Page 1

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

HygroLab Bench Top Indicator version 4

Instruction Manual

Instruction Manual

Document Type

Page 1 of 51

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 2

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 2 of 51

Table of contents

1 Overview ....................................................................................................................................3

2 General description ..................................................................................................................4

2.1 Power requirements................................................................................................................4

2.2 Probes and probe inputs.........................................................................................................4

2.3 Analog outputs (optional) ........................................................................................................6

2.4 Serial interface (HygroLab 2 and 3)........................................................................................7

2.5 Optional Ethernet (TCP/IP) interface (HygroLab 2 and 3)......................................................9

3 Optional configuration and communication software ........................................................10

4 How to configure the HygroLab ............................................................................................10

4.1 Internal service connector (HygroLab configuration)............................................................10

4.2 Baud rate compatibility requirements ...................................................................................11

4.3 Ethernet local area network ..................................................................................................11

4.4 RS-485 multi-drop network (HygroLab 2 and 3)...................................................................12

4.5 Selection of the probe supply voltage (main PCB) ...............................................................14

5 Operation.................................................................................................................................14

5.1 Unit system ...........................................................................................................................15

5.2 Display and keypad...............................................................................................................15

5.3 Probe Input Selection............................................................................................................16

6 Function menu ........................................................................................................................16

6.1 CALCULATE (HygroLab 2 and 3).........................................................................................17

6.2 MODE (HygroLab 3) .............................................................................................................18

6.3 DISPLAY (HygroLab 2 and 3)...............................................................................................21

6.4 ADJUST M.PT ......................................................................................................................21

6.5 ADJUST 1PT.........................................................................................................................23

6.6 ADJUST REF........................................................................................................................24

6.7 PROBE..................................................................................................................................25

6.8 SETTINGS ............................................................................................................................25

6.9 SYS STATUS........................................................................................................................26

7 Error and status messages....................................................................................................26

8 Connectors..............................................................................................................................27

9 Environmental limits ..............................................................................................................28

10 Maintenance of the ROTRONIC probes ................................................................................29

11 Specifications..........................................................................................................................30

12 Practical advice for measuring humidity .............................................................................31

13 Probe calibration basics ........................................................................................................31

13.1 Temperature calibration ........................................................................................................31

13.2 Humidity calibration...............................................................................................................32

14 Humidity definitions ...............................................................................................................33

15 Dew point accuracy ................................................................................................................36

16 ASCII communications protocol ...........................................................................................37

17 Water activity measurement ..................................................................................................40

17.1 Water activity: definition and applications.............................................................................40

17.2 Using the HygroLab 2 or 3 to measure water activity...........................................................42

17.3 Principle of measurement .....................................................................................................43

17.4 General recommendations....................................................................................................44

17.5 Using the AwE mode (HygroLab 3) ......................................................................................45

17.6 Using the AwQuick mode (HygroLab 3) ...............................................................................47

18 Accessories for the HygroLab...............................................................................................50

19 Document releases.................................................................................................................51

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 3

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 3 of 51

Applicability:

This manual is valid for all instruments with firmware version 4.x, where 4.x can be 4.0, 4.1, etc.

(see Function Menu, SYS STATUS). Changes to the last digit of the version number reflect minor

firmware changes that do not affect the manner in which the instrument should be operated.

Note: Instrument configuration requires a PC with the optional ROTRONIC HW4 software version

1.2.2 or higher. Instructions for using the software are not included in this manual. These

instructions are shipped separately on the software CD ROM.

1 Overview

The HygroLab is a bench-top laboratory humidity temperature indicator that can be used with a

wide variety of probes to meet specific application requirements. The HygroLab operates with an

external AC adapter (9 to 15 VDC – nominal: 12 VDC).

The HygroLab is available in 3 different models:

HygroLab 1: basic indicator

- Accepts up to 2 probes: ROTRONIC HygroClip digital probes or analog probes

- Simultaneous display of relative humidity and temperature (one probe at a time)

- Software-based probe calibration (1-point or multi-point)

2)

1) ROTRONIC analog probes only – restrictions apply

2) Applies only to the ROTRONIC HygroClip digital probes

HygroLab 2: standard indicator

- Accepts up to 4 probes: ROTRONIC HygroClip digital probes or analog probes

- Relative humidity, temperature, dew point, wet bulb, mixing ratio, enthalpy, etc., or user

defined calculation such as the difference between temperature and dew point

- Software-based probe calibration (1-point or multi-point)

- Possibility of using one of the four probes as a reference to do a 1-point adjustment of the

other probes

3)

- RS232 and RS485 serial ports or Ethernet (TCP/IP), RS-232 and RS-485 ports

- Optional analog outputs (repeat analog probe input signals)

1) Third-party pressure probe or ROTRONIC analog probe – restrictions apply

2) Uses either a fixed barometric pressure value or the measurements from an analog pressure probe

for those parameters that require pressure as a computational input. The fixed pressure value can be

changed with the optional HW4 software.

3) Applies only to the ROTRONIC HygroClip digital probes

4) The optional HW4 software facilitates both networking and instrument configuration

3)

1)

1)

2)

4)

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 4

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

Instruction Manual

instruction manual

Document title

HygroLab 3: general purpose indicator with water activity functions

Same as HygroLab 2, except for:

- Accelerated water activity measurement with up to 4 probes (AwQuick mode): allows the

measurement of most products in typically 5 minutes

- Full equilibration measurement with up to 4 probes (Standard mode) with automatic

detection of equilibrium conditions

- Analog probe inputs with 12-bit resolution

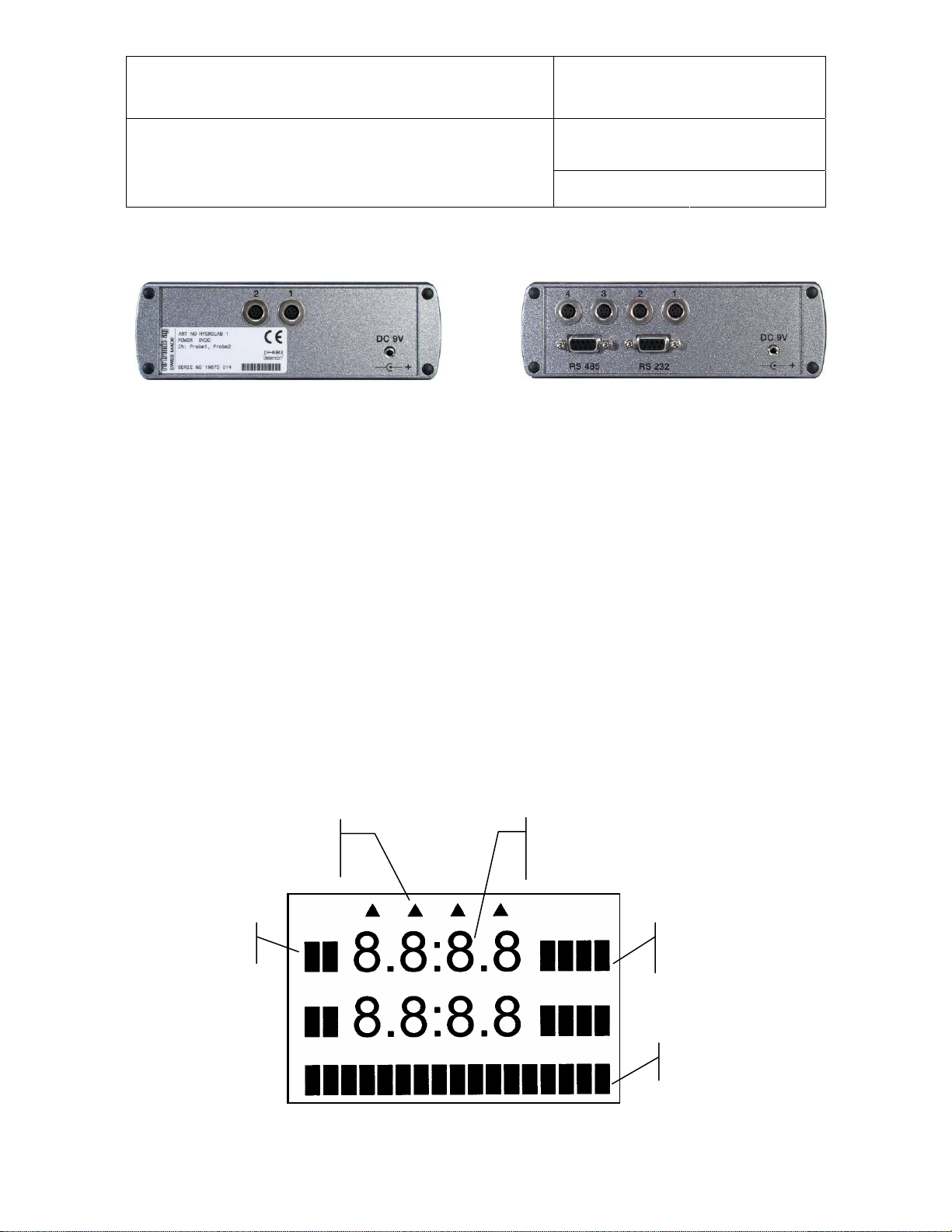

HygroLab 1 HygroLab 2 and 3

Page 4 of 51

Document Type

2 General description

2.1 Power requirements

The HygroLab operates with an external AC adapter providing 9 to15 VDC, 100 mA. The power

receptacle is a 3.5 mm Jack female with DC+ center.

Note: when equipped with the optional Ethernet module, the HygroLab requires an AC adapter

able to provide 300 mA.

