Page 1

Page 2

1.0 INTRODUCTION .......................................................................................................................................... 7

1.1 INSTALLING INSIGHT 2 .................................................................................................................................. 7

1.2 UNINSTALLING INSIGHT 2 .............................................................................................................................. 7

1.3 UPDATING INSIGHT 2 ................................................................................................................................... 7

2.0 LOGGING IN ............................................................................................................................................... 8

2.1 LOGIN SCREEN ............................................................................................................................................ 8

2.2 USER LEVELS .............................................................................................................................................. 8

2.2.1 Viewer ............................................................................................................................................. 8

2.2.2 User ................................................................................................................................................ 9

2.2.3 Service_Engineer ............................................................................................................................. 9

2.2.4 Administrator .................................................................................................................................. 9

3.0 HOME SCREEN ......................................................................................................................................... 10

3.1 LAYOUT .................................................................................................................................................. 11

3.2 MENU BAR .............................................................................................................................................. 12

3.2.1 File ................................................................................................................................................ 12

3.2.2 Connection .................................................................................................................................... 15

3.2.3 Security ......................................................................................................................................... 15

3.2.4 Tools ............................................................................................................................................. 16

3.2.5 Help .............................................................................................................................................. 17

3.3 ICON BAR ................................................................................................................................................ 18

3.3.1 Open Configuration ....................................................................................................................... 18

3.3.2 Save As .......................................................................................................................................... 18

3.3.3 Save .............................................................................................................................................. 18

3.3.4 Print .............................................................................................................................................. 18

3.3.5. Send Configuration ....................................................................................................................... 18

3.3.6 Read Configuration ........................................................................................................................ 18

3.3.7 Discard .......................................................................................................................................... 18

3.4 SIDE PANEL .............................................................................................................................................. 19

3.4.1 Offline ........................................................................................................................................... 19

3.4.2 Bluetooth ...................................................................................................................................... 19

3.5 RANGE PANEL .......................................................................................................................................... 20

3.6 PRESENTATION WINDOW ............................................................................................................................ 21

3.7 STATUS BAR ............................................................................................................................................. 21

3.7.1 Connection Status .......................................................................................................................... 21

3.7.2 Actuator Login Level ...................................................................................................................... 21

3.7.3 Insight 2 Login Level ...................................................................................................................... 21

4.0 CONNECTING AND DISCONNECTING DEVICES .......................................................................................... 22

4.1 SEARCHING FOR DEVICES ............................................................................................................................. 22

4.2 CONNECTING TO AN ACTUATOR .................................................................................................................... 23

4.3 CONNECTING TO A BLUETOOTH SETTING TOOL ................................................................................................. 23

4.4 DISCONNECTING FROM DEVICES .................................................................................................................... 23

5. CVA ............................................................................................................................................................ 24

5.1 CVQ/CVL DEVICE INFORMATION ................................................................................................................. 25

5.1.1 Valve Tag ...................................................................................................................................... 25

5.1.2 CVA/CVQ Type ............................................................................................................................... 25

5.1.3 CVA Main PCB Software Version .................................................................................................... 25

5.1.4 Manufacturing Data ...................................................................................................................... 25

5.1.5 Service Notes ................................................................................................................................. 25

5.1.6 Date of Manufacture ..................................................................................................................... 25

5.1.7 CVA Hardware ............................................................................................................................... 25

2

Page 3

5.1.8 Main Controller Serial No. .............................................................................................................. 25

5.1.9 UPS Controller Serial No. ................................................................................................................ 25

5.1.10 Position Sensor Serial No. ............................................................................................................. 25

5.1.11 Motor Sensor Serial No. ............................................................................................................... 25

5.1.12 Force Sensor Serial No. ................................................................................................................ 26

5.1.13 User Interface Serial No. .............................................................................................................. 26

5.2 ACTUATOR CONFIGURATION - CVA VALVE SETUP ............................................................................................. 26

5.2.1 Valve Action Settings ..................................................................................................................... 26

5.2.2 MOVTag ........................................................................................................................................ 26

5.2.3 Valve Action Settings ..................................................................................................................... 26

5.2.4 Input / Output Setup ...................................................................................................................... 27

5.3 ADVANCED SETTINGS 1 ............................................................................................................................... 27

5.3.1 Tight Shut Off ................................................................................................................................ 27

5.3.2 Obstruction Action Active .............................................................................................................. 27

5.3.3 Obstruction Values Setup ............................................................................................................... 28

5.3.4 Manual Test Knob Setup ................................................................................................................ 28

5.4 ADVANCED SETTINGS 2 ............................................................................................................................... 28

5.4.1 Travel Alarm Thresholds ................................................................................................................ 28

5.4.2 Bumpless Transfer Setup ................................................................................................................ 28

