Level 150 millivolts

Fre uency Response 100 hertz to 10 kilohertz k3 dB

q-54 dBu input)

Limiter Range 30 dB

Carbon Mic

Excitation Current 10 milliamperes, nominal

Storage

5%

to 95% non-condensing

Line Connections

Input XLR type 3-pin female

Loop/External XLR type 3-pin male

Mechanical

Dimensions

Weight 1.0 pounds, 0.45 kilograms

Finish Clear, anodized aluminum

SPECIFICATION NOTES:

=

0 dBu

0 dBm

(0 dBu, open circuit)

0.775 volts rms.

=

1

milliwatt = 0.775 volts rms. into 600 ohm load

Note:

All

products and specifications subject to

H

x

6.00

152.4

change without notice.

3.50 W x

H

x

88.9

1.75 D inches

W

x

44.5 D, millimeters

Pagc

6

Page 7

lo

I

I

SECTION

Follow the directions: "To Install the BP300n, below.

2.1

Method And Power Supply(ies)

Power Requirements

To maintain a bridging 10,000 ohms impedance to the

intercom line, the

DC. To operate in local power or battery modes, the

BP300 requires from +15 to +35 volts DC, but is

operable at reduced performance from +12 to

volts. Below that voltage, a safety circuit disables the

microphone switch on the

Twe of System

The BP300 can be installed in a (1) three wire system,

(2) two wire system, or (3) special two wire system.

power in^

Power is carried to the unit from a system power

supply using three different methods:

(1)

2:

INSTALLATION

Power Requirements, Type

BP300 requires +18 to +35 volts

Method

In a three wire system ("Series 17n type), the

power is separate from the audio and supplied

by

a central power supply.

Of

System, Powering

CC33 board.

+

17.9

A

voltage, cable resistartce, and surges.

approacli is

capacity.

In (3) above, a local power supply provides 12 to

volts DC at 120 milliamperes peak for each station,

or, for remote single station operation, two 9-volt

batteries in series may

In (1) and (3) above, the two wires carrying the audio

requlre one system termination consisting of a

ohm resistor and a 100 microfarad capacitor in series.

This combination is connected across the two wires.

If the capacitor is polarized, its negative terminal is

connected to the system circuit common.

To Install the BP300:

1.

2. Determine the mounting of the BP300: Portable

3. Read "Choosing Headsets or Handsets".

4. Determine the cabling requirements.

to

operate ti= system at no more than

be

used.

Determine the type of system in which the BP300

is to be installed. Determine the powering

method and power supply(ies).

or Permanent.

more prudent

80%

of

24

200

a

(2) In

(3)

In (1) above, the power supply is a regulated supply,

24

can operate up to 50 BP300 and 30 BP300L user sta-

tions.

For case (2) above, assuming the currents shown, the

power supplies versus maximum number of stations

powered are:

Power Supply

Model

Model PSI5 1.OA 27 16

Model PS3l 1.5A 41 25

N&:

allow for other variations such as lemnperaturc, litw

two wire system ("TW-e), the power and

audio may share the same wire. The power is

supplied centrally by a special "TW" type power

supply-

In a special two wire system (Local Power), each

BP300 is locally powered and operates on switch

channel two. The BP300s are interconnected

using two wire cable. Power is supplied by a bat-

tery or a local power supply. The local power

supply should be isolated from earth ground.

volts DC to 32 volts DC, 1.5 amperes. This supply

BP300 (37mA) BP300L (60mA)

PS8

(j.43AI

Operaiwn of a system at maxitnutn load docs not

11

7

&

5. Create a system block diagram

(if not already available), then install the system.

6. Verify correct system operation by using the

checkout procedure in this chapter (02.6).

Update the system block diagram, equipment list

and any other documentation to reflect the

stal1ed"configuration. If the system block dia-

gram was originally created by

a copy of the

to RTS Systems. This diagram will be used to up-

date the original documentation, and for future

service support.

2.2

Type Of Mounting

(1) One type of mounting for the BP300 is portable,

when it is worn on clothing or an equipment belt.

(2) Another type of mounting for the BP300 is

permanent or semi-permanent, either

mountn (sitting on a desk) or fastened to fur-

niture. Avoid placing the BP300 on a metal or

grounded metal surface. Contact between the

Model BP300 and metal surfaces may cause

unwanted noises on the intercom line.

"as

installedn system block diagram

equipment list

RTS

Systems, send

a

"as

"desk

in-

Page 7

Page 8

23

Choosing IIeadscts

Introduction Headset or handset choice depends on

operating environment, operating requirements, and

personal taste.

