Page 1

SM-6000

Installation Manual

Series

Redefining Flow Control

Rotary Actuators

with Local Remote Switch

Page 2

Contents

Section Page

Product Overview 3

1 - General Information 4

2 - Specifications 7

2.1 - Optional Equipment 8

3 - Installation 9

3.1 - Typical Wiring Diagram 12

3.2 - Microprocessor Based Motor 13

Drive & Controller Setup

4 - Operating your SM6000 14

4.1 - Status Description 16

4.2 - Start Up 17

4.2.1 - Select Automatic Mode 20

4.3 - Range of Operation - Setup 23

4.3.1 - Range of Operation 23

4.3.2 - Set Zero and SPAN 27

4.3.3 - Setting Limit Switches 32

4.3.4 - Operating Speed 34

5 - Setup & Calibration 36

5.1 - Setup & Calibration - Level 1 37

5.1.1 - Max Cmd Cal 38

5.1.2 - Min Cmd Cal 38

5.1.3 - Speed 39

5.1.4 - CMD Type 39

5.1.5 - LOS Act 39

5.1.6 - LOS Pos 40

5.1.7 - CUR P Gain 40

5.1.8 - CUR I Gain 40

5.1.9 - Min Pos 41

Section Page

5.1.10 - Max Pos 41

5.1.11 - Max Torque % 42

5.1.12 - Save Config 42

5.2 - Communications 43

5.2.1 - HART Control Options 43

5.2.2 - PROFIBUS Control Options 45

5.2.3 - Foundation Fieldbus 47

Control Options

5.3 - Setup and Calibration - Level 2 49

5.3.1 - MOTOR PWM 50

5.3.2 - MAX TORQUE 50

5.3.3 - INPUT VOLT 50

5.3.4 - MOTOR RATE 50

5.3.5 - PASS ENBLD 50

5.3.5.1 - PASSWORD 50

5.3.6 - LOOP 50

5.3.7 - LOAD FACT DEFS 50

6 - Faults & Troubleshooting 52

6.1 - Fault Status Indication 52

6.2 - Troubleshooting 53

7 - Local Operation - Handcrank Direction 54

8 - Mounting Conversion 55

9 - Parts Identification 56

10 - Drive Arm Dimensions 59

11 - Overall Dimensions 60

12 - Linkage Options 61

13 - User Settings 62

Notes 63

This manual contains important safety

information. Please ensure it is thoroughly

read and understood before installing,

operating or maintaining the equipment.

2

Due to wide variations in the terminal

numbering of actuator products, actual

wiring of this device should follow the

PRINT SUPPLIED with the unit.

Page 3

Product Overview

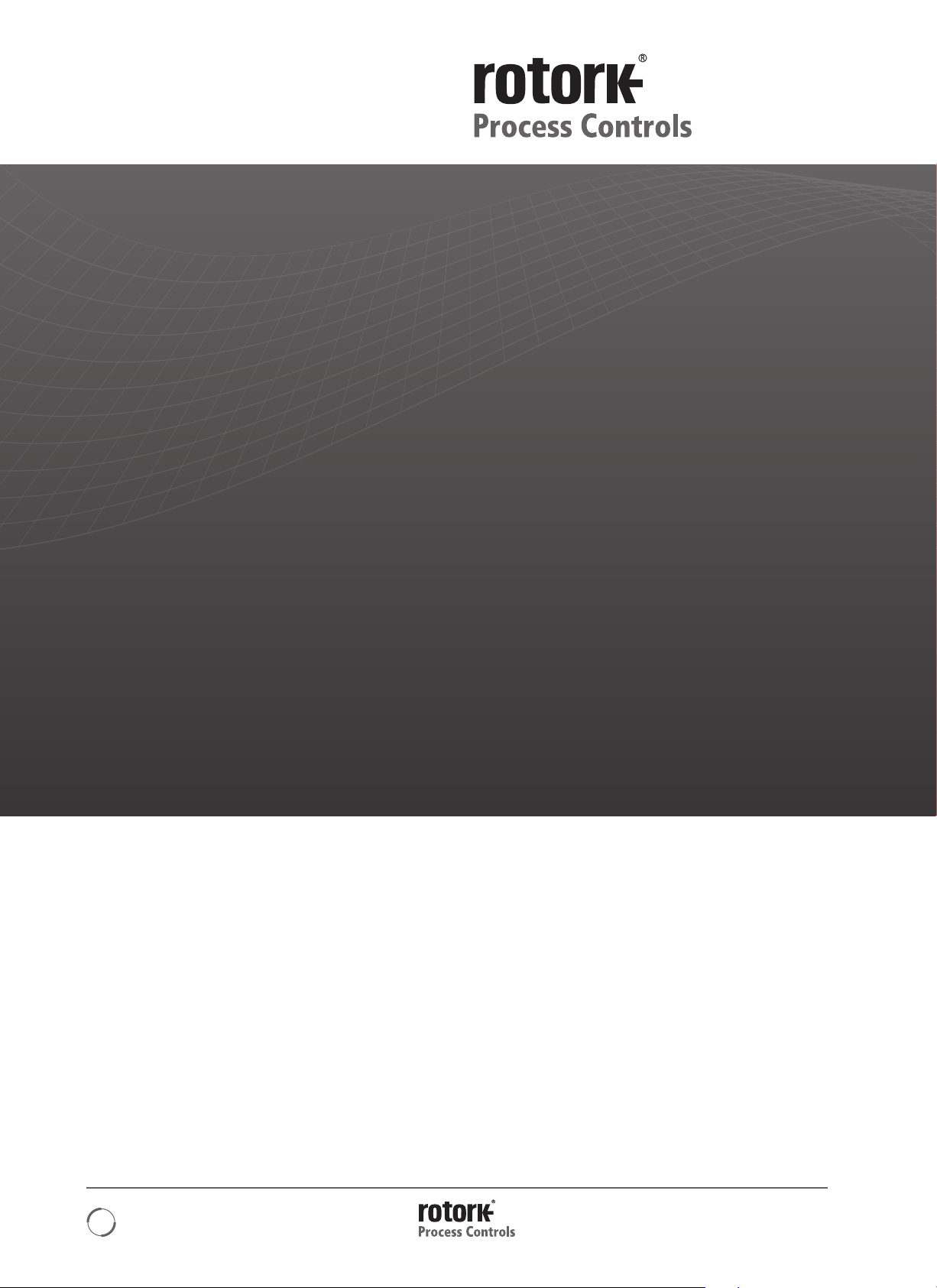

Rotork Process Controls designs and

manufactures high quality, durable actuators

designed for trouble-free performance under the

most demanding conditions.

With its field-proven design, the SM-6000 S2 is a perfect fit

for all of your high performance requirements. The SM-6000

S2 Series are rotary actuators internally geared to produce

up to 26,000 ft. lbs. (35,251 Nm) of torque at unrestricted,

continuous modulating duty.

These actuators are ideally suited for dampers, vanes, valves

and other process control applications requiring high speed,

high torque and exact positioning control.

The SM-6000 S2 actuator features a menu-driven nonintrusive setup using control knobs and vacuum fluorescent

display.

These controls are also used to programme the internally

mounted digital amplifier.

Features

• From 25º to 120º rotation.

• Torque range up to 35,256 Nm

(26,000 lbf-ft).

• Double ‘O’ ring sealing.

• Continuous unrestricted

modulating duty.

• Temperature range from -40 to +85 ºC

(-40 to +185 ºF).

• Automatic torque limiting.

• Self-locking drive system to hold in last

position and prevent backdriving.

• Manual override standard.

• HART, Profibus and Foundation

Fieldbus available.

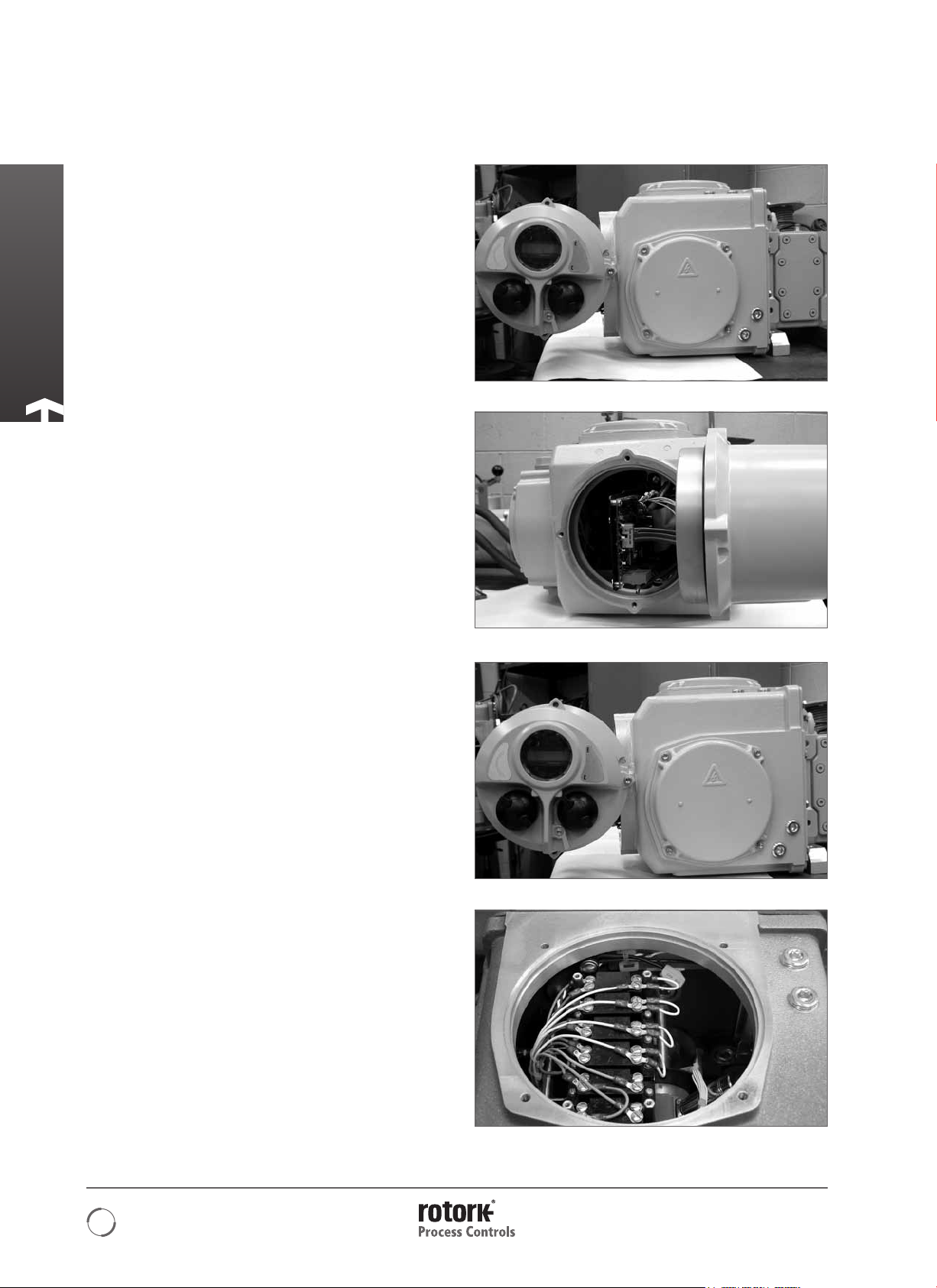

Figure 1.0. SM6000-S2 actuator

Redefining Flow Control

3

Page 4

1 - General Information

INTRODUCTION

Rotork Process Controls designs, manufactures, and

tests its products to meet national and International

standards. For these products to operate within their normal

specifications, they must be properly installed and maintained.

The following instructions must be followed

and integrated with your safety program when installing,

using, and maintaining Rotork Process Controls products:

Read and save all instructions prior to installing, operating,

and servicing this product. If any of the instructions are

not understood, contact your Rotork Process Controls

representative for clarification.

Follow all warnings, cautions, and instructions marked

on, and supplied with, the product. Inform and educate

personnel in the proper installation, operation, and

maintenance of the product.

Install equipment as specified in Rotork Process Controls

installation instructions and per applicable local and national

codes. Connect all products to the proper electrical sources.

To ensure proper performance, use qualified personnel to

install, operate, update, tune, and maintain the product.

When replacement parts are required, ensure that the

qualified service technician uses replacement parts

specified by Rotork Process Controls. Substitutions may

result in fire, electrical shock, other hazards, or improper

equipment operation.

RECEIVING / INSPECTION

Carefully inspect for shipping damage. Damage to the

shipping carton is usually a good indication that it has

received rough handling. Report all damage immediately to

the freight carrier and Rotork Process Controls, Inc.

Unpack the product and information packet - taking care to

save the shipping carton and any packing material should

return be necessary. Verify that the items on the packing list

or bill of lading agree with your own.

STORAGE

If the actuator will not be installed immediately, it should

be stored indoors in a clean, dry area where the ambient

temperature is not less than -20° F. The actuator should

be stored in a non-corrosive environment. The actuator is

not sealed to NEMA 4 until the conduit entries are properly

connected.

WARNING

Before installing the actuator, make sure that it is suitable

for the intended application. If you are unsure, consult

Rotork Process Controls prior to proceeding.

WARNING - SHOCK HAZARD

Installation and servicing must be performed only by

qualified personnel.

WARNING ELECTROSTATIC DISCHARGE

This electronic control is static-sensitive. To protect the

internal components from damage, never touch the

printed circuit cards without using electrostatic discharge

(ESD) control procedures.

4

Page 5

1 - General Information

EQUIPMENT RETURN

A Returned Goods authorization (RG) number is required to

return any equipment for repair. This must be obtained from

Rotork Process Controls. (Telephone: 414/461-9200) The

equipment must be shipped, freight prepaid, to the following

address after the RG number is issued:

Rotork Process Controls, Inc.

