Page 1

‘IQM’ & ‘IQML’ RANGE

Publication E420E issue 7/02

CONTROL AND

MONITORING

FACILITIES

Page 2

SPECIFICATION

The type IQM actuator specification is generally as described in

Publication No. E410E having a solid state reversing starter in

place of the electro-mechanical contactors, suitably rated 4pole winding, low inertia motor and with the “hammerblow”

backlash omitted from the output gear train.

All other standard and optional IQ actuator features are

available with IQM modulating actuators subject to the

following:

Supply Voltage - maximum 480 volts, 50/60Hz.

Apply for higher voltages up to 575 volts.

Minimum voltage for the size IQM30 is 380 volts, 50/60Hz.

PERFORMANCE

The actuators are suitable for up to 1200 starts per hour with a

duty in accordance with IEC 34-1 to S4 50%. See E410E for

temperature rating.

SOLID STATE STARTER

The actuator design incorporates a solid state starter to

achieve an increased design life. Five pairs of 1600 volt

thyristors switch all three phases of the incoming power

supply. Thyristors are considered to be more suitable than

triacs for reversing applications and have a higher resistance to

transients in the power supply.

The design also includes snubbing and transient protection

circuits.

DYNAMIC BRAKING

The facility for dynamic braking is included as standard with

the ability to select this function by fitting an electrical link at

the actuator terminal block.

POSITIONAL ACCURACY

Repeatability with pulse control is 0.1 output turns.

POWER FUSE

It is essential that the power supply for each actuator is

protected by suitably rated high speed fuses mounted at the

power distribution panel. The required fuse characteristics are

as follows:

IQM10 to IQM20 IQM25 and IQM35

Rated current 10A 20A

Pre-arcing 1

2

t 5.4 A2s1

2

t 30 A2s

Total 12t 55 A2s1

2

T 250 A2s

Rated voltage 660V (IEC) 660V (IEC)

Suggested fuse Ferraz G330010 Ferraz K330013

CIRCUIT DIAGRAM

Standard IQM actuators are in accordance with wiring diagram

5000-000 as shown on page 6.

For aplications requiring seperately mounted starters, please

see details of M Range Syncroset actuators given on page 11.