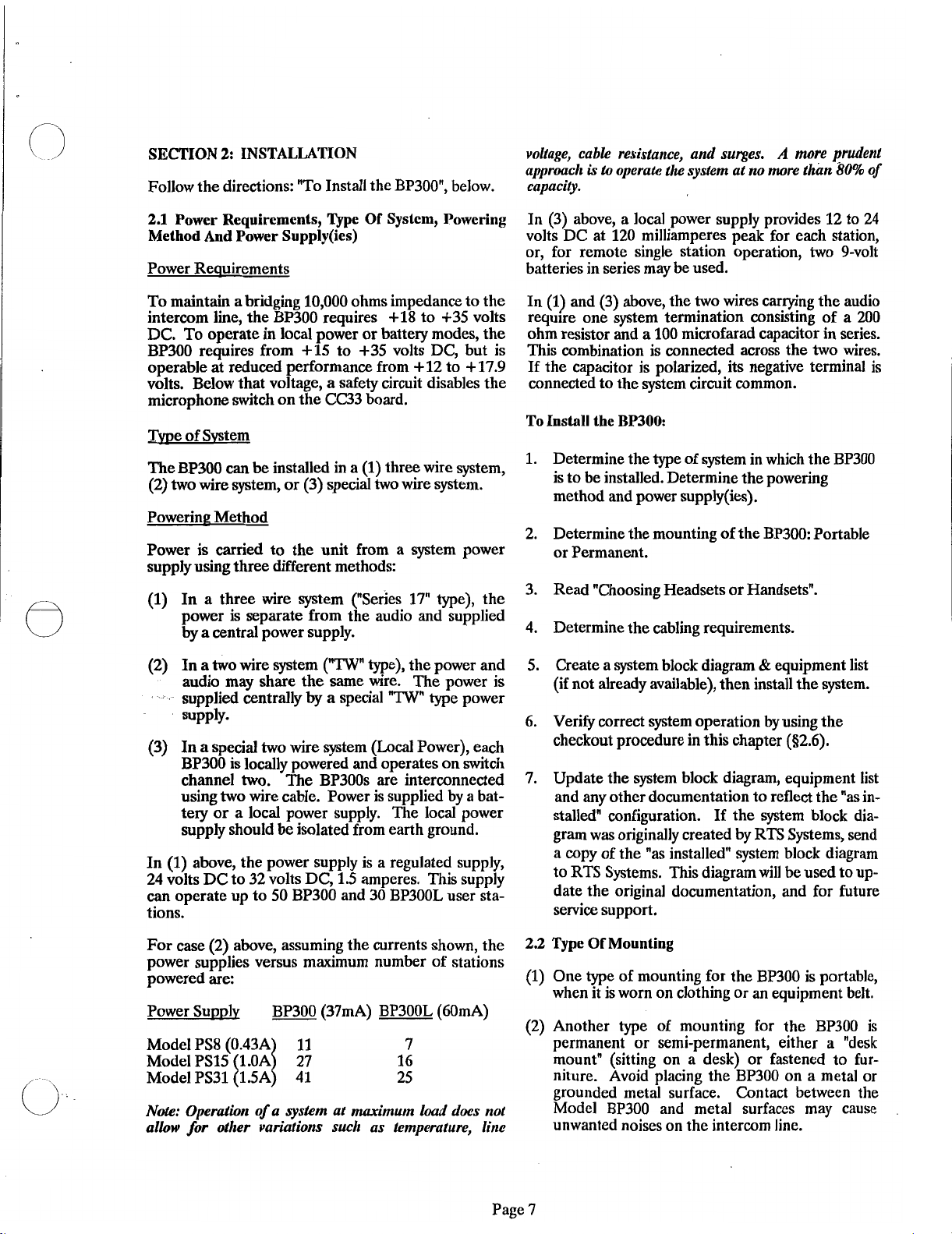

Operating Environment Table 2-1 shows typical oper-

ating environments and the amount of background

noise present.

A very quiet operating environment, such as a

television studio, may require that sound does not

leak from the headphones, meaning the headphones

should have good "acoustic isolation".

A

very noisy or loud environment usually requires

headphones that prevent outside sound from leaking

in (again, good acoustic isolation), headphones that

can produce a loud, clear sound, and noise cancelling

as

microphones,

Understanding speech in a noisy environment re-

quires that the sound from the headphones is as loud

or louder than the sound leaking into the headphones

from the noisy environment.

well.

is 23 milliamperes for the BP300,33 milliamperes for

the BP300L).

Headphone Sound Isolation

The ability of headphones to shut out unwanted envi-

ronmental noise varies from none (0 dB isolation) to

about 118th as loud (30 dB isolation). The degree of

isolation depends both on the design of the headset

and the frequency content of the environmental

noise. Lightweight, "open" headsets such as the RTS

Systems

muff), have almost no (0 dB) isolation. The trade-off

is that the LH267LH268 are very comfortable and

can be worn for long periods (8 to 12 hours) without

physical discomfort from the earmuffs or headband.

The LH267LH268 are low impedance and can be

turned up loud.

Because there is less acoustic isolation, care must be

taken that the sound signals from the LH267LH268

are not unintentionally leaked into microphones.

The DT108PT109 headsets have an isolation rang-

ing from 10 dB to 20 dB.

LH267 (single muff) and LH268 (double

Loudness In general, the loudness of a headphone

depends upon its ability to absorb power at a given

voltage (impedance) and the efficiency of its design.

Practically, the impedance has a larger effect with

present day headsets.

Impedance Low impedance headphones are louder,

causing the

power supply. High impedance headphones are not

as loud, drawing less current from the power supply.

The BP300 design range of impedances for the head-

phone

Headphone impedances 600 to 2000 ohms will oper-

ate at reduced levels. In a double muff headset such

as the Beyer

50 ohm headphones connected in parallel resulting in

an impedance of 25 ohms.

Efficiencv The BP300 produces the loudest sound in

low impedance headphones such as the DT109. In

this headphone, one milliwatt of electrical power

produces

Practical Loudness The BP300

duce an SPL of

DT108 headset. Low impedance headsets such

DT108 and DT109 headsets, cause the BP300

BP300L to require more power from the power sup-

ply. With DT109 headsets, BP300 peak current is 75

milliamperes. BP300L peak current is

80 milliamperes. With 600 ohm headphones, peak

current is 30 milliamperes for the BP300,

40 milliamperes for the BP300L. (Quiescent current

BP300 to draw more current from the

part

of the headset is 25 ohms to 600 ohms.

DT109 sold by RTS Systems, there are

94

dB SPL (Sound Pressure Level).

/

BP300L can pro-

111

dB in each ear of a DT109 or

as

the

At least four companies, Telex, Setcom, David Clark,

and Carter Engineering sell headsets intended for

heavy industrial, aerospace, and military markets.

These headsets can provide acoustic isolation figures

of 20dB to 40dB. Generally speaking, these headsets

are heavier and less comfortable to wear.

Isolation, Headset

In high noise environments, the headset microphone

should be a noise cancelling type.

Comfort In general, the comfort of headsets depends

upon their weight, padding and design.

In the headset connecting cable, prevent coupling be-

tween the microphone and headphone leads

at least a shielded wire for the microphone, and a

separate pair of wires for the headphone(s). Better

isolation may be possible with a twisted, shielded pair

for the microphone leads. Do not allow headphone

ground to contact microphone ground or shield. Tie

the shield to microphone ground or microphone low.

Do not tie the shield to the case of the connector or

the case of the user station. In general the maximum

length for the headset cable is ten feet (3.1 meters).

Lengths over ten feet require a special extension

/

cable. Check with RTS Systems for help with longer

cables.

Microvhones

by

using

Page 8

Page 9

2.4.

Cabling Requirements

2.4.1

Wire Size and Maximum Operating Distance

Wire sue determines the maximum operating dis-

tance (where the DC voltage drop is the limiting fac-

tor). The following equations apply for a conductor

sue of #22 AWG, a minimum user station voltage of

18.0 volts, and a minimum power supply voltage as

stated below.

For Models PS10, PS30, PS31, PS50, PS60 (Vmin

=

28.4 WC):

=

Distance,, (feet)

Distan%, (meters)

322,181

=

/

99,133

Itot

(milliamperes).

/Itot

(milliamperes)

Another benefit of not "earthn grounding the circuit

return is that it prevents the introduction'of'noise

through "earth" currents from other equipment. If

RTS

the

currents, it is likely that they will be heard

Systmes circuit ground conducts these

as

interfering noise on the communication line.

2.43

Signal

The number of conductors required to interconnect

user stations is:

-

No. of

No. of

Conductors Channels

=

For Models PS8, PSI5 (Vmin

Distanc&, (feet)

Distan%, (meter)

Example:

The BP300L with 25 ohm headphones uses

=

185,874

=

56,654

24.0 VDC):

/Itot

(milliamperes)

/

Itot

(milliamperes)

up to 60 milliamperes. With a PS8 supply the maxi-

mum operating distance for this station is 185,874160

=

milliamperes

3098 feet (944 meters). And with a

PS31 power supply the maximum operating distance

=

is 322,181160 milliamperes

5370 feet (1652 meters).

The maximum operating distance using a PS8 power

supply and a BP300 with 25 ohm phones (37

185,874137

*

h

>.'

2.4.2

=

5024 feet (1531 meters).

Grounding

mA)

is

System circuit ground should not be directly con-

nected to "earth" or "chassisn ground (directly means a

connection an ohmmeter would show). Each user

station is bypassed to its own chassis via a 0.1 mi-

crofarad capacitor, establishing a radio frequency

(RF) ground to reduce radio frequency interference

from radio transmitters.

