Rough Country 609S User Manual

JEEP JK 3 1/2” SUSPENSION KIT

92160900

W/ ROUGH COUNTRY N2.0 SHOCK ABSORBERS

Thank you for choosing Rough Country for your suspension needs.

Please read instructions before beginning installation. Check the kit hardware against the parts list. Be sure you have all

needed parts and know where they go. Also please review tools needed list and make sure you have needed tools.

PRODUCT USE INFORMATION

Rough Country Suspension products are intended to improve off road performance. Modifying your vehicle for off road

use may result a vehicle in the vehicle handling differently than a factory equipped vehicle. Avoid situations where a side

rollover may occur. Seat belts and shoulder harnesses should be worn at all times.

Do not add, alter, or fabricate any factory or after-market parts to increase vehicle height over the intended height of the

Rough Country product purchased. Mixing component brands is not recom mended.

This 3 1/2” suspension system was developed using a 35X12.50X17 tire with 4.5” to 4.75” of back spacing on aftermarket wheels. Stock wheels can be used with this kit with up to a 35x12.5 tire, but different tire manufactures designs may

result in a tire width that could result in contact with the lower control arm and/or front sway bar link in a sharp turn.

Please consult with your tire and wheel expert before purchasing. Stock Wheels can be used with the addition of a 1 1/2”

wheel spacer.

If questions exist we will be happy to answer any questions concerning the design, function, and correct

use of our products by calling 1-800-222-7023.

IMPORTANT NOTES : Upon completing the install of this kit the draglink must be adjusted to center the steering

wheel BEFORE

the vehicle is driven. Failure to do so will cause the Vehicle Stability Program to not function

properly , odd vehicle handling, and poor performance.

On 07-11 Automatic equipped vehicles; due to use of an oversize driveshaft from the factory and inade-

quate factory clearance it may be possible for the front driveshaft to come in contact with the automatic transmission pan tearing the factory boot and rubbing on the shaft. Generally this occurs during heavy articulation

when front sway bar links are disconnected and longer shocks are installed. If this is found to occur, the proper

procedure would be to replace the oversize factory shaft with an aftermarket smaller diameter shaft to increase

clearance between the transmission and front driveshaft. Rough Country does offer this driveshaft if needed.

Also on 2012 Models, additional exhaust modification on the passenger side crossover pipe will be required for

adequate clearance on the front driveshaft.

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the inside of

the windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics.

10mm Wrench

14mm Wrench

16mm Wrench

18mm Wrench

18mm Socket

19mm Wrench

19mm Deep Well Socket

7/8” Wrench

13/16” Socket

Tools Needed:

21mm Socket

21mm Wrench

7/16” Wrench

9/16” Wrench

9/16” Socket

Jack

Jack Stand

13/32” Drill Bit

Drill

Pitman arm puller

WD-40

3/8” Drill Bit

Torque Specifications

GRD-5 GRD-8

5/16” 15 ft/lbs 20 ft/lbs

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

5/8” 135 ft/lbs 175 ft/lbs

3/4” 185 ft/lbs 280 ft/lbs

Metric (Grade) 8.8 10.9 12.9

14MM 85ft/lbs 120ft/lb. 145ft/lbs

Rear Coil (2)

KIT COMPONENTS

Rear Track

Bar Bracket

Rear N2.0 Shocks

Brake Line

Brackets (4)

RR Bump-stop brkts

Pitman Arm

Front Coil Springs (2)

RR coil shims (2)

Rr Sway Bar Links

Fr Lower Arms

Front Track Bar Bracket

Kit Contents:

1609C:

Front Coil Springs (2)

Rear Coil Springs (2)

1609Box1:

Front Track Bar Bracket

Stabilizer Bracket

Front Lower Control Arms (2)

Front Bump-Stop Spacer (2)

Rear Bump-Stop Brackets (2)

Rear Track Bar Bracket

Rear Track Bar Bracket Brace

Pitman Arm

Front and Rear Brake Line Brackets (4)

Rough County N2.0 Shock Absorbers

Rear Coil Angle Correction brackets (2)

For Front Track Rod Bracket:

1609BAG2

3-3/8” x 1 1/4” Bolt

3-3/8” Flat Washer

5-3/8” Flange Lock Nut

1-3/8” x 2 1/2” x 3 1/4”U-Bolt

1-14mm x 80mm” Bolt

1-14mm Lock nut

2-14mm Washer

1-Crush Sleeve

For Front Bump Stop:

1609BAG7

2-3/8” x 3” Bolt

4-3/8” Flat Washers

2-3/8” Lock Nut

For Front Brake Line Bracket:

1152BAG

2-1/4” x 1” Bolts

4-1/4” Flat Washers

2-1/4” Lock Nuts

For Front Cross-Member:

1609BAG5

4-1 1/4” Thick Washers

For Front Shocks:

1609BAG3

4-Stud Bushings

4-Cup Washers

2-9/16” Stud Nuts

Front N2.0 Shocks (2)

For Rear Track Rod Bracket:

1609BAG5

1-Crush Sleeve

2-14mm x 80mm Bolt

4-14mm Flat Washer

2-14mm Lock Nut

2-3/8” x 1” Bolt

1-3/8” x 1 1/4” Bolt

3-3/8” Flange Lock Nuts

3-3/8” Flat Washers

For Rear Bump Stop:

1609BAG6

4-3/8” x 3/4” Bolts

4-3/8” Flat Washers

4-3/8” Flange Lock Nuts

For Rear Brake Line Brackets:

1152BAG

2-1/4” x 1” Bolt

4-1/4” Flat Washers

2-1/4” Lock Nut

For Rear Sway Bar Links:

1681BAG3

4-Sleeves

4-1/2” x 2 3/4” Bolts

8-1/2” Flat Washers

4-Lock Nuts

FRONT INSTALLATION INSTRUCTIONS

1. Prior to installing this kit, with the vehicle on the ground, measure the heights of your vehicle. This measurement can

be recorded from the center of the wheel straight up to the top of the inner fender lip. Record the measurements.