2.2 Probes and probe inputs

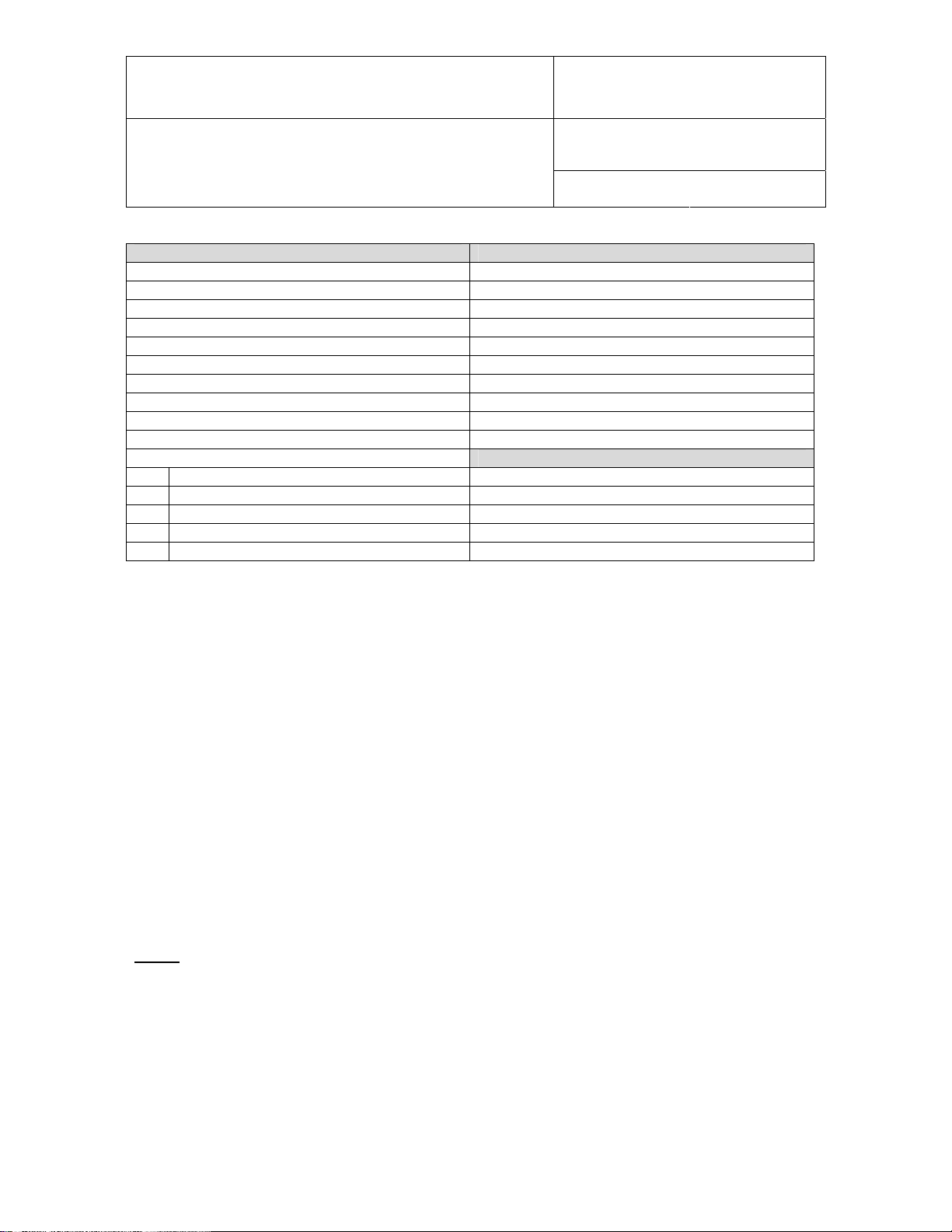

Model HygroLab 1 HygroLab 2 HygroLab 3

Number of probe inputs 2 4 4

Probe types 1) ROTRONIC Digital

ROTRONIC Analog

Number of digital input channels 2 4 4

Number of analog input channels 4 8 8

Analog input A/D resolution 10-bit 10-bit 12-bit

1) Unless otherwise specified when ordering, all probe inputs are factory programmed to accept a HygroClip

digital probe and the voltage powering the probe is the AC adapter voltage (12 VDC nominal). Prior to using

any analog probe, the corresponding probe input should be re-programmed. With the HygroLab 2 and 3, this

can be done with the HW4 software after connecting the RS232 port of the HygroLab to a PC (see separate

software manual).

ROTRONIC Digital

ROTRONIC Analog

Third Party Analog

ROTRONIC Digital

ROTRONIC Analog

Third Party Analog

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 5

IN-E-HyLab-V4_11

(

(

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 5 of 51

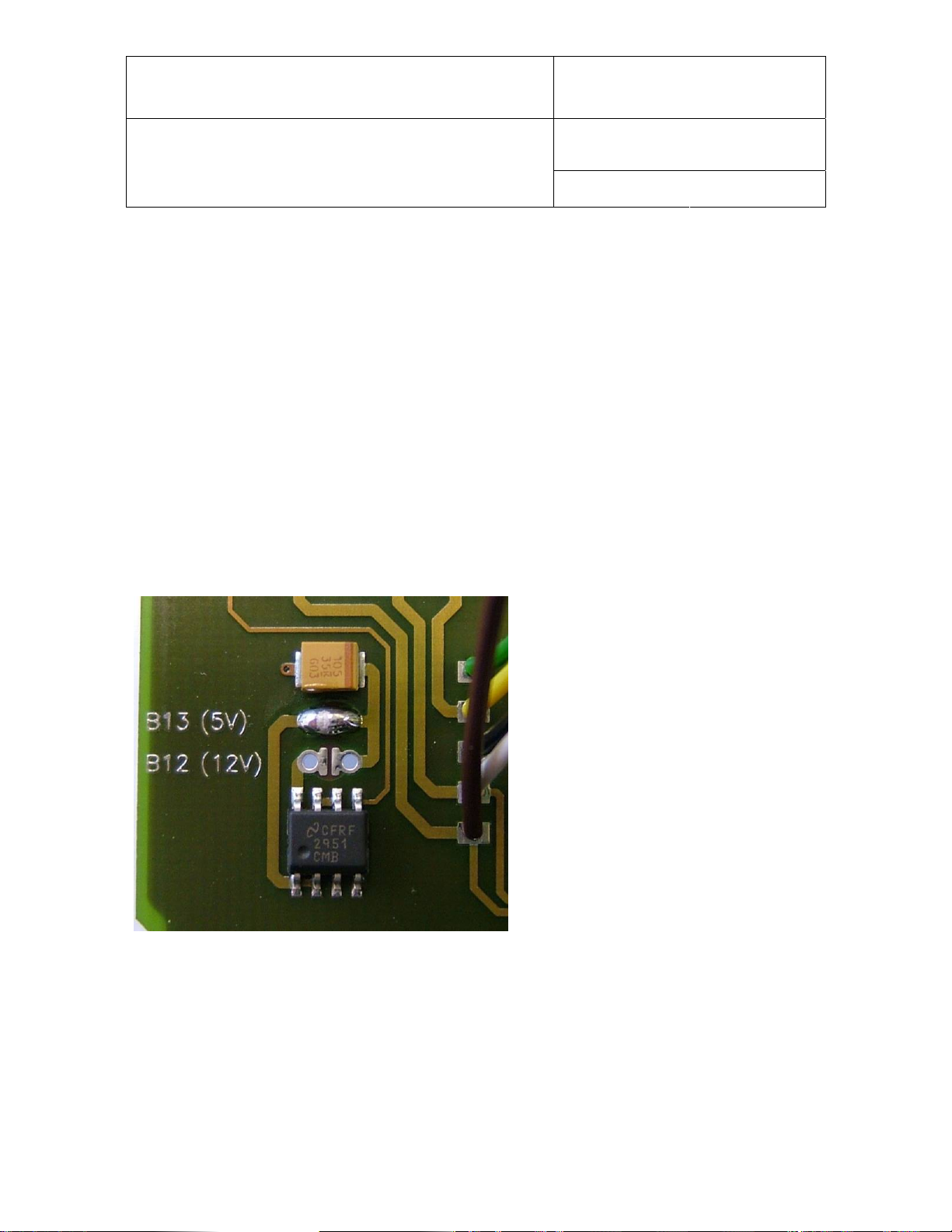

IMPORTANT: All probes connected to the HygroLab can be supplied with 5 VDC by opening solder pad B12

and closing solder pad B13 on the main PCB

. – see page 13: selection of the probe supply voltage.

2.2.1 HygroClip digital probes

The HygroLab is primarily designed for use with the ROTRONIC HygroClip digital humidity

temperature probes. These probes permit to take full advantage of all the features and functions of

the HygroLab.

The ROTRONIC HygroClip digital probes are highly accurate and are calibrated entirely by means

of software (no adjustment potentiometers). Because calibration and other data are stored in the

probe non-volatile memory, the probes are fully interchangeable. When a probe requires calibration

or has to be repaired, it can be replaced with another probe in a few seconds.

The ROTRONIC HygroClip digital probes are available in different configurations so as to meet the

requirements of each application:

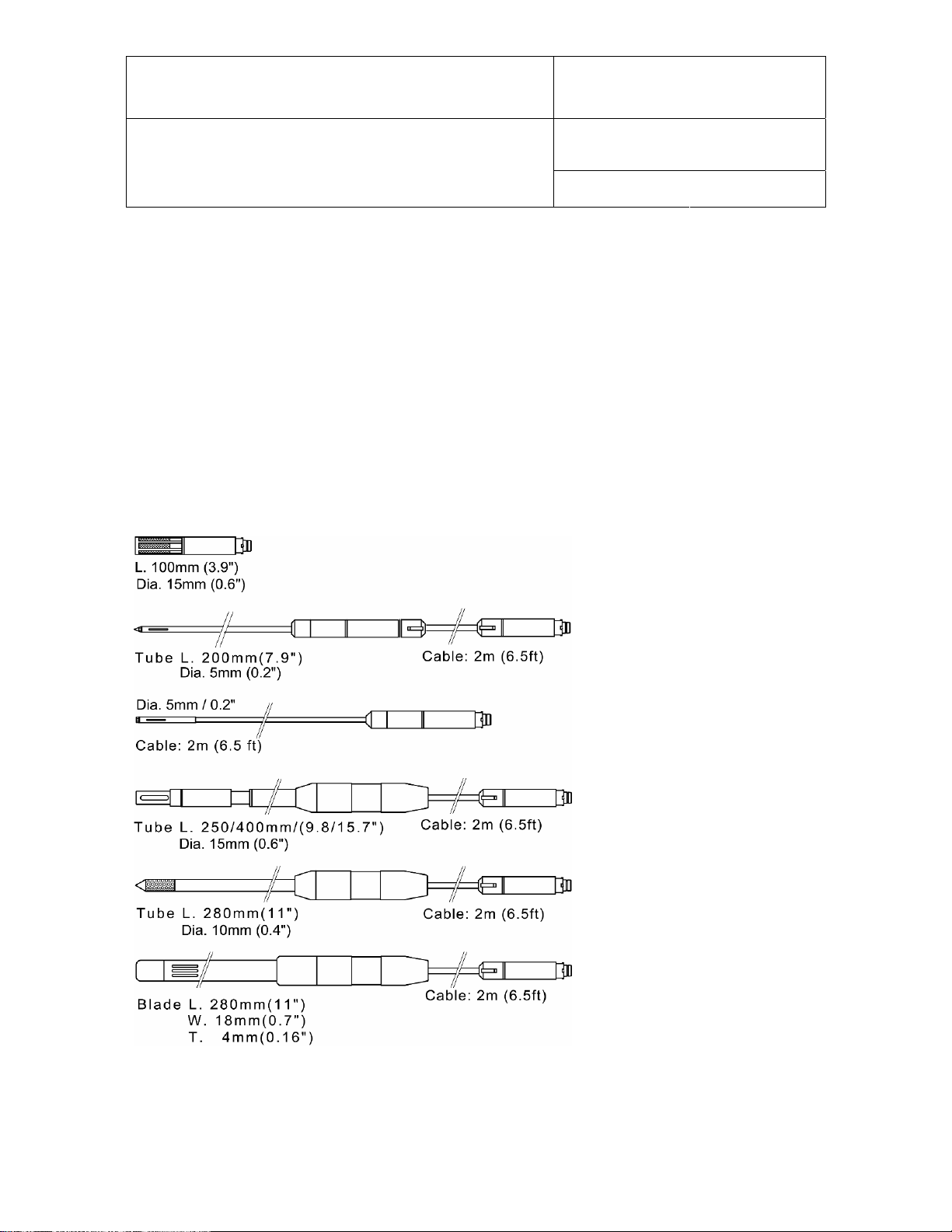

HygroClip S

measurement in air

max. 85°C (185°F)

