928931000

Brake Line Instruction Sheet

Any work pertaining to the brake line system on the installed vehicle must be performed by a certified techni-

Prior to installation, carefully compare the new hose to the original hose to ensure proper fitment.

Warning: Brake Fluid contains Polyglycol Ethers and Polyglycols. Avoid contact with eyes and wash hands

thoroughly after handling. If brake fluid comes in contact with eyes, flush eyes with water for 15 minutes. Get

medical attention if irritation persists. If taken internally, induce vomiting and get medical attention immediately.

We will be happy to answer any question concerning the design, function and correct use of our products.

Any vehicle equipped with any Rough Country product must have the “Warning to Driver” decal installed on the sun visor

or dash. The decal is to act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics.

1. Inspect the brake system and repair / replace components as necessary.

2. Remove the stock hoses. On disc brake applications be sure the stock crush washers are removed as they will not

be reused. New crush washers are furnished with this kit.

3. Thoroughly clean and inspect all mounting surfaces.

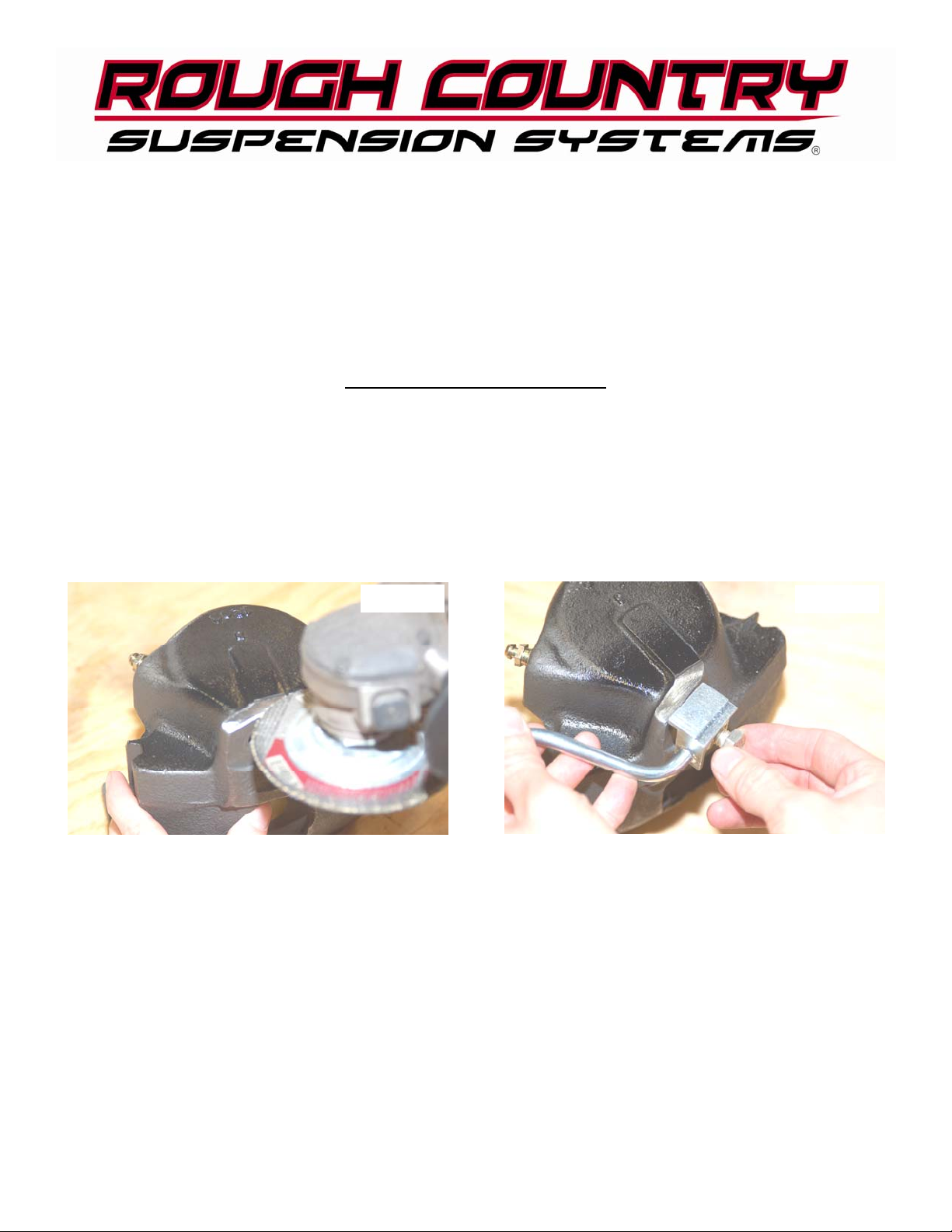

4. It may be necessary on some vehicles especially those equipped with aftermarket calipers to lightly dress the caliper

in order for the brake line to be installed. See Photo 1 & 2.

Thank you for choosing Rough Country for your suspension needs.

cian. A factory manual is recommended for proper tightening and installation.

Notice to Dealer and Vehicle Owner

INSTALLATION INSTRUCTIONS

Photo 1

Photo 2

5. Install the new Rough Country hoses. Route the new hoses in the same manner and use the stock mounting hardware. Be sure to use the new supplied crush washers. NOTE: Some brake lines fit multiple applications and may

include a threaded plug for the brake line. Install this threaded plug in the brake line if included and needed.

6. With the suspension supporting the vehicle, tires and wheels installed and vehi cle on the ground, cycle the steering

lock to lock and check for adequate clearance and hose length. The hose length can al so be checked by expanding

the suspension at full droop.

On some disc brake applications, it may be necessary to slightly bend the metal brake line leader where it comes off the

caliper block in order to gain clearance. Likewise, a slight amount of modification may be needed at the upper mounting

tab as well. The need to bending and moving these brake lines depends primarily on tire size and rim offset.

7. Bleed the air from the brake system as instructed by the factory service manual. Avoid getting the brake fluid on

painted surfaces.

Warning: It is critical that the brake hoses do not come in contact with any other component (s) at any time during turning and during the suspensions entire compression / extension cycle. If a clearance problem arises, im-

mediately correct the clearance problem or chafing and failure may occur.

Tech Assistance……...731-285-9000

Loading...

Loading...