Rough Country 785.22 User Manual

921788000

JEEP JK 6” LONGARM

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the parts list. Be sure you have all

needed parts and know where they go. Also please review tools needed list and make sure you have needed tools.

As a general rule, the taller a vehicle is, the easier it will roll. Seat belts and shoulder harnesses should be worn at all

times. Avoid situations where a side rollover may occur.

Generally, braking performance and capability are decreased when larger/heavier tires and wheels are used. Take this

into consideration while driving. Do not add, alter, or fabricate any factory or after-market parts to increase vehicle height

over the intended height of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered.

This suspension system was developed using a 37X12.50X17 tire with 4.5” to 4.75” of back spacing on aftermarket

wheels. Stock wheels can be used with this kit with up to a 35x12.5 tire, but different tire manufactures designs may result in a tire width that could result in contact with the lower control arm and/or front sway bar link in a sharp turn. Please

consult with your tire and wheel expert before purchasing. Also note that if wider tires are desired, offset wheels will be

required.

• IMPORTANT NOTE : Upon completing the install of this kit the draglink must be adjusted to center the steering wheel BEFORE the vehicle is driven. Failure to do so will cause a computer error, odd handling, and

poor performance.

• Driveshafts are available from Rough Country. The stock driveshafts do not have enough range of motion,

thus the shaft joints bottom out and damage will occur. It is highly recommended that the stock shafts not

be used and new yoke style shafts are installed.

• 2012 and newer JK will need exhaust modifications. An aftermarket 180 degree exhaust pipe is required.

If question exist we will be happy to answer any questions concerning the design, function, and correct use of our products by calling 1-800-222-7023

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the inside of

the windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation instructions on

to the vehicle owner for review. These instructions should be kept in the vehicle for its service life.

Torque Specs:

Size Grade 5 Grade 8

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

5/8” 135 ft/lbs 175 ft/lbs

3/4” 185 ft/lbs 280 ft/lbs

Class 8.8 Class 10.9

12MM 55ft/lbs 75ft/lbs

14MM 85ft/lbs 120ft/lbs

16MM 130ft/lbs 165ft/lbs

18MM 170ft/lbs 240ft/lbs

PRODUCT USE INFORMATION

• 10mm thru 22mm Sockets and Wrenches

• 5/8” thru 7/8” Sockets and Wrenches

• Adjustable Wrench

• Gloves

• Safety glasses

• Hand grinder

• Plasma cutter

• Resipiciating saw

• Tape measure

• 1 1/4” hole saw

• 3/8”, 17/64”, 13/32” drill bit

• Drill Motor

Tools Needed:

KIT PICTURE

M

D

P

S

N

G

V

C

T

E

Y

J

Z

L

A

X

W

P

E

T

U

B

J

R

N

F

D

M

I

O

Q

•

Crossmember (A)

•

Crossmember brace driver (B)

•

Crossmember brace passenger (C)

•

Front bumpstop ext. (D)

•

Rear bumpstop ext. (E)

•

Driver front lower control arm (F)

•

Passenger front lower control arm (G)

•

Driver upper control arm (H)

•

Passenger upper control arm (I)

•

Front swaybar disconnects (J)

•

Front brake lines (K)

•

Rear brake lines (L)

•

Front 2.2 shocks (M)

•

Rear 2.2 shocks (N)

•

Front coil spring (O)

•

Rear coil spring (P)

•

Adjustable front track bar (Q)

BB

AA

K

Kit Contents

CC

•

Driver rear lower control arm (R)

•

Passenger rear lower control arm (S)

•

Rear upper control arms (T)

•

Driver rear control arm bracket (U)

•

Passenger rear control arm bracket (V)

•

Rear track bar bracket (W)

•

Rear sway bar links (X)

•

4-Door skid plate bracket (Y)

•

Skid plate (Z)

•

Front track bar bracket (AA)

•

Stabilizer bracket (BB)

•

Pitman arm (CC)

H

O

FRONT INSTALLATION INSTRUCTIONS

1. Prior to installing this kit, with the vehicle on the ground, measure the heights of your vehicle. This measurement can

be recorded from the center of the wheel straight up to the top of the inner fender lip. Record the measurements.

