Page 1

Publication PUB089-005-00_0618

Mk3 Foundation Fieldbus

Option Card

Technical Manual

Page 2

Foundation Fieldbus CP Option Card Technical Manual

2 of 116 Publication PUB089-005-00_0618

Note 1: Throughout this manual the Foundation Fieldbus may be abbreviated to FF

Note 2: Throughout this manual the FF Interface Card may simply be referred to as the FF CP card.

Note 3: The information in this manual relates to the FF CP card firmware / hardware versions:

M3.1 / T1.4 / H1.1 (or newer)

Note 4: The screen dumps used in the manual have generally be taken from a National Instruments FF

configurator tool’s screen. Other configurator tools may show the same data on a different set of

screens.

Note 5: This manual is to be used in conjunction with the relevant actuator setting manual and assumes a

pre-existing level of knowledge of using both FF and the particular actuator type. It is advised that

the relevant technical manual is read before attempting to set-up FF within the actuator.

Note 6: The FF CP card described in this manual contains static-sensitive devices. Suitable

precautions, such as wearing an earthed anti-static wrist strap, should be taken before

handling the card. It should be kept in an anti-static bag or box while it is not fitted within an

actuator.

As we are continually developing our products their design is subject to change without notice.

© The contents of this document are copyright and must not be reproduced without the written permission

of Rotork.

The name Rotork is a registered trademark.

Foundation is a registered trademark of the Fieldbus Foundation.

NI-FBUS is a registered trademark of National Instruments.

Windows is a registered trademark of The Microsoft Corporation.

The names; Allen, Bluetooth, Modbus, Rotork and Torx are registered trademarks.

Page 3

Contents

Publication PUB089-005-00_0618 3 of 116

Contents

Glossary of Terms: ......................................................................................................................... 6

Abbreviations used: ....................................................................................................................... 8

Supporting Documents: ................................................................................................................. 8

1 INTRODUCTION ................................................................................................ 9

2 FF CARD PROPERTIES ................................................................................. 11

2.1 Mechanical properties ........................................................................................................11

2.2 Electrical properties ...........................................................................................................12

2.3 Operation and storage .......................................................................................................12

3 FITTING THE FF CP CARD ............................................................................ 13

3.1 Inside a Rotork Actuator ..................................................................................................13

3.1.1 Inside an IQ3/IQT3 actuator ...............................................................................13

3.1.2 Inside an SI3 actuator .........................................................................................15

3.1.3 Inside a CVA actuator .........................................................................................16

3.1.4 Inside a CMA actuator ........................................................................................17

3.1.5 Inside a K range actuator ...................................................................................18

3.1.6 Inside a CK actuator ...........................................................................................19

3.2 Replacing or Fitting an FF CP Option Card .....................................................................20

3.3 Socket, LED and Jumper functions of the FF card .........................................................21

4 IEC 61158 DATA HIGHWAY AND CONNECTIONS ....................................... 23

4.1 Data highway ......................................................................................................................23

4.2 Fieldbus power supply .......................................................................................................24

4.3 Termination network ..........................................................................................................26

5 THE ACTUATOR INPUT AND OUTPUT SIGNALS ........................................ 27

5.1 Controls ...............................................................................................................................28

5.1.1 Controls priority ..................................................................................................31

5.1.2 Foundation control using DO blocks only ...........................................................32

5.1.3 Foundation control using the AO block only .......................................................32

5.1.4 Foundation control using both DO and AO blocks .............................................33

5.1.5 The ‘S’ contacts (RLY 1 to RLY 4) controlled by the DO blocks ........................34

5.1.6 Foundation network control disable feature .......................................................34

5.2 Discrete Input status feedback .........................................................................................35

5.2.1 Discrete Inputs ....................................................................................................36

5.2.3 Discrete Inputs reporting the FF CP card condition ...........................................40

5.3 Actuator Analogue Input feedback ...................................................................................41

Page 4

Foundation Fieldbus CP Option Card Technical Manual

4 of 116 Publication PUB089-005-00_0618

6 FUNCTION BLOCKS ...................................................................................... 43

6.1 Resource Block ..................................................................................................................44

6.2 Transducer Block ...............................................................................................................47

6.2.1 Transducer block parameters .............................................................................47

6.2.2 Changing the settings in the Transducer block. .................................................53

6.2.3 Editing the Foundation specific parameters 1-23 and 99 ...................................54

6.2.4 Editing the actuator setup parameters 50-67 .....................................................54

6.2.5 Editing the control parameters 65 - 66 ...............................................................59

6.3 Analogue Input blocks .......................................................................................................60

6.4 Discrete Input blocks .........................................................................................................61

6.5 Analogue Output block ......................................................................................................63

6.6 Discrete Output blocks ......................................................................................................65

6.6.1 Multiple block – single bit control ........................................................................66

6.6.2 Single block – multiple bit control. ......................................................................66

6.7 PID Control block ...............................................................................................................68

6.8 Control Selector block .......................................................................................................69

7 LINK ACTIVE SCHEDULER (LAS) ................................................................. 71

7.1 Creating a schedule ...........................................................................................................74

7.2 Connecting the blocks .......................................................................................................75

7.3 Downloading the schedule ................................................................................................75

7.4 Optimising the downloaded schedule ..............................................................................76

8. SETTING UP THE FF CP CARD (QUICK START GUIDE) ............................. 77

8.1 Setting up with the Setting Tool .......................................................................................78

8.2 Insight 2 ...............................................................................................................................79

8.3 Methods ...............................................................................................................................81

8.4 Control output function block settings ............................................................................82

8.4.1 Analogue Only control ........................................................................................83

8.4.2 Discrete Only control ..........................................................................................83

8.4.3 Mixed Analogue and Discrete control .................................................................84

8.4.4 Hard-wired inputs - Aux Input Function ..............................................................84

8.5 Status feedback function block settings .........................................................................85

8.5.1 Analogue position and torque data .....................................................................85

8.5.2 Discrete Input data .............................................................................................85

8.6 Default settings ...................................................................................................................86

8.7 Using the DTM (with FDT) ..................................................................................................87

9 THE FF CP CARD FIRMWARE AND DD FILES ............................................. 89

9.1 Firmware ..............................................................................................................................89

9.2 Device Description Files ....................................................................................................89

Page 5

Contents

Publication PUB089-005-00_0618 5 of 116

APPENDIX A – HANDLING FAULT CONDITIONS. ................................................ 91

APPENDIX B – FUNCTION BLOCK MODE – LO ................................................... 92

APPENDIX C – PID APPLICATION. ....................................................................... 93

APPENDIX D – ITK6 FF SPECIFICATION DATASHEET ....................................... 96

D.1 Basic Fieldbus Function Blocks .......................................................................................96

D.2 Channel Allocation .............................................................................................................96

D.3 Segment Information ..........................................................................................................97

APPENDIX E – NAMUR NE 107 - GUIDELINES FOR SETTING UP ...................... 98

E.1 Background info: ................................................................................................................98

E.2 Test set up for FD_...._ACTIVE: ......................................................................................101

E.3 Test set up for FD_...._ALM: ............................................................................................104

APPENDIX F – CHANGING THE ITK REVISION .................................................. 106

APPENDIX G – DTM .............................................................................................. 110

APPENDIX H – HOST INTEROPERABILITY SUPPORT TEST (HIST) ................ 113

APPENDIX I – COMMON PROBLEMS ................................................................. 114

Page 6

Foundation Fieldbus CP Option Card Technical Manual

6 of 116 Publication PUB089-005-00_0618

Glossary of Terms:

Automatic (AUTO) A possible mode of a function block which means the block runs its

algorithms, producing data at its inputs or outputs.

Basic Device A basic device is any device not having the capability to control

communications on an H1 fieldbus segment.

Back calculation output This parameter is available on output function blocks, and provides a

(BKCAL_OUT) feedback mechanism to control blocks such as PID.

Capabilities File A file describing the communication objects in a fieldbus device. A

configuration device can use Device Description (DD) Files and

Capabilities Files to configure a fieldbus system without having the

fieldbus devices online.

Cascade (CAS) A possible mode of a function block which refers to an input derived

from the output of another function block.

Device Description (DD) A machine-readable description of all the blocks and block parameters

of a device.

Fieldbus The digital, two-way, multi-drop communication links.

Fieldbus Interface Card (FIC) The option card fitted to the actuator which provides the

communications interface between the DCS and the actuator.

Function Block (FB) Also known as standard function block. This is a named block

consisting of one or more inputs and outputs. These are built into

fieldbus devices to achieve the desired control functionality. The FF

CP has Analogue Input (AI), Analogue Output (AO), Digital Input (DI),

Digital Output (DO), Control Selector (CS) and PID control (PID).

H1 A term used to describe a FF highway operating at 31.25 kbit/sec.

Initialization Manual (IMAN) The forward path to a physical output is broken and the output is

tracking the downstream block. This will result in the control action

being suspended.

Interoperability The capability for a device from one manufacturer to interact with that

of another manufacturer, on a fieldbus network, without loss of

functionality.

Input / Output Options This parameter is contained within output function blocks and

(IO_OPTS) allows different parameters to appear at various connection points.

Link Active Scheduler (LAS) One Link Master (LM) device functions as the fieldbus LAS at any one

time. The LAS is the Fieldbus device that is currently controlling

access to the Fieldbus. A device that is responsible for keeping a link

operational. The LAS executes the link schedule, circulates tokens,

distributes time, and probes for new devices.

Page 7

Contents

Publication PUB089-005-00_0618 7 of 116

Local Override (LO) A possible mode of a function block where the block can only be

monitored, and no changes can occur to its set points.

Manual (MAN) A possible mode of a function block where the final element is

manually input by a user, as opposed to being controlled by its

algorithms.

Out Of Service (OOS) A possible mode of a function block which means the block does not

run its internal algorithms and cannot be used.

Process Variable (PV) A process variable is a condition of the process fluid (a liquid or gas)

that can change the manufacturing process in some way. Common

process variables include pressure, temperature, flow rate, etc.

