Rough Country 599S User Manual

92159900

09-UP FORD F150 4” LIFT KIT

THANK YOU FOR CHOOSING ROUGH COUNTRY FOR YOUR SUSPENSION NEEDS.

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the parts list. Be sure you have

all needed parts and know where they go. Also please review tools needed list and make sure you have needed tools.

PRODUCT USE INFORMATION

As a general rule, the taller a vehicle is, the easier it will roll. We strongly recommend, because of rollover possibility that

seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur.

Generally, braking performance and capability are decreased when larger/heavier tires and wheels are used. Take this

into consideration while driving. Do not add, alter, or fabricate any factory or after-market parts to increase vehicle height

over the intended height of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered. If questions exist we will be happy to answer them concerning the design, function, and correct use of our products.

The 4”suspension system was developed using a 35X12.50/18 tire with 18 x 9 wheel with 4 1/2” backspace. When using

a stock wheel the maximum tire width is 11 1/2”. The lifts were designed to lift the front to level the vehicle. Due to

manufacturing, dimension variances, and inflation all tire and wheel combination s sh ould be tested prior to installation on

all oversized / wider then stock tires We recommend a wheel not exceeding 8" in width be used with a minimum backspacing of 4.5" to a maximum of 5".

Some 2011 vehicles will require the EPAS (Electronic Power Assist Steering) plugs to be disconnected prior to

beginning installation of this kit. See installation instructions. Failure to disconnect these plugs may result in

damage to the EPAS module resulting in an error message being displayed, which will require replacement of

the EPAS module.

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the inside of

the windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoe ver is operating the vehicle of its unique handling characteristics.

Tools Needed:

5mm Allen Wrench

8mm Allen Wrench

8mm wrench /socket

10mm wrench /socket

12mm Wrench

13mm wrench / socket

15mm wrench /socket

16mm wrench /socket

18mm wrench /socket

19mm wrench /socket

21mm wrench /socket

22mm wrench /socket

24mm wrench /socket

30mm wrench /socket

Floor Jack

Jack stands

Reciprocating Saw

Hammer

9/16 wrench /socket

1 1/16” Wrench

Drill

1/4” Drill Bit

5/8” Drill Bit

41/64” Drill Bit

11/32” Drill Bit

Torque Specs:

Size Grade 5 Grade 8

5/16” 15 ft/lbs 20 ft/lbs

3/8” 30 ft/lbs 35 ft/lbs

7/16” IN 45 ft/lbs

60 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

Class 8.8 Class 10.9

10MM 32ft/lbs 45ft/lbs

18MM 170ft/lbs 240ft/lbs

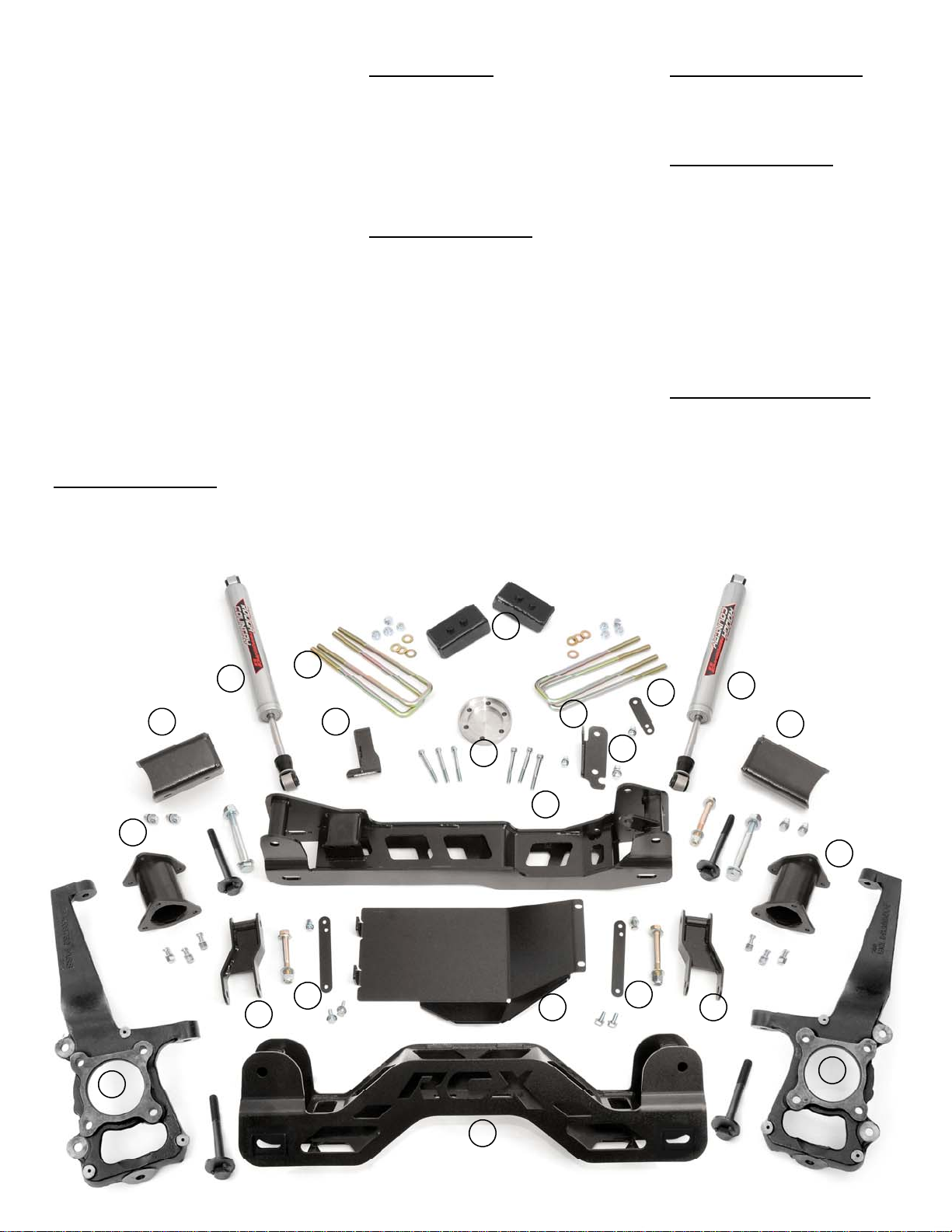

Kit Includes:

1598Box1:

1-Driver Side Knuckle (A)

1598Box5:

1-Pass Side Knuckles (B)

1598Box2:

1-Fr Cross-Member (C)

1-Rr Cross-Member (D)

1598Box3

2-Dr & Pass Diff Bracket (E)

1-Pass Side Diff Brace Bracket (F)

1-Dr Side Sway Bar Bracket (G)

1-Pass Side Sway Bar Bracket (H)

2-Fr Brake Line Brackets (I)

1-Front Lower Skid Plate (J)

1-Rear E-Brake Bracket (K)

1-Front Driveshaft Spacer (L)

1-Rear Brake Line Bracket (M)

1599Box1

2-Rear Blocks (N)

2-Rear RCX 2.2 Shocks (O)

2-Fr Strut Spacers (P)

4-9/16” x 11” U-bolts (Q)

1598Bag1 Containing:

For Fr Dr Side Upper Diff Mount:

1– 9/16” x 4” Bolt

2-9/16” Flat Washers

1-9/16” Lock Nut

For Fr Dr Side Lower Diff Mount:

1-9/16” x 4” bolt

2-9/16” Flat Washers

KIT CONTENTS

Bag1 Continued:

For Rr / Fr Cross-Member:

2-18mm x 160mm Bolts

4-18mm Flat Washers

2-18mm Lock Nuts

For Fr Drivers Side Diff Mount:

1-9/16” x 4 1/2’ Bolt

2-9/16” Flat Washers

1-9/16’” Lock Nut

1598Bag2 Containing:

For Front Lower Control Arms:

4-18mm x 160mm Cam Bolts

4-Flat Washers

4-18mm Lock Nuts

For Front Skid Plate:

4-3/8” x 1” Bolt

4-3/8” Flat Washers

For Front Driveshaft:

6-10mm x 80mm Allen Bolts

For Front Brake Line Bracket:

2-5/16” x 3/4” Bolt

4-5/16” Flat Washer

2-5/16” Lock Nut

For Sway Bar Brackets:

4-3/8” x 1’ Bolts

8-3/8’ Flat Washers

4-Lock Nuts

For 2010 Models with 16mm Caliper bolts

4-5/16” thick washers

N

3/8” Stud Bag Containing:

For Front Strut Spacers:

6-3/8” Self Clinch Studs

6-3/8” Lock Washer

6-Hex Nuts

1598Bag3 Containing:

For Rear Brake Line Brkt:

1-3/8” x 1’ Bolt

2-3/8” Flat Washers

1-3/8” Lock Nut

For Rear E-brake Bracket:

1-7/16” x 1” Bolt

2-7/16” Flat Washers

1-7/16” Lock Nut

1-5/16” x 3/4” Bolt

2-5/16” Flat Washers

1-5/16” Lock Nut

9/16” Bag For Rear Blocks:

4-9/16” Axle U-Bolts

8-9/16” Nuts

8-9/16” Flat Washers

B

P

H

O

E

Q

O

G

F

L

M

Q

K

D

P

I

J

I

E

A

C

INSTALLATION INSTRUCTIONS

1. Chock the rear wheels and jack up the front of the vehicle.

2. Place jack stands under the frame rails and lower onto jack stands.

3. Remove the wheels/tires using a 21mm socket.

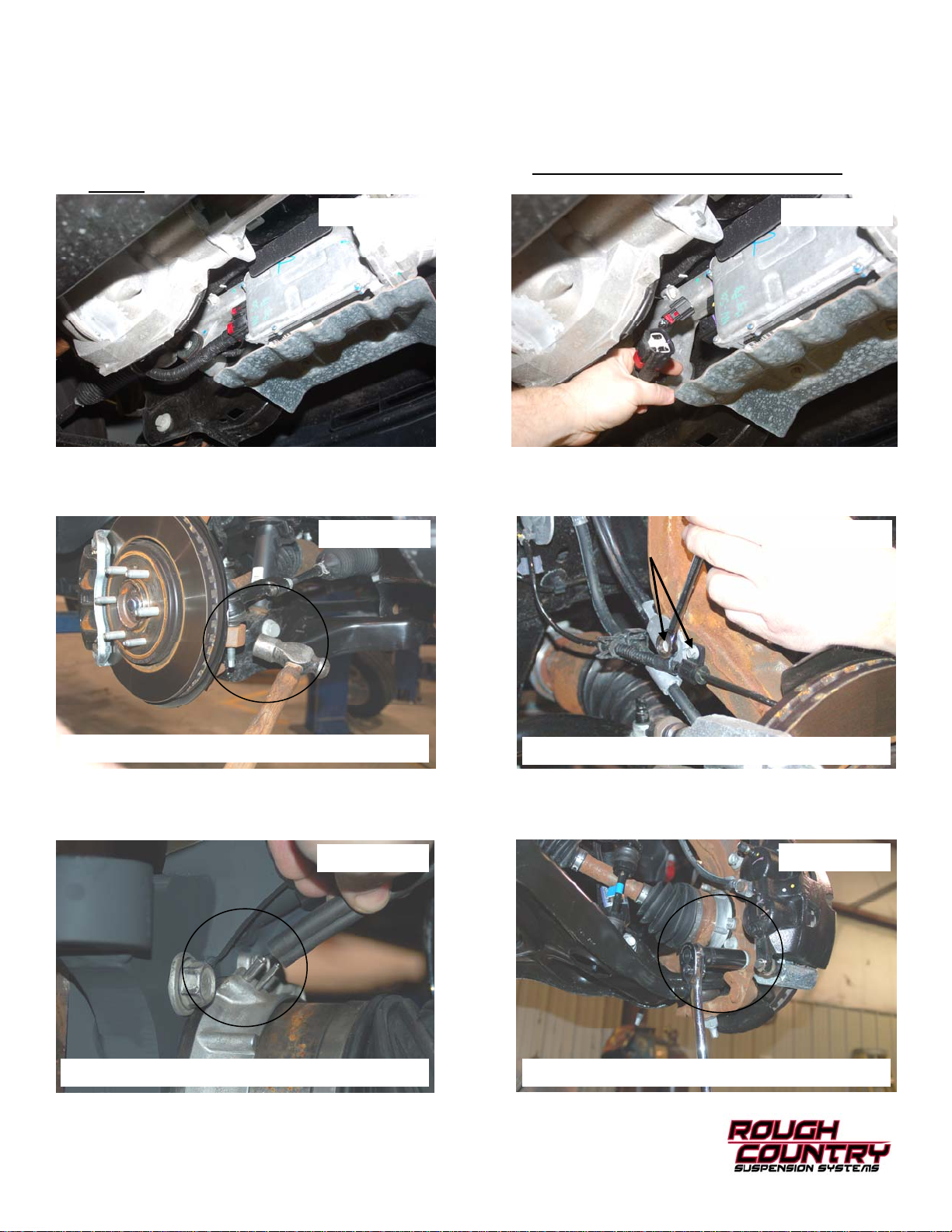

4. On 2011 models and if equipped, remove the EPAS (Electronic Power Assist Steering) Plugs as shown located on

the steering assembly by the front differential. See Photo 1 & 2. This must be done BEFORE installation is

started.

