HygroClip2 ADVANCED

Humidity Temperature Probes

© 2016 ROTRONIC AG Bassersdorf Switzerland

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

Table of contents

1

Overview ................................................................................................................................................. 3

1.1Hardware and software compatibility ................................................................................................... 3

2Models .................................................................................................................................................... 4

3General description ............................................................................................................................. 18

3.1Power supply...................................................................................................................................... 18

3.2Measured parameters ........................................................................................................................ 18

3.3Calculated parameters ....................................................................................................................... 18

3.4Analog output signals ......................................................................................................................... 18

3.5Digital interface .................................................................................................................................. 19

3.6Communication protocol .................................................................................................................... 19

3.7Connector .......................................................................................................................................... 20

3.8Filter and probes overview matrix ...................................................................................................... 20

3.9Sensor protection (dust filter) ............................................................................................................. 21

4User configurable settings and functions ......................................................................................... 23

4.1Function overview .............................................................................................................................. 24

4.2Factory default settings ...................................................................................................................... 26

5Mechanical installation ....................................................................................................................... 27

6Electrical installation ........................................................................................................................... 28

6.1General connection information ......................................................................................................... 28

6.2Signal cable information ..................................................................................................................... 28

6.3Analog signal wiring ........................................................................................................................... 29

6.4Digital signal wiring ............................................................................................................................ 29

6.5Grounding .......................................................................................................................................... 29

7Operation .............................................................................................................................................. 30

7.1Minimum load requirements for the probe voltage outputs ................................................................ 30

7.2Connectivity examples for stand-alone probes .................................................................................. 31

7.3Hand-held probes used with an indicator ........................................................................................... 32

8Maintenance ......................................................................................................................................... 33

8.1Cleaning or replacing the dust filter .................................................................................................... 33

8.2Periodic calibration check .................................................................................................................. 33

8.3Validation of the output signals transmission ..................................................................................... 33

9Firmware updates ................................................................................................................................ 34

10Technical data ...................................................................................................................................... 35

11Accessories and parts ........................................................................................................................ 38

12Supporting documents ....................................................................................................................... 39

13Document releases .............................................................................................................................. 40

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 2 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

Applicability:

This manual applies to all HC2A probes with firmware version 1.x. Changes to the last digit of the version

number reflect minor firmware changes that do not affect the manner in which the probe should be operated.

1 Overview

The HC2A series are digital humidity-temperature probes based on the AirChip3000 technology. These probes

feature a UART serial interface and two 0…1 V linear analog output signals.

The HC2A probes are designed for use with the HygroClip2 generation of ROTRONIC humidity-temperature

instruments: transmitters, data loggers, hand-helds, etc.

The HC2A probes can also be used as a stand-alone device using either the analog output signals or the probe

digital interface. Connectors, cables and digital interface adapters are available to this purpose. Digital

integration with OEM applications is facilitated by the probe communication protocol options.

The HC2A probes offer the following user functions:

o User configurable settings

o Calculation of the dew or frost point

o Humidity temperature calibration and adjustment

o Simulator mode

o Data recording

The ability for the user to easily update the AirChip3000 firmware means that the HC2A probes can be kept up-

to-date regarding any future functionality improvement.

Available in different configurations, the HC2A probe series is designed to meet the requirements of a large

number of applications and environments.

1.1 Hardware and software compatibility

The HC2A probes are compatible only with the AirChip3000 generation of ROTRONIC humidity-temperature

instruments.

Configuration of the HC2A probes and access to the probe functions requires a PC with the ROTRONIC HW4

software version 3.7 or higher or connection to a compatible instrument from ROTRONIC.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 3 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

2 Models

In the following tables, we have indicated the type of instrument primarily used with each probe model. The

following should also be noted:

o The HC2A probes can be directly connected to a PC or to an Ethernet network using one of the available

digital interface adapters (see separate document E-M-HC2-accessories).

o The HC2A Probes can also be used as a standalone device with two analog output signals. Different

connectors are available to this purpose (see separate document E-M-HC2-accessories).

Regardless of the probe model, the analog outputs signals are always scaled in the same way by the factory

(0…1 V = 0…100 %RH and 0…1 V = -40…60 °C). The user is responsible for reconfiguring the probe analog

outputs (requires the ROTRONIC HW4 software) and for providing power to the probe.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 4 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

Climate measurement

For use with indicators, data loggers and transmitters, with or without an extension cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits: -50…100 °C (-58…212 °F)

Diameter: 15 mm (0.6”)

HC2A-S

HC2A-S3

Length: 108 mm (3.3”)

Housing material: Polycarbonate, black

Standard dust filter: Polyethylene, 40 µm

®

Sensor: HYGROMER

HT-1

Weight: 17 g (0.6 oz)

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits: -50…100 °C (-58…212 °F)

Diameter: 15 mm (0.6”)

Length: 108 mm (3.3”)

Housing material: Polycarbonate, white

Standard dust filter: Polyethylene, 40 µm

®

Sensor: HYGROMER

HT-1

Weight: 17 g (0.6 oz)

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits: -50…100 °C (-58…212 °F)

Diameter: 15 mm (0.6”)

HC2A-S-HH

Length: 108 mm (3.3”)

Housing material: Polycarbonate, black

Standard dust filter: None

Sensor: HYGROMER

Weight: 17 g (0.6 oz)

®

HH-1

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 5 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

Climate measurement

For use with indicators, data loggers and transmitters, with or without an extension cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits: -50…100 °C (-58…212 °F)

Diameter: 15 mm (0.6”)

HC2A-SM

Length: 108 mm (3.3”)

Housing material: Stainless steel, DIN 1.4301

Standard dust filter: Wiremesh filter, 10 µm, DIN 1.4401

®

Sensor: HYGROMER

Weight: 50 g (1.76 oz)

HT-1

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 6 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Process measurement

For use with transmitters and data loggers

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 15 mm (0.6”)

Length (probe head): 144 mm (5.7”)

HC2A-IC102

HC2A-IC105

HC2A-IC302

HC2A-IC305

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 230 g / 8.1 oz, 2 m cable

470 g / 16.6 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 15 mm (0.6”)

Length (probe head): 294 mm (11.6”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 260 g / 9.2 oz, 2 m cable

500 g / 17.6 oz, 5 m cable

®

HT-1

®

HT-1

Manual

1

(-148…374 / 392 °F)

1

(-148…374 / 392 °F)