5607 West Douglas Avenue

Milwaukee, Wisconsin 53218

Attn: Service Department

To facilitate quick return and handling of your equipment,

include:

1. RG Number on outside of box

2. Your Company Name, Contact Name, Phone/Fax

3. Address

4. Repair Purchase Order Number

5. Brief description of the problem

IDENTIFICATION LABEL

An identification label is attached to each actuator. When

ordering parts, requesting information or service assistance,

please provide all of the label information. YOU MUST

SUPPLY THE SERIAL NUMBER WITH ALL ENQUIRIES.

ABBREVIATIONS USED IN THIS MANUAL

A Ampere

AC Alternating Current

°C Degrees Celsius

CW Clockwise

ACW Anti-clockwise

CCW Counter-clockwise

DC Direct Current

°F Degrees Fahrenheit

G Earth Ground

Hz Hertz

in. lbs Inch Pounds

kg Kilogram

L Line (power supply)

lbs Pounds Force

LVDT Linear Variable Differential Transformer

mA Milliamp

mfd Microfarad

mm Millimeters

N Newton (force)

NEMA National Electrical Manufacturing Association

Nm Newton Meter

NPT National Pipe Thread

PCB Printed Circuit Board

PH Phase

PL Position Limit switch

RPM Revolutions per Minute

SEC Second

SPDT Single Pole Double Throw

TL Torque Limit Switch

V Volts

VA Volt Amps

VAC Volts AC

VDC Volts DC

VFD Vacuum Fluorescent Display

VR Variable Resistance

W Watt

Figure 1.1. Actuator identification label.

Redefining Flow Control

5

Page 6

1 - General Information

Figure 1.2. SM6000-S2 actuator.

GENERAL DESCRIPTION, ACTUATOR

The SM-6000 is an AC input, DC driven electric actuator

designed for high modulation service. This actuator uses a

Rotork Process Controls locally mounted, or remotely located

microprocessor- based motor drive and controller. A wide

array of standard options are available for this actuator.

The SM-6000 Series actuators provide the highest speed,

torque, modulation rate, and positioning accuracy of any

electric actuator in the Rotork Process Controls product line.

With the standard control electronics, they are self-contained

automatic positioning devices capable of moving the largest

loads at speeds typical of electrohydraulic devices, and with

an unrestricted modulation rating. These high-performance

actuators are electrically controlled, self-contained, high

speed, high torque devices. With essentially unlimited

rotational travel, they provide a superior solution for any

modern actuation application.

The SM-6000 is designed using an all steel gear train

submersed in an oil bath, and conservatively rated bearings.

This design assures the longest possible life while reducing

the risk of costly repairs and unscheduled maintenance.

An internally mounted electronic controller converts AC

power input to DC power.

The DC power is then controlled by a microprocessor based

digital servo amplifier that efficiently controls speed and

torque of the drive motor.

The motor drives through high efficiency helical bevel gearing

that provides smooth and quiet operation at rated load

indefinitely in the event of power loss or shutoff.

A holding brake at the rear of the motor will hold the full

rated load in the last position until power is restored. The

holding brake is always in the released state whenever power

is applied to the actuator. It is an electrically released, spring

set type holding brake. The brake is constantly in a stand-by

mode, and does not stop the motor. The motor does the

braking electrically, so there is no wear on the brake because

the brake is only holding, and not stopping the load. The load

is always supported by the motor, even when the command

input is not changing.

A local override handcrank at the rear of the motor can

be used to manually position the load when power is

interrupted.

The SM-6000 is well equipped with popular standard

features, and a wide variety of standard options are available

to suit most applications.

Special factory supplied options and designs are also available.

6

Page 7

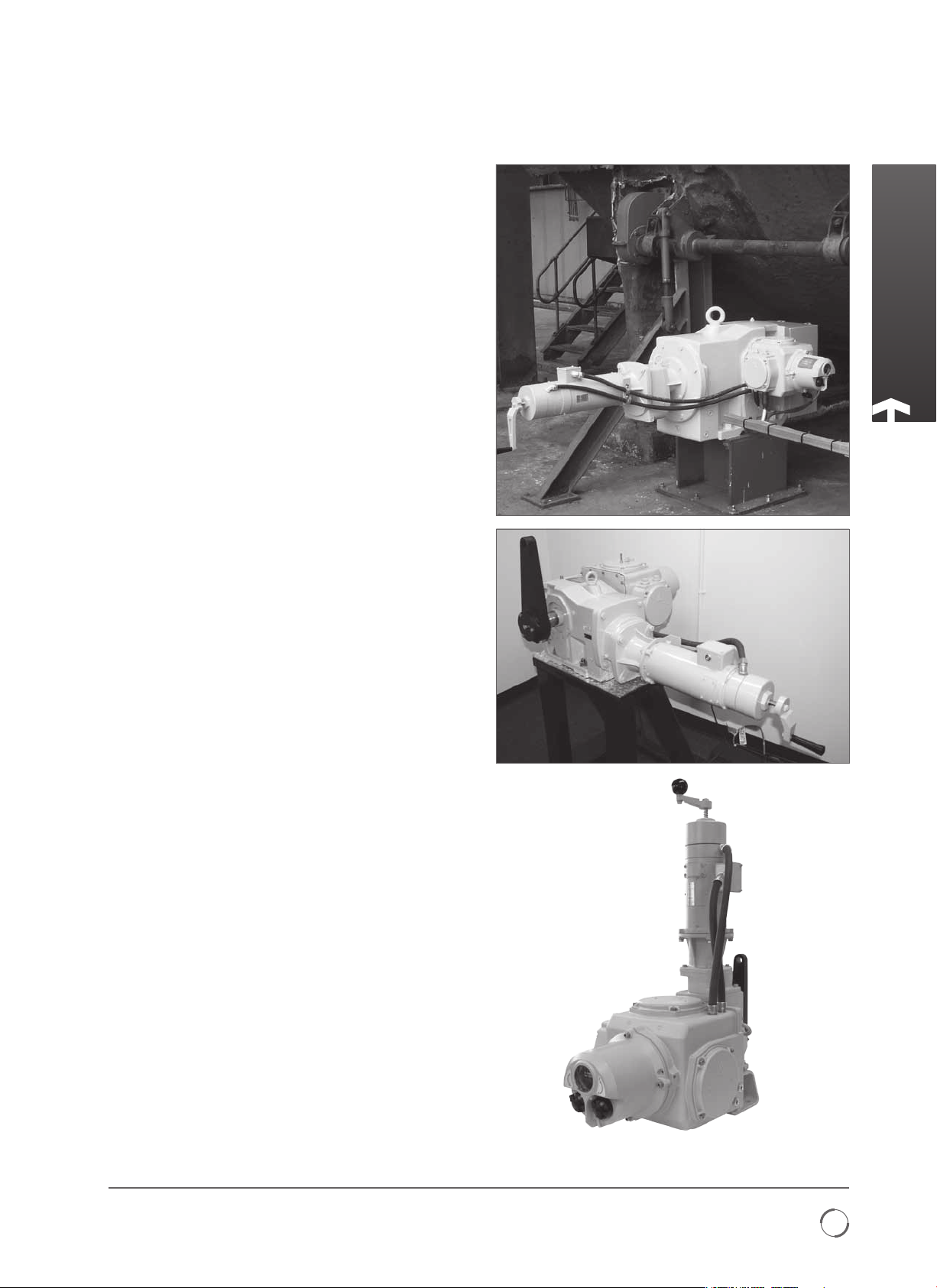

2 - Specifications

Output

Torque

ft. lb. (Nm) (RPM) (sec/90°) Running Stall lbs. kg inch mm

370 (502) 1.50 10 120-240/1-3/50-60/3@120 2 6 186 85 1.25 31.75

550 (746) 1.50 10 120-240/1-3/50-60/4@120 2 6 186 85 1.25 31.75

800 (1085) 1.56 10 120-240/1-3/50-60/5@120 3 9 204 93 1.375 34.925

1400 (1898) 1.52 10 120-240/1-3/50-60/8@120 4 12 254 115 1.75 44.45

2500 (3389) 1.57 10 120-240/1-3/50-60/12@120 6 12 403 183 2.375 60.325

4400 (5965) 1.65 10 240/1-3/50-60/7 7 12 613 279 2.875 73.025

6200 (8406) 1.56 10 240/1-3/50-60/8 8 12 956 435 3.625 92.075

8000 (10846) 1.19 12 240/1-3/50-60/12 12 12 1589 722 4.375 111.125

11000 (14914) 0.86 18 240/1-3/50-60/12 12 12 1589 722 4.375 111.125

16500 (22371) 0.58 26 240/1-3/50-60/12 12 12 2196 998 4.75 120.65

26000 (36540 0.36 42 240/1-3/50-60/12 12 12 3453 1570 5.5 139.7

• Rotation: 25º - 120 º.

• Duty Cycle: Unlimited and unrestricted continuous duty.

• Temperature: -40 to 185 °F (-40 to 85 °C). A high

temperature version to 225 °F (107 °C) is available.

• Environment Ratings: NEMA Type 4 (IP65).

• Lubrication Type: Synthetic oil bath.

• Oil Change Interval: 20 years for normal operation,

10 years for extreme operation.

• Gearing: All steel bevel and helical gearing.

• Hold on Loss of Power: Spring locking brake.

Output

Speed

Shift

Time

Input Power

Volts/Ph/Hz

Current Draw (A)

at 240 VAC Input

Actuator

Weight

Output Shaft

Diameter

• Command Signal Input: 4-20 mA, 0-5 VDC or

0-10 VDC.

• Position Transmitter: 4-20 mA transmitter used to

remotely track actuator position when power is available

to the actuator. Requires separate 24 VDC loop-power

supply for operation.

• Terminations: Screw type terminals accepting up to

#14 AWG wire.

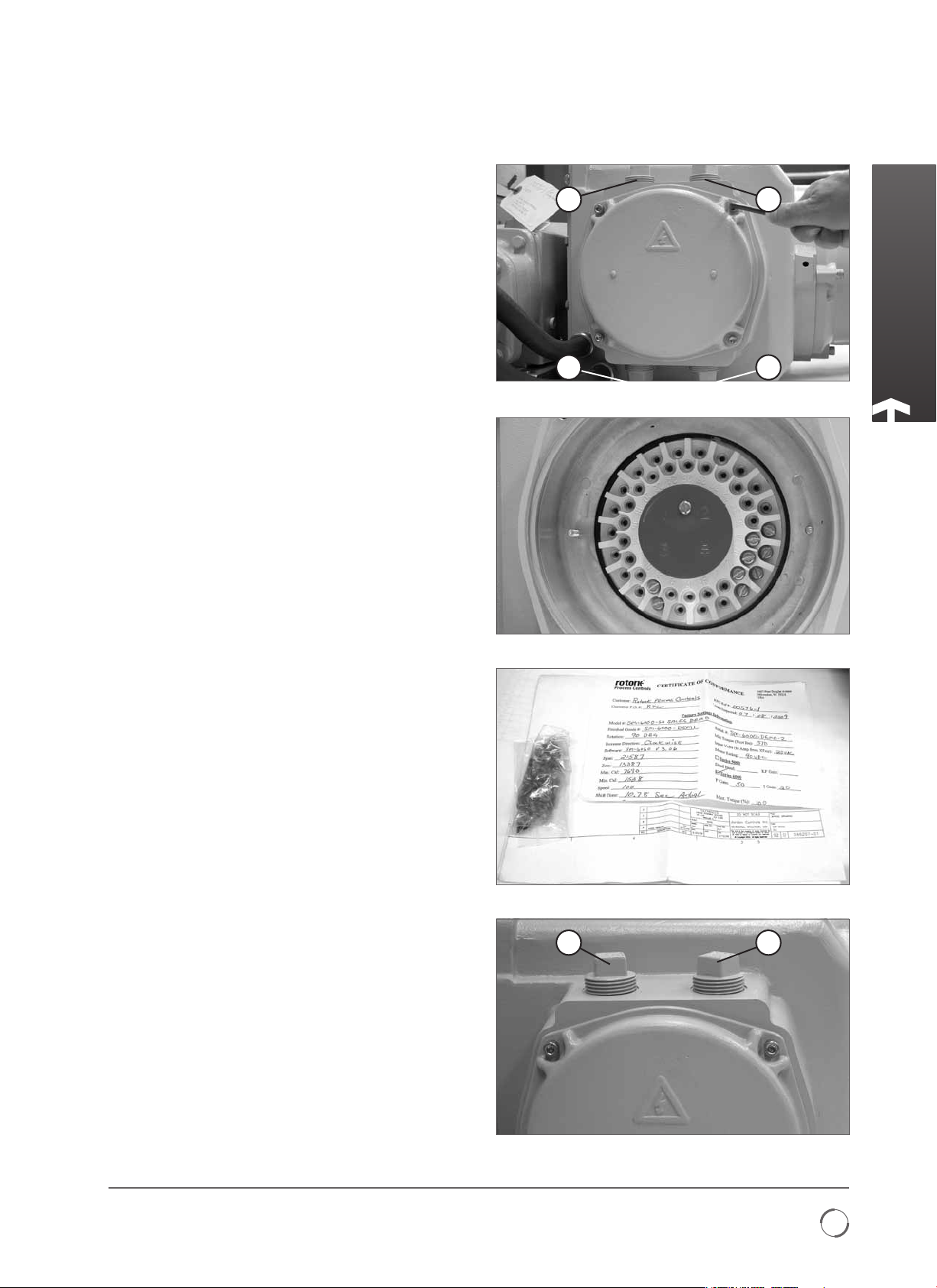

• Mounting Orientation: Left hand, right hand

or vertical.

RH LH

• Mounting: Conventional foot mounted.

• Anti-Condensation Heater: 120 or 240 VAC, 30 Watt

with thermostat set for 110 °F (43.3 °C).