Readback This is the parameter in an output function block which indicates the

actual feedback of a process, as opposed to the desired value.

Remote Cascade (RCAS) A possible mode of a function block which refers to an input derived

from non-function block outputs.

Resource Block (RB) A block that describes the characteristics of the fieldbus device such

as; the device name, manufacturer and serial number.

Schedules Communication events that occur at the same time during each

control cycle. The schedule defines when Function Blocks (FBs)

execute and when data / status information is published on the bus.

Segment A Foundation Fieldbus network is made up of devices connected by a

serial bus. This serial bus is called a segment (also known as a link).

A section of an H1 fieldbus that is terminated in its characteristic

impedance. Segments can be linked by Repeaters to form a longer

H1 fieldbus. Each Segment can include up to 32 H1 devices.

Transducer Block (TB) A block that is an interface to the physical, sensing hardware in the

device. It also performs the digitising, filtering, and scaling

conversions needed to present input data to function blocks, and

converts output data from function blocks. The block decouples the

Function Blocks from the local input/output (I/O) functions required to

read the limit switches and command the actuator to move.

Virtual Communication Preconfigured or negotiated connections between virtual field devices

Relationship (VCR). on a network. The quantity of VCRs able to be handled by an H1

gateway, or Link Master usually determines the number of devices on

an FF highway.

Virtual Field Device (VFD) The virtual field device is a model for remotely viewing data described

in the object dictionary. The services provided by the Fieldbus

Messaging Specification allow you to read and write information about

the object dictionary, read and write the data variables described in

the object dictionary, and perform other activities such as uploading or

downloading data and invoking programs inside a device.

Page 8

Foundation Fieldbus CP Option Card Technical Manual

8 of 116 Publication PUB089-005-00_0618

Abbreviations used:

AI Analogue Input (Blocks AI1, AI2)

AO Analogue Output (Block A0)

BTST Bluetooth Setting Tool

CFF Common File Format

Comms Communications

CP Common Protocol

CS Control Selector Block

DCS Distributed Control System

DD Device Description

DI Digital Input (Blocks DI1, DI2, DI3, DI4, DI5)

DO Digital Output (Blocks DO1, DO2, DO3, DO4)

DSM (Actuator) Digital Switch Mechanism

DTM Device Type Manager

ESD Emergency Shut Down

FB Function Block

FDT Field Device Tool

FF Foundation Fieldbus

FIC Fieldbus Interface Circuit

HIST Host Interoperability Support Test

ITK Interoperability Test Kit

LAS Link Active Scheduler

LM Link Master

MSM (Actuator) Mechanical Switch Mechanism

NIC Network Interface Circuit

PCS Process Control System

PDA Personal Digital Assistant

PID Proportional, Integral, Derivative; A type of function block which refers to a closed

loop control algorithm

PST Partial Stroke Test

RAM Random Access Memory

RB Resource Block

ROM Read Only Memory

SW Software

TB Transducer Block

VCR Virtual Communication Relationship

Supporting Documents:

Available from the Fieldbus Foundation, Austin, Texas

Technical Overview of Foundation Fieldbus FD-003 (all parts).

Wiring and Installation 31.25 kbit/s, AG-140

Page 9

Introduction

Publication PUB089-005-00_0618 9 of 116

1 INTRODUCTION

This manual is designed to be an aid to commissioning and will assist with achieving a

successful integration of Rotork’s FF product into a DCS’s FF network. Correct installation

should ensure a lifetime of trouble free use. This is not a manual on how to use FF. Due to the

complex nature of the protocol, Rotork strongly recommends users attain a sufficient level of

FF competency prior to attempting any FF commissioning work.

The FF CP option card is the third evolutionary step in Rotork’s Foundation Fieldbus journey. It has

been certified as conforming to the open fieldbus standard IEC 61158 and is suitable for use on an FF

H1 highway. The H1 highway uses two copper wires to both to carry the digital messages and to

supply power to all the devices connected on the highway. As such it is necessary to have a suitable

power supply and termination filter on the highway for the FF nodes to function.

The current version of the FF card may be fitted into any of the current Rotork Controls’ actuator

product range. The FF card is an integral part of the actuator in which it is housed and is fitted within

the main electrical housing. This electrical housing need never be opened once the actuator leaves

the assembly plant. All adjustments to the settings for the FF card may be made via the Foundation

data highway using a suitable network configuration tool. There is no external marking on the actuator

to show the FF card serial number since the whole module may be replaced if it should fail.

The FF card’s circuits do not impinge on the actuator control electronics; the actuator itself remains

fully self-protecting. The card performs the tasks of IEC 61158 interface, actuator data collection and

the issuing of actuator commands.

The FF CP card may command the actuator into which it is fitted to open, stop, close, perform an ESD

operation, perform a partial stoke operation or move to a set position. Commands to the module come

from the network and may be generated in another actuator or device on the network using peer to

peer, publisher/subscriber communication. Additionally, digital and analogue status information

relating to the actuator is published for the other devices to read.

For a quick start guide see section 8.

Fig 1.1: Some of the actuators which use the FF CP card

Page 10

Foundation Fieldbus CP Option Card Technical Manual

10 of 116 Publication PUB089-005-00_0618

1.1 General

The FF CP card is capable of performing the following functions:–

a) Link Master / Link Active Scheduler

b) Basic Device

The in-built function blocks vary in availability between the different actuator types. The input and

output blocks are used to link to the transducer block and tie to the available actuator functions. For

example the AI block associated with actuator torque measurement is only available in the DSM

actuator type. The following table lists the function blocks and their related availability in each actuator

type.

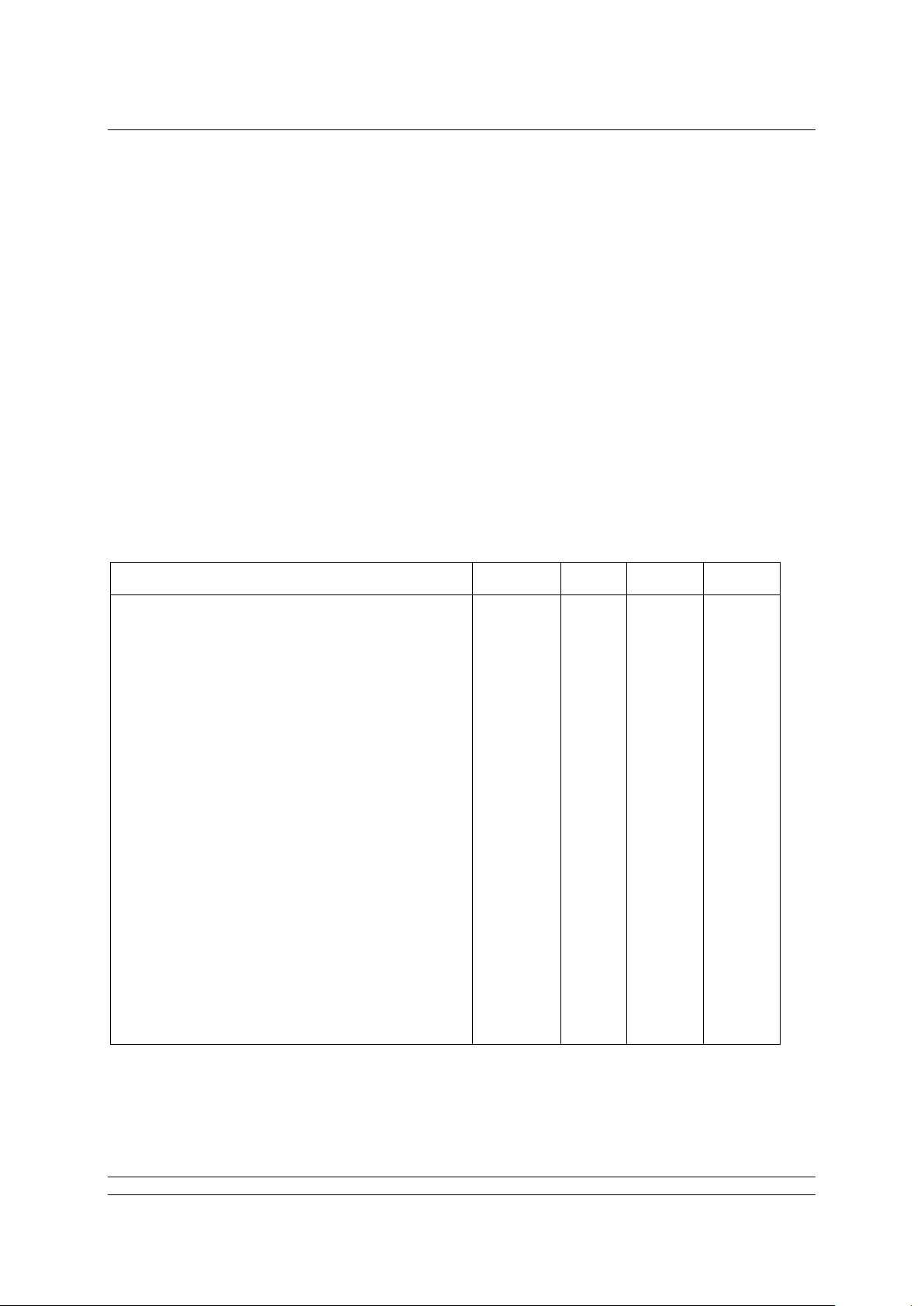

Function Block Type

Resource Block – System information

Transducer Block – Device configuration

Digital Inputs

DI 1 Closed limit or multistate

DI 2 Open limit or multistate

DI 3 Selector in remote or multistate

DI 4 General alarm or multistate

DI 5 Actuator moving or multistate

Digital Outputs

DO 1 Open or multistate

DO 2 Close or multistate

DO 3 Stop or multistate

DO 4 Single bit selectable or multistate

Analogue Inputs

AI 1 Analogue position feedback

AI 2 Torque / Thrust

Analogue Output

AO Desired position (set point command)

Controllers

PID (3 term controller)

Control Selector

Page 11

FF CP Card Properties

Publication PUB089-005-00_0618 11 of 116

2 FF CARD PROPERTIES

2.1 Mechanical properties

The FF CP card consists of a single network interface card that fits directly to the main actuator control

PCB. It consists of two isolated parts, the actuator interface and the network interface

Network Interface

This carries the FF highway connections and the processor handling the data highway

communication and function blocks. The Network Interface contains the FF connector (SK3),

polarised to prevent incorrect insertion. This connects to the three wire loom routed to the

terminal compartment of the actuator. Power for the Network Interface is taken from the FF

highway.