1

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 7 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IC402

HC2A-IC405

HC2A-IC502

HC2A-IC505

Manual

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

2

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 15 mm (0.6”)

Length (probe head): 444 mm (17.5”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 290 g / 10.2 oz, 2 m cable

530 g / 18.7 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 15 mm (0.6”)

Length (probe head): 594 mm (23.4”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 320 g / 11.3 oz, 2 m cable

560 g / 19.8 oz, 5 m cable

(-148…374 / 392 °F)

2

(-148…374 / 392 °F)

2

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 8 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IC702

HC2A-IC705

Manual

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

3

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 15 mm (0.6”)

Length (probe head): 744 mm (29.3”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 350 g / 12.3 oz, 2 m cable

590 g / 20.8 oz, 5 m cable

(-148…374 / 392 °F)

3

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 9 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Process measurement for hydrogen peroxide H2O2 applications

For use with transmitters and data loggers

Accuracy: ±1.2 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -50…120 °C (-148…392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 144 mm (5.7”)

HC2A-IC102-HH

HC2A-IC105-HH

HC2A-IC302-HH

HC2A-IC305-HH

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 230 g / 8.1 oz, 2 m cable

470 g / 16.6 oz, 5 m cable

Accuracy: ±1.2 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -50…120 °C (-148…392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 294 mm (11.6”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 260 g / 9.2 oz, 2 m cable

500 g / 17.6 oz, 5 m cable

®

HH -1

®

HH -1

Manual

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 10 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IC402-HH

HC2A-IC405-HH

HC2A-IC502-HH

HC2A-IC505-HH

Manual

Accuracy: ±1.2 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -50…120 °C (-148…392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 444 mm (17.5”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

Weight: 290 g / 10.2 oz, 2 m cable

530 g / 18.7 oz, 5 m cable

Accuracy: ±1.2 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -50…120 °C (-148…392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 594 mm (23.4”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 320 g / 11.3 oz, 2 m cable

560 g / 19.8 oz, 5 m cable

HH -1

®

HH -1

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 11 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IC702-HH

HC2A-IC705-HH

Manual

Accuracy: ±1.2 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -50…120 °C (-148…392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 744 mm (29.3”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

Weight: 350 g / 12.3 oz, 2 m cable

590 g / 20.8 oz, 5 m cable

HH-1

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 12 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

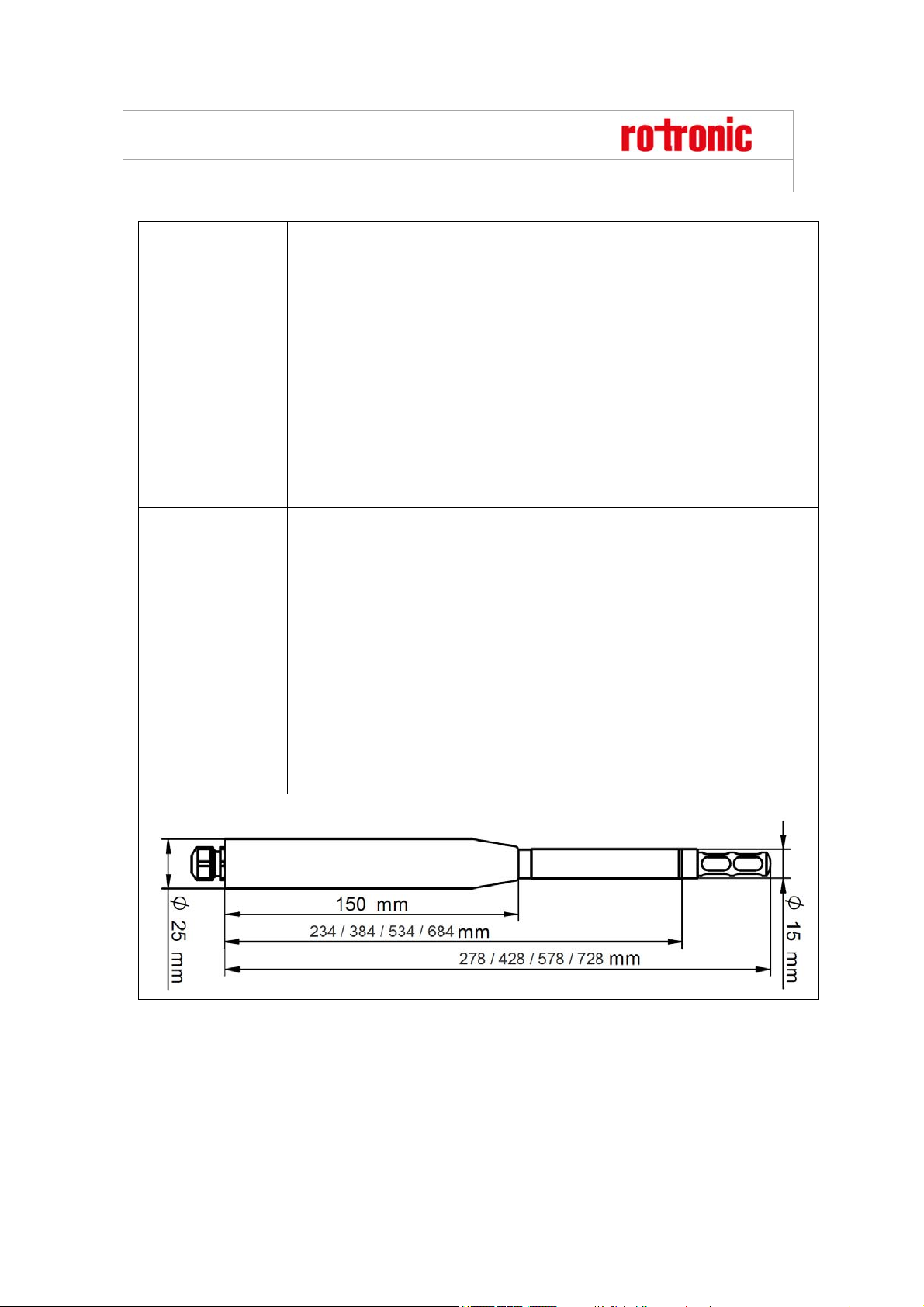

Process measurement

For use with transmitters and data loggers

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 25 / 15 mm (1.0 / 0.6”)

Length (probe head): 278 mm (10.9”)

