Page 1

IQT Range

Installation and

Maintenance Instructions

Publication number E175E

Date of issue 07/04

Please ensure that this publication is thoroughly read and understood

Addendum

For the latest information on

commissioning this actuator see

the addendum starting on p78.

Click HERE to go to addendum.

Page 2

The Rotork Setting Tool allows actuator control, indication and protection functions

to be configured to suit site requirements. It is essential that all the actuator

settings are checked for compatibility with the process and control system

requirements before the actuator is put into service. Please read this publication.

When Rotork personnel or nominated agents are contracted to carry out site

commissioning and/or acceptance, documentation of commissioned actuator

configuration can be made available for customer records.

Page 3

This manual covers IQT range actuators:

* IQT - Operation of isolating/regulating 1/4 turn valves.

* IQTM - Operation of modulating 1/4 turn valves.

* IQTF - Operation of part-turn and slow speed multi-turn

valves.

It provides instruction on:

* Manual and electrical (local and remote) operation.

* Preparation and installation of the actuator onto the

valve.

* Commissioning and adjustment of the

Primary Settings for correct valve operation.

* Commissioning and adjustment of the Secondary

Settings to suit site-specific control and indication

requirements.

* Maintenance – Troubleshooting.

* Sales and Service.

Refer to Publication E185E for repair, overhaul and

spare part instructions.

THE ROTORK IQT RANGE – THE FIRST 1/4TURN VALVE ACTUATOR

THAT YOU CAN COMMISSION AND INTERROGATE WITHOUT

REMOVING ELECTRICAL COVERS.

Using the supplied infra-red Setting Tool to access the actuator set up

procedures, “point and shoot” setting of torque levels, position limits and

all other control and indication functions can be made safely, quickly and

conveniently, even in hazardous locations. The IQT allows commissioning

and adjustment to be carried out with the main power supply to the

actuator switched on or off.

Standard diagnostics access information about the control system, valve

and actuator status in the form of display icons and help screens.

Instantaneous valve torque and position can be monitored on the actuator

with a single key press of the Setting Tool.

The on board Datalogger captures operational and valve torque data

enabling informed maintenance choices to be made. IQ Insight software

for PC allows the Datalogger to be interrogated, as well as the complete

actuator set up to be configured and recorded.

The actuator containing the Setting Tool will be identified with a yellow

label on the terminal cover.

Visit our web site at www.rotork.com for more information on the IQT and

other Rotork actuator ranges.

Page 4

Page 5

Page

1

1 Health and Safety 2

3

2 Storage 3

3 Operating your IQ Actuator 3

3.1 Operating by Hand 3

3.2 Operating Electrically 3

3.3 Display – 4

Local Indication

3.4 Display – Alarm Indication 5

4 Preparing Drive Bush 7

4.1 Bases F05 to F07 7

and FA05 to FA07

4.2 Bases F10 to F14 7

and FA10 to FA14

4.3 Machining the Drive Bush 7

4.4 Fitting the Drive Bush 7

5 Mounting the Actuator 8

5.1 IQT Actuators 8

5.2 IQTM Actuators 8

5.3 IQTF Actuators 8

5.4 Lifting the Actuator 8

5.5 Securing Actuator to Valve 8

5.6 Stop Bolts 9

6 Cable Connections 10

6.1 Earth/Ground Connections 10

6.2 Removing Terminal Cover 10

6.3 Cable Entry 10

6.4 Connecting to Terminals 10

6.5 Replacing Terminal Cover 10

7 Commissioning 11

7.1 The Setting Procedure 11

7.2 The Setting Tool 12

7.3 Entering the Actuator 13

Setting Procedure

7.4 Setting Mode – Password 13

7.5 New Password 13

7.6 Checking Mode 13

7.7 Procedure Branch – 14

Crossroad

7.8 The Actuator Display – 14

Setting/Checking Mode

7.9 Returning to Valve 14

Position Display

8 Commissioning –

Primary Functions 15

Primary Functions Contents 16

9 Commissioning –

Secondary Functions

25

Secondary Functions Contents 27

Default Options 60

10 Maintenance, Monitoring

and Troubleshooting

62

10.1 Help Screens 64

10.2 IrDA Diagnostics & Configuration 69

11 Weights and Measures 71

Binary, Hexadecimal and Decimal 72

Conversion Table

12 IQ Approvals 73

CONTENTS

Page Page

Page 6

This manual is produced to enable a

competent user to install, operate,

adjust and inspect Rotork IQT range

valve actuators.

The electrical installation, maintenance

and use of these actuators should be

carried out in accordance with the

National Legislation and Statutory

Provisions relating to the safe use of

this equipment, applicable to the site of

installation.

For the UK: Electricity at Work

Regulations 1989 and the guidance

given in the applicable edition of the

“IEE Wiring Regulations’’ should be

applied. Also the user should be fully

aware of his duties under the Health

and Safety Act 1974.

For the USA: NFPA70, National Electrical

Code ® is applicable.

The mechanical installation should be

carried out as outlined in the manual

and also in accordance with relevant

standards such as British Standard

Codes of Practice. If the actuator has

nameplates indicating that it is suitable

for installation in Hazardous Gas Areas

then the actuator is suitable for use in

Zone 1 and Zone 2 (or Div 1 and Div 2)

explosive atmospheres only. It should

not be installed in atmospheres where

gases are present with an ignition

temperature less than 135°C, unless

suitability for lower ignition

temperatures has been indicated on the

actuator nameplate.

Any test instruments applied to the

actuator should be of equivalent

certification. The electrical installation,

maintenance and the use of the

actuator should be carried out in

accordance with the code of practice

relevant for that particular Hazardous

Gas Area certification.

No inspection or repair should be

undertaken unless it conforms to the

specific Hazardous Gas Area

certification requirements. Under no

circumstances should any modification

or alteration be carried out on the

actuator as this could invalidate the

conditions under which its certification

was granted.

Access to live electrical conductors is

forbidden in the hazardous area unless

this is done under a special permit to

work, otherwise all power should be

isolated and the actuator moved to a

non-hazardous area for repair or

attention.

Only persons competent by virtue of

their training or experience should be

allowed to install, maintain and repair

Rotork actuators. Work undertaken

must be carried out in accordance with

instructions in the manual. The user

and those persons working on this

equipment should be familiar with their

responsibilities under any statutory

provisions relating to the Health and

Safety of their workplace.

Thermostat Bypass

If the actuator is configured to bypass

the thermostat, when using the ESD

function, the hazardous area

certification will be invalidated.

Control and Indication

Where the actuator build allows remote

control and indication supplies higher

than 150V a.c. but below 300V a.c.

(refer to actuator wiring diagram) the

remote control and indication supplies

must be derived from a supply which is

designated as installation category

(overvoltage category) ll as defined in

BSEN 61010 (Safety Requirements For

Electrical Equipment for measurement,

control and laboratory use).

Enclosure Materials

IQT actuators are manufactured from

aluminium alloy with stainless steel

fasteners.

The user must ensure that the

operating environment and any

materials surrounding the actuator

cannot lead to a reduction in the safe

use of, or the protection afforded by,

the actuator. Where appropriate the

user must ensure the actuator is

suitably protected against it’s operating

environment.

Should further information and

guidance relating to the safe use of the

Rotork IQT range of actuators be

required, it will be provided on request.

WARNING: Operating by Hand

With respect to handwheel operation

of Rotork electric actuators, see

warning on p3.

2

Health and Safety

1

Page 7

If your actuator cannot be installed

immediately store it in a dry place until

you are ready to connect incoming

cables.

If the actuator has to be installed but

cannot be cabled it is recommended

that the plastic transit cable entry plugs

are replaced with metal plugs which are

sealed with PTFE tape.

The Rotork double-sealed construction

will preserve internal electrical

components perfectly if left

undisturbed.