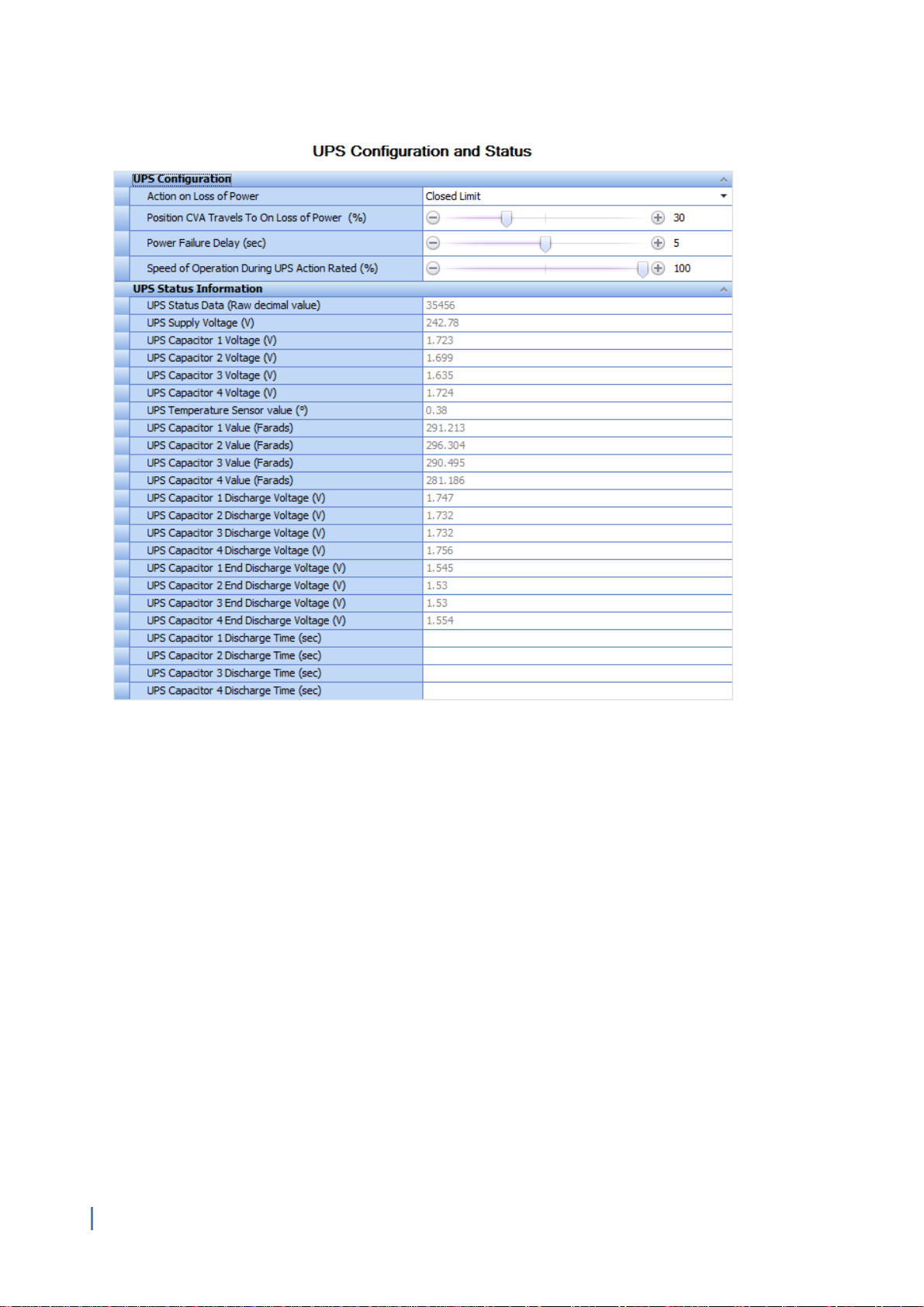

5.5 UPS CONFIGURATION AND STATUS ............................................................................................................... 29

5.5.1 UPS Configuration ......................................................................................................................... 29

5.5.2 UPS Status Information .................................................................................................................. 30

5.6 CVA STATUS ............................................................................................................................................ 30

5.6.1 Actuator Position (%) ..................................................................................................................... 30

5.6.2 Actuator Torque (%) ...................................................................................................................... 30

5.6.3 Analogue Demand Input (mA) ........................................................................................................ 30

5.6.4 Analogue Position Feedback (mA) .................................................................................................. 30

5.6.5 ESD Input Status ............................................................................................................................ 30

5.7 CVA MAIN DATALOGGER ............................................................................................................................ 31

5.7.1 Event Logger ................................................................................................................................. 31

5.7.2 CVA Dwell Log ............................................................................................................................... 34

5.7.3 CVA Torque Logs ............................................................................................................................ 34

5.7.4 CVA Movement Log ....................................................................................................................... 35

6.0 IQ3 SETTINGS ........................................................................................................................................... 36

6.1 ACTUATOR INFORMATION ........................................................................................................................... 38

6.1.1 Actuator User Information ............................................................................................................. 38

6.1.2 Actuator Serial Numbers ................................................................................................................ 38

6.1.3 Actuator Manufacturing Information ............................................................................................. 39

6.2 ACTUATOR NAME PLATE ............................................................................................................................. 40

6.2.1 Actuator Name Plate Info .............................................................................................................. 40

6.2.2 Valve Manufacturing Information .................................................................................................. 41

6.2.3 Gearbox Manufacturing Information ............................................................................................. 42

6.3 ACTUATOR SETTINGS .................................................................................................................................. 43

6.3.1 Basic Settings ................................................................................................................................ 43

6.3.2 ESD Configuration.......................................................................................................................... 44

6.3.3 REMOTE CONFIGURATION ........................................................................................................................ 45

6.3.4 Local Configuration........................................................................................................................ 45

6.3.5 Special Mode Configuration ........................................................................................................... 46

6.4 TORQUE SETTINGS ..................................................................................................................................... 47

6.4.1 Current Torque Readings ............................................................................................................... 47

6.4.2 Actuator Torque Settings ............................................................................................................... 47

6.4.3 Torque Advanced Settings.............................................................................................................. 47

6.4.4 Torque Profile Settings ................................................................................................................... 48

6.5 POWER SETTINGS ...................................................................................................................................... 48

