92RC61000

Jeep YJ 2” Body Lift

Thank you for choosing Rough Country for all your suspension needs.

This body lift fits both manual and Automatic equipped vehicles!!!

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassembly and reassembly procedures as well as post install ation checks must be known. Attempts to

install this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read the instructions before beginning the installation. Check the kit hardware against the Kit Contents shown.

Be sure you have all needed parts and know where they go. If there are any questions about the installation or installation steps call our tech line at 800-222-7023.

As a general rule, the taller a vehicle is, the easier it will roll. Offset, as much as possible, what is lost in rollover resistance by increasing tire track width. In other words, go "wide" as you go "tall". Many sportsmen remove their mud tires

after hunting season and install ones more appropriate for street driving; always use as wide a tire and wh eel combination as possible to enhance vehicle stability.

Seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur. Generally, braking performance and capability are decreased when significantly larger/heavier tires and wheels are used. Take

this into consideration while driving.

height over the intended height of the Rough Country product purchased. Mixing component brands is not recom mended. Rough Country makes no claims regarding lifting devices and excludes any and all i mplied claims. We will not

be responsible for any product that is altered.

If you have any questions concerning the design, function, and/or correct use of our products please contact one of our

customer service representatives us at 800-222-7023.

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the

inside of the windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoever is oper-

ating the vehicle of its unique handling characteristics.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation instructions on

to the vehicle owner for review. These instructions should be kept in the vehicle for its service life.

Prior to beginning this installation it is always good to use a penetrating oil and spray all body mount hardware

that will be removed. Typically the stock body bushings will need to be checked to ensure they are in good condition. If the stock body bushings are cracked or deteriorated they must be replaced. This should be performed

as the body lift is installed. Failure to perform this maintenance could jeopardize the operating safety of the vehicle.

Refer to last page of this Instruction sheet for Automatic transmission bracket installation.

PRODUCT USE INFORMATION

Do not add, alter, or fabricate any factory or after-market parts to increase vehicle

NOTICE TO DEALER AND VEHICLE OWNER

IMPORTANT PRE—INSTALLATION INSTRUCTIONS

Tools Needed:

Floor Jack

Jack Stands

Wood Blocks

3/8” Socket / Wrench

7/16” Socket / Wrench

1/2” Socket / Wrench

5/8” Socket / Wrench

3/4” Socket / Wrench

Drill Motor

1/4” Drill Bit

11/32” Drill Bit

Hammer

Penetrating Oil

Phillips Screwdriver

Flat Screwdriver

7mm Socket / Wrench

8mm Socket / Wrench

13mm Socket / Wrench

16mm Socket / Wrench

19mm Socket / Wrench

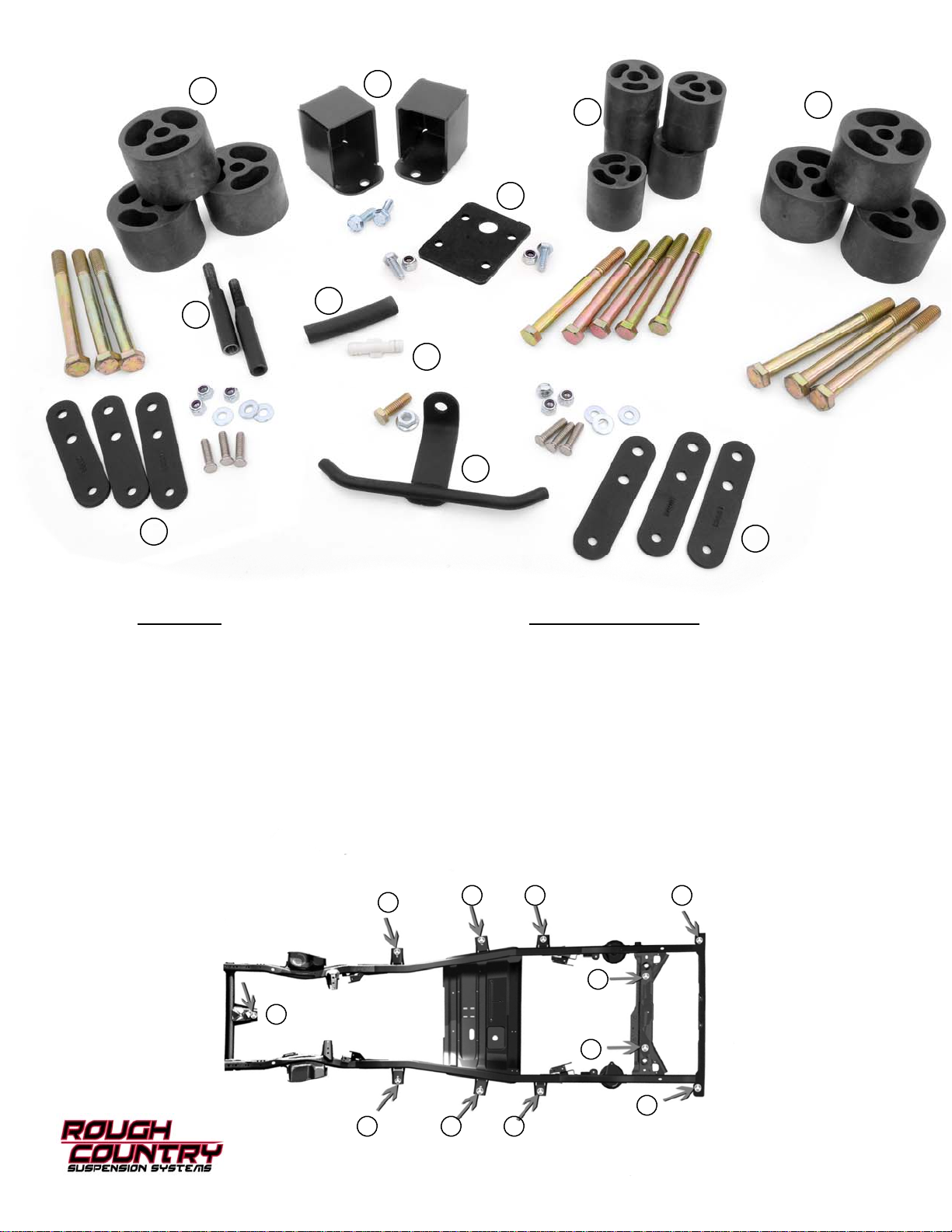

A

D

B

A

I

E

G

F

H

C

Kit Includes:

6-2” x 3” Diameter Body Pucks (A)

5-2” x 2” Diameter Body Puck (B)

6-Radiator Shroud Drop Brackets (C)

2-Radiator Core Support Brackets (D)

2-Shifter Ext Brackets (E)

(1 for manual shifter and 1 for 4wd)

1-Brake Booster Hose Coupler (F)

1-3” Brake Booster Extension Hose (G)

1-Exhaust Bracket (H)

1-Auto Trans Bracket (I)

C

Kit Hardware Breakdown:

RC610Bag1:

6-1/2” x 5 1/2” Bolt

5-7/16” x 4 1/2” Bolt

6-1/4” x 1” Self Clinch Stud

6-1/4” Lock Nut

6-1/4” Flat Washer

2-5/16” Self Tapping Bolt

1-5/16” x 1” Bolt

1-5/16” Flange Lock nut

1668Bag4: For Auto Trans Brkt

2-1/4” x 3/4” Bolts

2-1/4” Lock Nuts

2

1

DIAGRAM 1

1 1

1

1 1

2

2

2

2

INSTALLATION INSTRUCTIONS

1. Disconnect the negative battery cable using 1/2 wrench.

2. Remove plastic jeep cover from front of vehicle using 3/8 wrench and metal plate that also hold brake line.

3. Disconnect air intake from air filter housing and from throttle body. Depending on year remove power steering reservoir from fan shroud. Use a 13mm wrench.