It is not necessary to remove any

electrical compartment covers in order

to commission the IQT actuator.

Rotork cannot accept responsibility for

deterioration caused on-site once the

covers are removed.

Every Rotork actuator has been fully

tested before leaving the factory to give

years of trouble free operation,

providing it is correctly commissioned,

installed and sealed.

3.1 Operating by Hand

WARNING

With respect to handwheel

operation of Rotork electric

actuators, under no circumstances

should any additional lever

device such as a wheel-key or

wrench be applied to the

handwheel in order to develop

more force when closing or

opening the valve as this may

cause damage to the valve and/or

actuator or may cause the valve

to become stuck in the

seated/backseated position.

Fig. 3

To engage handwheel drive, turn the

Hand/Auto lever clockwise whilst

turning the handwheel, see Fig 3. The

lever can now be released upon which

it will return to its original position. The

handwheel will remain engaged until

the actuator is operated electrically

when it will automatically disengage

and return to motor drive. If required

the Hand/Auto lever can be locked in

either position using a padlock with a

6.5mm hasp.

3.2 Operating Electrically

Check that power supply voltage agrees

with that stamped on the actuator

nameplate. Switch on power supply. It

is not necessary to check phase

rotation.

Do not operate the actuator

electrically without first checking,

using the infra-red Setting Tool,

that at least the Primary Settings

have been made

(refer to Section 8

page 15).

Selecting Local/Stop/Remote

Operation

The red selector enables either Local or

Remote control, lockable in each position

using a padlock with a 6.5mm hasp.

When the selector is locked in the Local

or Remote positions the Stop facility is

still available. The selector can also be

locked in the Stop position to prevent

electrical operation by Local or Remote

control.

Fig. 3.1

Local Control

With the red selector positioned at

Local (anti-clockwise) the adjacent black

knob can be turned to select Open or

Close. To Stop, turn red knob

clockwise.

Remote Control

Rotate the red selector to the Remote

position (clockwise), this gives remote

3

3

Storage

2

Operating your

IQ Actuator

Page 8

control only for Open and Close but

local Stop can still be used by turning

the red knob anti-clockwise.

3.3 Display–Local Indication

Fig. 3.2 The Actuator Display

The display consists of:

1. Red – position indication lamp

2. Yellow – position indication lamp

3. Green – position indication lamp

4. Liquid crystal display screen (LCD)

5. Infra-red sensors

6. Infra-red signal confirmation

indicator (Red)

The liquid crystal display screen has 2

modes of position indication:

1. Valve position – power on

2. Valve position – power off

On power up the actuator’s liquid

crystal display screen is back-lit with a

“soft amber” light and one of the

indicator lamps will be on, dependent

on position. The display screen will

show percentage open or an end of

travel symbol. (See Figs 3.3, 3.4 and

3.5)

As standard, red lamp signifies valve

open, yellow intermediate, and green

lamp signifies valve closed. Open and

closed colour functions can be reversed

on request.

Open

Red indicator and open symbol

displayed

Fig. 3.3

Mid Travel

Yellow indicator and percentage open

value displayed

Fig. 3.4

Closed

Green indicator and closed symbol

displayed

Fig. 3.5

With the main power supply switched

off, the liquid crystal display screen is

powered by a battery and continues to

display actuator position. However, the

battery does not support screen backlighting, or position indicator lamps.

4

1

4

3

2

6

5

Page 9

3.4 Display–Alarm Indication

The IQT display incorporates valve,

control system, actuator and battery

alarm indication in the form of four

display icons. Located in the top portion

of the display, each icon represents

certain alarm conditions. Standard help

screens are also available to assist in

determining the actuator operational

and alarm status (refer to Help Screens

page 64).

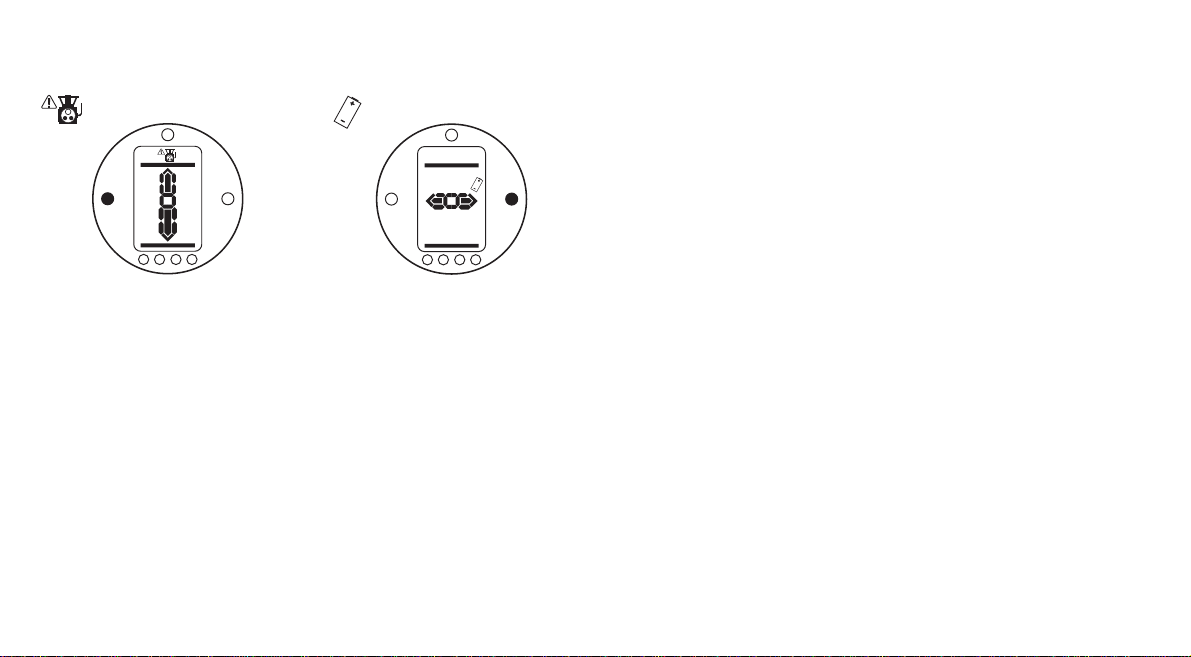

Valve Alarm

Fig. 3.6

The valve alarm icon, Fig 3.6, is

displayed when a valve problem causes

the actuator to “trip-off’’ due to the

configured torque value being

developed (refer to [tC]/[tO] pages

20/21).The possible causes are:

•

Valve tight or obstructed in mid travel.

• Valve stuck or jammed

• Valve process conditions changed

(increase in pressure, flow etc.)

Once the actuator has tripped off on

torque, electrical operation in the same

direction is inhibited. The icon will

remain displayed until movement in the

opposite direction takes place.

The valve alarm icon will not be

displayed when stopping at end of

travel for valves configured to torque

seat or torque back seat at end of

travel (refer to [C2]/[C3] pages 18/19).

Tr y handwheel operation of the valve to

‘‘feel’’ for stiffness (refer to page 3).

Control Alarm

Fig. 3.7

The control system alarm icon, Fig 3.7,

is displayed when the remote control

system maintains an active ESD or

interlock signal (the ESD, interlock

function or conditional control having

been enabled.)

Local and Remote operation will be

inhibited while an active ESD or

interlock signal is present (refer to [A1]

ESD Action page 30, [A8] External

Interlocks page 32 and Conditional

Control [A9] page 32.)

Investigate the operational conditions

of the actuator remote control system.

5

Page 10

Actuator Alarm

Fig. 3.8

The actuator alarm icon, Fig. 3.8, is

displayed when an active actuator

alarm is present.