HygroClip SP05

measurement in air ducts

max. 85°C (185°F)

HygroClip SC05

measurement in tight spaces

max. 100°C (212°F)

HygroClip HK25 / HK40 air probe

measurement at high temperature

HK25: max. 100°C (212°F)

HK40: max. 200°C (392°F)

wire mesh filter

HygroClip HP28 insertion probe

measurement of materials in bulk

max. 85°C

185°F)

HygroClip HS28 sword probe

measurement of paper stacks/rolls

max. 85°C

185°F)

Note: all of the above probes are designed for use with the HygroPalm indicator and have a

DAT05 connector. An adapter cable MOK-01-B5 is required for connection to the HygroLab (see

Accessories). Similarly, the HygroClip probes designed for use with the HygroFlex transmitter

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 6

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 6 of 51

have a T7 connector (not shown here). These probes can be connected to the HygroLab with the

T7-03-B5 adapter cable.

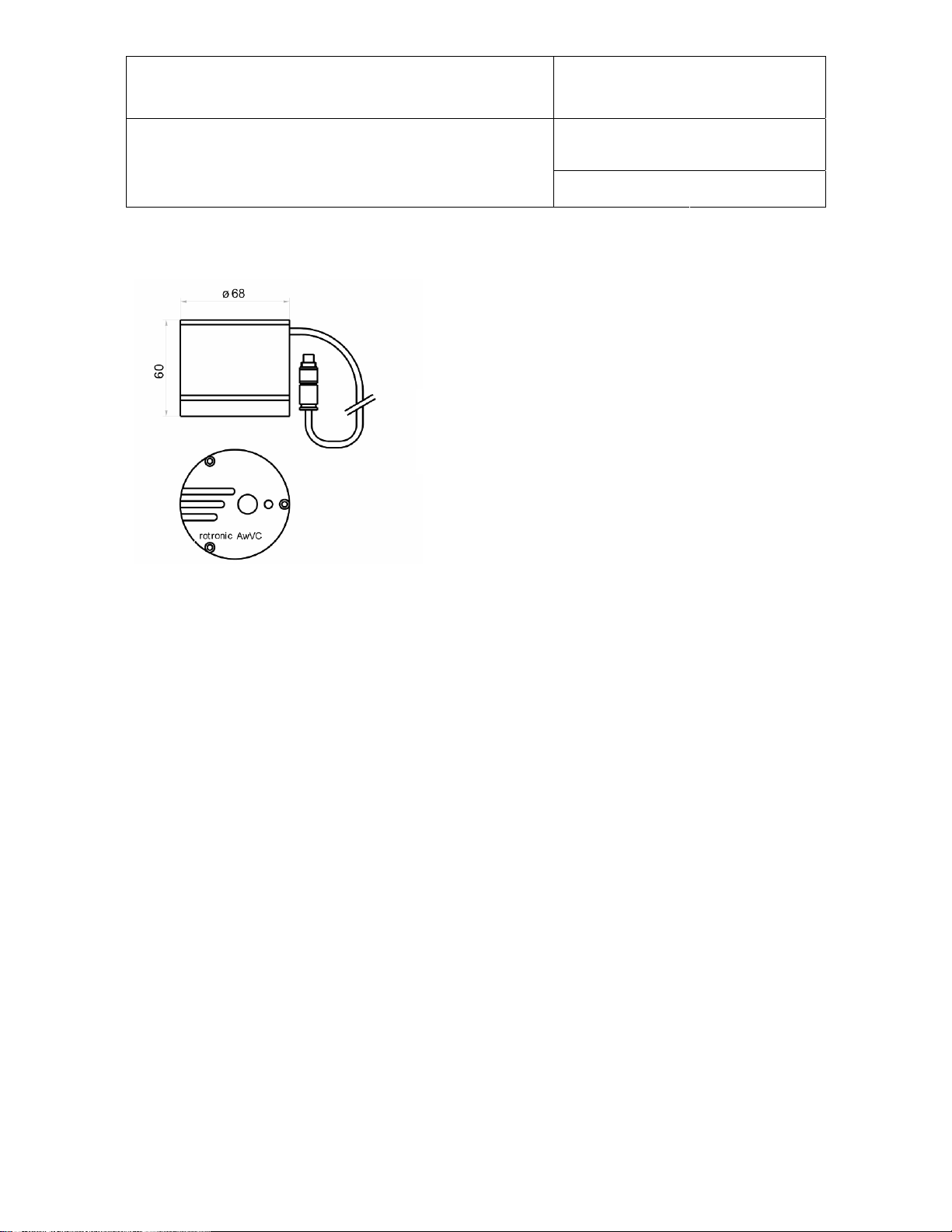

AW-DIO and AwVC-DIO water activity probes

Direct connection to the HygroLab

(probe has a B5 connector)

2.2.2 Analog probes

The HygroLab can be used with one or more analog probes. The corresponding probe input(s) as

well as

using the probe(s). For example, an analog pressure probe may used to provide the local value of

barometric pressure for the computation of parameters such as the wet bulb temperature, mixing

ratio or enthalpy.

Use of analog probes is subject to the following restrictions and limitations:

a. ROTRONIC analog humidity-temperature probes with the standard temperature output signal of

b. Third-party analog probes: single channel probes (one signal), output signal within the range of

c. Resolution is limited by the 10-bit A/D converter

the scale and unit of the analog input signal(s) should be programmed with the HW4 software prior to

– 0.5…2.0 V = -50…200°C: because the HygroLab cannot read a negative voltage signal,

temperature measurement is generally limited to values above freezing.

0 to 2.5 VDC, supply voltage: 9 VDC or less, maximum current consumption: 10 mA.

1)

used for the analog inputs. This converter

provides a theoretical maximum of 1024 counts for an input voltage span of 2.5 VDC. In theory,

this gives a resolution of 2.5 / 1024 = 0.00244 V. In practice, it is not possible to get 100% of the

counts from an A/D converter and the actual resolution should be about 0.0027 V (typical). For

example, if a probe with a temperature signal of 0…1 V = 0…100°C is being used, the signal

resolution will be about 100 x 1 x 0.0027 = 0.27°C.

1) HygroLab 3: 12-bit A/D converter

2.3 Analog outputs (optional)

Analog outputs are optional on the HygroLab 2 and 3. These outputs simply repeat the analog

inputs (if any analog probe is being used). See Connectors - Optional analog output connector.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 7

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 7 of 51

2.4 Serial interface (HygroLab 2 and 3)

Both the HygroLab 2 and 3 have external receptacles (located on the back panel) that provide both

a RS-232 and a RS-485 interface.

Serial interface settings

The HygroLab indicator is compatible with the ROTRONIC HW4 software (version 1.2.2 or higher)

and backward compatible with the ROTRONIC HW3 software. Each software uses a different

communications protocol and different settings regarding the parity, number of data bits and

number of stop bits. When interrogated, the HygroLab automatically recognizes which software and

which protocol is being used. This allows the HygroLab to be used with either HW3 or HW4 without

requiring a manual configuration of the HygroLab serial settings.

When used with HW4, the HygroLab automatically sets its serial interface as follows:

Parity : none

Data bits : 8

Stop bits : 1

When used with HW3, the HygroLab automatically sets its serial interface as follows:

Parity : even

Data bits : 7

Stop bits : 1

Note: the HygroLab will automatically set its serial interface to the above settings when interrogated

by a third-party software that uses the same ASCII commands as HW3 to request data. On models

with the optional Ethernet interface, the internal module must be re-configured as indicated in

document IN-E-TCPIP-Conf_11 (available in PDF format).

IMPORTANT: The HygroLab can be configured by the user with a Baud rate of 57600. The factory

default Baud rate of 19200 is compatible with both HW3 and HW4. The Baud rate of 57600 is

compatible only with HW4.

RS-232 interface

This interface is used to read measurement data, adjust any HygroClip probe connected to the

HygroLab and to configure the HygroFlex. The RS-232 allows direct connection of the HygroLab to

the COM port of a PC (up to 150 m / 490 ft separation)

The HW4 software (version 1.2.2 or higher) should be installed on the PC.

It is also possible to connect the HygroLab 2 or HygroLab 3 to an Ethernet network by using a

device server with a RS-232 port (TCP/IP encapsulation). Depending on the software used to

communicate with the HygroLab, the serial port of the device server should be configured as

indicated below:

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 8

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 8 of 51

1) PC with HW4 (version 1.2.2 or higher):

Parity : none

Data bits : 8

Stop bits : 1

2) PC with a third-party software using the same ASCII commands as HW3 to request data (see

ASCII communications protocol).

Parity : even

Data bits : 7

Stop bits : 1

RS-485 interface

This interface is used to connect together a number of HygroLab indicators (as well as other

ROTRONIC devices) so as to form a RS-485 multi-drop. This is useful when the number of PC

ports is limited and provides savings on cabling costs. The RS-485 interface has the same

functionality as the RS-232 interface (measurement data, adjustment of HygroClip probes and

device configuration).