6.5.1 Power Type.................................................................................................................................... 48

6.6 DIGITAL INPUT SETTINGS ............................................................................................................................. 49

3

Page 4

6.6.1 DI Function .................................................................................................................................... 49

6.6.2 DI Input Type ................................................................................................................................. 49

6.7 PARTIAL STROKE SETTINGS........................................................................................................................... 50

6.7.1 Partial Stroke Enable ..................................................................................................................... 50

6.7.2 Partial Stroke Initial Position .......................................................................................................... 50

6.7.3 Partial Stroke Position (%) .............................................................................................................. 50

6.7.4 Partial Stroke Time to Position (sec) ............................................................................................... 50

6.7.5 Partial Stroke Time to Limit (sec) .................................................................................................... 50

6.8 RELAY SETTINGS ........................................................................................................................................ 51

6.8.1 Monitor Relay Function.................................................................................................................. 51

6.8.2 Relay Settings ................................................................................................................................ 52

6.9 OPTION CONTROL ..................................................................................................................................... 53

6.9.1 Option Source Selection ................................................................................................................. 53

6.9.2 Auxiliary Mask Configuration ......................................................................................................... 54

6.9.3 Option 1-4 Configuration ............................................................................................................... 54

6.10 CONTROL SETTINGS ................................................................................................................................. 55

6.10.1 Position Settings .......................................................................................................................... 55

6.10.2 Interrupter Timer ......................................................................................................................... 56

6.11 UI SETTINGS .......................................................................................................................................... 57

6.11.1 Indication Configuration .............................................................................................................. 57

6.11.2 Communication Configuration ..................................................................................................... 58

6.12 LANGUAGE SETTINGS................................................................................................................................ 58

6.12.1 Display Language ........................................................................................................................ 58

6.12.2 Language Option Details .............................................................................................................. 59

6.13 NAMUR SETTINGS ................................................................................................................................... 59

6.13.1 Namur Status .............................................................................................................................. 59

6.13.2 Namur Mask Settings (All groups) ................................................................................................ 60

6.14 ANALOGUE CONTROL/CPT/CTT/AIO OPTION............................................................................................... 60

6.15 EXTRA RELAYS S5-S8 ............................................................................................................................... 60

7.0 IQ3 DATA LOGGER.................................................................................................................................... 61

7.1 EVENT LOGGER ......................................................................................................................................... 62

7.1.1 Time Line ....................................................................................................................................... 62

7.1.2 Trace View..................................................................................................................................... 63

7.1.3 List View ........................................................................................................................................ 64

7.2 TORQUE PROFILE ...................................................................................................................................... 65

7.3 TORQUE LIMIT PROFILES ............................................................................................................................. 65

7.4 TORQUE REFERENCE PROFILE ....................................................................................................................... 66

7.5 TORQUE REFERENCE LIMIT PROFILES .............................................................................................................. 67

7.6 STARTS LOG ............................................................................................................................................. 68

7.7 MOVEMENT LOG ...................................................................................................................................... 69

7.8 CURRENT PARTIAL STROKE PROFILE ............................................................................................................... 70

7.9 VIBRATION TREND LOG ............................................................................................................................... 71

7.10 BATTERY VOLTAGE AND TEMPERATURE TREND LOG ......................................................................................... 72

7.10.1 Battery Voltage Trend .................................................................................................................. 72

7.10.2 Temperature Trend ...................................................................................................................... 72

7.11 MOTOR STARTS AND OUTPUT TURNS TREND LOG ........................................................................................... 73

7.12 MISCELLANEOUS DATALOG DATA ................................................................................................................ 74

7.12.1 Motor Related Data ..................................................................................................................... 74

1.12.2 Power Related Data ..................................................................................................................... 74

1.12.3 Limit Related Data ....................................................................................................................... 75

1.12.4 Environmental Related Data ........................................................................................................ 75

8.0 EH PRO AND SI PRO SCREENS ................................................................................................................... 76

8.1 BASIC SETTINGS ........................................................................................................................................ 78

8.1.1 Valve Tag ...................................................................................................................................... 78

8.1.2 Close Action ................................................................................................................................... 78

4

Page 5

8.1.3 Open Action................................................................................................................................... 78

8.1.4 Close Pressure (Limit) (%) ............................................................................................................... 78

8.1.5 Close Pressure (Mid) (%) ................................................................................................................ 78

8.1.6 Open Pressure (Limit) (%) ............................................................................................................... 78

8.1.7 Open Pressure (Mid) (%) ................................................................................................................ 78

8.1.8 Closed Limit ................................................................................................................................... 78

8.1.0 Open Limit ..................................................................................................................................... 78

8.2 CONTACT RELAYS ...................................................................................................................................... 79

8.2.1 Contact – Function ......................................................................................................................... 79

8.2.2 Contact – Value ............................................................................................................................. 79

8.2.3 Contact – Form .............................................................................................................................. 79

8.3 GENERAL SETTINGS .................................................................................................................................... 80

8.3.1 Remote Select ................................................................................................................................ 80

8.3.2 Configure Local Controls ................................................................................................................ 80

8.3.3 Low Power Mode ........................................................................................................................... 80

8.3.4 Closed LED Colour .......................................................................................................................... 80

8.4 DIGITAL CONTROL ..................................................................................................................................... 81

8.4.1 Remote Priority ............................................................................................................................. 81

8.4.2 Hold Position ................................................................................................................................. 81

8.4.3 Position Hysteresis ......................................................................................................................... 81

