rotork IQ Range, IQ Multi-Turn, IQT Part-Turn Full Configuration, Status And Monitoring User Manual

Page 1

IQ Range

IQ and IQT full configuration,

status and monitoring user manual

Keeping the World Flowing

IQ Multi-Turn and IQT Part-Turn

Electric Valve Actuators

Page 2

2

Page 3

Table of Contents

1. Introduction

1. Introduction __________________________3

ACTUATOR

SETTING TOOL

1.1 Using the Rotork Setting Tool ___________4

1.2 Connecting to the actuator _____________6

1.3 Password Security _____________________7

2. Settings ______________________________8

2.1 Settings – Limits _______________________8

2.2 Settings – Indication __________________11

2.3 Settings – Control ___________________ 14

2.4 Settings – ESD ______________________ 32

2.5 Settings – Security ___________________ 34

2.6 Settings – Defaults ___________________ 35

3. Status ______________________________ 36

3.1 Status – Control _____________________ 36

3.2 Status – Alarms _____________________ 40

3.3 Status – Movement ___________________41

3.4 Status – Indication ___________________ 42

3.5 Status – Diagnostics __________________ 43

4. Data Log ___________________________ 44

4.1 Data Log – Torque Logs ______________ 45

4.2 Data Log – Event Logs ________________ 47

4.3 Data Log – Trend Logs ________________51

4.4 Data Log – Operation Logs ____________ 54

4.5 Data Log – Partial Stroke Logs _________ 58

4.6 Data Log – Set Log Date ______________ 59

This manual provides instruction on the

setup and analysis of the actuator.

It is structured so that instruction on using the

Setting Tool, navigation and password security

is contained in Section 1. This must then be

applied when changing settings and viewing

information as set out in Sections 2 - 5.

The user must therefore be familiar with the

operations contained in Section 1 before

proceeding.

This manual should be read in conjunction with

PUB002-039 IQ Range Instructions for Safe Use,

Installation, Basic Setup and Maintenance and

PUB002-065 IQT Range Instructions for Safe

Use, Installation, Basic Setup and Maintenance

supplied with the actuator.

5. Assets ______________________________ 60

5.1 Assets – Actuator ___________________ 61

5.2 Assets – Valve _______________________ 64

5.3 Assets – 2nd Stage Gear Box __________ 64

5.4 Assets – Service History ______________ 65

5.5 Assets – Service Alarms ______________ 65

5.6 Assets – NAMUR 107 ________________ 66

5.7 Assets – Online Help _________________ 67

IQ3 Full Confi guration Man ual – Secti on: Introduc tion 3

Page 4

ACTUATOR

SETTING TOOL

1.1 Using the Rotork Setting Tool

The Setting Tool is used to connect to the actuator, navigate

through menus, change settings and view information presented

on the actuator display.

1

9

4

7

8

5

11

3

6

2

10

Name General Operation

1. Key Scroll up.

2. Key Scroll down / Connect via Bluetooth®.

3. Key Decrease value / Toggle setting / Scroll left.

4. Key Increase value / Toggle setting / Scroll right.

5. Key Select the highlighted item.

Save the highlighted setting.

Stop actuator running (when Setting Tool

control is enabled, refer to 2.3.1).

6. Key Return to previous menu.

7. Key Cycle between standard and zoom view on data

logger torque graphs.

8. Key Actions the pre-configured mission stored on

the Rotork Bluetooth® Setting Tool Pro.

9. Infrared transmitter window.

10. Key Send a close command to the connected

actuator (when enabled refer to 2.3.1).

11. Key Send an open command to the connected

actuator (when enabled refer to 2.3.1).

Navigation

To navigate through screens, menus and pages, the

and keys are used. A single key press results in one

movement. Holding the key will result multiple movements in

succession. Menus, pages and dropdowns wrap round. This

means that an item at the bottom of a screen can be accessed by

pressing while at the top.

Shorthand Instructions

This manual uses shorthand instruction (example):

(meaning select, edit setting, save) to prompt the user with the

key operations required. The display will also indicate the relevant

keys at the bottom left.

Pages, Functions and Index

The display indicates the number of each function as it is

highlighted along with the total number of functions on that

page. In the example below, Action is function 2 out of a total of

15 functions on that page:

2/15

This manual uses the display function number as reference

for instructions.

Action (highlighted) is function 2 out of a total 15

on the LIMITS page.

Selection

The key is used to select a main menu item, menu items or

instruction buttons. For a setting, is used to select when a

change is required. The first time this occurs in a communication

session, a password will be requested, refer to 1.3. Subsequent

changes within the same session will not require the entry of

a password. When selected, a menu item will be opened or a

setting or function will be highlighted.

Information, instruction and password entry screens require an

or button to be selected. Navigate to highlight

the required button using or and press to select.

Setting controls

There are four types of setting control used. When a function is

selected, the ability to change the function, setting or value is

made available using drop down list boxes, check boxes, slider

controls or numerical values.

Drop down list boxes

Drop down list boxes are indicated by .

Contacts

Monitor Relay

Mode Available

S1

Function Closed Limit

Contact

Position 0%

Function Open Limit

Contact

Position 0%

2/37

The example of the S1 indication contact Function (highlighted)

dropdown list box is shown on the next page. When selected

(password entered if applicable, refer to 1.3), the current set

function will be highlighted within the drop down list.

N/O N/C

S2

N/O N/C

4 IQ3 Full Co nfiguration M anual – Sec tion: Introd uction

Page 5

1.1 Using the Rotork Setting Tool

continued

ACTUATOR

SETTING TOOL

Contacts

Monitor Relay

Mode Available

Function Closed Limit

Contact

Position 0%

Function Open Limit

Contact

Position 0%

2/37

Disabled

S1

Closed Limit

Open Limit

N/O N/C

End Position

Pos. % Open

S2

Mid Travel

Motor Running

N/O N/C

Closing

The symbol in the drop down box indicates more functions

are available by scrolling or .

Use or to scroll through the list until the required function

is highlighted. Press to select. The drop down list box will

close and the selected function will be saved and shown on the

page.

To exit the drop down list without saving a new setting

press to return to the previous page.

Checkboxes

Check boxes are indicated by or .

Contacts

Monitor Relay

Mode Available

S1

Function Closed Limit

Contact

Position 0%

Function Open Limit

Contact

Position 0%

3/37

An example for the S1 indication contact type check box is

shown above.

Mode Available

Function Closed Limit

Contact

Position 0%

Function Open Limit

Contact

Position 0%

3/37

When selected (password entered if applicable, refer to 1.3), the

current mode will be highlighted.

Use either the or to toggle between modes.

Once the required mode is checked, press to select. The

selected mode will be saved and shown as checked on the page.

To exit the checkbox without saving a new setting, press

to return to the page.

N/O N/C

S2

N/O N/C

Contacts

Monitor Relay

S1

N/O N/C

S2

N/O N/C

Slider controls

Slider controls graphically indicate the set value followed by the

exact numerical value, for example:

Position 35%

The range covered by the slider is fixed and is determined by

its function.

Contacts

Monitor Relay

Mode Available

S1

Function Pos % Open

Contact

Position 35%

Function Open Limit

Contact

Position 0%

4/37

N/O N/C

S2

N/O N/C

An example of the S1 indication position value is shown above.

The S1 contact function of Pos.% Open indication will show the

valve position at which the contact will change state.

Press (enter password if applicable, refer to 1.3).

Use or to decrease or increase the value.

Slider controls wrap round so a key press on a minimum value

will wrap round and indicate the maximum value. The value step

changes increase as or is held down.

Once the required value is set press to select. The selected

value will be saved and shown on the page.

To exit the slider control without saving a new setting,

press to return to the page.

Numerical values

Numerical values relate to fields such as time or address - shown

in the example below.

Stopped

Pakscan

Address 3

Baud Rate 2400

Position

Update Times (s)

Deviation 5%

Update Times (s) 5

Press (enter the password if applicable, refer to 1.3).

Use or to decrease/increase the numerical value.

Press to select.

To exit the numerical value control without saving a new

value, press to return to the previous page.

1

Torque

1/8

IQ3 Full Confi guration Man ual – Secti on: Introduc tion 5

Page 6

ACTUATOR

SETTING TOOL

1.2 Connecting to the actuator

The Rotork Bluetooth® Setting Tool Pro incorporating Bluetooth

wireless technology is shown below. It is identified by the key

symbols and a clear band between the top and bottom casings

being transparent.

The Rotork Infrared Setting Tool Pro is identified by solid yellow

keys and a yellow band between casings:

Yellow: Rotork Infrared Setting Tool Pro

Clear: Rotork Blueto oth® Setting Tool Pro

Connecting to the actuator using Bluetooth

The actuator must be powered up to connect using Bluetooth. The

default security set in the actuator for Bluetooth connection is by

initiation using an infrared command. This means that the user must

be in close proximity and in direct line of sight of the actuator.

Point the Setting Tool at the infrared sensor located at the lower

right of actuator display window within a range of 0.25 m (10 in)

and press until the key flashes blue.

The screen will change to the Main Menu screen.