In a RS-485 multi-drop, the master is automatically the device that is connected to a COM port,

USB port or network port (Ethernet) of the PC. Any ROTRONIC device that is equipped with both a

RS-232, USB or Ethernet interface and a RS-485 interface can be used as the master. The other

devices in the RS-485 multi-drop are slaves. Any HygroLab 2 or HygroLab 3 indicator can be used

either as a slave or a master, without special configuration other than giving a unique RS-485

address to each device and setting each device to use the same Baud rate.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 9

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 9 of 51

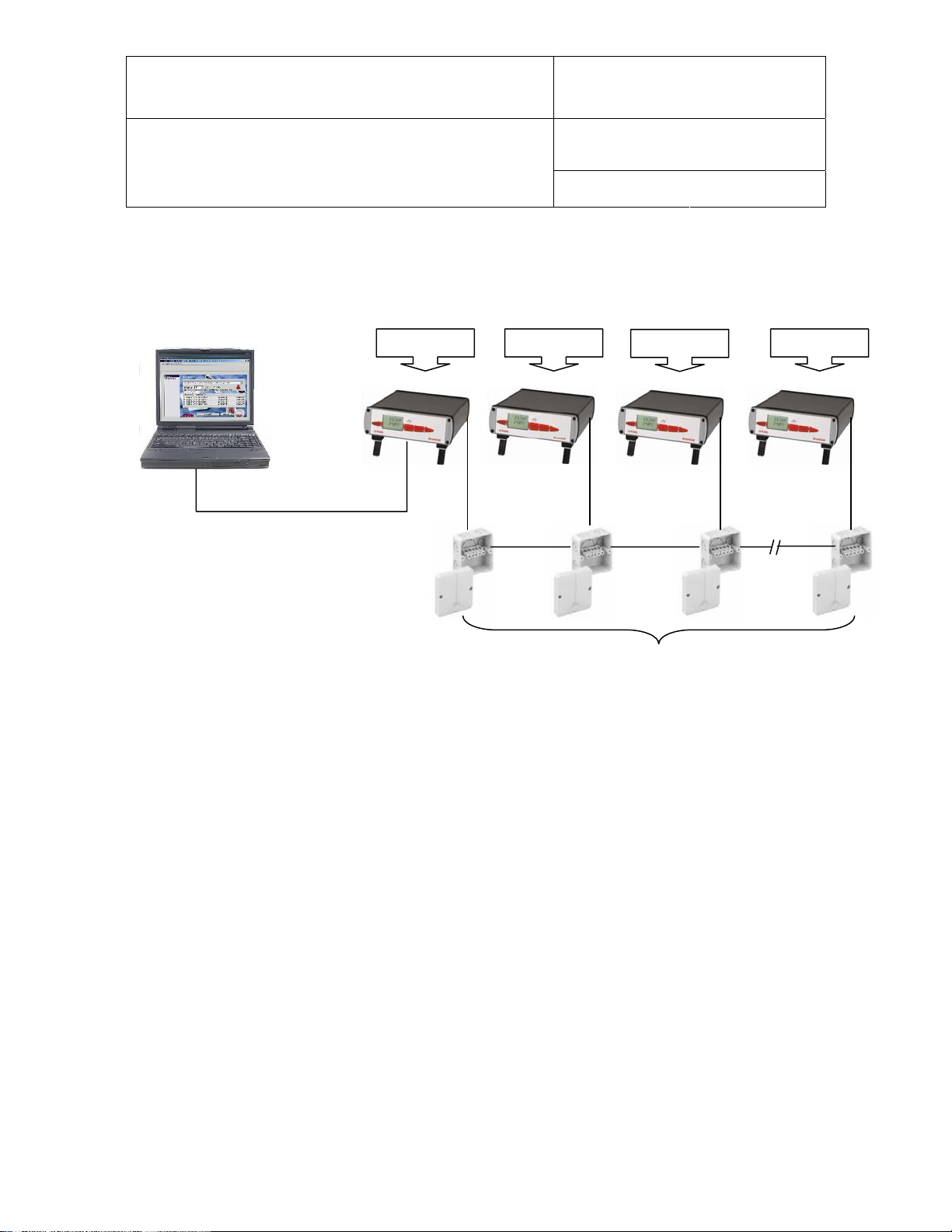

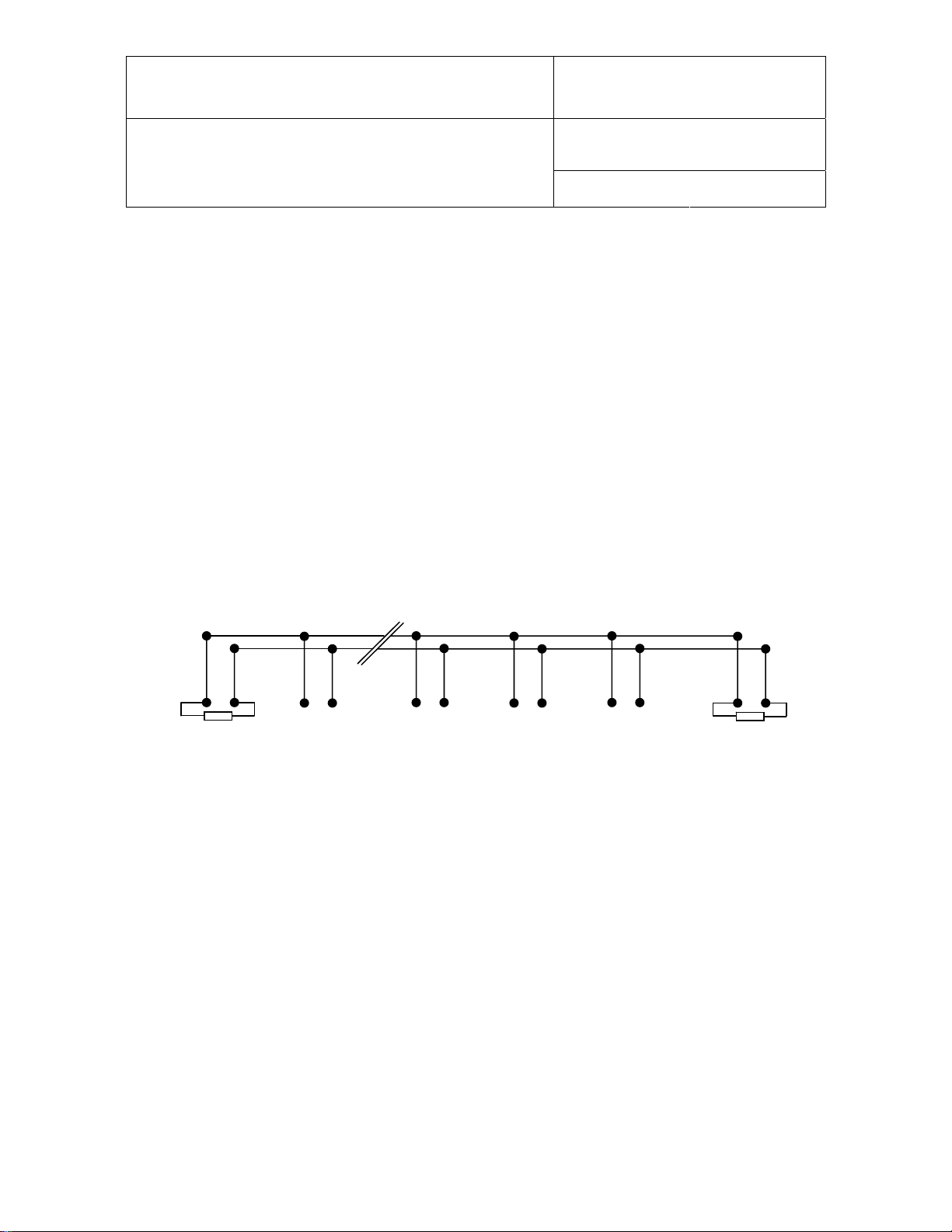

Example of a RS-485 multi-drop

In the following example, the master (address 1) is directly connected to a COM port of the PC

(RS-232). Units 2 to 64 are slaves.

Address 3

RS232: 3 wires

(incl. ground)

max. 150 m

Address 64 Address 2 Address 1

RS485: 2 wires, up to 1000m

Important:

- All devices connected to the same RS-485 multi-drop should use the same baud rate

- Each device within the same RS-485 multi-drop should have a unique address

- In theory, HW4 allows an unlimited number of masters, each with up to 63 slaves. Practical limits

to the total number of devices are set by the PC.

PC with HW4: Except for the distance limitations specific of a RS-232 connection, the above

diagram applies also when the master (for example HygroClip DI interface) is connected to a USB

port or to an Ethernet network.

2.5 Optional Ethernet (TCP/IP) interface (HygroLab 2 and 3)

As an option, both the HygroLab 2 and HygroLab 3 can be ordered with an Ethernet (TCP/IP)

interface in addition to the standard RS-232 and RS-485 serial interface. All different types of

interface offer the same functionality. The HW4 software accepts connection to the PC by means of

an Ethernet network.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 10

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 10 of 51

3 Optional configuration and communication software

Depending on the model of HygroLab, the ROTRONIC HW4 software (version 1.2.2 or higher)

offers additional functionality such as:

- Networking (unlimited number of masters, up to 64 units per multi-drop)

- Instrument configuration (unit system, etc.)

- Adjustment of the ROTRONIC HygroClip digital probes

- Data logging to a PC disk file

- Graphic functions (both on and off-line)

- Alarm functions (on-screen display, reports, notification by e-mail, etc.)

HW4 is compatible with Windows XP, NT4 with SP6a or higher. For more details see separate

instruction manual provided with the software.

The HygroLab is backward compatible with the ROTRONIC HW3 software (Windows 98 or NT)

4 How to configure the HygroLab

The HygroLab is configured by the factory as specified when the instrument was ordered. The

configuration can be modified by the user and this requires connecting the HygroLab to a PC with

the ROTRONIC HW4 software installed (version 1.2.2 or higher).

Depending on the model of HygroLab, the following can be configured by the user with Device

Manager in HW4 (where relevant, the factory default is indicated in bold):

- Device name

- RS-485 address [0]

- Device write protection with password [disabled]

- Fixed barometric pressure value used in some psychrometric calculations [1013.25 hPa]

- Dew or frost point calculation below freezing [frost point]

- Language and unit system

- Probe input type (HygroClip probe, analog pressure probe, other analog probe)

- Input name

- Calculated parameter (HygroClip probe only)

- Barometric pressure (fixed value or read from an input) [fixed]

- Alarm threshold (low and high) for humidity, temperature, calculated parameter or other.

- Parameter or custom calculation associated with each analog output and output scale

- Custom calculation (example: difference between two parameters such as dew point)

- Optional display configuration (resolution, trend indicators, parameters to be displayed)

- Keypad: restricted menu access [not restricted]

- Baud rate (serial interface) [19200]

For more details see separate instruction manual provided with the software.