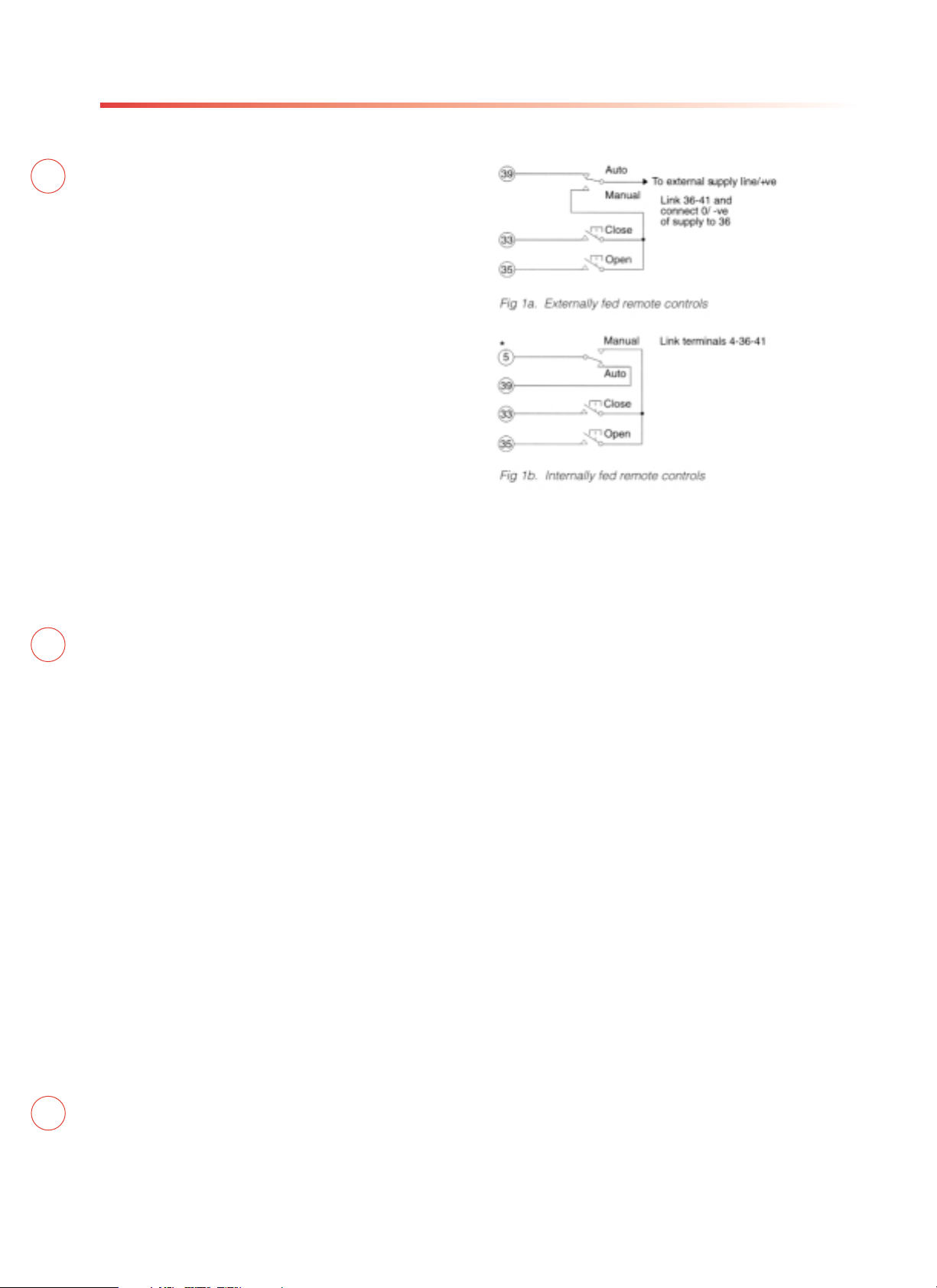

CONTROL

Opto-isolators are used to interface the actuator’s internal

logic circuits with the remote controls. The basic circuits permit

various control facilities to be selected whether internally or

externally fed. As standard the actuators are designed for

positive switching remote control from digital signals.

Various control functions may be configured on site at the

time of commisioning using the Rotork IQ Setting Tool. In the

absence of specific instructions, actuators will be dispatched

with the control functions configured as shown on the

diagram on page 6.

PULSE CONTROL

Where pulse control is used the minimum pulse length should

be 18ms and the minimum time between pulses should be

500ms. Typical duration of motor energisation in response to

each minimum pulse control signal in the same direction will

be between 20 and 30ms. Where special units designed for use

with AC remote control supplies are required, the minimum

pulse length should be 300ms.

REMOTE CONTROL POWER SUPPLIES

Remote controls may be powered by the internally derived 24

volt DC power supply. Alternatively remote controls may be

powered by an external supply of 24DC. The appropriate

connections are shown on page 6. Please apply if suitability for

other remote control supplies is required.

LOCAL CONTROLS

The actuator is provided with Open, Close and Stop facilities

and Local/Remote selection, Local, Open and Close control is

configurable to either self-maintained or push-to-run.

EXTERNAL INTERLOCKS

Facilities are provided for the connection of external contacts

to inhibit Open and/or Close valve operation.

STATUS FEEDBACK

Four configurable status feedback contacts and monitor relay

are available as standard with IQM actuators.

PROTECTION

The motor is protected against single phasing or incorrect

phase rotation by the Rotork patented, Syncrophase circuit and

against overheating by the thermostat in the motor winding.

Opto-isolators provide protection against high voltage

transients for the interface with the remote controls.

EMERGENCY SHUTDOWN (ESD)

The ESD facility may be configured for Open or Close

operation with the option of by-passing the motor protection

thermostat, using the IQ Setting Tool.

IQM - STANDARD FACILITIES

Page 3

3

OPTIONAL FACILITIES

The following optional facilities are available, and are covered

by the appropriate alternative wiring diagrams as indicated in

the wiring diagram number matrix on page 5.

FOLOMATIC CONTROLLER

The Folomatic enables standard IQM actuators to control the

position of a valve in proportion to an analogue current or

voltage signal.

A voltage derived from the actuator position sensor is

electronically compared with a voltage proportional to the

input signal. The difference between them (error) triggers the

open or close thyristor circuit, via logic circuits, to drive the

actuator in the direction which will cancel the error. Valve

position is therefore automatically adjusted in proportion to

analogue signal. Unnecessarily frequent switching is prevented

by the Motion Inhibit feature.

The Folomatic can be configured to suit the following:

Analogue signals/ 0-5mA/1k ohm 0-5v/1 M ohm

input impedence: 0-10mA/500 ohm 0-10v/78 kohm

0-20mA/250 ohm 0-20V/52 kohm

Position corresponding Closed limit, or percentage Open

to low input signal: or Open limit.

Position corresponding Closed limit, or percentage Open

to high imput signal: or Open limit.

Deadband: 0-9.9% of travel between Open

and Closed limit positions.

Motion Inhibit time: 2-99 secs. between actuator

movements.

Action on loss of Stay-put or move to high signal

input signal: position or move to low signal

position. Available for minimum

set ‘low’ signal of 0.5mA.

Response on loss of signal will

occur if signal falls below 50% of

set ‘low’ signal.

