92187500

Nissan Titan

6” Front & 4” Rear Suspension Kit

Thank you for choosing Rough Country for all your suspension needs.

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the kit contents on the next page.

Be sure you have all needed parts and know where they go. Also please review tools needed list and make sure you

have needed tools.

As a general rule, the taller a vehicle is, the easier it will roll. We strongly recommend, because of rollover possibility, that

seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur.

Generally, braking performance and capability are decreased when larger/heavier tires and wheels are used. Take this

into consideration while driving. Do not add, alter, or fabricate any factory or after-market parts to increase vehicle height

over the intended height of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered. We will be happy to answer any questions concerning the design, function, and

correct use of our products by calling our toll free number @ 800-222-7023.

Prior to installation, carefully inspect the vehicle's steering and driveline systems paying close attention to the tie rod

ends, ball joints, and wheel bearing preload. Additionally check the steering to frame and suspension to frame attaching

points for stress cracks. The overall vehicle must be in excellent working condition. Repair or replace all warn or damaged parts.

This kit is packaged as a leveling kit—raising the front 6” and the rear 4”.

On 2011 & 2012 models

joint. As a stock un-lifted vehicle, this oversize shaft coupled with the lack of adequate clearance with the floor

pan from the factory, may cause the shaft to contact with the floor pan. This kit does not minimize the clearance

in this area but is usually recognized with the addition of larger tires and aggressive power-train torque both in

on road and off road situations. If contact does occur, modification of the floor pan may be needed to gain clearance on the oversize driveshaft. This is accomplished by creating more space between the driveshaft and the

floor pan by manipulation of the body pan directly above and to the side of the u-joint on the driveshaft.

Due to differences in manufacturing, dimension and inflated measurements, tire and wheel combinations should be test

fit prior to installation. For this application we recommend a 17” or larger wheel not to exceed 8” in width with a minimum

backspacing of 4.5” to a maximum of 5”, a 9” wide wheel with 5” of backspacing is acceptable. Additionally a quality tire

of radial design is recommended, not exceeding 35” tall and 13.0” wide is recommended. Please note that use of a 35” x

12.5” tire may require modification to the front valance. . On some 2004-2007 models, not all 17” wheels will accommodate the larger brake calipers. Please check with the dealer for more information on fitment. On 2008 Models the use of

a 18” wheel or larger is mandatory due to the brake caliper size.

Install the supplied “Warning to Driver” decal installed on the inside of the windshield or on the vehicle’s dash. The decal

should act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics.

We hope installing your Rough Country lift kit is a positive experience. Please note that variations in construction and assembly in the vehicle manufacturing process will virtually ensure that some parts may seem difficult

to install. Additionally, the current trend in manufacturing of vehicles results in a frame that is highly flexible

and may shift slightly on disassembly prior to installation. The use of pry bars and tapered punches for alignment is considered normal and usually does not indicate a faulty product. However, if you are uncertain about

some aspect of the installation process, please feel free to call our tech support department at 800-222-7023. We

do not recommend that you modify the Rough Country parts in any way as this will void any warranty expressed or implied.

PRODUCT USE INFORMATION

, the vehicle was equipped from the factory with a 4 1/2” diameter driveshaft at the u-

NOTICE TO DEALER AND VEHICLE OWNER

KIT CONTENTS

Please confirm that you have all the needed parts and know where they go prior to beginning installation.

1875 Box1

Front Cross Member

Rear Cross Member

Front Sway Bar Links (2)

1875 Box2

Dr Knuckle

Pass Knuckle

Kicker Bar (2)

1875 Box3

Sway Bar Spacer (2)

Fr Brake Line Bracket (2)

Front Skid Plate

Front Strut Spacer (2)

Driver Side Bump Stop Spacer

Pass Side Bump Stop Spacer

Rear Brake Line Bracket

Rear E Brake Line Bracket

1875 Box4

Kicker Bar (2)

Rear Shock Absorber (2)

Rear Block (2)

Front Sway Bar Links (2)

9/16” x 2.5” x 12” U-Bolt (4)

Hardware Bags

1875 Bag1

For Front Cross Member

9/16” x 4.5” Bolt (2)

9/16” Nylon Lock Nuts (2)

9/16” Washers (4)

For Front Cross Member—Ctrl Arm Mt

Cam Bolt (2)

Cam Nut (2)

For Front Skid Plate

3/8” x 1” Bolt (4)