8.4.4 Over Pressure Hysteresis ................................................................................................................ 81

8.4.5 Under Pressure Hysteresis .............................................................................................................. 81

8.5 ESD/PARTIAL STROKE ................................................................................................................................ 82

8.5.1 ESD ............................................................................................................................................... 82

8.5.2 Partial Stroke ................................................................................................................................. 83

8.5.3 Reference Partial Stroke Test Recorded Values ............................................................................... 83

8.6 ANALOGUE CONTROL ................................................................................................................................. 84

8.6.1 Analogue Control ........................................................................................................................... 84

8.6.2 Flow Characterisation .................................................................................................................... 85

8.7 INTERRUPTER TIMER .................................................................................................................................. 86

8.7.1 Interrupter Timer ........................................................................................................................... 86

8.7.2 Interrupter Timer Direction ............................................................................................................ 86

8.7.3 Interrupter Timer Start (%) ............................................................................................................. 86

8.7.4 Interrupter Timer Stop (%) ............................................................................................................. 86

8.7.5 Interrupter Timer Interval .............................................................................................................. 86

8.7.6 Interrupter Timer On Time ............................................................................................................. 86

8.7.7 Interrupter Timer Off Time ............................................................................................................. 86

8.7.8 Interrupter Timer with ESD Enabled ............................................................................................... 86

8.8 ACTUATOR STATISTICS ................................................................................................................................ 87

8.8.1 Number of Times Open Limit Reached ............................................................................................ 87

8.8.2 Number of Times Close Limit Reached ............................................................................................ 87

8.8.3 Time Spent Moving Open (sec) ....................................................................................................... 87

8.8.4 Time Spent Moving Closed (sec) ..................................................................................................... 87

8.8.5 Number of ESD Events ................................................................................................................... 87

8.8.6 Number of Motor Starts ................................................................................................................. 87

8.8.7 Number of Accumulator Recharges ................................................................................................ 87

9.0 BLUETOOTH SETTING TOOL SCREENS ....................................................................................................... 88

9.1 BTST INFORMATION .................................................................................................................................. 88

9.1.1 Firmware Version .......................................................................................................................... 88

9.1.2 Battery Status (mV) ....................................................................................................................... 88

9.1.3 Number of Files ............................................................................................................................. 88

9.1.4 Free Space on the BTST (Bytes) ...................................................................................................... 88

9.1.5 Flash Memory size on BTST (Bytes)................................................................................................. 88

9.2 CVA ...................................................................................................................................................... 88

9.3 IQ2 ....................................................................................................................................................... 89

9.4 EHP ...................................................................................................................................................... 89

5

Page 6

9.5 IQ3 ....................................................................................................................................................... 89

9.6 SIP ........................................................................................................................................................ 89

9.7 MISSIONS ................................................................................................................................................ 89

9.7.1 Create Missions ............................................................................................................................. 89

9.7.2 Custom Mission ............................................................................................................................. 92

9.7.3 Review/Edit Mission ...................................................................................................................... 93

9.7.4 Delete Mission ............................................................................................................................... 93

9.7.5 Delete All Missions......................................................................................................................... 93

9.7.6 Format BST .................................................................................................................................... 94

6

Page 7

1.0 Introduction

1.1 Installing Insight 2

1.2 Uninstalling Insight 2

1.3 Updating Insight 2

1.1 Installing Insight 2

The Insight 2 program can be downloaded from the Insight 2 download page on:

www.rotork.com/en/support/index/downloads

You will be required to Log in with your Rotork Internet Portal Account to access this page.

(To register for a free Rotork Internet Portal Account click register and fill out the application form)

On the IQ Insight 2 download page you can view information about the software and the minimum

PC operating requirements. It is worth noting down the program access passwords for future use.

When you are satisfied that your machine is compatible with Insight 2, click Download IQ-Insight 2

Software for PC. This will begin the software package download for the latest version of Insight 2.

Once the download is complete, extract the install package to a user specified save location. Open

the Setup.exe file to load the installation wizard and begin the program install process. Follow the

on-screen prompts to install Insight 2.