HC2A-IC302-A

HC2A-IC305-A

HC2A-IC402-A

HC2A-IC405-A

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 290 g / 10.2 oz, 2 m cable

530 g / 18.7 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 25 / 15 mm (1.0 / 0.6”)

Length (probe head): 428 mm (16.9”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 320 g / 11.3 oz, 2 m cable

560 g / 19.8 oz, 5 m cable

®

HT-1

®

HT-1

Manual

4

(-148…374 / 392 °F)

4

(-148…374 / 392 °F)

4

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 13 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IC502-A

HC2A-IC505-A

HC2A-IC702-A

HC2A-IC705-A

Manual

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

5

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 25 / 15 mm (1.0 / 0.6”)

Length (probe head): 578 mm (22.8”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 350 g / 12.3 oz, 2 m cable

590 g / 20.8 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Diameter barrel: 25 / 15 mm (1.0 / 0.6”)

Length (probe head): 728 mm (28.7”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: PEEK

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 380 g / 13.4 oz, 2 m cable

770 g / 27.1 oz, 5 m cable

(-148…374 / 392 °F)

5

(-148…374 / 392 °F)

5

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 14 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IM102-M

HC2A-IM105-M

HC2A-IM302-M

HC2A-IM305-M

67

Accuracy:

±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

8

Temperature limits at sensor: -100...190 °C / 200 °C

(-148…374 / 392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 130 mm (5.2”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: Stainless steel, DIN 1.4301

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 310 g / 10.9 oz, 2 m cable

470 g / 16.6 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

8

Temperature limits at sensor: -100...190 °C / 200 °C

(-148…374 / 392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 280 mm (11.0”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: Stainless steel, DIN 1.4301

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 460 g / 15.9 oz, 2 m cable

690 g / 24.3 oz, 5 m cable

Manual

6

HC2A-IM102-M (120 mm barrel length) - to avoid measurement errors due to temperature gradients fully

immerse the probe barrel in the environment to be measured.

7

To avoid measurement errors, temperature should be the same on both sides of the mounting wall.

8

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 15 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

HC2A-IM402-M

HC2A-IM405-M

HC2A-IM502-M

HC2A-IM505-M

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

9

Temperature limits at sensor: -100...190 °C / 200 °C

(-148…374 / 392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 430 mm (16.9”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: Stainless steel, DIN 1.4301

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 590 g / 20.8 oz, 2 m cable

820 g / 28.9 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

9

Temperature limits at sensor: -100...190 °C / 200 °C

(-148…374 / 392 °F)

Diameter barrel: 15 mm (0.6”)

Length (probe head): 580 mm (22.8”)

Cable length: 2 m (6.5 ft)

5 m (16.4 ft)

Housing material: Stainless steel, DIN 1.4301

Standard filter: None, must be ordered separately

®

Sensor: HYGROMER

HT-1

Weight: 730 g / 25.7 oz, 2 m cable

970 g / 34.2oz, 5 m cable

Manual

9

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 16 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Measurement in compressed air conduits and vessels

For use with transmitters and data loggers

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Thread: G1/2”

Recommended torque: 70 Nm

HC2A-IE102-M

HC2A-IE105-M

HC2A-IE302-M

HC2A-IE305-M

Pressure resistant: 100 bar / 1450 PSI

Length (probe head): 148 mm (5.8”)

Cable length: 2 m (6.5 ft) / 5 m (16.4 ft)

Housing material: Stainless steel, DIN 1.4301

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 290 g / 10.2 oz, 2 m cable

660 g / 23.2 oz, 5 m cable

Accuracy: ±0.8 %RH, ±0.1 K at 10…30 °C

Humidity measuring range: 0…100 %RH

Temperature limits at sensor: -100...190 °C / 200 °C

Thread: NPT ½”

Recommended torque: 70 Nm

Pressure resistant: 100 bar / 1450 PSI

Length (probe head): 148 mm (5.8”)

Cable length: 2 m (6.5 ft) / 5 m (16.4 ft)

Housing material: Stainless steel, DIN 1.4301

Standard filter: None, must be ordered separately

Sensor: HYGROMER

Weight: 290 g / 10.2 oz, 2 m cable

660 g / 23.2 oz, 5 m cable

®

HT-1

®

HT-1

Manual

10 11

(-148…374 / 392 °F)

10 11

(-148…374 / 392 °F)

10

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

11

The sealing ring withstands only -40…85°C

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 17 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

3 General description

3.1 Power supply

When a voltage source of 3.3…5 VDC is not available, the probe should be used together with a voltage adapter

(see separate document E-M-HC2-accessories) so as to provide 3.3…5 VDC to the probe. Use of a voltage

adapter allows powering the probe from a voltage source of 5 to 24 VDC or 5 to 16 VAC.

The HC2A probes are polarity protected by a keyed connector. There is no electrical polarity protection.

3.2 Measured parameters

The HC2A probe measures relative humidity with a ROTRONIC HYGROMER® HT-1 capacitive sensor and

temperature with a Pt100 RTD.

3.3 Calculated parameters

Using the ROTRONIC HW4 software, the HC2A probe can be configured by the user to calculate either the dew

point or the frost point.

3.4 Analog output signals

The HC2A probe features two 0…1 V linear analog output signals. The default factory settings are as follows:

Output 1: 0…1 V (humidity) = 0…100 %RH

Output 2: 0…1 V (temperature) = -40…60˚C

Using the ROTRONIC HW4 software any output signal can be made to correspond one of the following:

o Relative humidity

o Temperature

o Dew or frost point

The scale of each analog output can be set within the numerical limits of -999.99 and 9999.99. If so desired,

any output can also be disabled (no signal).

The D/A converters used to generate the analog output signals feature a 16-bit resolution. The 0…1 V analog

output signals exhibit a small positive offset of 10 mV or less at 0 V.

Minimum load requirements apply to the external device or circuit connected to the probe voltage outputs. These

requirements are defined in the “Operation” chapter.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 18 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

3.5 Digital interface

The HC2A probe features a UART interface (Universal Asynchronous Receiver Transmitter) that allows two-

way communication with the probe. For connecting the HC2A probe to a PC, use a digital adapter cable AC3001

(see document E-M-HC2-accessories). The probe can also be indirectly connected to a PC using an instrument

from the ROTRONIC program.