Actuator Interface

The primary connection to the actuator circuits is by a multi-pin connector on the base of

Interface Card. The PCB design ensures it may only be fitted in the correct polarisation. The

Actuator Interface on the FF CP card is powered from within the actuator.

Network Connector

Fig 2.1: The FF card, showing the network connector

Page 12

Foundation Fieldbus CP Option Card Technical Manual

12 of 116 Publication PUB089-005-00_0618

2.2 Electrical properties

The FF CP card does not sit in the main control path for the actuator and does not affect the actuator

control integrity.

Internally stored programs control the processors on the module. The Network Interface processor

software may be updated by connecting a suitable test cable and loading the new code directly, but

this cannot be done in the field The FF system allows all settings for the data highway and module

communication functions to be held in non-volatile memory on the Network Interface Card.

The FF data highway connection is fully isolated from the actuator electronics.

2.3 Operation and storage

The Module is designed to be stored in the actuator and operated within the same environment as the

actuator.

The constraints are:

Operating temperature: -40

o

C to +70oC

Storage temperature: -50

o

C to +85o C

Relative Humidity: 5% to 95% (<50

o

C) non-condensing

Refer to actuator manuals for range applicable for the particular actuator type.

Page 13

Fitting the FF CP card

Publication PUB089-005-00_0618 13 of 116

3 FITTING THE FF CP CARD

3.1 Inside a Rotork Actuator

3.1.1 Inside an IQ3/IQT3 actuator

The FF CP card is suitable for fitting into IQ3 actuators. When factory-fitted, their wiring diagrams will

contain an ‘F’, e.g. 100F2000. The FF CP can be located in one of 2 or 4 option ‘slots’ located on the

back of the control module PCB, housed in the electrical cover. There are 2 slots for directly

connecting the option module to the control module and where those slots are already filled, the option

card can be fitted on top of the existing modules. The modules can be stacked 2 high where a ‘deep’

electrical cover is fitted.

Back of the control module

Fig 3.1: The FF CP card’s location behind the control module in an IQ3

With the IQ3 actuators, the remote inputs are always present (they are conditioned by the control

board) and there is an option to include Digital Outputs from relay contacts. If the FF CP is required to

operate the 4 digital outputs that can be controlled from the card, then an Extra Relay Indication card

associated with these outputs must be fitted into another option slot in the actuator.

The FF CP is connected to the control module by a 10 way header (SK2). The wiring harness from the

actuator terminal bung connects the FF H1 highway field connections to SK3.

Option Slots

Page 14

Foundation Fieldbus CP Option Card Technical Manual

14 of 116 Publication PUB089-005-00_0618

Replacing or Fitting an FF CP Option Card

The FF CP card should be replaced or fitted only in a suitable environment. The actuator must be

made electrically safe before opening any covers. The electrical housing cover should be removed

after unscrewing the four 6mm Allen machine screws. Unplug the electrical housing loom from the

control board and remove the cover. Unplug the grey ribbon cable from the edge of the control board

and unplug the black plastic carrier frame from the frame legs. Unplug the loom from the FF card.

Unscrew the Torx 20 screws holding the FF card into the frame and carefully unplug the FF card from

the control board. The replacement board is fitted in the reverse order to removal. The wiring harness

connectors are polarised so that only the correct one will fit its mating part on the circuit boards. Don’t

forget to re-connect the grey ribbon cable to the edge of the control board.

If the operation is to fit an FF CP card for the first time, then the necessary wiring loom must be added

to the internal wiring harness of the actuator. The actuator wiring diagram shows the connectors and

harness used. The wiring harness is fitted inside the actuator before attempting to fit the FF CP. This

requires that you remove the terminal bung, which is held in place by a large circlip. Be careful to

attach the wiring loom to the correct terminals, which are numbered. Re-fit the terminal bung.

Once the loom is in place, connect it to the FF CP, then fit the FF CP to the actuator main board

connector. Attach the FF CP to the frame, using the Torx 20 screws.

Once the module is fitted, the actuator should be re-assembled.

Once power is applied, the field unit parameters should be checked and corrected, where necessary.

Some FF TB parameters can be set and adjusted either by using the Infra-red and Bluetooth setting

tools or by Insight 2 using Bluetooth. The parameter setting procedure is covered by the IQ3 Full

configuration, status and monitoring user manual, PUB002-040-00, available on the Rotork web site,

www.rotork.com

Page 15

Fitting the FF CP card

Publication PUB089-005-00_0618 15 of 116

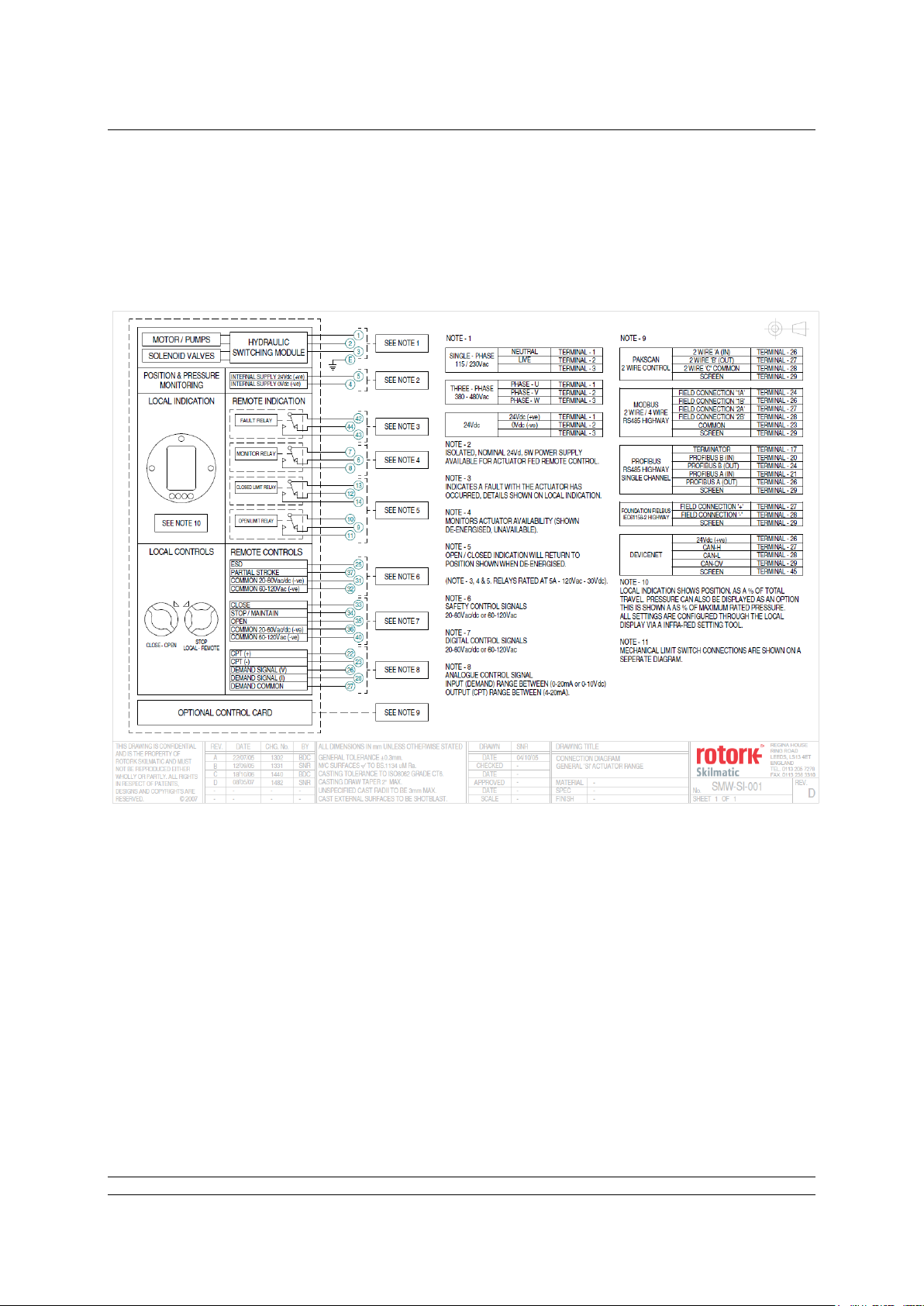

3.1.2 Inside an SI3 actuator

The FF CP is suitable for fitting into SI3 actuators. When factory-fitted, the network connections will be

as in the diagram below:

Fig 3.2: The SI3 highway interface connection table

The internal layout of the actuator will be similar to that of the IQ3, when considering installation of the

FF CP, as above.