To prevent a buildup of voltage across the system

ca-

pacitance, the power supply has a bleeder resistor to

chassis ground (22 kilohms). If the system has

no

RTS Systems power supply, add a bleeder resistor at a

central point in the system.

The benefit of not "earthn grounding the RTS System

circuit return is that continued

o~eration is ~ossible

during an accidental system grouid fault. This acci-

dental grounding can happen when

a

wire is pinched

or a cable scraped across a sharp edge. One acciden-

tal ground can

can

fault

be

tolerated by the system until the

be cleared and (with luck) before a second

ground fault can cause noise or overload or bring the

system down.

Wirin~ICabling (See Cable Wiring Diagrams in Sec-

tion

7,

Application Information)

"TW"

Two channel

applications, or single channel,

three wire applications may use either standard mi-

crophone cabfe (for conveGence) or two-twisted-pair

cable (less expensive than microphone cable). Stan-

dard

wire sue for the system is #22 gauge wire for

interconnection. For permanent installations each

channel should have

an

individually shielded twisted

pair of at least #22 gauge wire; such as Belden 8723

for 2 channels, and 8777 for 3 channels. For plenum

and

/

or 200" C wiring, use Belden 88723 and 88777.

The plenum cable has a slightly smaller diameter, is

Teflon insulated, and about three times the price of

Wire using Cable Wiring Diagrams, Section 7, to re-

duce interference and help maintain a low crosstalk

figure between channels.

The audio signal line level is between 10

dBu and

0 dBu (between 0.24 and 0.77 volts rms). These levels

are low enough to prevent crosstalk into other equip-

TV

ment (such as

mize external interference to the

cameras) yet high enough to mini-

TW

System.

The 200 ohm line impedance is high enough to allow

communication over line lengths of 1.6 kilometers

(one mile) and low enough to permit an adequate

speech bandwidth with 3.2 kilometers of accumulated

cable. In most systems the 200 ohm impedance gives

a high fidelity bandwidth with low losses.

When using equipment in rain or conditions of exces-

sive moisture, always protect the equipment with plas-

tic covers and make sure all cable connectors are

lifted out of mud, snow or moisture and protected

with plastic. Water mud and snow in connectors can

cause noise.

Page 9

Page 10

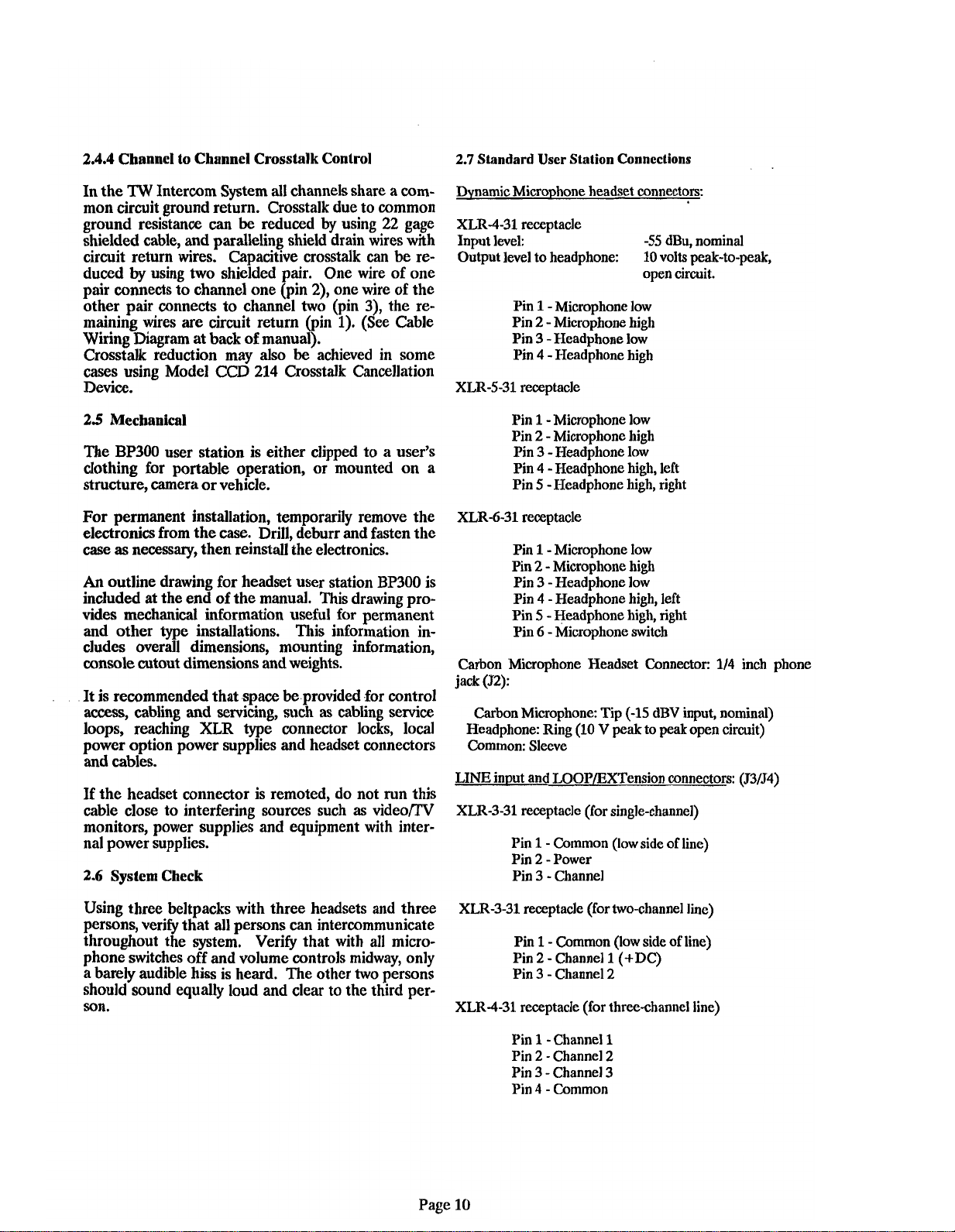

2.4.4

Channel to Channel Crosstalk Control

2.7

Standard User Station Connections

In the

TW

Intercom System all channels share a com-

mon circuit ground return. Crosstalk due to common

ground resistance

be reduced by using

22

gage

can

shielded cable, and paralleling shield drain wires with

circuit return wires. Capacitive crosstalk can be re-

duced by using two shielded pair. One wire of one

pair connects to channel one (pin

other pair connects to channel two (pin

2),

one wire of the

3),

the re-

maining wires are circuit return (pin 1). (See Cable

Wiring Diagram at back of manual).

Crosstalk reduction may also be achieved in some

CCD

cases using Model

214 Crosstalk Cancellation

Device.

25

Mechanical

The BP300 user station is either clipped to a user's

clothing for portable operation, or mounted on a

structure, camera or vehicle.

For permanent installation, temporarily remove the

electronics from the case. Drill, deburr and fasten the

case

as

necessary, then reinstall the electronics.