The ROTRONIC HW4 software (version 3.7.0 or higher) allows full access to the following:

o Measurement data (humidity and temperature) and calculated parameter (dew or frost point)

o Probe information: name, RS-485 address, humidity sensor status, etc.

o Probe alarm functions

o Probe data logging function

o Probe calibration and probe adjustment functions

o Probe configuration

o Firmware update of HygroClip2 probes

3.6 Communication protocol

The probe measurement data can be read without having to use the ROTRONIC HW4 software. The HC2A

probe offers the following communication protocol options (ASCII) which can be selected by connecting the

probe to a PC running the ROTRONIC HW4 software:

o RO-ASCII: this is the standard (default) communication protocol used by all AirChip 3000 devices and

by the HW4 software. In principle, this protocol supports all of the AirChip 3000 functions but some of

the functions require a certain amount of computations to be carried out by an external device such as a

PC.

o Custom: this communication protocol can be used to provide compatibility of the HC2A probe with an

existing communication system. The Custom communication protocol is limited to reading measurement

data from the HC2A probe. Functions such as device configuration, humidity and temperature

adjustment, etc. are not supported. The Custom protocol is applicable to all AirChip 3000 devices with a

digital interface and allows RS-485 networking

o I2C: The I2C protocol available with the HC2A probe does not allow the networking of devices and is

limited to a one way communication where the HC2A probe automatically sends data during each refresh

interval to an external device with I2C input.

When using either the RO-ASCII or the Custom protocol, the HC2A probe can be set to send data automatically

after each refresh cycle without requiring a data request. When this mode is enabled, the receiving device must

be listening at all times in order to get the measurement data.

For details, see document E-M-AC3000-CP

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 19 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

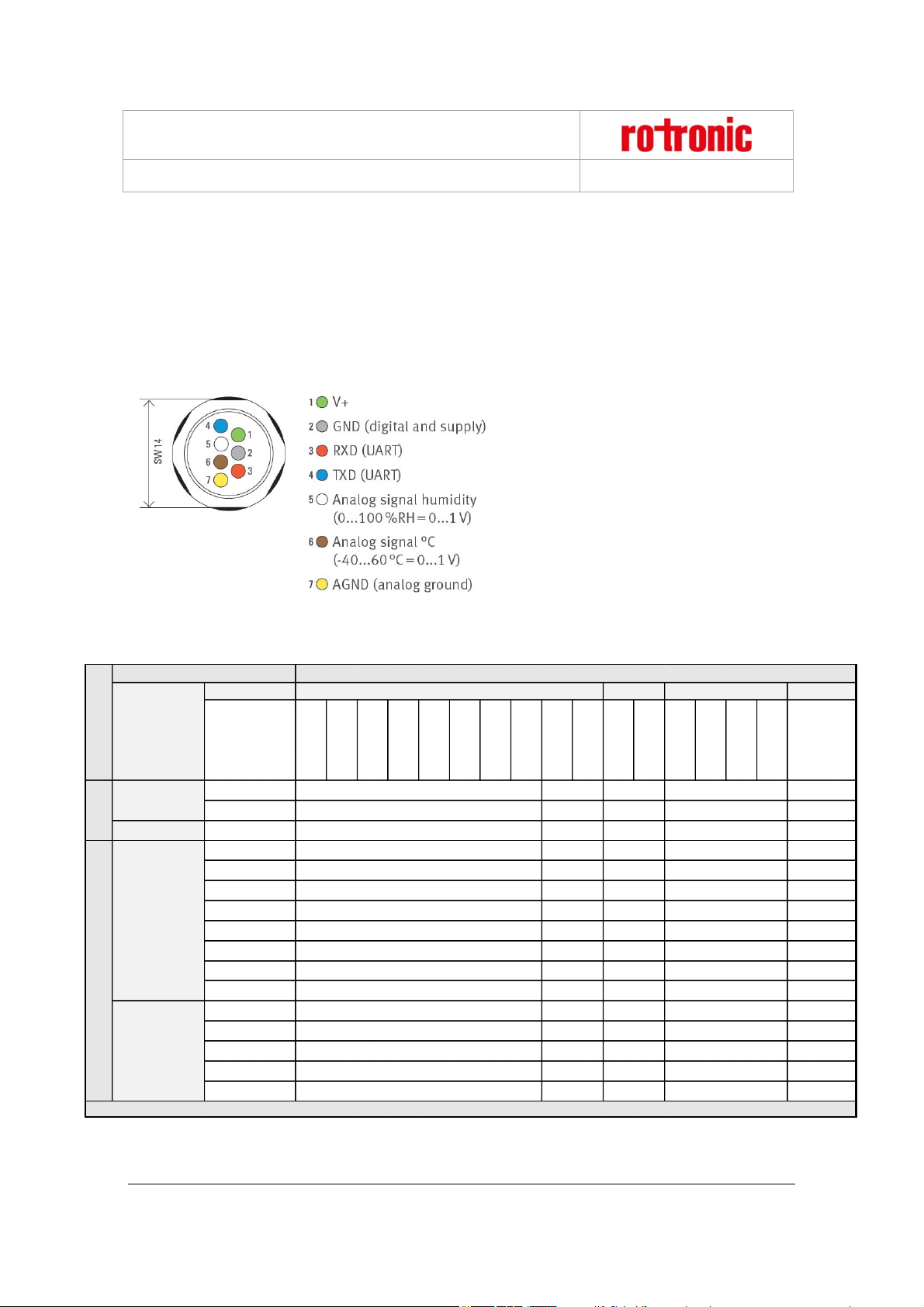

3.7 Connector

All standard probe models of the HC2A series use the same keyed connector (male). The connector is located

either directly on the probe body or at the end of a cable. The probe connector is secured to the matching female

connector with a threaded collar.

Pin-out diagram (7-pin male – looking at probe)

3.8 Filter and probes overview matrix

Probes

‐50…100°C ‐40…85°C ‐100…200°C

temperature

range

‐50…100°C

Carrier

‐100…200°C SPA ‐SS X

‐50…100°C

Filter&Carrier

‐100…200°C

Attention!Theareaofapplicationdependsonthecomponentwiththemostrestrictedtemperaturerange.