Electrical operation will be inhibited

while an alarm is present. The possible

causes are:

• Transformer thermostat tripped

• Battery low on power up*

• Power supply fault

*see Battery Alarm

(To identify the specific cause of the

alarm refer to Help Screens).

Battery Alarm

Fig. 3.9

The battery alarm icon, Fig. 3.9, is

displayed when the actuator detects its

battery as being low, discharged or

missing.

If, on power up, the actuator detects a

discharged battery and actuator power

loss inhibit feature [OS] is enabled

(refer to page 58), both battery and

actuator alarm icons (Fig.3.8 and 3.9)

will be displayed. Electrical operation

will be inhibited.

When the battery alarm icon

is displayed, the battery should be

replaced immediately (refer to page 62).

The actuator checks the battery status

at approximately 10 minute intervals.

After replacing a battery the alarm icon

will continue to be displayed until the

next check indicates the battery is

healthy. This may take up to 10

minutes.

6

Page 11

4.1 Bases F05 to F07

and FA05 to FA07

The base adaptor must be removed to

give access to the drive bush. Remove

the four capscrews and base adaptor as

shown in figure 4.

Fig. 4

Clear access to the drive bush is now

available as shown in figure 4. Using

the a 3mm allen key, unscrew the two

capscrews retaining the drive bush and

remove the drive bush from the

actuator.

Fig. 4.1

4.2 Bases F10 to F14

and FA10 to FA14

Removal of the drive bush does not

require the removal of the actuator

base. Using a 3mm allen key, unscrew

the two capscrews retaining the drive

bush.

Capscrews can be used to remove the

drive bush by screwing into the drive

bush as shown in figure 4.2.

Fig. 4.2

The range of IQT drive bushes is shown

in figure 4.3. Please refer to publication

E110E for maximum stem acceptance

details.

Fig. 4.3

4.3 Machining the Drive Bush

Once removed, the drive bush can be

machined to suit the valve stem. Ensure

machined position allows correct

orientation of actuator-to valve flange

and correct direction to close the valve.

4.4 Fitting the Drive Bush

Note: The drive bush can be fitted in

two possible positions, 180º apart. Fit

the drive bush into the centre column

ensuring that the stem orientation,

actuator position and direction of

operation are correct for valve

operation. Secure the drive bush with

the capscrews. For F05, FA05, F07 and

FA07 bases, refit the base adaptor and

secure with the four capscrews.

7

Preparing Drive Bush

4

Page 12

5.1 IQT Actuators

The IQT range of actuators are suitable

for part turn applications requiring up

to 60 starts per hour.

5.2 IQTM Actuators

The IQTM range of actuators are

suitable for modulating control duty of

up to 1200 starts per hour in

accordance with IEC 34-1 to S4 50%.

Commissioning of IQTM range

actuators is identical to the standard

IQT (refer to Sections 7, 8 and 9).

5.3 IQTF Actuators

The IQTF range of actuators are

suitable for part-turn and multi-turn,

non-thrust applications requiring low

speed and low operating turns.

Commissioning of IQTF range actuators

is similar to the standard IQT (refer to

Sections 7, 8 and 9).

5.4 Lifting the Actuator

(Refer to Weights and Measures page

71 for actuator weight.)

Ensure the valve is secure before fitting

the actuator, as the combination may

be top heavy and therefore unstable.

If it is necessary to lift the actuator

using mechanical lifting equipment

certified slings should be attached as

indicated in Figure 5. At all times

trained and experienced personnel

should ensure safe lifting, particularly

when mounting actuators.

A suitable mounting flange conforming

to ISO 5210 or USA Standard MSS

SP101 must be fitted to the valve.

Actuator to valve fixing must conform

to; Material Specification ISO Class 8.8,

yield strength 628 N/sq mm.

WARNING:

Do not lift the actuator and valve

combination via the actuator. Always

lift the valve/actuator assembly via the

valve.

Fig. 5

WARNING:

The actuator should be fully supported

until full valve stem engagement is

achieved and the actuator is secured to

the valve flange.

Fig. 5.1

5.5 Securing Actuator to Valve

Before engagement ensure that the

actuator and valve are in the same

position (i.e. closed) and the drive bushmachining matches the stem position.

Actuator position can be determined

using the display (refer to section 3.3

page 4) and if necessary can be moved

using the handwheel (refer to section

3.1 page 3). It may be necessary to

adjust the stop bolts to enable

sufficient travel. Refer to section 5.6

page 9.

8

Mounting the Actuator

5

Page 13

Secure actuator to valve with four fixing

bolts. Check that the cast groove in

actuator base is not obstructed see Fig

5.1. Its purpose is to protect the

actuator in the event of a product leak

from the valve stem/gland packing.

Check base fixing bolts are tight.

5.6 Stop Bolts

It is recommended that stop bolt

adjustment be carried out by the

valvemaker/supplier before the valve is

fitted into pipework. Once installed, the

valve maker/supplier should be

consulted before stop bolt readjustment is carried out. Stop bolts

can be wired to prevent tampering.

After setting or adjustment of stop

bolts the actuator limits must be reset,

refer to Limits LC, LO page 22.

The IQT stop bolts are located below

the terminal compartment. Stop bolt

adjustment allows +/- 5º variation of

travel at each end position. Screwing

bolts in reduces movement, out

increases movement. For clockwise

closing valves the right hand bolt is the

closed stop as shown with spanner in

fig 5.2. The left is the open stop. Stop

bolts are factory set to give a nominal

90º travel.

Fig. 5.2

Stop Bolt sizes.

IQT 125 to 500: M12 bolt requiring

19mm AF spanner.

IQT1000 & 2000: M20 bolt requiring

30mm AF spanner.

Adjustment for non seating

valves types

For closed and open stop position

adjustment:

Undo stop bolt lock-nut. Move actuator

and valve to the required stopping

position (it may be necessary to

unscrew stop bolt to allow more travel).

Screw stop bolt in until a stop is felt.

Tighten stop bolt lock nut.

Adjustment for seating valves

types

For closed and open stop position

adjustment:

Undo stop bolt lock-nut. Move actuator

and valve to the required seating

position of the valve (it may be

necessary to unscrew stop bolt to allow

more travel). Screw stop bolt in until a

stop is felt and then back off by 3

turns. Tighten stop bolt lock-nut.

Reset actuator limits

Refer to Limits LC, LO page 22.

9

Page 14

Ensure all power supplies are

isolated before removing

actuator covers.

Check that the supply voltage agrees

with that stamped on actuator

nameplate.

A switch or circuit breaker must be

included in the wiring installation of the

actuator. The switch or circuit breaker

shall be mounted as close to the

actuator as possible and shall be

marked to indicate that it is the

disconnecting device for that particular

actuator. The actuator must be

protected with overcurrent protection

devices rated in accordance with Rotork

publication No. E135E Electric motor

performance data for IQT range

actuators.

WARNING:

Actuators for use on phase to

phase voltages greater than 600V

a.c.must not be used on supply

systems such as floating, or

earth-phase systems, where

phase to earth voltages in excess

of 600V a.c. could exist.

6.1 Earth/Ground Connections

A lug with a 6mm diameter hole is cast

adjacent to the conduit entries for

attachment of an external protective

earthing strap by a nut and bolt. An

internal earth terminal is also provided,

however it must not be used alone as

the protective Earth Connection.

6.2 Removing Terminal Cover

Using a 6mm Allen key loosen the four

captive screws evenly. Do not attempt

to lever off the cover with a screwdriver

as this will damage the “O” ring seal

and may damage the flamepath on a

certified unit.

Actuators containing a Setting Tool

fitted to the inside of the terminal

compartment cover are identified with

a self-adhesive yellow label on the

outside of the terminal compartment

cover.

The wiring code card fixed in the cover

is particular to each actuator and must

not be interchanged with any other

actuator. If in doubt check the serial

number on the code card with that of

the actuator.