LF:__________ ,RF:___________, LR:__________, RR:___________

2. Place vehicle in park and chock the rear wheels. Using a 21mm socket, remove bolt securing the front track bar to

the frame. Retain stock hardware. See Photo 1. Raise the front of the vehicle with a jack and secure a jack stand

beneath each frame rail behind the front control arms. Ease the frame down onto the stands. Support the axle with a

floor jack.

3. Remove the front tires/wheels, using a 19mm deep well socket.

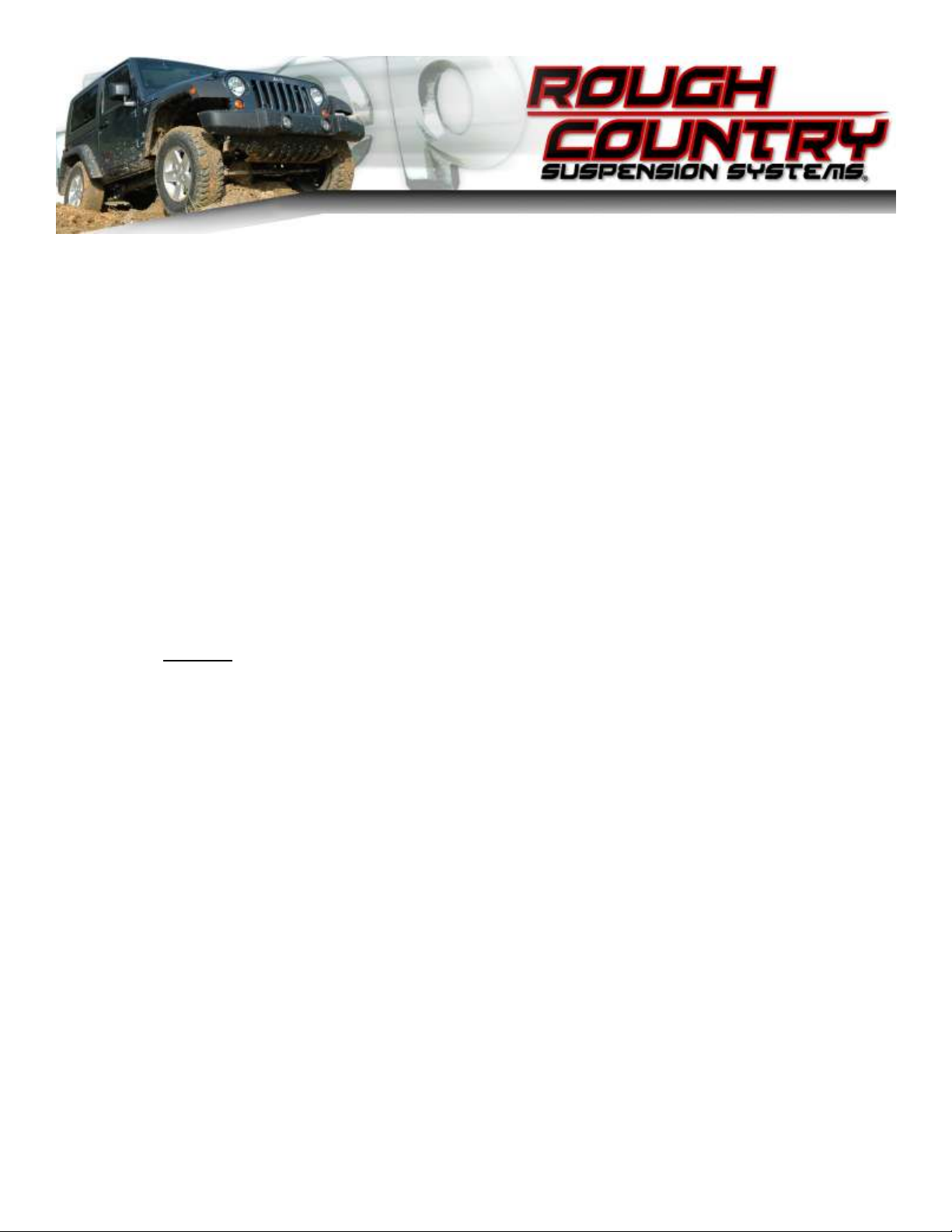

4. Using a 18mm socket and wrench remove the bottom sway bar bolts. See Photo 2.

5. Using a 18mm socket and 19mm wrench, remove the top of the sway bar link.

6. Remove the front factory skid plate with a 18mm socket.

PHOTO 1

PHOTO 2

7. Remove the lower shock bolt using a 18mm socket and wrench. Using a 14mm wrench unbolt the top of the shock

and remove. See Photo 3. Retain stock hardware.