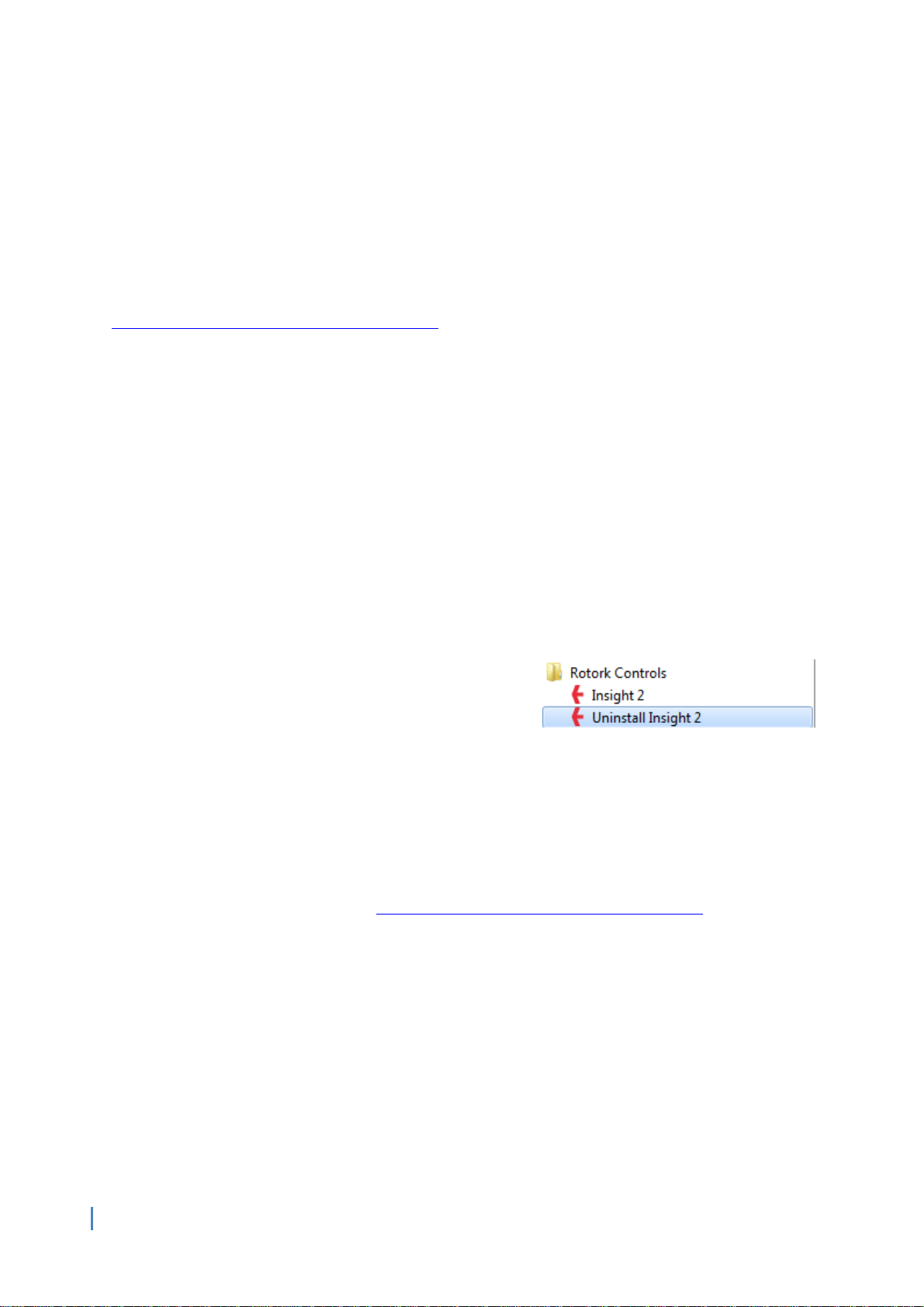

1.2 Uninstalling Insight 2

To uninstall Insight 2 use the Uninstall Insight 2 start menu shortcut or proceed through the standard

Windows software management feature. This can be found within the control panel.

For XP users use the “Add/Remove Programs” feature.

For Vista and 7 users use the “Uninstall a program”

feature.

Select Insight 2 from the program list and select uninstall. Follow the onscreen wizard to complete

the removal of Insight 2.

1.3 Updating Insight 2

Insight 2 will be updated periodically to add new features and increased compatibility with new

Rotork actuators. To update your copy of Insight 2 please follow instructions detailed on the

download page of the Rotork website www.rotork.com/en/support/index/downloads.

7

Page 8

2.0 Logging In

2.1 Login Screen

2.2 User Levels

2.2.1 Viewer

2.2.2 User

2.2.3 Service Engineer

2.2.4 Administrator

2.1 Login Screen

Below is the login screen for Insight 2.

This screen provides the user with four access levels on a drop down menu that require the

corresponding passwords to be entered. The check box in the bottom left allows Insight 2 to

remember your login details for easy access to the program in the future.

2.2 User Levels

The Privilege Level drop down menu presents 4 selections.

This selection will determine the available access levels visible when connecting to a Rotork

Bluetooth device.

2.2.1 Viewer

As a Viewer you can connect to any Bluetooth equipped Rotork device. These include: IQ3, CVA, EH

Pro, SI Pro and Rotork Bluetooth Setting Tool Pro. Viewer level prevents operators from modifying

the settings of an actuator.

Default Insight 2 Viewer Password: ROTORK

8

Page 9

2.2.2 User

As a User you can perform all the tasks of a Viewer with the ability to modify setting values. An

actuator User login allows you to change some settings within the actuators configuration.

Default Insight 2 User Password: ROTORK

2.2.3 Service Engineer

This login is reserved for the use of Rotork Service Engineers.

2.2.4 Administrator

This Login is reserved for the use of Rotork Engineers.

9

Page 10

3.0 Home Screen

3.1 Layout

3.2 Menu Bar

3.2.1 File

3.2.2 Connection

3.2.3 Security

3.2.4 Tools

3.2.5 Help

3.3 Icon Bar

3.3.1 Open Configuration

3.3.2 Save As

3.3.3 Save

3.3.4 Print

3.3.5 Send

3.3.6 Receive Configuration

3.3.7 Discard

3.4 Side Panel

3.4.1 Offline

3.4.2 Bluetooth

3.5 Range Panel

3.6 Presentation Window

3.7 Status Bar

3.7.1 Connection Status

3.7.2 Actuator Login level

3.7.3 Insight 2 Login Level

10

Page 11

3.1 Layout

Description

Colour

Menu Bar

Blue Icon bar

Orange

Side Panel

Purple

Range Panel

Yellow

Presentation Window

Green

Status Bar

Red

For the purpose of this manual the main Insight 2 screen has been split into six areas as shown

below.