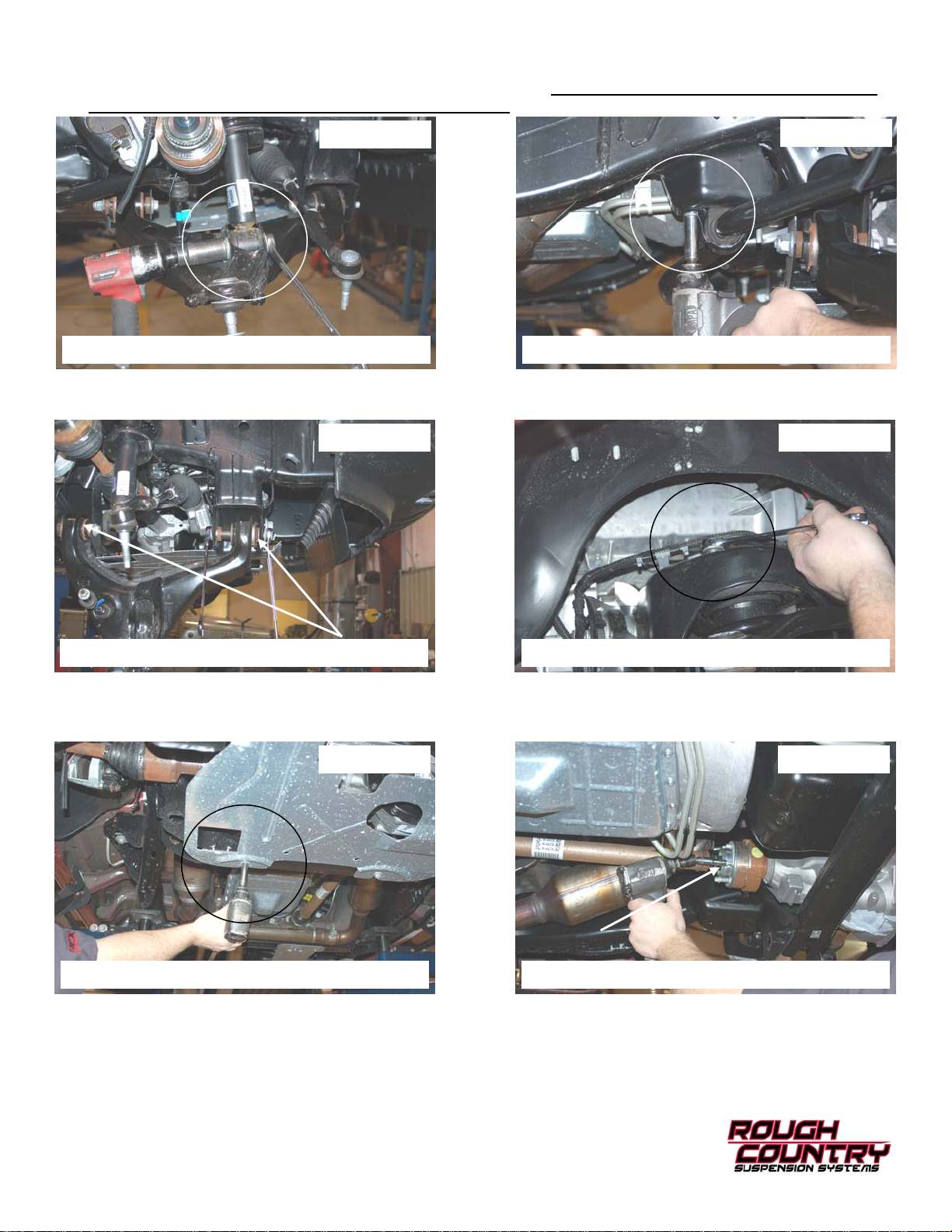

PHOTO 1 PHOTO 2

5. Remove tie-rod end using a 21mm wrench. Using a hammer hit the side of the knuckle to pop tie-rod out. Photo 3.

6. Remove the ABS and brake line bracket from the knuckle using a 8mm wrench for the ABS wire and a 10mm

wrench for the brake line bracket. Retain hardware for reuse. See Photo 4.

PHOTO 3

TAP TO LOOSEN THE TIE ROD

REMOVE BRACKET FROM KNUCKLE

PHOTO 4

7. Remove the vacuum line from the hub. See Photo 5.

8. Using a 19mm socket & 21mm wrench, remove brake caliper as shown in Photo 6. Hang caliper out of way. Do not

let caliper hang by brake hose as this will damage hose. Retain hardware for reuse. Remove rotor.