An

outline drawing for headset user station BP300 is

included at the end of the manual. This drawing pro-

vides mechanical information useful for permanent

and other type installations. This information in-

cludes overall dimensions, mounting information,

console cutout dimensions and weights.

It is recommended that space

access, cabling and servicing, such

loops, reaching

XLR

be.provided .for control

as

cabling

type

connector locks, local

service

power option power supplies and headset connectors

and cables.

If the headset connector is remoted, do not run this

cable close to interfering sources such

as

videom

monitors, power supplies and equipment with inter-

nal power supplies.

2.6

System Check

Dynamic Microphone headset connectors:

XLR-4-31 receptacle

Input level: -55 dBu, nominal

Output level to headphone:

1

-

Microphone low

Pin

2 - Microphone high

Pin

Pin

3

-

Headphone low

Pin 4

-

Headphone high

XLR-5-31 receptacle

Pin

1

-

Microphone low

Pin

2

-

Microphone high

-

Headphone low

Pin 3

Pin

4

-

Headphone high, left

-

Headphone high, right

Pin 5

XLR-6-31 receptacle

1

-

Microphone low

Pin

Pin

2 - Microphone high

-

Headphone low

Pin 3

-

Headphone high, left

Pin 4

Pin 5

-

Headphone high, right

Pin

6

-

Microphone switch

Carbon Microphone Headset Connector: 114 inch phone

jack (52):

Carbon Microphone: Tip (-15

Headphone: Ring (10

Common: Sleeve

LINE input and LOOPIEXTension connectors: (J3lJ4)

XLR-3-31 receptacle (for single-channel)

1

-

Common (low side of line)

Pin

Pin

2

-

Power

-

Channel

Pin 3

10 volts peak-to-peak,

open circuit.

dBV

input, nominal)

V

peak to peak open circuit)

Using three beltpacks with three headsets and three

persons, verify that all persons

can

intercommunicate

throughout the system. Verify that with all micro-

phone switches off and volume controls midway, only

a barely audible hiss is heard. The other two persons

should sound equally loud and clear to the third per-

son.

Page 10

XLR-3-31 receptacle (for two-channel line)

1

-

Common (low side of line)

Pin

Pin 2

-

Channel

Pin 3 - Channel

XLR-Q-31 receptacle (for three-channel line)

Pin

1

-Channel

Pin

2

-

Channel

Pin 3 - Channel 3

4

-

Common

Pin

1

(+DC)

2

1

2

Page 11

Table 2-1

Table 2-2

Typical Operating Environments,

Environmental Noise, Sound Pressure Level,

at 10 meters distance

Source

Aircraft

Orchestra, 75 piece, (Peaks) or 140 dB

Pipe Organ, (Peaks)

Rock Concert

Piano, Peaks 120 dB

Blaring Radio 110 dB

Centrifugal Ventilating Fan 110 dB

Auto on Highway 100 dB

Vaneaxial Ventilating Fan 90 dB

Voice, Shouting 90 dB

Factory

Voice, Conversational 70 dB

120 dB to 160 dB

110 dB to 140 dB

-

SPL

75

dB

Typical Operating Environments,

Sound Pressure Level,

at Ear

Source

Maximum Allowable

Impulse Exposure 140 db

LH267

10 db below Clipping 114 db

DT109

10 db below Clipping

LH268

10 db below Clipping

Setcom Series 5

10 db below Clipping

Headphones with 20 db Acoustic

Isolation at 130 db Rock Concert 110 db

(Mouth Closed)

Headphones with 40 db Acoustic

Isolation at 140 db Rock Concert 100 db

(Mouth Closed)

+

BP300,

+

BP300,

+

BP300,

+

BP300,

-

SPL

111

db

110 db

99

db

+:Residence 45 dB

Television Studio

Voice, Whisper 30 dB

25 dB to 35 dB

Page 11

Page 12

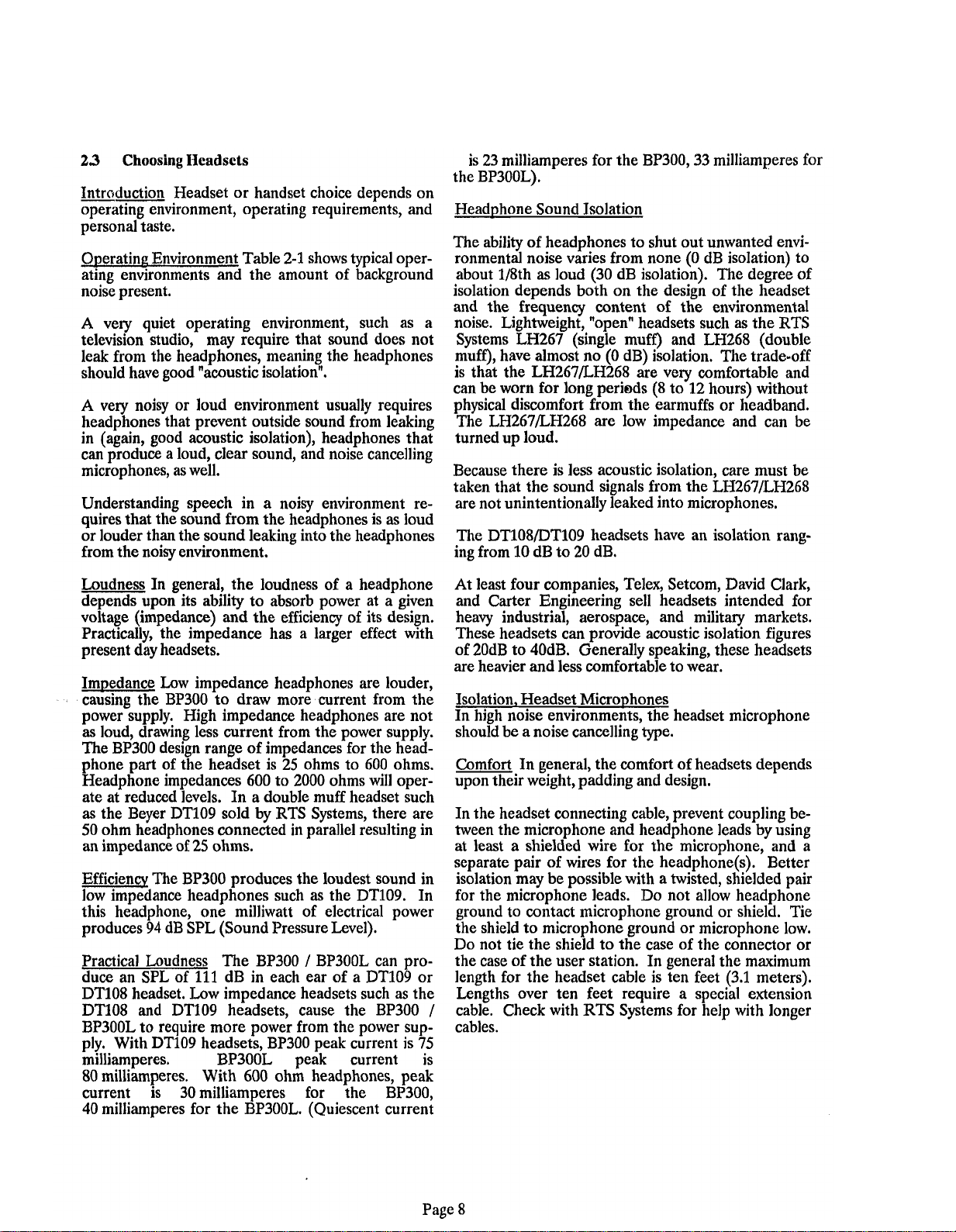

Figure 3-1A

Front Panel, Model BP300 Portable Belt Pack User Station

CAR6

,

Figure

3-1U

Rcar Pancl, Modcl BP300 Portablc Bclt Pack Uscr Station

Page

12

MIC

HDST~

Page 13

SECTION

3.1

Operating Controls And Connectors

Table 3-1 below lists the Model BP300 user station controls and connectors. The reference numbers in Table

