Rough Country 170P User Manual

92754500

88-98 GM 2-3” SUSPENSION KIT

Thank you for choosing Rough Country for your suspension needs.

Rough Country recommends a certified technician installs this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read all the instructions before beginning the installation. Check the kit hardware against the parts list. Be sure

you have all the needed parts and understand where they go. Also please review the tools needed list and make sure

you have needed tools.

PRODUCT USE INFORMATION

As a general rule, the taller a vehicle is the easier it will roll. We strongly recommend, because of rollover possibility, that

seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur.

performance and capabilities are decreased when significantly larger/heaver tires and wheels are used. Take this into

consideration while driving. Also, speedometer recalibration is necessary when larger tires are installed.

Do no add, alter, or fabricate any factory or after-market parts which increase vehicle height over the intended height of

the Rough Country product purchased. Mixing component brands, lifts, and/or combining body lift with suspension lifts

voids all warranties. Rough Country makes no claims regarding lifting devices and excludes any and all implied claims.

We will not be responsible for any product that is altered.

This kit is packaged as a leveling kit—raising the front 2”-3” and the back 1.5”. If you desire a different look or if your

truck has a tool box or something else that is going to bring the rear end down, please consult with your sales repetitive

about option higher block and u-bolt options.

The 2.5” suspension kit was developed for 285/75x16 tire on 16” wheel. With the addition of larger tires, trimming will

have to be performed for adequate tire clearance.

NOTICE TO DEALER AND VECHICLE OWNER

Any vehicle equipped with any Rough country product must have the “Warning to Driver” decal installed on the sun visor

or dash. The decal is to act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics. INSTALLING DEALER—It is your responsibility to install the warning decal and to forward these installation in-

Braking

Kit Contents

6112– Rear Add-a-Leaf

7545– Kit Box Including

Drivers Side Upper Control Arm

Pass Side Upper Control Arm

Dr Upper and Lower Diff Drop Brkts

Pass Axle Drop Bracket

Skid Plate Spacers

Driver & Pass Side Shock Bracket

7545 Bag1 Differential Hardware

7545 Bag2 Axle Bracket Bag

7545 Bag4 Instruction Bag

7545 Bag5 Shock Bag

8101/9101 Front Shocks

8134/9134 Rear Shocks

Tools Needed

10mm Wrench 1/2” Drill Bit

11mm Socket Punch

13mm Wrench 15mm Socket

Hammer

18mm socket

18mm Wrench

21mm socket

21mm Wrench

1 1/16” wrench

3/8” Allen Wrench

Drill

Jack Stands

Torsion Bar Tool

Torque Specs:

Size Grade 5 Grade 8

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

FRONT INSTALLATION INSTRUCTIONS

1. Chock the rear wheels to prevent movement. Place a jack under the lower control arm and jack the vehicle up.

Place jack stands on the frame rails to support the vehicle. Remove tires and wheels.

2. Measure the length of adjustment bolt for later reference. See Photo 1.

3. Remove the torsion bar adjuster bolt. See Photo 2.

PHOTO 1 PHOTO 2

MEASURE BOLT

4. The next step will require a torsion bar tool to safely unload the torsion bars . Part # 1067 is available from Rough

Country. Please Note the torsion bar is under extreme load. Substituting a tool for an actual torsion bar tool

may result in injury.

5. On either side of the vehicle, position unloading tool on cross member. See Photo 3. Apply light lubricating grease

to tool threads. Be sure to leave adequate clearance to remove the adjuster block from the cross member.

6. Tighten tool on torsion bar adjuster to relieve tension on the bolt .Loosen the adjuster bolt and remove the threaded

block from cross member. See Photo 4.

