Page 1

Skilmatic SI Range

3rd Generation Skilmatic SI

Full configuration, status and monitoring user manual

Keeping the World Flowing

SI Electro-Hydraulic

Valve Actuators

Page 2

2

Page 3

Table of Contents

1. Introduction

1. Introduction __________________________3

ACTUATOR

SETTING TOOL

1.1 Using the Rotork Setting Tool __________4

1.2 Connecting to the Actuator ___________6

1.3 Password Security ____________________7

2. Settings ______________________________8

2.1 L imit s ______________________________8

2.2 Stroke Tests ________________________11

2.3 Indication __________________________13

2.4 Control ___________________________ 16

2.5 Security ___________________________ 35

2.6 Default ___________________________ 37

3. Status ______________________________ 38

3.1 Control ___________________________ 38

3.2 Movement ________________________ 42

3.3 Alarms ___________________________ 43

3.4 Indication _________________________ 46

4. Data Log ___________________________ 48

4.1 Service Log ________________________ 49

4.2 Life Log ___________________________ 50

4.3 Pressure Profile _____________________51

4.4 Starts Profile _______________________51

4.5 Trend Logs ________________________ 52

4.6 Events Logs _______________________ 55

4.7 Alarm Log ________________________ 57

4.8 Partial Stroke ______________________ 58

4.9 Full Stroke ________________________ 58

4.10 Data Log − Bluetooth Log ___________ 59

4.11 Data Log − Set Log Date ____________ 59

This manual provides instruction on the set-

up and analysis of the actuator.

It is structured so that instruction on using the

setting tool, navigation and password security is

contained in section 1.1.

This then must be applied when changing

settings and viewing information as set out in

section 2.5.

The user must therefore be familiar with

the operations contained in section 1 before

proceeding.

This manual should be read in conjunction

with PUB21-057-00-1015 SI Range Instructions

for Safe Use, Installation Basic set-up and

Maintenance supplied with the actuator and

also available at www.rotork.com

5. Assets ______________________________ 60

5.1 Actuator __________________________ 61

5.2 NAMUR 107_______________________ 63

5.3 Valve _____________________________ 64

5.4 Online Help _______________________ 65

SI Full Config uration Manu al – Secti on: Introduc tion 3

Page 4

ACTUATOR

SETTING TOOL

1.1 Using the Rotork Setting Tool

The setting tool is used to connect to the actuator, navigate

through menus, change settings and view information presented

on the actuator display.

1

9

4

7

8

5

11

3

6

2

10

Name General Operation

1. Key Scroll up.

2. Key Scroll down / Connect via Bluetooth®.

3. Key Decrease value / Toggle setting / Scroll left.

4. Key Increase value / Toggle setting / Scroll right.

5. Key Select the highlighted item.

Save the highlighted setting.

Stop actuator running (when setting tool

control is enabled, refer to 2.3.1).

6. Key Return to previous menu.

7. Key Cycle between standard and zoom view on data

logger pressure graphs.

8. Key Actions the pre-configured mission stored on

the Rotork Bluetooth® Setting Tool Pro.

9. Infrared transmitter window.

10. Key Send a Close command to the connected

actuator (when enabled refer to 2.3.1).

11. Key Send an Open command to the connected

actuator (when enabled refer to 2.3.1).

Navigation

To navigate through screens, menus and pages, the

and keys are used. A single key press results in one

movement. Holding the key will result multiple movements in

succession. Menus, pages and dropdowns wrap round. This

means that an item at the bottom of a screen can be accessed by

pressing while at the top.

Shorthand instructions

This manual uses shorthand instruction (example):

(meaning select, edit setting, save) to prompt the user with the

key operations required. The display will also indicate the relevant

keys at the bottom left.

Pages, functions and index

The display indicates the number of each function as it is

highlighted along with the total number of functions on that

page. In the example below, Action is function 1 out of a total of

12 functions within that menu.

This manual uses the display function number as a

reference for instructions.

Close settings

Action Limit Pressure

Pressure Limit 90%

Pressure Mid 0%

Semi Auto Setup On Off

Set Limit

Sensor Position 15%

Open settings

Close Limit

1/12

Action (highlighted) is function 1 out of a total 12

on the LIMITS page.

Selection

The key is used to select a main menu item, menu items

or instruction buttons. For a setting, the key is used to

select when a change is required. The first time this occurs in

a communication session, a password will be requested on the

screen, refer to 1.3. Subsequent changes within the same session

do not require the entry of a password. When selected, a menu

item will be opened or a setting / function will be highlighted.

Information, instruction and password entry screens require an

or button to be selected. Navigate to highlight

the required button using or and press to select.

Setting controls

There are four types of setting control used. When a function

is selected, the ability to change the function, setting or value

is made available using drop down list boxes, checkboxes, slider

controls or numerical values.

Drop down list boxes

Drop down list boxes are indicated by .

Close Limit

Monitor Relay

Mode Available

Temperature Trip

Temp. High oC 60

Temp. Low oC -30

S1

Function Closed Limit

Contact N/O N/C

1/39

The example of the S1 indication contact Function (highlighted)

dropdown list box is shown below. When selected (password

entered if applicable, the current set function will be highlighted

within the drop down list.

4 SI Full Conf iguration M anual – Sec tion: Intro duction

Page 5

1.1 Using the Rotork Setting Tool continued

ACTUATOR

SETTING TOOL

Open Limit

Option Control

Ctrl Source 1 Profibus

Ctrl Source 2

Ctrl Selection

Analogue 0%

Profibus 0%

Disabled 0%

3/16

Disabled

Disabled

Available

Hardwired

Option mmmmmmmmmmm

Source 1

Hardwired / Source 1

Source 1 / Source 2

Src 1 Ang Source 2

0%

The symbol in the drop down box indicates more functions

are available by scrolling or .

Use or to scroll through the list until the required function

is highlighted. Press to select. The drop down list box will

close and the selected function will be saved and shown on

thepage.

To exit the drop down list without saving a new setting,

press to return to the page.