8. On some models it will be necessary to remove the brake line bracket from the frame to allow the coils to be removed. Using a 10MM socket, remove the brake line bracket from the stock location.

9. Lower the axle with the floor jack to allow room for the coils to be removed. Remove stock coil springs. Retain upper

coil isolators.

10. Remove the bolts securing the upper control arms to the axle and frame using a 18mm wrench/socket. It may be

necessary to cut out the passenger side upper bolt as shown in Photo 4 to remove the control arm. A new bolt is

supplied in the hardware bag to replace this factory bolt. Retain factory axle end hardware.

PHOTO 3

PHOTO 4

11. Using a 21mm wrench, remove the bolts that secure the lower control arm to the axle and frame then remove the

control arm. Retain factory axle end hardware.

12. Next the upper and lower factory control arm pocket have to be removed to make clearance for the longer arms.

This will be done using a plasma cutter or cut off wheel in a die grinder. Always use gloves and safety glasses.

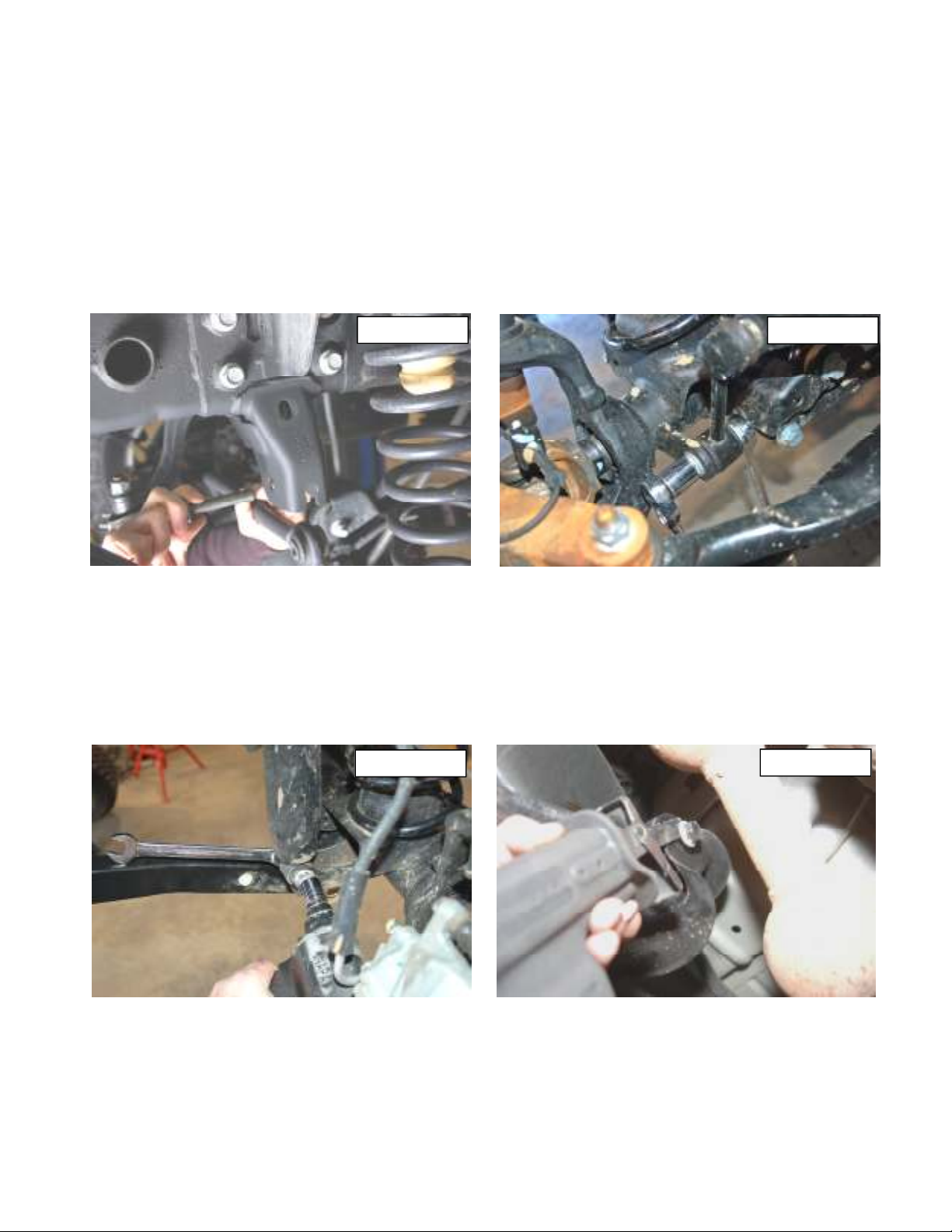

13. First cut half of the lower control arm pocket on the passenger side as shown in Photo 5. Follow around the bottom

edge where the bracket tapers down to the frame. Be careful not to cut through the frame. In Photo 6 you can see

where the first cut is made.

14. Next cut the other half of the control arm pocket as shown in Photo 6. Follow around the bottom edge where the

bracket tapers down to the frame, then cut the bottom side of the bracket flush with the bottom of the frame.

PHOTO 5

15. Finally cut the upper control arm pocket as shown in Photo 7. Follow around the bottom edge where the bracket

tapers down to the frame.