• Torque Limit: Adjustable from 1 to 200% of rated

torque. Warning: continued operation of unit in excess

of rated load will damage the actuator and connected

equipment.

• Positioning Accuracy: 0.1% of 90°.

• Position Limit Switches: Two single pole double throw

(SPDT) switches for end of travel use, rating: 20 amp,

120/240 VAC resistive load.

• Feedback: Absolute Encoder.

• Local Controls & Display: Front cover mounted control

Figure 2.1. Left and right hand mounting orientation.

knobs and Vacuum Fluorescent Display (VFD).

Redefining Flow Control

7

Page 8

2.1 - Optional Equipment

• Performance: Faster speeds are available.

Consult factory.

• Drive Arm: Steel, for dimensions see section 10.

• Mechanical Stops: A plate that bolts to the front of the

actuator and limits drive arm movement is available

• Relays: Customer usable relay contacts are available to

detect: loss of feedback, loss of command signal, loss of

power or overtorque (stall).

• 1000 Ohm Potentiometer: Allows for ambient

temperature to 225 °F (107 °C). Requires remote

control enclosure.

Other options may be limited, consult factory.

• Auxiliary Position Limit Switches:

20 Amp, 120/240 VAC resistive load, (Quantity, 2-4)

5 Amp, 125 VDC resistive load, (Quantity, 2-4)

3 Amp, 250 VDC resistive load, (Quantity, 2-4)

• 2P + ST: Adds a second, tandem mounted feedback

potentiometer and one ST-4130 loop powered transmitter

assembly inside the electrical enclosure.

Requires separate 24 VDC power supply for operation,

or specify ST-4110 for sourced 4-20 mA operation.

• Pluggable Connections: Pluggable connectors on the

control enclosure for quick-disconnection using Cannon

style connectors. Typically used for remote mounted

control enclosure applications.

• Input Power: Internally mounted transformer to allow

operation on other input voltages. Standard optional

Input voltages are 480 VAC, 575 VAC. A 120 VA to 240

VAC step-up transformer is also available for applications

using 180 VDC motors when only 120 VAC input power

is available.

• Transitional Adapter Mounting Bases: Matches

SM-6000 to existing actuator footprint in the field for

replacement applications. Consult factory.

• High Temperature: Optional for ambient temperature to

225 °F (107 °C). Requires remote control enclosure. Other

options may be limited, consult factory.

• Linkage Adapter/Clevis Kit: Used to connect drive

arm to driven load for linkage applications. Includes two

clevises, two adjustment rods with lock nuts, two pipe

adapters, two pins for clevises.

8

Page 9

3 - Installation

INSTALLATION NOTES

CAUTION

READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING

THE INSTALLATION IN ORDER TO ACCUSTOM YOURSELF

WITH THIS EQUIPMENT. FOLLOW ALL INSTRUCTIONS

DURING THE INSTALLATION. DO NOT APPLY POWER UNTIL

TOLD TO DO SO OR PERMANENT DAMAGE CAN RESULT.

1. Use care whenever carrying, setting, or working around

the actuator. This is a precision piece of equipment that

will be permanently damaged if dropped or mistreated

during handling. Damage due to abuse or mishandling is

not covered by the factory warranty.

2. The installation site must have environmental conditions

compatible with the actuator design. Do not use this

product in temperatures higher than the design allows,

or in explosive environments if it is not rated accordingly.

To maintain the environmental ratings, all covers must be

tightly closed at all times. All cover fittings must be used

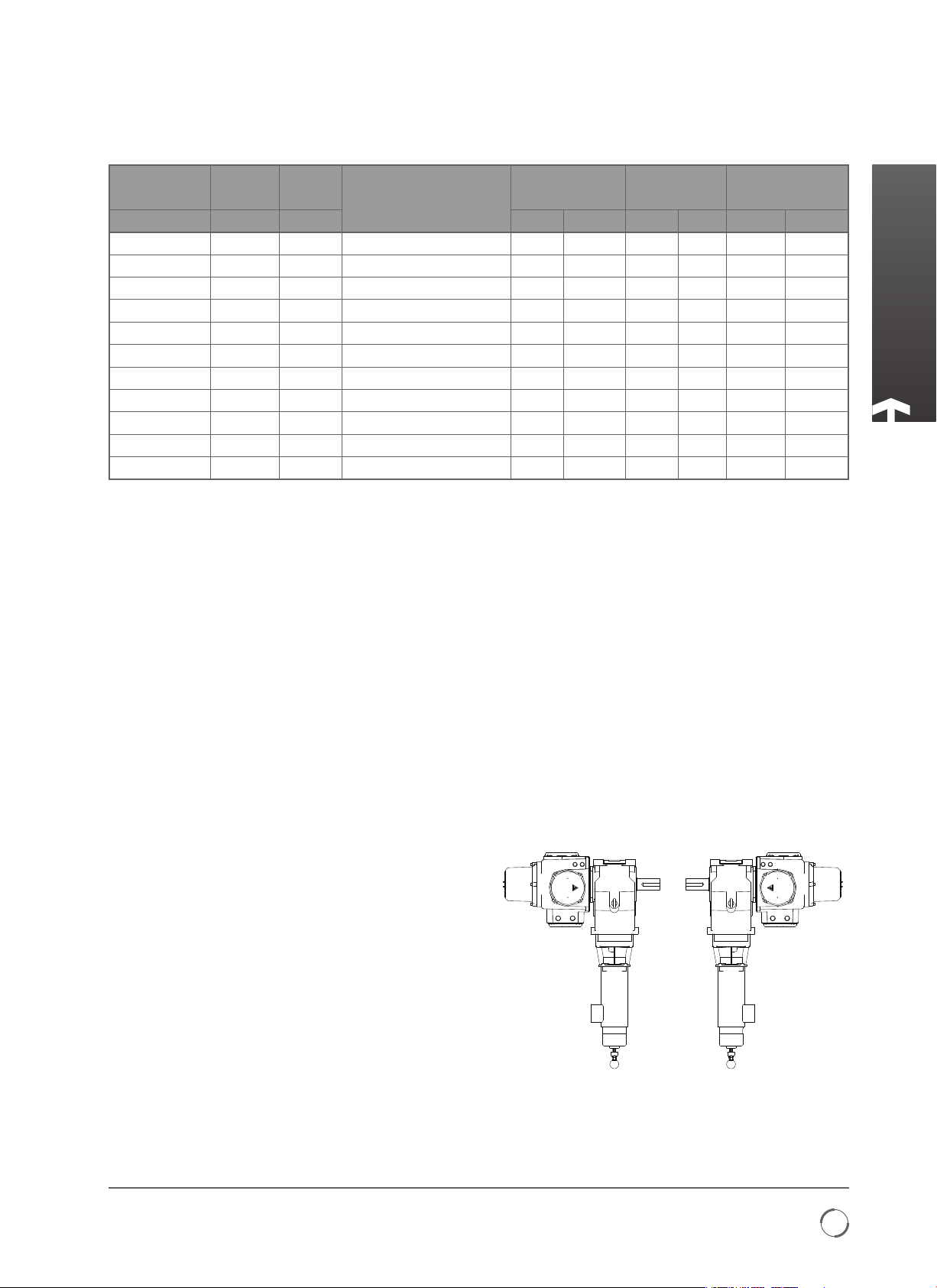

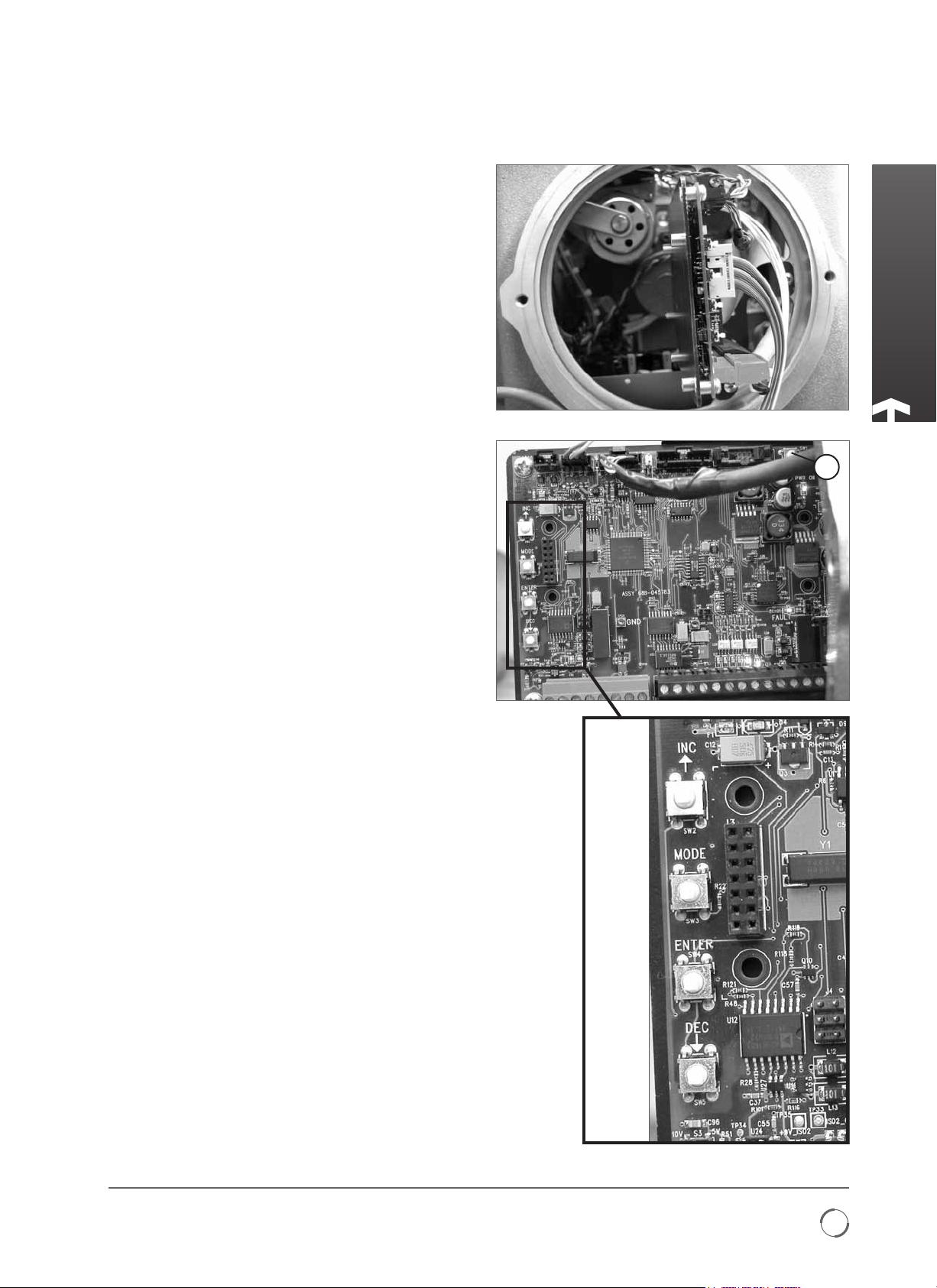

and fastened securely. Using a

four capscrews securing the terminal compartment cover

(Fig. 3.1). The actuator is supplied with a wiring diagram,

certificate of conformance and terminal fixings stored in

the terminal compartment area (Fig 3.2 and Fig 3.3).

3. Read the actuator nameplate located on the outside of

the unit. It will reference a specific wiring diagram. Refer

to the wiring diagram to identify functions of terminals

(Fig. 3.2). Check that the supply voltage is the same as

that marked on the actuator nameplate. That diagram

MUST be used for wiring this product. Run wires as

indicated, but DO NOT apply power until later. To prevent

electrical noise pickup, power and signal wires must be

routed through separate metallic conduit and the signal

wires must also be shielded and the shield grounded (Fig.

3.1. A,B,C,D).

For actuators where the control enclosure must be

located away from the actuator, do not exceed a wire

run distance of fifty feet between the actuator and

the control enclosure.

When all connections are made, replace the wiring

diagram in the terminal compartment.

4. Replace Terminal Cover Ensure cover o-ring seal and

joint are in good condition and lightly greased before refitting cover. Seal any unused conduit entries with metal

plugs (Fig. 3.4. C,D).

3

/16’’ Hex key, remove the

C

A B

Figure 3.1. Terminal compartment cover

Figure 3.2. Terminal compartment.

Figure 3.3. Terminal fixings.

C

D

D

Figure 3.4.

Redefining Flow Control

9

Page 10

3 - Installation cont.

5. The actuator must be securely anchored to a rigid

foundation before any load is applied to the output

shaft. All of the actuator mounting holes designed for

anchoring must have a bolt or stud, which should be of

the largest size that fits in the mounting hole (Fig. 3.5. A).

6. The drive arm (if used) should be attached to the actuator

output shaft using the hardware supplied. The drive arm

has a hole to attach the linkage to the load. This linkage

should be connected to the drive arm with a flexible

rod-end to accommodate misalignment, and the rod-end

must be sized for approximately twice the actuator full

load rating (Fig. 3.5. B).

7. The actuator is designed to withstand the rigors of

industrial environments. To maintain the environmental

ratings, all cover fixings must be used and fastened

securely (Fig. 3.6).

Mounting:

The outline and mounting dimensions for a standard unit

are shown in this manual. Sufficient room to remove the

cover should be provided for servicing and upgrade.

Orientation:

The unit is oil filled and must be mounted in the

configuration ordered. When mounting the unit, be sure

that no excessive axial or side loading is applied to the

output shaft.

B

A

Figure 3.5.

Output Drive Shaft:

The limit switches and position feedback are directly

connected to the output shaft. Positively secure the

output to the driven load shaft to prevent slippage, which

would cause misalignment or damage.