Fig. 6

A plastic bag in the terminal

compartment contains: Terminal screws

and washers, spare cover “O” ring

seal,wiring diagram and instruction

book.

6.3 Cable Entry

Only appropriate certified ExplosionProof entry reducers, glands or conduit

may be used in hazardous locations.

Remove red plastic transit plugs. Make

cable entries appropriate to the cable

type and size. Ensure that threaded

adaptors, cable glands or conduit are

tight and fully waterproof. Seal unused

cable entries with a steel or brass

threaded plug. In hazardous areas an

appropriately certified threaded

blanking plug must be used.

6.4 Connecting to Terminals

On EExde enclosure units connections

to the power and control terminals

must be made using AMP type 160292

ring tabs for power and earth terminals

and AMP type 34148 ring tabs for the

control terminals.

Refer to the wiring diagram inside the

terminal cover to identify functions of

terminals. Check that supply voltage is

the same as that marked on the

actuator nameplate.

Remove power terminal screen.

Begin by connecting these cables and

replace screen.

When all connections are made ensure

wiring diagram is replaced in the

terminal compartment.

6.5 Replacing Terminal Cover

Ensure cover “O” ring seal and spigot

joint are in good condition and lightly

greased before re-fitting cover.

10

Cable Connections

6

Page 15

7.1 The Setting Procedure

The Rotork IQ range of actuators is the

first that enables commissioning to be

carried out without removing covers.

Setting torque, limit and other

functions is achieved by using the InfraRed Setting Tool. The Setting Tool is

certified Intrinsically Safe to allow

commissioning in hazardous areas.

All the commissioning functions are

stored in non-volatile memory in the

actuator. The Setting Tool enables the

user to view all the functions in turn via

the actuator display window. As each

function is viewed its setting can be

checked and, if required, changed

within the bounds of that function.

Commissioning may be carried out with

main power switched on or off. Refer

to page 15 for Power Off Setting.

The setting procedure is divided into

two stages:

1. Primary Functions

Settings for end of travel limit

actions, torque values, limit

positions etc.

2. Secondary Functions

Settings covering the control,

indication and optional

equipment functions.

All IQT actuator functions are

configured before dispatch to

Rotork standard default settings

unless alternatives have been

specified with the order. Should

difficulty be encountered during

commissioning the default

settings can be reinstated,

returning the actuator

configuration to its original

manufactured state. Site

commissioning can then begin

again

(refer to Section 9.17).

The default function should be used

with caution as settings selected after

manufacture may be essential for the

safe operation of the valve and/or

plant.

Actuator Display

11

Commissioning

7

Position Display 50 This may be an open or closed symbol

or a percentage open value.

Q

To rque and Position Refer to Section 10.

Q

Password P?

O

PC

O

Ir

O

Ic

Q

Setting Branch cr

O

(crossroad)

Q

Primary Functions Secondary Functions

Direction Indication Contacts

Limit Actions Control Mode

To rque Values Options

Limit Positions Help Screens

Defaults

Note: The Primary Functions

must be commissioned first.

Page 16

7.2 The Setting Tool

Specification

Enclosure IP67

Certification EEx ia IIC T4 (intrinsically safe)

FM, INT SAFE, Class I & II Div 1 Groups A B C D E F G, T4A

CSA, Exia, Class I, II Div 1 Groups A B C D

Power supply 9V Battery (supplied and fitted)

Operating range 0.75m (from actuator display window)

Name Instruction

1. Q Key* Display next function down

2.

O

Key* Display next function across

3.

-

Key Decrease/change displayed function’s value or option setting

4.

+

Key Increase/change displayed function’s value or option setting

5. Key Enter displayed value or option setting

* Pressing the two arrow keys together returns the actuator display to the position

indication mode

Infra-red local operation (when enabled)

5. Key Stop actuator

6. Key Open actuator

7. Key Close actuator

8. Infra-red Transmitter Window

Fig. 7 The Setting Tool

Setting Tool Battery Replacement

Battery status can be checked by looking at the Infra-red transmitter window while

depressing any Setting Tool button. A flashing red indicator should be seen.

Battery replacement must be carried out in a safe area. To replace the battery

remove the six caphead screws in the back of the Setting Tool. Remove the back

cover to expose the battery.

In order to maintain hazardous area certification fit only Duracell MN1604 or

Rayovac Alkaline Maximum NoAL-9V battery types. Refit cover ensuring red

indicator LED faces the transmitter window in the back cover.

When a button is depressed the Setting Tool transmits the relevant instruction to

the actuator by infra-red pulses and must therefore be directly in front of the

actuator indicator window and at a distance no greater than 0.75m.

12

8

2

4

6

7

5

3

1

Page 17

7.3 Entering the Actuator

Setting Procedure

With the actuator securely mounted on

the valve, the mains supply on and

Local control or Stop selected.

PRESS THE Q KEY.

The actuator display will change and

the Torque & Position display will be

seen. (For instantaneous torque &

position monitoring, refer to Section

10, page 62.)

PRESS THE Q KEY.

The actuator display will change and

the password protection display will

be seen.

The Actuator Function Settings

can be protected by the Use

of a Password

7.4 Setting Mode – Password

To enable setting and adjustment of the

actuator functions the correct password

must be entered. The factory set (default)

password is [ld]. If the actuator has

previously been set with a site password

this must be displayed.

Use the

+

or -keys to scroll through the

available passwords 00–FF (hexadecimal).

With the correct password displayed press

the enter key.

PRESS THE KEY

.

Two “setting” bars will appear and will

remain visible on every function display

screen.

Default Password,

Setting Mode Enabled

7.5 New Password [PC]

To configure a new password, the

actuator must be in setting mode with

the password display – setting mode

enabled – showing,

PRESS THE OKEY.

The display will change to [PC]. Using the

+

or -key scroll through the available

passwords until the desired password is

displayed.

PRESS THE KEY.

Password Changed to [IE]

NOTE: The new password becomes

effective the next time setting mode is

entered.

7.6 Checking Mode

The actuator function settings can be

checked without entering the correct

password. The settings can only be

viewed and not altered. The setting bars

will not be seen.

Password Display, Checking Mode

Once the procedure has been entered in

the required mode

PRESS THE Q KEY.

The procedure branch [Cr] (crossroad)

display

can now be seen (refer to Section

7.7 page 14).

13

Page 18

7.7 Procedure Branch –

Crossroad [Cr]

To access the Primary Function settings

press the arrow Q key (refer to

Section 8 Commissioning Primary

Functions page 15).

To access the Secondary Function

settings press the arrow

O

key (refer

to Section 9 Commissioning Secondary

Functions page 25).

7.8 The Actuator Display –

Setting/Checking Mode

Actuator functions as laid out in the

Primary and Secondary commissioning

stages, can be individually displayed by

using the Setting Tool arrow keys.

The

Q arrow key will always display

the FIRST function on the next level

DOWN within the procedure.

The

O

arrow key will always display

the NEXT function on the SAME level

and will wrap around the functions on

the same level.

The actuator display indicator lamps will

continue to indicate valve position.

Actuator functions are displayed in

code form in the top portion of the

liquid crystal display screen.

The setting for the displayed function is

shown in the lower portion of the

screen. Depending on the actuator

function displayed, its setting may be

an option or a value. In setting mode

the Setting

Tool

+

or

-

keys will cause the setting

to be changed. In checking mode the

settings cannot be altered.

In setting mode, once displayed, a new

setting can be entered into the actuator

memory by pressing the key.

The setting will flash off and back on,

confirming its selection.

TOP PORTION

Function e.g.

tC = Torque Close

LOWER PORTION

Function Setting

e.g. Value = 40%

Typical Actuator Function Display

Setting Mode Enabled

7.9 Returning to

Valve Position Display

There are four ways of returning to

valve position display:

1. Approximately 5 minutes after the

last Setting Tool operation the

display will automatically return to

position display.

