rotork IW Series, MOW Series, MTW Series, IB Series, IS Series Installation Manual

Gearbox Installation Manual

Rotork Gears IW, MOW, MTW, IB and IS ranges

(Electronic copy available on www.rotork.com)

! This manual contains important safety information. Please ensure it is

thoroughly read and understood before installing the gearbox.

! This manual is produced to enable a competent person to install, operate,

adjust and inspect Rotork gearboxes. Only persons competent by virtue of

their training or experience should install, maintain and repair Rotork

gearboxes.

! The gearbox weight is recorded on the packaging and on a label attached to

the gearbox.

! WARNING: Gearbox may present an unbalanced load.

! WARNING: With respect to handwheel operation of Rotork gearboxes, under

no circumstances should any additional lever device such as a wheel-key or

wrench be applied to the handwheel in order to develop more force when

closing or opening the valve as this may cause damage to the valve and/or

gearbox or may cause the valve to become stuck in the seated/backseated

position.

! WARNING: Damage to protective coatings should be correctly rectified and

may invalidate warranty.

RG-INSTALL-009 / PUB027-027_0917 Page 1 of 15

Date 26/09/2017

Contents

1. Introduction ............................................................................................................................................... 3

2. Health and Safety ..................................................................................................................................... 3

3. Storage ...................................................................................................................................................... 3

4. Unpacking ................................................................................................................................................. 3

5. Handling .................................................................................................................................................... 3

6. Installation & Maintenance of Worm Combinations ............................................................................. 4

6.1. Output Sleeve Removal, Machining and Re-Fitting ..................................................................... 4

Important Notes in Figure 2: ........................................................................................................................... 4

6.2. Mounting to the Valve ..................................................................................................................... 6

6.3. Baseplate Thread Depths ................................................................................................................ 7

6.4. Setting the Gearbox Stops to Suit the Valve (IW and MOW Only) .............................................. 7

6.5. Worm Combination Maintenance ................................................................................................... 8

7. Installation & Maintenance for Multi-Turn IB & IS Combinations ........................................................ 9

7.1. Output Sleeve Removal, Machining and Re-Fitting ..................................................................... 9

7.2. Mounting to the Valve ................................................................................................................... 10

7.2.1. Gearboxes IB2 to IB13 and IS2 to IS13, IS15 and IS17. ..................................................... 11

7.2.2. Gearboxes IB14 and IS14, IS16, and IS18-IS21 ................................................................... 12

7.2.3. All IB and IS Gearboxes ........................................................................................................ 13

7.3. Maintenance Instructions for IB & IS Gear Operators................................................................. 13

8. Paint Repair Procedure .......................................................................................................................... 14

9. Reference ................................................................................................................................................ 14

10. Handwheel Types .............................................................................................................................. 15

RG-INSTALL-009 / PUB027-027_0917 Page 2 of 15

Date 26/09/2017

1. Introduction

Unless otherwise specified the gearbox is supplied assembled. In the case of quarter turn gearboxes, the

gearbox stops have been set to a nominal 90° open and close position.

! The IW gearbox stops must be re-set for the stroke of the valve after combination installation.

2. Health and Safety

Work undertaken must be carried out in accordance with the instructions in this and any other relevant

manuals. The user and those persons working on this equipment should be familiar with their responsibilities

under any statutory provisions relating to the Health and Safety of their workplace. Due consideration of

additional hazards should be taken when using the gearbox with other equipment. Should further information

and guidance relating to the safe use of the Rotork products be required, it will be provided on request.

The mechanical installation should be carried out as outlined in this manual and also in accordance with

relevant standards such as British Standard Codes of Practice. No inspection or repair should be undertaken

unless it conforms to the specific hazardous area certification requirements. For maintenance of the actuator,

refer to the actuator installation and maintenance manual.

! WARNING: The gearbox enclosure materials may include cast iron, SG iron, carbon steel or

stainless steel.

3. Storage

If your gearbox cannot be installed immediately store it in a clean dry place until you are ready to install in

situ. Recommended storage temperature range: 0°C to 40°C (32°F – 104°F).

4. Unpacking

Gearboxes are packed in a variety of configurations depending on size, type and quantity of the

consignment.