For Differential Vent Hose

Differential Vent Hose Ext

Hose Coupler

For Front Brake Line Brkts

Front Brake Line Brkt (2)

3/8” x 1” Bolt (2)

3/8” Nylon Lock Nut (2)

3/8” Washer (4)

For Upr Ball Joint and Tie Rod Ends

Cotter Pin (4)

1875 Bag4

For Rear Cross Member

9/16” x 4.5” Bolt (2)

9/16” Nylon Lock Nuts (3)

9/16” Washers (6)

For Rear Kicker Bracket

1/2” X 1 1/2” Bolt (2)

1/2” x 3.5” Bolt (2)

1/2” Nylon Lock Nuts (4)

1/2” Washers (8)

For Kicker Bracket Eye

Poly 1/2 Bushing (4)

Sleeve (2)

For Rear Kicker Bracket

5/8” x 2.5” Bolt (2)

5/8” Nylon Lock Nuts (2)

5/8” Washers (4)

For Rear Cross Member—Ctrl Arm Mt

Cam Bolt (2)

Cam Nut (2)

1875 Bag5

For Fr Sway Bar Links

4-12mm x 65mm Bolts

4-12mm Flange Locknuts

4-12mm Flat Washers

4-12mm Sleeves

For Bump Stop Exts.

5/16” x 1” Bolt (2)

5/16” Nylon Lock Nut (2)

5/16” Washer (4)

9/16 U-Bolt Bag

9/16” Lock Nut (8)

9/16” Washer (8)

Strut Spacer Hardware Bag

3/8” x1.25” Self Clinch Blt (6)

3/8” Nut (6)

3/8” Lock Washer (6)

1875 Bag2

For Rear Brake Line Brkt

5/16” x 1.25” Bolt (2)

5/16” Nylon Lock Nut (2)

5/16” Washer (4)

8mm x 25mm Bolt (2)

HARDWARE KEY

8mm Washer (2)

For Rear E Brake Brkt

5/16” x .75” Bolt (2)

12mm

8 mm

5/16” Nylon Lock Nut (2)

5/16” Washer (4)

1875 Bag 3—Inst. Sheet Bag

Instruction Sheet

5/8”

9/16”

1/2”

3/8”

5/16”

Warning to Driver Decal

Shock Decal (2)

4”

3”

2”

1”

U Bolt (4)

Lift Block (2)

Front Skid Plate

Brake Line Brkt

E Brake Line Brkt

Rear Cross Member

Kicker Brace (2)

Rear Shock (2)

Vent Tube Ext

Pass Knuckle

Strut Ext (2)

Pass Bump Stop Ext

Brake Line Brkt (2)

Torque Specs:

Size Grade 5 Grade 8

5/16” 15 ft/lbs 20 ft/lbs

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

5/8” 135 ft/lbs 175 ft/lbs

Class 8.8 Class 10.9

8MM 18ft/lbs 23 ft/lbs

12MM 55ft/lbs 75ft/lbs

Front Cross Member

Sway Bar Spacer (2

Tools Needed:

Floor jack

Jack stands

Ratchet

13/16” socket

5mm Socket

10mm Socket

12mm Socket

14mm Socket

15mm Socket

Driver Knuckle

Driver Bump Stop Ext

Sway Bar Link (2)

)

17mm Socket

19mm Socket

21mm Socket

22mm Socket

30mm Socket

32mm Socket

Pliers

Hammer

FRONT INSTALLATION INSTRUCTIONS

1. Jack up the front of the vehicle and support the vehicle with jack stands, so that the front wheels are off the ground