3-1

correspond to the circled numbers in Figure 3-1A and Figure 3-1B.

3:

OPERATION

Table

3-1

F3

u

Ref No. Name

--

1)

2) MIC ON-OFF toggle A latching-action switch.

3)

3)

4)

5)

7)

8)

CHannel Select Switch

MIC ON-off push button A momentary-action microphone enable switch on the Model BP300

CALL push button

VOLUME

DYNamic MICrophone

HeaDSeT Connector.

INPUT Plug in the Line connector here. Connects the belt pack user station to

LOOP/EXTension

CARBon MICrophone

HeaDSeT Connector

Description

1

2

Selects 1 of 2 channels (standard) or 1 of 3 channels (optional). The

optional Call Light operates on the channel selected by this switch. The

CHannel select switch is omitted in the Single Channel (SC) option.

-

-

(Standard

(Optional) The CALL push button in Model BP300L (No momentary

mic).

A headphone VOLUME control. (May be a dual control for the Dual

Listen (DL) or Program

A

dynamic microphone type headset plugs in here.

TW

the

A convenience connector

connected to the

A carbon microphone type headset plugs in here. The headset may also

be a carbon microphone emulate type headset.

without the Call Light option).

intercom system.

TW

intercom system.

(E)

option).

- -

allows another belt pack user station to be

Always

3.2

To communicate directlywith another station or stations:

1)

2)

3)

4)

turn the volume control

Operation (After connecting station to the intercom line and plugging in headset).

Turn the VOLUME control all the way counterclocliwise (to the left) before plugging in the headset.

Select the channel using the CHannel select switch.

Set the listening level in the headset using the VOLUME control.

When you want to talk, set the

button) and speak into the microphone. Return the switch to the OFF position to eliminate unnecessary

noise on the intercom line.

all

the way counterclockwise

MIC

ONIOFF toggle switch to the "ONn position (or push the MIC push

Page 13

(to

the left) before plugging in the headset

CAUTION!

Page 14

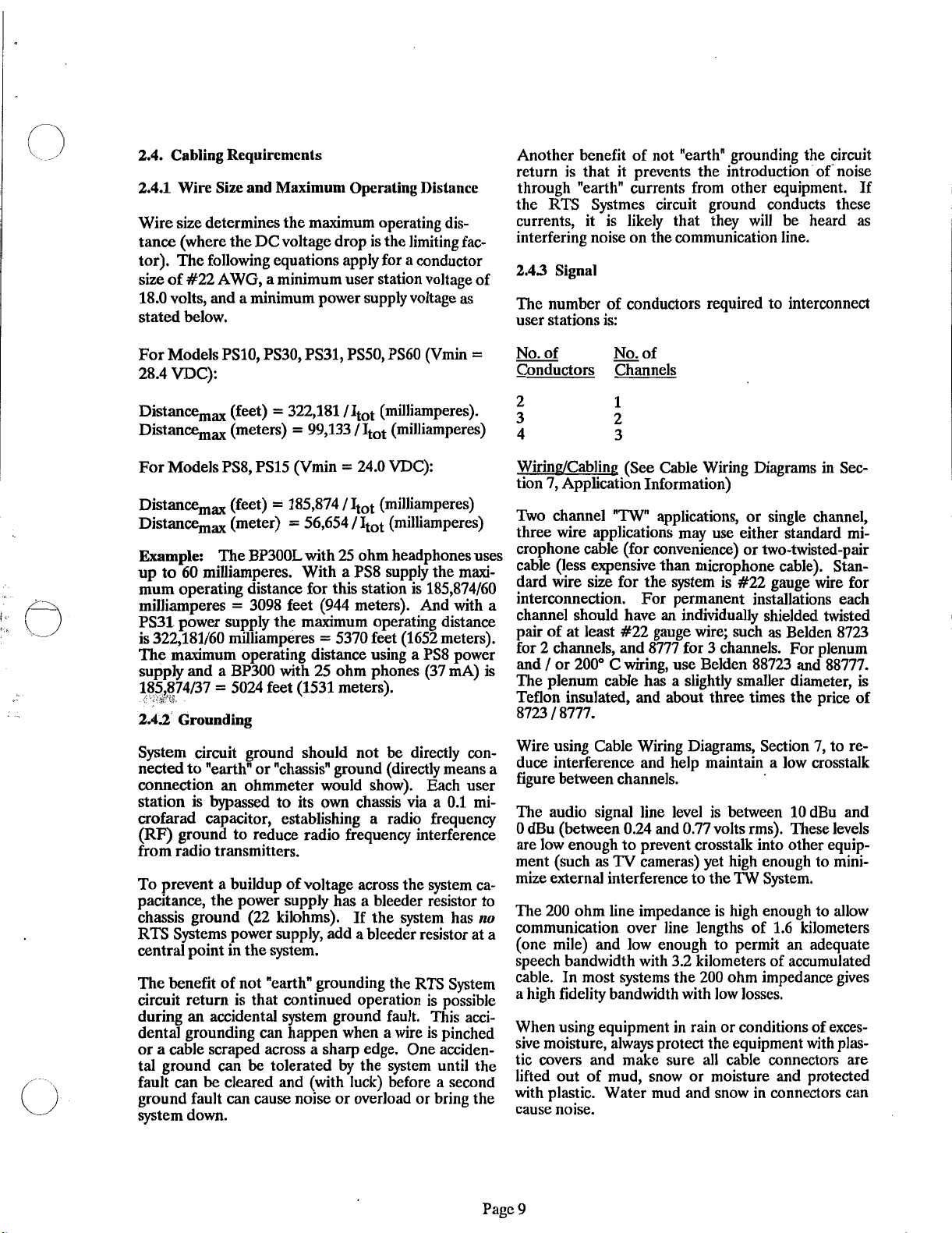

Figure

I%lock

Iliagram, Model

Page

3-2

RI'300

14

Page 15

SECTION

4.1

WHERE TO OBTAIN PARTS

4:

REPLACEMENT PARTS

ltem No.

FRONT PANEL ASSEMBLY

*to Drawing #AS1787 for ltem No.

Description

Part No.