Open Limit

The Setting Tool will automatically connect using

Bluetooth which takes up to 5 seconds.

Connection is indicated by a blue light on the tool and in the

actuator display window. Once connected, the tool can be used

without pointing it at the actuator display window.

Bluetooth connection will be maintained while Setting Tool key

commands are made. After a period of 6 minutes with no key

commands, Bluetooth connection will be turned off and the

Setting Tool and display blue lights will go out. To manually

disconnect Bluetooth at any time, press and together.

Connecting to the actuator using Infrared

Infrared communication is used when:

• Bluetooth communication has been disabled

(refer to 2.5).

• configuration is required without power being applied to

the actuator.

• legacy infrared only Rotork Setting Tool is used

(yellow banded tool).

The Infrared only tool has solid yellow keys and a yellow band

between casings.

Communication is by direct line of site infrared commands within

a range of 0.25 m (10 in). Keys have the same function as shown

in this manual. Each key press sends a discreet infrared command

and therefore the tool must be in range.

6 IQ3 Full Co nfiguration M anual – Sec tion: Introd uction

Page 7

1.3 Password Security

ACTUATOR

SETTING TOOL

Menus, pages and settings may be viewed when the actuator is

set to Remote, Stop or Local. To change a setting, the actuator

must be selected to Local or Stop using the red selector and the

correct password must be entered.

The password will be requested the first time a function

is selected. Once correctly entered, other changes can be

made without re-entering the password for the duration

of the Setting Tool session with the actuator.

If the actuator is selected to Remote and a setting is selected, the

following information screen will be displayed:

Press to return to the page. Set the red selector to Local or

Stop to proceed with setting.

With the actuator selected to Local or Stop and when any setting

function is selected, the Password screen will be displayed:

If the user has set their own password the following screen will

be displayed:

Enter user selected Password:

Use to highlight new password entry box and press

Use

to scroll through alphanumeric values to display

required character.

Use to move to the next character.

Use to delete the highlighted character.

Use when selected password is complete.

Navigate to the OK button using

.

Press

The factory set default password ROTORK is displayed and the

OK button is highlighted.

Press . The setting page from which the function was

selected will be displayed with the function highlighted.

IQ3 Full Confi guration Man ual – Secti on: Introduc tion 7

Page 8

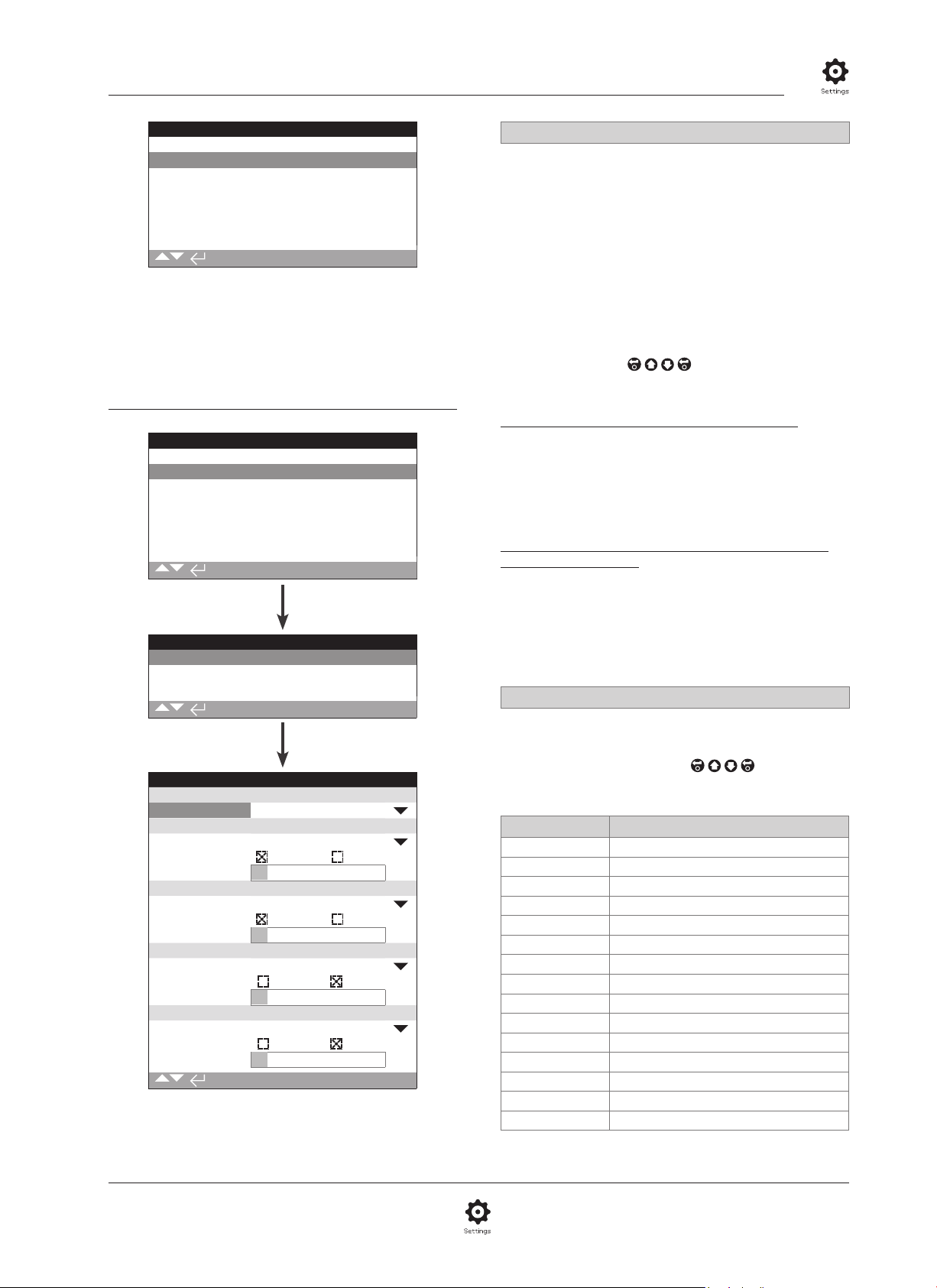

2. Settings 2.1 Settings – Limits

Limits

Indication

Control

ESD

Security

Defaults

2. Settings Menu Page

2.1 Limits 8

2.2 Indication 11

2.2.1 Contacts 11

2.2.2 Local Display 12

2.2.3 Analogue 14

2.3 Control 14

2.3.1 Local Control 15

2.3.2 Remote Control 16

2.3.3 Interrupter Timer 31

2.4 ESD 32

2.5 Security 34

2.6 Defaults 35

Settings

Limits

Settings

Indication

Control

ESD

Security

Defaults

Close Settings

Direction Clock Anti

Action

Torque 40%

Set Limit

Action

Torque 40%

Set Limit

Turns 14.9

Position

*

Speed

Opening

OP Bypass Pos 5%

Closing On Off

CL Bypass Pos 95%

1/15

Limit Torque

Open Settings

Limit Torque

49.6

90%

Torque Limit Bypass

On Off

* IQT builds only

The Limits page is shown above with the default settings.

Close Settings

1/15 Close Direction

Sets the output rotation direction required to close the valve.

Using the handwheel, manually operate the actuator to establish

valve closing direction.

Clock (default) – clockwise rotation of the actuator closes the

valve.

Anti – anti-clockwise (counter clockwise) rotation of the actuator

closes the valve.

To change,

closing direction.

2/15 Close Action

The actuator can be configured to close on torque for seating

valve types or limit for non-seating valve types.

Refer to Valve manufacturer for recommended setting.

In the absence of valvemaker instruction refer to the

following table:

. The checkbox will indicate the set

8 IQ3 Full Co nfiguration M anual – Sec tion: Setti ngs

Page 9

2.1 Settings – Limits

continued

Valve Type

Close Action

Open Action

Wedge gate Torque Limit

Globe Torque Limit

Butterfly Limit Limit

Through conduit Limit Limit

Ball Limit Limit

Plug Limit Limit

Sluice gate Limit Limit

Penstock Limit Limit

Parallel slide Limit Limit

Limit (default) – The actuator will move the valve to the set

Closed Limit position and stop.

Tor que – The actuator will move the valve to the set Closed

Limit position and then apply the set torque (3/15) to seat the

valve.

To change,

closing action.

3/15 Close Torque

The value of torque available to close the valve can be limited

between 40% and 100% of its nameplate rated torque. If the

actuator experiences the set torque when closing between the

limits, it will stop and must then be reversed before it will move

closed again. Operational torque can be monitored using the

data log (refer to 4) and using the torque-position home screen

(refer to 2.2.2).

The default setting for closed torque limit is 40%. If a

value of torque was specified at time of order, the %

value equating to the specified torque will have been set

by Rotork.

If the actuator was delivered complete with valve, the

valvemaker may have set the closed torque limit based on

testing and/or design requirements.

In the absence of valvemaker instruction, set the minimum

value required to close the valve under process conditions.

To change,

closing torque value.

4/15 Close Limit

Limits must only be set when the actuator is coupled to the valve.