4.1 Internal service connector (HygroLab configuration)

All HygroLab models have an internal RS-232 service connector (MTA) located on the main PCB

(see PCB connections). Cable AC1623 is required to connect the HygroFlex MTA connector to

COM port of a PC.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 11

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Use of the MTA service connector is limited to configuring the instrument (unit system, output

range, display, etc.). Both the HygroLab 2 and HygroLab 3 can also be configured via one of the

external digital ports.

Instrument configuration requires a PC with the HW4 software installed. Instructions for configuring

the HygroLab are provided in the software manual.

Instruction Manual

Document Type

Page 11 of 51

4.2 Baud rate compatibility requirements

Depending on the model, devices from ROTRONIC use one of the following Baud rates as the

factory default:

• 57600 bps: HygroLog NT data logger and docking stations

• 19200 bps: HygroPalm and HygroLab indicators, HygroFlex and M33 transmitters, HygroClip

Alarm programmable alarm card, HygroClip DI interface, HygroStat MB Thermo-Hygrostat

The factory default Baud rate of the HygroLab is compatible both with both the ROTRONIC HW4

and HW3 software and is the recommended Baud rate for the HygroLab.

IMPORTANT:

• All devices connected to a RS-485 multi-drop network (master and slaves) must use the

same Baud rate

• Models with the optional Ethernet (TCP/IP) interface: after using HW4 – Device Manager to

change the Baud rate, you should also change the configuration of the internal Ethernet

module to the new Baud rate (see separate HW4 manual).

Devices and internal Ethernet modules with mismatched Baud rate will not communicate together.

• The Baud rate configuration of a ROTRONIC device can be changed with the Device

Manager function (Digital Interface tab) available from within the HW4 software.

• The Baud rate of a Digi Module can be changed only from the module web interface. See

separate document IN-E-TCPIP-Conf_11 (available in PDF format).

4.3 Ethernet local area network

ROTRONIC devices with an Ethernet (TCP/IP) interface presently use an internal module

manufactured by Digi International (Digi Connect ME for a wired connection, Digi Connect WI-ME

for a wireless connection). Both types of module feature a web interface that is used to configure

the module.

IMPORTANT: The TCP/IP settings of models with an Ethernet (TCP/IP) interface should be

configured to be compatible with the local area network. Detailed instructions are provided

separately in document IN-E-TCPIP-Conf_11 (available in PDF format).

Models with an Ethernet (TCP/IP) interface are shipped with a Device Configuration Certificate that

provides information about the factory configuration settings of both the Ethernet module and

device. See example below:

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 12

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Setting Value

DHCP or Static Address Static

IP Address 192.168.1.1

Subnet Mask 255.255.255.0

Default Gateway 192.168.1.0

TCP Port 2101

MAC Address 00:40:9D:28:2D:2A

Firmware Release (device) 1.4

User Name (web interface) rotronic

Password (web interface) wlan

Serial Port Configuration Profile TCP Sockets

Basic Serial Settings

Baud Rate 57600

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Instruction Manual

Document Type

Page 12 of 51

4.4 RS-485 multi-drop network (HygroLab 2 and 3)

Both the HygroLab 2 and HygroLab 3 feature a RS-485 connector. When the number of available

PC ports is limited, this connector can be used to connect together up to 64 HygroLab (or other

devices) in a multi-dropped arrangement. In principle, an unlimited number of such networks can

be monitored with the HW4 software, but each RS-485 multi-drop network is limited to 64 devices.

The HygroLab can be used either as a slave or a master, without special configuration. The master

is automatically the device that is directly connected to the PC or LAN by means of a RS-232 port

or TCP/IP port.

RS-485 Address: the RS-485 address is used to identify the individual devices that are connected

to a RS-485 multi-drop and must be unique to each device. This address is part of the HygroLab

communications protocol. The factory default for the RS-485 address is 00. In general, this address

should not be changed manually (see note below). As far as HW4 is concerned, all masters can

share the same RS-485 address. When the HW4 command “Search for RS-485 slaves” is being

used, HW4 automatically changes from 00 to 01 the RS-485 address of any master that has slaves

attached. As a result, all masters end up with the same RS-485 network address (01). In addition,

HW4 automatically changes the RS-485 address of the slaves in each multi-drop from 00 (factory

default) to a unique address ranging from 02 to 64. The same address range (02 to 64) is used

again when there is more than one multi-drop RS485 network.

Notes:

- We recommend using HW4 to give each HygroLab a unique name for easier identification.

- In the situation where an RS-485 network is to be monitored by software other than HW4, you

will have to use HW4 to give each device a unique RS-485 address prior to connecting to the

network.

- If you change an instrument from master to slave, be sure to change the RS address of the

instrument to 00 before establishing the RS-485 connection. Not doing so may prevent HW4

from detecting the instrument. After detecting the instrument, HW4 will automatically change

the RS address to 02 or higher. Please note that HW4 may eventually change the address of

any master with address 00.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 13

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 13 of 51

- All devices within a multi-drop should use the same Baud rate. See Baud rate compatibility

requirements.

- Models with Ethernet (TCP/IP) interface: please note that the Baud rate of the HygroLab and

the Baud rate of the internal Ethernet module should be set to the same value.

RS-485 Cable: Using a symmetrical transmission method in combination with low capacity/ low

attenuation twisted pair cables, allows extremely reliable long distance connections. The use of a

high grade shielded cable avoids cross talk between the transmitted signals and also reduces the

potential of external interference. For the RS-485 cable, we recommend using a cable

Cat. 5e ANSI/ TIA /EIA-568-A-5.

In general the RS-485 cable should be shielded and comply with the following specifications:

- Cable capacitance <=300pF/m or 90 pF/ft

- Line impedance 100 Ω ±15 Ω

- Line resistance 140 Ω/km or 225 Ω

- Signal lines Twisted pair

In addition, we recommend terminating each end of the RS-485 cable with a 240 Ohm resistor.

RS485 Network:

240 Ω

Note: all instruments connected to the network should use the same baud rate

Voltage potential issues: The existence of a voltage-potential between instruments that are

interconnected can be a source on concern in large installations, installations with different mains

power supply and in inter-building networking.

As a first measure, the shield of a signal cable should be connected at both ends. In the case of a

data cable, a low-resistance potential equalization cable may also have to be used. This cable

should be run parallel and as near as possible to the data cable, preferably in the same conduit.

The shield of the data cable should under no circumstances be used as equalization cable! The

conductors of the potential equalization cable should ideally be stranded in order to be effective

also in case of high- frequency interference.

Addr. 1 Addr. n

RS485 device connectors

240 Ω

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 14

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 14 of 51

The following points should also be observed:

• Close the parasitic circuit

• Connect all devices to the potential equalizing cable as often as possible. Electrical

conductors such as machine elements, metal tubes or supporting constructions should be

integrated into the system.

• Protect the potential-equalization cable and connections against corrosion.

• Select the cross-section of the potential equalization cable according to the maximum

equalization current.

If these different measures do not correct the problem, a galvanic separation according to

ISO 9549 may have to be installed. You may also want to consider the use of fiber-optic cables.

4.5 Selection of the probe supply voltage (main PCB)

Starting with PCB number 66.0739.0302, the probes can be powered with either 5 VDV or directly

from the AC adapter (nominal 12 VDC). The default factory setting is to use the voltage from the

AC adapter. All probes connected to the HygroLab can be supplied with 5 VDC by opening solder

pad B12 and closing solder pad B13 on the main PCB. Depending on the probe model, changing

the probe supply voltage may require the probe to be re-adjusted (please, consult factory).

5 Operation

Connect the AC adapter to the Power connector of the HygroLab and connect a probe

the ON/OFF key. After a brief test and introductory message, the measurements appear on the LC

display. Measurements are updated to the display at the rate of 0.75 sec. x number of digital

probes (HygroClip) connected to the HygroLab.

1) Unless otherwise specified when ordering, all probe inputs are factory programmed to accept a HygroClip

digital probe. Prior to using any analog probe, the corresponding probe input should be re-programmed. This

can be done with the HW4 software after connecting the RS232 port of the HygroLab to a PC (see separate

HW4 manual).

© 2006; Rotronic AG IN-E-HyLab-V4_11

1).

Press on

Page 15

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

HygroLab 1 HygroLab 2 and 3

Instruction Manual

Document Type

Page 15 of 51

5.1 Unit system

The unit system can easily be set to Metric or English from the keypad (except HygroLab 1) -see

MENU, SETTINGS. The unit system can also be changed from a PC with the optional HW4

software installed. In that case, connect the HygroLab to a free COM port of the PC using either the

internal service connector (all models) or the RS232 port (HygroLab 2 and 3)

Note: except for the HygroLab 1, the instrument can be configured to display water activity instead

of relative humidity: (instrument configuration with the HW4 software):

1.000 Aw = 100.0 %RH

To change the factory configuration for humidity either use the keypad MENU, SETTINGS (except

HygroLab 1) or use the optional HW4 software installed on a PC and the appropriate connecting

cable: cable AC1623 for all models (see Accessories) or cable type RS232 9pol ST-BU for the

HygroLab 2 and HygroLab 3 (see Connectors for part number).