Parts may be obtained directly from Telex

TelexIRTS Systems

12000 Portland Ave.

Burnsville,

877-863-4169

Fax: 800-323-0498

4.2

MECHANICAL PARTS

(Refer to Drawing #AS1786 for ltem No. locations)

NO.

item

PARTS

CF, Carbon Film; CM, Ceramic Monolithic; EL,

Electrolytic; MF, Metal Film; Rad, Radial Leads;

Tant, Tantalum.

MN

)

Front Panel Assy, BP300

PCB Assy, CC33

Back Panel Assy

Case

Screw, #8-32 X 112

Belt Clip

Rivet

Jack, Phone, 3-cond, Double

Closed Circuit

Cap, Gray With Dot

Knob, Gray

Nut Cover, Gray

Mylar,

#73 Shield Bead

Shrink Sleeving,

Lockwasher

Potentiometer, Audio, 50K

Nut, Hex 318"

Washer, Lock, 318" Internal

Tooth

Switch, SPDT

Switch, DPDT Toggle

Nut

Dress Nut, Satin Finish

Washer, Teflon (for Volume

Cont)

LIST

ABBREVIATIONS:

S.

55337

FINAL ASSEMBLY

Description

3-112" X 100 Ft

114"

at:

I

CD,

Ceramic Disk;

part

NO.

Back Panel

Connector, 4-Pin Female

Switch, Pushbutton

Lens, Mic On

Lug, Solder,

Screw, 4-40

Nut, Hex, KEP 6-32

(Refer to Drawing #AS1788 for ltem No. locations)

item

NO.

I

Back Panel

Connector, 3-Pin Female,

Canon AXR 3-31

Connector, 3-Pin Male

Jack, Phone, 3-Cond, Double

Closed Circuit

Washer,

Wires, Local Purchase

Screw, 4-40

Nut, Hex, KEP 6-32

4.3

ELECTRICAL PARTS

CC-33 CIRCUIT BOARD ASSEMBLY

Ref. No.

I

C19

I

c20

C21

I

Capacitor, CM, 0.1 pF, 50V

Capacitor, CM, 0.033 pF, 50V

Capacitor, Tant, 10 pF, 6.3V,

1

20%

Capacitor, CM, 0.1 pF, 50V

Capacitor, EL, Rad, 33 pF, 16V

Capacitor, CM, 0.01 pF, 50V

Capacitor, CM, Rad, 100 pF,

50V

Capacitor, CM, 0.1 pF, 50V

Capacitor, EL, 10 pF, 16V

Capacitor, CM, 0.01 IF, 50V

Capacitor, CM, 0.1 pF, 50V

Capacitor, CD, 10 pF, 500V

Capacitor, EL, Rad, 47 pF, 16V

Capacitor, CM, 0.1 pF, 50V

Capacitor, Mylar, 0.001 pF,

I

Capacitor, EL, Rad, 4.7 pF, 16V 1 1513R4754E

Capacitor, Tant, 1.0 pF, 35V,

1

20%

I

Capacitor, CM, 0.1 pF, 50V

#4

X

318"

BACK PANEL ASSEMBLY

Description

:378 ID

X

318"

Description

Part

No.

I

part

NO.

1511R10421

1

151 1 R33321

1

1515R1063B

151 1 R10421

151 3R3364E

151 1R10321

I

1514R1022L

I

1515R1053G

1

1511R10421

I

1

I

1

I

1

Page 16

CC-33 CIRCUIT BOARD ASSEMBLY

Ref. No.

C27

C28,C29

D1-D3

D4

D5,D6

D7

D8

D9-Dl1

Q1 ,Q2

R 1

R2

R3

R4

R5

R6

R7

R8

R9

R10

Rll

R12

R13

R14,R15

R16

R17

R18,R19

R20

R22

R23

R26

R27

R28

R29

R30

R3 1

R32

R33

R34

R35,R36

S 1

S2

U 1

U2

U3

U4

Capacitor, CM, Rad, 0.01 pF,

200v

Capacitor, EL, 10 pF, 50V

Diode, Signal 1 N6263

Diode, 1 N5231 B

Diode, 1 N4004, IA, 400V

Diode, 1 N5245B Zener, Voltage

Reg l5V

Diode, 1 N5365B Zener, Voltage

Reg 36V

Diode, 1 N4004, lA, 400V

Transistor, Siliconix J305lE305

Resistor, CF, 470 Ohm, 1/4W, 5%

Resistor, CF, 820 Ohm, 1/4W, 5%

Resistor, CF, 220 Ohm, 1/4W, 5%

Resistor, CF, 68K, 1/4W, 5%

Resistor, CF, 5.1M, 1/4W, 5%

Resistor, CF, 330K, 1/4W, 5%

Resistor, CF, 10K, 1/4W, 5%

Resistor, CF, 22K, 1/4W, 5%

Resistor, CF, IOOK,

Resistor, CF, 22 Ohm, 1/4W, 5%

Trim Pot, 100K

Resistor, CF, 22K, 1/4W, 5%

Resistor, CF, 200K, 1/4W, 5%

Resistor, MF, 60.4K, 1/4W, 1%

Trimpot, 10K

Resistor, CF, 270K, 1 /4W, 5%

Resistor, MF, 20.OK, 1/4W, 1%

Resistor,

Resistor, CF, 22K, 1/4W, 5%

Resisbr, CF, 2.2K, 4/4W, 5%

Resistor,

Resistor, CF, 4.7 Ohm, 1/4W, 5%

Resistor, CF, 22K, 1/4W, 5%

Resistor, CF, 100 Ohm, 114W, 5%

Resistor, CF, 36 Ohm, 1/4W, 5%

Resistor, CF, 1.3K, 1/4W, 5%

Resistor, CF, 12K Ohm, sO/O, 118W

Resistor, CF, 1 K, 1/4W, 5%

Resistor, CF, 3.3 Ohm, 1/8W, 5%

Resistor, CF, 100K. 114W,

Switch, SPDT

Switch, DPDT Toggle

IC,

IC, CD4053BE

IC, Op Amp, National LM386N-1

IC, Voltage Regulator, National

LM317MP

Insulator w/o Hole, Silicon

IC Socket, 16-Pin

IC Socket, 8-Pin

Description

1

/4W, 5%

CF,

loOK, 114W,

CF,

1.2K, 114W,

Signetics NE5532N

s0/o

5%

5%

PARTS LIST ABBREVIATIONS: CD,

CF,

Carbon

Electrolytic;

Tant,

Film;

MF,

Tantalum.

CM,

Metal

Ceramic

Film;

Rad,

Monolithic;

Radial

Part

1514R10320

1513R10641

1601626300

160352310B

1601400400

1601524508

1601536508

1601400400

1602030500

140247005D

140282005D

1402220050

140268025D

140251045D

1402330350

1402100250

140222025D

1402100350

140222R05D

1409001 100

140222025D

140220035D

140360422D

1409000300

1402270350

140320022D

140210005D

140222025D

44022P15D

140212015D

14024R705D

140222025D

140210005E

140236R05E

140213015D

140212025D

140210015D

14023R305B

140210035D

1903000100

1903000200

160355320N

16034053BE

1603038600

1603031 7MP

91301 84000

2001000300

2001000100

Ceramic

EL,

Leads;

No.