The minimum number of output turns between set Closed and

Open Limits is 2.5 or 30º (IQT). A Closed Limit position cannot

be set if the actuator is at its set Open Limit or within 2.5 (30º)

turns of an Open Limit position. Should a condition arise where

this occurs, for example where an actuator at its Closed Limit

position is coupled to a valve at its open position, refer to 2.6

Defaults - Limits.

If the actuator was delivered complete with valve, the

valvemaker should have set the Closed and Open limit

position, refer to testing below.

The Closed Limit position must be set by moving the actuator to

the valve Closed Limit position and pressing

The actuator will display the following Instruction:

. The checkbox will indicate the set

. The slider will indicate the set

.

Move the actuator and valve to the close position. Allow for

overrun by winding open by ½ to 1 output turn.

Press to select OK.

The Closed Limit will be set at the current valve position. If not

previously illuminated, the closed indication LED (default green,

refer to 2.2.2) will be turned on.

Testing: The limit position can be confirmed by opening the

actuator until the indication LED changes colour and then

moving closed until the Closed Limit indication LED colour is

turned on at the set Closed Limit position.

Open Settings

5/15 Open Action

The actuator can be configured to open on torque for backseating valve types or limit for non back-seating valve types.

Refer to valve manufacturer for recommended setting.

In the absence of valvemaker instruction set open action

to Limit.

Limit (default) – The actuator will move the valve to the set

Open Limit position and stop.

Tor que – The actuator will move the valve to the set Open Limit

position and then apply the set torque (6/15) to back-seat the

valve.

To change,

opening action.

6/15 O pen Torq ue

The value of torque available to open the valve can be limited

between 40% and 100% of its nameplate rated torque. If the

actuator experiences the set torque when opening between the

limits, it will stop and must then be reversed before it will move

open again. Operational torque can be monitored using the data

log (refer to 4) and using the torque-position home screen (refer

to 2.2.2).

The default setting for open torque limit is 40%. If a value

of torque was specified at time of order, the % value

equating to the specified torque will have been set by

Rotork.

If the actuator was delivered complete with valve, the

valvemaker may have set the closed torque limit based on

testing and/or design requirements.

In the absence of valvemaker instruction, set the minimum

value required to open the valve under process conditions

but higher than that set for closed torque.

To change,

of opening torque value.

. The checkbox will indicate the set

. The slider will indicate the set limit

IQ3 Full Confi guration Man ual – Secti on: Setting s 9

Page 10

2.1 Settings – Limits

continued

7/15 Set Open Limit

Limits must only be set when the actuator is coupled to the

valve.

The minimum number of output turns between set Open and

Closed Limits is 2.5. An Open Limit position cannot be set if

the actuator is at a set Closed Limit position or within 2.5 turns

of a Closed Limit position. Should a condition arise where this

occurs, for example where an actuator at its Open Limit position

is coupled to a valve at its closed position, refer to 2.6 Defaults

- Limits.

If the actuator was delivered complete with valve, the

valvemaker should have set the Closed and Open limit

positions, refer to testing below.

The Open Limit position must be set by moving the actuator to

the valve Open Limit position and pressing

The actuator will display the following Instruction:

Move the actuator and valve to the open position. Allow for

overrun by winding closed by ½ to 1 output turn.

Press to select OK.

The Open Limit will be set at the current valve position. If not

previously illuminated, the open indication LED (default red, refer

to 2.2.2) will be turned on.

Testing: The limit position can be confirmed by closing the

actuator until the indication LED changes colour and then

moving open until the Open Limit indication LED is turned on at

the set Open Limit position.

8/15 Tu rns

Shows the actuator output turns between the set Closed and

Open Limit positions.

9/15 Position (non-editable)

Shows the actuator current position on 0-100%.

10/15 Speed (IQT only)

The default speed for a standard IQT is 100% (rated) or 50% for

IQTM. Speed can be adjusted to suit operation/process needs.

To cha nge ,

set speed.

. The slider will indicate the current

.

Torque Limit Bypass

The default setting for opening and closing torque limit bypass is

Off (torque protection active at all times). Bypassing the torque

protection allows torque up to approximately 150% of rated to

be available.

The valve maker or integrator should be consulted to

confirm the valve structure and interface components can

withstand the additional torque/thrust.

11/15 Opening

Opening torque limit protection can be bypassed over a portion

of the opening stroke, refer to 12/15. When set to On, torque

of up to approximately 150% of rated is available for opening

"sticky" valves.

To cha nge ,

opening torque limit bypass status.

12/15 Opening Bypass position

When opening torque limit bypass is set to On (refer to

11/15), the position over the opening stroke where torque

limit protection is bypassed can be set. If torque limit bypass

open is set to Off, the opening bypass position control will be

greyed out.

The available position range over which torque limit protection

is bypassed is 0% (Closed Limit) to 95% open. Outside the set

bypass position, torque switch protection will revert to that set

for 6 /15.

To cha nge ,

set position range over which opening torque limit is

bypassed.

13/15 Closing

Closing torque limit protection can be bypassed over a portion of

the closing stroke, refer to 14/15. When set to On, torque of up

to approximately 150% of rated is available for closing the valve.

To cha nge ,

closing torque limit bypass status.

14/15 Closing Bypass position

When closing torque limit bypass is set to On (refer to 13/15), the

position over the closing stroke where torque limit protection is

bypassed can be set. If torque limit bypass closed is set to Off,

the closing bypass position control will be greyed out.

The available position range over which torque limit protection

is bypassed is 100% (Open Limit) to 5% open. Outside the set

bypass position, torque switch protection will revert to that set

for 3 /15.

To cha nge ,

position range over which closing torque limit is bypassed.

. The checkbox will indicate the set

. The slider will indicate the

. The checkbox will indicate the set

. The slider will indicate the set

10 IQ3 Full Co nfiguratio n Manual – Sec tion: Sett ings

15/15 Auto Limit Setting

Sets the open and close limits automatically. Then end of travel

for the lower and upper limits is established when 40% torque

has been reached in each direction. The Actuator must be in

Local to complete this function.

Page 11

2.2 Settings – Indication

Limits

Indication

Control

ESD

Security

Defaults

Instruction is provided on:

2.2.1 Contacts

2.2.2 Local display

2.3.3 Analogue

2.2.1 Indication – Contacts

Settings

Limits

Indication

Control

ESD

Security

Defaults

Contacts

Local Display

Analogue

Mode Available

Function Closed Limit

Contact

Position 0%

Function Open Limit

Contact

Position 0%

Function Closed Limit

Contact

Position 0%

Function Open Limit

Contact

Position 0%

1/37

The Monitor Relay and S contact settings page is shown in

their default setting.

Refer to actuator wiring diagram for available contacts.

Settings

Indication

Contacts

Monitor Relay

S1

N/O N/C

S2

N/O N/C

S3

N/O N/C

S4

N/O N/C

1/37 Monitor Relay – Mode

The monitor relay provides remote indication of actuator status.

It provides a volt free change over contact, refer to actuator

circuit diagram. There are 2 modes that can be set:

Available (default) – Actuator available for remote control.

Monitors power supplies, motor thermostat, detected internal

fault and remote control selected. A loss in one or more will

cause the monitor relay to de-energise indicating "not available"

for remote control.

Fault – Actuator fault. Monitors power supplies, motor

thermostat and detected internal fault. A loss in one or more

will cause the monitor relay to de-energise indicating "actuator

fault".

To change the mode,

will close and the selected mode will be shown:

. The drop down list box

S Contact function, contact type and position

Each relay contact can be set to one of the functions shown

in the table below and its contact type can be set as Normally

Open (NO) or Normally Closed (NC). If Pos % Open function is

selected, the position at which the relay operates can be set. For

all other functions the position control slider will be greyed out.

Standard Contacts S1-S4, Option S5-S8 and S9-S12

Contacts when fitted

The method for setting all S contacts is the same. S1 to S4 are

fitted as standard. A further 8 extra contacts are available as

options grouped: S5 to S8 and S9 to S12, refer to actuator wiring

diagram. If extra contacts are fitted their configuration screens

are accessed by scrolling down. If not fitted their configuration

settings will be greyed out.

2/37 Contact Function

The available contact functions included in the drop down list

box are shown below.