2. Press the

Q and

O

arrow keys

together.

3. Press the Q arrow key until the

display returns to position.

4. With any actuator function screen

displayed, select Remote control

using the red Local/Stop/Remote

selector.

14

Page 19

Fig. 8

The actuator’s Primary Function settings

affect the correct operation of the valve

by the actuator. If the actuator has

been supplied with the valve, the valve

maker or supplier may have already

made these settings.

ELECTRICAL OPERATION MUST NOT

TAKE PLACE UNTIL THE PRIMARY

SETTINGS HAVE BEEN MADE AND

CHECKED.

This instruction assumes setting mode

has been entered (refer to section 7.4

page 13).

Viewing the Primary

Function Settings

With the actuator mounted on the

valve, the power supply on and Local or

Stop control selected, point the Setting

Tool at the actuator indicator window

from a distance of no more than

0.75m. By pressing the Q key and,

when appropriate, the Okey, it is

possible to move through the

procedure, displaying the various

functions and their settings as shown in

Fig. 8.1 (refer to page 16).The righthand side of Fig.8.1 explains the

function of each LCD display.

Power Off Setting

IQT allows settings to be viewed and

set without main power. To enable this

function, engage handwheel drive and

rotate until the output drive moves

(refer to page 3). The Setting Tool can

now be used. As long as a Setting Tool

key press takes place within the 30

seconds timeout period, Power Off

Setting will remain enabled. If no infrared Setting Tool communication takes

place the display will return to

indicating position. The actuator must

then be operated by handwheel to

re-enable Power Off Setting.

Settings and operation must be

verified by electric operation and

function test of the actuator to

ensure correct operation.

15

8

Commissioning –

Primary Functions

Page 20

Viewing the Primary Function Settings

Position Display

50

(This may be an open or closed symbol or a % open value.)

Refer to Section 7

QQ

Commissioning

To rque and Position Display

QQ

P? OPC OIr OIc Password

O

Password ChangeOIrDAOCell Phone

QQ

cr Procedure Branch (crossroad)

QQ

c1 Oc2 Oc3 Direction to Close

O

Close ActionOOpen Action

QQ

tC OtO To r que Value Closing

O

To rque Value Opening

QQ

LC OLO Limit Closed

O

Limit Open

QQ

50 Position Display

Fig. 8.1 Primary Setting Function Displays

16

PRIMARY FUNCTIONS CONTENTS

page

C1 Direction to Close 17

C2 Close Action 18

C3 Open Action 19

tC Torque Value Closing 20

tO Torque Value Opening 21

LC Set Limit Closed 22

LO Set Limit Open 22

AA Actuator Speed Setting 23

The actuator can be configured to be clockwise or anti-clockwise to close.

Page 21

Manually operate actuator and valve to

establish correct closing direction. If the

handwheel labelling is found to be

incorrect please apply to Rotork for

conversion labels.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

Using the +or -key, display character

conforming to correct closing direction.

[C] in the Setting Field Indicating

Clockwise to Close

[A] in the Setting Field Indicating

Anti-clockwise to Close

Having ensured that the display

corresponds to the established

closing direction

PRESS THE KEY.

The displayed option will flash,

indicating that it has been set.

PRESS THE OKEY.

17

Direction to Close

C1

Page 22

IQT actuators are designed to stop at

the end of travel by torque limitation

against the actuator stop bolts. Stop

bolts should therefore be set to the

precise stopping position required, refer

to section 5.6.

IQTF actuators can be configured to

close on torque or limit. Refer to valve

manufacturers instructions.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

Using the +or -key, display the

desired option.

[Ct] in the Setting Field Indicating

Close on Torque - defualt setting.

[CL] in the Setting Field Indicating

Close on Limit

Having selected the required option

PRESS THE KEY.

The displayed option will flash,

indicating that it has been set.

PRESS THE OKEY.

NOTE:

When set to close on torque,

the actuator will apply the value of

torque as set for [tC] in seating the

valve (refer to [tC] page 20).

18

Close Action

C2

Page 23

IQT actuators are designed to stop at

the end of travel by torque limitation

against the actuator stop bolts. Stop

bolts should therefore be set to the

precise stopping position required, refer

to section 5.6.

IQTF actuators can be configured to

close on torque or limit. Refer to valve

manufacturers instructions.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

Using the +or -key display the desired

option.

[Ot] in the Setting Field Indicates

Open on Torque - defualt setting.

[OL] in the Setting Field Indicates

Open on Limit

PRESS THE KEY.

The displayed option will flash,

indicating that it has been set.

PRESS THE OKEY.

NOTE:

When set to open on torque,

the actuator will apply the value of

torque as set for [tO] in back seating

the valve (refer to [tO] page 21).

19

Open Action

C3

Page 24

The value of torque available in the

close direction can be configured. Refer

to valve manufacturer for

recommended value.

The closing torque value can be varied

between 40% and Rated, in 1%

increments.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

Using the +and -keys display

recommended value. In the absence of

a recommended torque value, try a low

setting and increase until satisfactory

valve operation is achieved.

PRESS THE KEY.

The displayed value will flash, indicating

that it has been set.

Should the set value of torque be

developed in closing, the actuator will

torque trip and stop.

PRESS THE OKEY.

NOTE: Rated torque is quoted on the

actuator nameplate.

40% of Rated Torque

99% of Rated Torque

Rated Torque

20

To rque Value Closing

tC

Page 25

The value of torque available in the

open direction can be configured. Refer

to valve manufacturer for

recommended value.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

The opening torque value can be varied

between 40% and Rated, in 1%

increments. In addition “Boost” can be

configured when no open torque

protection is required.

BOOST SHOULD NOT BE

SELECTED WHEN THE ACTUATOR

HAS BEEN CONFIGURED TO OPEN

ON TORQUE (refer to [C3] page 19)

unless back seating at Rated torque is

acceptable.

Using the

+

and -keys display the

recommended torque value.

In the absence of a recommended

torque value, try a low setting and

increase until satisfactory valve

operation is achieved.

NOTE: Rated torque is quoted on the

actuator nameplate. Boost torque is at

least 140% of Rated torque.

PRESS THE KEY.

The displayed value will flash, indicating

that it has been set.

Should the set value of torque be

developed in opening, the actuator will

torque trip and stop.

PRESS THE Q KEY.

40%

99%

Rated

Boost

In checking mode, on pressing the

Q

key after reviewing open torque setting,

the display will revert to valve position.

21

To rque Valve Opening

tO

Page 26

NOTE: It is possible to set the Open

Limit Position [LO] first.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

NOTE:

When in checking mode Set

Limit Closed [LC] does not appear.

With [LC] displayed

Limit Closed

Move valve manually to the closed

position. Allow for overrun by winding

actuator output open by two

handwheel turns.

PRESS THE KEY.

The two bars will flash and the closed

indicator lamp will illuminate, indicating

closed limit position has been set.

PRESS THE OKEY.

To check closed limit position hand

wind valve open until the amber lamp

illuminates. Wind valve back closed

until the closed lamp illuminates.

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

NOTE:

When in checking mode Set

Limit Open [LO] does not appear.

With [LO] displayed

Limit Open

Move valve manually to the open

position. Allow for overrun by winding

actuator output closed by two

handwheel turns.

PRESS THE KEY.

The two bars will flash and the open

indicator lamp will illuminate, indicating

open limit position has been set.

PRESS THE Q KEY.

The open symbol (refer to Fig. 3.3.

page 4) should now appear.

22

Set Limit Closed

LC

Set Limit Open

LO

Page 27

With [AA] displayed

Use the

+

and -key to select the

required actuator operating time. The

settings are displayed in hexadecimal

and can be related to the actuator

speed as shown in Fig 8.2.