Local Overide:

When local override is required, push in handcrank

(Fig 3.7) and turn the crank in the appropriate direction

for the desired output shaft movement. Note: Do not

force handcrank if there is an obstruction as excessive

torque will be generated at the output shaft. The load or

actuator may be damaged as a result.

CAUTION - LOCAL OPERATION

WITH RESPECT TO HAND CRANK OPERATION OF

SM6000 SERIES ELECTRIC ACTUATORS, UNDER NO

CIRCUMSTANCES SHOULD ANY ADDITIONAL LEVER

DEVICE SUCH AS A WHEEL-KEY OR WRENCH BE APPLIED

TO THE HAND CRANK MECHANISM IN ORDER TO

DEVELOP MORE FORCE WHEN MOVING THE ACTUATOR

IN EITHER DIRECTION AS THIS MAY CAUSE DAMAGE

TO ACTUATED DEVICE, ASSOCIATED LINKAGES OR

ACTUATOR ITSELF.

Figure 3.6.

Figure 3.7.

10

Page 11

3 - Installation cont.

If, during local operation, electric power is restored to the

actuator, the power cannot drive back through the manual

handcrank and harm the operator. Upon completion of

hand operation, the handcrank will spring return to its home

position allowing electric operation to resume.

The handcrank and holding brake compartment at the rear

of the motor relies upon the cover to maintain the watertight

NEMA Type 4 rating. This cover should be removed only

when work is being done internally, and should be reinstalled

tightly immediately upon completion.

This unit contains no internal mechanical stops as standard.

If it runs outside of the initial factory alignment of the limit

switches, a realignment of switches and feedback may be

required. However, no internal damage will occur.

The actuator is designed to give long, troublefree life when

installed and operated in accordance with factory guidelines.

Position Limit Switches

The actuator is supplied with two Position Limit Switches

PL1 (cam#1) & PL2 (cam#2) as standard (Fig. 3.8 and Fig.

3.9). These switches are mounted behind the control cover

assembly and are typically set to operate outside the normal

limits of travel to act as motor shutoff devices in the event of

over travel.

Two optional switches PL3 (cam#3) and PL4 (cam#4) can be

fitted to provide external travel limit switch indication.

Up to 4 additional switches can be supplied to provide

external travel limit switch indication.

Figure 3.8. Figure 3.9.

Redefining Flow Control

11

Page 12

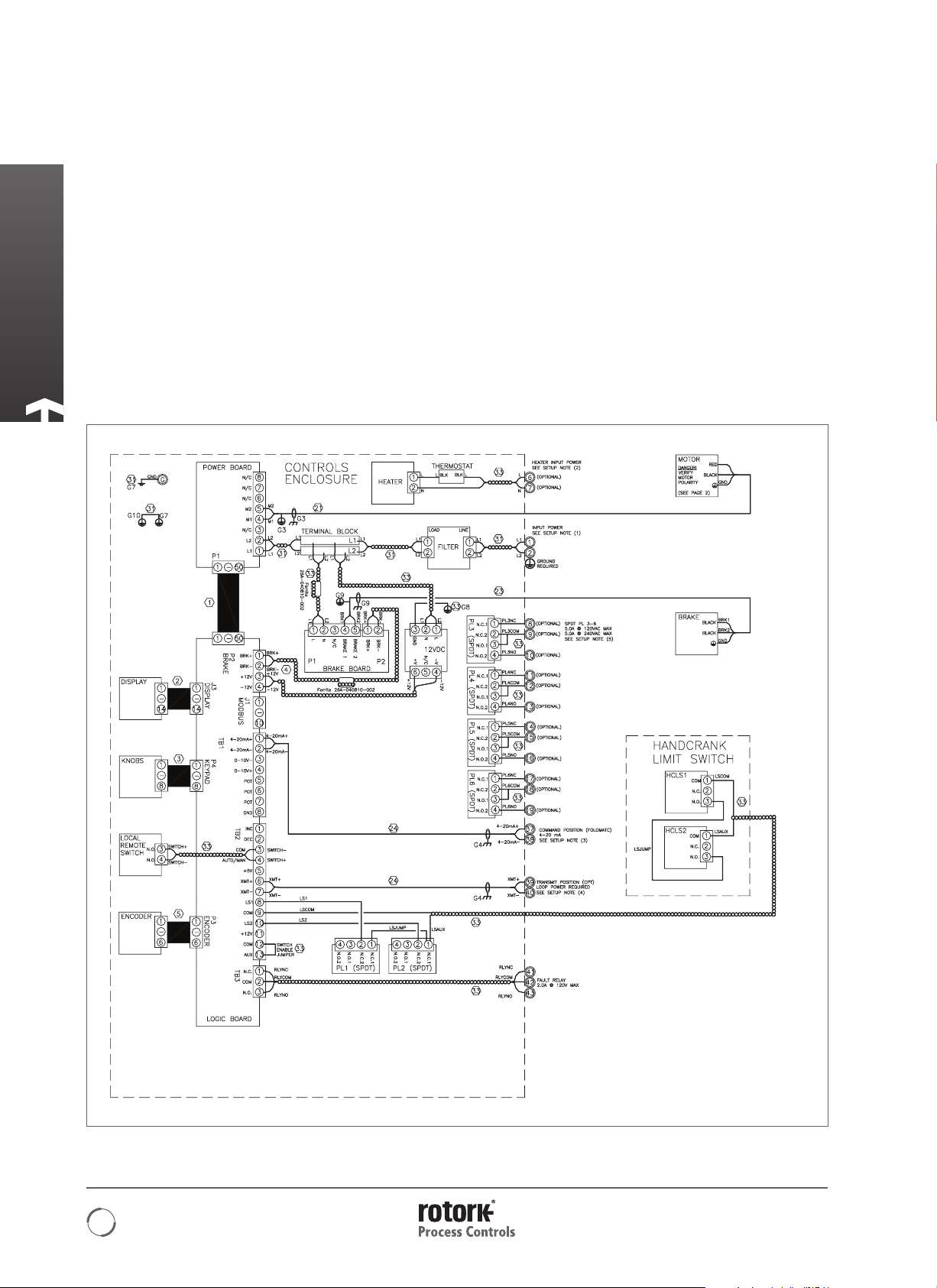

3.1 - Installation Wiring & Typical Wiring Diagram

A typical wiring diagram is shown below. Actual wiring

should follow the print supplied with the actuator. The

wiring diagram shows the fundamental connections for the

standard control scheme, and standard permanent magnet

DC motor. Items shown on print arrangement include limit

switches, feedback potentiometers, heater and encoders. To

meet special requirements, certain items shown may not be

supplied. In all instances the wiring diagram appropriate

to the equipment will be supplied with each unit.

TYPICAL WIRING DIAGRAM

Wiring should be routed to the actuator through customer

supplied conduit entries located on the control enclosure.

Generally, one conduit will contain input power and earth

ground wires. The other conduit would then contain low level

input and output signal wiring. It is required that all low level

signal wiring be a shielded type with the shield grounded at

source common.

After installation, it is required that all conduits be sealed to

prevent water damage and to maintain watertight NEMA 4

enclosure ratings.

Figure 3.10. Typical SM6000-S2 Wiring Diagram

12

Page 13

3.2 - Microprocessor Based Motor Drive & Controller Setup

GENERAL DESCRIPTION

The microprocessor-based motor drive and controller is

designed for integral local or remote mount to control

appropriate Rotork Process Controls actuators.

A microprocessor-based control and an IGBT-based intelligent

power module (IPM) are used to drive the actuator to perform

highly accurate, bidirectional positioning.

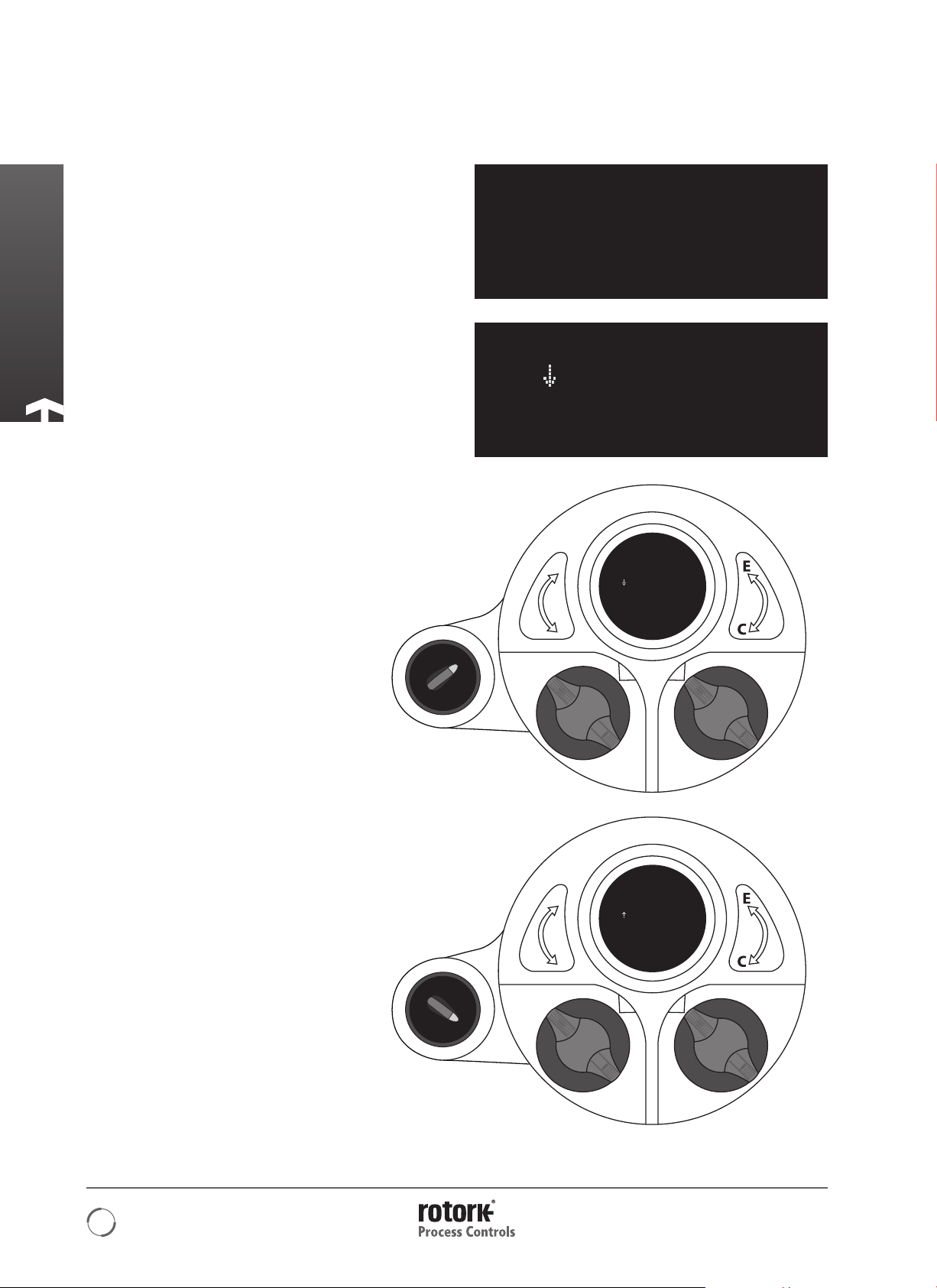

The ‘Standard Setup’ is made via front cover-mounted local

control knobs and a local display (VFD) on the outside of the

actuator. See figure 4.2 for location of the local control knobs

and display.

The ‘Alternative Setup’ feature allows actuator setup using

push-buttons (no potentiometers or jumpers). See figures

4.13 and 4.14 for location of the push buttons. Self

diagnostics and prompts are available through an on-board

lighted display.

Specifications

• PowerInput:120/240VAC,+/-10%,singleorthree

phase, 50/60 Hz.

• PowerOutput:Upto90VDC/180VDC,

15 Amperes Peak.

• CommandInputs:4-20mAinto200Ohmshunt

0-10 VDC into 100k minimum impedance or 0-5

VDC into 100k minimum Impedance.

• PositionFeedback:AbsoluteEncoder,1000Ohm

potentiometer (optional), 4-20 mA (optional).

NOTE: THE FACTORY DEFAULT FEEDBACK SETTINGS

WERE FULLY TESTED AND INITIALLY SETUP AT THE

FACTORY AND NO OTHER ADJUSTMENT OF THE

ABSOLUTE ENCODER AND 1000 OHM POTENTIOMETER

SHOULD BE REQUIRED.

IF ADJUSTMENTS ARE NECESSARY PLEASE CONTACT

ROTORK PROCESS CONTROLS.

• PositionSignalOutput: Looppowered,isolated,

2-wire 4-20 mA signal.

Shows actuator position.

• EndofTravelPositionLimitSwitches:SwitchCams1

(CCW) & 2 (CW) to stop the actuator if end of travel

position is exceeded.

• PositionIndicationSwitches:(Optional)

Switch cams 3 & 4 for additional position indication

outputs. Up to 6 switches.

• AutomaticMode:Actuatorrespondstoremote

command input controls. Typically 4-20 mA or

bus communication.

• LocalMode:Actuatorrespondstolocal

pushbutton commands.

• OtherOutputs:

Form C fault relay output

Contact Rating

120 VAC, 2 Amperes

Active when any of the following conditions

are present:

• Lossof4-20mAcommandsignal

• Lossofpositionfeedbacksignal

• MIN/MAXlimitswitchreached

• Motorstalledcondition

• Handcrankengaged

• TorqueLimitExceeded.

Redefining Flow Control

13

Page 14

4 - Operating your SM6000 Actuator

WARNING

Actuator may move when SPAN, ZERO or PRESET

functions are selected.