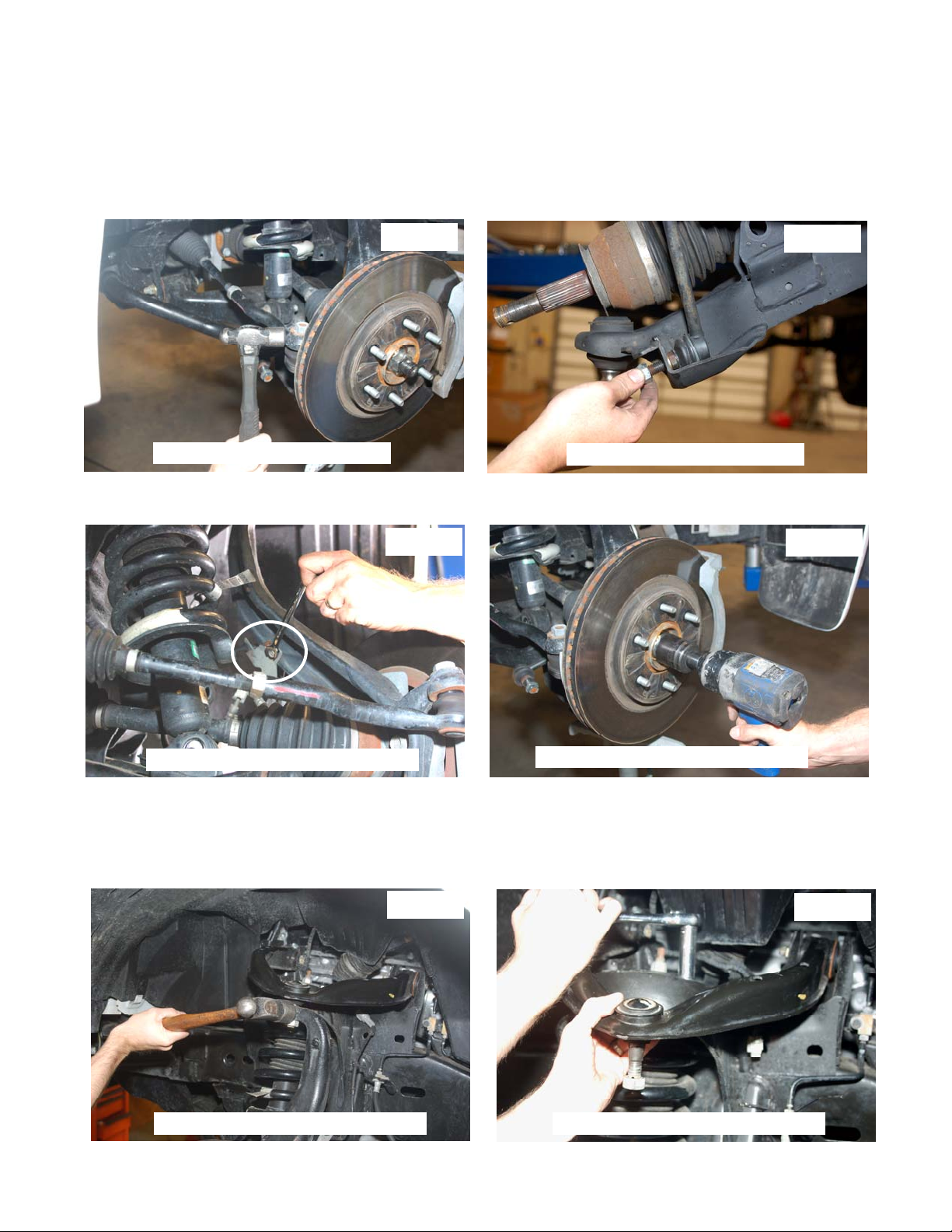

2. Using 13/16” socket remove the front tires/wheels.

3. Using 22mm socket remove the nut from the steering linkage. Usi ng a hammer hit on the side of the knuckle as

shown, and remove the linkage from the knuckle. Push linkage forward to make room for installation. Retain factory

hardware See Photo 1.

4. Using a 17mm wrench, remove the stock sway bar link from the sway bar and the lower control arm, allowing the

sway bar to drop. See Photo 2.

Photo 1

Remove Steering Linkage

Remove Sway Bar Link

5. Using a 10mm wrench remove the brake line bracket from the back side of the knuckle. See Photo 3.

6. Remove the axle nut using a 30mm socket as shown in Photo 4. (4WD ONLY)

Photo 3

Photo 2

Photo 4

Remove Brake Line Brkt From Knuckle

Remove Brake Line Brkt From Knuckle

7. Remove cotter pin from the upper control arm ball joint nut. Place jack stand under the knu ckle for sup port. Using 22

mm socket remove nut. Using a hammer hit the knuckle as shown to allow the ball joint to separate from the upper

control arm See Photo 5. Do not allow the knuckle to pull out far enough that it pulls the shaft out of the differential.

8. Using a 14mm socket, remove the strut nuts on the upper strut tower that holds the assemb ly in place. See Photo 6.

One nut can be left on the upper bolts to hold the strut in place.