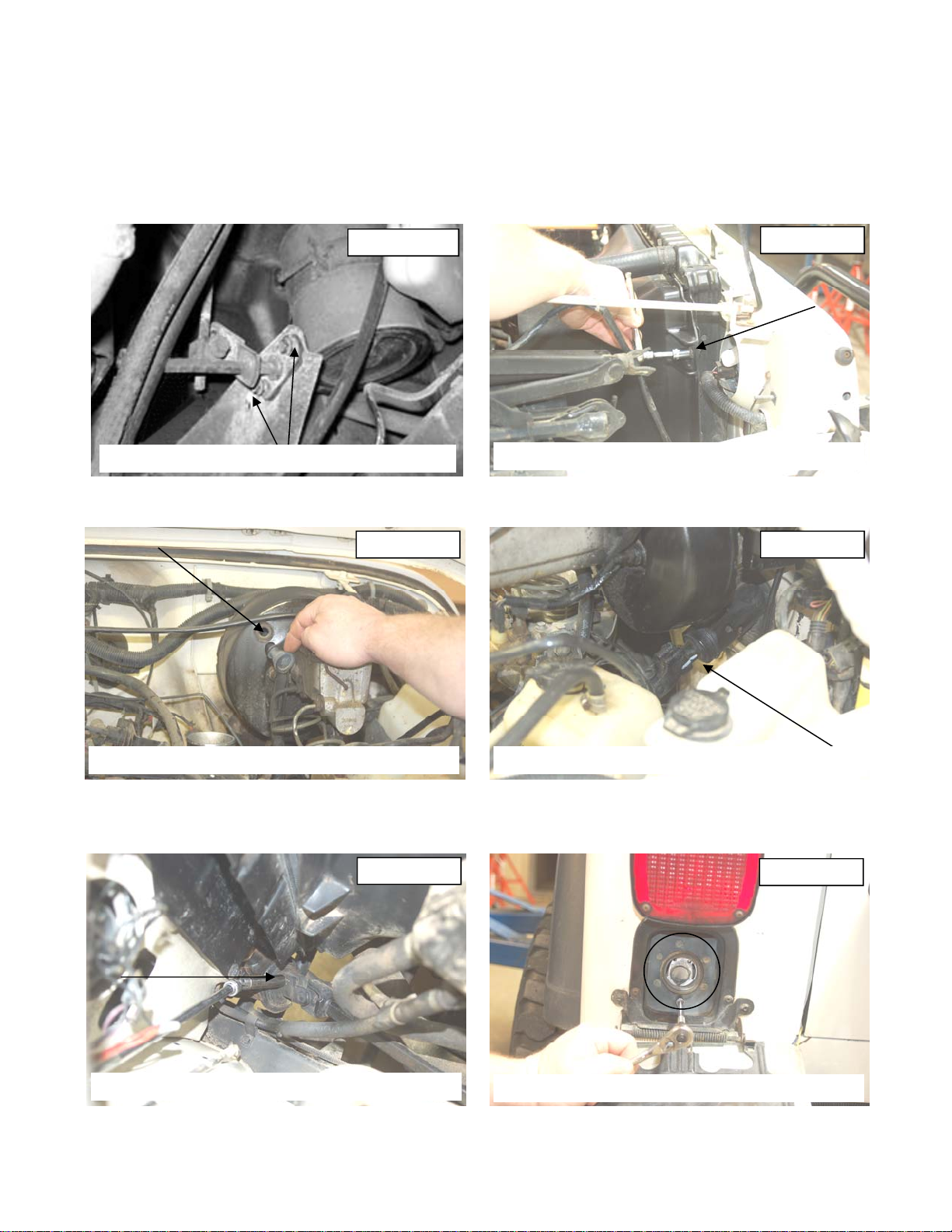

4. (AUTO TRANSMISSION ONLY) Remove the linkage on the frame to allow the body to be moved up by removing

the two bolts and remove the cotter pin securing it to the engine bracket. Allowing the shifter cross shaft to hang

freely. Retain hardware for reuse. See Photo 1

5. Remove the 4 bolts from radiator shroud using 13mm socket. See Photo 2.

Photo 1

AUTO ONLY—REMOVE SHIFTER BRACKET

Remove the radiator shroud bolts

Photo 2

6. Unplug vacuum hose from brake booster. See Photo 3.

7. Mark the steering shaft and take apart using 1/2 socket on both upper and lower parts of shaft. See Photo 4 & 5.

Photo 3 Photo 4

Remove the booster line Mark the steering shaft

8. Remove hard brake lines from hold down clips on frame just below master cylinder.

9. Remove gas cap and remove the bolts that attach the fuel filler hose to the plastic fuel filler bezel using a 8mm

socket. See Photo 6. Be sure to push the filler hose back in the hole to avoid it hanging when jacking up the body.