16. Using a hand grinder clean up and sharp burrs or jagged edges left from cutting off the control arm pockets. Paint

the frame with a durable spray paint to prevent rusting. See Photo 8

PHOTO 7

PHOTO 6

PHOTO 8

17. Repeat steps 13-16 on the driver side control arm pockets.

18. Steps 19 & 20 are only used if you have a 2012 or newer JK that has a 180 degree exhaust loop on the driver side.

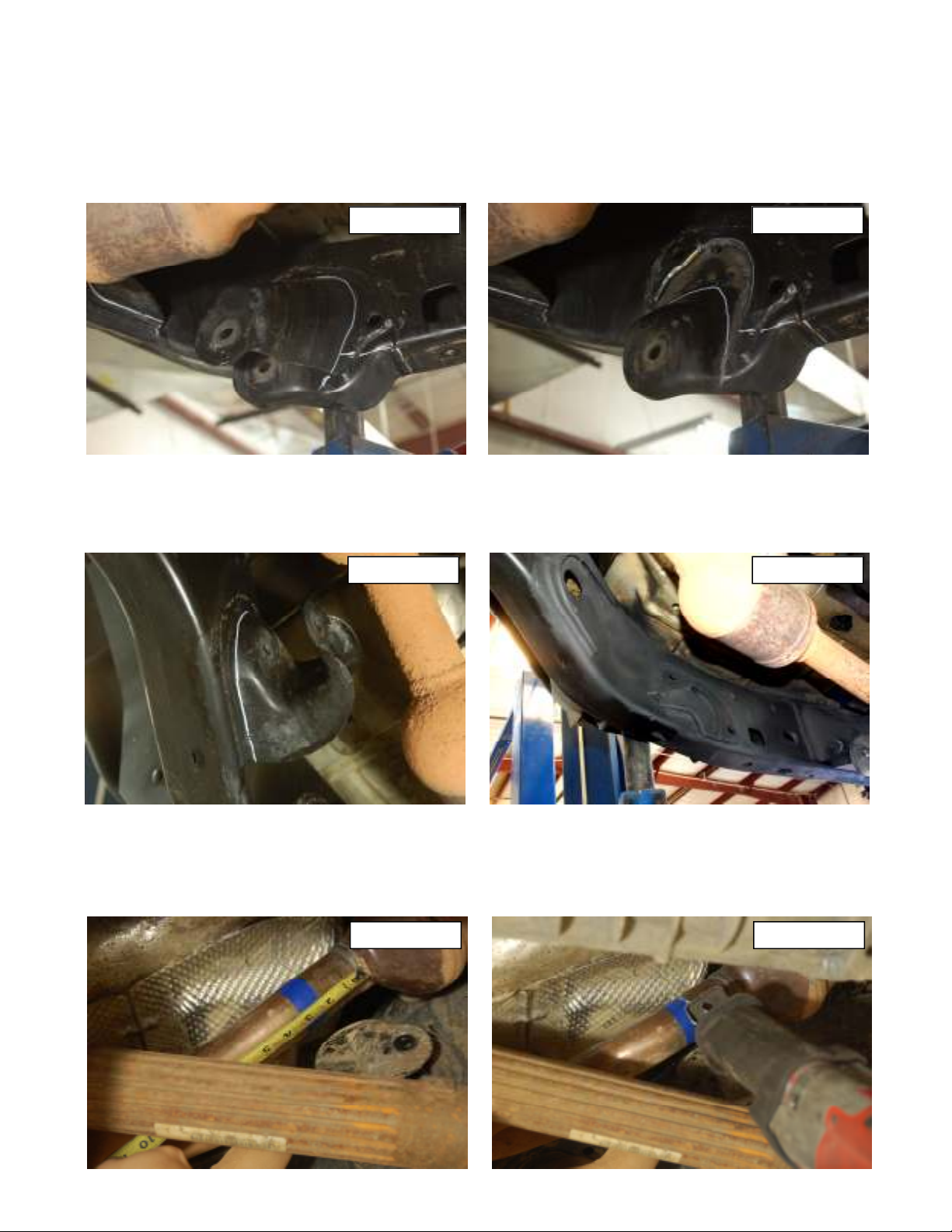

19. Measure back 2 inches as shown in Photo 9 and mark the exhaust, next cut the exhaust pipe with a saw as shown

in Photo 10. Using a 13mm wrench remove the exhaust flange bolts so the cut section of exhaust can be removed.

20. An aftermarket 180 degree exhaust pipe will have to be installed for added clearance.

PHOTO 9 PHOTO 10

21. Support the transmission with a jack stand and remove the three factory bolts from the bottom of the crossmember

that holds the transmissions with a 15mm socket. Next remove the two factory bolts that connect the skid plate to the

crossmember using 15mm socket. Retain factory bolts.

22. Remove four factory bolts holding the crossmember with a 18mm socket and wrench, then remove the crossmeber.

Retain factory hardware.

23. Next install the supplied new crossmember as shown in Photo 11 with the control arm pockets facing forward. Insert

the four factory bolts from the back side of the crossmember with the thread side forward. Do not tighten at this time.

24. Using a transfer punch or a old bolt knock the factory thread insert out of the frame where the factory skid plate

bolted to the bottom side of the passenger side frame rail. See Photo 12

PHOTO 11

25. Slide the passenger side crossmember support bracket over the factory crossmember bolts as shown in Photo 13.

Hand tighten with the factory nuts.