Photo 5

Separate Ball Joint From Knuckle Remove Strut Nuts from Tower

Photo 6

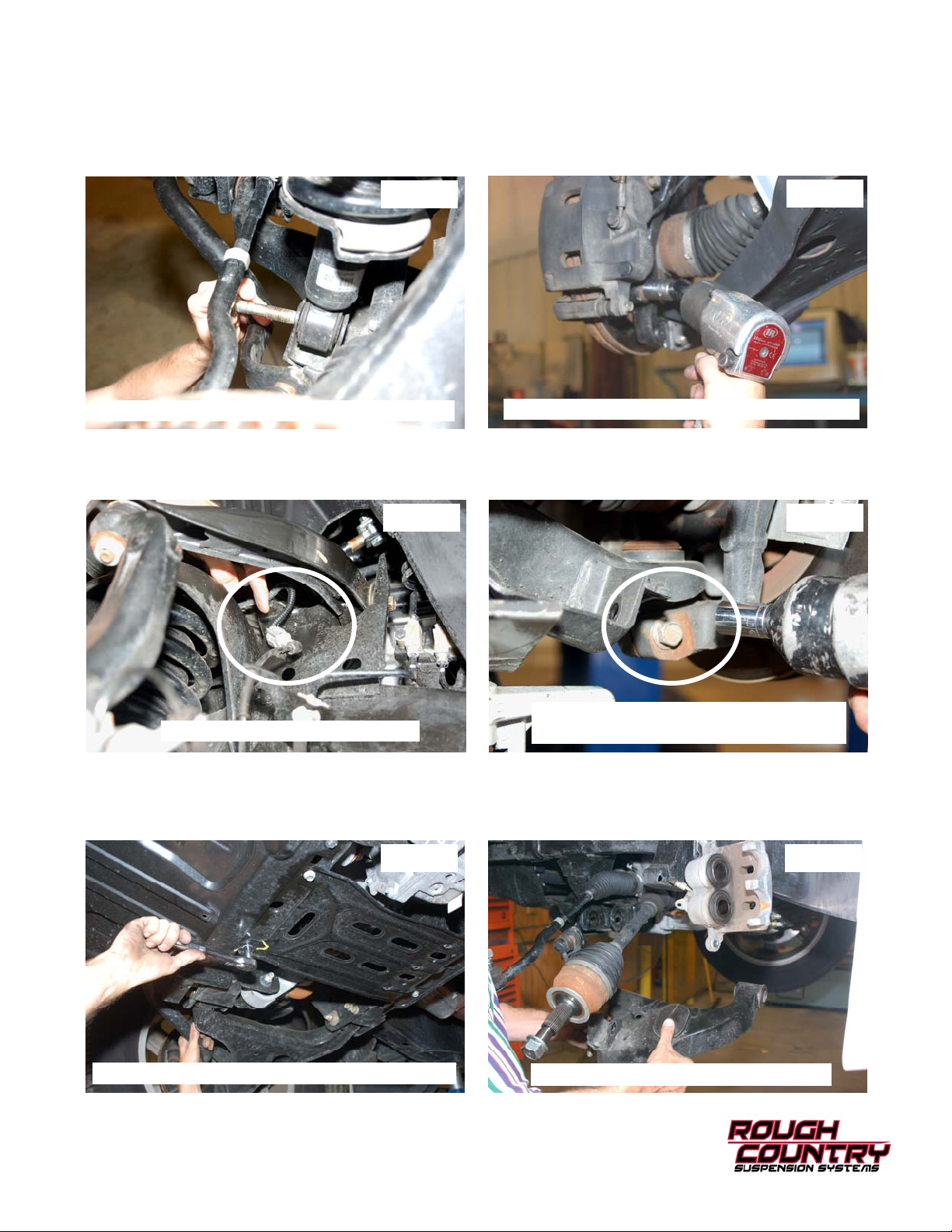

9. Using a 19mm socket and wrench, remove the strut bolt from the lower control arm an d remove the strut assembly

from the vehicle. Retain the factory lower bolt for reassembly. Note the direction of the bolt for reassembly. See

Photo 7.

10. Using a 21mm socket remove the brake caliper assembly from the knuckle/rotor. See Photo 8. Secure the caliper.

Place an alignment mark on CV and Dif Flange for reinstallation. Do not let the caliper hang. Retain the hardware

for reuse.

Photo 7

Remove Lower Strut Nut and Strut Assembly

Remove Lower Strut Nut and Strut Assembly

Photo 8

11. Unplug the ABS wire as shown in Photo 9.

12. Using a 17mm socket, remove the bolt securing the knuckle to the lower ball joint as shown in Photo 10 and remove

the knuckle from the vehicle.