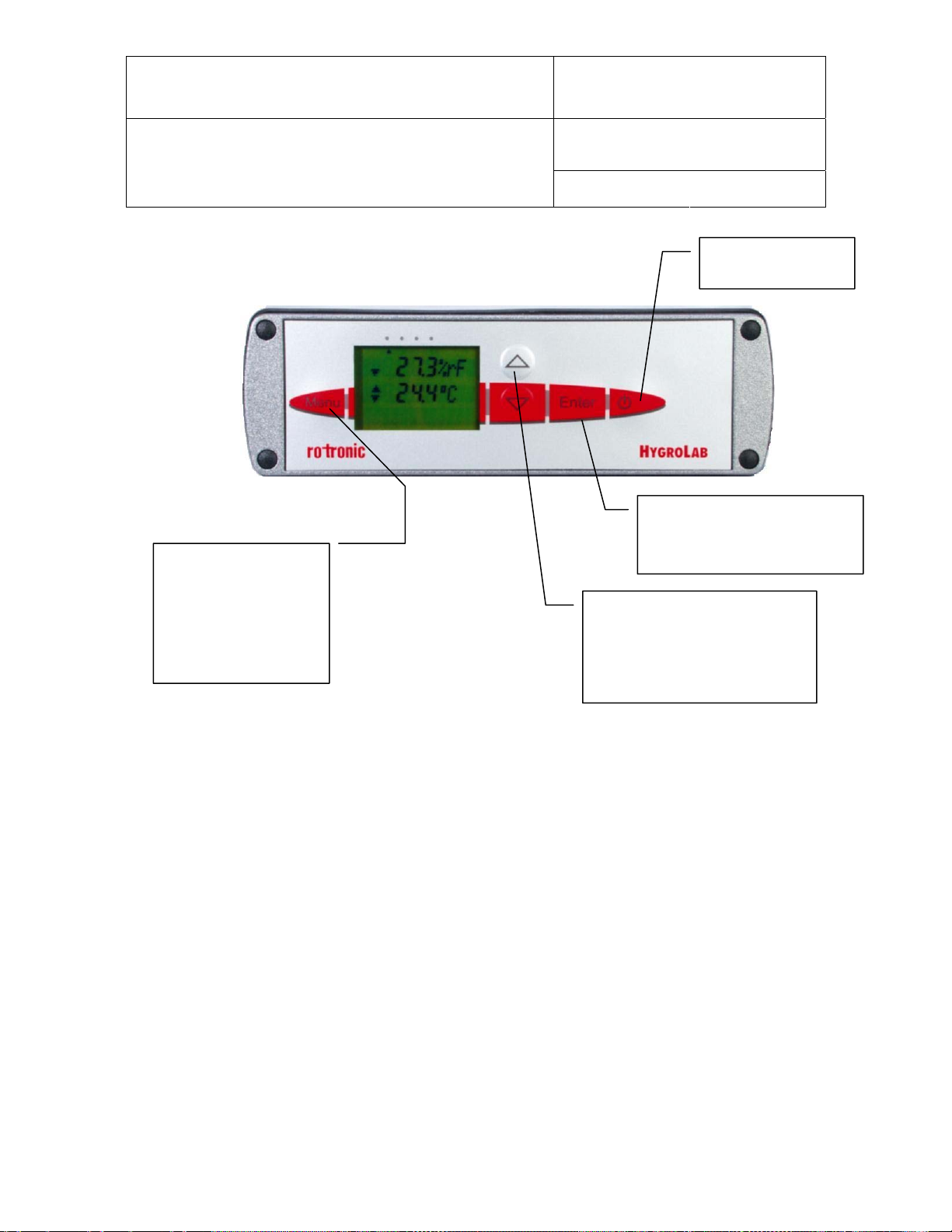

5.2 Display and keypad

The LC display shows which probe input is being displayed (small indicator on top of the display)

and up to 2 parameters measured by the probe, with the associated engineering unit. When

relevant, the message line provides additional information.

(1-4) from left to right

Probe Input

Humidity and Temperature

Calculated Value and Temperature

Calculated Value and Humidity

Parameter or

Engineering

Units

Message Line

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 16

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

MENU : press this key

to activate the functions

menu. The different

menu items appear on

the LCD message line.

Press this key again to

exit the menu

Instruction Manual

Document Type

Page 16 of 51

ON/OFF: turns the

instrument on or off

ENTER: when the menu is

active, press this key to confirm

a selection

UP / DOWN: press one of these

keys to change the probe input

that is being displayed. When the

menu is active, use these keys to

navigate the menu, make a

selection or to change a number

5.3 Probe Input Selection

The display can be switched between probes with the ▼ or ▲ key. The selection is confirmed on

the message line of LC display as well as by an indicator located at the top of the display.

6 Function menu

To access the function menu, press the MENU key. The first menu item appears on the message

line of the LC display. Use the ▼ or ▲ key to navigate the menu. When the desired menu item

appears on the message line of the LC display, press the ENTER key to select. Some menu items

have sub-items. These can be selected with the ▲ or ▼ and ENTER keys. To exit the menu and

return to the normal display mode, press the MENU key. The instrument also returns automatically

to the normal display mode when no key is being pressed for some time (main menu: 10 sec.,

submenu: 30 sec.).

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 17

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 17 of 51

6.1 CALCULATE (HygroLab 2 and 3)

Definition

This function is used to select or view the humidity parameter that is calculated by the instrument.

The calculated parameter is selected individually for each probe connected to the instrument

Prior to entering this function, select on the display the probe to program.

1) Does not apply to third-party analog probes.

The unit system (Metric or English) can be changed with the keypad (see Functions, Settings) or

with the optional HW4 software, when the HygroLab is connected to a PC.

Selections

Parameter Metric English Lab 1 Lab 2 Lab 3

Dew Point / Frost Point 1)

°C °F

N/A

x x

1)

.

Wet Bulb Temperature 2)

°C °F

Enthalpy 2) J/g BTU/lb N/A

Vapor Concentration g/m3 gr/cuft N/A

Specific Humidity 2) g/kg gr/lb N/A

Mixing Ratio 2) g/kg gr/lb N/A

Vapor Concentration

at Saturation

Partial Pressure

of Water Vapor

Saturation Pressure

of Water Vapor

3

g/m

gr/cuft N/A

hPa PSI or In Hg N/A

hPa PSI or In Hg N/A

N/A

x x

X X

X X

X X

X X

X X

X X

X X

1) The standard factory setting is frost point for values below freezing. This setting can be changed to dew

point with the optional HW4 software

2)

Calculation of this parameter requires barometric pressure as an input. The fixed value used for barometric

pressure can be changed either directly from the keypad - see MENU, SETTINGS - or with the optional HW4

software (all models). The HygroLab 2 or 3 can also be configured to accept the input from an analog

pressure probe (variable pressure value).

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 18

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 18 of 51

6.2 MODE (HygroLab 3)

Definition

This function is used to set the operating mode of the HygroLab 3

Selections

Standard : normal operating mode (relative humidity, temperature, dew point, etc.)

Q AwQuick : water activity measurement with the AwQuick algorithm for measurements in

typically 5 minutes.

E AwE : conventional water activity measurement with automatic detection of equilibrium

conditions.

Note:

The operating mode selection applies to all probe inputs. Upon start up, the HygroLab 3

remembers in which mode it was before being turned off

● Standard Mode:

This mode is the default mode of the HygroLab 3. Upon powering the HygroLab 3, the instrument

automatically defaults to the standard mode.

In the standard mode, the HygroLab 3 displays the humidity and temperature measured by the

selected probe. Trend indicators appear one minute after powering up the instrument (▲ or ▼

arrow to the left of the water activity and temperature values). These indicators are used to detect

equilibrium conditions as required for example during probe calibration. The probe is at equilibrium

when both the up and down arrow are displayed at the same time.

● AwE mode:

This mode is essentially the same as the standard mode with the difference that the HygroLab 3

automatically detects equilibrium conditions and ends the measurement at that time by freezing the

display.

● AwQuick mode:

This mode accelerates the measurement of water activity and provides a result in typically 5

minutes. When temperature conditions are stable (both at the product and probe), the

measurement obtained with the AwQuick mode is generally within ± 0.005 aw of the measurement

that would be obtained by waiting for full equilibration of the product and probe.

Depending on the mode that was selected, proceed as follows

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 19

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

a) Standard Mode:

No further action is required after selecting this mode. Simply proceed with the measurements.

b) AwE Mode:

Upon selecting this mode, the HygroLab 3 displays the following:

0. 0 0 0

1

Instruction Manual

Document Type

Page 19 of 51

E H S [ A w / m i n ]

Use the ▼ or ▲ arrow to set the definition of stable humidity. In the above example, the HygroLab

will consider humidity to be at equilibrium when the rate of change of the humidity signal is less

than 0.0001 Aw per minute. Default value: 0.0001 Aw / min

Press the ENTER key to record and confirm this setting. The display now shows the following:

E T S [

Use the UP or DOWN arrow to set the definition of stable temperature. In the above example, the

HygroLab will consider temperature to be at equilibrium when the rate of change of the temperature

signal is less than 0.01 °C per minute. Default value: 0.01 °C / min

Press the ENTER key to record and confirm this setting. The AwE mode is now active.

When ready to measure, press the ENTER key to access and start the AwE mode. Press the

ENTER key again to stop the AwE mode at any time and return to the Standard mode.

Notes:

When the HygroLab 3 is in the AwE mode, pressing the ENTER key automatically starts the

AwE mode, unless the MENU key was pressed immediately before pressing the ENTER key.

The ON / OFF key is inoperative in the AwE mode. You must stop the AwE mode in order to be

able to turn the power of with the red ON/OFF key.

For instructions on using the AwE mode, see Water Activity Measurement.

0. 0 1

°

C/min]

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 20

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

c) AwQuick Mode:

Upon selecting this mode, the HygroLab 3 displays the following:

4

Instruction Manual

Document Type

Page 20 of 51

Q D w e l l [ m i n ]

Use the ▼ or ▲ arrow to set the dwell time. In the above example, the HygroLab 3 will wait 4

minutes before processing the humidity data with the AwQuick algorithm.

Default value: 4 min (recommended value)

Press the ENTER key to record and confirm this setting. The display now shows the following:

Q T S [

Use the UP or DOWN arrow to set the definition of stable temperature. In the above example, the

HygroLab will consider temperature to be stable when the rate of change of the temperature signal

is less than 0.01 °C per minute.

Default value: 0.01 °C / min

Press the ENTER key to record and confirm this setting. The AwQuick mode is now active.

When ready to measure, press the ENTER key to access and start the AwQuick mode. Press the

ENTER key again to stop the AwQuick mode at any time and return to the Standard mode.

Notes:

When the HygroLab 3 is in the AwQuick mode, pressing the ENTER key automatically starts

the AwQuick mode, unless the MENU key was pressed immediately before pressing the

ENTER key.

The ON / OFF key is inoperative in the AwQuick mode. You must stop the AwQuick mode in

order to be able to turn the power of with the red ON/OFF key.

For instructions on using the AwQuick mode, see Water Activity Measurement.

© 2006; Rotronic AG IN-E-HyLab-V4_11

0. 0 1

°

C/min]

Page 21

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 21 of 51

6.3 DISPLAY (HygroLab 2 and 3)

Definition

This function is used to select which parameters the instrument displays. The display mode is

specified globally for all probes connected to the instrument.

Selections

- Measurement

Relative humidity (in %RH or as water activity: Aw) and temperature or the parameter

measured by any third party probe connected to the instrument.

- Calculated + Temperature

Calculated parameter (as selected under CALCULATE) and temperature. This selection is

not available with third-party probes.

- Calculated + Humidity

Calculated parameter (as selected under CALCULATE) and relative humidity. This

selection is not available with third-party probes.