SPA‐PCB

SPA‐PCW

SPA‐PCB‐PE

SPA‐PCB‐PTFE

SPA‐PCB‐WM

SPA‐PCW‐PE

SPA‐PCW‐PTFE

SPA ‐PCW‐ WM

SPA‐SS‐PE

SPA‐PE

SPA‐SS‐PTFE X

SPA‐SS‐WM X

SPA‐SSS X

SPA‐WM X

SPA‐PTFE X

HC2 A‐S

HC2 A‐S 3

HC2 A‐S‐ I

HC2 A‐SH

HC2A‐S3 ‐I

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

HC2A‐S3 H

HC2 A‐S‐ HH

HC2 A‐S3 ‐HH

HC2 A‐S M

X

X

X

X

X

X

X

XX

XD33A‐S3X

HC2 A‐S M‐HH

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

HC2A‐ICxxx

XD33 A‐S3X‐ I

HC2A‐ICxxx‐I

X

X

X

X

X

X

HC2A‐IMxxx

‐50…120°C

HC2A‐IExxx

HC2A‐ICxxx‐HH

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 20 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

3.9 Sensor protection (dust filter)

Most probes of the HC2A series are supplied with a filter to protect the sensors against dust particles and high

air velocity. Following filters and carriers are available:

Filter carrier

Order code Picture Drawing Material Temperature range

SPA-PCB

Polycarbonate, black

-50…100 °C

(-58…212 °F)

SPA-PCW

SPA-SS

Polycarbonate, white

Stainless steel, 1.4301

-50…100 °C

(-58…212 °F)

-100…200 °C

(-148…392 °F)

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 21 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

Carrier only Wire mesh filter PE filter PTFE filter Stainless steel

Filter

Material

Pore size

Temperature

range

Response

time %RH

12

Response

time °C

13

Response

14

time °C

Waterproof

(dipping 50mm)

Max. wind

speed

PC / 1.4301

1.4401 Polyethylene PTFE 1.4404

-

-50…100 °C

12 s 12 s 15 s 18 s 15 s

-100…200 °C

(-148…392 °F)

80 s

120 s

No

5 m/s

50 m/s 50 m/s 50 m/s 70 m/s

10 µm 40-50 µm 10 µm 25 µm

-50…100 °C

(-58…212 °F)

180 s 180 s 170 s -

190 s 210 s 210 s 200 s

No Yes Yes No

-80…200 °C

(-112…392 °F)

-100…200 °C

(-148…392 °F)

Suitable for

fine dust

General

information

Application

No

Fast response

time

Sterilization,

,

H

2O2

handheld

devices

No >10 µm Yes No

High

temperature, fast

response time,

fast drying,

mechanically

robust

Meteo,

agriculture,

climatic

chambers,

storage rooms,

cheese cellar

Standard filter

HVAC, office,

storage rooms,

laboratory, clean

rooms

High chemical

resistance, fine

dust risistant,

high temperature

Cleanrooms,

medical, injection

chamber, meal

manufacturing

High wind speed,

abrasive

environment, high

mechanical

protection

HVAC with high

wind speed,

industrial

applications

12

T63: 100 %RH 30 %RH

13

PC carrier: 70 °C 23 °C

14

Stainless steel carrier: 70 °C 23 °C

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 22 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

4 User configurable settings and functions

The HC2A probe ships configured as per the factory defaults:

o Users who intend to use the probe as a stand-alone analog device can use the probe as any conventional

humidity and temperature probe. A connecting cable with active electronics may be required to power

the probe. Most such users will never have to use the probe configurable settings and functions.

o Users who purchased a probe for use with another ROTRONIC instrument can also use the probe right

away and do not necessarily have to use the probe configurable settings and functions

o Users that intend to use the probe as a stand-alone digital device typically need to use a connecting

cable with active electronics and generally need to configure either the probe or the PC

Making use of the probe configurable settings and functions is entirely up to the user and the appropriate settings

depend on the user application. We have provided below a short description of the probe functions and also

indicated the factory default settings.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 23 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

4.1 Function overview

MEASUREMENT ACCURACY AND RELIABILITY

AirChip3000 Functions Description

o 1-point or multi-point humidity calibration or adjustment

o 1-point or 2-point temperature calibration or adjustment

► Humidity / temperature adjustment

► Data recording

MEASUREMENT LOOP VALIDATION

o Generate a time stamp for calibrations and adjustments

o Retain and view last adjustment date and adjustment values

o Generate calibration and adjustment protocols

The data recording function differs from a true data logging

function in the sense that the AirChip3000 does not time stamp

the data. This data recording function can be used to investigate

events such as a sensor malfunction as well as to retrieve data

that would otherwise be lost.

o Start or stop data recording - up to 2000 value pairs (%RH

and temperature). Starting a recording session erases all

previously recorded data.

o The recording mode and log interval can be specified.

o When the probe is powered off, the recording session is

paused but not ended. As long as the recording session has

not been ended, the probe automatically resumes recording

data when powered up again.

o The recorded data can be downloaded to a PC with the

HW4 software, time stamped and viewed.

Manual

AirChip3000 Functions Description

Used to make the probe generate fixed values for the humidity,

► Simulator mode

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 24 of 40

temperature and calculated parameter. Can be configured,

enabled or disabled.

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

SAFEGUARDS

AirChip3000 Functions Description

Used to protect the probe with a password to prevent

► Device write protection

PROCESS PROTECTION / PROTECTION OF OTHER DEVICES

AirChip3000 Functions Description

► Out-of-limit value alarm

► Bad sensor alarm

► Fail safe mode

unauthorized digital access by a digital user. Can be

configured, enabled or disabled

Used to specify the normal range for humidity, temperature

and the calculated parameter depending on the user

application. Can be configured, enabled or disabled.

Out-of-limit values trigger a digital alarm

Built-in function. Cannot be disabled

A bad humidity or temperature sensor triggers a digital alarm

Used to specify a "safe" fixed value for humidity and for

temperature in the event of a sensor failure. Can be

configured, enabled or disabled

Manual

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 25 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

4.2 Factory default settings

Configurable Settings Factory default

Unit system (Metric or English) Metric

Psychrometric calculation None

Output 1 parameter, scale and unit Humidity: 0…100%RH

Output 2 parameter, scale and unit Temperature: -40…60 ˚C

Communication protocol RO-ASCII

RS-485 address 0

Device name HC2A

Functions Factory default

Humidity / temperature adjustment Enabling / Disabling only by HW4 user rights possible

Device write protection Disabled

Out-of-limit value digital alarm Disabled

Data recording Disabled

Fail safe mode Disabled

Simulator mode Disabled

For a detailed description of all AirChip3000 / probe main functions see document E-T-AC3000-DF-V1.