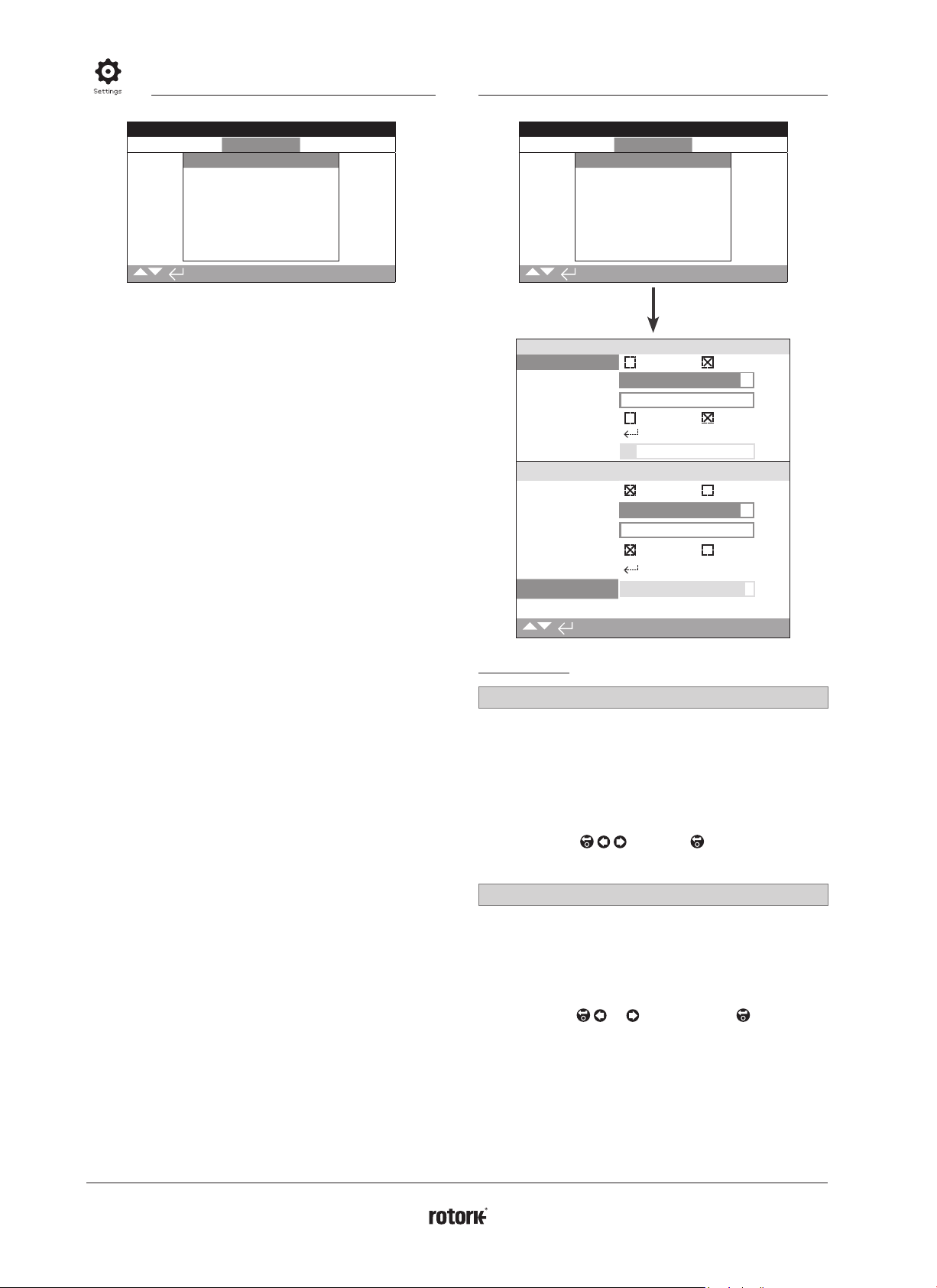

Checkboxes

Checkboxes are indicated by or .

Close Limit

Close Settings

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup

Set Limit

Sensor Position

On Off

Open Settings

1/12

An example for the limit setting checkbox is shown.

Waiting For Status

Close settings

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup

Set Limit

Sensor Position

Open Settings

On Off

1/12

When selected (password entered if applicable, refer to 1.3), the

current mode will be highlighted.

Use either the or to toggle between modes.

Once the required mode is checked, press to select. The

selected mode will be saved and shown as checked on the page.

To exit the checkbox without saving a new setting, press

to return to the page.

90%

0%

15%

95%

0%

0%

Slider controls

Slider controls graphically indicate the set value followed by the

exact numerical value, for example:

To Position

80%

The range covered by the slider is fixed and is determined by

its function.

Waiting For Status

Function Pos % Open

Contact N/O N/C

Pressure Limit

Function Open Limit

Contact N/O N/C

Position

S1

S2

10%

50%

10/40

An example of the S1 indication position value is shown above.

The S1 contact function of Pos.% Open indication will show the

valve position at which the contact will change state.

Press (enter password if applicable). Use or to decrease

or increase the value.

Slider controls wrap round so a key press on a minimum value

will wrap round and indicate the maximum value. The value step

changes increase as either of the keys is held down.

Numerical values

Numerical values relate to fields such as time or address - shown

in the example.

Waiting For Status

Close Settings

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup

Set Limit

Sensor Position

On Off

Open Settings

2/12

Press (enter the password if applicable). Use or to

decrease / increase the numerical value. Press to select when

the correct value is attained.

To exit the numerical value control without saving a new

value, press to return to the previous page.

95%

0%

0%

SI Full Config uration Manu al – Secti on: Introduc tion 5

Page 6

ACTUATOR

SETTING TOOL

1.1 Using the Rotork Setting Tool continued 1.2 Connecting to the Actuator

The Rotork Bluetooth® Setting Tool Pro incorporating Bluetooth

wireless technology is shown below. It is identified by the key

symbols and a clear band between the top and bottom casings

being transparent.

The Rotork Infrared Setting Tool Pro is identified by solid yellow

keys and a yellow band between casings:

Yellow: Rotork Infrared Setting Tool Pro

Clear: Rotork Bluetoot h® Setting Tool Pro

Connecting to the actuator using Bluetooth

The actuator must be powered up to connect using Bluetooth. The

default security set in the actuator for Bluetooth connection is by

initiation using an Infrared command. This means that the user must

be in close proximity and in direct line of sight of the actuator.

Point the setting tool at the Infrared sensor located at the lower

right of actuator display window within a range of 0.25 m (10")

and press key until the key flashes blue.

The screen will change to the Main Menu screen.

Close Limit

Settings

Data Log

The setting tool will automatically connect using

Bluetooth which takes up to 5 seconds.

Connection is indicated by a blue light on the tool and in the

actuator display window. Once connected, the tool can be used

without pointing it at the display window.

Bluetooth connection will be maintained while setting tool key

commands are made. After a period of 5 minutes with no key

commands, Bluetooth connection will be turned off and the

setting tool and display blue lights will go out. To manually

disconnect Bluetooth at any time, press and keys together.

Status

Assets

Connecting to the actuator using Infrared

Infrared communication is used when:

1. Bluetooth communication has been disabled.

2. Legacy Infrared tool is used (yellow banded).

Communication is by direct line of site, within 0.25 m (10"). Keys

have the same function as previously shown.

6 SI Full Conf iguration M anual – Sec tion: Intro duction

Page 7

1.3 Password Security

ACTUATOR

SETTING TOOL

Menus, pages and settings may be viewed when the actuator is

set to Remote, Stop or Local. To change a setting, the actuator

must be selected to Local or Stop using the red selector and the

correct password must be entered.

The password will be requested the first time a function

is selected. Once correctly entered, other changes can be

made without re-entering the password for the duration

of the setting tool session with the actuator.

If the actuator is selected to Remote and a setting is selected, the

following will be displayed:

Open Limit

Press the key to return to the previous page. Set the red

selector to Local or Stop to proceed with the setting change.

With the actuator correctly selected and when any setting

function is selected, the password screen will be displayed.

If the user has set their own password the following screen will

be displayed:

Waiting For Status

ROTACT

Enter user selected Password:

Use key to highlight new password entry box

and press key.

Use keys to scroll through alphanumeric values to display

required character.

Use key to move to the next character.

Use key to delete the highlighted character.

Use key when selected password is complete.

Navigate to the OK button using the

accept the password.

Password levels

Viewer − ROTORK

Modify − R OTACT

keys then press to

The factory set default password ROTORK is displayed and the

OK button is highlighted.

Press key. The setting page from which the function

was selected will be displayed with the function

highlighted.

SI Full Config uration Manu al – Secti on: Introduc tion 7

Page 8

2. Settings 2.1 Settings − Limits

Close Limit

Settings

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

2. Settings Menu Page

2.1 Limits 8

2.2 Stroke Tests 11

2.3 Indication 13

2.3.1 Contacts 13

2.3.2 Local Display 15

2.3.3 Analogue 16

2.4 Control 16

2.4.1 Local Control 17

2.4.2 Remote Control 18

2.4.3 ESD 33

2.4.4 Stepping Control 34

2.5 Security 35

2.6 Defaults 37

Close Limit

Settings

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Close Settings

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup On Off

Set Limit

Sensor Position

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup On Off

Set Limit

Sensor Position

Open Settings

12/12

90%

0%

15%

90%

0%

93%

Close Settings

1/12 Action

The actuator can be configured to Close on pressure or to Close

on limit.

Pressure (default) − The actuator will move the valve to the set

Closed limit and then travel to the mechanical stop.

Limit − The actuator will move the valve to the set Closed limit

position and stop.

To change, press

will indicate the set closing direction.

2/12 Pressure Limit

This setting allows the maximum cut-off pressure while travelling

from the Closed electrical limit to the mechanical end stop to be

set. The value is a % of the maximum available pressure, which is

limited by the pressure relief valve.