PRESS THE KEY.

The displayed value will flash, indicating

that it has been set.

All speed settings are adjustable in unit

increments of hexadecimal. Any value

of hex outside of the range stated will

not be accepted into the actuator

memory.

% Speed Hex Setting

25 19

30 1E

35 23

40 28

45 2D

50 32

55 37

60 3C

65 41

70 46

75 4B

80 50

85 55

90 5A

95 5F

100 64

Fig 8.2

NOTE: Mains power has to be on

for speed setting to be carried out.

23

Speed Setting

AA

Positional Display

Q

Q

P?

OPCOIrO

Ic

Q

Contact Function

cr

O

Contact S1

r1

Q

Contact S2

r2

Q

Contact S3

r3

Q

Contact S4

r4

Q

ESD Action

Control Mode

Configuration

A1

Q

Extra Indication Folomatic Remote Bus

Contacts CPT

Remote Control Control Source

System

Option Selection OE O OI O OF O Od O OP

[On]

Q

PA

Q

50

IQT operating time can be adjusted

between 25% and 100% of the

maximum time (50% and 100% for

IQT2000). IQT are factory set at the

maximum speed. IQTM actuators are

dispatched with the minimum speed set.

To access speed setting [AA] screen, bus

system [OP] has to be set to [O

n], using

the +and -key.

After this setting, proceed to screen [AA].

IrDA

comms

Primary

Functions

IQT Speed

Setting

AA

Q

Cell

Phone

Page 28

50

Q

Q

P? OPC OIr OIc

Q

cr

Q

c1 Oc2 Oc3

Q

tC OtO

Q

LC OLO

Q

50

If the procedure has been followed as

described, the positional display will

indicate that the actuator is in the open

position.

Select Remote control momentarily,

using the red selector to exit setting

procedure and then select required

control: Local, Stop or Remote.

With the correct settings made electric

operation can now be carried out

safely.

24

Return to

Positional Display

Page 29

Fig. 9

The Secondary Functions can be

configured to suit site control and

indication requirements. It is important

that Primary Functions such as limits

and torque switch settings are set

before work commences on

commissioning the Secondary

Functions. The layout of the Secondary

Functions accessed with the Setting

Tool are detailed in Fig. 9.1. To

successfully commission the Secondary

Functions, information about the site or

process control system will be required.

The supplied actuator Wiring Diagram

details control and indication devices

fitted to the actuator along with

terminal connection detail and standard

remote control wiring systems.

Power Off Setting

IQT allows settings to be viewed and

set without main power. To enable this

function, engage handwheel drive and

rotate until the output drive moves by

one turn (refer to section 3).The

Setting Tool can now be used. As long

as a Setting Tool key press takes place

within the 30 seconds timeout period,

Power Off Setting will remain enabled.

If no infra-red Setting Tool

communication takes place the display

will return to indicating position. The

actuator must then be operated by

handwheel to re-enable Power Off

Setting.

Settings and operation must be

verified by electric operation and

function test of the actuator to

ensure correct operation.

25

9

Commissioning –

Secondary Functions

Page 30

26

Positional Display

Q

Q

P?

OPCOIrO

Ic

Q

Contact Function

Value Contact Form

cr

O

Contact S1

r1

O

r1

O

r1

Q

Contact S2

r2

O

r2

O

r2

Q

Contact S3

r3

O

r3

O

r3

Q

Contact S4

r4

O

r4

O

r4

Q

ESD ESD Thermostat ESD Overide ESD Override Maintained 2-wire External Conditional Torque Switch

ESD Action Contact Type Bypass Interlocks Local Stop Local Control Control Interlocks Control Bypass

Control Mode

Configuration

A1 O A2 O A3 O A4 O A5 O A6 O A7 O A8 O A9 O At

Q

Extra Indication Folomatic Remote Bus Interrupter Setting Tool Power Loss

Contacts CPT

Remote Control Control Source

System Timer Local Control Inhibit

Option Selection OE O OI O OF O Od O OP O OJ O Or O OS

Q

Option Functions - If OE, OF, OP, or OJ are fitted and selected “ON” their appropriate set-up screens will be inserted here.

Q

Help Screens H1 O H2 O H3 O H4 O H5 O H6 O H7 O H8 O H9

Q

Default Option d1 O d2

Q

Return to Positional Display Fig. 9.1 Secondary Functions

50

IrDA

comms

Primary

Functions

Q

Cell

Phone

Page 31

Having established that the Primary

Functions have been correctly set, the

Secondary Functions can now be

configured to suit site control and

indication requirements.

It is possible to move through the

various Secondary Functions as shown

in Fig. 9.1 using the

O

and Q keys.

The actuator wiring diagram will

indicate any options fitted.

Options Setting Tool Local Control [Or]

and Power Loss Inhibit [OS] are

standard features, their use being

optional.

In order to display the Secondary

Functions it is necessary to press the

Qkey until [Cr] appears.

If you have chosen to enter Secondary

Functions in the checking mode the

display will be as Fig. 9.2.

If you have chosen to enter Secondary

Functions in the setting mode the

display will be as Fig. 9.3 (refer to

Section 7).

Fig. 9.2 Fig. 9.3

PRESS THE O KEY.

27

9.1

SECONDARY FUNCTIONS CONTENTS

page

9.0 Commissioning Secondary Functions 25

9.1 Accessing the Secondary Settings 27

9.2 Indication Contacts S1, S2, S3 and S4 28

9.3 Control Mode Configuration 30

9.4 Option Extra Indication Contacts S5–S8 33

9.5 Option CPT (Current Position Transmitter) 34

9.6 Option Folomatic Remote Control 35

9.7 Remote Control Source 38

9.8 Bus System Option Pakscan 39

9.9 Bus System Option Modbus 43

9.10 Bus System Option Profibus DP 47

9.11 Bus System Option DeviceNet 51

9.12 Bus System Positioning Control Settings 54

9.13 Option Interrupter Timer 56

9.14 Setting Tool Local Control 58

9.15 Inhibit Operation After Power Loss 58

9.16 Actuator Type Setting 59

9.17 Default Options 60

9.18 Default Options 61

10.0 Maintenance,Monitoring and Troubleshooting 62

10.1 Help Screens 64

10.2 IrDA Diagnostics and Configuration 69

Accessing the

Secondary Functions

Page 32

Contact S1 - Function

r1

Contact S1 - Value

r1

Indication contacts S1 [r1], S2 [r2], S3

[r3] and S4 [r4] may each be set to trip

for any one of the following functions:

Code Function

[CL] closed end position

[OP] open end position

[Po] intermediate position

[tC] torque trip close

[tO] torque trip open

[tt] torque trip any position

[tl] torque trip mid travel

[dC] actuator closing

[dO] actuator opening

[d?] actuator rotating

[St] motor stalled

[bA] battery low

[HA] hand operation

[bL] blinker

[LS] local stop

[Ol] open interlock

[Cl] close interlock

[lL] interlock active

[ES] ESD signal

[LP] lost phase

[Lo] local selected

[

rE] remote selected

[AA] actuator alarm *

[24] 24V power failure

[

rr] motor running

[UA] Valve alarm*

[Ht] thermostat tripped

[CA] Control alarm*

[

rP] relay parity

The S contact form can be set normally

open [no] or normally closed [nc].

The procedures for setting up contacts

S2, S3 and S4 are the same as those

shown for S1.

Unless specified with order, the

default settings for indication

contacts are as follows:

S1 – [CL] closed end position [no]

S2 – [OP] open end position [no]

S3 – [CL] closed end position [nc]

S4 . [OP] open end position [nc]

* Contact alarm indication will operate

under the same conditions as the

display alarm indication icons (refer to

page 5 for information).

Using the

+

or -key display the desired

function.

PRESS THE KEY.

The displayed function will flash

indicating that it has been set.