Instructions regarding the configuration of the probe and access to its functions are provided in the following

manuals:

E-M-HW4v3-Main

E-M-HW4v3-F2-001

E-M-HW4v3-DR-001

E-M-HW4v3-A2-001

E-M-AC3000-CP

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 26 of 40

HygroClip2 ADVANCED

OK

OK

E-M-HC2A-V1_2.docx

Manual

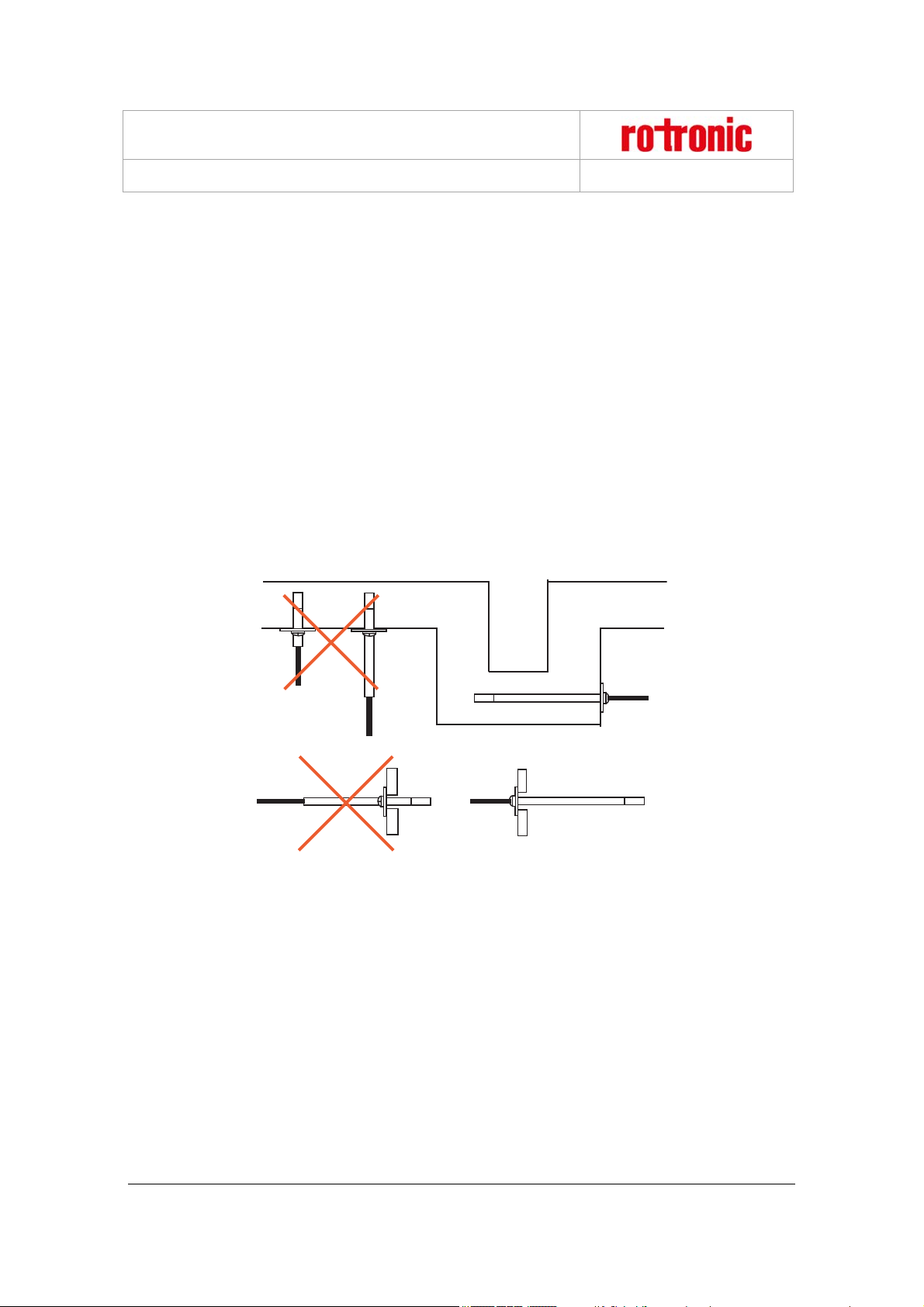

5 Mechanical installation

For best results, please observe the following guidelines:

o Install the probe at a location where humidity, temperature and pressure conditions are representative

of the environment or process to be measured. Avoid the following: (a) Close proximity of the probe to a

heating element, a cooling coil, a cold or hot wall, direct exposure to sun rays, etc. (b) Close proximity of

the probe to a steam injector, humidifier, direct exposure to precipitation, etc. (c) Unstable pressure

conditions resulting from excessive air turbulence.

o When installing the probe on a wall, do not place the probe right above a heat producing device of

instrument such as a transmitter or an Ethernet adapter (warm air tends to rise).

o If possible, choose a location that provides good air movement at the probe: air velocity of at least 1

meter/second (200 ft/ minute) facilitates adaptation of the probe to changing temperature.

o When installing the probe through a wall, immerse as much of the probe as possible in the environment

to be measured.

OK

Position the probe so as to prevent the accumulation of condensation water at the level of the sensor leads.

Install the probe so that the probe tip is looking downward. If this is not possible, install the probe horizontally.

Depending on the probe model, a probe holder (mounting flange with a compression fitting) can facilitate

installation through a wall.

Future maintenance can be made easier by providing next to the probe a calibration access orifice. During

maintenance, this permits the insertion of a reference probe (calibrator).The calibration access orifice should

have the same size as the orifice used to install the probe and can be equipped with a probe holder.

OK

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 27 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

6 Electrical installation

This section describes the general safety precautions for electric wiring.

6.1 General connection information

Heavy machinery and instrumentation should not share the same power supply wiring. If this cannot be avoided,

noise filters and surge protectors should be used. Most UPS devices have those features already integrated.

6.2 Signal cable information

The following guidelines are derived from the European standard EN 50170 for the transmission of signals by

copper wires. Note on installation planning: when determining the position of machinery and equipment, the

rules given in EN 50170 should be followed with due regard to local circumstances.

Whenever the level of electromagnetic interference is expected to be high, both the instruments and signal

cables should be placed as far away as possible from the source of interference.