Page 16

Foundation Fieldbus CP Option Card Technical Manual

16 of 116 Publication PUB089-005-00_0618

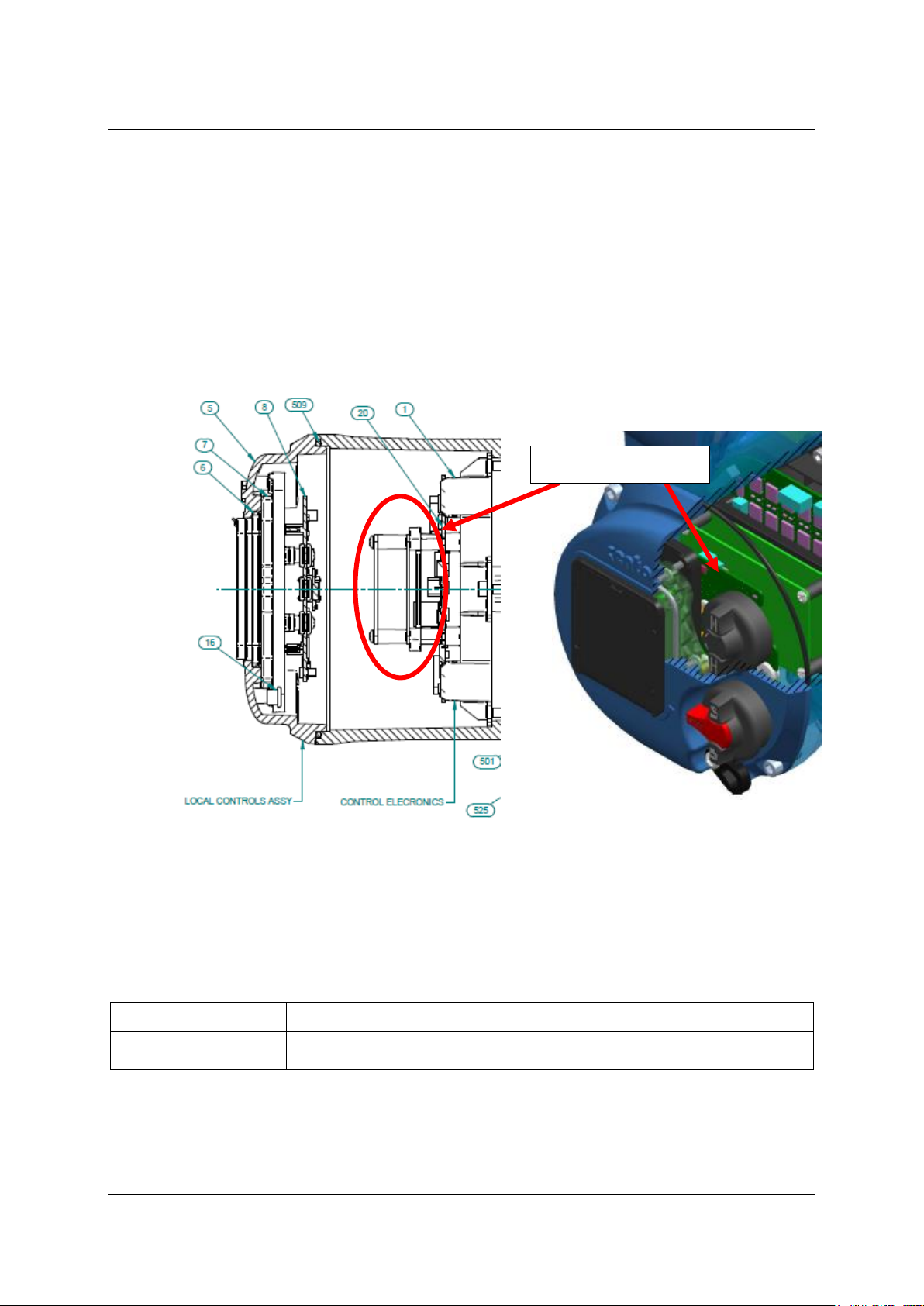

3.1.3 Inside a CVA actuator

The FF CP is suitable for fitting into CVA actuators. When factory-fitted, the wiring diagram will be

CXX-80 (where X can be any value). This details the option card connections to the terminal bung.

The FF CP module is fitted in the only option board slot inside the CVA electrical housing - on the

underside of the Main PCB assembly. The FF CP should be replaced or fitted only in a suitable

environment.

Fig 3.3: The FF CP located on the underside of the control PCB in a CVA actuator

To fit an FF CP card, begin by removing power from the actuator and wait until the LED on the

selector knob stops illuminating. This may take several minutes if a reserve power pack of capacitors

is fitted.

Remove the six M10 machine screws from the upper cover and lift it off carefully, while removing its

ribbon cable connector from the socket on the Main PCB.

Remove the various wiring looms from the sockets on the edges of the Main PCB, noting carefully

where they attach. Each connector is different to avoid error.

Remove the Main PCB in its plastic chassis by gently pushing the chassis legs inwards to release

them from a groove in the actuator housing.

Fit the FF CP to the underside of the Main PCB using the hardware supplied with the FF CP card.

The wiring loom from the actuator terminal bung connects the FF H1 field connections to SK3. If a new

card is being fitted as an upgrade, then the actuator will need to have the loom fitted. Remove the

terminal bung by removing the circlip and gently pulling the bung. Attach the loom and replace the

bung.

The FF CP is connected to the control module by a header, SK2.

The FF CP in the CVA must be enabled. This would usually be done during factory test, but may be

required to be completed on site for conversions to FFs or if a replacement card is fitted. To enable

the card, the Rotork PDA software Enlight (downloadable from the Rotork web site) is required to be

used to change parameter 34. It must be read and then have 2048 decimal added to it.

This procedure is best performed by a Rotork Engineer.

Page 17

Fitting the FF CP card

Publication PUB089-005-00_0618 17 of 116

3.1.4 Inside a CMA actuator

The FF CP is suitable for fitting into CMA actuators, wiring diagrams MXX-FX (where X can be any

value) detail the option card connections on the terminal strip. The FF CP module is fitted in the only

option board slot inside the CMA electrical housing.

Fig 3.4: The FF CP located in a CMA actuator

The FF CP should be replaced or fitted only in a suitable environment. The actuator must be made

electrically safe before opening any covers. The electrical housing cover should be removed after

unscrewing the four 6mm Allen machine screws.

The FF CP should be fitted in the position shown in the illustrations above. It plugs into the control

board at the 10-way header, which is SK2 on the FF CP board. There is a wiring loom which brings

the FF H1 network connection to SK3 on the FF CP.

Connection details are shown in the illustrations on the next page.

The CMA actuator will need configuring, so that it is aware that control from the field is through the FF

CP card. This is done by accessing the menu structure as shown in the CMA Installation and

Maintenance manual, PUB094-003, found on the Rotork web site.

Option location

Page 18

Foundation Fieldbus CP Option Card Technical Manual

18 of 116 Publication PUB089-005-00_0618

3.1.5 Inside a K range actuator

The FF CP is suitable for fitting into K-Range actuators; wiring diagrams similar to 1612ZFD detail the

option card connections. The FF CP module is fitted in the only option board slot inside the K-Range

electrical housing.

SK2 on the FF CP card plugs directly onto SK9 on the Main card, while a terminal bung loom brings

the FF highway signals to SK3.

FF Option Card

Main Card

Fig 3.5: The FF card located in a K-Range actuator

The FF card should be replaced or fitted only in a suitable environment. The actuator must be made

electrically safe before opening any covers. The electrical housing cover should be removed after

unscrewing the four 8mm Allen machine screws.

The FF card is attached to the main card by three plastic pillars, with one metal pillar, Torx 20 screw

and a fibre washer; as shown in the illustration above.

If an actuator is having the FF fitted for the first time, then the terminal bung loom must also be fitted.

The terminal numbers will be found in the appropriate wiring diagram, which should be included in the

fitting kit.

Page 19

Fitting the FF CP card

Publication PUB089-005-00_0618 19 of 116

3.1.6 Inside a CK actuator

The FF CP card is suitable for fitting into CKC / CKRC actuators with Px5xxxxx and Kx5xxxxx series

wiring diagrams. The connections and fitting in a CKRC are the same as the CKC so the following

information effectively relates to both actuator types. The FF CP card is normally located in the first

option board slot inside the electrical housing, using Main PCB connection SK2.

The Interface card must be correctly profiled and loaded with the appropriate connectors to match the

actuator. The illustration below shows the location of the cards in the Centronik unit.

Within the actuator the remote inputs are always present (they are conditioned by the FF CP card) and

there is an option to include Digital Outputs from relay contacts. If the FF CP card is required to

operate the 4 digital outputs that can be controlled from the card, then the Extra Relay Indication card

associated with these outputs must be fitted into the actuator. The following table describes the wiring

harnesses and their function in the Centork actuator.

FF card Socket

Wiring Harness

SK2

Power and CANbus from actuator.

SK3

FF H1 highway connection.

Fig 3.6: The FF CP card located in a Centronik unit.

Option Card Location

Page 20

Foundation Fieldbus CP Option Card Technical Manual

20 of 116 Publication PUB089-005-00_0618

3.2 Replacing or Fitting an FF CP Option Card

The FF card should be replaced or fitted only in a suitable environment. The actuator must be made

electrically safe before opening any covers.

Warning: Removal of certain covers will void warranty, it is advised that a Rotork approved

engineer perform this function.

Suitable anti-static precautions should be taken, as the actuator circuitry contains static-sensitive

components.

If an upgrade kit has been purchased please carefully follow the instructions given in the

documentation provided. It will also be necessary to have the relevant actuator maintenance manual

to hand when adding a new card.

The electrical housing cover should be removed and the existing FF card carefully unplugged from its

main connector. The Interface card will be attached to the Main PCB mounting ring by four screws,

which are T20 (or T15 if two cards are present). Once removed from the main connector the wiring

loom connectors should be removed. The replacement board is fitted in the reverse order to removal.

The wiring harnesses are polarised so that only the correct one will fit its mating part on the circuit

board.

If the operation is to fit an FF card for the first time then the necessary wiring looms must be added to

the internal wiring harness of the actuator. The actuator wiring diagram shows the connectors and

harnesses used. The wiring harnesses are fitted inside the actuator before attempting to fit the FF

card. Once the looms are in place connect them to the FF card, then fit the card to the actuator control

board/main board connector.

Once the module is fitted the actuator should be re-assembled. If an option card is fitted into an

actuator after it has left the factory then the actuator needs to be set-up to use this card in the

software, the card will not do anything until this has been done. This can be done using the local HMI

or Insight but ideally needs to be done by a Rotork service engineer. This is not necessary if a card is

being replaced with the same type of card, e.g. replacing an FF with a new FF card.