Contact S1 Configured to Trip

at Valve Closed Limit

PRESS THE O KEY.

When the S contact function is set to

[P0], the required intermediate position

value must be set.

No other contact function requires

a value to be set.

The value can be set from 1% open to

99% open in 1% increments.

Using the

+

or -key, display the

required value.

PRESS THE KEY.

The displayed value will flash indicating

that it has been set.

Value Set to Indicate

25% Open

PRESS THE O KEY.

28

9.2

Indication Contacts

S1, S2, S3 and S4

Page 33

Use the +or -keys to select between

[nO] (normally open) and [nC]

(normally closed).

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Contact S1 Configured as a

Normally Open Contact

NOTE: If function [PO] is selected and

it is configured as a normally open

contact it will make at the set value

with the actuator moving in the open

direction.

To access S2–S4

PRESS THE Q KEY.

(Refer to Fig 9.1)

29

r1

Contact S1

Contact Form

Page 34

The Control Mode Configuration affects

how the actuator will respond under

conditions of emergency shut down,

local control, remote control interlocks,

and 2-wire remote control. Also

included is an unseating torque switch

bypass function. Unless specified with

order, the control mode configuration

will be set as shown for default

configuration on page 60.

If it is necessary to change the

configuration follow the instructions in

this section.

There are 10 configurable control

functions:

A1 ESD action

A2 ESD contact type

A3 ESD thermostat bypass

A4 ESD override interlock

A5 ESD override local stop

A6 Maintained local control

A7 2-wire remote control

A8 External interlocks

A9 Conditional Control

At Torque switch bypass.

An active ESD signal applied to the

actuator will override any existing or

applied local or remote control signal.

ESD can be configured to override the

transformer thermostat, active

interlocks or local stop selection. Refer

to A3, A4 and A5.

The default action under an active ESD

signal is to stay put [SP].

Press the

+

or -key to select the

required ESD action:

[CL] Close on ESD

[SP] Stay put on ESD

[OP] Open on ESD

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

ESD Set to Close

The default setting for ESD Contact

Type is [

nO].

The actuator responds to a remote

control ESD signal derived from a

normally open contact making. For ESD,

where a remote control ESD signal is

derived from a normally closed contact

breaking, the signal being removed,

press the

+

or -key.

The display will change to [

nC].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Actuator Responds to a Remote,

Normally Open ESD Contact

Making (Signal Applied)

Note: If Folomatic analogue control is

required A2 must be set to [

nO].

The default setting for Thermostat

Bypass is [OF] during ESD. The

thermostats remain in circuit and

enabled during ESD.

The thermostats can be bypassed

during ESD as a factory set, hard-wired

option only. Contact Rotork for

information.

Danger: Actuator hazardous area

certification is invalidated while

the thermostats are bypassed.

A3 should be set to reflect the factory

set configuration of thermostat bypass.

During an ESD event:

[A3]=[OF] thermostats enabled

[A3]=[O

n] thermostats bypassed

Thermostats Enabled During ESD

30

9.3

ESD Action

A1

ESD Contact Type

A2 A3

Control Mode

Configuration

ESD Thermostat

Bypass

Page 35

The default setting for ESD Override

Interlocks is [OF]. ESD action will not

override an active interlock applied to

the actuator.

If an applied ESD signal is required to

override active interlocks causing the

ESD action as set for A1, press the

+

or

-

key. The display will change to [On].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

ESD Override Interlock – Off

The default setting for ESD Override

Local Stop is [OF]. ESD will not override

local stop when selected.

If an applied ESD signal is required to

override local stop causing the ESD

action as set for A1, press the

+

or

-

key. The display will change to [On].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

ESD Override Local Stop – Off

The default setting for Local Actuator

Pushbutton control is self-maintained

[O

n].

If non-maintained actuator pushbutton

control is required (jogging, inching,

push to run), press the

+

or -key. The

display will change to [OF].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Self-Maintained Local Control

The default setting for 2-wire Remote

Control is Stayput [SP]. If a open and

closed remote control signal are applied

simultaneously the actuator will stayput

(stop if running). Refer to actuator

wiring diagram or publication E120E.

Use the

+

or -key to select the

required priority:

[OP] Open

[SP] Stay put

[CL] Close

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

2-wire Control – Stayput Priority

31

A4

ESD Override

Interlocks

A5

ESD Override

Local Stop

A6

Maintained

Local Control

A7

2-wire Remote

Control

Page 36

Actuators are delivered with the

interlock facility disabled [OF] Refer to

the actuator wiring diagram or

publication E120E for interlock control

circuits.

To enable remote external interlocks

press the

+

or -key.

The display will change to [O

n].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Interlocks Disabled

Note: If interlocking is required in only

one direction, it will be necessary to

connect a link between the actuator

terminals associated with the other

direction.

Where a high level of safety integrity is

required, Conditional Control can be

configured. In this mode two discreet

signals are required for remote

operation. Remote control will be

conditional on both a control signal

(open or close) and the appropriate

interlock signal being applied

simultaneously. Failure of either or a

spurious signal will not cause operation.

Interlocks [A8] must be set [O

n].

Interlock signals are not required for

local operation.

The default setting for conditional

control is [OF]. To enable conditional

control press the

+

or -key.The display

will change to [On].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Conditional Control Off

The default setting for Torque Switch

Bypass is [OF], the torque switches are

not bypassed during the unseating

movement.

To bypass the torque switches during

the unseating movement press the

+

or

-

key.

The display will change to [O

n].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

The torque switches will be bypassed

from closed limit to 5% open when

opening and from open limit to 95%

when closing. Bypassing the torque

switches makes torque in excess of

rated and up to actuator stall available

for unseating a ‘‘sticky’’ valve. Outside

these positions the torque setting will

revert to the values set for [tC], see

page 20 and [tO] page 21.

Torque Switch Bypass Off

32

External Interlocks

A8

Conditional Control

A9

To rque Switch Bypass

At

Page 37

Extra indication contacts S5 [r5], S6

[r6], S7 [r7] and S8 [r8] are available as

an option.

Check actuator circuit diagram for

inclusion.

When the Extra Contact Option is

included the set-up procedure and

available contact functions for S5 – S8

are identical to S1–S4 (refer to Section

9.2 page 28).

Unless specified with order the default

setting for the extra indication contacts

will be as follows:

S5 [r5] Close limit indication

S6 [r6] Open limit indication

S7 [r7] To r que trip mid travel

S8 [r8] Remote control selected

NOTE: If the Extra Contact Option is

not included in the actuator build, any

settings made for S5–S8 will have no

effect on the indication output of the

actuator.

The action of turning on the Extra

Contact Option makes an additional

series of set-up screens available

Enabled Disabled

Extra Contact Set-up Displays

Press the

+

or -key to select the Extra

Contact Option set-up screens [O

n].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

PRESS THE Q KEY TO ACCESS S5

TO S8 SET-UP DISPLAYS.

The procedure for setting S5 to S8

is the same as that for S1 to S4

(refer to Section 9.2 page 28).

33

9.4

Option Extra

Indication Contacts

OE

Display Extra Contact

Set-up Screens

Page 38

Setting instructions for actuators

including a CPT providing 4-20

mA analogue position feedback.

The CPT is an optional extra. It may be

internally or externally powered.

Check wiring diagram for inclusion and

connection details.

With [HI] Displayed, the (CPT)

20mA Output will Correspond to

Actuator Fully Open

If 20mA is required to correspond to

actuator closed use the

+

or -key to

change to [LO].

PRESS THE KEY.

The displayed option will flash

indicating that the option has been set.

NOTE: If the actuator has options

Folomatic and CPT, redefining the CPT,

will require the Folomatic to be

recommissioned (refer to Section 9.6

Folomatic [OI] page 35).