LF:__________ ,RF:___________,

LR:__________, RR:___________

2. Place vehicle in park and chock the rear wheels. Raise the front of the vehicle with a jack and secure a jack stand

beneath each frame rail behind the front control arms. Ease the frame down onto the stands.

3. Remove the front tires/wheels

, using a 19mm deep well socket.

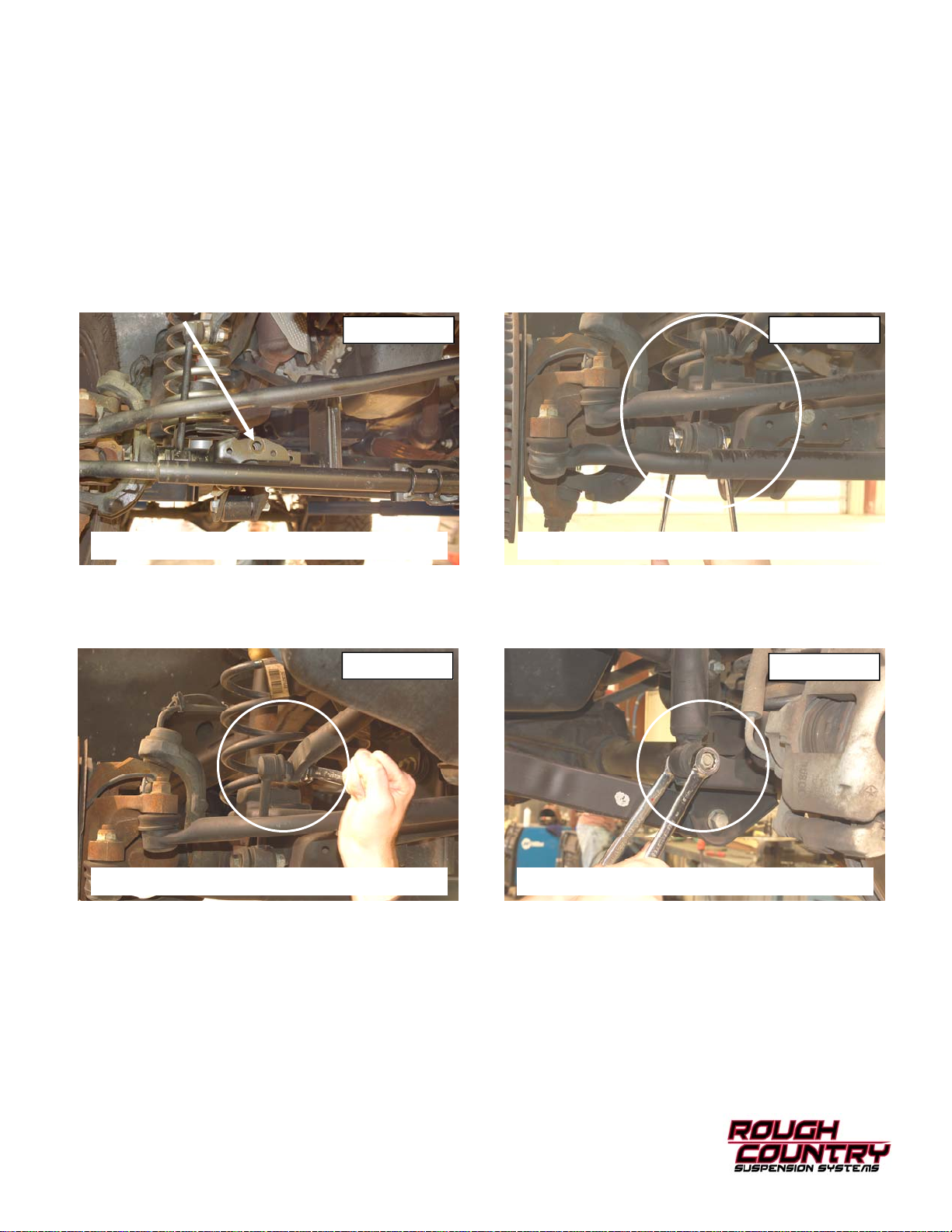

4. Using a 21mm socket, remove bolt securing the front track bar to the axle. Retain stock hardware. See Photo 1.

5. Using a 18mm socket and wrench remove the bottom sway bar bolts. See Photo 2.

PHOTO 2

REMOVE TRACK BAR

PHOTO 1

REMOVE LOWER SWAY BAR LINK

6. Using a 19mm socket and 18mm wrench, remove the top of the sway bar link. Retain hardware for later use. See

Photo 3.

7. Remove the lower shock bolt using a 18mm socket and wrench as shown in Photo 4. Using a 16mm wrench unbolt

the top of the shock and remove. Retain stock hardware.

PHOTO 3

PHOTO 4

REMOVE UPPER SWAY BAR LINK REMOVE THE SHOCK ABSORBER

8. On some models it will be necessary to remove the brake line bracket from the frame to allow the coils to be removed. Using a 10MM socket, remove the brake line bracket from the stock location. Note: The ABS wire may

have to be unclipped from the brake line to allow the axle to be lowered to remove the coil springs.

9. Push down on the axle to allow room for the coils to be removed. Remove stock coil spring s. Retain stock coil isolators.

10. With the axle supported, using a 21mm socket and wrench remove the lower control arm bolts at the axle and frame.

Retain the stock hardware for reuse.

Loading...

Loading...