It is advisable to check the software version numbers are the same between the new and old card to

ensure consistent operation. It is also advisable to check the ITK revision of the old FF card as it may

be necessary to modify the new FF card’s ITK revision. If this needs to be done, see Appendix F.

Page 21

Fitting the FF CP card

Publication PUB089-005-00_0618 21 of 116

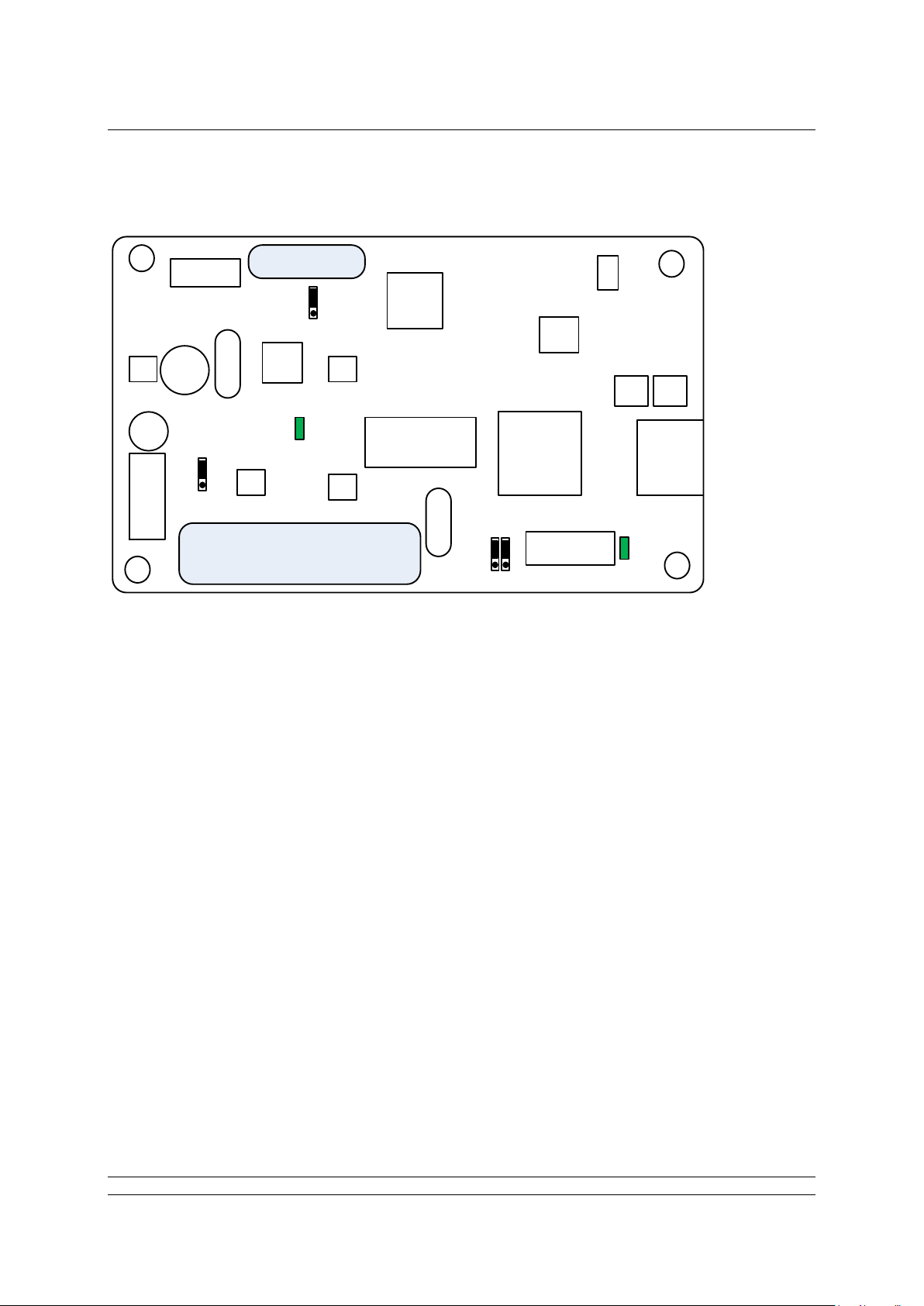

3.3 Socket, LED and Jumper functions of the FF card

Bar code

Bar code

LED 2

LED 1

JP2

SK 3

JP1

JP3

JP4

SK 1

The FF CP card includes two connectors (SK1 and SK3), two LED indicators (LED1 and 2) and four

jumpers, (JP1 – 4). The position of these jumpers should not normally require alteration from the

factory default positions. The illustration shows the default positions. The LEDs can be used to help

with system diagnostics in some cases.

The function of each connector, LED and jumper is as follows:

SK1 This socket connects the FF CP card to the actuator’s control PCB via a CANbus

highway

SK3 This socket connects the FF CP card to the FF highways via the actuator’s

terminal bung connections.

Note there are two other connectors which are used to program the FF CP card and which are

not described in this document

LED 1 Indicates the FF CP Card is communicating with the actuator’s control PCB.

LED 2 When flashing, this Indicates there is an active connection to the fieldbus highway.

When on (i.e. not flashing), this indicates the fieldbus highway power is present.

Fig 3.7: Network Interface Card - Jumper and LED functions.

Page 22

Foundation Fieldbus CP Option Card Technical Manual

22 of 116 Publication PUB089-005-00_0618

JP1, Simulation In simulation mode, the user is permitted to write to primary input/output

Mode Jumper actuator variables through the status and value attributes normally written to

by the transducer block. With JP1 ‘On’ a function block may have its simulation

‘active’ parameter enabled. When JP1 is ‘Off’ the primary actuator variables are

not write enabled. The normal position is ‘Off’, as shown on the schematic above.

See the appendix section for more information on simulation mode operation.

JP2, Hard-Write A setting can be made in the ‘FEATURE_SEL’ parameter of the Resource block

Lock which prevents the writing/changing of all configuration parameters in the FF CP

card. If the FEATURE_SEL is set to ‘Hard W Lock’, the jumper function becomes

write protect ‘On’ and ‘Off’. (See section 6.1 Resource Block). The normal position

is ‘Off’ as shown above.

JP3, CANbus This must be left in the “Off” position as shown in the fig 9 above

Terminator

JP4, Slot 0 / 1 In fig 3.7, this is shown in the slot 0 position. The jumper is moved to the slot 1

Selector position when two FF CP cards are fitted into the same actuator and one of them

already has slot 0 selected.

Fig 3.8: Simulate has been activated in the AI function block.

Page 23

IEC 61158 Data Highway

Publication PUB089-005-00_0618 23 of 116

4 IEC 61158 DATA HIGHWAY AND CONNECTIONS

4.1 Data highway

The Foundation Fieldbus network is based on the IEC 61158 data highway using copper conductors.

The network also carries the power used to supply each node on the network. In the case of the FF

card, the FF interface is powered from the fieldbus network. Only two wires are used for the data

highway and these carry both the data signal and the module power. The actuator interface card is

powered from the actuator itself and the card can only report actuator data when both the FF highway

and actuator are powered up.

The data highway must be terminated with proper balancing devices at either end. The highway can

use spur or stub connections to the devices but it is recommended to keep any stub lengths to a

minimum for successful operation. The length of the highway and number of devices connected will

vary from project to project. The standard permits up to 32 devices before a repeater in the highway

must be used, however it’s extremely unlikely that this many devices will be connected to a highway.

Similarly, the standard calls for a maximum segment length of 1900 metres before a repeater must be

used. On a 1900 metre highway, the stipulated maximum length for a stub with one actuator is 120

metres. The data highway cable type is given by the Foundation as ‘type A’. A typical example of this

type of cable is Belden 3076F.

Cable Specification

Type A Cable (e.g. Belden 3076F)

Type

2 cores, twisted pair plus overall screen

Shielding

Minimum 90% copper shielding, braid or foil

Size

18 AWG (0.8 mm2)

Resistance

24 Ohms/km max

Nominal Capacitance

80 pF/m

Fig 4.1: Typical Foundation Data Highway

Trunk

(Main highway segment)

Spurs

T

Power

supply

H1 Gateway

Field Junction Box

(including terminator)

Fieldbus power supply

(including terminator)

T

JB

JB

Page 24

Foundation Fieldbus CP Option Card Technical Manual

24 of 116 Publication PUB089-005-00_0618

4.2 Fieldbus power supply

The FF card takes power from the H1 data highway. This means the internal function blocks are

available for control connection between devices even when the actuator has no power.

The power is taken from a special DC power supply connected onto the network through a suitable

filter. The power consumption of each FF node on the network is 20 mA and the absolute minimum

voltage at the actuator terminals is 9 volts. The power supply has to contain an inductive network to

prevent attenuation of the fieldbus signal by the low impedance of the power supply itself. The

inductive network in the power pack makes sure that its equivalent impedance is quite high at the

31.25 kbits/sec frequency whilst still allowing a DC current to be drawn for the line-powered devices.

Since each node on the fieldbus consumes power from the DC supply, great care must be taken in the

design of the installation. The design must ensure that the volt drop from the power pack to the

actuator still leaves at least 9V (absolute minimum) for the FF card and ideally at least 10 Volts. The

actuators can withstand a maximum voltage of 32V from the power pack and since the current

consumption is virtually constant, a simple Ohm’s law calculation can be used to determine the

potential at each point in the network. On power up there is no additional inrush current, i.e. the inrush

current value is the same as the nominal.

The Foundation fieldbus wiring guide (AG -140) provides examples of how to calculate the voltage at

each point.

Fig 4.2: Calculating the Voltage Drop

Page 25

IEC 61158 Data Highway

Publication PUB089-005-00_0618 25 of 116

Example of voltage drop calculation:

Assume the cable is Type A (24 Ohm per km per conductor), the resistance of each 1000 metre pair

is 24 x 2 = 48 Ohms per km.

The current drawn by each node A1 to A6 is 20 mA.