Overall accuracy (actuator 0.5% of maximum signal with

mechanical output position/

dynamic braking and minimum

demand value): of 10 turns for full valve stroke,

assuming a deadband setting of

<0.2%.

CONNECTIONS

The analogue signal should be connected to terminals 26 (+ve)

and 27 (-ve). If no remote manual control is required, link

terminals 39 to 5 and 41 to 4. Terminal 39 is provided for

remote manual/auto selection. The remote control connections

for actuators to standard wiring diagrams are as follows:

CURRENT POSITION TRANSMITTER (CPT)

The CPT provides an internally powered electrically isolated 420mA analogue valve position feedback signal, which is

available at terminals 22 (+ve) and 23 (-ve). The maximum

external impedence that may be connected to the signal is 500

ohms. Repeatability is within ±1% and linearity ±2.5% of total

valve travel.

ALARM RELAYS

A set of three alarm relays can be provided with the following

functions:

Relay 1 ‘Battery low’ signal (Normally open contact

rated for 5A 250 volts AC, 30 volts DC).

Relay 2 ‘Thermostat tripped’ signal (change-over

contact rated for 30 Watts, 62.5VA, 110 Volts).

Relay 3 ‘Remote selected’ signal (contact as Relay 2)

The following optional facilities available on standard IQ

actuators are also available on IQM units.

Negative Switching (see publication E120E)

Interrupter Timer (see publication E120E)

Pakscan (see publication S000E)

IQM - OPTIONAL FACILITIES

Page 4

4

IQM - ACTUATOR CONTROL CIRCUITS

BASIC IQM ACTUATOR WIRING DIAGRAM 5000-000

Positive switching remote controls. Refer to Rotork for nonstandard voltage option. Circuit is drawn with power supply off.

Transformer Tapping Options

Type 1

TAP NOM 50/60HZ 50HZ 60HZ

W 220/230 176-242 198-259

X 380/400 304-418 342-446

Y 415/420 332-457 374-487

Z 440/460 352-484 396-517

Fuse FS1 - 250mA Anti-Surge

Type 2

TAP NOM 50/60HZ 50HZ 60HZ

W 346/380 285-388 321-419

X 480/500 406-552 432-564

Y 240/240 192-261 216-282

Z* 550/575 445-605 501-654

Fuse FS1 250mA Anti-Surge

NOTE *150mA Anti-Surge

The actuator must be protected using

suitably rated high speed semi-conductor

fuses on the incoming supply.

Suggested fuses:-

IQ10-20: 10 Amp Ferraz G330010

IQ25-35: 20 Amp Ferraz K330013

All transformer types - PS1 Self resetting fuse

NOTE

Where customers wish to have the

thermostat by-passed during emergency

shutdown operation, it should be noted that

any actuator hazardous enclosure

certification will be invalidated while the

thermostat is by-passed.

Max external load on terminals 4&5 to be

5W.

For typical remote control

indicating,monitoring and alarm circuits see

publication E420E

Control signal threshold voltages to be

minimum ‘ON’ 20V AC/DC maximum ‘OFF’=

3V minimum control signal duration to be

100mS.

Current drawn from each remote control

signal is 5mA on 24V DC

Wires are identified at each end by terminal

No. or tag No.

Iindication contacts S1-S4 are shown in their

default configuration. Contacts may be

configured for any of the functions described

in E170E.

OPEN

%

S4

S1

S2

S3

MONITOR

RELAY

SK.3

SK.1

SK.4

2

1

3

1

2

3

4

5

6

7

8

24

30

SK.14

SK.10

SK2

SK1 SK4

SSS MODULE

SK9

SK11

MOTOR

3456

2A 2B

1

LK1

U

V

U

W

XWYZ

24V DC SUPPLY

0V DC SUPPLY

3

24VDC

0VDC

24VDC

NOMINAL SUPPLY

2

1

5

4

1

5

4

PS1

W

U

V

1

3

2

SK.1

SK.3

FS1

E

3

PHASE

SUPPLY

CIRCUIT DRAWN WITH POWER SUPPLY OFF

9

7

10

13

11

12

8

6

43

44

42

SK.12SK.1

LOCAL

CONTROL

PCB

SK.7

SK.9

2

1

LIMIT

PCB

SENSING

SK.1

-

+

BATTERY

FS2 100mA(ONLY FITTED

ON CENELEC ACTUATORS)

32

31

38

25

36

34

37

40

35

33

T/STAT BYPASS - ESD

OPEN

CLOSE INTERLOCK

OPEN INTERLOCK

STOP/MAINTAIN

CLOSE

COMMON -VE 24V DC

COMMON -VE 24V DC

SK.2

SK.8

3

4

2

1

5

1

4

3

5

2

TORQUE

SENSOR

4

5

SK.6

SK.5

FS2

INFRA-RED

DIGITAL POSITION

INDICATION UNIT

2W

1

V

U

1pm

2pm

3pm

3

MAKE AT FULLY

SHUT

MAKE AT FULLY

OPEN

BREAK AT FULLY

SHUT

BREAK AT FULLY

OPEN

Page 5

5000-000 5100-000 5000-100 5100-100

5010-000 5110-00 5010-100 5110-100

5

IQM - OPTIONAL FEATURES

STANDARD ACTUATOR DIAGRAMS

The typical remote control interlock and monitoring circuits

illustrated are applicable to actuators with the following

standard Rotork wiring diagrams.