Default = 90%

To change press or arrow key then again. The

slider will indicate the set closing pressure %. (Factory

default is 90% of working pressure).

keys then

again. The checkbox

8 SI Full Conf iguration M anual – Sec tion: Set tings

Page 9

2.1 Settings - Limits continued

3/12 Close Pressure Mid

This settings allows the maximum / minimum cut-off pressure

whilst travelling from the Open electrical limit to the Closed

electrical limit. If the value is set for 0, on the slider this then

defaults to the setting previously set for the pressure limit.

Default = 0%

To change press or arrow key then again. The

slider will indicate the set mid travel closing pressure %.

(Factory default is 00).

4/12 Semi Auto Set-up

With the setting switch On the actuator Closed limit is initially

set at the mechanical stop of the valve / actuator with the

software then scaling back this setting by approximately 2% of

travel, to move the electrical limit away from the mechanical

stop. This prevents any issues with failure to reach the electrical

limit when the actuator is in service. Switching Off allows the

actuator to travel further.

Default = ON

To change press

checkbox will indicate the set action. (Factory default is

or arrow key then again. The

Semi Auto set up On).

5/12 Set Closed Limit

A Closed limit position cannot be set if the actuator is at the

Open limit.

If the actuator has been delivered complete with the valve, the

valve maker should have already set the Closed and Open limit

positions, refer to testing below.

The Closed limit is set by ensuring the actuator is at the

mechanical Closed limit position and then pressing key

asbelow.

Close Limit

Close Settings

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup On Off

Set Limit

Sensor Position

Open Settings

95%

0%

15%

The actuator will then display the following instruction.

Move to closed limit

Move the actuator and valve to the Closed position and press

key to select OK. This will set the Closed limit at the current

valve / actuator position and if not previously illuminated,

the Closed limit indication LED (factory default green) will

beilluminated.

Testing: The limit position can be confirmed by opening the

actuator until the indication LED changes colour and then

moving closed until the Closed limit position is displayed and the

LED is turned on at the set Closed position.

6/12 Sensor Position

Sensor Position

15%

This slider shows the current position of the position sensor and

cannot be adjusted, this setting for the Closed limit position

needs to read above 5% to prevent a fault condition occurring.

Open settings

7/12 Open Action

The actuator can be configured to Open on pressure or to Open

on limit.

Pressure − The actuator will move the valve to the set Open

limit and then travel through to the mechanical stop.

Limit (default) − The actuator will move the valve to the set

Open limit position and stop.

To change press

checkbox will indicate the set closing action.

or arrow key then again. The

6/12

Continued over page

SI Full Config uration Manu al – Secti on: Settin gs 9

Page 10

2.1 Settings − Limits continued

8/12 Pressure limit

This setting allows the maximum cut-off pressure while travelling

from the Open electrical limit to the mechanical end stop limit to

be set. The value set is a % of the maximum available pressure,

which is limited by the pressure relief valve. Default = 90%.

To change press

slider will indicate the set closing pressure %.

or arrow key then again. The

9/12 Open Pressure Mid

This setting allows the maximum/minimum cut-off pressure

whilst travelling from the Closed electrical limit to the Open

electrical limit to be set. If the value is set to 0, on the slider, this

then defaults to the setting previously set for the pressure limit.

To change press key then either or arrow

key then again. The slider will indicate the set

closingpressure%.

Default = 0%

10/12 Semi Auto Set-up

With the setting switch On the actuator Closed limit is initially set

at the mechanical stop of the valve / actuator with the software

then scaling back this setting by approximately 2% of travel, to

move the electrical limit away from the mechanical stop. This

prevents any issues with failure to reach the electrical limit when

the actuator is in service. Switching Off allows the actuator to

travel further.

Default = ON

To change press

checkbox will indicate the set action.

or arrow key then again. The

11/12 Set Limit

An Open limit position cannot be set if the actuator is at the

Closed limit.

If the actuator has been delivered complete with the valve, the

valve maker should have already set the Closed and Open limit

positions, refer to testing below.

The Open limit is set by ensuring the actuator is at the

mechanical Open limit position and then pressing key

asfollows.

Open Settings

Action Limit Pressure

Pressure Limit

Pressure Mid

Semi Auto Setup On Off

Set Limit

Sensor Position

12/12

95%

0%

0%

The actuator will then display the following instruction.

Move to open limit

Move the actuator and valve to the Open position and press

key to select OK. This will set the Open limit at the current

valve / actuator position and if not previously illuminated, the

Open limit indication LED (factory default red) will beilluminated.

Testing: The limit position can be confirmed by closing the

actuator until the indication LED changes colour and then

moving Open until the Open limit position is displayed and the

Open LED is turned on at the set Open position.

10 SI Full Conf iguratio n Manual – Sec tion: Set tings

12/12 Sensor Position

This slider shows the current position of the position sensor and

cannot be adjusted. This setting for the Open limit position needs

to be reading below 95% to prevent a fault condition occurring.

Sensor Position

0%

Page 11

2.2 Settings − Stroke Tests

Full Stroke Tests

By utilising this procedure during the initial commissioning of the

actuator assembly, the electronics will give a command to the

actuator to perform a full stroke test from either the Closed or

Open limit, recording the position and pressure against a time

reference.

Before starting this process the actuator requires the

Closed and Open limits to be set.

Close Limit

Full Stroke Tests

Partial Stroke Tests

1/13 Setup

Prior to starting the test place the remote selector switch into the

local position.

Once at the Setup option, press the key to initiate the full

stroke set up, once entered the actuator will run from either the

Closed or Open limit to the opposite position, returning back for

two to three complete cycles. During this process the electronics

will store both the Opening, Closing and ESD times. These times

will be used as a reference for all subsequent full stroke tests and

for setting up the partial stroke reference.

2/13 Setup

To operate the full stroke test, use the Bluetooth setting tool and

press the key. Once this has been done the screen will give a

warning that the full stroke test is about to proceed. Press the

key again to OK this. The full stroke test runs the actuator from

either the Open or Closed limit. If the actuator is at the Open

limit and the full stroke test is selected the actuator will run from

the Open limit to the Closed limit then back to the Open limit.

This will be done two to three times with the times for each

Open and Closed movement are stored in a table found below

this menu selection.

Setup

Test

Result (Last test)

Open (Setup) 8.33

Open (Min) 6.65

Open (Max)

Control

Close Limit

Full Stroke

Full Stroke Times (Secs)

9.98

3/13 Result (Last Test)

The results from the full stroke test are found below this menu.

All timings including the opening time, closing time and ESD

time. Also tolerances will be shown along with the most recent

full stroke test times to compare. If any timing is close to, or is

over the time tolerance a warning will be shown on the screen.

4/13 Open (Setup)

This will show the timing of the actuator's opening speed when

the first full stroke set up was complete.

5/13 Open (Min)

This shows the minimum opening time allowed including the

fixed 10% tolerance.

6/13 Open (Max)

This shows the maximum opening time allowed including the

fixed 10% tolerance.

7/13 Open (Last Test)

The times shown in this menu section is the opening time that

was stored from the actuator on the last test performed.

8/13 ESD (Setup)

This will show the ESD time from when the actuator was first set

up and a test was run.

9/13 ESD (Min)

This shows the minimum time allowed for the actuator to

perform an ESD including the 10% fixed tolerance.

10/13 ESD (Max)

This shows the maximum time allowed for the ESD including the

fixed 10% tolerance.

11/13 ESD (Last Test)

This section shows the time recorded on the last full stroke ESD

test performed.

12/13 Close (Setup)

This section shows the closing time of the actuator when the first

full stroke set up was performed.

13/13 Close (Last Test)

This shows the closing time of the actuator on the most re-cent

full stroke test operation.

1/13

Continued over page

SI Full Config uration Manu al – Secti on: Settin gs 11

Page 12

2.2 Settings − Stroke Tests continued

Partial stroke setup must be done after the full stroke set

up and test have being complete.