Voltage drop Power supply to A1 = current x resistance

= (6 x 0.020) x (0.8 x 48) = 4.6 volts

Voltage drop A1 to A2 = (5 x 0.020) x (0.2 x 48) = 0.96 volts

Voltage drop A2 to A3 = (4 x 0.020) x (0.2 x 48) = 0.768 volts

Voltage drop A3 to A4 = (3 x 0.020) x (0.2 x 48) = 0.576volts

Voltage drop A4 to A5 = (2 x 0.020) x (0.2 x 48) = 0.384volts

Voltage drop A5 to A6 = (1 x 0.020) x (0.2 x 48) = 0.192volts

Total system volt drop = 4.6 + 0.96 + 0.768 + 0.576 + 0.384 + 0.192 = 7.48 volts

If the power supply is a 24 V unit, then the voltage at actuator A6 will be (24 – 7.48) = 16.52 volts

which is within the specified limits.

Whilst we have shown the power supply at one end of the segment, they can be fitted to the middle of

the network. This would reduce the voltage drop.

Fig 4.3: Voltage Drop Example

Page 26

Foundation Fieldbus CP Option Card Technical Manual

26 of 116 Publication PUB089-005-00_0618

4.3 Termination network

Each highway must be terminated correctly at the two ends of the data highway. The terminator

comprises at least one resistor and capacitor in series and they provide a characteristic impedance of

100 Ohm at 39 kHz. They need not be placed on the absolute ends of the highway but should be on

the ends of the main trunk section. They are usually incorporated inside the field junction box.

There are no highway termination facilities inside the actuator itself.

Page 27

Actuator Input Output Signals

Publication PUB089-005-00_0618 27 of 116

5 THE ACTUATOR INPUT AND OUTPUT SIGNALS

The FF CP card provides feedback data about its status and that of the actuator to the Foundation

highway. This data is contained in the Transducer function block and is fully listed in the section on

Function Blocks. The actuator is normally controlled by signals from the Foundation highway

connecting to the Output blocks and the Transducer block. There are local controls on the actuator

itself and there is the possibility to wire in direct contacts to control the movement. This section

explains the primary data available and the meaning of the signals generated by the actuator.

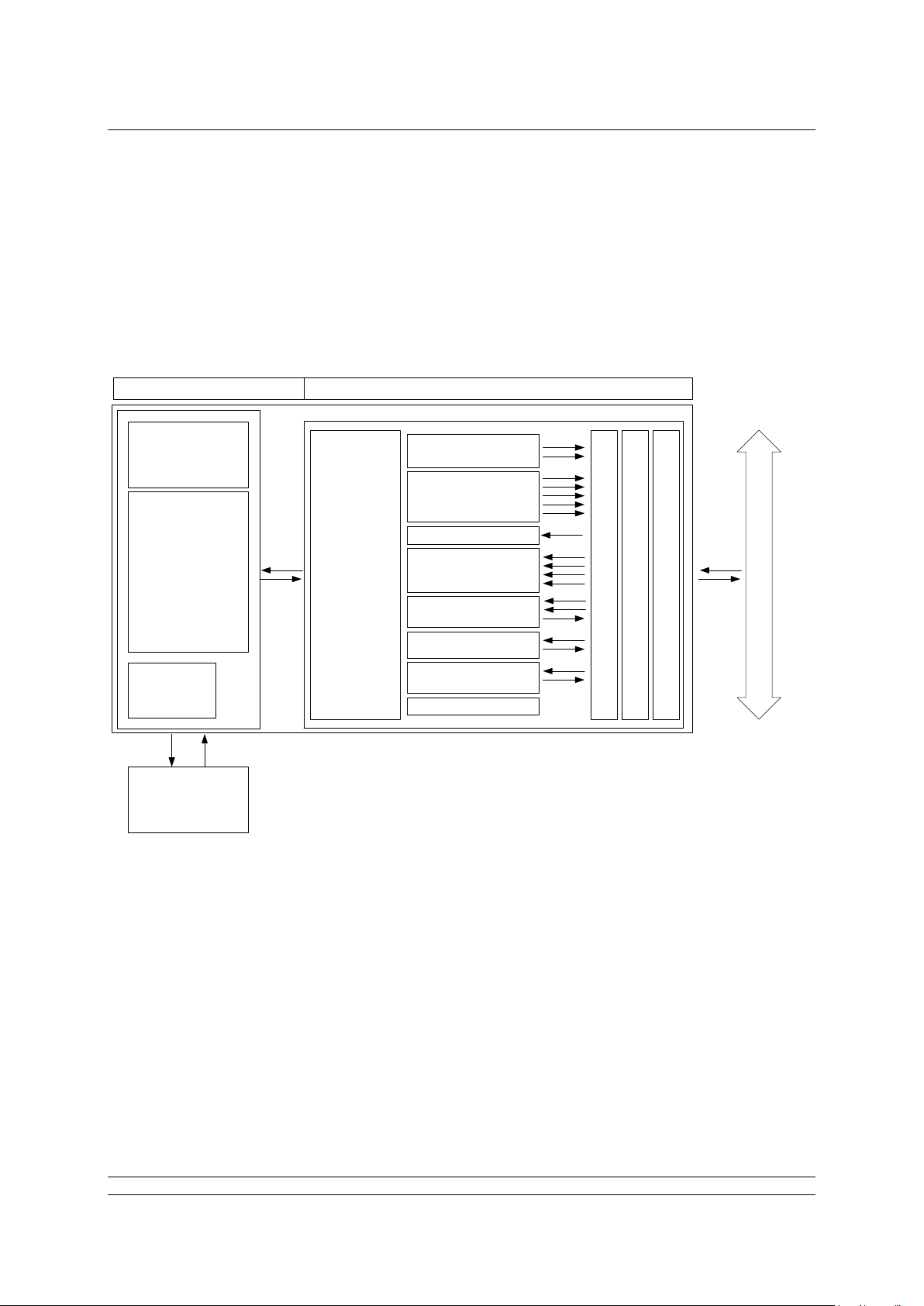

Actuator FF CP card

Motor &

Starter

Controls

Actuator

Control PCB

Local

Controls

Hard-wired

Control Inputs

& Outputs

Actuator

Interface

2 x AI

5 x DI

4 x DO

1 x PID

1 x CS

1 x Transducer

1 x Resource

Fieldbus Message Specification

Fieldbus Access Sublayer

Data Link Layer

1 x AO

FF H1 Data Highway

Input signals are those returned by the actuator to the network about the status of the actuator and

valve whilst output signals are those used to command the actuator to move or operate its internal

relays. An actuator control signal such as a command to open is an output, whilst a reported status

such as open limit switch reached is a feedback input.

Fig 5.1: Actuator and FF CP Card Block Diagram

Page 28

Foundation Fieldbus CP Option Card Technical Manual

28 of 116 Publication PUB089-005-00_0618

5.1 Controls

The FF CP card can be used to control the actuator and position the valve. The valve may be moved

fully closed, fully open or to an intermediate position. Additionally, the actuator can make the valve

adopt an Emergency Shut Down position and in some actuators perform a partial stroke test. Most

actuator types can be prevented from moving by the presence of an Interlocking signal from another

device on the plant. The actuator may also be operated from its local controls or by hard-wired direct

contact inputs. Note that to do this the Auxiliary Mask must be correctly set.

As well as controlling the actuator the FF CP can also be used to operate 4 discrete output relays

when the actuator is fitted with a relay card, assuming the DO block itself isn’t in IMAN, LO or OOS.

The control commands have three potential sources:

Foundation Fieldbus generated commands

Actuator Local Controls

Direct Hard-wired input controls

The full list of commands is shown in the table. The actuator types show whether the command is

applicable to that actuator type.

Command

IQ3, IQT3

& SI3

CVA &

CMA

CK

K

Foundation Network

Open

✓ ✓ ✓

✓

Close

✓ ✓ ✓

✓

Stop

✓ ✓ ✓

✓

Emergency Shut Down

✓ ✓ ✓

✓

Analogue Position Demand

✓ ✓ ✓

✓

Partial Stroke

✓ X ✓

X

Relay 1 output

✓

X

✓

X

Relay 2 output

✓

X

✓

X

Relay 3 output

✓

X

✓

X

Relay 4 output

✓

X

✓

X Local Actuator Controls

Open

✓ X ✓

✓

Close

✓ X ✓

✓

Stop

✓ X ✓

✓

Direct Hard-Wired Inputs

Open

✓ X ✓

✓

Close

✓ X ✓

✓

Stop/Maintain

✓ X ✓

✓

Emergency Shut Down / Net disable

✓ X ✓

✓

Open Interlock (active prevents opening)

✓ X ✓

✓

Close Interlock (active prevents closing)

✓ X ✓

✓

Note: – Requires an extra relay board to be fitted.

Fig 5.2: Available command options

Page 29

Actuator Input Output Signals

Publication PUB089-005-00_0618 29 of 116

The FF commands operate on the Transducer block through Digital Output (DO) blocks that are

already connected in the default configuration. The network commands will operate the actuator

provided:–

• Local/Local Stop/Remote selector is in ‘Remote’ (or “Run” in a CVA).

• Foundation commands are not inhibited by the ‘Inhibit/HW_DI-4’ input parameter setting

and HW_DI-4 condition.

• No interlock is active.

• There is no active hard-wired control input or FF control input present.

• No alarm condition prevents the actuator from moving.

• The Transducer and Resource blocks are in AUTO.

Open A digital command to cause the actuator to open to the fully open

position as indicated by the Open limit switch. Under correct operation

the actuator stops either when the open limit switch is reached, when

the torque exceeds the value set and the open limit switch has been

reached, or a new command is sent over the network.

Close A digital command to cause the actuator to close to the fully closed

position as indicated by the Close limit switch. Under correct operation

the actuator stops either when the close limit switch is reached, when

the torque exceeds the value set and the close limit switch has been

reached, or a new command is sent over the network.

Stop With no other command present, this digital command causes an

actuator motor that is running to stop.