To change the contact function,

down list box will close and the selected function will be

shown:

Function Indication:

Disabled Contact disabled

Closed Limit Closed limit position (exact)

Open Limit Open limit position (exact)

End Position Both Closed and Open Limit positions

Pos % open Set position mid-travel – opening and closing

Mid Travel Not at Closed or Open Limits

Motor Running Motor running

Closing Travelling in the close direction - motor or handwheel

Opening Travelling in the open direction - motor or handwheel

Moving Travelling – motor or handwheel

Handwheel During handwheel operation

Blinker Travelling (make/break at 1 second intervals)

Valve Alarm On torque trip mid-travel or motor stall condition

Torque Trip CL Torque trip closing - any position

Torque Trip OP Torque trip opening - any position

. The drop

Continued over page

IQ3 Full Confi guration Man ual – Secti on: Setting s 11

Page 12

2.2.1 Indication – Contacts

continued

2.2.2 Indication – Local Display

Function Indication:

Torque Trip Torque trip closing or opening - any position

Torque Trip Mid Torque trip mid-travel, closing or opening

Motor Stall

Mid Travel Stall

Stop Selected Red selector set to STOP

Local Selected Red selector set to Local

Remote Selected Red selector set to Remote

Control Alarm ESD signal and/or interlock active

Monitor Monitor relay de-energised

ESD Active ESD signal applied

OP Interlock Active Open Interlock active

CL Interlock Active Close interlock active

Interlock Active Open and/or closed interlock active

Actuator Alarm Internal fault detected

Motor Over Temp Motor thermostat has tripped

Lost Phase 3-phase only: monitored phase 3 lost

24 V Supply Fail Internal 24 VDC supply failed (Terminals 4 & 5)

P Stroke Active Partial stroke underway

P Stroke Fail Partial stroke not completed

P Stroke Pass Partial stroke completed

Bluetooth Bluetooth communication in progress

Battery Low Battery low

Battery Discharged Battery discharged or missing

Digital Output Network option controlled

Maintenance Scheduled maintenance due

Hi Torque Alarm Set Hi torque value reached

Hi Hi Torque Alarm Set Hi-Hi torque value reached

Src 1 Coms Loss Communication failure with option 1 card

Src 2 Coms Loss Communication failure with option 2 card

NAMUR Maint. A NAMUR maintenance condition is active

NAMUR Out Of Spec. A NAMUR out of specification condition is active

NAMUR Func. Check A NAMUR function check condition is active

NAMUR Failure A NAMUR failure condition is active

Over Modulation Starts per hour has been exceeded

Motor Enable

Maintain Enabled Open/Close signals are maintained

HMI Loss HMI will not be lit up

General alarm

Bat Backup Avail

Bat Backup Ctrl Checks if the battery is in control

At limit, motor energised – no output movement

detected

Not at limit, motor energised – no output movement

detected

Active when motor enable is inhibiting electrical

operation

Anything which constitutes an alarm out of the

‘function’ list triggers this alarm

Checks availability of battery, checks if battery is

charged

4/37 Position

If the relay function relates to an actuator position, for example

Pos % Open, this setting will become available to edit. Range

0% - 100%.

To change use

the set position value.

Limits

Indication

Control

ESD

Security

Defaults

Contacts

Local Display

Analogue

Home Screen Position

Power Save On Off

Close LED Green Red

Mid Travel LED Off

Alarm LED Alarms

LCD / LED Test

1/7

. The slider control will indicate

Settings

Indication

Local Display

LCD

LED

The Local Display settings page is shown in its default

setting.

LCD

The displayed home screen language can be selected and power

save mode can be activated.

1/7 Home Screen

If NAMUR 107 relay functions are used, refer to 5.6 for NAMUR

107 condition settings.

3/37 Contact

Each relay contact output can be configured as normally open

(make on condition) or normally closed (break on condition).

N/O - The contact will complete the circuit when the set function

is present, normally open, refer to 2/37 Contact Function.

N/C - The contact will break the relay circuit when the set function

is present, normally closed, refer to 2/37 Contact Function.

To change use

selected contact type.

. The checkbox will indicate the

12 IQ3 Ful l Configurati on Manual – Se ction: Set tings

Refer also to PUB002-039 (IQ) or PUB002-065 (IQT)

Available Home screens included in the drop down list box:

Position (default) - Display indicates the current valve position

to one decimal place. Icons are used for closed and open

limit positions.

Torque (A) + Pos – Display indicates current valve position

to one decimal place as Position (above) plus analogue torque

indication scaled 0% to 100% of rated torque, shown at the top

of the display.

Torque (D) + Pos – Display indicates current valve position

to one decimal place as Position (above) plus digital torque

indication scaled 0% to 99% of rated torque. If the actuator

develops torque greater than 99% then "Hi" will be displayed.

Page 13

2.2.2 Indication – Local Display

continued

Positioner – Used only with analogue or network position

control. Display indicates current valve position ( ) to one

decimal place plus the position equating to the applied demand

signal ( ). In addition, an analogue indication of demand and

position is provided scaled 0% to 100% of valve position.

To set the home screen,

list box will close and the selected home screen will be

indicated.

2/7 Power Save

The LCD has a white backlight to maximise contrast of the

segment display and matrix characters. It may be switched off

when not required if a bright display is disruptive within its

environment.

Off (default) - The display backlight is permanently illuminated

when the actuator is powered up.

On - The display backlight automatically switches off when the

actuator is not operating. The segments/matrix remain on. The

display backlight will switch on when the local control selectors

are moved, electrical or handwheel operation takes place or

when the Setting Tool is communicating with the actuator. The

backlight will switch off again approximately 30 seconds after

the above events have taken place.

To change the power save mode,

will indicate the selected mode.

. The drop down

. The checkbox

LED

The function of the display green, red and yellow LED lights can

be set.

3/7 Close Colour

Green (default) – The green lights illuminate at the Closed Limit

position, red at open.

Red – The red lights illuminate at the Closed Limit position,

green at open.

To change the Closed Limit position indication light,

colour.

4/7 Mid Travel LED

. The checkbox will indicate the selected closed

5/7 Alarm LED

Alarm LED Function will be greyed out unless 4/7 Mid Travel LED

is set to On/Alarm or Off/Alarm.

Disabled (default) – The yellow lights do not indicate an

active alarm.

Alarms – The yellow lights indicate active alarms.

Service – The yellow lights indicate active service alarms only.

A service alarm indicates the actuator requires service due to set

duty parameters being met. Refer to Section 5.5.

Service/Alarms – The yellow lights indicate active alarms and

active service alarms. A service alarm indicates the actuator

requires service due to set duty parameters being met. Refer to

Section 5.5.

Information regarding the nature of the alarm(s) will be shown at

the top of the display.

To change the Alarm LED Mode,

down list box will close and the selected mode

will be shown.

6/7 LCD / LED Test

The LCD/LED test function operates a test procedure to check all

of the local display functions. It will cycle periodically between

screen and LED functions to provide visual indication that the

display is in fully working order.

Press

local display menu once the test is complete.

7/7 Language

The language used on the display can be selected.

English (default), French, German and Spanish are available

as standard. Other available languages may be downloaded from

the Rotork website, loaded into the Setting Tool using Insight2

and uploaded into the actuator. Visit www.rotork.com

To change the display language,

down list box will close and the selected language will be

active for all screens and pages.

Available for actuators with a build date after December 2013

(12/13).

to begin the test. The screen will return to the

. The drop

. The drop

On (default) – The yellow lights are on when mid-travel.

Off – The yellow lights are off when mid-travel.

Blinker – The yellow lights flash at approximately 0.5 second

intervals when travelling in mid-travel (electric or handwheel

operation). When stationary, the lights will remain on.

On/Alarm – The yellow lights are on when mid-travel. If an

alarm is active the yellow lights flash alternately at approximately

0.5 second intervals. Refer to 5/7 Alarm LED.

Off/Alarm – The yellow lights are off when mid-travel. If an

alarm is active the yellow lights flash alternately at approximately

0.5 second intervals. Refer to 5/7 Alarm LED.

Information regarding the nature of the alarm(s) will be shown at

the top of the display.

To change the mid-travel LED Mode,

down list box will close and the selected mode will be

shown.

. The drop

IQ3 Full Confi guration Man ual – Secti on: Setting s 13

Page 14

2.2.3 Indication – Analogue

2.3 Settings – Control

Limits

Indication

Control

ESD

Security

Defaults

Indication

Contacts

Local Display

Analogue

Analogue

Analogue

Invert On Off

1/1

Settings

Limits

Indication

Control

ESD

Security

Defaults

Instruction is provided on:

2.3.1 Local control

Settings for vandal resistant build, Setting Tool control,

maintained local control, delay control and action on

loss of actuator user interface.

2.3.2 Remote control

Settings for control source; hardwired, networks,

analogue and partial stroke setup.

2.3.3 Interrupter Timer

The Interrupter Timer is an optional extra, check circuit

diagram for inclusion. If it is not enabled it will not be

included in the display menu. It is used to control

closing and/or opening operating time under both

local and remote control.

Settings

Analogue position indication screen is shown above with

its default setting.

Analogue position indication (4-20 mA) is an optional extra, refer

to circuit diagram for inclusion. If the option is not fitted the

Analogue menu item will not be present in the Indication menu.

The analogue output signal auto ranges to the set limits and

cannot be calibrated.

1/1 Invert

Off (default) – 4 mA output at Closed Limit position / 20 mA

output at Open Limit position.

On – 4 mA output at Open Limit position / 20 mA output at

Closed Limit position.

To change the analogue output mode,

checkbox will indicate the selected mode.

. The

14 IQ3 Ful l Configurati on Manual – Se ction: Set tings

Page 15

2.3.1 Control – Local

Limits

Indication

Control

ESD

Security

Defaults

Settings

Local

Remote

Interrupter Timer

Control

Local Control

Vandal Disabled

Setting Tool Yes No

Maintained Yes No

Delay Control Yes No

Loss Of HMI Stayput Remote

Remote Hand Station

Enabled On Off

1/6

The local control configuration page is shown with the

default settings.

