Rough Country 592.20 User Manual

92159200

08-09 F250 8” SUSPENSION KIT

Thank you for choosing Rough Country for your suspension needs.

Rough Country recommends a certified technician installs this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read all the instructions before beginning the installation. Check the kit hardware against the parts list. Be sure

you have all the needed parts and understand where they go. Also please review the tools needed list and make sure

you have needed tools.

PRODUCT USE INFORMATION

As a general rule, the taller a vehicle is the easier it will roll. We strongly recommend seat belts and shoulder

harnesses should be worn at all times. Avoid situations where a side rollover may occur.

Braking performance and capabilities are decreased when significantly larger/heaver tires and wheels are used. Take

this into consideration while driving. Also, speedometer recalibration is necessary when larger tires are installed.

Do no add, alter, or fabricate any factory or after-market parts which increase vehicle height over the intended height of

the Rough Country product purchased. Mixing component brands, lifts, and/or combining body lift with suspension lifts

voids all warranties. Rough Country makes no claims regarding lifting devices and excludes any and all implied claims.

We will not be responsible for any product that is altered.

This kit is packaged as a leveling kit—raising the front 8” and the back 7”. If you desire a different look or if the vehicle

has a tool box or added weight in the rear, please consult with your sales representative about block / u-bolt options.

This 8” suspension system was developed for 37x12.50x17 tire on an after market wheel w/ 4.5” back spacing.

NOTICE TO DEALER AND VECHICLE OWNER

Any vehicle equipped with any Rough country product must have the “Warning to Driver” decal installed on the sun visor

or dash. The decal is to act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics. INSTALLING DEALER—It is your responsibility to install the warning decal and to forward these installation instructions on too the vehicle owner for review and to be kept in the vehicle for its service life.

Kit Contents:

9298 Diesel Coil Springs

1580Box1 Upper Control Arms

1580Box2 Lower Control Arms

1592Box2 Stabilizer Drop Brackets

Track Bar Bracket

Control Arm Bracket

Sway Bar Link

Hardware Bags

Pitman Arm

Stainless Front Lines

Carrier Bearing Drop Brkt

1580Box4 Fr Shocks

Rear Shocks

1592Box1 Rear block / U-Bolt Kit

Block Shims (4)

Tools Needed:

8mm Wrench 1 1/8” Wrench

10mm Wrench 1 13/16” Wrench

12mm Wrench Jack Stands

15mm Wrench Jack

17mm Wrench Drill

17mm Socket Drill Bits-13/16-7/8

18mm Wrench

18mm Socket

19mm Wrench

21mm Wrench

24mm Socket

30mm Socket

Torque Specs:

Size Grade 5 Grade 8

5/16” 15 ft/lbs 20 ft/lbs

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

5/8” 135 ft/lbs 175 ft/lbs

3/4” 185 ft/lbs 280 ft/lbs

Size Grade 8.8 Grade 10.9

8MM 18ft/lbs 23 ft/lbs

FRONT INSTALLATION INSTRUCTIONS

1. Block the rear wheels of the vehicle. Raise the front of the vehicle and support the frame with jack stands. Remove

the front wheels and tires and set aside. Position a hydraulic jack under the front axle and raise the jack until the