Emergency Shut Down

A digital command that causes the actuator to drive to its Emergency

position. There are settings within the actuator to determine if this is a

closed, open or stay-put action.

Analogue Position Demand

This function is only available over the Foundation network. To initiate

Analogue Position Control this bit must be set to 1 and all other

actuator control bits must be set to 0. This enables the AO block to

function. The actuator will then move to within the deadband of

whatever position value has been set in the AO block output

parameter (range 0-100%, resolution 0.1%).

Provided limited range positioning is not invoked, the values 0% and

100% written to the AO output parameter produce a special case

output where the command is revised so as to fully close the valve to

its tight shut-off position (0%) and to fully open the valve (100%).

Note:

Many multi-turn actuators are set to open until the open limit switch is reached and close until

the closing on torque switch trips, but it is dependent on the type of valve. The quarter turn

actuators normally operate 90-degree valves, use stop-bolts on the actuator or gearbox, and

stop when these are reached. The control room indication is always taken from the end of travel

limit switch settings

Page 30

Foundation Fieldbus CP Option Card Technical Manual

30 of 116 Publication PUB089-005-00_0618

Note:

The following functions are not an option with all actuators – see Fig: 5.2.

Partial Stroke The actuator will move the valve to an intermediate position and back

to the start position provided it is at the correct end of travel position

when the command is issued. The end to start from and the amount of

travel are selected by parameters in the transducer block.

Relay Output 1 to 4

These 4 commands are used to energise and de-energise the internal

relays on the additional relay board (if fitted). (These outputs are

referred to as S5-S8 in the standard actuator documentation when

there is no FF CP card in the actuator). The resulting outputs can be

used for operating other equipment such as a pump or indication light.

The actuator itself is not able to control these relays directly from the

main board when the FF CP card is fitted; they may only be controlled

by the DO blocks. They will maintain their last state if power is

removed from the actuator. On restoration of power, the relays will be

reset to their de-energised condition.

Hard-Wired Open and Close

These commands operate the actuator in the same way as the open

and close commands sent over the Foundation highway, assuming

the auxiliary input mask has been set correctly.

Hard-Wired Stop The hard-wired stop input acts as a change of state input. If the

actuator is moving, opening the Stop input will stop the actuator. If the

Stop input is already open and a Foundation DO command is sent to

the actuator, the Foundation command will be initiated. To stop the

actuator the hard-wired input must be closed and opened again.

Hard-wired ESD (Network Disable)

The hard-wired ESD may be set to causes the actuator to drive to its

Emergency position. Alternatively, the input can be used to disable

Foundation network control. The function of the input is determined by

a parameter in the transducer block.

Page 31

Actuator Input Output Signals

Publication PUB089-005-00_0618 31 of 116

5.1.1 Controls priority

Since there can be several potential sources for control inputs the actuator and FF CP card assigns a

priority for those occasions when two or more commands are applied simultaneously.

Local controls go direct to the main board and override any Foundation controls and any hard-wired

controls except hard-wired ESD. An actuator that has Local selected cannot be controlled over the

Foundation network.

In addition, the remote control hard-wired inputs can be used as discrete input signals, to report the

status of other devices or as control inputs. The associated Auxiliary Input Mask parameter must be

set to select the required function. When selected for control, the hard-wired inputs take priority over

the Foundation controls, but are subordinate to the local controls (except for ESD). If there is a

Foundation command still present when a Local or Hard-wired command is removed, the Foundation

command will re-assert itself.

In the case of the hard-wired input for ESD, this can be configured either as an ESD/HW_DI-4 signal

or as a ‘Foundation Command Inhibit’ to prevent network control signals from moving the actuator.

High Priority Low Priority

Local Stop Local Close Hard-Wired Close

Foundation Close

Local Open Hard-Wired Open Foundation Open

Hard-Wired ESD Hard-Wired Stop Foundation Stop

Foundation ESDFoundation Position

Foundation Part Stroke

Mechanically interlocked to prevent both at the same time.

The actuator can be set so that Local Stop has a higher priority than ESD.

Only one Foundation command should be applied at a time.

If a Foundation command is applied whilst Hard-Wired Stop is present, stop is cancelled.

Fig 5.3: Controls Priorities

Page 32

Foundation Fieldbus CP Option Card Technical Manual

32 of 116 Publication PUB089-005-00_0618

5.1.2 Foundation control using DO blocks only

Discrete action control is achieved using the DO blocks in the FF CP card. Each DO block output has

a value between 0 and 255. If the host DCS system uses its ‘Boolean Fan In’ function, most of the

discrete controls can be achieved using one DO block – see table below. The selected block is put in

service and the appropriate value sent to its output. Only one value is permitted at a time in each

block. If Boolean functions are not available, then several blocks may need to be used to achieve the

desired control actions.

DO Block Output Actions

Block No.

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

DO 1

Close

Open

Stop

ESD

Position

RLY 1

RLY 2

RLY 3

DO 2

Open

Close

Stop

ESD

PST

RLY 1

RLY 2

RLY 3

DO 3

Stop

Close

Open

Position

RLY 1

RLY 2

RLY 3

RLY 4

DO 4 Mode 0

Position

Close

Open

ESD

RLY 1

RLY 2

RLY 3

RLY 4

DO 4 Mode 1

ESD

Close

Open

Position

RLY 1

RLY 2

RLY 3

RLY 4

DO 4 Mode 2

RLY 1

Close

Open

ESD

Position

RLY 2

RLY 3

RLY 4

DO 4 Mode 3

PST

Close

Open

ESD

RLY 1

RLY 2

RLY 3

RLY 4

DO 4 Mode 4

Analogue block control (AO) only

DO 4 Mode 5

0 = Close, 1 = Open, any other value Stop

DO 4 Mode 6

Position

PST

Close

Open

Stop

ESD

RLY 1

RLY 2

Fig 5.4: DO Block Options

Select Multiple/Single bit control in the Transducer block.

Enable the appropriate DO blocks.

If DO 4 is being used, set its mode in the Transducer block.

The Transducer block includes parameters to select single or multiple bit support.

- If multiple bit support is available (using Boolean Fan In) only one block may be used.

- If single bit control is selected, all four blocks can be used but each block uses Bit 0 only.

The action of DO 4 is selected using the mode control parameter in the Transducer block.

5.1.3 Foundation control using the AO block only

In order to place the FF CP card into position control mode, so that the AO block output values

determine the actuator position, it is necessary to set the Control Mode in the Transducer block to

Mode 4. The actuator will then use the value of the AO block output as the setpoint for the internal

positioner and the actuator will move to the setpoint (subject to the status of the Local and Hard-wired

controls, the Interlocks and the actuator deadband and hysteresis settings). Output block DO 4 does

not need to be added to the schedule and can remain set Out of Service (OOS).

Set the Mode Control in the Transducer block to Mode 4.

Set the positioner parameters (hysteresis, deadband, motion inhibit time etc.).

Page 33

Actuator Input Output Signals

Publication PUB089-005-00_0618 33 of 116

If the AO output is set to 0% and limited range positioning is not being used (selected via the

Transducer block), the actuator will operate as though a ‘close’ command had been sent. Similarly, if

the AO output is set to 100% under these conditions, the actuator will interpret the instruction as an

‘open’ command.

Note that when limited range positioning is used and the actuator is in the range from fully closed to

the 0% position, an AO command of 0% will not be acted upon. Likewise, if the actuator is in the

range from fully open to the 100% position, an AO command of 100% will not be acted upon. See

section 6.2.4 for more information on limited range positioning.

5.1.4 Foundation control using both DO and AO blocks

With mixed position control using the AO and discrete (open/stop/close/ESD) control using the DO

blocks, the control settings must be carefully observed. Discrete actions will take priority over the

Position requests.

The single/multiple bit control option for the discrete controls has to be determined. When Boolean

Fan In is available, multiple bit control is set and a single DO block is used for the open/stop/close

discrete control actions. The DO block chosen must also include a condition to select Position Control.

With single bit control each discrete action requires a DO block to be enabled and the Position option

is in DO 4 which must be set to Mode 0.

When the AO value is to be adopted for the valve position, the control scheme must select the DO

block to be in its Position value. With multiple blocks DO 4 must be set to ‘1’, all the others being ‘0’.

As soon as the discrete control changes to ‘Position’, the AO output value becomes the desired

actuator position and the position controller will move the valve.

DO control values of Open/Stop/Close/ESD have priority over the AO value.

The DO value must equal ‘Position Control’ for the AO value to become active.

The position controller will be subject to the considerations mentioned in 5.1.3 with regard to 0% and

100% values.

Page 34

Foundation Fieldbus CP Option Card Technical Manual

34 of 116 Publication PUB089-005-00_0618

5.1.5 The ‘S’ contacts (RLY 1 to RLY 4) controlled by the DO blocks

Note:

This option is not available on all actuator types, see fig 5.2.

The actuator has four ‘S’ contact outputs that may be configured to report the status of the actuator

with signals such as Open Limit, Closed Limit etc. These are identified as S1 to S4.

In addition, an optional additional relay board can be fitted with four more relays. The status of these

relays is then adjusted by Foundation DO block commands on outputs Relay 1 to Relay 4. Setting the

appropriate DO block output to the value corresponding to the relay will energise the relay whilst the

output from the DO is present. Setting a different value will de-energise the relay. Note that these

relays are latching and, if energised, will not change state when the actuator power is removed. On

restoration of power the relays will be reset to their de-energised condition.

5.1.6 Foundation network control disable feature

Note:

This option is not available on all actuator types, see fig 5.2.

It is possible to set the ESD/HW_DI-4 input so that the actuator ignores open, stop, close, ESD, PST

and position control signals sent over the Foundation network. If the HW_DI-4 ESD / Net Disable

parameter in the Transducer block is set to ‘1’ then when the ESD input connection is detected as

being logic 1, Foundation control is not allowed. This feature is dependent of the Auxiliary mask

setting and can be configured as an NO or NC input. When the HW_DI-4 ESD / Net Disable parameter

is set to ‘1’, no hard-wired ESD will be available.

