Rough Country PERF679 User Manual

9262400

JEEP JK 2 1/2” SUSPENSION KIT

w/SHOCK RELOCATION BRACKETS

Thank you for choosing Rough Country for all your suspension needs.

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the kit content list on this page and

the kit layout on the back page. Be sure you have all needed parts and know where they go. Also please review tools

needed list and make sure you have needed tools. As a general rule, the taller a vehicle is, the easier it will roll. Seat

belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered.

This system was developed to provide a level stance to the Jeep after it is lifted. You will note that the front lift is 2.5”

and the rear lift is 2”. This is intentional and is the look most often requested. Also you will note that this lift does not

modify the front or rear track bar or its mounting points. This will result in what is generally considered an insignificant

shift in both the front and rear axle of approx 1/4 of an inch. Rough Country offers an optional rear track bar bracket to

address this. Please call your nearest Rough Country dealer to inquire.

This suspension system was developed using a 285/75R17” tire with factory wheels. If bigger/wider tire are used with the

factory wheels or factory offset wheels you must carefully check the clearance during turning between the tires and the

lower control arm and the front sway bar link before driving. If you have any questions concerning the design, function,

and correct use of our products contact us at 800-222-7023.

IMPORTANT NOTES : The draglink must be adjusted to the center steering wheel BEFORE the vehicle is driven.

Failure to do so will cause a computer error in the Jeep’s traction control system.

On Automatic equipped vehicles; due to use of an oversize driveshaft from the factory and inadequate

factory clearance it may be possible for the front driveshaft to come in to contact with the automatic transmission pan tearing the factory boot and rubbing on the shaft. Generally this occurs during heavy articulation when

front sway bar links are disconnected and longer shocks are installed. If this is found to occur, the proper procedure would be to replace the oversize factory shaft with an aftermarket smaller diameter shaft to increase

clearance between the transmission and front driveshaft. Rough Country does offer this driveshaft if needed.

Kit Contents:

2— Front Coil Springs

2— Front Brake Line Brkts

2— Rear Coil Springs

2— Front Shock Extension

2— Rear Shock Extension

2—Rr Brake Line Ext Brkts

Poly Bags Containing:

4-10mm x 80mm Bolts

4-10mm flat washers

2-Rear spacer retainers

2-12mm nuts

2-12mm x 65mm bolt

2-5/16 x 3/4” bolt

2-5/16” nuts

4-5/16” washers

4-1/4” x 1” Bolts

4-1/4” Lock Nuts

8-1/4” Flat washers

Rear Shock

Extender

Bracket (2)

Front Shock Bracket(2)

Front And Rear Brake Line Brkts

Rear Coils (2)

Front Coils (2)

Tools Needed:

10mm Wrench16mm Wrench

16mm Socket18mm Wrench18mm Socket19mm Deep Well SocketJack

Jack Stands

1/2” Socket/ Wrench

7/16” Socket / Wrench

Torque Specs:

Size Grade 5 Grade 8

5/16” 15 ft/lbs 20 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

19mm Deep Well SocketJack

Jack Stands

1/2” Socket/ Wrench

7/16” Socket / Wrench

Class 8.8 Class 10.9

10MM 32ft/lbs 45ft/lbs

12MM 55ft/lbs 75ft/lbs

FRONT INSTALLATION INSTRUCTIONS

1. Chock the rear wheels and jack up the front of the vehicle and support the vehicle with jack stands so that the front

wheels are off the ground.