1/6 Vandal

Actuators built as vandal resistant type 1 do not have the black

and red control selectors fitted. Selection of Local control (using

the Setting Tool open, close and stop keys) and Remote control is

made using the vandal setting:

Disabled (default) – Actuator is not vandal resistant build and

control selectors are present.

Local – Actuator selected for Local control using the Setting Tool

(Bluetooth or infrared), refer to 1.1. Infrared local control has a

range of approximately 0.25 m (10") and must be in direct line of

site. Bluetooth Local control has a range up to approximately 10 m

(30 ft) depending on environment.

Remote – Actuator selected for Remote control. Setting Tool

control keys are inactive and the actuator responds only to

remote control signals.

Switched – This option is available with an external PCB (i.e.

DIO), the actuator uses the input to switch the vandal between

local and remote.

To change,

the selected control mode will be indicated.

. The drop down list will close and

2/6 Setting Tool

With control selectors fitted to the actuator, the Setting Tool

close, open and stop control keys can be used to operate the

actuator:

Yes – Setting Tool control keys active, control is possible only

when the red selector is set to Local, refer to 1.1 – using the

Setting Tool. Infrared local control has a range of approximately

0.25 m (10") and must be in direct line of site. Bluetooth Local

control has a range up to approximately 10 m (30 ft) depending

on environment. The black close/open selector remains active.

No (default) – Setting Tool close, open and stop control keys

disabled. Local control is by close/open/ stop selectors fitted to

the actuator.

To change,

selected Setting Tool control mode.

. The checkbox will indicate the

3/6 Maintained

Sets the action as a response to local open or close control

signals:

Yes (default) – The actuator will self-maintain as a response

to a fleeting local open or close control signal. It will run until it

receives a stop command, it reaches a travel limit or is reversed –

Maintained control.

No – The actuator will run only while an open or close control

signal is applied – Push to run local control.

To change,

selected action.

. The checkbox will indicate the

4/6 Delay Control

If there is a risk of a local close or open control signal being

applied due to the selector moving inadvertently or by being hit

momentarily, a delay can be set to help prevent an unintended

operation:

Yes – A local close or open signal must be held for approximately

2 seconds before the actuator responds.

No (default) – The actuator responds immediately to a local

close or open control signal.

To change,

selected local selector response.

. The checkbox will indicate the

5/6 Loss of HMI

The Human Machine Interface consists of the actuator display

and red and black selectors. If for any reason the HMI stops

responding, the response of the actuator can be set.

Stayput (default) – The actuator will stayput and alarm using

the monitor relay. It will not respond to remote control signals.

Remote – The actuator will alarm using the monitor relay. It will

continue to respond to remote control signals.

To change,

selected HMI failure response.

. The checkbox will indicate the

6/6 Remote Hand Station

When fitted, the Remote Hand Station (RHS) can be enabled by

this setting.

Off (default) – RHS not activated and the sub-menus will be

hidden.

On – RHS enabled and the sub-menus will appear in the main

Control menu. Refer to PUB002-059 for full setup.

IQ3 Full Confi guration Man ual – Secti on: Setting s 15

Page 16

2.3.2 Control – Remote

Limits

Indication

Control

ESD

Security

Defaults

Local

Remote

Interrupter Timer

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Analogue

Pakscan

Profibus

HART

Modbus

Extra I/O

Settings

Control

Remote Control

The Remote Control menu is shown left listing all possible

entries. Some menu items shown are optional remote control

forms requiring additional hardware to be fitted in the actuator

(see table below). The menu list displayed on the actuator will

show only the option(s) fitted. Options not fitted will not be

included in the menu list, check wiring diagram for option

inclusion.

The table below lists the available standard and option

remote control forms, their type and the section of this

manual where instruction is provided.

Remote Control Form Included as: Type Section

Hardwired Standard Hardwired

Control Source Standard Software

Partial Stroke Standard Hardwired

Positioning Option See Note

Auxiliary Mask Option See Note

Analogue Option Analogue

Pakscan Option Network

Profibus Option Network

HART Option Analogue

Modbus Option Network

Extra I/O* Option Hardwired

Foundation Fieldbus* Option Network

* When Foundation Fieldbus is fitted it will be included in the remote

control menu for information only. The Foundation Fieldbus option is

configured remotely over the Fieldbus network and therefore does not

have a setup page. Control Source, Positioning and Auxiliary Mask pages

will be included to allow associated setting to be made when Foundation

Fieldbus is fitted.

Extra I /O is an option card providing additional digital inputs to the

standard build. Inputs may be control or indication (configurable).

2.3.2-1

2.3.2-2

2.3.2-3

2.3.2-4

2.3.2-5

2.3.2-6

2.3.2-7

2.3.2-8

2.3.2-9

2.3.2-10

2. 3 . 2 -11

N/A

Instruction is provided on the setup of standard hardwired

and remote control options.

Note: When any of the analogue or network remote

control options are fitted, Auxiliary Mask and Positioning are

automatically included in the remote control menu. These items

allow access to settings that are common to all fitted options.

See Examples below.

Example 1: For a basic actuator with no control options fitted,

the remote control menu is shown below.

Hardwired

Control Source

Partial Stroke

Remote Control

Example 2: For an actuator with a remote control option, the

remote control menu will automatically display the appropriate

items relating to that option. The example below shows the

menu for an actuator including the Profibus option with the

associated Positioning and Auxiliary Mask items.

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Profibus

Remote Control

16 IQ3 Full Co nfiguratio n Manual – Sec tion: Sett ings

Page 17

2.3.2-1 Control – Remote – Hardwired

Hardwired

Control Source

Partial Stroke

Remote Control

Remote Control

2-Wire Priority Stop

Interlocks

Mode Disabled

Motor Enable

Motor Enable Disabled

1/3

Hardwired Control is a standard feature. The default

settings are shown above.

Hardwired Control is a standard remote control form

available on all actuators. It allows settings for hardwired

2-wire priority control and interlocks.

1/3 2-Wire Priority

Sets the action the actuator perform when a close and open

signal are applied simultaneously. Hardwired remote control

form C uses the priority action (open or closed) to set the

actuator response when 2 signals are applied. Refer to the

wiring diagram and its referenced RWS control diagram.

On applying hardwired close and open signals together, the

actuator will:

Open – The actuator will move open.

Stop (default)

–

The actuator will not move, or will stop if running.

Close – The actuator will move closed.

To change,

the selected 2-wire control mode will be indicated.

. The drop down list will close and

Conditional – Close and open interlock inputs are enabled,

interlocking is available and will be active in remote control

only. The actuator will not run under remote control unless

interlock signals are applied to the closed control and closed

interlock input or the open control and open interlock input.

Remote control is conditional on 2 signals being applied

simultaneously and therefore integrity of operation due to

spurious control signals is increased. Local control is available

without interlock inputs.

Partial Stroke – Partial stroke testing demonstrates the

operational integrity of the valve and actuator by moving them

for a set portion of stroke. A remote "partial stroke" hardwired

signal applied to the open interlock input is used to initiate a

partial stroke test. For setting the partial stroke test parameters,

refer to 2.3.2-3. When set to partial stroke, the closed interlock

is disabled. Partial stroke initiated via a network command (with

a network option fitted), does not require the interlocks to be

configured for partial stroke.

To change the settings use

list will close and the selected interlock mode will be

. The drop down

indicated.

3/3 Motor Enable

Sets the remote control maintain function when the motor

enable feature is used. When using motor enable, the maintain

line on terminal 34 becomes the permissive input.

Disabled (default) – Maintain function is controlled by applying

a signal to terminal 34.

Push to Run – Remote controls are push to run. On removal of

the remote open or close command, movement will stop.

Maintained – Remote controls are self maintained so only a

pulse is required. Removal of the remote open or close signal will

not stop operations. To stop movement, you must remove the

motor enabled signal.

2/3 Interlocks

Sets the mode for the interlock inputs, refer to wiring diagram.

External interlocks can be used to prevent operation of the

actuator until a certain process condition is met. An example is a

main and bypass valve system. The main valve is interlocked with

the bypass valve such that it cannot be opened until the bypass

valve is fully open.

Disabled (default) – The interlock inputs are disabled,

interlocking is not available.

Enabled – Close and open interlock inputs are enabled,

interlocking is available and will be active in both local and

remote control. The actuator will not run in local or remote

control unless interlock signals are applied to the closed or the

open interlock input. If only one interlock is required, for example

an interlock to prevent closed operation, the open interlock must

be linked out.

IQ3 Full Confi guration Man ual – Secti on: Setting s 17

Page 18

2.3.2-2 Control – Remote – Control Source

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Analogue

Remote Control

Option Control

Ctrl Source 1 Analogue

Ctrl Source 2 Disabled

Ctrl Selection Source 1

Options Fitted

Analogue

Disabled

Disabled

Disabled

Analogue

Lost Sig Time (s) 0

Lost Signal Act.

Signal Loss Pos. 0%

1/20

Off

The Control Source setting page shown above is an

example of an actuator with the Analogue remote control

option.

The actuator display will indicate fitted options.

Refer to wiring diagram for options fitted.