NOTES

1 Data logger - diagram number changes to ‘1’ for fifth

digit, e.g. 600-000 becomes 600-010.

2 For negative switching - diagram number changes to ‘7’

for first digit, e.g. 600-000 becomes 700-000.

IQ SETTING TOOL

The IQ Setting Tool makes it possible to read and set all the

actuator functions, such as valve travel and torque or travel

limit control, without removing any covers. The IQ Setting Tool

transmits signals to an infra-red receiver built into the actuator.

The IQ Setting Tool has a ‘programming’ mode which enables

the valve manufacturer to configure the actuator to suit his

valve and the site commisioning engineer to configure the

actuator for a variety of different control functions. The IQ

Setting Tool also has a ‘checking’ mode which enables all the

existing actuator settings to be interrogated. Protection against

unauthorized changes to setting is provided by a ‘password’.

CONFIGURATION

The following actuator functions are configured by the IQ

Setting Tool:

• Direction of actuator output rotation for closing the valve.

• Selection of torque or turns limitation for valve opening

and closing travel.

• Torque setting for Open and Close valve operation.

• Setting of actuator output turns to suit the valve travel.

• “Open/close” remote control signal priority.

• Selection of function and contact mode for each of the

four standard indication contacts.

• Valve to Open or Close with ESD signal.

• External interlock facility.

The standard configuration for the IQM actuator is given on page 6.

In addition, the IQ Setting Tool will enable configuration of the

following optional assemblies when fitted to the actuator:

• CPT - selection of open or closed valve position

corresponding to a maximum signal.

• Pakscan - address, baud rate and protocol.

• Folomatic - signal range, increasing signal is to correspond

to opening or closing of the valve, action on loss of signal,

amount of deadband and the motion inhibit time delay.

Publication E170E, supplied with each actuator gives full

instructions for the operation of the IQ Setting Tool.

Page 6

6

IQM - REMOTE DIGITAL CONTROL CIRCUITS

The infra red setting tool enables various different remote

controls to be configured. Unless specified requirements are

stated with the order, actuators will be supplied configured as

follows:

Maintained local control

Clockwise to close

Thermostat by-passed on ESD

Open and closed interlocks enabled

Close signal priority

The typical remote control circuits shown below apply to these

unless otherwise stated.

Max. external load on 24v DC supply from

acutuator terminals 4 - 5 to be 5W.

Form A

Open/close push to run control

(local control remains self maintained).

Form F

Emergency shut-down to close valve overriding

thermostat (actuator hazardous enclosure

certification is invalidated while thermostat

overidden) and any existing signal may be

added to any of the circuits above.

Actuators may be configured so that thermostat

is not by-passed during ESD operation.

To override external interlocks on ESD additional

remote contacts must be provided.

Brake enable connections

† Note

Remote controls may be fed from the internal 24V DC supply at

terminal 5 when terminals 4-36 must be linked, or from an

external supply when the zero/-ve of the supply should be

connected to terminal 36.

Terminals 4-36 also to be linked for form A and F control.

The input to the IQ series actuator logic circuits associated with

the remote controls may be used with cable capacitance of up

to 2µF between cores.

Page 7

7

IQML10 TO IQML25 ACTUATOR DIMENSIONS

IQML10 IQML25

Page 8

As part of a process of on-going product

development, Rotork reserves the right

to amend and change specifications

without prior notice.

Published data may be subject to change.

For the very latest version release, visit

our website at www.rotork.com

The name Rotork is a registered trademark.

Rotork recognizes all registered trademarks.

Published and produced in the UK by

Rotork Controls Limited.

A full listing of our worldwide

sales and service network

is available on our website at

www.rotork.com

UK head office

Rotork Controls Limited

telephone Bath 01225 733200

telefax 01225 333467

email mail@rotork.co.uk

USA head office

Rotork Controls Inc

telephone Rochester (585) 328 1550

telefax (585) 328 5848

email info@rotork.com

Rotork Controls Ltd, Bath, UK

Rotork Controls Inc, Rochester, USA

‘IQM’ & ‘IQML’ RANGE

CONTROL AND

MONITORING

FACILITIES

Loading...

Loading...