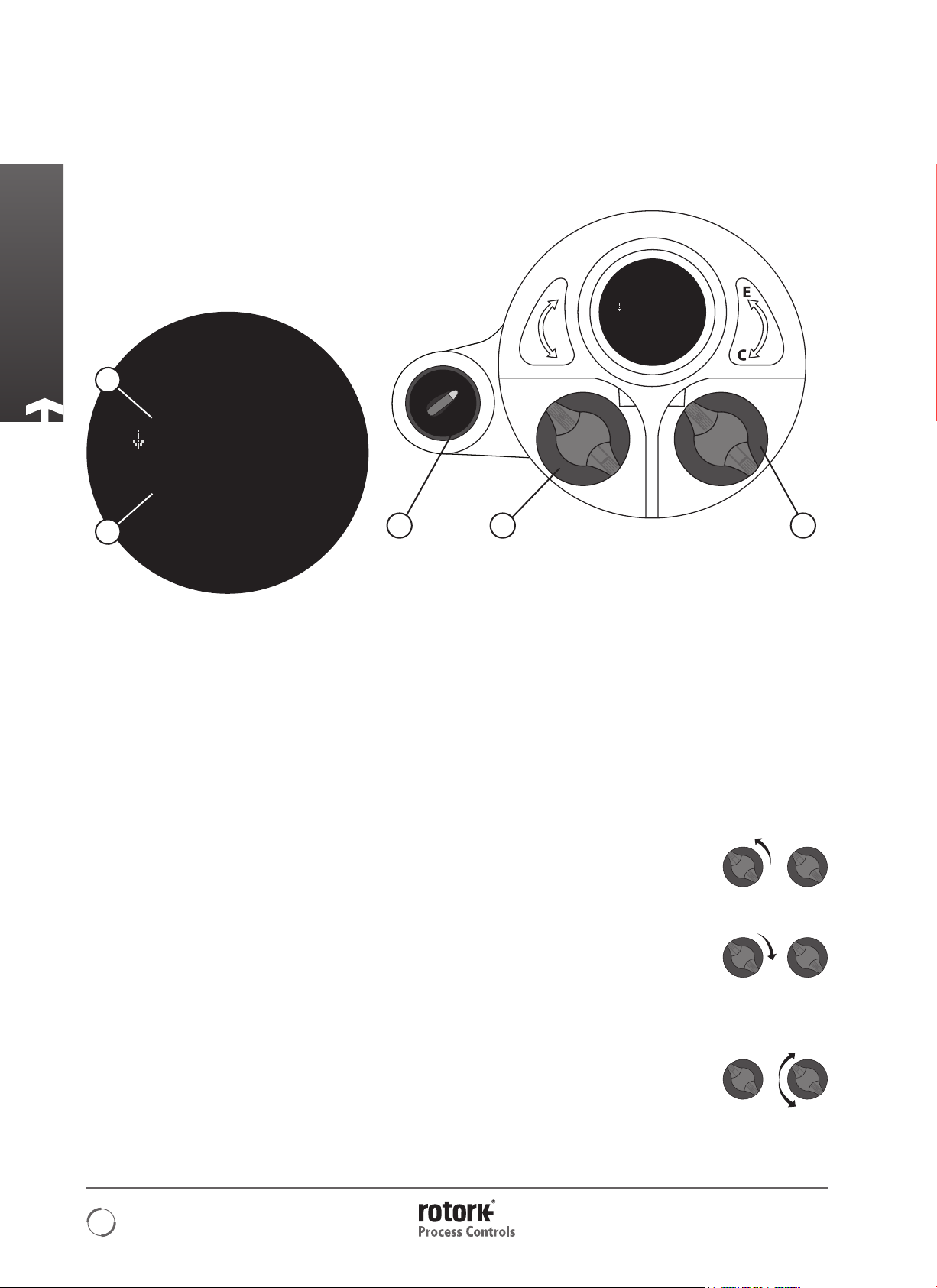

Display-Local Indication

A

L P= 100 C= 100

Act Strts = 19

B

Figure 4.1.

Local Control Knobs

L P= 100 C= 100

Act Strts = 19

L

R

A

Figure 4.2.

The actuator has two control knobs located below the VFD

Display window.

BC

The actuator Vacuum Fluorescent Display (VFD) provides 2 x

16 Character lines to allow setup and calibration of all user

parameters. The display can also be utilised to access the

diagnostic menus.

Line 1 (Fig. 4.1. A).

L = Local Mode

R = Remote Control

C = Remote Communications Mode

In Local, Remote and Automatic Modes line 1 shows actuator

Position and Command request in percentage of Zero - Span

range.

P = Actual Position

C = Command Position

Line 2 (Fig. 4.1. B).

Act strts = Actuator starts

Provides status or fault information depending on

Mode selected.

UP/DOWN SELECTOR KNOB (Fig. 4.2. A).

Located on left hand side as viewed from the front.

Depending on mode selected different functions apply

(see below).

ENTER/CANCEL KNOB (Fig. 4.2. B).

Located on right hand side as viewed from the front.

Allows parameters to be changed and accepted or

toggles between menus.

Local Mode

Rotate the selector knob anti-clockwise (UP)

and hold to move actuator output towards

the Span Position. Release when the

actuator has reached the desired position.

Rotate the selector knob clockwise (Down)

and hold to move actuator towards the

Zero position. Release when the actuator

has reached the desired position.

Setup Mode

Rotate the selector knob to the UP or

DOWN position to cycle through the

setup menu parameters.

14

Page 15

4 - Operating your SM6000 Actuator

LOCAL/REMOTE SWITCH. (Fig. 4.2. C).

Located on the left hand side of the electrical housing as

viewed from the front.

NOTE:The switch can be fitted with a padlock to

prevent unauthorised operation.

LOCAL MODE

When the actuator is set to local mode It is possible to

position the actuator using the UP/DOWN selector knob.

Using the ENTER /CANCEL selector knob it is possible to

access and change parameters.

REMOTE MODE

Actuator will respond to remote control or communication

bus card commands.

Redefining Flow Control

15

Page 16

4.1 - Status Description

STATUS DESCRIPTION

In REMOTE or Local mode Line 2 of the display shows status

parameters when no faults are active.

To cycle through the menu structure select LOCAL operation.

Using the ENTER/CANCEL selector knob it is possible to access

and change parameters.

Use the Enter/Cancel knob to cycle through the information

(Fig. 4.4).

1 Act Starts = xxxx

Total times the motor has been started since last power up.

2 Amp Starts = xxxxx

Total times the amplifier has been powered up or reset.

3 Temp. °C xx

Temperature in °C of the lower internal PCB’s.

4 Voltage xxx

Absolute value of DC motor voltage.

5 Current +/- xxxx

Motor current.

6 TORQUE

CurrenttorqueoutputXXX%.

7 FAULT HISTORY

Lists the last 10 faults or events. Select ENTER to

activate. F0 is the most recent event, F10 would be

the oldest.

Figure 4.4

L P= 100 C= 100

Act Strts = 19

Enter (E)

Cancel (C)

MAIN MENU

ACT STRTS

AMP STRTS

TEMP

VOLT

Figure 4.3.

CURRENT

TORQUE %

L Fault History

FLT HIST

F0 LOS CMD

LEVEL 2 ONLY

MOTOR

THEO PSN

CMD PSN

SPD

ERR

FEED FWD

RAW PSN

ZERO CURR

MOTOR

16

Page 17

4.2 - Start Up

The actuator is fully tested and initially setup at the factory.

The factory default settings should be used to initially

commission the actuator on site.

WITH POWER OFF & LOAD DISCONNECTED

Verify that all wiring is correct and that the supply voltage

matches the voltage shown on the actuator identification

label. Refer to the wiring diagrams supplied with the actuator

for specific details (Fig. 4.5).

Ensure all electrical connections are tight and splash guard

refitted. Cable screens/shields must be suitably connected to a

reliable earth ground (Fig. 4.6).

To maintain the environmental ratings, all cover fixings must

be used and fastened securely (Fig. 4.7).

REMOVE CONTROL ASSEMBLY COVER (OPTIONAL)

CAUTION

DO NOT FULLY REMOVE COVER UNLESS THE WIRING

LOOMS ARE DISCONNECTED FROM THE MAIN PCB.

It is only necessary to remove the control cover assembly to

adjust and setup the position limit switch assemblies located

inside the control housing.

If the limit switches do not require adjustment leave the cover

assembly in place and go to Page 20 (Fig. 4.16).

Locate and remove four socket cap screws using a

key which secure the control assembly cover to the gearcase

(Fig. 4.7). Remove the cover far enough to clear the electrical

chassis taking care not to damage cables connecting the

VFD display and control knobs to the Logic control PCB. If

necessary disconnect the two cables from the Logic Control

PCB to the cover assembly (Fig. 4.8).

1

/4” Hex

Figure 4.5.

Figure 4.6.

Figure 4.7.

Figure 4.8.

Redefining Flow Control

17

Page 18

4.2 - Start Up cont.

The cover assembly can now be relocated on to the left or

right hand side of the gear-case to facilitate setup. Use one of

the original fixings to secure the control cover assembly to the

gear-case (Fig. 4.9).

Reconnect looms to the main PCB if necessary (Fig. 4.10).

Figure 4.9.

REMOVE TOP & SIDE COVER ASSEMBLIES

The top and side cover assemblies may be removed for

clearer access to the Limit Switch assemblies. 3/16” Hex key.

Figure 4.12 shows top cover removed of an actuator fitted

with additional position limit switches for remote indication.

Figure 4.10.

Figure 4.11.

18

Figure 4.12.

Page 19

4.2 - Start Up cont.

Figure 4.13 shows the front view of the electrical chassis.

LOGIC CONTROL PCB

Figure 4.14 shows the logic Control PCB.

The PCB has one push button switch (SW1) (Fig. 4.13. A)

located at right top corner of the PCB and four push button

switches (SW2 to 5) located on the forward edge of the PCB.

If desired the switches SW2 to 5 can be used to duplicate the

function of the control knobs.

SW1 RESET

Clears microprocessor registers and restarts the control

program. Do not press during normal operation.

SW2 INCREASE

Local Mode: Press and hold to move the actuator

towards the Span position.

Setup Mode: Press to cycle through the setup menu

parameters.

Actuator will move when SPAN, ZERO or PRESET functions

are selected.

Figure 4.13.

A

SW3 MODE

Switches between LOCAL and

SETUP mode. Aborts a parameter change

when in SETUP mode.

SW4 ENTER

Allows changed parameters to be stored

and cycling of diagnostic display.

SW5 DECREASE

Local Mode: Press and hold to move the actuator

towards the Zero position.

Setup Mode: Press to cycle through the setup menu

parameters. Actuator will move when

SPAN, PRESET and ZERO functions

are selected.

Figure 4.14.

SW2

SW3

SW4

Figure 4.15.

Redefining Flow Control

SW5

19

Page 20

4.2 - Start Up cont.

ENSURE THAT LOAD IS DISCONNECTED FROM

ACTUATOR OUTPUT DRIVE SHAFT.

APPLY POWER TO ACTUATOR

The actuator display should now illuminate showing actuator

model and software version for 5 seconds before displaying

the top menu (Fig. 4.16).

The actuator is set to Local Mode when it leaves the factory

(Fig. 4.17).

LOCAL MODE - OPERATION

With no load connected to the actuator output drive shaft.

Rotate the UP/DOWN Control knob clockwise and

anti-clockwise to test electrical operation. Confirm that

the direction of travel corresponds with the rotation of

the knob. Refer to Section 4.

Figure 4.16.

L P= 100 C= 100

Act Strts= 19

Figure 4.17.

L

SM-6060

Ver. 4.00

L P= 100 C= 100

Act Strts= 32

4.2.1 AUTOMATIC MODE - OPERATION

The actuator control mode must now be changed to

‘REMOTE’ to function test the actuators response to Analogue

control signal commands.

Ensure that actuator has been correctly configured for current

or Volts before applying any analogue command inputs.

If actuator is supplied with a Bus or HART input card

please refer to section 5.

R

Figure 4.18.

L

R

Figure 4.19.

L P=-0.0 C= 0.0

Act Strts= 65

20

Page 21

4.2 - Start Up cont.

ENTER KNOB - SELECT ‘CANCEL’

SETUP MODE

Display now shows Setup Menu (Fig. 4.20).

C

S / pick param

Press

Figure 4.20.

Redefining Flow Control

21

Page 22

4.2 - Start Up cont.

SAVE CONFIG

ENTER KNOB - SELECT ‘ENTER’

SAVING TO EEPROM

All changes saved to EEPROM (Fig. 4.22). All changes to

Parameters will be saved when cycling of power occurs.

S / pick param

Save Config

Figure 4.21.

E

S / pick param

Saving to EEPROM

Figure 4.22.

ENTER KNOB - SELECT ‘CANCEL’

Display returns to top menu and LOCAL Mode is now active.

The lower section of the display will show the last selected

menu option.

Actuator will now respond to applied Analogue Remote input

signal. Apply a 50% command signal (mA or Voltage) to the

actuator. Verify that the actuator moves the output to desired

position (Fig. 4.23).

Apply a 00% command signal (mA or Voltage) to the

actuator. Verify that the actuator moves the output to

desired position (Fig. 4.24).

Apply a 100% command signal (mA or Voltage) to the

actuator. Verify that the actuator moves the output to

desired position (Fig. 4.25).

INITIAL COMMISSIONING COMPLETE.

C

L P=49.8 C=50.1

Temp. .C 33 27

Figure 4.23.

L P=-0.2 C= 0.0

Temp. .C 33 27

Figure 4.24.

L P= 100 C= 99.7

22

Temp. .C 33 27

Figure 4.25.

Page 23

4.3 - Range of Operation - Setup

4.3.1 RANGE OF OPERATION

The following procedure will calibrate the ZERO and SPAN

limits of travel and adjustment of the Position Limit Switches

if necessary.

With Linkage disconnected apply power to the unit.