26. Next insert the crossmember brace threaded tab through the frame hole in Photo 14. Align the holes in the tab and

bracket, using the supplied 7/16” x 1.5” long bolts, washers, and lock washers out of 1787bag1. See Photo 15

Tighten with a 5/8” socket.

PHOTO 13

PHOTO 12

PHOTO 14

27. Finally tighten the crossmember bolts with a 18mm socket and wrench. Make sure the crossmember centered between the frame before the bolts are tightened.

28. Repeat steps 24-27 on the driver side.

29. Remove the jack stand holding the transmission and let

the transmission studs drop into the crossmember. Using

a 15mm socket insert and tighten the three nuts holding

the transmission to the crossmember.

30. Insert two of the crossmember flag nuts into the slotted

holes in the crossmember and align the flag nuts with the

two factory holes in the skid plate. Tighten factory bolts

with a 15mm socket.

PHOTO 15

31. Adjust the supplied front lower control arms to the length of 34 3/4” center to center. Install the flex joint end of the

lower control arm to the crossmember using the supplied 9/16” x 4” long bolts, nuts, and washers from 1787bag3.

See Photo 16. Tighten with a 21mm socket and a 22mm wrench. Use a adjustable wrench to tighten the jam nut.

32. Insert the rubber bushing end of the lower control arm to the factory axle mount, use factory hardware and tighten

with a 21mm socket and wrench.

33. Adjust the supplied upper control arm to the lenth of 17 1/4” center to center. Install the flex joint end of the upper

control arm to the bracket on the lower control arm using the supplied 10mm x 80mm long bolts, washers, and nuts.

Tighten with a 5/8 socket and a 11/16 wrench. See Photo 17.

34. Install the bracket end of the upper control arm to the factory axle mount using factory hardware. Tighten using a

18mm socket and wrench.