Introduction

In addition to standard hardwired control, the actuator can have

up to two remote control options fitted. For most remote control

systems employed by end-users, only one control option is used.

For control systems using Analogue control only or where

Analogue and Network (such as Modbus) control is used,

control (Hardwired/Analogue or Analogue/ Network) can be

switched by the user using the Manual/Auto input available with

the analogue option and the settings made in Control Source.

When Analogue and Network options are fitted and Analogue

is switched to control, the Network option cannot control the

actuator but will continue to report actuator status.

The control source will be set by Rotork to the defaults

required for the option(s) fitted. Refer to Table: Control

Source Settings.

For analogue control, if both Manual (hardwired control

inputs) and Auto (analogue control) is to be used, the

control selection will require re-setting. If only analogue

control is required, the default settings for Control Source

will be correct. Refer also to 2.3.2-6.

The control source is used to:

• Control Source 1/Source 2 - Associate fitted control option(s)

to a source of control (source 1 or source 2).

• Control Selection - Set which control source (1 or 2) has

priority when Manual/Auto input is used to switch between

Analogue and Network option sources.

• Lost Signal - Determines the actuator response to a lost

analogue signal or network communication.

Table: Control Source Settings

Options Control

Settings

Hardwired

(no options)

Analogue Only

Ctrl Source 1 Disabled Analogue Analogue Network Analogue

Ctrl Source 2 Disabled Disabled Disabled Disabled Network

Ctrl Selection Hardwired Source 1

Options Fitted

Disabled Analogue Analogue Network Network

Disabled Disabled Disabled Disabled Analogue

Disabled Disabled Disabled Disabled Disabled

Disabled Disabled Disabled Disabled Disabled

Analogue and

Hardwired

Hardwired /

Source 1

Network Only

Analogue

and Network

Source 1 Src1 (Ang) / Source 2

KEY: For "Network", display will indicate the fitted option(s): Pakscan/Profibus/Modbus/Foundation Fieldbus (FF)/HART.

18 IQ3 Full Co nfiguratio n Manual – Sec tion: Sett ings

Page 19

2.3.2-2 Control – Remote – Control Source

continued

1/20 Control Source 1

Control Source 1 will be set by Rotork for the fitted remote

Analogue or Network control option(s). Refer to Table: Control

Source Settings.

2/20 Control Source 2

Control Source 2 will be set by Rotork for the fitted remote

Analogue or Network control option(s). Refer to Table: Control

Source Settings.

3/20 Ctrl Selection

Control Selection is used to select the control source and if

required, for Analogue option or Analogue with Network

options, allow hardwired switching between sources using the

Manual/Auto input.

Disabled – All remote control disabled. The actuator can only be

operated using the local controls.

Hardwired – Remote control by hardwired inputs only. This

setting is the default for actuators with no option cards fitted.

If a Network option is fitted but is not required for

control,

to select Hardwired.

Source1 – Control by the option listed for Control Source 1.

If Control Source 1 is a Network option, control will be via its

auxiliary mask inputs, refer to 2.3.2-5.

Hardwired / Source1 – Control available only when Analogue

option is fitted. This mode enables the user to select between

control by hardwired inputs or source 1 (Analogue) control by

applying or removing a signal to the Manual/Auto input, refer to

wiring diagram. Manual will enable hardwired control and Auto

will enable Source1 control.

If an Analogue option is fitted and Manual/Auto switching

is required,

to select Hardwired/Source 1.

Source 1 (Ang) / Source 2 – Control by Analogue and a

Network option only. This mode enables the user to select

between Source 1 (Analogue) and Source 2 (Network) control, by

applying or removing a signal to the Manual/Auto input available

with the Analogue option, refer to wiring diagram. Manual will

enable source 2 and Auto will enable source 1, refer to 2.3.2-6.

Source 1 / Source 2 – For future use with two Network control

options.

If Analogue and Network options are fitted and Manual/

Auto switching is required,

(Ang) / Source 2.

to select Source 1

4/19 to 7/19 Options Fitted

Not editable. Factory set for the control options fitted. Up to 4

options can be fitted and will be indicated in the list. Unused

allocations will be set to Disabled.

If a control option is fitted after manufacture, the allocation will

be set to the fitted option type by Rotork Service. Where the

user upgrades an actuator to include a new control option using

a kit supplied by Rotork, this must be set before the control

mode settings can be made. Contact Rotork for access.

8/20 to 19/20 Lost Signal

Sets the actuator response for when the analogue signal

or Network communications of the control source

are lost.

There are 3 settings for determining the actuator response on

loss of signal and these are common for all option types fitted.

Each group of 3 will be headed with the applicable option type

- example Analogue. For actuators including one control option,

settings 8/20 to 10/20 will be available and settings 11/20 to

20/20 will be greyed out. For 2 options fitted, 8/20 to 13/20

will be available and so on up to 4 options. This instruction is

therefore common for as many options as are fitted.

8/19 Lost Signal Time

Sets the amount of time in seconds that a signal must be lost

before the set lost signal action is performed. Range 0 to 65

seconds:

For the analogue option, time must be set to 0 seconds.

To change,

signal action will be implemented and indicated.

. The time set after which the lost

9/19 Lost Signal Action

Sets the action performed when the signal is lost:

Off (default) – The lost signal feature is disabled. An actuator

with Analogue control will run to the set low signal position. An

actuator with Network Control will stay at its current position

when communication is lost.

Stayput – If the actuator is not moving it will Stayput, if it is

moving it will Stop.

Close – The actuator will run to the Close Limit.

Open – The actuator will run to the Open Limit.

Position – The actuator will run to the mid-travel position set for

Signal Loss Position, refer to 10/19.

To change,

the selected action will be indicated.

. The drop down list will close and

10/19 Lost Signal Position

When the lost signal action is set to Position the actuator will

run to the mid-travel position set. Range is 0% (Closed Limit) to

100% (Open Limit). This control should be used if a lost signal

position in mid-travel is required.

Whenever the actuator is running under positioning mode, the

parameters in the Positioning menu will apply. Refer to 2.3.2-4.

To change,

mid-travel position the actuator will move to when the

. The slider control will indicate the

control/network signal is lost.

IQ3 Full Confi guration Man ual – Secti on: Setting s 19

Page 20

2.3.2-3 Control – Remote – Partial Stroke

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Analogue

Remote Control

Partial Stroke

Enable No Yes

From Limit

To Position 95%

Out Time (s)

Return Time (s) 60

Test

1/6

Open Close

60

Partial Stroke is a standard feature. The default settings

are shown above.

Partial stroke testing is used to demonstrate the operational

integrity of the valve and actuator by moving over a set portion

of valve stroke. In addition, partial stroking may be used

to exercise infrequently operated valves to help keep them

mechanically free. Partial stroke test can only be initiated when

the actuator is at the set From Limit position.

A partial stroke test may be initiated by a remote partial stroke

signal applied to the open interlock*, a network command

(network option fitted) or using the test control on the partial

stroke page.

*Interlocks must be set to partial stroke, refer to 2.3.2-1.

Partial stroke test results (torque and pass/ failure status) are

captured by the data log.

Partial stroke operation, pass and failure can be indicated by the

S contacts, refer to 2.2.1.

1/6 Enable

No (default) – Partial stroking testing is disabled

Yes – Partial stroke testing is enabled.

To change,

stroke test status.

. The checkbox will indicate partial

2/6 From Limit

Selects the start/finish limit position for the partial stroke test.

Open (default) – The partial stroke test will start from the Open

Limit position, move close to the position set for 3/6 To Position

and then return to the Open Limit position.

Close – The partial stroke test will start from the Closed limit

position, move open to the position set for 3/6 To Position and

then return to the Close Limit position.

To change,

stroke start/finish position.

. The checkbox will indicate partial

3/6 To Position

Range 0% (closed) to 97% Open

Selects the intermediate position for the partial stroke test.

Sets the position in valve stroke to where the actuator will move

when a partial stroke test is initiated. For example a test starting

at Open Limit with a To Position of 70% set, will move from

Open Limit to 70% open and then return to the Open Limit. A

minimum of 3% travel is required to adequately perform the

partial stroke test.

To change,

position the actuator will move to for the partial stroke

. The slider control will indicate the

test.

4/6 - 5/6 Out Time - Return Time

Range 0 to 3600 seconds.

For IQ actuators, out time and return time must be set to the

same value. They are used to ensure that the partial stroke test

is completed in a quantified period of time. Alarms can be set

to indicate a failure in meeting the set time, indicating a valve

problem.

Measure or calculate the time to complete the set partial stroke

test. Add 10% to this value then half it. The resulting time should

be entered into both Out Time and Return Time.

To change,

time will be indicated.

. The set partial stroke out/return

6/6 Test

To initiate a partial stroke test using the Setting Tool, the

actuator must be set to Local control using the red selector and

at the limit position set for 2/6 From Limit.

To initiate a partial stroke test, . The partial stroke test

will be initiated as set.