The actuator should be in local mode to start this operation as

noted in Figure 4.18. Refer to section 4 for instructions. The

unit may have been moved out of its normal limits of electrical

travel for shipping purposes. In this case Figure 4.27 shows

the actuator at 149% of travel. The actuator will respond to

decreasing requests only, until it reaches the 100% position of

travel, after which it may be driven in either direction between

limits (Fig. 4.28).

During operation it is possible that one end of travel switch

is tripped and adjustment is required to facilitate movement

to the desired SPAN or ZERO position. In this case it will be

necessary to adjust one or both of the travel limit switches.

Fig 4.28 shows that the increasing limit switch cam#1 has

been activated.

WARNING

Isolate power supply before inserting tools in to the

electrical housing.

Figure 4.26.

L P= 149 C= 149

Temp. .C 32 27

Figure 4.27.

L P= 100 C= 100

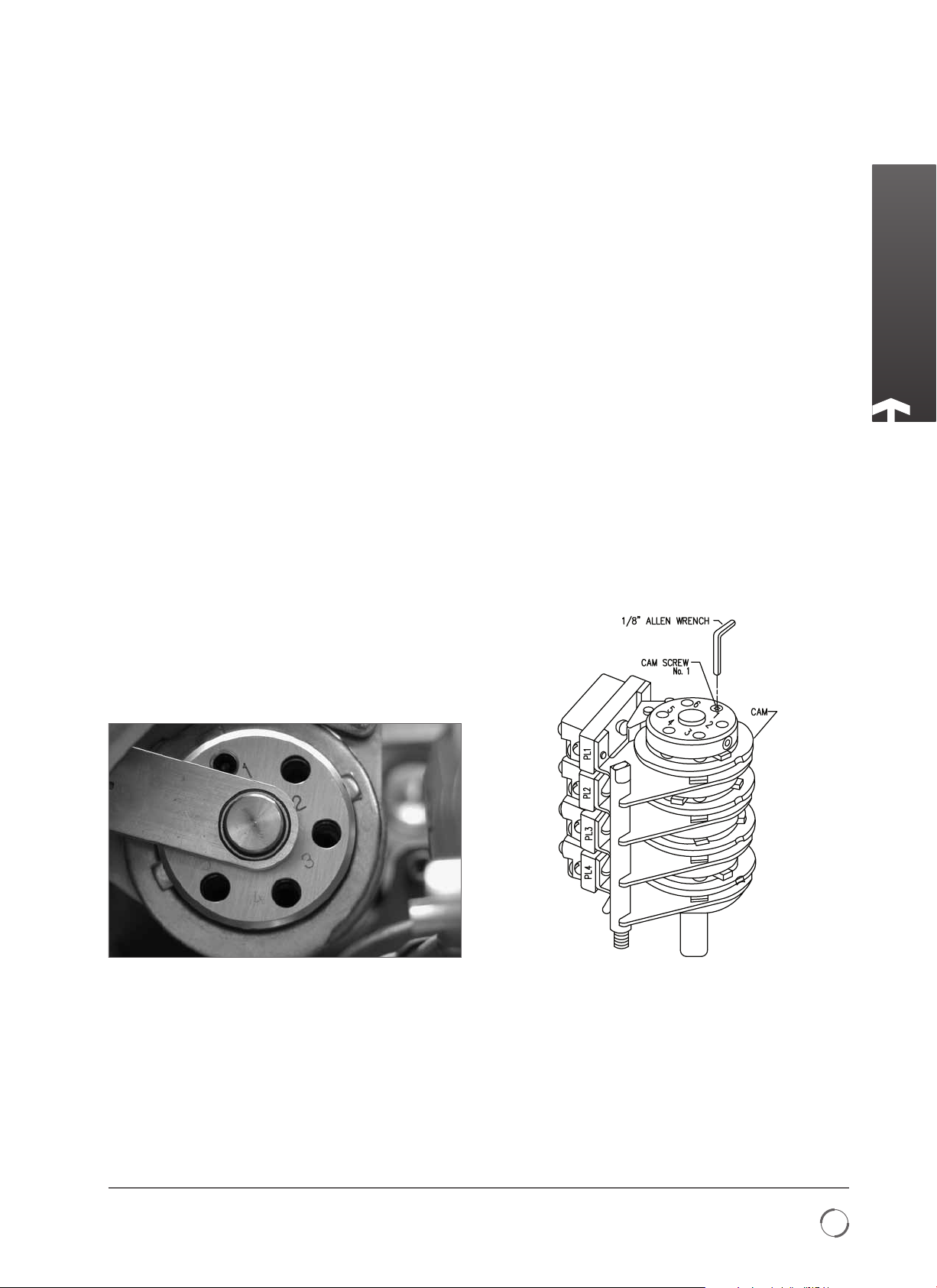

Move actuator output shaft in the increasing direction and

observe rotation of cam switch assembly to verify CW or

ACW operation. Using a 1/8” hex wrench loosen the

appropriate locking screw (screws are numbered on the

cam end plate) (Fig 4.29).

Move the switch cam in the decreasing direction to allow the

actuator to run its full required position of travel.

Once adjusted tighten the locking screw.

Repeat the procedure for the Decreasing travel limit

if necessary.

Flt: Inc Limit

Figure 4.28.

Figure 4.29.

Figure 4.30.Figure 4.31.

Redefining Flow Control

23

Page 24

4.3 - Range of Operation - Setup cont.

L

R

OPERATING SPEED

The actuator output speed is factory preset to 100%. During

the initial calibration of this unit it is recommended that the

speed is reduced to 10% to achieve greater accuracy when

setting the ZERO and SPAN position limits.

To change the actuator speed.

Select ‘LOCAL’ operation

Figure 4.32.

L P= 149 C= 149

Temp. .C 32 27

C

UP/DOWN KNOB - SELECT ‘SPEED SETUP MENU’

Use the UP/DOWN knob to scroll through menus.

Until‘Speed=XXX’isdisplayed(Fig.4.33).

ENTER KNOB - SELECT ‘ENTER’

The motor speed can now be adjusted by using the

UP/DOWN knob.

D

S / pick param

Speed = 100

Figure 4.33.

E

/ to Speed

ENT = acpt 100

Figure 4.34.

24

Page 25

4.3 - Range of Operation - Setup cont.

UP/DOWN KNOB - HOLD TO REDUCE SPEED

Hold the UP/DOWN KNOB until the actuator speed indicates

10% (Fig. 4.35).

D

/ to Speed

ENTER KNOB - ENTER TO SAVE VALUE

Select ‘ENTER’ to set the actuator speed to 10% (Fig. 4.36).

UP/DOWN KNOB - SELECT ‘SAVE CONFIG’

Actuator configuration should be saved to EEPROM before

exiting the menu (Fig. 4.37).

ENT = acpt 10

Figure 4.35.

E

S / pick param

Speed = 10

Figure 4.36.

S / pick param

Save Config

Figure 4.37.

Redefining Flow Control

D

25

Page 26

4.3 - Range of Operation - Setup cont.

ENTER KNOB - ENTER TO SAVE TO EEPROM

ENTER KNOB - SELECT ‘CANCEL’ TO RETURN TO TOP

MENU (Fig. 4.39).

E

S / pick param

Saving to EEPROM

Figure 4.38.

C

L P= 26.4 C= 26

Volt = 0 816

Figure 4.39.

26

Page 27

4.3 - Range of Operation - Setup cont.

4.3.2 SET ZERO AND SPAN

ENSURE THAT LOAD IS DISCONNECTED

FROM ACTUATOR OUTPUT DRIVE SHAFT.

The operating speed of the actuator is now set to 10% of

rated. The ZERO and SPAN can now be set.

Note: Careful attention must be used during the setting

of the ZERO and SPAN of the actuator. Typically the ZERO and

SPAN positions are set just inside or at the full open and full

closed positions. If necessary, use two people during the setup

procedure. One person to run the actuator and the second

person to verify the position of the device coupled to the

actuator.

Figure 4.40.

End of Travel Position Limit Switches:

The actuator is fitted with two Position Limit switches to

prevent electrical operation beyond the set Zero and Span

positions.

During operation it is possible that the Position Limit Switches

are tripped and ‘Flt. Inc or Dec Limit, is displayed (Fig. 4.41).

(To adjust Limit switch positions (see start of section 4.3).

L P= 100 C= 100

Flt: Inc Limit

Figure 4.41.

L P= 26.4 C= 26.4

Volt = 08168

Figure 4.42.

Redefining Flow Control

27

Page 28

4.3 - Range of Operation - Setup cont.

SET ZERO POSITION

The ZERO position is the position that the actuator will travel

to when given its minimum command. Typically this is the

closed position of the device. To set the ZERO position, follow

the procedure below:

ENTER KNOB - SELECT ‘CANCEL’ TO ENTER

SETUP MODE

Figure 4.43.

UP/DOWN KNOB - SELECT ‘ZERO’ MENU

The actuator position in this menu is shown as a 5 digit

encoder count (Fig. 4.44).

C

S / pick param

Press

S / pick param

ZERO = 06616

Figure 4.44.

D

28

Page 29

4.3 - Range of Operation - Setup cont.

Use UP/DOWN knob to move actuator output to desired

ZERO position.

ENTER KNOB – SELECT ‘ENTER’ TO ADJUST

ZERO POSITION

Whilst at the desired ZERO position - Select ‘ENTER’ to Set the

new ZERO position. (Fig. 4.45).

Note: the parameter changes must be saved to

configuration to prevent loss of data.

UP/DOWN KNOB - SELECT ‘SAVE CONFIG’ MENU

Rotate the UP/DOWN knob until the display reads Save Config

(Fig. 4.46).

E

/ to ZERO

ENT = acpt 13028

Figure 4.45.

D

ENTER KNOB - ENTER TO SAVE TO EEPROM

Actuator configuration must be saved to EEPROM before

exiting the menu (Fig. 4.47).

S / pick param

Save Config

Figure 4.46.

E

S / pick param

Saving to EEPROM

Figure 4.47.

Redefining Flow Control

29

Page 30

4.3 - Range of Operation - Setup cont.

SET SPAN POSITION

The SPAN position is the position that the actuator will travel

to when given its maximum command. Typically this is the

open position of the device. To set the SPAN position, follow

the procedure below:

ENTER KNOB - SELECT ‘CANCEL’ TO ENTER

SETUP MODE

Figure 4.48.

L P= 26.4 C= 26.4

Volt = 08168

C

S / pick param

Press

UP/DOWN KNOB - SELECT ‘SPAN’ MENU

SET SPAN POSITION

ENTER KNOB - SELECT ‘ENTER’ TO

ADJUST POSITION

Use UP/DOWN knob to move actuator output to desired

SPAN position.

ENTER KNOB - SELECT ‘ENTER’ TO SAVE

SPAN POSITION

Whilst at the desired SPAN position - Select ‘ENTER’ to Set

the new SPAN position. The actuator position in this menu is

shown as a 5 digit encoder count (Fig. 4.51).

Note: the parameter changes must be saved to configuration

to prevent loss of data.

Figure 4.49.

D

L / pick param

SPAN = 20243

Figure 4.50.

E

/ to SPAN

30

ENT = acpt 20031

Figure 4.51.

Page 31

4.3 - Range of Operation - Setup cont.

UP/DOWN KNOB - SELECT ‘SAVE CONFIG’ MENU

Rotate the UP/DOWN knob until the display reads Save

Config. (Fig. 4.52).

D

S / pick param

Save Config

ENTER KNOB - ENTER TO SAVE TO EEPROM

Actuator configuration must be saved to EEPROM before

exiting the menu (Fig. 4.53).

ENTER KNOB - SELECT ‘CANCEL’

Select ‘CANCEL’ to exit setup mode.

The SPAN position has now been set (Fig. 4.54).

If limits have not been set adjustment of the position limit

switches is required. See start of section 4.3.

Figure 4.52.

E

S / pick param

Saving to EEPROM

Figure 4.53.

C

L P= 0.0 C= 0.0

Volt = 1 8168

Figure 4.54.

Redefining Flow Control

31

Page 32

4.3 - Range of Operation - Setup cont.

4.3.3 SETTING LIMIT SWITCHES

SET INCREASING POSITION LIMIT

SWITCH CAM#1

It is now possible to set the CW & AC W position limit

switches.

With actuator set to LOCAL mode (see section 4.2) move

output shaft to the AC W end of travel position. As viewed

from the lever output shaft end.

This could be the ZERO or SPAN position depending on

configuration.

The switch acts as an emergency backup to de-energize

the motor drive and is generally set to trip if the actuator is

operated outside the SPA N or ZERO travel positions.

Locate locking set screw #1 on the switch cam end plate

assembly.

1

With a

screw (Fig. 4.55).

Rotate the cam CW until the switch operates (Fig. 4.57) then

back off so that the cam just releases the switch.

Tighten the set screw (Fig. 4.58).

The switch is now set to operate just after the anti-clockwise

(ZERO or SPAN ) position is reached.

/8” Hex key loosen (DO NOT REMOVE) locking grub

Figure 4.55.

SET DECREASING POSITION LIMIT

SWITCH CAM#2

With actuator set to LOCAL mode (see section 4.2) move

output shaft to the CW end of travel position. As viewed

from the lever output shaft end.

This could be the ZERO or SPAN position depending on

configuration.

Locate locking set screw #2 on the switch cam end plate

assembly (Fig. 4.56).

1

With a

screw.

Rotate the cam ACW until the switch operates then back off

so that the cam just releases the switch (Fig. 4.57).

Tighten the set screw (Fig. 4.58).

The switch is now set to operate just after the ACW (ZERO

or SPAN) position is reached.

/8” Hex key loosen (DO NOT REMOVE) locking grub

Figure 4.56.

Figure 4.57.

Note:

CW = Clockwise

ACW = Anti-Clockwise (Counter- Clockwise)

32

Figure 4.58.

Page 33

4.3 - Range of Operation - Setup cont.

SET ADDITIONAL LIMIT SWITCHES (If fitted)

Repeat the procedure for switches CAM #3 to #6

as required.