By utilising this procedure during the initial commissioning of the

actuator assembly, the electronics will command the actuator to

perform a partial stroke from either the closed or open limit. This

procedure will Open or Close the actuator to a certain position

selected by the operator with the use of a slide bar.

E.g. If the actuator is at the Open limit and a partial stroke is

selected, the actuator will Close to the position setting selected

then Open to 100%.

Before starting this process the actuator requires the

Closed and Open limits to be set.

1/8 To Position

A slider bar is available on this selection to choose what position

the partial stroke operates to. If 80% is selected, from the Open

limit when the actuator is partial stroked it will Close to 80%

then re-open.

Close Limit

Full Stroke

To Position

Partial Stroke Setup

Partial Stroke Test

Result (Last test) Under time to target

ESD (Setup) 1628

ESD (Last test) 461

Normally Closed Settings (ms)

3/8

80%

3/8 Test

When selected the actuator will need to be in the relevant

position. The actuator will perform a partial stroke test moving

from the Open limit to the percentage selected using the use of

the slider bar. The times will be recorded and compared to the

initial partial stroke setup times. If solenoid redundancy is turned

on this test will be performed 2-3 times. Also a partial ESD test

will be performed and the time recorded.

4/8 Results (Last Test)

The results from the partial stroke test are found in this menu. All

operating times including the opening time, closing time and ESD

time are also available. Also tolerances will be shown along with

the most recent full stroke test times. If any times are close to, or

is over the time tolerance a warning will be shown on the screen.

5/8 Open (Set Up)

This shows the time that the actuator opened in when the partial

stroke was first set up.

6/8 Open (Last Test)

This shows the time the actuator opened in on the most recent

partial stroke test.

7/8 ESD (Setup)

This shows the actuator's ESD time when the first partial stroke

was setup.

2/8 Setup

To operate the partial stroke set up with the use of the Bluetooth

setting tool scroll to the ‘Partial Stroke Setup’ and press the the

key. You will then be asked to confirm this, press the key

again and the setup will start.

When this is selected the actuator will Close to the specified

position with the use of the slider bar allocated next to the ‘To

Position’ section on the screen. The setup will partially Close

then Open the actuator recording the times to compare with any

partial stroke tests that are done after the initial partial stroke

setup. If the actuator’s solenoid redundancy is turned on, each

individual solenoid will partial stroke, meaning the actuator will

perform this test 2-3 times automatically. It will also perform a

partial ESD stroke set up and record the time of this operation.

Set partial stroke test

will be run.

Ok to proceed.

8/8 ESD (Last Test)

This shows the actuator's ESD time on the most recent partial

stroke test.

12 SI Full Configurati on Manual – Se ction: Set tings

Page 13

2.3 Settings − Indication 2.3.1 Indication − Contacts continued

Close Limit

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Settings

Instruction is provided on:

2.3.1 Contacts

2.3.2 Local Display

2.3.3 Analogue

2.3.1 Indication – Contacts

Close Limit

Indication

Contacts

Local Display

Analogue

Close Limit

Monitor Relay

Mode Available

Temperature Trip

Temp. High oC 60

Temp. Low oC -30

S1

Function Closed Limit

Contact N/O N/C

1/39

Refer to actuator's specific wiring diagram for available contact

relays options.

1/4 Monitor Relay—Mode

The monitor relay provides remote indication of actuator status.

It provides a volt free change over contact, refer to actuator

circuit diagram. There are 2 modes that can be set:

Available (default) – Actuator available for remote control.

Monitors power supplies, motor thermostat, detected internal

fault and remote control selected. A loss in one or more will

cause the monitor relay to de-energise indicating “not available”

for remote control.

Fault – Actuator fault. Monitors power supplies, motor

thermostat and detected internal fault. A loss in one or

more will cause the monitor relay to de-energise indicating

“actuatorfault”.

To change the mode press the enter button on the

Bluetooth setting tool. The actuator will then ask you to

enter the password. Once done use the and arrow

keys then select the setting you require by pressing the

keyagain.

S contact function, contact type and position

Each relay contact can be set to one of the functions shown

in the table below and its contact type can be set as Normally

Open (NO) or Normally Closed (NC). If Pos % Open function is

selected, the position at which the relay operates can be set. For

all other functions the position control slider will be greyed out.

Standard contacts S1-S4, option S5-S8 and S9-S12

contacts when fitted

The method for setting all S contacts is the same. S1 to S4 are

fitted as standard. A further 8 extra contacts are available as

options grouped: S5 to S8 and S9 to S12, refer to actuator wiring

diagram. If extra contacts are fitted their configuration screens

are accessed by scrolling down. If not fitted their configuration

settings will be greyed out.

2/4 Contact Function

The available contact functions included in the drop down list for

each available relay function are shown in the table below.

To change the contact function using the Bluetooth setting

tool select function the relay you are wanting to change

using the enter button, a drop down box will then appear,

use the and arrow keys along with the key when

the desired function is highlighted.

Function Indication:

Function Indication

Disabled Contact relay disabled

Closed limit Closed limit position (exact)

Open limit Open limit position (exact)

Temperature trip Tripped at high or low temperature

Pos % Open Set position mid-travel – Opening and Closing

Stop selected Red selector set to Stop

Local selected Red selector set to Local

Remote selected Red selector set to Remote

P-stroke active Partial stroke underway

P-stroke pass Partial stroke complete

P-stroke fail Partial stroke not complete

Continued over page

SI Full Config uration Manu al – Secti on: Settin gs 13

Page 14

2.3.1 Indication - Contacts continued

Function Indication:

F-Stroke active Full stroke underway

F-Stroke pass Full stroke complete

F-Stroke fail Full stroke not complete

Opening Actuator moving in the Open direction

Closing Actuator moving in the Close direction

Moving Actuator moving in any direction

Motor running The motor is running

General alarm A general alarm is present

Process alarm A process alarm is present

Over press (MID) Actuator over pressured mid travel

Over press (Limit) Actuator over pressured at limit

Over press (ANY) Actuator over pressured

Stall (MID) Actuator stalled mid travel

Stall (LIMIT) Actuator stalled at limit

Stall (ANY) Actuator stalled

Motor thermostat Motor thermostat trip

Control alarm Control alarm present

Lost phase Phase loss (3 phase only)

ESD active Actuators ESD signal active

Manual reset Manual reset is required

Manual operation Manual operation is selected

Actuator alarm Actuator alarm is present

Loss of HMI HMI loss (digital display)

Bluetooth Bluetooth coms

Customer supply Customer supply lost

3/4 Contact Function

Each contact relay can be configured to be normally Open (make

on conduction) or normally Closed (break on conduction).

Normally Open − The contact will complete the circuit when

the set function is present, normally Open.

Normally Closed − The contact will complete the circuit when

the set function is present, normally Closed.

4/4 Position

If the relay function relates to an actuator’s position, for example

Pos % Open, this setting will become available to edit with a

slider bar. A range of 0-100% will be available. To adjust use

the Bluetooth setting tool, enter button along with the left and

rightarrows.

Close Limit

Settings

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Close Limit

Indication

Contacts

Local Display

Analogue

Close Limit

LCD

Home Screen Position

Power Save Off

Contrast 52%

LED

Choose LED Green Red

Mid Travel LED On

Alarm LED Disabled

1/3

LCD

The display home screen language can be selected and the

power save mode can be activated within this section.

14 SI Full Co nfigurati on Manual – Se ction: Set tings

Page 15

2.3.2 Indication - Local Display

1/8 Home Screen

Refer to publication − PUB021-057-00.

Available home screens included in the drop down box list are

shown on the next page.

Position − Display indicates the current valve position to

one decimal place. Icons are used for Closed and Open limit

positions.

Pressure (A)+Pos − Display indicates current valve position to

one decimal place as Position (above) plus analogue pressure

indication scaled 0% to 100% of pressure, shown at the top of

the display.