Disk;

C20

C23

C25

C26

C27

C28

C29

C30

C3 1

C32

C42

CR2

CR3

CR4

CR5

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R14

R15

R16

R17

R18

R19

R20

R2 1

R22

R23

R24

R25

Capacitor, CD., 22 pF, 50V

Capacitor, EL, Rad., 10

Capacitor, EL, Rad., 100 uF, 10V

Capacitor, Mylar, Rad., .001 uF,

l00V

Capacitor, EL, Rad., 10 uF, 16V

Capacitor, CM Rad., 1 uF, 50V

Capacitor, EL, Rad., 100uF, 10V

Capacitor, EL, Axial, 2200 uF, 16V

Capacitor, EL, Axial, 2200 uF, 16V

Capacitor, EL, Rad., 100 uF, 16V

Capacitor, CM Rad., 1 uF, 50V

Capacitor, CD, 100 uF, 50V

Diode, 1 N6263

Diode, 1 N6263

Diode, 1 N6263

Diode, 1 N914B

Resistor, CF, 820 Ohm, 1/4W, 5%

Resistor, CF, 220 Ohm, 114W, 5%

Resistor, CF, 68K, 1/4W, 5%

Resistor, CF, 220K, 1/4W, 5%

Resistor, CF, 10M, 1/4W, 5%

Resistor, CF, 22K, 1/4W, 5%

Resistor, CF, 10K, ll4W. 5%

Potentiometer, Trimmer, 2.5 TO

1 OK

Resistor, CF, loOK, 1/4W, 5%

Resistor, CF, 22 Ohm, 1/4W, 5%

Resistor, CF, 22K, 1/4W, 5%

Resistor, CF, 22K, 1/4W, 5%

Resistor, CF, 22 Ohm, 1/4W, 5%

Resistor, CF, 2.2K, 1/4W,

Resistor, CF, 2.2K, 1/4W, 5%

Potentiometer, Trimmer, 2.5

1 OK

Resistor, MF, 60.4K, 1/4W,

Resistor, MF, 60.4K, l/4W, 1%

Resistor, MF, 20K, 1/4W, 1%

Resistor, CF, 1 K, 1/4W, 5%

Resistor, CF, 100 Ohm, 1/4W, 5%

Resistor, MF, 20K, 1/4W, 1%

uF, 50V

5%

TO

1%

51821 110

51821 529

4R1022L

151

51821230

151 1R10421

51821529

151 3A2284E

151 3A2284E

51821524

151 1R10421

521 57330

1601626300

1601626300

1601626300

160109140B

521 54283

521 54297

521 54237

521 54225

521 54 185

521 54249

521 54257

46643P1

521 54233

521 54321

521 54249

521 54249

521 54321

521 54273

521 54273

46643P1

54045604

54045604

54045200

521 5428 1

521 54305

54045200

Page 17

Ref.

No.

R26

R28

R29

R36

R38

R39

R40

R4 1

R42

R43

R44

R45

R49

U1

U2

U3

U4

U5

VR1

90301 41 800,B

CC-40145 CIRCUIT BOARD ASSEMBLY

Description

5%

X

521 54482

52154233

521 54233

521 54249

521 54301

52154343

521 54249

52154493

521 54278

521 54255

521 54281

521

521 54289

53293000

160334580P

160308200M

1603031 7MP

16034053BE

86266008

160152450B

160153650B

2001000100

2001000100

2001000100

53041 30 1

91301 84000

51379024

Resistor, CF, 100 Ohm,

Resistor, CF, loOK, 114W, 5%

Resistor, CF, loOK, 114W, 5%

Resistor, CF, 22K, 114W, 5%

Resistor, CF, 150 Ohm, 114W, 5%

Resistor, CF, 2.7 Ohm, 1/4W, 5%

Resistor, CF, 22K, 114W, 5%

Resistor, CF, 36 Ohm, 1/2W, 5%

Resistor, CF, 1.3K, 114W, 5%

Resistor, CF, 12K, 114W, 5%

Resistor, CF, 1 K, 1 14W, 5%

Resistor, CF, 3.3 Ohm, 1/8W, 5%

Resistor,

IC, NE5534N

IC, MC3458P

IC, SGS TBA-820-M

IC, LM317MP

IC, Analog Switch

Voltage Regulator, 5.1 V, 5%,

Voltage Regulator, 15V, 5%.

Voltage Regulator, 36V, 5%

IC Socket, 8 Pin

IC Socket, 8 Pin

IC Socket. 8 Pin

IC Socket, 16 Pin DIP

Insulator wlo Hole, Silicone

ShrinkTubing, Clear, .25 Dia.

I

CF,

N5231 B

1

1 N5245B

1 N5365 B

1.0 Lg.

470 Ohm,

1/2W, 5%

1/4W,

Part No.

54120

Ref. No.

CG18SL CIRCUIT BOARD ASSEMBLY

[

Description

I

I

Capacitor, CD, 330 pF1 50V

Capacitor, 220 pF150V

Capacitor, Mylar, ,022 uF/ l00V

Capacitor, Cer, .0033 uF150V

Capacitor, Mylar, .047 uF/ 50V

Capacitor, CM, .1 uF150V

Capacitor, CD,

Capacitor, Mylar, .O1 uFI50V

Capacitor, Tant, 1 uF, 35V

Diode, Signal, 1 N914B

Transistor, MPSU45

Resistor, CF, 68K, 114 W, 5%

Resistor, CF, 470K, 114 W, 5%

Resistor, Variable Trim, 20K

Resistor, MF,

Resistor, CF, 22K, 114 W, 5%

Resistor, CF, 22M, 114 W, 5%

Resistor, CF, 2M, 114 W, 5%

Resistor, CF, 10M, 114 W, 5%

Resistor, CF, 22K, 114 W, 5%

Resistor, CF, 4.7K, 114 W, 5%

Resistor, Variable Trim, 5K

Resistor, CF, IOK, 114 W, 5%

Resistor, CF, 0 Ohm, 114 W, 5%

Resistor, MF, 12.7K, 1

lC, CD4001AE

IC, NE567N

lC, LM78L05AC2W

Wire, 24 AWG, Blk, 3.0" LG.

Wire, 24 AWG, Blu, 3.0" LG.

Wire, 24 AWG, Red.

Wire, 24 AWG, Brn, 3.0" LG.

Pin, Cambion

IC Socket, 14-Pin DIP

I

IC Socket, 8-Pin DIP

OG

680

pFl5OV

63.4K, 114 W, 1

%

3.0"

LG.

%

part

.

NO.

.

\)

PARTS

CF,

LIST ABBREVIATIONS:

Carbon

Electrolytic;

Tant,

Tantalum.

Film;

MF,

CM,

Metal

Ceramic

Film;

Rad,

CD,

Ceramic

Monolithic;

Radial

Leads;

Disk;

EL,

Page 18

This

page intentionally left blank.