REFIT TOP AND SIDE COVERS

Check condition of o-ring seals (replace if necessary) and refit

cover assemblies.

REFIT LOCAL CONTROL COVER ASSEMBLY

Remove the control cover assembly from its temporary

position and refit to front of control housing. Take care not

to damage looms between the cover assembly and the main

PCB. Disconnect wiring looms if necessary. Be sure to check

condition of the o-ring seals (replace if necessary) and refit

with cover.

Figure 4.59.

Redefining Flow Control

33

Page 34

4.3 - Range of Operation - Setup cont.

4.3.4 OPERATING SPEED

The actuator output speed can now be changed to suit the

process requirement.

To change the actuator speed.

Figure 4.60.

ENTER KNOB - SELECT ‘CANCEL’

L P= 149 C= 149

Temp. .C 32 27

C

S / pick param

Ctrl Type = Man

UP/DOWN KNOB - SELECT ‘MENU’

Use the UP/DOWN knob to scroll through menus until ‘Speed

=XXX’isdisplayed(Fig.4.62).

UP/DOWN KNOB - SELECT SPEED

The motor speed can now be adjusted by using the

UP/DOWN knob until the display shows the desired

speed (10 - 100%) (Fig. 4.62).

Figure 4.61.

D

S / pick param

Speed = 100

Figure 4.62.

U

34

D

Page 35

4.3 - Range of Operation - Setup cont.

ENTER KNOB - ENTER TO SAVE VALUE

Set new speed setting.

NOTE:

CYCLING THE POWER TO THE ACTUATOR

AT THIS STAGE WILL REMOVE RECENT CHANGES.

TO AVOID LOSS OF SETTINGS USE UP/DOWN

KNOB TO SCROLL TO THE ‘SAVE CONFIG‘

MENU (Fig. 4.64).

E

/ to Speed

ENT = acpt 100

Figure 4.63.

D

S / pick param

ENTER KNOB - ENTER TO SAVE VALUE

Save new speed setting to EEPROM (Fig. 4.65).

ENTER KNOB - CANCEL TO EXIT MENU

Save Config

Figure 4.64.

E

S / pick param

Saving to EEPROM

Figure 4.65.

Redefining Flow Control

C

35

Page 36

5 - Setup and Calibration

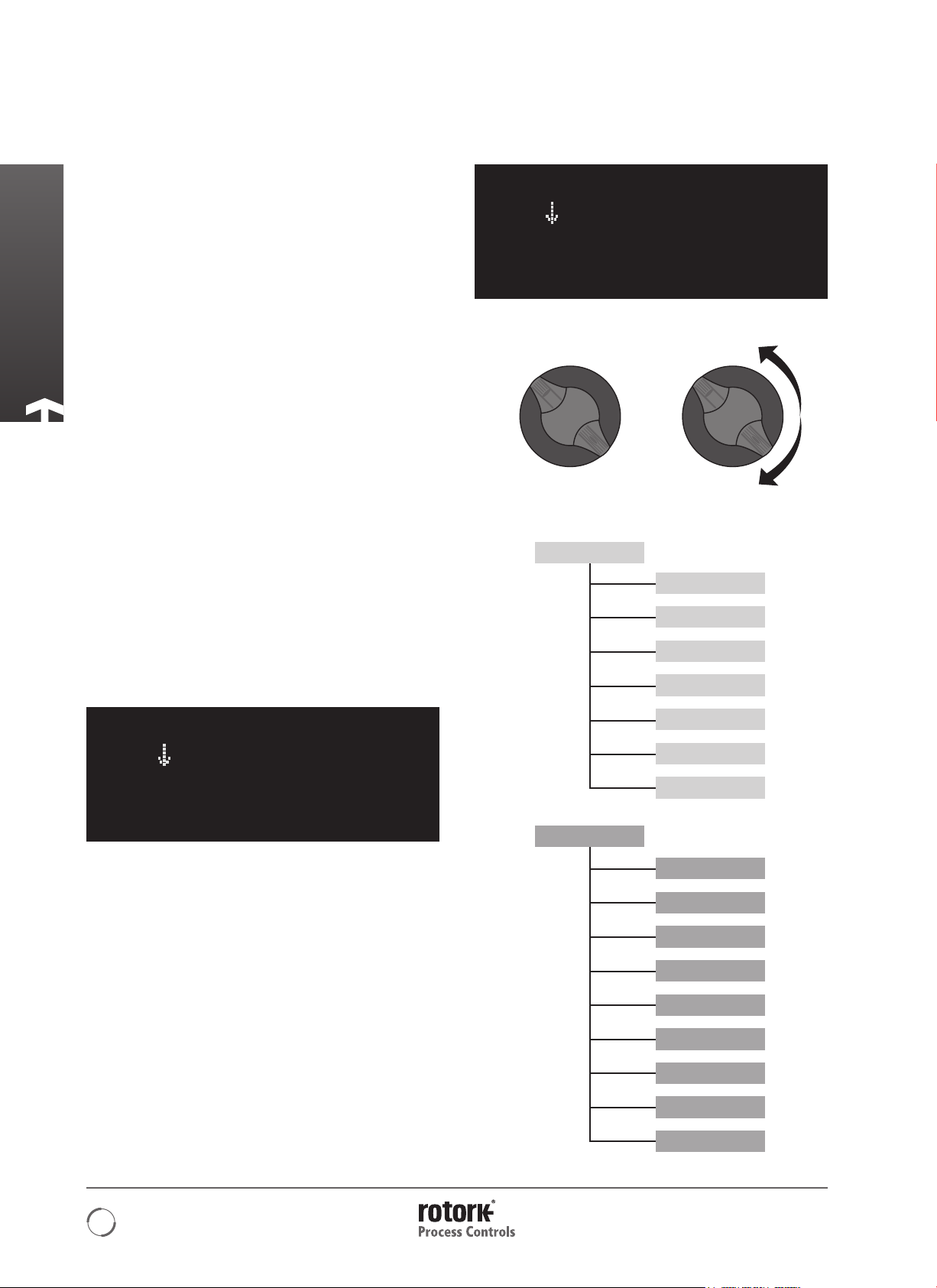

SM-6000 S2 MENU STRUCTURE

SECT 5.1 SETUP & CALIBRATION

SECT 5.2 COMMUNICATIONS

SETUP MODE

There are two levels of Setup and Calibration.

Level 1: Customer Settings for initial setup and fine

tuning of the actuator operation.

Level 2: Diagnostic and Advanced Settings (Section 5.3).

User may wish to consult Rotork Process Controls

before making changes to level 2 parameters.

LEVEL 1 MENU STRUCTURE

SPAN

ZERO

MAX CAL

MIN CAL

SPEED

COMMS OPT

CMD TYPE

LOS ACT

MAX TORQUE

HART

LOS POS

CUR P GAIN

CUR I GAIN

MIN POS

MAX POS

SAVE CONFIG

CTRL MECH

HART ADDR

COM LOS ACT

COM LOS P

PROFIBUS

CTRL MECH

PROFI ADDR

FB POS LIM

COM LOS ACT

FFBUS

CTRL MECH

FB POS LIM

COM LOS ACT

COM LOS P

Figure 5.1. Level 1 Menu Structure

36

COM LOS TO

COM LOS P

COM LOS TO

COM LOS TO

Page 37

5.1 - Setup and Calibration - Level 1

WARNING: SETTING THE OUTPUT TORQUE HIGHER

THAN 100% RATED MAY RESULT IN DAMAGE TO THE

ACTUATOR AND OR LINKAGE.

CAUTION: OPERATION AND CALIBRATION OF THE UNIT

MAY BE AFFECTED.

WARNING! ACTUATOR OUTPUT SHAFT

MAY MOVE DURING LEVEL 1 SETUP.

LEVEL 1

SPAN

Used to set the maximum travel limit of the actuator.

ZERO

Used to set the minimum travel limit of the actuator.

CTRL TYPE

Used to set the control mode of the actuator.

L = Local Mode (Fig 5.2)

When Local /Remote selector switch is set to Local operation

actuator can be operated by using the UP/DOWN selector

knob.

NOTE:

CYCLING THE POWER TO THE ACTUATOR AT THIS

STAGE WILL REMOVE RECENT CHANGES.

TO AVOID LOSS OF SETTINGS USE UP/DOWN KNOB TO

SCROLL TO THE ‘SAVE CONFIG‘ MENU.

L P= 100 C= 100

Amp Strts = 159

Figure 5.2. Local Mode

R= REMOTE Mode (Fig 5.3)

When Local/Remote selector set to Remote actuator responds

to hardwired remote control inputs only.

C = Remote Communications mode (Fig 5.4)

When Local/Remote selector set to Remote actuator responds

to serial commands when bus option cards are fitted.

S = Setup Mode (Fig. 5.5)

Allows access to menus and parameter changes.

R P= 100 C= 100

Flt: LOS-command

Figure 5.3. Automatic Mode

C P= 100 C= 100

Curr = -0.2 4052

Figure 5.4. Remote Communications Mode

S / pick param

Ctrl Type = REMOTE

Figure 5.5. Setup Mode

Redefining Flow Control

37

Page 38

5.1 - Setup and Calibration - Level 1 cont.

5.1.1 MAX CMD CAL

Used to calibrate the analogue command signal to the

desiredMAXposition.

This maximises resolution and optimises accuracy.

The analogue control signal should be applied to

terminals as follows.

Voltage TB2-1 (+ve) TB2-2 (-ve)

Current TB2-4 (+ve) TB2-3 (-ve)

Refer to the identification label located on the outside

of the actuator for wiring diagram details.

1 - Enter setup mode (see section 4.2).

2 - Use the ENTER knob to scroll through menus until

’MAX=XXXX’isdisplayedonline2.

3 - Select ‘ENTER’.

SETCMNDTOMAXwillappearonline1ofthedisplay.

4 - Apply the maximum input command e.g. 20 mA.

5 - Select ‘ENTER’ to accept the new Max Cal value,

Select ‘CANCEL’ to exit the Max Cal setup mode.

5.1.2 MIN CMD CAL

Used to calibrate the analogue command signal to the desired

MIN position.

This maximises resolution and optimises accuracy.

1 - Enter setup mode (see section 4.2).

2 - Use the ‘Enter‘ knob to scroll through menus until

’MIN=XXXX’isdisplayedonline2.

3 - Select ‘ENTER’.

SET CMND TO MIN will appear on line 1 of the display.

4 - Apply the minimum input command e.g. 4 mA.

5 - Select ‘ENTER’ to accept the new Min Cal value,

Select ‘CANCEL’ to exit the Min Cal setup mode.

E

C

S / pick param

Max Cal = 7684

Figure 5.6. MAX CMD CAL

E

C

S / pick param

Min Cal = 1541

38

Figure 5.7. MIN CMD CAL

Page 39

5.1 - Setup and Calibration - Level 1 cont.

5.1.3 SPEED

The actuator output speed is adjustable from 1 - 100% of its

rated value.

1 - Enter setup mode (see section 4.2).

2 - Use the UP/DOWN knob to scroll through menus until

‘Speed=XXX‘appearsonline2ofthedisplay.

3 - Select ‘ENTER’.

4 - Hold the UP/DOWN knob until desired value is displayed.

5 - Select ‘ENTER’ to accept new Speed value, or select

‘CANCEL’ to abort without changing the speed value.

5.1.4 CMD TYPE

Used to select between Current (4-20 mA) or Voltage

(0-5 VDC or 0-10 VDC).

1 - Enter setup mode (see section 4.2).

2-UseUP/DOWNknobuntil‘COMMAND=XXXX’is

displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select Current or Voltage.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

U

D

S / pick param

Speed = 100

Figure 5.8. SPEED

U

D

S / pick param

Cmd Type = Volt

5.1.5 LOS ACT

Used to determine the actuator action on loss of analogue

control signal when the actuator is set to Automatic Mode of

operation.

LOCK - Stayput or Lock in place.

POS - Go to Preset Position.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until LOS ACT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select desired value.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

Figure 5.9. CMD TYPE

U

D

S / pick param

LOS Act = Lock

Figure 5.10. LOS ACT

Redefining Flow Control

39

Page 40

5.1 - Setup and Calibration - Level 1 cont.

5.1.6 LOS POS

Used to determine the position that the actuator will move to

on loss of analogue control signal.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until LOS POS is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select desired value.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

5.1.7 CUR P GAIN

Used to adjust the proportional gain of the actuator.

Modifies the response of the actual position against desired

position. Range 1-99.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until CUR P GAIN is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select desired value.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

U

D

S / pick param

LOS Pos = 18844

Figure 5.11. LOS POS

U

D

S / pick param

Cur P Gain = 40

5.1.8 CUR I GAIN

Used to adjust the integral gain of the actuator where system

response varies over time. Range 0-99.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until CUR I GAIN is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select desired value.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

Figure 5.12. CUR P GAIN

U

D

S / pick param

Cur I Gain

Figure 5.13. CUR I GAIN

= 20

40

Page 41

5.1 - Setup and Calibration - Level 1 cont.

5.1.9 MIN POS

Used to set the position regarded as ZERO when limited range

positioning is required. Only applicable when the FB Pos Limit

is active. For example if MIN POS is set to 10% this is reported

as the ZERO (0%) position.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until MIN POS is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to move the actuator to the

desired position.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

5.1.10 MAX POS

Used to set the position regarded as SPAN when limited

range positioning is required. Only applicable when the FB Pos

Limit is active. For example if MAXPOSissetto90%thisis

reported as the SPAN (100%) position.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until MIN POS is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to move the actuator to the

desired position.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

U

D

S / pick param

Min Pos = 0

Figure 5.14. MIN POS

U

D

S / pick param

Min Pos = 100

Figure 5.15. MAX POS

Redefining Flow Control

41

Page 42

5.1 - Setup and Calibration - Level 1 cont.