Pressure (D)+Pos − Display indicates current valve position

to one decimal place as Position (above) plus digital pressure

indication scaled 0% to 100% of pressure.

Positioner − Used only with analogue or network position

control. Display indicates current valve position to one decimal

place plus the position equating to the applied demand signal.

In addition, an analogue indication of demand and position is

provided scaled 0% to 100% of valve position.

To set the home screen using the Bluetooth setting tool

use the enter button along with the up and down arrows

to select the desired home screen.

2/8 Power Save

The LCD has a white backlight to maximise contrast of the

segment display and matrix characters. It may be switched off

when not required or if a bright display is disruptive within its

environment.

Off (default) − The display backlight is permanently illuminated

when the actuator is powered up.

On − The display backlight automatically switches off when the

actuator is not operating. The segments / matrix remain on. The

display backlight will switch on when the local control selectors

are moved, electrical or a manual operation takes place or

when the setting tool is communicating with the actuator. The

backlight will switch off again approximately 30 seconds after

the above events have taken place.

To change the power screen using the Bluetooth setting

tool, use the enter button along with the left and right

arrows. The checkbox will indicate the selected mode.

3/8 Contrast

Contrast is the brightness of the screen. This can be adjusted

with the use of a slider bar with values set in %.

To change this use the Bluetooth setting tool’s enter

button along with the left or right arrows.

5/8 Mid Travel LED

On (default) − The yellow lights will illuminate when the

actuator is in mid travel.

Off − The yellow light are off when in mid travel.

Blinker − The yellow light will flash at approximately 0.5 seconds

intervals when in mid travel (electrical or manual operation).

When stationary the lights will remain on.

On / Alarm − The yellow lights are on when in mid travel. If an

alarm is active the yellow lights flash alternately at approximately

0.5 second intervals. Refer to 6/8 Alarm LED.

Off / Alarm − The yellow light are off in mid travel. If an alarm

is active the yellow light flash alternately at approximately 0.5

second intervals. Refer to 6/8 Alarm LED.

Information regarding the nature of the alarms will be shown at

the top of the display.

6/8 Alarm LED

Alarm LED function will be greyed out unless 5/8 mid travel LED

is set to On / Alarm or Off / Alarm.

Disabled (default) – The yellow lights do not indicate an

activealarm.

Alarms – The yellow lights indicate active alarms.

Service – The yellow lights indicate active service alarms only.

A service alarm indicates the actuator requires service.

Information regarding the nature of the alarm(s) will be shown at

the top of the display.

7/8 Alarm LED

The LCD / LED test function operates a test procedure to check all

of the local display functions. It will cycle periodically between

screen and LED functions to provide visual indication that the

display is in fully working order.

Press the enter button on the Bluetooth setting tool to begin

thetest.

8/8 Language

The language used on the display can be selected.

English (default) as standard. Other available languages

may be downloaded from the Rotork website, loaded into the

setting tool using Insight2 and uploaded into the actuator. Visit

www.rotork.com

4/8 Close Colour

Green (default) − The green lights illuminate at the Closed limit

position and red lights illuminate at the Open position.

Red − The red lights illuminate at the Closed position and the

green lights illuminate at the Open position.

This can be changed using the Bluetooth setting tools

enter button along with the left and right arrows to select

the checkbox.

SI Full Config uration Manu al – Secti on: Settin gs 15

Page 16

2.3.3 Indication − Analogue 2.4 Settings − Control

Close Limit

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Contacts

Local Display

Analogue

Invert On Off

Set CPT Low

Set CPT High

1/3

Settings

Close Limit

Indication

Close Limit

Analogue

Analogue position indication screen is shown above with

the default setting.

Analogue position indication (4-20 mA) is an optional extra, refer

to circuit diagram for inclusion. If the option is not fitted the

analogue menu item will not be present in the indication menu.

The analogue output signal auto ranges to the set limits and

cannotw be calibrated.

Close Limit

Settings

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Instruction is provided on:

2.4.1 Local control

Settings for vandal resistant build, setting tool control,

maintained local control, delay control and action on

loss of actuator user interface.

2.4.2 Remote Control

Settings for control source, hardwired, networks,

analogue and partial stroke setup.

2.4.3 ESD

Refer to actuator wiring diagram.

Control under an ESD control signal has higher priority

than local or remote Open / Closed signals. For ESD,

the control signal must be maintained for the duration

of the ESD action required.

2.4.4 Stepping Control

This is used to control closing and / or opening times

under both local and remote control however, it can

only be used on the hydraulic stroke.

Stepping control is used when the operator is

required to achieve a certain time in the hydraulic

strokedirection.

1/1 Invert

Off (default) − 4 mA output at the Closed limit position and

20mA output at the Open limit position.

On − 4 mA output at Open limit position and 20 mA output at

the Closed limit position.

To change this with the use of the Bluetooth setting tool,

use the enter button along with the left and right

arrows to check the checkbox of the required mode.

16 SI Full Co nfiguratio n Manual – Section: Set tings

Page 17

2.4.1 Control − Local Control

Close Limit

Local

Remote

Temporary Loss

Stepping control

Vandal Disabled

Setting Tool On Off

Maintained On Off

Delay Control On Off

Dead Man Local On Off

Loss of HMI Stayput Remote

Enabled On Off

1/7

Control

Open Limit

Local

Remote Hand Station

The local control configuration page is shown with the

defaultsettings.

1/7 Vandal

Actuator’s built as vandal resistant type 1 do not have the black

and red control selectors fitted. Selection of local control (using

the setting tool Open, Close and Stop keys) and remote control is

made using the vandal setting:

Disabled (default) – Actuator is not vandal resistant build and

control selectors are present.

Local – Actuator selected for Local control using the setting tool

(Bluetooth or Infrared), refer to 1.1. Infrared local control has a

range of approximately 0.25 m (10”) and must be in direct line

of site. Bluetooth local control has a range up to approximately

10m (30 ft.) depending on environment.

Remote – Actuator selected for Remote control. Setting tool

control keys are inactive and the actuator responds only to

remote control signals.

2/7 Setting Tool

With control selectors fitted to the actuator, the Bluetooth

setting tool Close, Open and Stop control keys can be used to

operate the actuator:

On (default) – Setting tool control keys active, control is

possible only when the red selector is set to Local, refer to 1.1

– Using the setting tool. Infrared local control has a range of

approximately 0.25 m (10”) and must be in direct line of site.

Bluetooth local control has a range up to approximately 10m

(30ft.) depending on environment. The black Close / Open

selector remains active.

Off – Setting tool Close, Open and Stop control keys are

disabled. Local control is by Close / Open / Stop selectors fitted to

theactuator.

3/7 Maintained

Sets the action as a response to local Open or Close

controlsignals:

On – The actuator will self-maintain as a response to a fleeting

local Open or Close control signal. It will run until it receives

a Stop command, it reaches a travel limit or is reversed –

maintained control.

Off (default) – The actuator will run only while an Open or

Close control signal is applied – push to run local control.

4/7 Delay Control

If there is a risk of a local Close or Open control signal being

applied due to the selector moving inadvertently or by being hit

momentarily, a delay can be set to help prevent an unintended

operation:

On (default) – A local Close or Open signal must be held for

approximately 2 seconds before the actuator responds.

Off – The actuator responds immediately to a local Close or

Open control signal.

5/7 Dead Man Local

Sets the action as a response to local Open or Close

controlsignals:

On – Local control signal must be maintained, when the local

controls return neutral (either Open or Close) the actuator will

return to the failsafe position.

Off (default) – Actuator will respond normally to local

controlcommands.

6/7 Loss of Human Machine Interface (HMI)

The H

MI consists of the actuat

selectors. If f

of the actuat

or any reas

or ca

n be set.