11

Page 12

3.2 Menu Bar

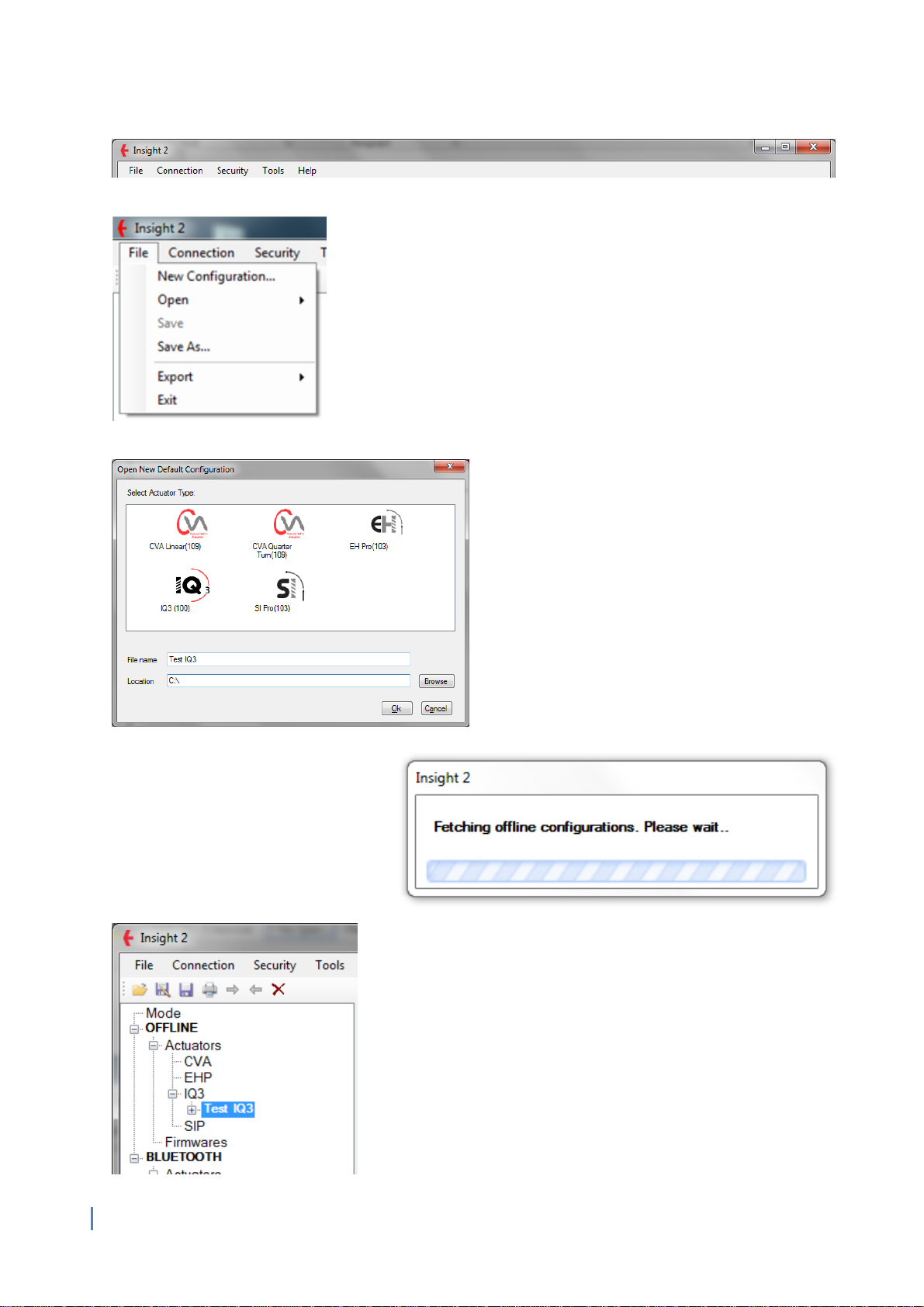

3.2.1 File

New Configuration

Use this function to create a new

default configuration for a compatible

Rotork product. There are 5 types of

actuator that can be configured with

Insight 2. The name and save location

of the configuration can be modified

appropriately if required.

Once “Ok” is selected the loading screen will appear as Insight 2

prepares the new configuration. This will appear in the Offline

section of the side menu (for side menu information see section

3.4.1) under the correct actuator type.

NOTE: using this function on a live actuator will clear any

previous configuration. Ensure a copy of the existing

configuration is saved before using this feature.

12

Page 13

Open

Configuration

The configuration option allows the user to open saved configuration files. Opened files will be shown in

the Offline section of the Side menu under the relevant actuator type.

Firmware

This function is only available for Rotork Service Engineers and Service centres.

Save

When a configuration in the Offline section is changed the user can save those changes.

13

Page 14

Save As

This function enables the user to save configuration files from the Offline or Online sections of the side

menu to a directory on the PC. These will be available for future offline use. This feature is to be used

for saving the configuration and datalogger files in the format to be read by Insight 2. For other formats

use the export feature.

Export

Configuration

This exports the current actuator configuration as either a Comma Separated Value (.csv) or a Text file

(.txt)

Configuration and DataLogs

This exports the current actuator configuration and data log file as either a Comma Separated Value

(.csv) or a Text file (.txt). The data log must be viewed within Insight 2 prior to exporting the data.

Exit

The Exit function will close Insight 2 and disconnect from any active Bluetooth device.

14

Page 15

3.2.2 Connection

Discover Devices

This initialises a search for all Bluetooth enabled actuators* and setting tools within the Bluetooth

adaptor range (setting tools can only be found whilst in slave mode, refer to the Bluetooth Setting Tool

manual for more information).