Photo 9 Photo 10

Remove Clinch Bolt on Lower Ball Joint

Disconnect ABS Wire

to Remove Knuckle

13. Remove the factory front skid plate and the lower skid plate from the frame as shown in Photo 11 using a 12mm

wrench. The skid plates will not be reused. The front skid plate must be removed for access to the oil filter or altered

to allow access to oil filter.

14. Remove the lower control arm as shown in Photo 12 using a 19mm socket/wrench.

Photo 11 Photo 12

Remove Front and Lower Skid Plate—if Equipped

Remove Lower Control Arms

15. Mark the front drive shaft orientation, remove front drive

shaft, retaining factory hardware. (4WD ONLY)

16. Using a 15mm remove the front shafts from the

differential as shown in Photo 13. (4WD ONLY). Retain

stock hardware.

17. Support the differential with a floor jack or jack stand

and remove the 2 lower differential bolt on the driver and

passenger side using a 22mm socket and 19mm wrench.

Passenger side differential bolt shown in Photo 14.

Driver shown in Photo 15. Retain the stock hardware for

reuse.(4WD ONLY)

18. With the skid plate removed, remove the cross member

as shown in Photo 16 using a 14mm wrench /socket.

19. Remove rear differential bolt on the driver side using a

19mm wrench. See Photo 17. (4WD ONLY)

Photo 14 Photo 15

Remove Passen-

ger Diff Bolt

Photo 13

Remove Front Drive Shafts

Remove Passenger Diff Bolt Remove Driver Side Diff Bolt

Photo 17 Photo 16

Remove Rear Cross Member

Remove Rear Diff Bolt on Driver Side

20. Remove the differential vent hose from the top of the differential and lower the differential from the vehicle. (4WD

ONLY)

21. Mark 2 1/2” from the center of the upper drivers old differential mounting hole as shown in Photo 18 and 4” from the

side of the frame through the center of the control arm hole as shown in Photo 19. (4WD ONLY)

Trim Driver Side Diff

Mount—Shown from Rear

Looking Forward

Photo 18 Photo 19

Trim Driver Side Diff

Mount—Shown from Rear

Looking Forward

22. Cut the control arm pocket as shown in Photo 20 & Photo 21. Paint and smooth cut area with grinder if needed.

Photo 20 Photo 21

Rear Driver Diff Mount Mod

Rear Driver Diff Mount Mod

23. Install new front cross-member using 9/16x 4 1/2”bolts.See Photo 22. Do not tighten at this time. NOTE: Due to

factory differences in the frame mounting points, it may be necessary to grind the top of the new cross members to

create clearance to slide all the way up in the frame to align the mounting holes. See Photo 23.

Photo 22

Photo 23

Grind if

needed on

Driver and

Passenger

Front Cross Member Installation

Front Cross Member Rear Bolt Installation

24. Install differential using a floor jack or jack stands using stock diff hardware in t he new cross member. Do not tighten

at this time. See Photo 24. (4WD ONLY)

25. Install rear cross-member with two supplied 9/16 x 4 1/2” bolts/washers. Passenger side is shown in Photo 25.

NOTE: Due to factory differences in the frame mounting points, it may be necessary to grind the top of the new

cross members to create clearance to slide all the way up in the frame to align the mounting holes a nd it may be

necessary to grinds down the raised steps on the inside portion of the mounting pockets.

Photo 24 Photo 25

Differential Mount to Front Cross Member Rear Cross Member Installation—Looking From Rear

26. Install supplied 9/16 x 4 “bolts/washers/nuts for rear differential as shown in Photo 26. (4WD ONLY)

27. Aligning to marks made during disassembly reinstall driveshaft using a 14mm wrench to tighten. See Photo 27.

(4WD ONLY)

Photo 26

Rear Cross Member Driver Diff Installation

Re-Install Drive Shaft

Photo 27

28. Install supplied hose and coupler on the stock diff hose and install on the differential. See Photo 28. (4WD ONLY)

29. Install control arm on truck using supplied cam bolts. Make sure all cam blocks off plates are installed with the notch

in same direction. See Photo 29.