PHOTO 16

35. Repeat steps 31-34 on the driver side.

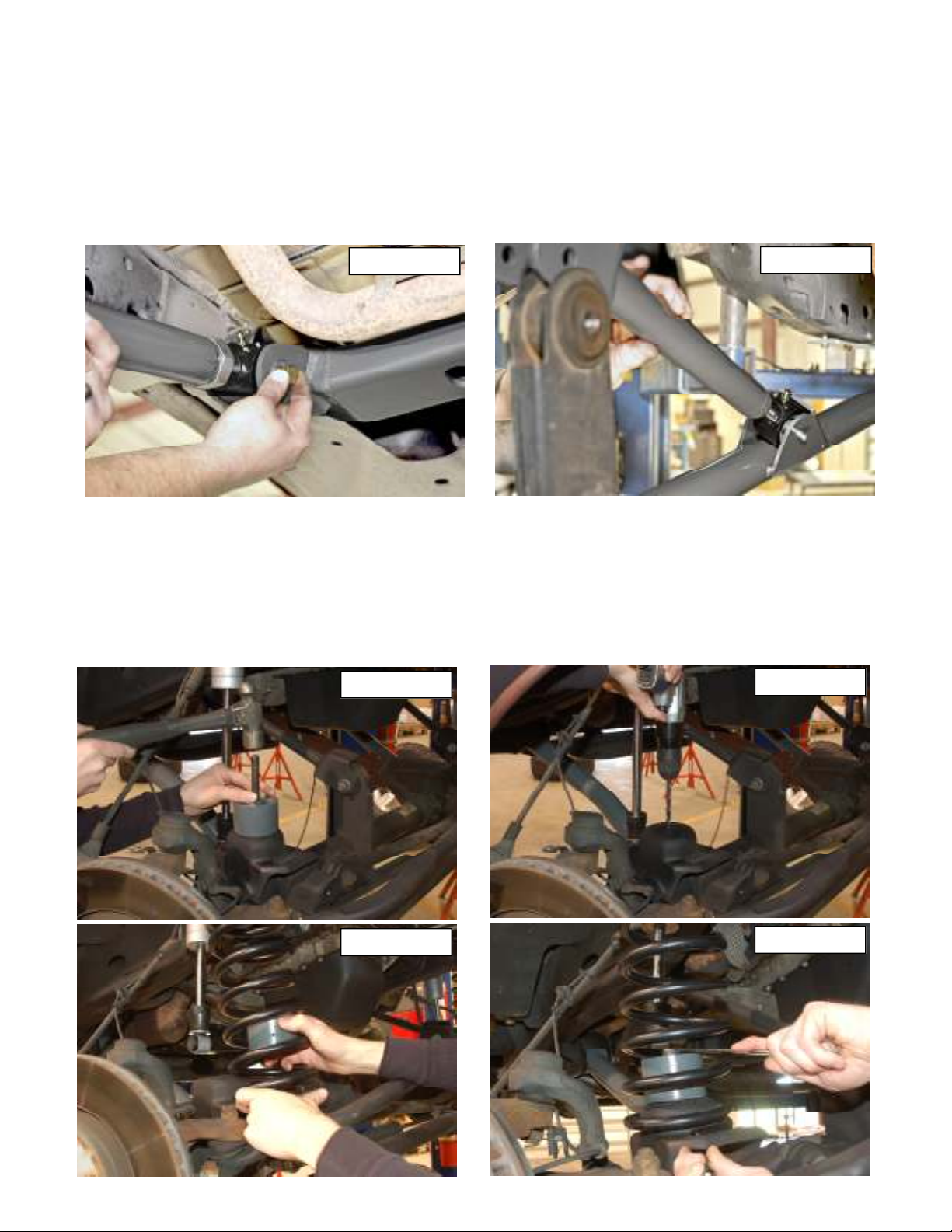

36. Place the supplied 2” bump stop in place on the lower coil seat as shown in Photo 18. Mark & drill using a 3/8” drill

bit. See Photo 19.

37. Be sure the factory rubber isolators are in place and install the front coil springs with the 2” bump stop pucks as

shown in Photo 20. Insert the coil into the upper tower first, followed by the lower seat.

38. Secure the bump stop to the drilled hole in the lower seat using the supplied 3/8” x 3” bolts, washers and nuts.

Tighten using a 9/16” wrench. See Photo 21.

PHOTO 18

PHOTO 17

PHOTO 19

PHOTO 20

PHOTO 21

Loading...

Loading...