Fig 5.5: Actuator relay outputs

Actuator

Controller

PCB

S1 – S4

S5 – S8

Relays 1 - 4

FF CP

card

Relay PCB

Page 35

Actuator Input Output Signals

Publication PUB089-005-00_0618 35 of 116

5.2 Discrete Input status feedback

The FF CP card has DI (Discrete Input) function blocks that may be used to report the valve and

actuator status over the network. The conventional contact indications are also available from the

actuator limit switches and indication contacts.

Each DI block output has a value between 0 and 255. If the host DCS system uses its ‘Boolean Fan

Out’ function, the returned value may be decoded into 8 individual bits, where each bit represents a

single piece of feedback data. If the DCS does not have this facility, then the state of the first bit in

each DI will be represented by 0 = not true and 1 = true. The complete list of DIs and the function of

the individual bits is indicated in section 5.2.1. The table below indicates which signals are available

from each actuator type.

DI Function:

Block Number/Bit Number

Status Feedback

IQ3,

IQT3

& SI3

CVA

&

CMA

CK

K

1 / 0

2 / 1 Close Limit

✓ ✓ ✓

✓

1 / 1

2 / 0 Open Limit

✓ ✓ ✓

✓

1 / 2 5 / 0

Actuator Moving

✓ ✓ ✓

✓

1 / 3

2 / 3 Running Closed

✓ ✓ ✓

✓

1 / 4

2 / 2 Running Open

✓ ✓ ✓

✓

1 / 5

3 / 0

Remote selected

✓ ✓ ✓

✓

1 / 6

3 / 1

Local Stop selected

✓ ✓ ✓

✓

1 / 7

3 / 2

Local selected

✓ ✓ ✓

✓

2 / 4 Not in Remote

✓ ✓ ✓

✓

2 / 5

4 / 0

General Alarm

✓ ✓ ✓

✓

2 / 6 Valve Obstructed

✓ ✓ ✓

✓

2 / 7 Valve Jammed

✓ ✓ ✓

✓

3 / 3

Moving Inhibited

✓ ✓ ✓

✓

3 / 4

5 / 5

Open Interlock active input

✓ ✓ ✓

✓

3 / 5

5 / 6

Close Interlock active input

3 / 6

Position Control Enabled

✓ ✓ ✓

✓

3 / 7

Slow Mode

4 /1 Thermostat Tripped

✓ ✓ ✓

✓

4 / 2

Monitor Relay

✓ ✓ ✓

✓

4 / 3

Valve Obstructed/Jammed

✓ ✓ ✓

✓

4 / 4

Part Stroke Error

✓ ✓ ✓

✓

4 / 5

Valve Moving by Hand

✓ ✓ ✓

✓

4 / 6

Battery Low

✓

N/A

N/A

N/A 4 /7 Watchdog Recovery

✓ ✓ ✓

✓

5 / 1

Hard-Wired HW_DI–1

✓

N/A

N/A

N/A

5 / 2

Hard-Wired HW_DI –2

✓

N/A

N/A

N/A

5 / 3

Hard-Wired HW_DI –3

✓

N/A

N/A

N/A

5 / 4

Hard-Wired HW_DI –4

✓

N/A

N/A

N/A

5 / 7

Partial Stroke in Progress

✓ ✓ ✓

✓

Notes over page:

- This bit is reported when within the slow mode band, but does not affect the actuator. Slow mode

is not an option in some of the actuators.

- This bit indicates the state of the Hardwired Partial stroke input

Page 36

Foundation Fieldbus CP Option Card Technical Manual

36 of 116 Publication PUB089-005-00_0618

5.2.1 Discrete Inputs

Close Limit This data bit indicates that the actuator has reached the closed

position. The limit switch should be set slightly within the actual valve

stroke to allow for torque seating or overshoot on closing without

damaging the valve. The data bit will remain true (1) even if the

position is passed through or exceeded.

Open Limit This data bit indicates that the actuator has reached the open position.

The limit switch should be set slightly within the actual valve stroke to

allow for torque seating or overshoot on opening without damaging

the valve. The data bit will remain true (1) even if the position is

passed through or exceeded.

Actuator Moving Whenever the actuator position is changing due to the motor running

or in the case of the IQ or IQT if the output drive is moving, this bit will

be set true (1).

Running Closed Whenever the actuator motor contactor used to drive the actuator in

the closing direction is energised this bit will be true (1).

Running Open Whenever the actuator motor contactor used to drive the actuator in

the opening direction is energised this bit will be true (1).

Remote Selected This bit is true (1) when the actuator three-position Remote/Local

Stop/Local selector is in the Remote position. The selector must be in

this position for Foundation control to be permitted.

Local Stop The actuator three-position selector passes from Local to Remote or

Remote to Local through the Local Stop position. The switch can also

be placed in Local Stop. When the switch is in the Local Stop position

this bit will be true (1). Remote control of the actuator is not possible

when the selector is in this position.

Local Selected This bit is true (1) when the actuator three-position Remote/Local

Stop/Local selector is in the Local position. Remote control of the

actuator is not possible when the selector is in this position.

Not In Remote This bit is true (1) when the actuator three-position Remote/Local

Stop/Local selector is not in the Remote position. The selector will be

in either the Local or Local Stop position. Remote control of the

actuator is not possible when the selector is in this position.

Page 37

Actuator Input Output Signals

Publication PUB089-005-00_0618 37 of 116

General Alarm If any of the following conditions are true this bit will be true (1):–

Thermostat tripped

Monitor Relay

Valve Obstructed

Valve Jammed

Manual Movement

Valve Obstructed This bit will be true (1) if the actuator stops in mid-travel when not

expected to do so after receiving a command to move. If the actuator

torque exceeds the trip value set during commissioning, then the

motor will stop and motion will cease. The reason for the actuator

stopping will be the high torque due to an obstruction and not a ‘Stop’

signal or reaching the desired setpoint position.

The bit will remain true (1) until the actuator position changes by 2%

or more.

Valve Jammed This bit will be true (1) if the actuator is stationary at the end of travel

and fails to move away from the seat of the valve when a network

command requests it to do so. The actuator will trip on excessive

torque due to the valve being jammed in the seat. The FF CP card

fails to see movement and reports this status after the time set in the

associated Transducer block parameter during set-up.

The bit will remain true (1) until the actuator position changes by 2%

or more.

Moving Inhibited This bit will be true (1) when the Motion Inhibit Timer is active or the

Interrupter Timer is active, or both are active.

The Motion Inhibit Timer is used in position control to prevent the

actuator from exceeding its prescribed number of starts per hour, or to

reduce the effects of hunting during closed-loop control.

The Interrupter Timer can be used over part or the entire actuator

stroke to slow down the effective speed of valve travel.

When under network control, the control signal does not need to be

re-applied when this bit is true, as the control action will continue once

the time has elapsed.

Note: Attempting to restart the actuator to move towards the obstruction (even if the

obstruction no longer exists) is not possible, the actuator will not restart. The actuator

must be electrically reversed away from the obstruction before attempting to continue in

the original direction.

Note: Attempting to restart the actuator to move out of the seated position is not possible. The

actuator must be reversed before it will run in the same direction again. The jammed

seat must first be released manually before electrical control is attempted. The problem

may be overcome by adjusting the actuator torque setting, which is designed to provide

extra power on leaving the seated position.

Page 38

Foundation Fieldbus CP Option Card Technical Manual

38 of 116 Publication PUB089-005-00_0618

Open Interlock The input contact to the Open Interlock is monitored. Whenever the

input contact is closed this bit will be true (1). If the actuator is not

using the interlock function, then this input can be used as a digital

status feedback for a plant signal not associated with the actuator. If

the interlock circuit is being used, then permission must be granted

before the actuator can be opened. The presence of this bit will

indicate that opening is permitted and permission is granted.

Close Interlock The input contact to the Close Interlock is monitored. Whenever the

input contact is closed this bit will be true (1). If the actuator is not

using the interlock function then this input can be used as a digital

status feedback for a plant signal not associated with the actuator. If

the interlock circuit is being used, then permission must be granted

before the actuator can be closed. The presence of this bit will

indicate that closing is permitted and permission is granted.

Position Control Enabled

This bit will be true (1) when a Position command is being actioned.

This data can be used to indicate that positioning mode has control of

the actuator.

Thermostat If the temperature of the motor windings rises above the thermostat

trip value, the thermostat contact will open and this signal will be

present (1). There are no adjustments for the temperature at which

the thermostat trip operates. The motor will be stopped if the

thermostat trips. Only once the motor (or transformer) has cooled

down and the thermostat has reset itself can a new Remote, Host or

Local command to move the actuator be carried out. A setting on the

actuator main board allows the ESD command to override the

thermostat. The bit will remain set at logic 1 until the thermostat resets

itself.

Monitor Relay This signal is true (1) when actuator remote control is not available.

The actuator Monitor Relay status is a composite signal for several

alarms. This signal will be set true if the actuator selector is in Local or

Local Stop (not in Remote) or if the thermostat trips.

Note on an IQ3/IQT3 actuator the Monitor Relay can be set to

trigger on “Available” or “Alarm”. When set to Alarm, Local or

Local Stop won’t cause a monitor Relay Alarm – see section 2.2

of PUB002-040: http://www.rotork.com/master-popup/8953/

The mains supply is always monitored and if one of the three phases

is lost, this bit is set. If the actuator is operated from a single phase

supply and this is lost, then communications with the actuator will also

be lost. Where a 3-phase supply is used, if the phase associated with

the control circuits is lost then communications with the actuator will

be lost.

Page 39

Actuator Input Output Signals

Publication PUB089-005-00_0618 39 of 116

Valve Obstructed/Jammed

This bit is a combination of the Valve Obstructed and the Valve

Jammed bits. If either is true this bit will be true (1).

Valve Moving by Hand

The manual movement of the valve is reported as true (1) if the

actuator is moved by the handwheel away from the last position. The

percentage of travel required to trip the indication is set in the

associated parameter in the Transducer block during set-up.