20 IQ3 Full Confi guration Ma nual – Sect ion: Settin gs

Page 21

2.3.2-4 Control – Remote – Positioning

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Analogue

Remote Control

Positioning

Deadband 5%

Hysteresis 2%

Inhibit Time (s)

Low Signal Pos. 0%

High Signal Pos. 100%

1/5

2

The Positioning option settings page with its default

settings is shown above.

Applicable for Analogue and HART control options

and for all Network control options where positioning

control is required. Settings are used to tune the actuator

positioning response.

• Deadband and Hysteresis are combined to set positioning

accuracy.

• Inhibit Time is used to set a dwell in the actuators response.

• Low/High Signal Position sets the range of the valve stroke

where positioning is required.

1/5 Deadband

Range 0% - 25.5%. Default setting: 5%.

Affects positioning accuracy as a response to the process

control system desired value (DV) signal position. A smaller

deadband increases accuracy, however the widest deadband

should be set whilst maintaining good control in order to protect

the mechanical valve from excessive wear and/or to keep the

actuator within its electrical rating.

Deadband setting should be combined with 2/5 Hysteresis

setting. The actuator will run towards the DV position until the

actual position is within the set deadband minus the hysteresis

setting. This has the effect of the actuator stopping nearer to the

DV position. The actuator will not restart unless it overshoots and

runs outside the deadband or a new command places the new

desired position outside the deadband. Refer to figure 2.3-1.

To change,

deadband setting.

. The slider control will indicate the

2/5 Hysteresis

Range 0% - 25.5%. Default setting: 2%.

Affects positioning accuracy as a response to the process control

system desired value (DV) signal position. A larger Hysteresis

setting will increase accuracy but the value set must not be

greater than that set for Deadband.

Hysteresis setting should be combined with 1/5 Deadband

setting. The actuator will run towards the DV position until the

actual position is within the set deadband minus the hysteresis

setting. This has the effect of the actuator stopping nearer to the

DV position. The actuator will not restart unless it overshoots and

runs outside the deadband or a new command places the new

desired position outside the deadband. Refer to figure 2.3-1.

To change,

hysteresis setting.

. The slider control will indicate the

3/5 Inhibit Time

Range 0 – 255 seconds. Default setting: 5 seconds.

Sets a delay after the actuator stops as a result of reaching a

position consistent with a new DV position. For the period set,

the actuator will not respond to a change in DV. Inhibit time

is used to prevent unwanted operation as a result of a rapidly

oscillating or fluctuating DV signal or to slow actuator response

in order to protect the mechanical valve from excessive wear

and/or maintain actuator within its electrical rating.

To change,

. The time set will be indicated.

IQ3 Full Confi guration Man ual – Secti on: Setting s 21

Page 22

2.3.2-4 Control – Remote – Positioning

continued

4/5 Low Signal Pos

Range 0% to 100% open positions.

Used to set the position the actuator will move to when the

low analogue signal is applied for Analogue control or for a 0%

position command for Network options. Normally this will be set

at Closed Limit position (0%), unless positioning is required over

a reduced portion of full valve travel, for example, to prevent full

closure where valve throttling is required.

To change,

position the actuator will move to when the low signal is

applied.

. The slider control will indicate the

5/5 High Signal Pos

Range 0% to 100% open positions.

Used to set the position the actuator will move to when the High

analogue signal is applied for Analogue control or for a 100%

position command for Network options. Normally this will be set

at Open Limit position (100%), unless positioning is required over

a reduced portion of full valve travel, for example, to increase

positioning resolution for a butterfly valve where positioning is

required from Closed Limit position to 60% open position.

To change,

position the actuator will move to when the high signal is

applied.

. The slider control will indicate the

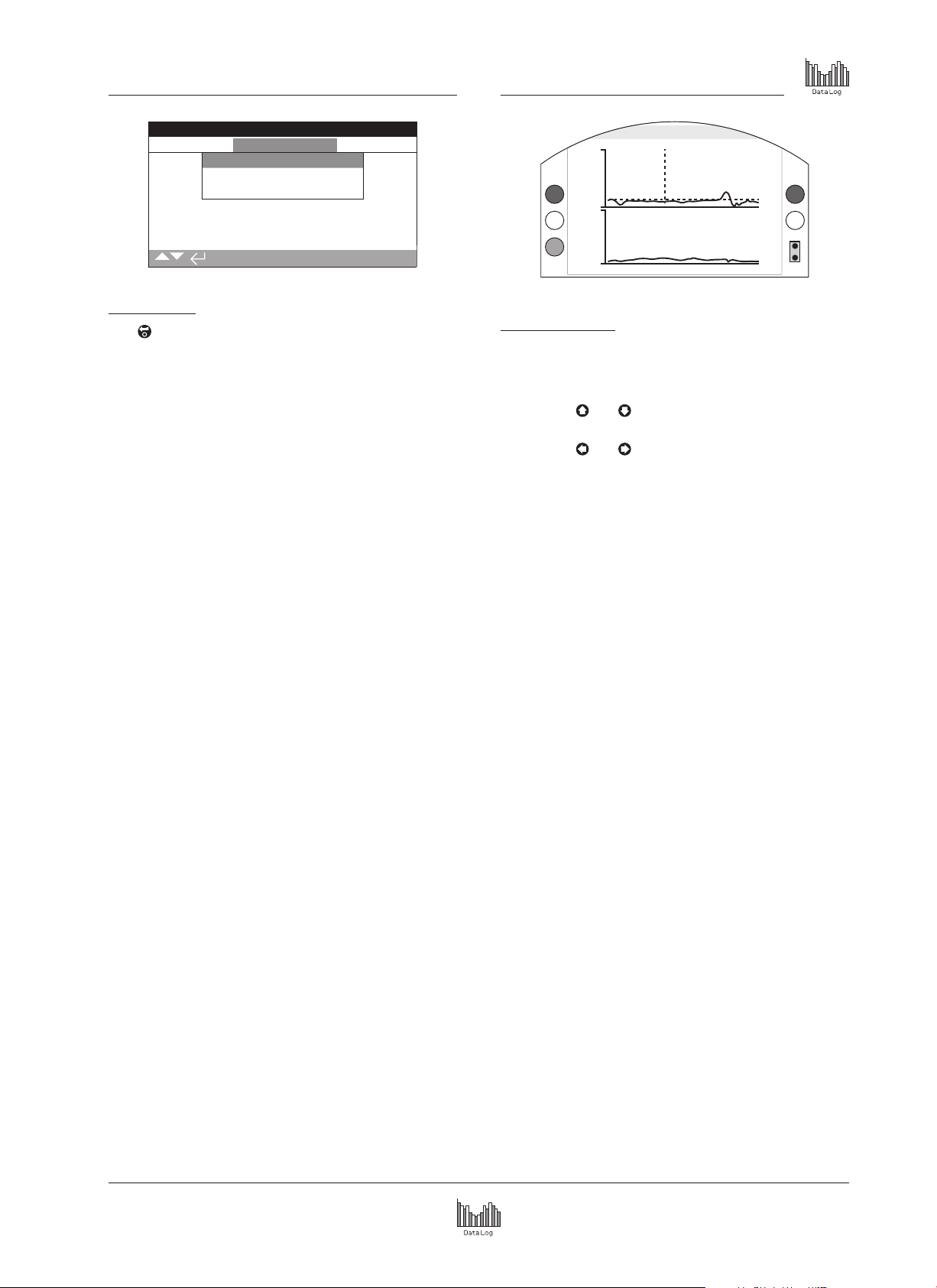

DV

47% 48% 49% 50% 51% 52% 53%

Hysteresis = 1%

Deadband = 3%

Figure 2.3-1 Example of Hysteresis and Deadband

Example: An actuator set with a 3% deadband and a 1%

hysteresis and a control system new Desired Value (DV) of 50%

will come to rest between 48% and 53% when moving from

a position less than 47%, and between 52% and 47% when

moving from a position greater than 53%.

OpenClose

The Deadband setting will be determined by the accuracy of

control required and valve overrun. Overrun is a factor of valve

and actuator inertia dependent on mass, speed, valve stiffness

and friction

22 IQ3 Full Confi guration Ma nual – Sect ion: Settin gs

Page 23

2.3.2-5 Control – Remote – Auxiliary Mask

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Analogue

Remote Control

Auxiliary Mask

Auxiliary 1 Dig In Open

Contact 1 N/O N/C

Auxiliary 2 Dig In Close

Contact 2 N/O N/C

Auxiliary 3 Dig In Maint.

Contact 3 N/O N/C

Auxiliary 4 Dig In ESD

Contact 4

1/8

N/O N/C

The Auxiliary Mask settings page is shown above with

default settings visible.

Introduction

When a Network option is fitted (Pakscan/Profibus/Modbus /

Foundation Fieldbus or HART) a facility to accept 4 Auxiliary

inputs is available. Auxiliary inputs can be set as supplementar y

control for the actuator (open, close, stop/maintain or ESD) or

as digital indication inputs whose status is reported over the

option network. It is also possible to have a combination of both

supplementary remote control and digital inputs to provide, for

example, open and close control as well as a high and low tank

level alarm indication from external level transducers.

Auxiliary inputs are in addition to the standard control and

feedback features incorporated into a Network option. Auxiliary

inputs are connected to the standard Open, Close, Stop/maintain

and ESD inputs. Refer to wiring diagram.