Stay put – The actuat

relay. It will not res

R

emote (default) – The actuat

pond to remote cont

relay. It will continue to res

or display a

nd red and blac

on the HMI stops responding, the res

or will stay put a

nd alarm using the monitor

rol signals.

or will alarm using the monitor

pond to remote cont

rol signals.

k

ponse

To change this setting with use of the Bluetooth setting

tool use the enter button along with the left and right

buttons . The checkbox will indicate the selected HMI

failure response.

7/7 Remote Hand Station

When fitted, the Remote Hand Station (RHS) can be enabled by

this setting.

Enabled – No (default) – RHS not activated and the sub-menus

will be hidden.

Enabled – Yes – RHS enabled and the sub-menus will appear in

the main Control menu. Refer to PUB002-059 for full setup.

SI Full Config uration Manu al – Secti on: Settin gs 17

Page 18

2.4.2 Control − Remote Control

Close Limit

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Local

Remote

ESD

Stepping Control

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analague

Settings

Close Limit

Control

Close Limit

Remote Control

Throughout this section instruction is provided on the set

up of standard, hard wired and remote control options.

The remote control menu is shown above listing all possible

entries. Some menu items shown are optional remote control

forms requiring additional hardware to be fitted within the

actuator. The menu displayed on the actuator will show only the

options fitted.

Options not fitted will not be shown or included in the menu list.

Check the actuator's specific wiring diagram for option inclusion.

The table on the right lists all available standard and option

remote control forms. Their type and the section of this manual

where instruction is provided.

Remote Control Form Included as: Type Section

Hardwired Standard Hardwired 2.4.2-1

Control source Standard Software 2.4.2-2

Positioning Option See note 2.4.2-3

Pressure control 2.4.2-4

Auxiliary mask Option See note 2.4.2-5

Analogue Option Analogue 2.4.2-6

Pakscan Option Network 2.4.2-7

Profibus Option Network 2.4.2-8

HART Option Analogue 2.4.2-9

Modbus Option Network 2.4.2-10

Extra I/O* Option Hardwired 2.4.2-11

Foundation Fieldbus* Option Network N/A

Device Net Option Network N/A

* When Foundation Fieldbus is fitted it will be included in the

remote control menu for information only. The Foundation

Fieldbus option is configured remotely over the Fieldbus network

and therefore does not have a setup page. Control source,

positioning and auxiliary mask pages will be included to allow

associated setting to be made when Foundation Fieldbus

isfitted.

* Extra I/O is an option card providing additional digital inputs

to the standard build. Inputs may be control or indication

(configurable).

Note: When any of the analogue or network remote control

options are fitted, auxiliary mask and positioning are

automatically included in the remote control menu. These items

allow access to settings that are common to all fitted options.

18 SI Full Conf iguratio n Manual – Sec tion: Set tings

Page 19

2.4.2-1 Remote Control − Hardwired

Close Limit

Remote Control

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analogue

Reset on Power

Hardwired

2-Wire Priority Stayput

Fast Remote On Off

1/2

1/2 2-Wire Priority

This sets the action that the actuator will perform when a Closed

and Open signal are both applied simultaneously. Hardwired

remote control form C uses the priority action (Open or Closed)

to set the actuator’s response when two signals are applied.

Refer to the actuator’s wiring diagram and its referenced RWS

controldiagram.

On applying hardwired Close and Open signals together the

actuator will:

Open − The actuator will move Open.

Stay put (default) − The actuator will not move, or will stop if

the actuator is currently running.

Close − The actuator will move Closed.

To change this setting, with the Bluetooth setting tool

use the enter button along with the up and down arrows

toselect.

2/2 Fast Remotes

This is only available on a 24 VDC signal NOT on AC inputs.

The setting will determine how long a signal needs to be present

for it to carry out the specific command.

On − When a remote signal is given, the actuator will wait

100ms before moving.

Off − When a remote signal is given, the actuator will wait

200ms before moving.

SI Full Config uration Manu al – Secti on: Settin gs 19

Page 20

2.4.2-2 Remote Control − Control Source

Close Limit

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analogue

Ctrl Source 1 Disabled

Ctrl Source 2 Disabled

Ctrl Selection Hardwired

Analogue

Disabled

Disabled

1/15

Settings

Close Limit

Remote Control

Close Limit

Option Control

Option Control

Introduction

In addition to standard hardwired control, the actuator can have

up to two remote control options fitted. For most remote control

systems employed by end-users, only one control option is used.

For control systems using analogue control only or where

analogue and network (such as Modbus) control is used. Control

(hardwired / analogue or analogue / network) can be switched

by the user using the manual / auto input available with the

analogue option and the settings made in control source.

When analogue and network options are fitted and analogue

is switched to control, the network option cannot control the

actuator but will continue to report actuator status.

The control source will be set by Rotork to the defaults

required for the option(s) fitted. Refer to table: Control

Source Settings.

For analogue control, if both manual (hardwired control

inputs) and auto (analogue control) is to be used, the

control selection will require re-setting. If only analogue

control is required, the default settings for control source

will be correct. Refer also to 2.3.2-6.

The control source is used to:

• Control source 1 / source 2 - Associate fitted control option(s)

to a source of control (source 1 or source 2).

• Control selection - Set which control source (1 or 2) has

priority when manual / auto input is used to switch between

analogue and network option source.

• Lost signal - Determines the actuator response to a lost

analogue signal or network communication.

The control source settings page shown above is an

example of an actuator with the analogue remote control

option. The actuator display will indicate fitted options.

- Refer to wiring diagram for options fitted.

Table: Control Source Settings

Control Source Settings

Option Control

Settings

Hard wired

(No Options)

Analogue only

Analogue and

Hardwired

Network Only

Analogue and

Ctrl Source 1 Disabled Analogue Analogue Network Analogue

Ctrl Source 2 Disabled Disabled Disabled Disabled Network

Ctrl Selection Hardwired Source 1

Hardwired /

Source 1

Source 1

Options Fitted

Disabled Analogue Analogue Network Network

Disabled Disabled Disabled Disabled Analogue

Disabled Disabled Disabled Disabled Disabled

Disabled Disabled Disabled Disabled Disabled

Network

Source 1 /

Source 2

20 SI Full Confi guration Ma nual – Sect ion: Setti ngs

Page 21

2.4.2-2 Remote Control − Control Source continued

1/15 Control Source 1

Control source 1 will be set by Rotork for the fitted remote,

Analogue or Network control option(s). Refer to table: Control

Source Settings.

2/15 Control Source 2

Control source 2 will be set by Rotork for the fitted remote,

analogue or network control option(s). Refer to table: Control

Source Settings.

3/15 Ctrl Selection

Control selection is used to select the control source. Also if

required, for analogue with network options, allowing hardwired

switching between sources using the manual / autoinput.

Disabled − All remote control disabled. The actuator can only be

operated using the local controls.

Hardwired − Remote control by hardwired inputs only. This

setting is the default for actuator’s with no option cards fitted.

If a network option is fitted but is only required for

monitoring, hardwired must be selected.

Source 1 − Control by the option listed for control source 1.

If control source 1 is a network option, control will be via its

auxiliary mask inputs. Refer to 2.3-2.5.

Hardwired / Source 2 − Control availability only when analogue

option is fitted. This mode enables users to select between

control by hardwired inputs or source 1 (analogue) control by

applying or removing a signal to the manual / auto input (refer to

wiring diagram). Manual will enable hardwired control and auto

will enable source 1 control.

If an analogue option is fitted and manual / auto switching

is required, hardwired / source 1 will be required to be

selected.

Source 1 / source 2 − For future use with two Network

controloptions.

4/15 to 6/15 Options Fitted

Not editable. Factory set for the control options fitted. Up to 3

options can be fitted and will be indicated in the list. Unused

allocations will be set to disabled.

If a control option is fitted after manufacture, the allocation will

be set to the fitted option type by Rotork Service. Where the

user upgrades an actuator to include a new control option using

a kit supplied by Rotork, this must be set before the control

mode settings can be made. Contact Rotork for access.

7/15 to 15/15 Lost Signal

Sets the actuator response for when the analogue signal

or network communications of the control source are lost.