Photo 28 Photo 29

Re-Install Diff Vent Hose with Extension

Install Lower Control Arm with Supplied Cam Bolts

30. Remove bump-stop off of control arm using 12mm wrench. Install bump-stop to the new bump-stop ext. (note there

is a left and right bump-stop). Then install to control arm using supplied 5/16 x1” bolts/washers & nuts. Tighten

using13mm wrench. Passenger side shown in Photo 30.

31. At this time tighten all cross-member bolts and differential bolt (4WD ONLY) using 21mm, 22mm and 19mm wrench

per torque specs for bolt size.

32. Remove the stock bolts from the sway bar mount on the frame on the driver and passenger side. Retain the stock

hardware for reuse. Install the supplied sway bar spacers as shown in Photo 31 between the sway bar and the

frame using the factory hardware. Passenger side shown.

Install Bump Stop Extensions

Photo 30

Install Front Sway Bar Spacer

Photo 31

33. Install the supplied sleeves in the sway bar links and install on the sway bar and control arm using 19mm wrench

and the supplied 12mm x 65mm bolts, washer s and flange lock nuts. See Photo 32.

34. Reinstall axle shafts per disassembly markings using 14mm socket. See Photo 33. (4WD ONLY)

Photo 32

Install Supplied

New Front Sway

Bar Links

Re- Install Front Axles

Photo 33

35. Install the kicker brackets on the rear cross-member using the 1/2” x 1” bolts, washers and nuts. See Photo 34.

36. Install bushings and sleeve into rear kicker braces. Install new kicker brace using two supplied 1/2 x 3 1/2” bolts,

washers & nuts. See Photo 35.

Photo 34

Photo 35

Install Kickers to Back Side of Rear Cross Member

37. Swing the kicker bar up to the cross member and secure them with the supplied 5/8 x 2 1/2” bolts, washers & nuts .

See Photo 36 & 37. Tighten 1/2 bolts using 19mm wrench and rear 5/8 bolts with 24mm wrench. Caution do not

over tighten rear bolts ,as it will crush trans cross-member. Torque to 35 ft lbs.

Photo 36 Photo 37

Install Kickers to Factory Cross Member on Pass Side Install Kickers to F actory Cross Member on Driver Side

38. Install the supplied 3/8” studs on the strut spacer as shown in Photo 38 using the 3/8” nuts. Torque the 3/8” nuts to

35-45 ft\lbs to lock the stud in place.

39. Install strut spacers on the stock strut with shorter side to the ba ck. See Photo 39. Tighten using stock hardware

with a 14mm wrench.

Photo 38

Lock Clinch

Suds into Place

Install Strut Spacer on Strut with Shorter Side to Back

Photo 39

40. Install the strut assembly on truck using the supplied 3/8 nuts & lock washers on the upper strut spacer and stock

hardware in lower control arm strut mount as shown in Photo 40. It may be necessary to use jack stand to install the

lower bolt. Tighten using a 14mm wrench and 19mm wrench

41. Remove the wheel bearing assembly from the stock knuckle as shown in Photo 41 using a 21mm socket. Note it

may be necessary to heat slightly to break factory lock tight. Retain the factory hardware.

Photo 40

Photo 41

Install Strut Assembly On Lower Control Arm Remove Wheel Bearing Assembly from Stock Knuckle

42. Install wheel bearing assembly into new knuckle as removed from the stock knuckle using factory hardware. See

Photo 42.

43. Install knuckle onto truck using stock hardware on the lower ball joint and upper ball joint See Photo 43. Note : The

upper control arm will pull down at full droop until it makes contact with strut tower—this is as designed and not a

problem. Be sure to line up the splines on the axle shaft with the splines on the knuckle/bearing assembly.

Photo 42

Install Bearing Assembly on New Lifted Knuckle Install Lifted Knuckle Using Stock Hardware

Photo 43

44. Torque the lower ball joint to 130ft/lbs with a 19mm and a17mm wrench.

45. Tighten upper ball joint with 22mm wrench.

46. The driver side and passenger side tie rod ends need to be exchanged to provide adequate tire clearance. The stud

will be facing down. Install them on the new knuckle using a 22mm wrench with stock hardware. .

47. Tighten axle nut with stock hardware using a 32mm socket.

Photo 44

Photo 45

Un Bolt Brake Line Block

48. Remove the brake line block as shown using a 10mm

socket and remove the brake line clip securing the brake

line to the frame mount. See Photo 44.

49. Using a cutting tool, cut the factory bracket as shown to

release the brake line. See Photo 45.