It is the responsibility of the individual unpacking and handling the combination to carry out a risk

assessment for the supplied arrangement to ensure safe working. Refer to Section 5 Handling.

Packaging material used may include wood, cardboard, polyethylene and steel. Packaging should be

recycled according to local regulations.

5. Handling

! Individual weights for gearboxes are recorded on their respective nameplates

! Only trained and experienced personnel should carry out handling. At all times, safe

handling must be ensured.

! Each combination must be assessed to identify all risks associated with handling.

! The gearboxes must be fully supported until full valve shaft/stem engagement is achieved

and the gearbox is secured to the valve flange.

! Once connected to the valve, each assembly must be assessed on an individual basis for

safe handling/lifting. Never lift the complete combination-valve assembly via the gearbox.

! If it is necessary to lift the gearbox using lifting equipment, certified soft slings are

recommended. Damage to protective coatings should be correctly rectified and may

invalidate warranty.

! We recommend fitting a bolt and washer system onto the baseplate of IB and IS gearboxes

before moving them, as demonstrated in Figure 7 and Figure 8.

RG-INSTALL-009 / PUB027-027_0917 Page 3 of 15

Date 26/09/2017

6. Installation & Maintenance of Worm Combinations

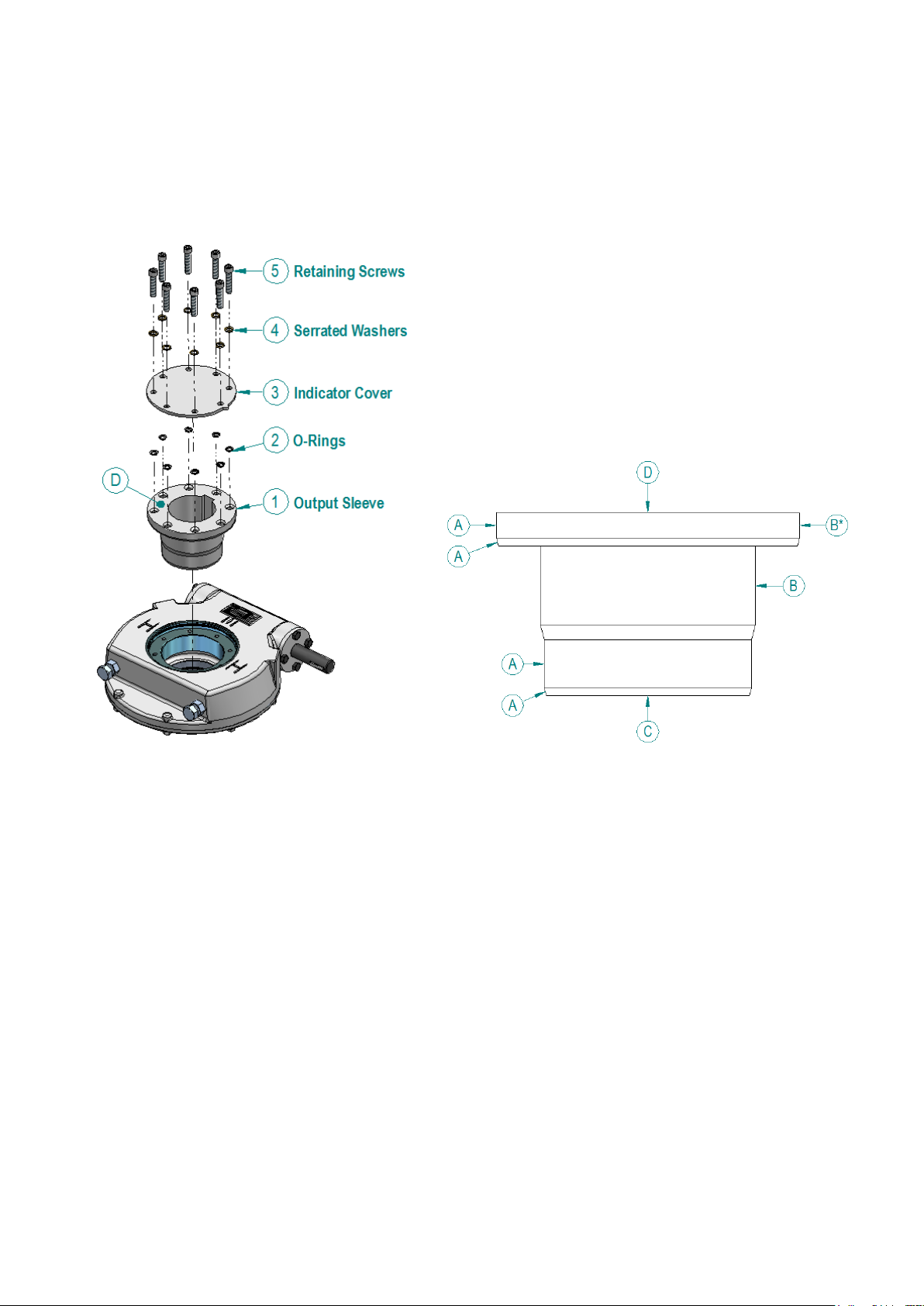

Figure 1 - IW3-11 Output Sleeve Fitting

Figure 2 - IW Output Sleeve, Important Surfaces

6.1. Output Sleeve Removal, Machining and Re-Fitting

Gearbox sizes IW12 to IW16 have an output which is directly machined as specified with the order. All other

worm gearbox combinations have a removable output sleeve. See Item 1, Figure 1.

Figure 1 shows the removal of the output sleeve from the gearbox. See Figure 2 for removing the output

sleeve without damaging the sealing faces.

Important Notes in Figure 2:

A: The surfaces marked ‘A’ are sealing or bearing faces and must not be damaged.

B: The surfaces marked ‘B’ can be used for chucking the output sleeve. *Note, this surface can

only be used for chucking on MTW gearboxes. NOT IW or MOW units.

C: To remove the output sleeve from the gearbox, a force may have to be applied to the face

marked ‘C’ of the output sleeve.