front suspension begins to compress

2. Disconnect the track bar from the driver side frame bracket, using a 30mm wrench.

3. Disconnect the sway bar end links from the axle and the sway bar, using a 18mm wrench. Remove end links and

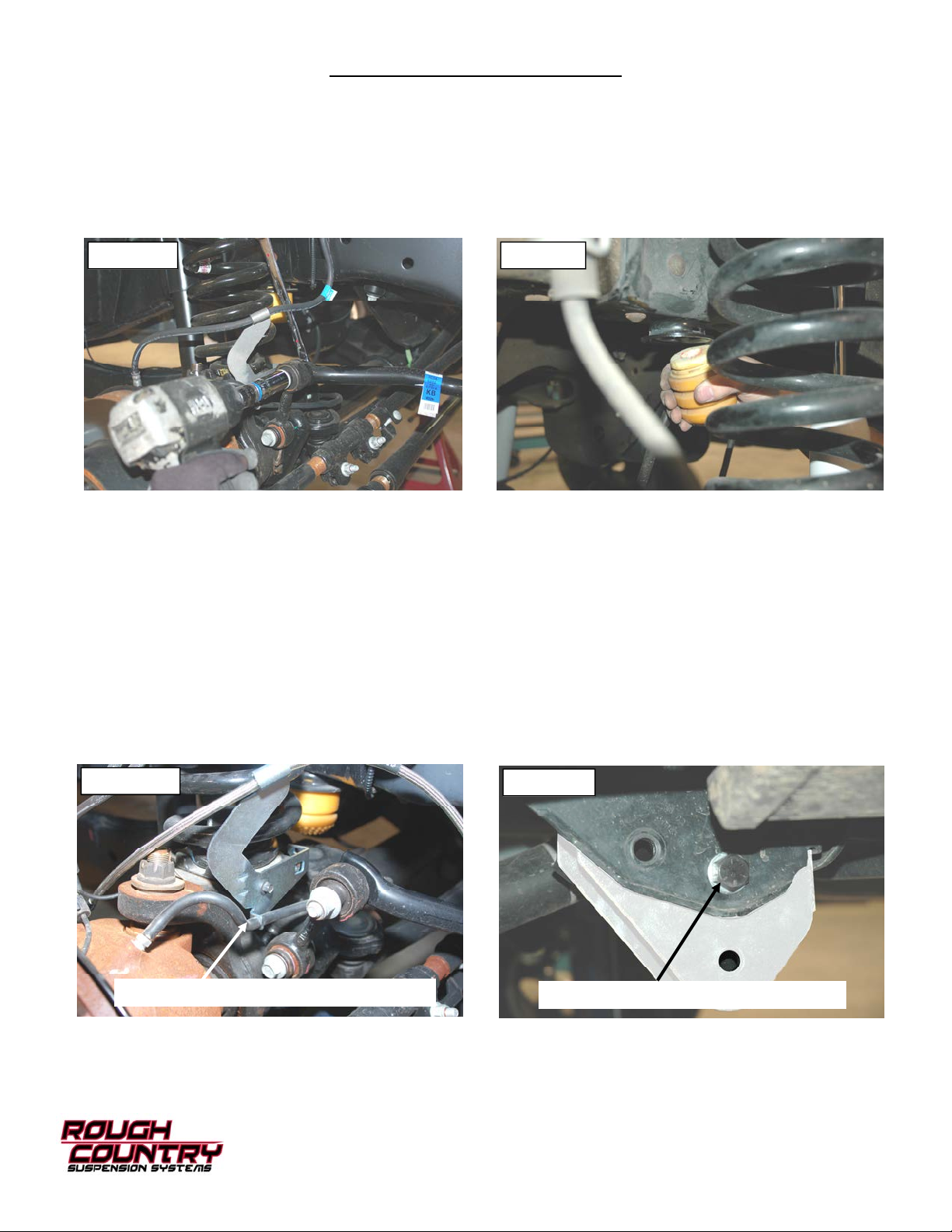

retain the hardware for reuse. See Photo 1.

4. Remove the bump stop from the cup shaped bracket. Remove the bracket from the frame rail using a 10mm wrench.

See Photo 2.

Photo 1 Photo 2

5. Disconnect the ABS sensor wire from the lower spring seat and the radius arm, using a 8mm wrench.

6. Unbolt the brake line brackets from the axle, using a 10mm wrench. Remove the center disconnect vacuum lines

from the clamp on the axle.( If equipped with automatic hubs). Remove the stock brake line from the stock steel line

and install the supplied braided brake lines in the factory location with the factory hardware. Please note there is a

driver and passenger side brake hose . Photo 3 Shows the new line being installed. Bleed brake system.

7. Using a 19mm wrench remove the nut, retaining washer and rubber bushing from the upper shock mounts.

18mm wrench remove the lower shock bolts. Retain hardware for re-use.

8. Carefully lower the jack until the coil springs are free. Remove the coil springs from the vehicle. Note: use of a coil

spring compressor may be required for spring removal.

9. Support both radius arms with jack stands. Using a 24mm wrench, and socket remove the bolt holding the radius

arm to the frame. Using a 24mm wrench, and socket remove the 2 bolts each side holding the radius arm to the

axle. Retain stock hardware for reuse.

10. Insert the radius arm drop bracket into the stock location. Bolt into place using a 3/4” x4.75” bolt, crush sleeve, nut

and washer provided in the kit bag. Do not tighten at this time. See Photo 4.