In general, signal cables should be installed in bundles or channels / conduits, separate from other cables as

indicated in the table below:

o Bus signals such as RS485

o Data signals for PCs, printers etc.

o shielded analog inputs

o unshielded direct current (<= 60V)

o shielded process signals (<= 25 V)

o unshielded alternate current (<= 25V)

o coaxial cables for CRT monitors

o direct current from 60 V to 400 V

(unshielded)

o alternate current from 25V to 400 V

(unshielded)

o direct and alternate current > 400 V

(unshielded)

o Telephone lines

o lines leading into EX-rated areas

in common bundles or channels / conduits

in separated bundles or channels /

conduits, without minimum distance

in separated bundles or channels /

conduits, without minimum distance

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 28 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

6.3 Analog signal wiring

Preferably use a shielded cable to connect the analog outputs of the HC2A to other devices. The maximum

cable length is determined by the maximum error that the user will accept. This can be calculated as follows:

Error (V) = cable resistance x current through load

6.4 Digital signal wiring

Use one of the available connecting cables (see Accessories) to connect the UART digital interface of the HC2A

probe to other devices. Without a signal booster, the maximum cable length should not exceed 5 m (16 ft).

6.5 Grounding

In the case of a fixed installation, ground the HC2A probe, especially if the electronics will be subjected to a low

humidity environment (35 %RH or less). The power supply and digital ground (GND) and the analog ground

(AGND) should be tied separately to a proper ground so as to avoid spikes in the analog signals.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 29 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

7 Operation

The HC2A probes are compatible with a large number of indicators, data loggers and transmitters from

ROTRONIC. Operating instructions are provided in each device manual. The HC2A probes can also be used

as a conventional analog probe. See Accessories, supply voltage adapters, connectors and cables. Use the

HW4 software to configure the probe as desired, complete the mechanical and electrical installation and power

up the probe.

7.1 Minimum load requirements for the probe voltage outputs

In the situation where the external device uses an internal pull-up resistor the value of this resistor should meet

the requirements shown below. It is also necessary to add a pull-down resistor RL connected to ground in order

to be able to read 100% of the range of the probe voltage output.

Voltage Output

HC2A

VCC

GND

R Pull-up

RL

HC2A signal VCC R pull-up RL

0…1V 3.3V ≥250 kOhm 1 kOhm

0…1V 5.0V ≥400 kOhm 1 kOhm

0…1V 10.0V ≥1 MOhm 1 kOhm

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 30 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

7.2 Connectivity examples for stand-alone probes

Stand-alone operation as a digital probe (PC or network)

The HC2A probes can be connected to a PC or to an Ethernet network with one of the available digital interface

adapters (see Accessories). Probe configuration and full access to all probe functions requires a PC with the

ROTRONIC HW4 software installed. When using the standard RO-ASCII protocol, access to some of the probe

functions is also possible without HW4. For details, see document

Digital connection example: RS-485 network

240

Note:

The master device can be either a transmitter such as the HF5 (USB or TCP/IP interface) or an adapter

o

such as the AC3010 cable (USB)

o

Power to the combination E2-01XX-MOD and HC2A probe can be provided by an individual AC adapter

or by a central voltage source connected to the RS-485 network (requires cables with 2 twisted pairs:

one for the data, the other for power)

Master

Addr. 1

USB or TCP/IP port

RS-485 device connectors

(T Connection)

E-M-AC3000-CP

E2-01XX-MOD

Adapter

Slave

HC2A probe

Addr. n

.

240

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 31 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Analog connection example:

E2-01XX-ACT

Voltage

Adapter

HC2A probe

Cable ended with open wires

2 x analog signal

0…1 VDC

7.3 Hand-held probes used with an indicator

Manual

Voltage Source

5…24 VDC

or

5…16 VAC

Controller

(or other)

The most common source of error when measuring relative humidity with a hand-held probe is a difference

between the temperature of the probe and the temperature of the environment. At a humidity condition of 50

%RH, a temperature difference of 1C (1.8 F) typically results in an error of 3 %RH on relative humidity.

When using a humidity probe with a portable indicator, it is good practice to monitor the display for temperature

stability. When moving the probe from one area to another, the probe should be given sufficient time to

equilibrate with the environment to be measured. This time can be shortened, and errors avoided, by using the

probe configuration that fits best for your application.

In extreme situations, condensation may occur on the sensors when the probe is colder than the environment.

As long as the humidity / temperature limits of the humidity sensor are not exceeded, condensation does not

alter the calibration of the sensor. However, the sensor has to dry out before it can provide a valid measurement.

Non-moving air is an excellent insulator. When there is no air movement, surprising differences in temperature

and humidity can noted over short distances. Air movement at the probe generally results in measurements that

are both faster and more accurate.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 32 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

8 Maintenance

8.1 Cleaning or replacing the dust filter

Depending on the conditions of measurement, the filter should be checked from time to time. Corroded,

discolored or clogged filters should be replaced.

8.2 Periodic calibration check

Both the Pt 100 RTD temperature sensor and associated electronics are very stable and should not require any

calibration after the initial factory adjustment.

®

Long term stability of the ROTRONIC HYGROMER

For maximum accuracy, calibration of the probe should be verified every 6 to 12 months. Applications where

the probe is exposed to contaminants may require more frequent verifications. Calibration and adjustment of

the HC2A probe can be done with either a PC with the HW4 software installed or with the HP23 hand-held

calibrator. For connecting the HC2A probe to a PC, use a digital adapter cable AC3001 (see document E-M-

HC2-accessories).

Procedure for adjusting the HC2A probe with the ROTRONIC HW4 software:

o

Connect the HC2A probe to the HW4 PC as explained in the HW4 manual E-M-HW4v3-Main

o

Start HW4 software on the PC and search for the HC2A probe.

o

After finding the HC2A probe with HW4, expand the device tree to see the HC2A probe functions

and select Probe Adjustment.

o

For further instructions see HW4 manual E-M-HW4v3-A2-001

humidity sensor is typically better than 1 %RH per year.

8.3 Validation of the output signals transmission

If so desired, transmission of the HC2A probe output signals can be validated by using the probe simulator

function. The HW4 software is required to enable and configure this function. When the function is enabled the

probe generates digital and analog signals corresponding to values specified by the user.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 33 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

9 Firmware updates

Firmware updates will be available on the ROTRONIC website for downloading. For connecting the HC2A probe

to a PC, use a digital adapter cable AC3001 (see document E-M-HC2-accessories).