34

9.5

Option CPT [OI]

(Current Position Transmitter)

Page 39

Setting instructions for actuators

including a Folomatic

(proportional) Controller for use

in (analogue) valve position

control.

The Folomatic is an optional

control device. Check actuator

wiring diagram for inclusion.

Before setting the parameters for

Option Folomatic ensure Remote

Control Source [Od] has been

selected to [bo] in Section 9.7.

Folomatic set-up screens can be turned

OFF to provide extra security.

Once selected ON the option function

displays allow commissioning of the

Folomatic to be undertaken.

NOTE: Tu rning ON/OFF the Folomatic

set-up screens (when fitted) does not

affect its operation.

This instruction lists the Folomatic

function displays in their sequence and

assumes that all Folomatic functions are

to be checked/set.

The actuator should be selected in Local

or Stop with the set point signal

connected to terminals 26(+ve) and

27(-ve) (refer to wiring diagram).

Before commissioning of the Folomatic

functions can begin, the Folomatic

Feedback must be set to suit the

applied set point signal.

With [HI] displayed, an increasing set

point signal will correspond to valve

opening.

If a high set point signal is required to

correspond to valve closing use the

+

or

-

key to change to [LO].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

If setting [OI] is modified after

commissioning the Folomatic, it will be

necessary to recommission the

Folomatic.

Press the

O key to access the

Folomatic set-up display [OF].

The action of turning on the Folomatic

option makes an additional series of

settings available.

Folomatic Folomatic

Set-up Screens Set-up Screens

OFF ON

Use the +or -key to select Folomatic

Display [On].

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Press the

Q key to access the

Folomatic set-up displays.

35

9.6

Option Folomatic

Remote Control

Folomatic Feedback

OI 9.4

Display Folomatic

Set-up Screens

Page 40

Using the +or -key select [ l] for

current set point signal or [ U] for

voltage set point signal.

Current Mode Selected

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Press the

O key to display [Fr].

Using the

+

or -key select [05], [10] or

[20] to correspond with the set point

signals within the range of 0–5mA or

volts, 0–10mA or volts or 0–20mA or

volts (i.e. 4–20mA).

0–20mA or Voltage

Range Selected

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Press the

O key to display [FL].

APPLY MINIMUM

SET POINT SIGNAL

Using the +or -key select:

[

][ ] = valve closed

[01] to [99] = percent open

[] = valve open

to correspond with the LOW set point

signal.

Valve Closed

on LOW Signal

PRESS THE KEY.

The displayed value will flash indicating

that it has been set.

Press the

O key to display [FH].

APPLY MAXIMUM

SET POINT SIGNAL

Using the +or -key select:

[

][ ] = valve closed

[01] to [99] = percent open

[] = valve open

to correspond with the HIGH set point

signal.

Valve Open

on HIGH Signal

PRESS THE KEY.

The displayed value will flash indicating

that it has been set.

Press the

O key to display [Fd].

36

FI

Set Point

Signal Type

Fr

Set Point

Signal Range

FL

Valve Position

LOW Set Point

FH

Valve Position

HIGH Set Point

Page 41

If the actuator hunts or responds

unnecessarily to a fluctuating set point

signal the deadband must be increased.

If more accurate control is required the

deadband may be decreased.

Use the

+

or -key to select the

deadband width. Range 00–99

corresponds to 0–9.9% of setpoint

signal.

NOTE: Maximum deadband is 9.9% of

valve stroke. Normally minimum

deadband should not be less than 1%.

Deadband Set to 1.2%

of Valve Stroke

PRESS THE KEY.

The displayed value will flash indicating

that it has been set.

Press the

O key to display [Ft].

The motion inhibit timer introduces a

delay in the actuator response to a

rapidly fluctuating set point signal,

preventing unnecessary movement.

Once the system stabilises the actuator

will respond to steady changes in the

set point signal as necessary.

Use

+

or -key to adjust motion inhibit

time in seconds: range 0–99. Normally

it is recommended that motion inhibit

time should not be set to less than 5

seconds (refer to note on page 58).

Motion Inhibit

Time Set to 5 Seconds

PRESS THE KEY.

The displayed value will flash indicating

that it has been set.

Press the

O key to display [FA].

Use

+

or -key to enable [On] or disable

[OF] action on loss of set point signal.

[O

n] – Failsafe as determined by [FF].

[OF] – Failsafe to position

corresponding to low set point.

Enabled

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

NOTE: Failsafe action “ON” will be

effective only for systems using an

offset or live zero signal range, for

example 4–20 mA.

Press the

O key to display [FF].

Failsafe action when [FA] enabled.

Use

+

or -key to select, on loss of set

point signal:

[Lo] – move valve to position

corresponding to minimum set

point.

[SP] – stayput on loss of set point.

[Hl] – move valve to position

corresponding to maximum set

point.

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Commissioning of the Folomatic is now

complete. Remote control may be

selected.

37

Ft

Motion Inhibit

Timer Adjustment

Fd

Deadband

Adjustment

FA

Action On Loss of

Set Point Signal

Failsafe Action

FF

Page 42

The available forms of remote control

are listed below:

Standard hardwired control

Analogue control-Option Folomatic

Network control including:

Option Pakscan

Option Modbus

Option Profibus

The setting for Remote Control Source

will depend on the type of remote

control required and the option

specified and fitted. Check actuator

circuit diagram for remote control form.

The setting of Remote Control Source

will be determined by the option that

has been fitted, if any.

[

rE] Standard hardwired remote

control.

[bO] Option Folomatic.

[OP] Options Pakscan, Profibus,

Modbus, Foundation Fieldbus

or DeviceNet.

[OF] All remote control disabled

(Actuator available for local

control only).

To change the remote source press the

+

or -key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Standard Hardwired

Remote Control

38

Remote Control Source

9.7

Remote Control Source

Od

Page 43

Setting instructions for actuators

including an optional Pakscan Field

Control Unit – check wiring diagram for

inclusion.

Before setting the parameters for

Option Pakscan ensure Remote

Control Source [Od] has been

selected to [oP] in Section 9.7.

Pakscan set-up screens can be turned

off to provide extra security. The action

of turning screens on or off does not

affect its operation.

Use the

+

or -key to turn on Pakscan

set-up screens.

Pakscan Set-up Screens ON

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Press the

Q key to display the Pakscan

set-up screens.

The actuator Pakscan Field Control Unit

must be allocated a unique loop

address.

The actuator must be in “Loopback”

for its address to be set or changed.

Loopback can be achieved in two ways:

1. Turn OFF the master station.

2. Isolate the actuator from the

2-wire control loop.

Using the

+

or -keys display the

required loop address.

Address to be set within the range

01–F0 Hexadecimal. (refer to table on

page 72).

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Press the

O key to display [Pb].

The actuator Pakscan Field Control Unit

baud rate must be set to the loop baud

rate. For a Pakscan 2-wire control loop

the selected baud rate must be common

to the master station and all the field

control units included in the loop.

The actuator must be in “Loopback”

for its baud rate to be set or changed.

Loopback can be achieved in two ways:

1. Turn OFF the master station.

2. Isolate the actuator from the

2-wire control loop.

Continued

39

9.8

Bus System

Option Pakscan [OP]

Pakscan Address

PA Pb

Pakscan

Baud Rate

Page 44

Using the +or -keys display the

required baud rate.

01 = 110 baud

03 = 300 baud

06 = 600 baud

12 = 1200 baud

24 = 2400 baud

2400 baud rate set

PRESS THE KEY.

The displayed option will flash

indicating that it has been set.

Press the

O key to display [PF].

40

Pakscan Baud Rate

Pb

The IQT actuator has the facility to accept 4 auxiliary inputs (AUX1–AUX4). These

are used when supplementary remote control or digital auxiliary inputs are required

in addition to the standard control and feedback features incorporated into the