Recent Discovered Devices

This provides a list of previously connected devices that the operator can connect to without requiring a

Bluetooth search*.

*Actuators must be in a Bluetooth visible mode and within range of the Bluetooth adapter to be

discovered with Insight 2.

3.2.3 Security

Change Privilege

This enables the user to change their privilege level within Insight 2 by re-opening the Login screen (see

section 2 Logging In).

Change Application Password

This function enables the current user to change the Insight 2 login passwords for the current privilege

level and any lower privilege level.

15

Page 16

Change Actuator Password

This function is reserved for Rotork Service Engineer use only.

3.2.4 Tools

Sensor Calibration

This function is reserved for Rotork Service Engineer use only.

Zero Thrust

This function is reserved for Rotork Service Engineer use only.

CP Chat

This function is reserved for Rotork Service Engineer use only.

Unit Setting

The units displayed within Insight 2 can be set to Metric or Imperial to suit various global markets

(Insight 2 default = Metric).

Install Actuator Devices

This function enables Insight 2 to be updated using a compressed ADF file package provided by Rotork.

All future updates will be supported via this feature to ensure reliable compatibility with the continually

expanding Rotork product offering.

To download the latest ADF file please visit the Insight 2 download page:

http://www.rotork.com/customers/index/iqinsight2.

Save the ADF file to an accessible PC directory and then browse to the file through the Install Actuator

Devices function.

16

Page 17

On successful installation of the update you will be requested to restart Insight 2.

3.2.5 Help

View Help

Insight 2 Help

This help file is currently under construction. Future releases will include information about various

Insight 2 functions.

Actuator Help

This help file is currently under construction. Future releases will include information about various

Rotork actuator functions relevant to the connected actuator type.

About Us

Shows the current version number of the Insight 2 program and contains a brief description about the

purpose of Insight 2.

17

Page 18

3.3 Icon Bar

3.3.1 Open Configuration

This allows the user to open a saved Configuration file (.icf) from a PC directory in the Offline

section of the Side panel.

3.3.2 Save As

This function enables configuration files from the Offline or Online sections of the side menu to

be saved in a PC directory.

3.3.3 Save

When a configuration is open in the Offline Section, this function enables the user to save any

modifications to the settings.

3.3.4 Print

This will print the current information in the presentation window as it is shown on the screen

(only available when actuator information is displayed within the window).

3.3.5. Send Configuration

This function will send all visible configuration changes to the connected actuator. Send

Configuration will only be possible when connected to a Bluetooth device.

3.3.6 Read Configuration

This function will read a device’s current configuration. Read Configuration will only be possible

when connected to a Bluetooth device.

3.3.7 Discard

Removes any unsaved configuration changes (highlighted yellow) displayed within the

presentation window.

18

Page 19

3.4 Side Panel

Fig 1

Fig 2

3.4.1 Offline

Actuators

All offline actuator configurations opened in Insight 2 are stored for the session under their respective

actuator type (see Fig 1). Configurations can be edited and viewed (with the correct privilege level) from

the expanded menu (See fig 2).

Firmware

This function is reserved for Rotork Service Engineer use only.

3.4.2 Bluetooth

Actuators

All actuators that have been found by after a Bluetooth search (see 1.0 and 4.0) will be visible here. The

expanded menu can only be accessed once a connection to the device has been established.

19

Page 20

Bluetooth Setting Tool

All visible Bluetooth Setting Tools currently in slave mode and available for connection (See Bluetooth

Setting Tool Manual for details) will be visible in this section. The expanded menu can only be accessed

once a connection to the Bluetooth Setting Tool has been established.

3.5 Range Panel

The Range Panel will indicate which actuator range the current configuration or data log belongs to. If

the device is currently connected through Insight 2 the serial number and valve tag will also be

displayed.

20

Page 21

3.6 Presentation Window

The presentation window is where all configuration and data log information is displayed. Any setting

entries that are shaded grey are non-editable at the current privilege level.

3.7 Status Bar

Current status of actuator connection, actuator privilege level and Insight 2 privilege level are displayed

at all times within the Insight 2 window.

3.7.1 Connection Status

Connection status for Insight 2 is visible in the left portion of the status bar. An online connection will

show the actuator Bluetooth tag or Bluetooth Setting Tool tag and the connection method. If a

Bluetooth connection is not currently active an offline status will be displayed.

3.7.2 Actuator Login Level

Current actuator login level is shown in the middle portion of the status bar. There are three levels

available: Viewer, User and Engineer.

3.7.3 Insight 2 Login Level

The current privilege level access for Insight 2 is displayed in the right portion of the status bar. To

change access level, click on this part of the status bar or use the change privilege level option (See

3.2.3.1).

21

Page 22

4.0 Connecting and Disconnecting Devices

4.1 Searching for Devices

4.2 Connecting to an Actuator

4.3 Connecting to a Bluetooth Setting Tool

4.4 Disconnecting from Devices

4.1 Searching for Devices

Use the Discover Devices function (as detailed in 3.2). This will begin a search for all Rotork Bluetooth

enabled devices and setting tools within range of the Bluetooth adapter.

Please note only actuators with a Bluetooth Security setting of Medium or Low are visible within Insight

2. Bluetooth setting Tools have to be in slave mode to be found by Insight 2 (refer to the Bluetooth

Setting Tool Manual for information on how to activate Slave Mode).

Once the search is complete, all actuators found will be displayed in the expanded menu under the

relevant range heading. Each unit will be identified by Serial Number and Bluetooth Friendly Tag.