Using a

Photo 3

Disconnect Vacuum Line (Auto Hubs only)

Photo 4

Crush sleeve installs in bracket here

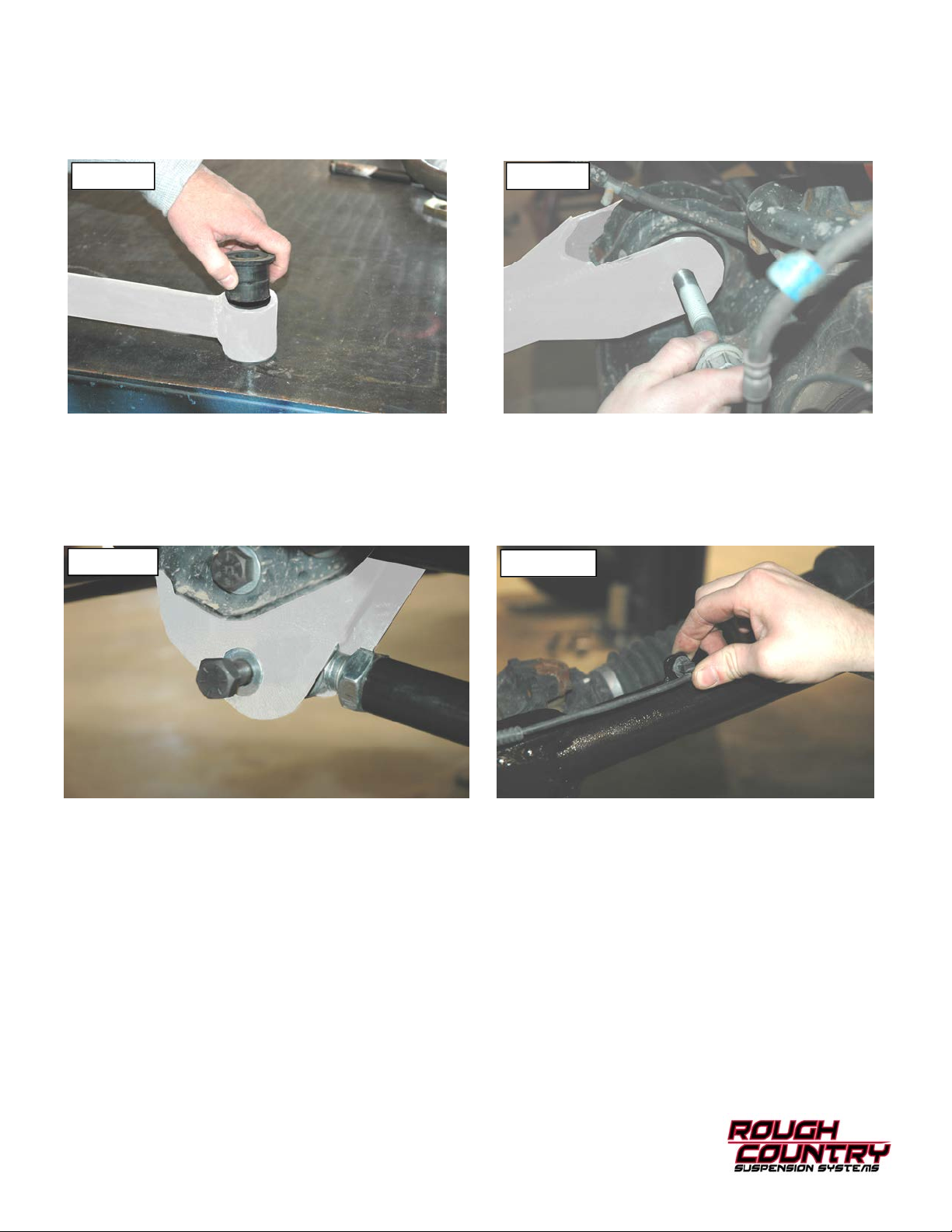

11. Insert bushings, and sleeves from kit bag into the upper control arm. See Photo 5.

12. Attach the upper control arm to the radius arm bracket in the top hole. Bolt into place using a 3/4” x4.75” bolt, nut

and washer provided in the kit bag. Do not tighten at this time

13. Attach the control arms to the axle using the stock hardware. See Photo 6. It may be necessary to use the rear

nut from the frame mount due to some models having the radius arm nut welded to the radius arm.

Photo 5 Photo 6

14. Attach the lower control arm to the axle using the stock hardware. Do not tighten at this time.

15. Insert the end of the lower control arm into the radius arm drop bracket. Bolt into place using a 3/4” x4.75” bolt, nut

and washer provided in the kit bag. See Photo 7. Using a 1 7/8” wrench tighten the jam nut against the arm body.

Center of bushing to center hole of opposite bushing should be 36 1/8”

16. Reattach the ABS wire to the upper control arm. See Photo 8.

17. Repeat step 12-18 on the opposite side.

Photo 7

Photo 8

Loading...

Loading...