PHOTO 5

PHOTO 6

REMOVE VACUUM LINE FROM HUB REMOVE THE CALIPER FROM KNUCKLE

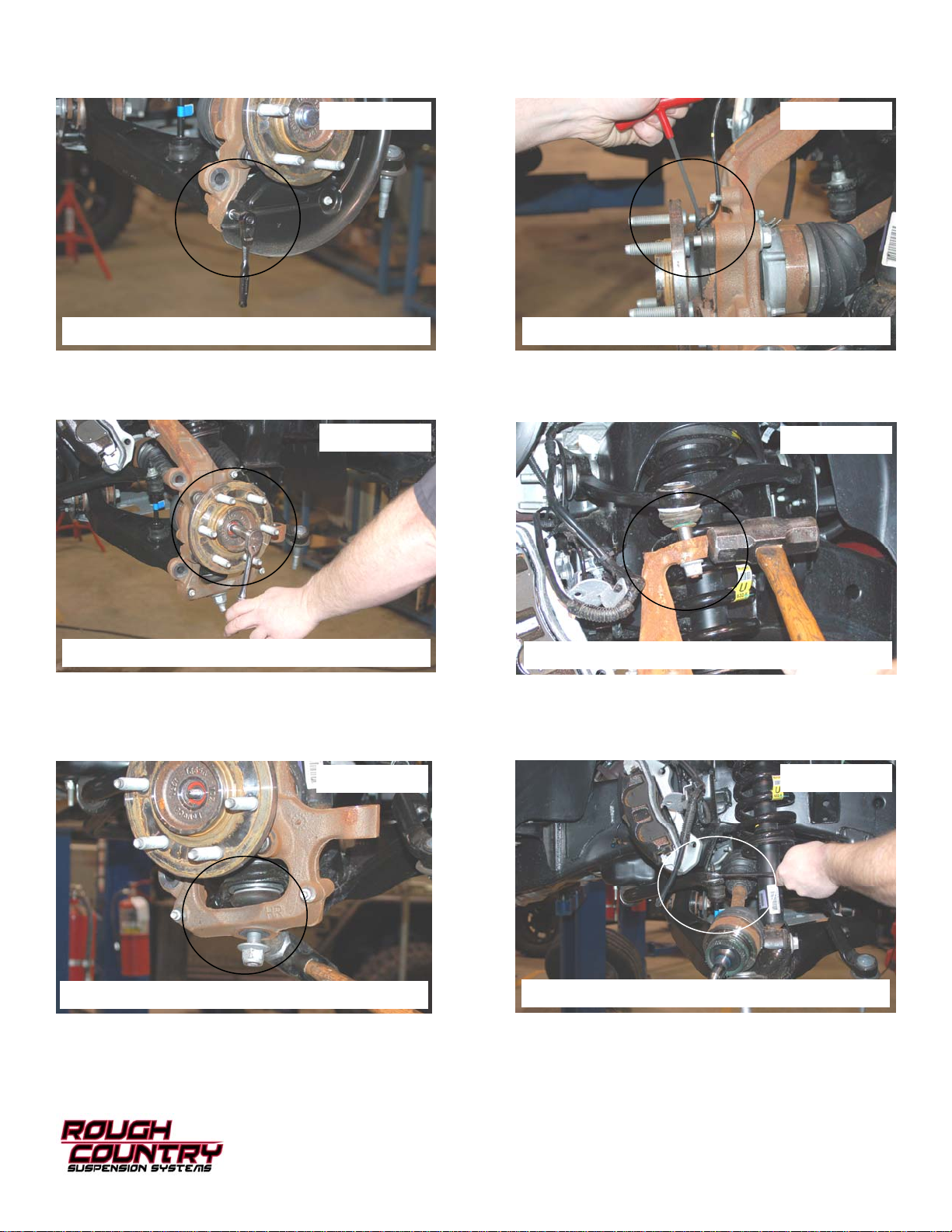

9. Remove the dust shield using a 8mm socket and dust cap. See Photo 7.

10. Remove the ABS wire from the bearing assembly using a 5mm allen wrench. See Photo 8.

PHOTO 7 PHOTO 8

REMOVE THE DUST SHIELD REMOVE THE ABS WIRE

11. Remove the axle nut using a 13mm socket. Retain hardware for reuse. See Photo 9.

12. Loosen the upper ball joint nut using a 21mm wrench. Tap lightly with a hammer to release ball joint from knuckle.

See Photo 10.

REMOVE THE AXLE NUT

PHOTO 9

TAP TO LOOSEN UPPER BALL JOINT

PHOTO 10

13. Loosen the lower ball joint using a 24mm wrench. Tap lightly with a hammer to release ball joint from knuckle. See

Photo 11.

14. Remove the upper and lower ball joint nuts and remove the knuckle from the vehicle.

15. Remove the sway bar links from the sway bar using a 19mm wrench. Retain hardware for reuse. See Photo 12.

PHOTO 11

PHOTO 12

TAP TO LOOSEN LOWER BALL JOINT

REMOVE UPPER SWAY BAR HARDWARE

16. Remove the lower strut bolt using a 30mm socket and 1 –1/16” wrench. See Photo 13. Retain hardware for reuse.

17. Remove the sway bar from the frame mount using a 15mm socket. Please note the position that the sway bar is in-

stalled from the factory to make sure it is reinstalled correctly. Retain hardware for re use. See Photo 14.

PHOTO 13

REMOVE THE LOWER STRUT BOLT REMOVE THE SWAY BAR FROM FRAME

18. Remove the lower control arm using a 21mm and 1-1/16” wrench. Retain hardware for reuse. See Photo 15.

19. Remove the strut from the upper mount using a 15mm socket / wrench. Retain hardware for reuse. See Photo 16.

PHOTO 15 PHOTO 16

PHOTO 14

REMOVE THE LOWER CONTROL ARM REMOVE THE UPPER STRUT HARDWARE

20. Remove the lower skid plate by removing the 4 bolts using a 13mm socket. See Photo 17.

21. Remove the driveshaft from the front differential using a 10mm socket. See Photo 18. Secure driveshaft out of the

way.