There are three settings for determining the actuator’s response

on loss of signal. These are all common for each type of option

fitted. Each group of three will be headed with the applicable

option type. For actuator’s including one control option, settings

8/19 to 10/19 will be available while settings 11/19 to 19/19

will be greyed out. For two options fitted, 8/19 to 13/19 will be

available and so on until up to four options. This instruction is

therefore common for as many options as are fitted.

7/15 Lost Signal Time

Sets the amount of time in seconds that a signal must be lost

before the lost signal action is performed. Range, 0 to 65

seconds. Default is set as 1 second.

For the analogue option, time must be set to 0 seconds.

To change this using the Bluetooth setting tool use

the enter button along with the left and right

followed by the enter arrow as select. The time set

after which the lost signal action will be implemented

asindicated.

8/15 Lost Signal Action

Sets the action to be performed when the signal is lost.

Off (Default) − the lost signal feature is disabled. An actuator

with analogue control will run to the set low signal position. An

actuator with network control will stay at its current position

when communication / signal is lost.

Stay put − If the actuator is not moving it will stay put. If it is

moving the movement will stop in that position.

De-energise all − All solenoid will de-energise.

Close − The actuator will run to the Closed limit.

Open − The actuator will run to the Open limit.

Position − the actuator will run to the mid travel position set for

signal loss position, refer to 9/15.

To change these settings using the Bluetooth setting tool

press the enter button along with the up and down

arrows

until the required selection on the drop down

box is highlighted. Follow up with the enter button .

The selected action will be indicated.

9/15 to 15/15 Lost Signal

When the lost signal action is set to position the actuator will

run to the mid travel position set. Range is 0% (Closed limit) to

100% (Open limit). This control should be used if a lost signal

position in mid travel is required.

Whenever the actuator is running under positioning mode, the

parameters in the positioning menu will apply. Refer to 2.4.2-3.

SI Full Config uration Manu al – Secti on: Settin gs 21

Page 22

2.4.2-3 Remote − Positioning

Close Limit

Limits

Stroke Tests

Indication

Control

Security

Defaults

Service

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analogue

Deadband Close

Hysteresis Close

Deadband Open

Hysteresis Open

Slow Mode

Current Demand

1/6

Settings

Close Limit

Remote Control

Close Limit

Positioning

0.00

0.8%

0.1%

0.8%

0.1%

5%

The positioning option settings page with its default

settings is shown above.

Applicable for analogue and HART control options and

also for all network control options where positioning

control is required. Settings are used to tune the actuator

positioning response.

• Deadband and hysteresis are combined to set

positioningaccuracy.

• Low / high signal position sets the range of the valve stroke

where positioning is required.

1/6 Deadband Close/Open

Range − 0% to 10% Defaults = 1%.

Affects positioning accuracy as a response to the process control

system desired value (DV) signal position. A smaller deadband

increases accuracy, however the widest deadband should be

set whilst maintaining good control in order to protect the

mechanical valve from excessive wear and / or to keep the

actuator within its electrical rating.

Deadband setting should be combined with 2/5 hysteresis

setting. The actuator will run towards the DV position until the

actual position is within the set deadband minus the hysteresis

setting. This has the effect of the actuator stopping nearer to the

DV position. The actuator will not restart unless it overshoots and

runs outside the deadband or a new command places the new

desired position outside the deadband. Refer to figure 2.4-1.

To change settings using the Bluetooth setting tool use

the enter button along with the left and right arrows

with the use of a slider bar until the desired % is

found. Use the enter button to select.

2/6 Hysteresis Close/Open

Range 0% − 10% Default setting = 0.5%.

Hysteresis affects positioning accuracy as a response to the

process control system desired value (DV) signal position. A larger

hysteresis setting will increase accuracy but the value set must

not be greater than that set for deadband.

Hysteresis setting should be combined with 1/5 deadband

setting. The actuator will run towards the DV position until the

actual position is within the set deadband minus the hysteresis

setting. This has the effect of the actuator stopping nearer to the

DV position. The actuator will not restart unless it overshoots and

runs outside of the deadband or a new command places the new

desired position outside the deadband. Refer to figure 2.4-1.

To change settings using the Bluetooth setting tool use

the enter button along with the left and right arrows

with the use of a slider bar until the desired % is

found. Follow up with enter as the select button.

22 SI Full Confi guration Ma nual – Sect ion: Setti ngs

Page 23

2.4.2-3 Remote − Positioning continued

Slowband (8%) Slowband (8%)

Initial direction of travel

SLOW

SLOW

Actual stopped position

3/6, 4/6, 5/6, 6/6 Deadband, Hysteresis, Slowband &

Selectable slowband, deadband and hysteresis values are used

to determine how closely the actuator position will match the

demand signal. Proper calibration settings provide accurate

positioning, prevent the system from hunting and reduce the

number of pump/motor starts. Some understanding of the

operational design parameters is required to optimally set

deadband ‘DB’, hysteresis ‘HS’ and slowband ‘SL’. The chart

below shows how the slowband, deadband and hysteresis

settings effect control of the actuator.

A slowband of 8%, deadband of 5% and hysteresis of 2% is

shown with a demand position of 50%. If the actuator is started

at 40%, the controller will command it to move in the Open

direction until it reaches 42% (demand-slowband). It will then

move Open at a slower rate until it reaches 47% (deadband-

Current Demand Example

STOP

42%

START

45%

OPENING

47%

DEMAND

POSITION

50%48%

(deadband-hysteresis)). Momentum/solenoid response time

within the system may cause the actuator to continue moving

after the Stop command has been issued as shown by the

‘actual stopped position’ at 48%. Movement is not commanded

again until the measured position falls outside of the deadband

on either side of the deadband position. If the deadband was

smaller, it would be possible for the actual stopped position to

have fallen the other side of the deadband in which case, the

actuator would be commanded to move in the opposite direction

to meet the demand. This would result in hunting as the actuator

oscillated around the demand point. By increasing the deadband

and also increasing the amount of hysteresis, the actual demand

position can be met without hunting occurring. Outside of the

slowband (<42% & >58%) normal fast operation should occur.

To change with the Bluetooth setting tool use the enter

button along with the left and right arrows to

select the desired position on the slider bar.

STOP

CLOSING

53%

START

55%

58%

Hysteresis (2%)

Deadband (5%)

Figure 2.4-1 Example of Positioning Control using Slowband (8%), Deadband (5%) and Hysterisis (2%)

Deadband (5%)

Hysteresis (2%)

SI Full Config uration Manu al – Secti on: Settin gs 23

Page 24

2.4.2-4 Remote Control − Pressure Control

Close Limit

Remote Control

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analogue

Close Limit

Pressure Control

Hold Pressure On Off

Deadband Over

Deadband Under

1/3

5%

5%

1/3 Hold Pressure

This setting allows the user to decide what action the actuator

should take if it drifts from its current position (across the full

actuator stroke), until another command to move is given.

This feature will compensate for any drift that occurs in

either direction by operating either the pump or solenoid to

maintainposition.

2/3 Deadband Over

This feature is used for pressure compensation to vent the

internal hydraulic pressure in the actuator in the event of thermal

expansion due to temperature fluctuations. Factor y default

setting is 10% with it being selectable between 0% - 25%.

3/3 Deadband Under

This feature is used for pressure compensation to increase the

internal hydraulic pressure in the event of the pressure falling

to a set defined value while the actuator is at a position limit.

This type of compensation is to allow for thermal contraction

again due to temperature fluctuations, with the default setting

being5%.

24 SI Full Config uration Manual – Sect ion: Settin gs

Page 25

2.4.2-5 Remote Control − Auxiliary Mask

Close Limit

Remote Control

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analogue

Close Limit

Auxiliary Mask

Auxiliary 1

Contact 1

Auxiliary 2

Contact 2

Auxiliary 3

Contact 3

1/6

Dig in Open

N/O N/C

Dig in Close

N/O N/C

Dig in Maint

N/O N/C

The auxiliary mask setting page is shown above.