- User Calc

User defined calculation such as the difference between temperature and dew point of any

probe. The display shows only the calculated value. See the separate HW4 manual for

instructions on how to program the HygroLab 2 or 3 to compute a user specified

parameter.

6.4 ADJUST M.PT

Definition

The Adjust M.PT function permits the full calibration of any ROTRONIC HygroClip digital probe

against a known reference environment. This function is designed to permit calibration at 2

temperature values and at up to 4 relative humidity values.

Selections

The Adjust M.PT function offers the following choices (use the UP and DOWN keys):

RHS: Humidity calibration using the ROTRONIC Humidity Standards

Humidity: Humidity calibration using any suitable reference environment

Temperature: Temperature calibration using any suitable reference environment

1)

For humidity calibration, ROTRONIC offers convenient, certified humidity standards to generate

known humidity values (for details, see Humidity Calibration).

© 2006; Rotronic AG IN-E-HyLab-V4_11

1)

Page 22

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 22 of 51

Procedure

When more than one probe is connected to the instrument, select the probe to be calibrated prior

to entering the function (this is the same as the probe that was last displayed).

Regarding the Adjust M.PT function, it is important to observe the following rules:

a) Always calibrate temperature first (if temperature needs to be calibrated)

b) When calibrating temperature (2 points), always calibrate at the low value first. The

instrument is programmed to use the low temperature value to compute the offset and the

high temperature value to compute the gain.

T-low < 40 °C (104°F) : used to compute the calibration offset

T-high ≥ 40 °C (104 °F) : used to compute the calibration gain

For best accuracy, we recommend using a T-low value close to 20°C (68°F).

c) When calibrating relative humidity (2, 3 or 4 points) with the ROTRONIC humidity

standards, always follow the sequence 35 %RH, 80 %RH, 10 %RH or 5 %RH, 0 %RH).

When using a reference other than the ROTRONIC humidity standards, use reference

conditions that are within the following brackets and observe the sequence:

>25 %RH…≤55 %RH

>55 %RH

1)

: used to compute the calibration gain

>1 %RH…≤25 %RH : sensor linearity adjustment

≤ 1 %RH : sensor linearity adjustment

The HygroLab is programmed to automatically recognize these brackets.

1) For best accuracy, we recommend using values close to 35 %RH and 80 %RH

When the probe is at equilibrium with the reference environment, activate the Adjust M.PT function

and make the appropriate selections:

a) RHS: press the ENTER key to select this item. The LC display shows the value read by the

probe at the time the ENTER key was pressed. The letters “RHS” are displayed on the

message line. Use the ▼ or ▲ key to change the humidity value to match the mean value

(at 23°C) written on the certificate supplied with the standard. For a faster change, keep

the key pressed down. Press the ENTER key when done.

Note: in the RHS mode, the software automatically compensates for the effect of

temperature on the humidity standard. No additional correction is required.

b) Humidity or Temperature: press the ENTER key to select. The LC display shows the

value read by the probe at the time the ENTER key was pressed. The word “humidity” or

“Temperature” is shown on the message line. Use the ▼ or ▲ key to change the humidity

or temperature value to match the value of the reference environment. For a faster change,

keep the key pressed down. Press the ENTER key when done.

© 2006; Rotronic AG IN-E-HyLab-V4_11

1)

: used to compute the calibration offset

Page 23

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

After pressing the ENTER key, the message “sure?” should appear on the LC display. Press

ENTER to confirm. Next, the LC display will confirm that the probe adjustment has been

successfully completed. At that time, press ENTER to exit or MENU to return to the function Adjust

M.PT and do another calibration point.

Instruction Manual

Document Type

Page 23 of 51

Carry on in the same manner for each calibration point, following the sequence described above.

Note: you can exit the function at any time (without calibrating the probe) by pressing the MENU

key.

6.5 ADJUST 1PT

Definition

The Adjust 1PT function permits to do a 1-point adjustment (temperature or humidity) of any

ROTRONIC HygroClip digital probe against a known reference environment. This function is limited

to a simple offset adjustment that is applied across the entire measuring range.

Warning

1-point adjustment can improve accuracy over a narrow range of conditions and may also be

detrimental to accuracy at other conditions.

Selections

The Adjust 1PT function offers the following choices (use the UP and DOWN keys):

RHS: Humidity calibration using the ROTRONIC Humidity Standards

Humidity: Humidity calibration using any suitable reference environment

Temperature: Temperature calibration using any suitable reference environment

1) For humidity calibration, ROTRONIC offers convenient, certified humidity standards that generate known

humidity values (for more details, see Humidity Calibration).

Procedure

When more than one probe is connected to the instrument, select the probe to be calibrated prior

to entering the function (this is the same as the probe that was last displayed).

When the probe is at equilibrium

and make the appropriate selections:

: a 1-point adjustment is no substitute for a full calibration (2 or more points). Doing a

1)

with the reference environment, activate the Adjust 1PT function

a) RHS: press the ENTER key to select this item. The LC display shows the value read by the

probe at the time the ENTER key was pressed. The letters “RHS” are displayed on the

message line. Use the ▼ or ▲ key to change the humidity value to match the mean value

(at 23°C) written on the certificate supplied with the standard. For a faster change, keep

the key pressed down. Press the ENTER key when done.

Note: in the RHS mode, the software automatically compensates for the effect of

temperature on the humidity standard. No additional correction is required.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 24

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

b) Humidity or Temperature

1

: press the ENTER key to select. The LC display shows the

Instruction Manual

Document Type

Page 24 of 51

value read by the probe at the time the ENTER key was pressed. The word “humidity” or

“Temperature” is shown on the message line. Use the ▼ or ▲ key to change the humidity

or temperature value to the value of the reference environment. For a faster change, keep

the key pressed down. Press the ENTER key when done.

1

1-point temperature adjustment: limited by the firmware to -20…< 40°C (-4…<104°F)

After pressing the ENTER key, the message “sure?” should appear on the LC display. Press

ENTER to confirm. Next, the LC display will confirm that the probe adjustment has been

successfully completed. At that time, press ENTER to exit.

Note: you can exit the function at any time (without calibrating the probe) by pressing the MENU

key.

6.6 ADJUST REF

Definition

Note: this function is not available with the HygroLab 1

When two or more ROTRONIC HygroClip digital probes are connected to the HygroLab, the Adjust

REF function uses probe #1 as a reference to do a 1-point adjustment (both humidity and

temperature) of all the other probes simultaneously.

Warning

point adjustment can improve accuracy over a narrow range of conditions and may also be

detrimental to accuracy at other conditions.

Procedure

Expose all probes to the same stable environment. Ventilation of the probes is highly

recommended. Observe the readings from all probes for complete equilibration with the reference

environment.

Press the ENTER key to enter the function. The display asks you to wait for a short time and then

shows the temperature and humidity read by the reference probe at the time the ENTER key was

pressed. Note that these values are not updated to the display as long as the function is active.

The message line of the display shows REF = Probe 1, indicating that probe #1 is the reference

(this cannot be changed).

Press the ENTER key to accept. After pressing the ENTER key, the message “sure?” should

appear on the LC display. Press ENTER to confirm. Next, the LC display will confirm that the probe

adjustment has been successfully completed. At that time, press ENTER to exit. Note: you can exit

the function at any time (without calibrating the probe) by pressing the MENU key.

: a 1-point adjustment is no substitute for a full calibration (2 or more points). Doing a 1-

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 25

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 25 of 51

6.7 PROBE

Definition

This function displays the version number and serial number of any ROTRONIC HygroClip digital

probe connected to the instrument.

Procedure

Prior to entering the function, select the probe to be displayed (this is the same as the probe that

was last displayed).

When entering the function, the version number of the probe is displayed first. Use the ▼ or ▲ key

to display the serial number of the probe.

6.8 SETTINGS

Definition

This function is used to do the following:

• Turn the trend indicators on or off

• change the symbol used for relative humidity or display humidity as Water Activity (aw)

• adjust the fixed value of barometric pressure used in some psychrometric computations

(except HygroLab 1)

• select between the Metric or English unit system

Procedure

Trend: use the ▼ or ▲ key to enable or disable the trend indicators.

The trend of humidity and temperature is shown on the display by an arrow (up or down) to the left

of the measured value. Both arrows are shown to indicate stable conditions. Stable conditions are

defined as rate of change of less than 0.02 %RH / min or °C / min.

Signal stability is first evaluated after 60 seconds into the measurement and is updated every 30

seconds.

Note: when the trend indicator is enabled, the symbol for the calculated parameter (e.g. Dp for dew

point) is no longer displayed to the left of the numerical value.

Humi Unit: use the ▼ or ▲ key to change the symbol used for relative humidity (depends on

country and language) or to display humidity as water activity.

Press. Const. (except HygroLab 1) : use the DOWN arrow key to select the digit to be changed.

Use the UP arrow key to change the value of the digit.

Units: use the ▼ or ▲ arrow key to toggle between Metric and English.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 26

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 26 of 51

6.9 SYS STATUS

Definition

This function displays the software version of the instrument, the RS232 configuration * (baud rate,

parity, bits and stop bit), the network address *, any user defined description for the instrument *

and the serial number of the instrument.

This information is for display only. Some parameters such as the network address can be

changed with the HW4 software, after connecting the instrument to a PC.

* except HygroLab 1

Procedure

When entering the function, the software version number is displayed first. Use the ▼ or ▲ key to

display the other data.

7 Error and status messages

The following is a list of coded messages (101, etc.) that the HygroLab may show on the bottom

line of the LC display or via RS232 / RS485.

Errors:

101

102

103

104

105

106

107

108

110

111

Warnings:

120

121

Status:

130

checksum error The checksum test did not pass during RS-communication.

bad command An unknown command was received

disallowed

command

unknown probe

input

argument error

HygroClip

A command was received that is reserved for production and

service

Reference was made to a non-existing analog or digital probe

input

Error in the number of the arguments in the command or in

the value of one of the arguments

The HygroClip probe does not answer or is not connected

communication error

The difference between the probe reading and the calibration

calibration error

point is larger than the maximum allowed by the INI

command.

calibration error

(overflow)

unknown reference

probe

Temperature error

Internal probe error (or the difference between the probe

reading and the calibration value is too large)

The reference probe is not connected or the reference probe

input does not exist

During humidity calibration, temperature should be within the

limits of 0 and 80°C (32 and 176°F)

no adjustment Calibration

No HygroClip probe

is connected

the probe was

Calibration

adjusted

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 27

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 27 of 51

8 Connectors

Internal service connector (HygroLab 1)

Open the instrument housing to access the service connector. This 3-pin connector is located on

the printed circuit board as shown below:

Probe input connectors

RS232 / RS485 (HygroLab 2 and 3)

Service connector

use cable # AC1623 to connect

to the COM port of a PC

RS232 connector (9-pin Sub D)

Pin # Function

2 TX

3 RX

5 GND

RS485 connector (9-pin Sub D)

Pin # Function

1 RI +

5 GND (normally not used)

9 RI -

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 28

IN-E-HyLab-V4_11

r

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 28 of 51

Optional analog output connector (HygroLab 2 and 3)

If any analog probe is being used, this connector simply repeats the analog probe input signals.