Page

18

Page 19

SECTION

5:

DIAGRAMS 1 DRAWINGS

0

F7

g$::

This drawing applies to

OD3415 Outline Drawing, BP300 20

----

----

Application Znformation

'I'M11786

Model

BP300

SD1464

AS 1821 Assembly Diagram, P.C.B., CC33 25

Model

BP300

standard units built between

SD1427-01

AS 1409 Assembly Diagram, P.C.B. CC40145 Layout 27

CC40

card detaileddiagrams

Title

BP300

Units with

CC33

or

CC40

cards. Units with CC45 cards are one inch longer.

...........................................

Cable Wiring Diagram, Two Channel System

Cable Wiring Diagram, Three Channel System

/

12-Volt Battery Operation

Dry

Line Operation (For extended distances)

User Stations with

Schematic Diagram, Series B Phase

CC33

Teleproduction System Example / Multi-channel Operation

card (Standard units and unit3 with Call Light Opfion).

3

User Station

................................

...............................

................................

.............................

......................................

User Stations with

(Simplified) Schematic Diagram, Phase I11 User Stations (CC40) sheet 1

1979

CC40

card (Units with various options or combinations of options. Also applies to

and

1981,

approximately.)

................................

Page

21

22

/

23

24

.................

26

SD1427-00

SD1427~00

Call Light Option used

Option).

SD1470 Servicing Diagram, Light Signaling Circuit, CC-18SL, Phase 3 Configuration

Exploded Views

AS 1786

AS 1787 Front Panel Assembly, Model BP300

AS 1788 Back Panel Assembly, BP I TWI

Schematic Diagram, Phase 3 User Stations, sheet 1 of 2.

Schematic Diagram, Phase 3 User Stations, sheet 2 of 2

by

both

Model

BP300

Final Assembly, Model BP300

User Stations with

CC33

........................................

...........................

card (Standard units and units with Call Light

.....................................

UNITS

..................................

..........................

28

29

...............

30

3

32

33

1

Page 19

Page 20

OD3415

Outline

BP300

Page

Drawing,

20

WEIGHT: 1 .OLBS

ALL

DIMENSIONS: INCHES(mrn)

(.45kg)

Page 21

Cable Wiring

Two

Channel System

Diagram

3

>

2"

>

I

A

w

>

-

-

4

To Supply

Channel

Common

Channel

Common

Drain Wires

2

1

----c-

w

To Station

3

>

2

>

-

-

>

-

1

Page

21

Page 22

Cable Wiring Diagram

Three Channel System

3

>

N.C.

-

N.C.

I

To

4.1

A

-

Supply

Grn Channel

Bl

k

Drain Wires

Common

3

---

Common

N.C.

A

.

To Station

A

w

w

3

>

4

-c-

Page

22

Page 23

12V

Battery

Operation

Page 24

Page 25

Page 26

8

DYNAMIC MIC

CONNECTOR

XLR-4 STANDARD

MOMENTARY

7

P.C.B. CC -40

6

5

4

3

2

ECO"

2523

ELO"

REVISIONS

ZMlE REV. DESCRlPMlN

D AEDRAWN

E

REVISED

F

CHbD

PER

NOTE 5 PER

31%

erL

1

DATE APPROVED

12-9-65

6.ZB.59

4.

14,40

h

D

-

C

-

A

SD1427-01

(Simplified) Schematic Diagram,

111

Phase

DYNAMIC

MIC

CONNECTOR

User Stations (CC-40)

HP

Lo

JI

Hp

I

I

I

I

HPHI

IO. THIS DRAWING DOES NOT SHOW OPT/ONAL PARTS. FOR OPTION

/NFORMAT/OAI, REFER TO SD /427-00.

9

FOR SPEAKER STATIOAIS) CHANGE

0LM317T ATzACIFO TO HEATSlNK>JUCI

AHAM

rt31o2.

8.

SEE 503362 FOR ALTERNATE HEADPHONE/

SPEAKER AMP TBA 820M AL7: PINOUT NOJFU.

t

#

z

SCHOTTKY DIODE, VF

AIOMIAIAL VALUE

5.

TEST JIG AND 5 ET

SET CHAIVAIEL JELECT FOR CH.2. DISCONNECT SPEAKER.

TEST SWIT%H

,

GENERATOR

HAY

VARY.

UP

FOR CALIBRATION 6 VOLTAGE READINGJ,

U4

TO AN LM317K TTNE

.-

-

0.1 JO 0.3V.

AS

4-

I

4.

ALL

TEST VOLTAGCS AND CURRENTS: LIO%

3.

-

-

LAST USED' C43,CR8,J4,83,R44,55,

NOT

USED:

CI,C18,CZI,C22)C33-C41,CRI,Q2,

R37,

R47)

R48

U5,

VR3

R2,R13,R27,

R30-R35,

I

WLEM

O~WlSE

OlYllMOHS

IRE

TWIINCEIAIE

FAA-

DE~UB

Ut

xxxz

YATEIlAL

FlMSH

WECIFIW

*1

INCHES

MLES

*

OPTIONS AND MNEMONICS ARE EAPLA/NED OAl THE

OPTION LIST, AND ON THE OPTIOAI DETAIL

2.

CAP.

VALUES ARE JHOWN: MICROFARADS/UOLTS.

I.

ALL

RESISTORS ARE CARBON

NOTES: (UNLESS OTHERWISE SPECIFIED)

cmcl

mr

-

--

DRAW

CHECKED

APPROVALS

NElLSOm

DATE

12-9-85

SCHEMATIC

USER

5T.4

NLM,1/4

DIAGAAM,

T/OM

SHEET:

WATT,+S%.

PHASE

(CC

-40)

A

ZZ

-

DO NOT

SCALE

L

4

DRAWlNO

SCALE SHEET

Page 27

Assembly Diagram,

P.C.B. CC40/45

Layout

Page 28

Page 29

E

OPTION

CC-45 ONLY

-RHC

(*M)

OPTION

MS6

OPTION (FOR

CC-45 ONLY

J1)

CONNECTION

VI

OPTION

J4

XLR-5-32 A5F

P4

(*B)

i

i

i

1

SD1427-00

Schematic Diagram,

3

Pl~ase

User Stations,

2

of

Sheet

Page

2

29

Page 30

Page 31

Page 32

#W

RIV.

REVlSlONS

DCIOlWmOU

OAn

A??noWO

_

BLUE

9"

I@P

DETAIL

3

1

A

DETAIL

B

>

A

REV/JED

PER

2

ECO

/266

REQD

7.5084

2.

I.

FOR

SEl

PC

ITEM

17fI8

PART

SEPARATE

9020-

ARE

NUMBERS

TW/STED

PARTS

/787-OCd

WIES.

oL

O€SCR/P7'ION

'

L/S

T

SEE

DETAIL

B

Page 33

MISTED PAlR

GRN

9'

MISTED PAlR

(PIN

MISTED PAlR

2)

I

(PIN

sd

fit

(PIN

3)

1)

DETAIL

A

II

SEE

DETAIL

A

SEE

DETAIL

B

Loading...

Loading...