Introduction

When a network option is fitted (Pakscan / Profibus / Modbus /

Foundation Fieldbus or HART) a facility to accept three auxiliary

inputs is available. Auxiliary inputs can be set as supplementary

control for the actuator (Open, Close, Stop / maintain) or as

digital indication inputs whose status is reported over the option

network. It is also possible to have a combination of both

supplementary remote control and digital inputs to provide. For

example, Open and Closed control. As well as high and low tank

level alarm indication from external level transducers.

Auxiliary inputs are in addition to the standard control and

feedback features incorporated into a network option. Auxiliary

inputs are connected to the standard Open, Close and Stop /

maintain inputs. Refer to wiring diagram.

Each auxiliary input can be set for the type of contact connected.

Refer to auxiliary input setup.

Auxiliary Input Setup

Input Auxiliary 1 Auxiliary 2 Auxiliary 3

Control Open Closed Stop / maintain

Indication Dig Dig Dig

Contact type Contact 1 Contact 2 Contact 3

Normally Open N/O N/O N/O

Normally Closed N/C N/C N/C

A normally Open contact is considered to be in the active

state when the contact is Closed. A normally Closed contact is

considered to be in the active state when the contact is Open.

(Using auxiliary 1 and contact 1 as an example).

1/6 Auxiliary 1

Refer to auxiliary input setup.

Dig in (default) − Network option will report digital input

status: 1 or 0.

Open − Hardwired Open command signal is required. Use

auxiliary 2 to 4 for Close or Stop / maintain.

To change with the use of the Bluetooth setting tool,

use the enter button along with the left and right

arrows . The checkbox indicates the set auxiliary 1

inputfunction.

2/6 Contact 1

Refer to auxiliary input setup.

N/O (default) − A normally Open contact is used to derive

input.

N/C − A normally Closed contact is used to derive input.

To change with the use of the Bluetooth setting tool,

use the enter button along with the left and right

arrows . The checkbox indicates the set contact 1

input type.

Continued over page

SI Full Config uration Manu al – Secti on: Settin gs 25

Page 26

2.4.2-6 Remote Control − Analogue Option

Close Limit

Remote Control

Hardwired

Control Source

Positioning

Pressure Control

Auxiliary Mask

Analogue

Close Limit

Analogue

Signal Type

Signal Range

Invert

Manual-Auto

Signal To Close

Signal To Open

1/6

mA Volts

20mA

On Off

On Off

The analogue option setting page is shown above.

The analogue menu item and its associated settings page will

only be shown when the analogue option is fitted. Refer to

wiring diagram. The analogue option settings page allows the

option to be set for the applied signal type and range. Signal low

and high values can also be calibrated.

For analogue options; deadband, hysteresis and

positioning settings, refer to 2.3.2-3.

1/6 Signal Type

mA (default) − Set for current (mA) Analogue control signal.

Volts − Set for voltage analogue control signal.

To change using the Bluetooth setting tool press the enter

button along with the left and right arrows

find the desired setting within the checkboxes.

to

2/6 Signal Range

Available ranges: 5 mA, 10 mA or 20 mA (default). 5 V,

10V or 20 V range for voltage control. For analogue signal

using 4 mA to 20 mA range, set 20 mA.

To change using the Bluetooth setting tool use the enter

button along with the up and down arrows

select the desired setting in the drop down box.

to

3/6 Invert

Off (default) − Lowe analogue signal will move the actuator in

the Close direction.

On - High analogue signal will move the actuator in the Close

direction.

To change using the Bluetooth setting tool press the enter button

along with the left and right arrows to find the desired setting

within the checkboxes.

4/6 Manual-Auto

With the analogue control option it is possible to have

manual / auto control by a user supplied remote switch selection.

Analogue Option

Fitted

Manual Hardwired Network

Auto Analogue Analogue

Analogue and

Network Options

fitted

When analogue and network options are fitted and auto is

selected, the network option fitted will continue to report

actuator status.

Hardwired ESD is available in both manual or auto. When

applied, ESD will override all other control signals.

For manual auto control, refer to wiring diagram and

referenced RWS diagram.

Off (default) − Manual / auto control is not used. Actuator will

be controlled by the analogue signal. Where a Network option

is also fitted, the network option will report the actuator’s

statusonly.

On − The actuator can be controlled by hardwired contacts or

the network (as applicable) or by the analogue signal.

To change using the Bluetooth setting tool press the enter

button along with the left and right arrows

find the desired setting within the checkboxes.

to

5/6 Set to Close

The actuator must be calibrated to the Close signal value. By

measuring this signal it will then be able to control the actuator

by moving it to the set to Close signal position, refer to 2.3.2-3

Apply the Close signal and select. The signal will be

measured and set as the Close signal position value.

6/6 Set to Open

The actuator must be calibrated to the Open signal value. By

measuring this signal it will then be able to control the actuator

by moving it to the set to Close signal position, refer to 2.3.2-3

Apply the Open signal and select. The signal will be

measured and set as the Close signal position value.

26 SI Full Confi guration M anual – Sec tion: Setti ngs

Page 27

2.4.2-7 Remote Control − Pakscan

Analogue

Pakscan

Profibus

HART

Modbus

Extra I/O

Remote Control

Pakscan

Address 1

Baud Rate 1200

Position

Update Time (s) Disabled

Deviation Disabled

Torque

Update Time (m) 1

Deviation Disabled

Filter Manual Auto

Valve Travel Time 1000

1/8

The Pakscan control option settings page is shown above

with its default settings. Pakscan is a control option, refer

to wiring diagram.

Depending on the Pakscan control scheme, other related settings

may be required, refer also to:

• 2.3.2-3 Positioning

• 2.3.2-5 Auxiliary Mask

1/8 Address

The Pakscan field control unit option must be allocated a unique

loop node address. Change made to the address will take effect

immediately. The range of address is 1 - 240.

2/8 Baud Rate

The actuator Pakscan Field control unit option must be set to

the loop baud rate. For Pakscan 2-wire control loop the selected

baud rate must be common in the master station and all the

field units included in the loop. Changes made to baud rate will

take immediate effect. The baud rate is selectable using the

drop down list box and the selections are: 110, 300, 600, 1200

and 2400.

3/8 Update Time(s)

Range 0 (disabled ) to 255 seconds.

Set when mid-travel positioning control is required. Update

time in seconds is the set period for updating the master station

with position. Refer to 4/6 deviation. The valve position will be

reported at time intervals equating to the set update time. If the

FCU updates to deviation whilst the valve is moving then the

update time should be set to approximately 10 times the loop

scan time. If the actuator is not used for mid-travel positioning

(i.e. isolating duty) then the update time should be turned off by

setting the time to zero (disabled).

4/8 Devi ati on (%)

Range 0 (disabled ) to 225 seconds.

This is set when mid travel positioning is required. Deviation is

the set amount of change that has to occur before the position

data is reported to the master station. Whilst the valve is in

motion, reports about its position will be made each time

the position changes by more than the deviation setting. The

recommended value is 5% where positioning data is required. If

the actuator is not used for mid-travel positioning (i.e. isolating

duty), then the deviation should be turned off by setting it to

zero (disabled).

Continued over page

SI Full Config uration Manu al – Secti on: Settin gs 27

Page 28

2.4.2-7 Remote Control − Pakscan continued

5/8 Update Time (m)

Range 5 to 255 minutes. Setting below 5 will

indicatedisabled.

Pressure update time (minutes) value is refreshed from a

stationary actuator. If pressure data is not required then its

update time should be disabled.

6/8 Deviation

Range 5% to 99%. Setting below 5% will indicate

disabled.

Set for amount of change in actuator measured pressure that has

to occur before pressure data is reported to the master station.

During valve travel pressure reporting will be made each time

the pressure changes more than the deviation setting. Where

continuous pressure data is required the recommended value is