Procedure for updating the firmware:

o

Connect the HC2A probe to the HW4 PC as explained in the HW4 manual E-M-HW4v3-Main

o

Copy the firmware update file from the ROTRONIC website to the PC.

o

Start HW4 software on the PC and search for the HC2A probe.

o

After finding the HC2A probe, expand the device tree to see the HC2A probe functions. Select Device

Manager. In the Device Manager menu bar select Tools > Firmware Update. For instructions see

document E-M-HW4v3-F2-001.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 34 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

10 Technical data

General

Device type Humidity temperature probe

Mechanical configuration See models

IP protection class IP65

Power supply and connections

Supply voltage (VDD) 3.3…5 VDC ±0%

Nominal current consumption <4.5 mA

Maximum start-up current unlimited <50mA during 2µs

Minimum start-up current 8 mA during 2ms and 5 mA during 2s

Maximum current spike during

operation

Polarity protection Mechanical only (keyed connector)

Humidity measurement

Sensor ROTRONIC HYGROMER® HT-1

Measuring range 0…100 %RH

Measurement accuracy

Repeatability 0.3 %RH

Long term stability <1 %RH / year

Sensor time constant

Temperature measurement

Sensor Pt100 RTD, IEC 751 1/3 class B

Measuring range -100…190 / 200 °C15 (see also environmental limits)

Measurement accuracy

Repeatability 0.05 °C

Long term stability <0.1 °C / year

Sensor time constant Typical 4 sec, 63 %RH of a step change (1 m/sec air flow at sensor)

1 mA during maximum 2µs

±0.8 %RH, at 10…30 °C (HC2A-S(3), HC2A-IC, HC2A-IM, HC2A-IE)

±0.5 %RH, at 10…30 °C / 10..90 %RH (HC2A-S(3)H)

Typical 10 sec, 63% of a 35 to 80 %RH step change (1m/sec air flow at

sensor)

±0.1 °C, at 10…30 °C

±0.3 °C, at 10…30 °C (HC2A-C04, HC2A-C05; see also

§10.3)

15

The peak load at 200 °C is 100 h. See the sensor data sheet for detailed information on the pollution loads for the

sensor.

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 35 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Calculated parameters

Psychrometric calculations Dew or frost point (user configurable)

Start-up time and data refresh rate

Start-up time 1.5 s (typical)

Data refresh rate 1.0 s (typical) – when not calculating any parameter

Configurable analog outputs

Output 1 Can be made to correspond to any parameter

Factory default parameter Relative humidity

Factory default scale 0…100 %RH

Output 2 Can be made to correspond to any parameter

Factory default parameter Temperature

Factory default scale -40…60 °C

Output 1 and Output 2

Signal type 0…1 V

User configurable scaling limits -999.99 … 9999.99 engineering units

Offset at 0 V +10 mV (maximum)

Ripple <1.2 mV/x 2µs

Short circuit tolerant Yes

Internal resistance <10 Ω

Minimum external load 1000 Ω

Deviation from digital signal <±1 mV from 0.002 to 1.0 V / + 2 mV from 0.0 to 0.002 V

Digital interface

Interface type UART (Universal Asynchronous Receiver Transmitter)

Organization Dialog, duplex

Baud rate : 19200

Parity : none

Default configuration

Tolerance 3 %

Baud rate configuration: No

Logical levels

Maximum cable length 5 m (16.4 ft) w/o signal booster

Data bits : 8

Stop bits : 1

Flow Control : none

Logical 0: ≤ 0.3V * VDD

Logical 1: ≥ 0.8V * VDD

Manual

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 36 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

General specifications

Housing material See Models

Collar material (connector) Stainless steel, DIN 1.4301

Dust filter material See Models

Physical dimensions See Models

Weight See Models

Conformity to standards

EMC Directive:

20.04.2016: 2014/30/EU

CE / EMC immunity

Solder type Lead free (RoHS directive 2011/65/EU)

FDA / GAMP directives compatible

Environmental limits

Storage and transit -50…+100 °C / 0…100 %RH, non condensing

Operating limits at electronics

Temperature limits at sensor See Models

Maximum humidity at sensor

Maximum air velocity at probe 50 m/s (3,28 ft /s), according to filter specifications

Critical environments See HT-1 data sheet

EN 61000-6-1: 2007, EN 61000-6-2: 2005

EN 61000-6-3: 2007+A1:2011+AC:2012, EN 61000-6-4: 2007+A1:2011

Performance criterion: www.rotronic.com

-50 … +100 °C

0…100 %RH, non condensing

The sensor withstands 93 °Cdp. This results in the following conditions:

100 %RH up to 93 °C (203 °F)

78 %RH at 100 °C (212 °F)

34 %RH at 125 °C (260 °F)

17 %RH at 150 °C (302 °F)

Manual

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 37 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

Manual

11 Accessories and parts

For accessories and parts such as the HW4 configuration software, extension cables, adapter cables, calibration

accessories and spare dust filters, please see document E-M-HC2-accessories

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 38 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

12 Supporting documents

Document File Name Contents

E-M-HC2-accessories

E-T-AC3000-DF-V1

E-M-HW4v3-DIR

E-M-HW4v3-Main

E-M-HW4v3-F2-001

E-M-HW4v3-A2-001

E-M-HW4v3-DR-001

E-M-AC3000-CP

Accessories and parts for probes, indicators and transmitters

AirChip3000 Description and Main Functions

List of the HW4 manuals

HW4 software version 3: General instructions and functions common to all

devices

HW4 software version 3: HC2A probe series

Device configuration and AirChip3000 functions

HW4 software version 3: Probe Adjustment function AirChip3000 devices

HW4 software version 3: Data Recording Function AirChip3000 Devices

AirChip3000 Communication Protocol

Manual

E-M-CalBasics

E-T-HumiDefs

Temperature and humidity adjustment basics

Instructions for using the ROTRONIC humidity standards

Humidity Definitions

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 39 of 40

HygroClip2 ADVANCED

E-M-HC2A-V1_2.docx

13 Document releases

Doc. Release Date Notes

V1_0 August 2016 Original release

V1_1 November 2016

V1_2 April 2017

Waterproof is specified more in detail, page 22

Max. wind speed adapted (technical specifications)

Technical drawings HC2A-SM

Filter and support specifications edited

Offset analogue output +10mV

Manual

© 2016 ROTRONIC AG Bassersdorf Switzerland Page 40 of 40

Loading...

Loading...