50. Install the supplied brake line bracket using the supplied

3/8” x 1” bolts, washers and nuts and install the brake line

in the new bracket as shown in Photo 46.

51. Swing the sway bar down and install the new sway bar link

on the lower control arm using a 17mm wrench. See

Photo 47.

52. Install ABS wire back into bearing using a 5mm allen

socket. Install brake rotor / brake caliper assembly using

stock hardware. Tighten using a 21mm wrench. See

Photo 48.

Cut Factory Brake Line Bracket to Release Line

Photo 46

Install Bracket to Factory Mount and Brake Line

Photo 48 Photo 47

Install New Sway Bar to Lower Control Arm

Re Install Brake Assembly

53. Install supplied cotter keys on the upper ball joint and tie rod ends. See Photo 49.

54. Install skid plate using supplied 3/8 x1” bolts on the front and rear cross member. Tighten with a 14mm socket. Rear

cross member shown in Photo 50.

55. Tighten lower control arm bolts using 22mm wrench.

Photo 50 Photo 49

Install Cotter Pins to Upper Ball Joint and Tie

Rod Ends

Install Lower Skid Plate

REAR INSTALLATION INSTRUCTIONS

If the vehicle is equipped with an electric locker, it will be necessary to free the line from the differential and

reroute to allow slack in the line. The lines can be secure with a zip tie to keep them out of harms way.

1. The next 2 steps will be performed with the vehicle on the ground. This is done to ensure adequate brake line length

when installing the rear blocks.

2. Remove brake lines from the brake line bracket on the axle using 12mm wrench and install new bracket in the stock

location using supplied 8mm x 25mm bolts /washers with 12mm wrench to secure the bracket to the axle. Relocate

the stock brake lines to the top of the new bracket and secure with the supplied 5/16” x 1 1/4” bolts, washers & nuts.

See Photo 1. Tighten with 13mm wrench.

3. Remove the 2 emergency brake cables from the frame using a 12mm wrench and install the new bracket to the

stock location using factory hardware. Relocate the e-brake cables to the bottom part of the bracket as shown in

Photo 2 and secure using the supplied 5/16” x 3/4” bolts, washers /nuts. Secure with a 13mm wrench.

Photo 1

Photo 2

Install Rear Brake Line Bracket Off Rear Axle Install Rear E Brake Line Bracket To Rear Frame

4. Chock the front tires and lift the rear of the vehicle,

position jack stands under the rear frame rails of the

Photo 3

vehicle and lower the vehicle on to the jack stands.

5. Place a floor jack in position under the rear differential for

support.

6. Remove shocks using 19mm wrench for upper and lower

bolts. Retain stock hardware.

7. With slight pressure on the rear axle, remove U-bolts

using a 22mm socket.

8. Lower the axle down to allow clearance to install the

supplied blocks. Align the blocks on the factory center pins

on the leaf spring and align the pin on the block with the

axle. NOTE: The hole and the pin in the new blocks are

slightly offset. The offset will go toward the front of

Install Rear Block and Ubolts

the truck moving the axle slightly forward.

9. Install the supplied shock absorbers with the stock hardware using a 19mm wrench.

10. Install supplied u-bolts and tighten with 13/16 socket. See Photo 3.

11. Install the wheels/tires. Jack up the vehicle and remove the jack stands and lower the vehicle to the floor.

POST INSTALLATION INSTRUCTIONS

1. Check all fasteners for proper torque. Check to ensure for adequate clea rance between all rotating, mobile, fixed,

and heated members. Verify clearance between exhaust and brake lines, fuel lines, fuel tank, floor boards and wiring

harness. Check steering gear for clearance. Test and inspe ct brake system.

2. Perform steering sweep to ensure front brake hoses have adequate slack and do not contact any rotating, mobile or

heated members. Inspect rear brake hoses at full extension for adequate slack. Failure to perform hose check/

replacement may result in component failure.

3. On some vehicles the front lower skirting will need to be trimmed if using certain wheel /tire combinations and with

heavy offset wheels. Trim only as needed.

4. Have a qualified alignment center align the vehicle immediately. Realign to factory specifications. Perform head

light check and adjustment to proper settings.

5. Check and retighten wheels at 50 miles and again at 500 miles.

6. All kit components must be retightened at 500 miles and then every three thousand miles after installation .

Periodically check all hardware for tightness.

7. Install “Warning to Driver” decal on sun visor

8. Note: Installation of larger tires will require speedometer recali bration.

Loading...

Loading...