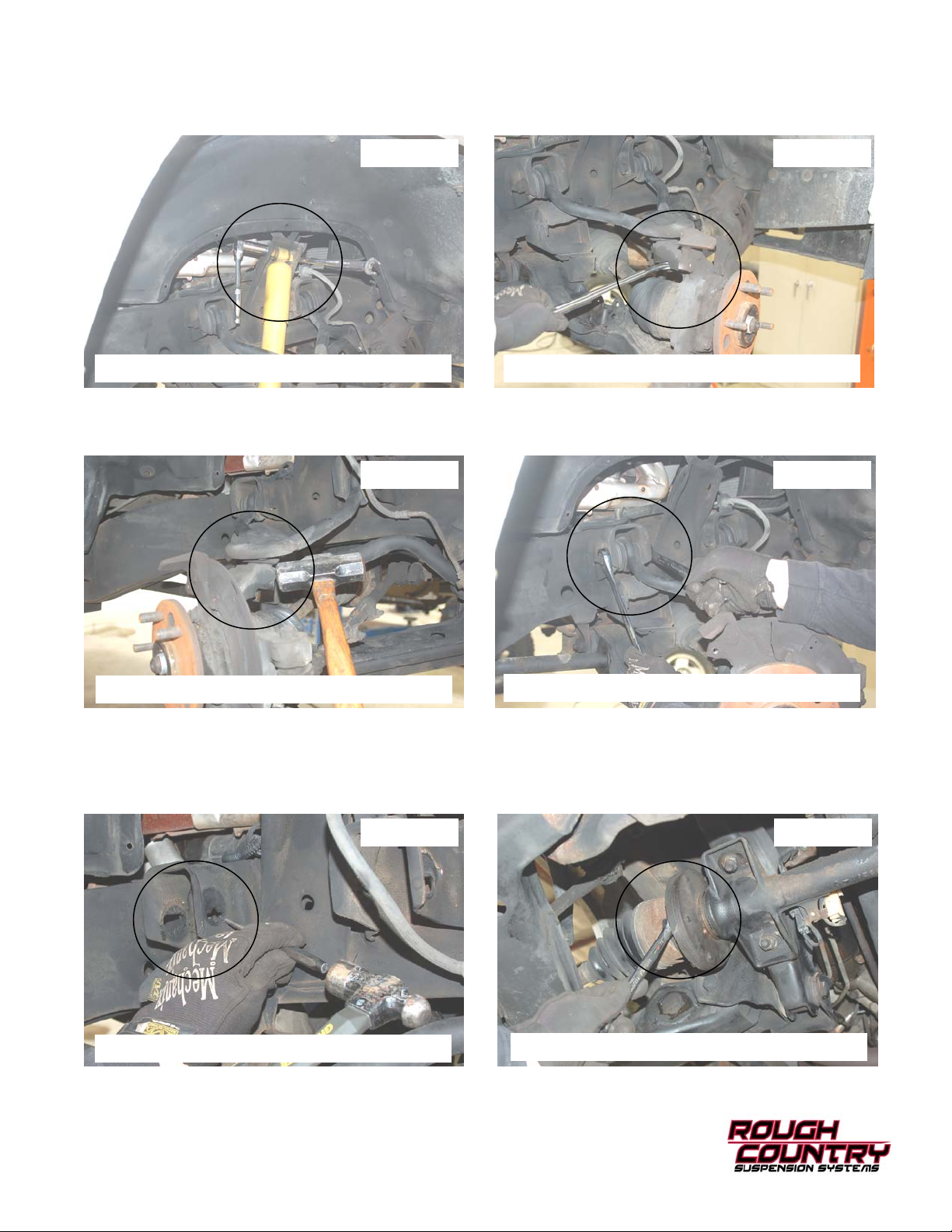

PHOTO 3 PHOTO 4

UNLOAD KEY USING TORSION BAR TOOL REMOVE THREADED ADJUSTER BLOCK

7. Slide the bar forward and the torsion bar adjuster will fall free. In the event the bar seems lodged, use a punch and

hammer routed through the hole in the back of the cross member to drive it forward. See Photo 5. Repeat on opposite side.

8. The supplied torsion bar keys will installed in a later step.

9. Remove brake caliper as shown in Photo 6 using a 3/8” allen wrench and secure out of harms way.

10. Remove the rotor.

REMOVE THE ADJUSTER BOLT

PHOTO 5

REMOVE THE TORSION BAR KEY

PHOTO 6

REMOVE THE BRAKE CALIPER

11. Remove the stock shock from the upper mount (Shown in Photo 7) and the lower mount using a 18mm socket /

wrench. Retain the stock hardware.

12. Remove the upper ball joint cotter pin and loosen the nut using a 1 1/16” wrench. See Photo 8. Retain the stock

hardware. Unplug the ABS sensor wire is equipped.

PHOTO 7 PHOTO 8

REMOVE THE SHOCK ABSORBER LOOSEN THE BALL JOINT HARDWARE

13. Support the lower control arm.

14. Strike the knuckle as shown to dislodge the upper ball joint. See Photo 9.

15. Remove the upper control arm hardware using a 21mm wrench / socket. See Photo 10.

PHOTO 9 PHOTO 10

DISLODGE THE UPPER BALL JOINT

REMOVE THE UPPER ARM HARDWARE

16. On Pre 94 models the upper control arm alignment tabs may need to be removed. If applicable remove the perforated area as shown. See Photo 11.

17. Remove the factory lower skid plate using a 15mm wrench if equipped.

18. Remove the 12 bolts-6 per side that secure the half shafts to the differential using a 15mm wrench. Retain the factory hardware. See Photo 12.

PHOTO 11 PHOTO 12

REMOVE THE TABS IF NEEDED

REMOVE THE CV SHAFT BOLTS

Loading...

Loading...