Optional

Analog Output

DB25F Connecto

13

Pin # Function

1 Probe 1 – Analog 1

2 Probe 1 – Analog 2

3 GND

4 Probe 2 – Analog 1

5 Probe 2 – Analog 2

6 GND

7 Probe 3 – Analog 1

8 Probe 3 – Analog 2

9 GND

10 Probe 4 – Analog 1

11 Probe 4 – Analog 2

12 GND

1

Optional RJ-45 (Ethernet) connector – HygroLab 2 and 3

Ethernet

9 Environmental limits

The HygroLab can operate in the temperature range of –10...55°C (14…131°F) and should not be

exposed to condensing humidity.

The operating limits at the probe depend on the probe model and are specified separately for each

probe.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 29

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 29 of 51

10 Maintenance of the ROTRONIC probes

Cleaning or replacing the dust filter

Most ROTRONIC probes come with one of the following types of dust filter: (a) protective

metal base with a removable filter cartridge or (b) plastic slotted cap with built-in (not

removable) filter element.

Depending on the conditions of measurement, the filter should be checked from time to time. If

the probe has a removable filter cartridge, this can be easily removed for cleaning.

If the probe has a plastic slotted cap with a built-in filter element, cleaning should be done

without

other strong chemicals. Either brush the filter or use a little bit of clean water.

Corroded, discolored or clogged filters should be replaced. If the probe has a removable

cartridge, simply replace the cartridge (leave the metal base on the probe).

If the probe has a plastic slotted cap with built-in filter element follow these instructions:

1) Unscrew the filter from the probe and pull it straight away, in the alignment of the probe, so

as not the catch the humidity and temperature sensors.

2) Before putting on a new dust filter, check the alignment of both sensors with the probe. The

wires that connect the sensors to the probe are very thin and bend easily. If necessary, correct

the alignment by tapping the sensor very gently

rod. Do not use sharp pliers or tweezers as this could puncture the sensor and do not pull

hard on the sensor.

removing the filter from the probe. In that case, do not use detergents, solvents or

Periodic calibration check

Long term stability of the ROTRONIC Hygromer humidity sensor is typically better than 1

%RH per year. For maximum accuracy, calibration of the probe should be verified every 6 to

12 months. Applications where the probe is exposed to significant pollution may require more

frequent verifications.

Both the Pt 100 RTD temperature sensor and associated electronics are very stable and

should not require any calibration after the initial factory adjustment.

For routine calibration checks, the probe should be verified at one or two values of humidity.

For more details, see Probe calibration basics and Functions – ADJUST M.PT.

with a smooth object such as a small plastic

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 30

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 30 of 51

11 Specifications

Power supply AC Adapter 12 VDC regulated,

100 or 300 mA

DC(+) Tip

Operating limits at electronics 0…99 %RH (non condensing)

-10...55°C (14...131°F)

Measured parameters

relative humidity indication range 0.0…100.0 %RH

temperature

barometric pressure 3) indication range

Calculated parameters

dew / frost point

wet bulb temperature

enthalpy

6)

indication range -99.9…9999 J/g or BTU/lb

vapor concentration indication range 0.000…9999 g/m3 or gr/cuft

specific Humidity

mixing ratio

6)

indication range 0.000…9999 g/kg or gr/lb

2)

indication range

2) 4)

5)

6)

indication range -99.9…999.9 °C / °F

6)

indication range 0.0…100.0 °C / 32.0…212.0 °F

indication range 0.000…9999 g/kg or gr/lb

-99.9…999.9 °C or °F

0.000…9999 hPa / PSI / In Hg

vapor concentration at saturation indication range 0.000…9999 g/m3 or gr/cuft

part. pressure of water vapor indication range 0.000…9999 hPa / PSI / In Hg

sat. pressure of water vapor indication range 0.000…9999 hPa / PSI / In Hg

Number of probe inputs HygroLab 1 2

HygroLab 2+3 4

Probe type

7)

All models ROTRONIC HygroClip digital probe

All models ROTRONIC analog probe

HygroLab 2+3 Third-party analog probe

A/D resolution (analog probes) HygroLab 1+2 10-bit

A/D resolution (analog probes) HygroLab 3 12-bit

Display Alphanumerical LC display

Serial output (except HygroLab 1) RS 232 / RS485

Optional Ethernet interface HygroLab 2+3 TCP/IP

Housing material Aluminum

Housing dimensions 220 x 170 x 55 mm (8.66 x 6.69 x 2.16”)

Weight 1.0 kg (2.2 lb)

1) HygroLab with optional Ethernet module requires : AC Adapter 12 VDC, 300 mA

2) Specify engineering units when ordering (can be changed by user with the optional HW4 software). See

separate probe specifications regarding the different range limits

3) Not available with HygroLab 1

4) Not available with HygroLab 1. The accuracy of the computed parameter is limited by the accuracy of the

measured parameters on which it is based

5) The standard factory setting is frost point for values below freezing. This setting can be changed to dew

point with the optional HW4 software

6) A fixed pressure value is used for the computations of this parameter. The fixed pressure value can be

changed by the user either from the keypad or with the optional HW4 software. The HygroLab 2 and 3 can

also be configured with the HW4 software to accept the input from a pressure probe (variable pressure

value)

1)

8)

8)

9)

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 31

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 31 of 51

7) Accuracy, repeatability and operating limits are specified separately for each model of probe

8) ROTRONIC analog probes: because the HygroLab cannot read a negative input voltage, temperature

measurement with probes having a standard output is generally limited to values above freezing. Thirdparty probe (pressure or other): linearized voltage output signal within the range of 0...2.5 VDC, supply

voltage 5 to 12 VDC, 10 mA max.

9) RS-485 network: requires the first instrument to be connected to the RS-232 COM port of a PC.

Compatibility with the ROTRONIC HW3 software requires a baud rate of 19200.

12 Practical advice for measuring humidity

The most common source of error when measuring relative humidity is a difference between the

temperature of the probe and the temperature of the environment. At a humidity condition of 50

%RH, a temperature difference of 1°C (1.8 °F) typically results in an error of 3 %RH on relative

humidity.

When using a humidity probe with an indicator, it is good practice to monitor the display for

temperature stability. The probe should be given sufficient time to equilibrate with the

environment to be measured. The larger the initial temperature difference between the probe

and the environment to be measured, the more time temperature equilibration requires. This

time can be shortened, and errors avoided, by using the probe configuration that fits best for

your application.

In extreme situations, condensation may occur on the sensors when the probe is colder than the

environment. As long as the humidity / temperature limits of the humidity sensor are not

exceeded, condensation does not alter the calibration of the sensor. However, the sensor has to

dry out before it can provide a valid measurement.

Non-moving air is an excellent insulator. When there is no air movement, surprising differences in

temperature and humidity can noted over short distances. Air movement at the probe generally

results in measurements that are both faster and more accurate.

13 Probe calibration basics

The following choices are available to calibrate the HygroClip probe(s) used with the HygroLab:

a) Calibration using the HygroLab display and keypad (see Functions).

b) Calibration using a PC with the optional HW4 software (see separate instructions for the

HW4 software) – This choice is available only with the HygroLab 2 and 3, after connecting

the HygroLab to the COM port of the PC.

c) Calibration of the probe alone (removed from the HygroLab), using a PC with the HW3

software and the MOK-WIN or T7-WIN calibration cable (see separate instructions for the

HW3 software).

Note: the HygroLab itself should not require any field calibration.

13.1 Temperature calibration

Note: the stability of the Pt100 RTD sensor used to measure temperature is such that

temperature calibration in the field is seldom required.

In order to be able to correctly evaluate the accuracy of the temperature measurements

provided by the probe, you should be able to meet the following requirements:

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 32

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

a) Both the probe and a reference thermometer should be ventilated with the same stream of

air. Any dust filter used to protect the sensors should be carefully removed from the probe.

If the probe has a protective slotted cap, this may be left on the probe.

b) Air velocity at the sensor should be within the limits of 200 to 500 feet/minute (1 to 2.5

meters/second). Any comparison between two instruments at a velocity under 200

feet/minute may not be valid. Air velocity above 500 feet/minute may damage the

unprotected humidity sensor.

c) The temperature of the air stream should be practically constant.

If you cannot meet the above requirements, you should not attempt to calibrate temperature.

Instruction Manual

Document Type

Page 32 of 51

13.2 Humidity calibration

ROTRONIC provides easy-to-use, certified humidity standards for customers who do not have

access to a humidity generator. To use these standards, you will need a calibration device that

is suitable for your probe.

Calibration device

The calibration device is a small airtight container that fits on the probe and seals around the

humidity sensor. During calibration, a known reference humidity is produced inside the

calibration device by means of a humidity standard (usually an aqueous salt solution). To find

out which model of calibration device is suitable for your probe, please consult the probe

documentation.

Certified humidity standards

The ROTRONIC certified standards are available in boxes of 5 glass ampoules of the same

value, which can be stored indefinitely. Standards in the range of 5 to 95 %RH are nonsaturated aqueous salt solutions that are precisely titrated at our factory for the right

concentration. The 0 %RH humidity standard is made of small granules of a highly porous

ceramic that have been dried at a high temperature. A Material Safety Data Sheet is available

for each standard. Since most standards are a salt solution, parts which have come in contact

with the liquid should be cleaned after each use.

Each box of standards comes with a certificate that provides statistical information on the

manufacturing batch of the standard. Information on the effect of temperature on each

standard is provided on the cover of each box of standard. When calibrating either with the

HygroLab or with the HW4 software, the effect of temperature on the standards is

compensated by the software and no further correction is required. The value of the standards

is not affected by altitude.

© 2006; Rotronic AG IN-E-HyLab-V4_11

Page 33

IN-E-HyLab-V4_11

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLab bench top indicator version 4:

instruction manual

Document title

Instruction Manual

Document Type

Page 33 of 51

Instructions for using the standards

• Install the calibration device on the probe so that the receptacle (or solution holder) is

under the probe. Check for a tight fit and remove the receptacle from the calibration device.