Photo 5

Remove the steering shaft bolts

Remove the filler neck from the body

Photo 6

10. Move parking brake cable over exhaust hanger to allow the body to be jacked. See Photo 7.

11. Using a 3/4 wrench to loosen the lock nut securing the manual shifter shift knob on shifter and 4x4 lever. Remove

both knobs. See Photo 8.

Photo 7

Reposition the E-brake cable over muffler mount

Remove shifter knobs

12. Remove shifter boot bolts using 8mm socket. See Photo 9.

13. Then remove screws holding in shifter bezel. See Photo 10. Pull bezel up past carpet.

Photo 9

Photo 8

Photo 10

Remove outer boot

Remove inner boot

14. Loosen but do not remove the 11 body bolts. One is under center of grill, three are under doors, two above rear axle

and two at each rear corner using a 5/8 socket. See Diagram 1 on Page 2.

15. Only remove bolts from one side at a time. Front center bolt must be remove for both sides. Using floor jack or jack

stand and a wood block slowly raise body from frame only enough to install body puck. Watch for wires, brake

lines and cables. Make sure nothing is binding. It may be necessary to unclip brake lines to allow for travel.

16. The 2” x 3” body puck go on the three body mounts under doors. See Diagram 1 on Page 2. Install the 3 supplied

1/2” x5 1/2” bolts. See Photo 11. Do not tighten at this time.

17. The smaller 2” x 2” body puck will go in the other 5 body mounts as shown in Diagram 1 on Page 2. See Photo 12.

Install the supplied 7/16” x4 1/2” bolts. Do not tighten at this time.

Photo 11

Install spacers Location 1( See Diagram 1)

Install spacers Location 2( See Diagram 1)

Photo 12

18. Repeat installation of the body pucks for opposite side.

19. Install the new front bump stop extension under the bump stop on radiator core support. See Photo 13. Use the

bracket as a template an mark and drill a 1/4” hole in frame. Secure using the supplied 5/16” self tapping bolt. Snug

using a 13mm socket. Do not over tighten the self tapping bolt. Repeat for opposite side.

20. After all body pucks and bump stop extension are in tighten all 1/2 bolts using 19mm and 16mm for 7/16 bolts.

21. Remove plastic bezel under fuel filler tube and pull filler neck out. Loosen the clamps on hose s at tank using a 5/16”

socket. Pull the hoses off of tank only enough to have slack in hose and be able to re-clamp. See Photo 14 & 15.

Install radiator core brackets

Photo 13

Move plastic cover

Photo 14

22. Test fit to make sure filler tube can be reattached to body. Tighten hose clamps and attach filler tube back to body

using stock hardware and use a 8mm socket to tighten. Reinstall plastic bezel trimming maybe needed to make fit

around fuel filler hose.

23. Install steering shaft with marks made earlier and use stock hardware and 1/2 socket to tighten. See Photo 16.

Note: The steering shaft may have to removed in order to free the slip joint in the shaft.

After the shaft is ex-

tended, reinstall shaft.

Photo 15

Photo 16

Loosen clamps and pull hose to allow slack

Reinstall steering shaft.

24. Make sure vacuum lines are clear from the steering shaft. Re-position the lines if necessary.

25. Remove vacuum hose end that installs in the brake booster.

26. Install the supplied rubber extension on the stock brake booster end.

27. Install the supplied coupler in the rubber extension and install the assembly on the stock line. See Photo 17.

28. Reinstall hose on the brake booster. See Photo 18.

Photo 17 Photo 18

Install stock end on hose Install the coupler on new hose and stock hose

29. Install the .25” self tapping bolt into supplied radiator drop brackets using a deep well 7mm socket and hammer, by

striking the bracket and pushing it on the stud. See Photo 19. Make sure stud is secured into bracket.