PHOTO 17 PHOTO 18

REMOVE THE LOWER SKID PLATE REMOVE THE DRIVE SHAFT

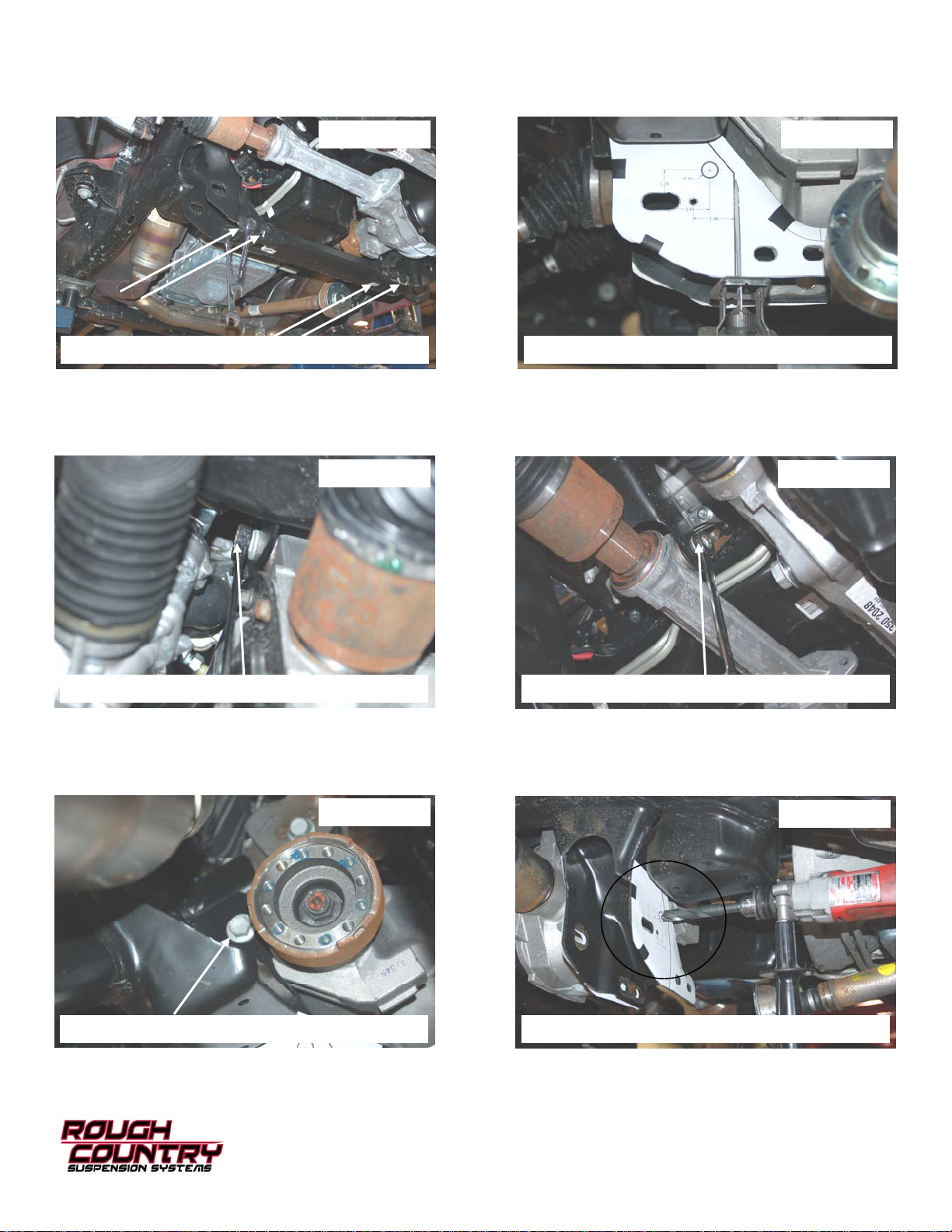

22. Remove the stock rear cross-member using a 15mm & 18mm socket. Retain hardware for reuse. See Photo 19.

23. Tape supplied cutting template on front and back side of the driver side lower cross-member mount. Using template

as a guide, trim cross-member mount to allow the differential to be removed. See Photo 20.

PHOTO 19 PHOTO 20

REMOVE THE REAR CROSS-MEMBER INSTALL THE TEMPLATES AND CUT

24. Remove the differential vent tube from the differential.

25. Support the differential using a floor jack and remove the upper driver side differential bolt using a 18mm wrench.

Retain hardware for reuse. See Photo 21.

26. Remove the passenger side differential bolt using a 18 & 21mm wrench. Retain hardware for reuse. See Photo 22.

PHOTO 21

PHOTO 22

REMOVE THE UPPER DRIVER DIFF BOLT REMOVE THE PASSENGER SIDE DIFF BOLT

27. Remove the lower rear driver side differential bolt using a 21mm socket / wrench. Lower and remove the differential

from the vehicle. See Photo 23.

28. Complete the trimming of the frame on the driver side using the template and drill a pilot hole in the center using 1/4”

drill bit. Finish the hole shown in Photo 24 using a 5/8” drill bit.

PHOTO 23

PHOTO 24

REMOVE THE DR UPPER DIFF BOLT DRILL HOLE USING THE TEMPLATES

Loading...

Loading...