D: It is recommended to apply silicon sealant to the face marked ‘D’ when fitting the indicator

plate.

Unless specifically requested at the ordering stage, the output sleeve will be supplied blank and must be

machined to suit the valve shaft.

Referring to the item numbers in Figure 1, the output sleeve can be easily removed from the top of the

gearbox by first removing the retaining screws (5). The screws are either serrated under their heads or are

fitted with serrated washers (4). Then remove the indicator/cover plate (3).

RG-INSTALL-009 / PUB027-027_0917 Page 4 of 15

Date 26/09/2017

Figure 3 - O-Ring Inspection

It is essential to fit the two part washers

the correct way round with the cam

faces of the washers joining. Place the

O-rings over the screw threads and

against the indicator plate.

Referring to Figure 3, O-rings (6) and (7) are to be inspected for damage, greased and properly seated

before re-fitting the output sleeve. If the O-ring is damaged then it should be replaced prior to fitting the

output sleeve.

! WARNING: Removing the retaining screws will result in the loss of control of the valve.

Referring to Figure 1, O rings (2) are used to seal the indicator plate, output sleeve and retaining screws.

Upon final installation on the valve, screws (5) must be tightened to the correct torque figures as shown on

the label on the underside of the indicator/cover plate.

Before re-fitting the output sleeve after machining, check that the surfaces marked ‘A’ in Figure 2 are not

damaged. Damaged surfaces can break the gearbox seals and cause water ingress or grease leakage.

Applying a thin layer of grease to the faces marked ‘A’ will make refitting of the sleeve easier.

As detailed in Figure 1 and Figure 2, it is recommended that silicon sealant is applied to face ‘D’ to seal the

indicator/cover plate to the output sleeve. Taking care not to apply sealant to the o rings (2) or the sealing

faces with the o rings.

Before re-assembly, clean and de-grease the top face of the output sleeve, underside of the indicator/cover

plate, and the socket head cap screws. Make a note of the tightening torque required for the output sleeve

screws on the label on the underside of the indicator plate. Insert the screws and washers into the holes in

the indicator/cover plate, as per Figure 1.

RG-INSTALL-009 / PUB027-027_0917 Page 5 of 15

Date 26/09/2017

Loading...

Loading...