30. Using a 7/16 socket remove the six bolts that hold radiator on. See Photo 20. Note: Use caution when removing

the radiator mounting bolts to not allow the radiator to fall and possibly damage the radiator or surrounding

components.

Photo 19 Photo 20

Install 1/2” studs

Remove the radiator bolts

31. Remove all 6 body clip from core support and install one on each of the radiator drop brackets. The clips will install

in the middle hole on the radiator brackets. See Photo 21 & 22.

Photo 21

Photo 22

Remove the stock clips Install the clips on the supplied brackets

32. Install radiator support drop brackets onto core support using the supplied washer 1/4” washers and 1/4” nuts.

Tighten bolts using 7/16” socket and make sure brackets are hanging straight down. See Photo 23.

33. Install radiator using stock hardware and use a 7/16” socket to tighten. See Photo 24.

Photo 23

Photo 24

Make sure all brackets are straight

Reinstall the radiator shroud

34. Reinstall fan shroud and power steering reservoir using stock hardware. Use a 1/2” socket to tighten bolts. Make

sure fan spins without contacting fan shroud.

35. Reinstall diff vent hose on the middle radiator mount.

36. Reinstall air filter housing if removed and battery cable. Install plastic jeep cover using stock hardware

37. Check operation of both shift levers. If there is contact with floor, slightly trim on the floor pan in the area the shifter is

hitting and check operation again. Do not over-trim the area.

38. Reinstall both inner and outer shift boots checking operation while installing them. Inner boot may need to be

trimmed to allow full throw of the shifter. Secure with stock hardware and use screwdriver on inner and 8mm socket

on outer boot to tighten.

39. (For Manual Shift) Install shifter rod extension using a 7/16 wrench. See Photo 25. Install shift knobs using 3/4

wrench to set and tighten knob. See Photo 26.

Photo 25 Photo 26

Install the shifter extensions Install 4wd selector knob

40. Bend parking brake cable bracket down located above driveshaft to allow slack. See Photo 27.

41. Remove rubber exhaust grommet from exhaust hanger.

42. Using a 3/8” socket remove bolt from exhaust hanger above muffler.

43. Enlarge the existing hole with a 11/32” drill bit. See Photo 28.

Photo 27 Photo 28

Bend bracket down to allow for slack

Enlarge hole

44. Install the new exhaust hanger drop bracket using the supplied 5/16” x 1” bolt and lock nut Tighten using a 13mm

wrench to tighten. Install rubber exhaust grommet onto new bracket and reinstall muffler. See Photo 29 & 30.

45. (AUTO TRANSMISSION ONLY) Proceed to installation instructions for automatic shifter bracket

46. Re-Check all fasteners / components to make sure nothing is binding or in the way of moving parts.

Photo 29 Photo 30

Install new muffler bracket

Reinstall the muffler grommets

AUTOMATIC SHIFTER BRACKET INSTALLATION

(FOR VEHICLE EQUIPPED WITH AUTOMATIC TRANSMISSION ONLY)

1. Using the supplied shifter location bracket, mount to the

stock shift linkage bracket with the supplied 1/4” hardware and tighten. Note: The bolts will point toward the

engine.

2. Mount the assembly in the stock location on the engine

bracket and secure with stock cotter pin.

3. Mount the assembly in place on the original frame location

with the stock hardware and tighten. See Photo 1.

Photo 1

POST INSTALLATION INSTRUCTIONS

1. Check all fasteners for proper torque. Check to ensure there is adequate clearance between all rotating, mobile,

fixed and heated members. Check steering gear for interference and proper working order. Test brakes.

2. Check to ensure metal brake lines have sufficient slack to eliminate interference and maintain proper working orde r.

Failure to perform inspections may result in component failure.

3. Readjust headlights to proper settings.

MAINTENANCE INFORMATION

It is the buyers ultimate responsibility to have all bolts/nuts checked for tightness after the first 100 miles and then

every 1000 miles. A qualified professional mechanic must inspect wheel alignment steering system, suspension and

driveline systems at least every 3000 miles.

Thank you for choosing Rough Country for all your suspension needs.

Loading...

Loading...