NOTE: If an Analogue option and a Network option are

fitted and hardwired ESD control is required (Auxiliar y 4 set to

ESD), ensure Auxiliary contact 4 setup is matched to the ESD

configuration when signal setting. Refer to 2.4.

The Auxiliary Mask page allows the user to setup the 4 Auxiliary

inputs as supplementary control, indication or a combination

of both. Each Auxiliary input can be set for the type of contact

connected. Refer to Auxiliary input setup.

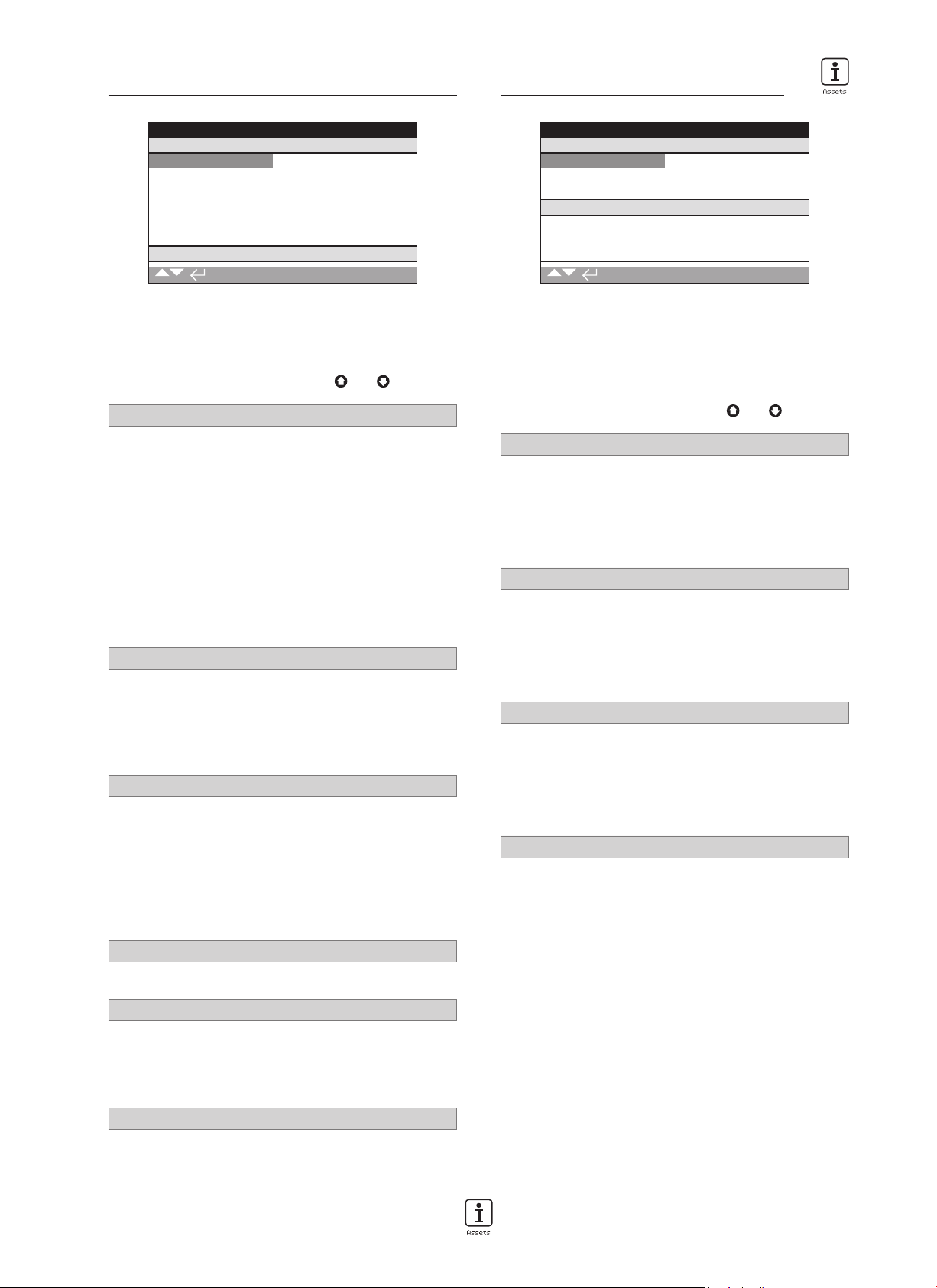

Auxiliary Input Setup

Input Auxiliary 1 Auxiliary 2 Auxiliary 3 Auxiliary 4

Control Open Close

Indication Dig Dig Dig Dig

Contact Type Contact 1 Contact 2 Contact 3 Contact 4

Normally

Open

Normally

Closed

N/O N/O N/O N/O

N/C N/C N/C N/C

Stop/

Maintain

ESD

A normally open contact is considered to be in the active

state when the contact is closed. A normally closed contact is

considered to be in the active state when the contact is open.

Using Auxiliary 1 and Contact 1 as an example:

1/8 Auxiliary 1

Refer to Auxiliary input setup.

Dig in (default) – Network option will report digital input

status: 1 or 0

Open – Hardwired open command signal is required. Use

Auxiliary 2 to 4 for close, stop/maintain and ESD.

To change the settings use,

indicate the set Auxiliary 1 input function.

. The checkbox will

2/8 Contact 1

Refer to Auxiliary input setup.

N/O (default) – A normally open contact is used to derive input.

N/C – A normally closed contact is used to derive input.

To change the settings use,

indicate the set Contact 1 input type.

. The checkbox will

IQ3 Full Confi guration Man ual – Secti on: Setting s 23

Page 24

2.3.2-6 Control – Remote – Analogue Option

Hardwired

Control Source

Partial Stroke

Positioning

Auxiliary Mask

Analogue

Remote Control

Analogue

Signal Type mA Volts

Signal Range 20mA

Invert On Off

Manual-Auto On Off

Set Low Signal

Set High Signal

1/6

The Analogue option settings page is shown above with

its default settings. Analogue is a control option.

The Analogue menu item and its associated settings page will

only be shown when the Analogue option is fitted. Refer to

wiring diagram. The Analogue option setting page allows the

option to be set for the applied signal type and range. Signal low

and high values can also be calibrated.

For Analogue option; deadband, hysteresis and

positioning settings, refer to 2.3.2-4.

4/6 Manual-Auto

With the Analogue control option it is possible to have Manual/

Auto control by a user supplied remote switch selection:

Analogue Option

Fitted

Manual Hardwired Network

Auto Analogue Analogue

Analogue and

Network Options

fitted

When Analogue and Network options are fitted and Auto is

selected, the Network option fitted will continue to report

actuator status.

Hardwired ESD is available in both Manual and Auto.

When applied, ESD will override all other control signals.

Refer to 2.4 ESD.

For Manual Auto control, refer to wiring diagram and

referenced RWS diagram.

OFF (default) – Manual/Auto control is not used. Actuator will

be controlled by the Analogue signal. Where a Network option is

also fitted, the Network option will report actuator status only.

On – Actuator can be controlled by hardwired contacts or the

Network (as applicable) or by the Analogue signal.

To change the settings use,

indicate the set Manual/Auto mode.

. The checkbox will

5/6 Set Low Signal

1/6 Signal Type

mA (default) – Set for current (mA) Analogue control signal.

Volts – Set for voltage Analogue control signal.

To change,

Analogue signal type.

. The checkbox will indicate the set

2/6 Signal Range

Available ranges: 5 mA, 10 mA or 20 mA (default) or 5 V, 10 V

or 20 V range for voltage control. For Analogue signal using a

4 mA to 20 mA range, set 20 mA.

To change,

the selected range will be indicated.

. The drop down list will close and

3/6 Invert

Off (default) – Low Analogue signal will move the actuator in

the close direction.

On - High Analogue signal will move the actuator in the close

direction.

To change,

Analogue signal action.

. The checkbox will indicate the set

The actuator must be calibrated to the Low Analogue signal

value. By measuring this signal it will then be able to control the

actuator by moving it to the Set Low Signal position, refer to

2.3.2-4.

APPLY THE LOW ANALOGUE SIGNAL and select .

The signal will be measured and set as the Low signal

position value.

6/6 Set High Signal

The actuator must be calibrated to the High Analogue signal

value. By measuring this signal it will then be able to control the

actuator by moving it to the Set High Signal position, refer to

2.3.2-4.

APPLY THE HIGH ANALOGUE SIGNAL and select .

The signal will be measured and set as the High signal

position value.

24 IQ3 Full Confi guration Ma nual – Secti on: Setting s

Page 25

2.3.2-7 Control – Remote – Pakscan

Analogue

Pakscan

Profibus

HART

Modbus

Extra I/O

Remote Control

Pakscan

Address 1

Baud Rate 1200

Position

Update Time (s) Disabled

Deviation Disabled

Torque

Update Time (m) 1

Deviation Disabled

Filter Manual Auto

Valve Travel Time 1000

1/8

The Pakscan Control option settings page is shown above

with its default settings. Pakscan is a control option, refer

to wiring diagram.