5.1.11 MAX TORQUE %

Used to limit the output torque produced by the actuator.

Exceeding the value will result in an over torque alarm being

displayed.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until Max TORQUE is displayed.

Max value = 200% of rated,

3 - Select ‘ENTER’

4 - Use UP/DOWN knob to select desired value.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

5.1.12 SAVE CONFIG

Used to save setup parameters to EEPROM. Any parameter

changes MUST be saved prior to power off. On power up

the on board processor will use the last values stored in the

EEPROM.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until SAVE CONFIG is displayed.

3 - Select ‘ENTER’ to save changes to EEPROM.

CANCEL to exit the menu.

U

D

S / pick param

Max Torq % = 100

Figure 5.16. MAX TORQUE %

U

D

SETUP COMPLETE

Set the REMOTE/Local parameter to REMOTE.

S / pick param

Save Config

Figure 5.17. SAVE CONFIG

42

Page 43

5.2 - Communications

COMMS OPT

Used to select specific menus when a BUS communications

option card is fitted.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COMS OPT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the actuator

control protocol.

Choices are:

NONE No Bus Protocol option fitted.

HART

PROFIBUS

FFBUS (Foundation Fieldbus)

5 - Select ‘ENTER’ to accept the change.

The selected communication protocol options will now be

available.

Note that the unit must be fitted with the appropriate Bus

system card to support the menus.

5.2.1 HART CONTROL OPTIONS

CTRL MECH

The actuator can be controlled via commands received over

the Hart protocol communications channel or as a direct

analogue (4-20 mA) input signal request.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until CTRL MECH is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the actuator control type.

Menu choices are:

COMMS = HART protocol control

ANALOG = 4-20 mA Analogue Control only.

5 - Select ENTER to accept the change.

CANCEL to exit the menu.

HART

CTRL

MECH

Figure 5.18

HART

ADDR

U

D

S / pick param

COMMS Opt = HART

Figure 5.19. COMMS OPT

U

D

S / pick param

Ctrl Mech = COMMS

Figure 5.20. CTRL MECH

U

COM

LOS ACT

COM

LOS P

COM

LOS TO

HART ADDR

Used to set the address assigned to the device on the

HART network. Range 1 to 64.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until HART ADDR is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob until desired address is displayed

5 - Select ‘ENTER’.

CANCEL to exit the menu.

Redefining Flow Control

D

S / pick param

HART Addr = 0

Figure 5.21. HART ADDR

43

Page 44

5.2 - Communications cont.

COM LOS ACT

Action on loss of HART communication.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS ACT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired action.

Menu choices are:

LOCK - Stayput or Lock in place.

POS - Go to Preset Position.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

COMM LOS P

Position actuator will move to on loss of HART

communication.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS P is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired position.

Range 0-100%.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

U

D

S / pick param

COM LOS Act = Stop

Figure 5.22. COM LOS ACT

U

D

S / pick param

COMS LOS P = 781

COMM LOS TO

Time delay before action is taken on loss of HART

communication. Maximum of 10 seconds.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS TO is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired delay time.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

NOTE: To avoid loss of settings use the ‘SAVE CONFIG’

menu to save changes to the EEPROM. See p42

for details.

Figure 5.23. COMM LOS P

U

D

S / pick param

COMS LOS TO = 63

Figure 5.24. COMM LOS TO

44

Page 45

5.2 - Communications cont.

5.2.2 PROFIBUS CONTROL OPTIONS

CTRL MECH

The actuator can be controlled via commands received over

the Profibus protocol communications channel or as a direct

analogue (4-20 mA) input signal request.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until CTRL MECH is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the actuator control type.

Menu choices are:

COMMS = Profibus protocol control

ANALOG = 4-20 mA Analogue Control only.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

PROFI ADDR

Used to set the address assigned to the device on the Profibus

network. Range 1 to 127.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until PROFI ADDR is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob until desired address is displayed.

5 - Select ‘ENTER’.

CANCEL to exit the menu.

PROFIBUS

CTRL

MECH

Figure 5.25

PROFI

ADDR

U

D

S / pick param

Ctrl Mech = COMMS

Figure 5.26. CTRL MECH

U

D

FB POS

LIM

COM

LOS ACT

COM

LOS P

COM

LOS TO

FB POS LIMIT

Feedback position limiting. When enabled the actuator

will return a zero value when the actuator is below the MIN POS

limitand100%abovetheMAXPOSLimit.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until FB POS LIMIT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN to select Enable or Disable function.

5 - Select ‘ENTER’.

CANCEL to exit the menu.

Redefining Flow Control

S / pick param

PROFI addr = 126

Figure 5.27. PROFI ADDR

U

D

S / pick param

FB Pos Limit = No

Figure 5.28. FB POS LIMIT

45

Page 46

5.2 - Communications cont.

COM LOS ACT

Action on loss of Profibus communication.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS ACT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired action.

Menu choices are:

LOCK - Stayput or Lock in place.

POS - Go to Preset Position.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

COMM LOS P

Position actuator will move to on loss of Profibus

communication.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS P is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired position.

Range 0-100%.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

U

D

S / pick param

COM LOS Act = Stop

Figure 5.29. COM LOS ACT

U

D

S / pick param

COMS LOS P = 781

COMM LOS TO

Time delay before action is taken on loss of Profibus

communication. Maximum of 10 seconds.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS TO is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired delay time.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

NOTE: To avoid loss of settings use the ‘SAVE CONFIG’

menu to save changes to the EEPROM. See p42

for details.

Figure 5.30. COMM LOS P

U

D

S / pick param

COMS LOS TO = 255

Figure 5.31. COMM LOS TO

46

Page 47

5.2 - Communications cont.

5.2.3 FOUNDATION FIELDBUS

CONTROL OPTIONS

CTRL MECH

The actuator can be controlled via commands received over

the FFBUS protocol communications channel or as a direct

analogue (4-20 mA) input signal request.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until CTRL MECH is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the actuator control type.

Menu choices are:

COMMS = FFBUS protocol control.

ANALOG = 4-20 mA Analogue Control only.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

FB POS LIMIT

Feedback position limiting. When enabled the actuator

will return a zero value when the actuator is below the

MINPOSlimitand100%abovetheMAXPOSLimit.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until FB POS LIMIT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN to select Enable or Disable function.

5 - Select ‘ENTER’.

CANCEL to exit the menu.

FFBUS

CTRL

MECH

Figure 5.32

FB POS

LIM

U

D

S / pick param

Ctrl Mech = COMMS

Figure 5.33. CTRL MECH

U

D

S / pick param

FB Pos Limit = No

COM

LOS ACT

COM

LOS P

COM

LOS TO

COM LOS ACT

Action on loss of Foundation Fieldbus communication.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS ACT is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired action.

Menu choices are:

LOCK - Stayput or Lock in place.

POS - Go to Preset Position.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

Redefining Flow Control

Figure 5.34. FB POS LIMIT

U

D

S / pick param

COM LOS Act = Stop

Figure 5.35. COM LOS ACT

47

Page 48

5.2 - Communications cont.

COMM LOS P

Position actuator will move to on loss of FFBUS

communication.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS P is displayed.

3 - Select ’ENTER’

4 - Use UP/DOWN knob to select the desired position.

Range 0-100%.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

COMM LOS TO

Time delay before action is taken on loss of FFBUS

communication. Maximum of 10 seconds.

1 - Enter setup mode (see section 4.2).

2 - Use UP/DOWN knob until COM LOS TO is displayed.

3 - Select ‘ENTER’.

4 - Use UP/DOWN knob to select the desired delay time.

5 - Select ‘ENTER’ to accept the change.

CANCEL to exit the menu.

NOTE: To avoid loss of settings use the ‘SAVE CONFIG’

menu to save changes to the EEPROM. See p42

for details.

U

D

S / pick param

COMS LOS P = 781

Figure 5.36. COMM LOS P

U

D

S / pick param

COMS LOS TO = 255

Figure 5.37. COMM LOS TO

RECORD YOUR USER SETTINGS IN SECTION 13.

48

Page 49

5.3 - Setup and Calibration - Level 2

SM-6000 S2 MENU STRUCTURE

Level 2: Diagnostic and Advanced Settings.

User may wish to consult Rotork Process Controls

before making changes to level 2 parameters.

SETUP MODE

LEVEL 2

MOTOR

MAX TORQUE

INPUT VOLT

MOTOR RATE

PASS ENBLD

LOOP

LOAD FACT DEFS

SAVE CONFIG

Figure 5.38. Level 2 Menu Structure

Redefining Flow Control

49

Page 50

5.3 - Setup and Calibration - Level 2 cont.

LEVEL 2 ADVANCED SETUP MENUS

CAUTION: SOME VARIABLES IN LEVEL 2 ARE FACTORY SET – DO NOT ADJUST!!

5.3.1 MOTOR PWM

Command used to represent motor speed in function of

maximum pulse width modulation.

To access the advanced setup and calibration menus rotate

the UP/DOWN knob clockwise and the ENTER/CANCEL knob

anti-clockwise.

Hold for 10 seconds.

5.3.2 MAX TORQUE

Used to match the motor output and control to the gearbox.

This value is factory set and must not be changed.

5.3.3 INPUT VOLT

Used to select the AC input voltage used by the Amplifier.

Check the actuator wiring diagram for additional notes on

selection of input power supplies.

This must match the hardware configuration. This value is

factory set and must not be changed.

5.3.4 MOTOR RATE

This is a factory set parameter and it is configured to match

the motor voltage as fitted.

This should not be changed.

U

D

S / pick param

Max Torq % = 100

Figure 5.39. MAX TORQUE

U

D

5.3.5 PASS ENBLD

Enable a 4 Digit system password. Select ‘YES’ to enable

password.

PASSWORD VALUE

Check function

5.3.5.1 PASSWORD

NOTE: IF PASSWORD IS SELECTED ‘ON’ THEN NO

CHANGES ARE ALLOWED UNLESS THE CORRECT

PASSWORD IS ENTERED.

Use UP/DOWN Selector to select ‘YES’.

Use CANCEL/ ENTER to enable Password.

Use UP/DOWN selector to select required password then

CANCEL/ENTER selector to store the new password.

Holding the UP/DOWN selector whilst changing the password

will increase the scroll rate accordingly.

MAKE A NOTE OF THE PASSWORD:

S / pick param

Input Volt = 120

Figure 5.40. INPUT VOLT

U

D

S / pick param

Pass Enbld = No

Figure 5.41. PASS ENBLD

50

Page 51

5.3 - Setup and Calibration - Level 2 cont.

5.3.6 LOOP

Closed loop or Open loop control. The default setting of the

actuator is Closed loop control. Open loop is used for factory

setup only.

This value is factory set and must not be changed.

5.3.7 LOAD FACT DEFS

Used to revert the actuator back to the Factory default

Settings.

U

D

S / pick param

Loop = Run

Figure 5.42. LOOP

U

CAUTION: SAVE CONFIG

Used to save setup parameters to EEPROM. Any

parameter changes MUST be saved prior to power off.

On power up the onboard processor will use the last

values stored in the EEPROM.

Use UP/DOWN knob until SAVE CONFIG is displayed.

Select ‘ENTER’ to save changes to EEPROM.

CANCEL to exit the menu.

SETUP COMPLETE

RECORD YOUR USER SETTINGS IN SECTION 13.

D

S / pick param

Load Fact Defs

Figure 5.43. LOAD FACT DEFS

Redefining Flow Control

51

Page 52

6 - Faults & Troubleshooting

6.1 FAULT STATUS INDICATION

Fault Diagnostics appear on line two of the display. When

more than one diagnostic is active, only the highest priority

will show.

Flt: Incr Limit

End of Travel Limit Switch for the increasing direction is

tripped.

Decrease actuator position to move off limit switch.

Flt: Decr Limit

End of Travel Limit Switch for the decreasing direction is

tripped.

Increase actuator position to move off limit switch.

Flt: Stalled

Actuator output speed is incorrect due to excessive load.

Momentary stall Flts are self-resetting.

Continuous or repetetive stall Flts indicate an improperly

loaded actuator. Reduce load.

Flt: LOS-Command

Loss of command signal.

Command signal is below 3.6 mA, or above 21.6 mA.

Return command signal to 4-20 mA range.

Flt: Crnk Engagd

The hand crank has been engaged.

Pull out hand crank to remove Flt.

Flt: LOS-Feedbk

If using an encoder, either the encoder is disconnected, the

encoder has reached the end of travel, or there is an internal

encoder fault.

If using a potentiomer, the feedback pot has been

disconnected or the feedback signal has risen above 4.9 V.

Flt: System Fail

Microprocessor has detected a system failure.

Simultaneously turn the UP/DOWN knob ACW and ENTER/

CANCEL knob CW to Clear the alarm.

Flt: Torq Limit

The current rating of the torque has been exceeded.

Simultaneously turn the UP/DOWN knob ACW and ENTER/

CANCEL knob CW to Clear the alarm.

Flt: Mtr Pol Re

Motor direction of operation or response is incorrect.

Motor leads possibly reversed.

Switch off and check motor wiring immediately!

Motor operation is checked automatically on power up.

52

U

C

Figure 6.1. Turn both knobs as shown to clear alarms.

Page 53

6 - Faults & Troubleshooting cont.

6.2 TROUBLESHOOTING

Trouble Possible Cause Remedy

Actuator will increase position but

not decrease

Actuator will decrease position,

but not increase

LS2 is tripped

Actuator is at zero position

LS1 is tripped

Increase actuator to normal operating

range. Check LS2 and Zero Setup

Decrease actuator to normal operating

range. Check LS2 and SPAN Setup

No actuator power

Actuator will not move

Actuator oscillates during

movement

Actuator overshoots position Too high of integral gain Reduce Cur I gain

Poor response to command signal

change

Actuator moves, but motor

gets hot

Actuator does not respond to a

change in command