2. Using a 19mm deep well socket remove the front tires/wheels,

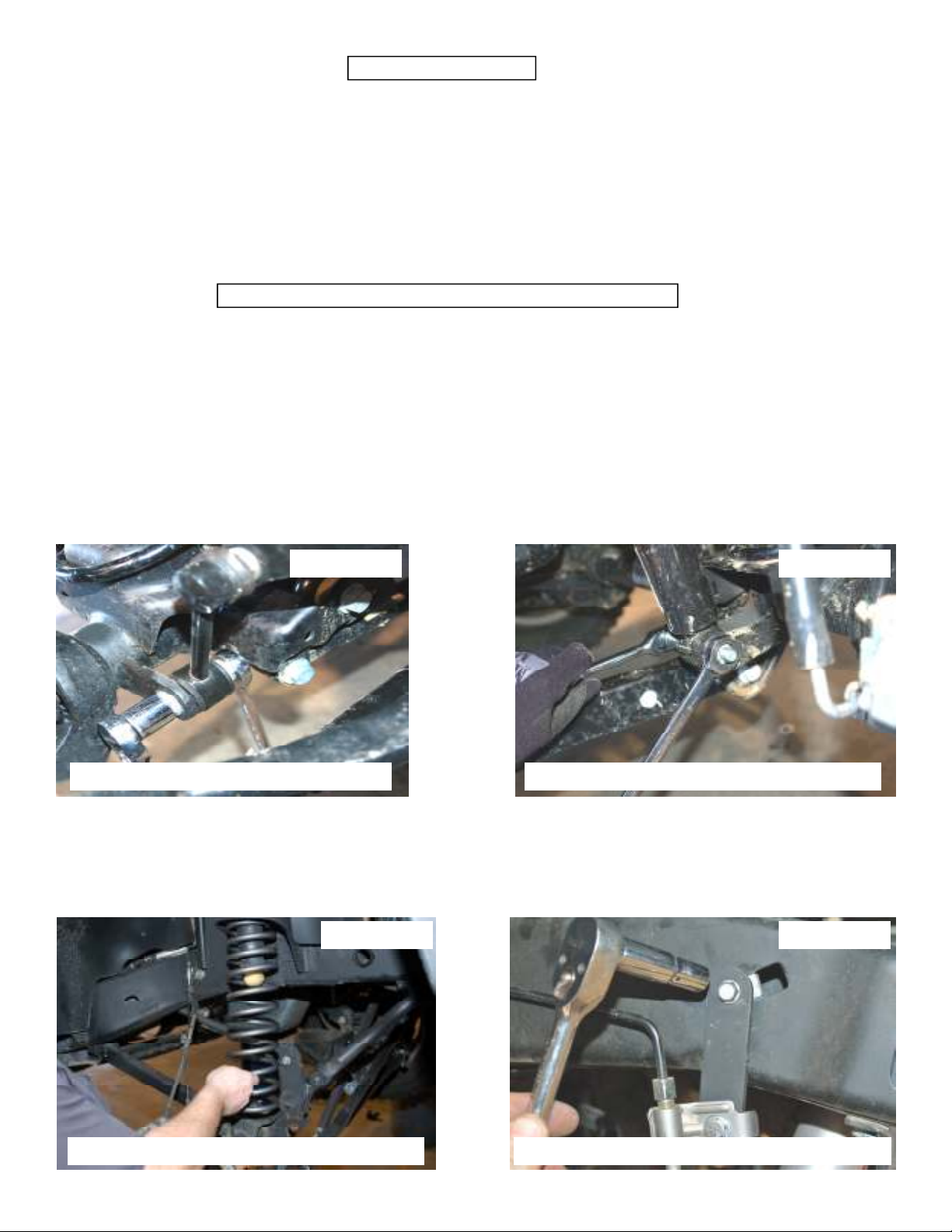

3. Using a 18mm socket and wrench remove the bottom sway bar bolts. Retain hardware for later use. See Photo 1

4. Using a 18mm socket and wrench remove the lower shock bolt. See Photo 2. Retain the lower hardware for reuse.

Photo 1 Photo 2

Remove the sway bar link from the axle Remove the shock from the axle

5. Using a 10MM socket, remove the brake line bracket from the stock location.

6. Push down on the axle to allow room for the coils to be removed. Remove coil springs, and factory spring isolator.

7. Install the coil spring over the factory bump stop with the factory isolator as shown See Photo 3.

8. Be sure to rotate the spring until the pigtail hits the stop.

9. Install the brake line extension bracket with the stock hardware to the frame. Install the stock line to the bracket with

the supplied 1/4” x 1’ bolt, washers and nut. See Photo 4.

Photo 4 Photo 3

Install the new coil spring Install the brake line bracket on frame and line

Loading...

Loading...