Bluetooth Setting Tools will be identified by the acronym BST and the Bluetooth MAC address.

22

Page 23

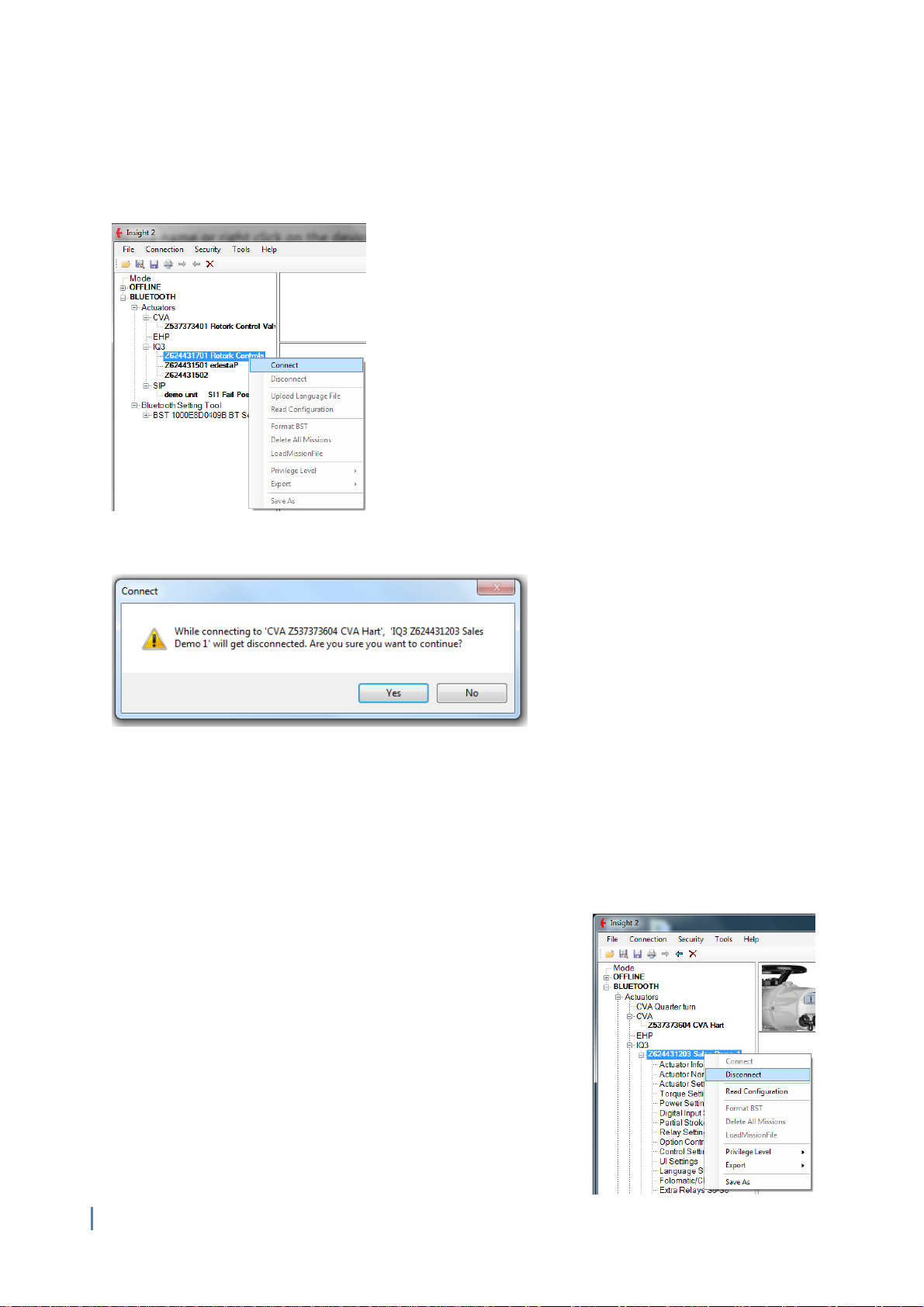

4.2 Connecting to an Actuator

To connect to an actuator, double click on the actuator name or right click on the actuator name and

click Connect.

If you try to connect to more than one actuator the warning box below will be shown.

4.3 Connecting to a Bluetooth Setting Tool

Connecting to a Bluetooth Setting Tool is performed in the same manner as connecting to an actuator.

Upon connection with Insight 2 the Setting Tool’s Enter key will rapidly flash blue indicating a

connection has been established. The connection privilege Level of the Bluetooth Setting Tool is

dictated by the current Insight 2 Privilege Level.

4.4 Disconnecting from Devices

You can disconnect from a device by right clicking the device and

selecting Disconnect from the drop down menu, this is applicable

to all Bluetooth devices.

23

Page 24

5. CVA

5.1 CVQ/CVL Device Information

5.1.1 Valve Tag

5.1.2 CVA/CVQ Type

5.1.3 CVA Main PCB Software Version

5.1.4 Manufacturing Data

5.1.5 Service Notes

5.1.6 Date of Manufacture

5.1.7 CVA Hardware

5.1.8 Main Controller Serial No.

5.1.9 UPS Controller Serial No.

5.1.10 Position Sensor Serial No

5.1.11 Motor Sensor Serial No.

5.1.12 Force Sensor Serial No.

5.1.13 User Interface Serial No.

5.2 Actuator Configuration - CVA Valve Setup

5.2.1 Valve Action Settings

5.2.2 MOVTag

5.2.3 Valve Action Settings

5.2.4 Input / Output Setup

5.3 Advanced Settings 1

5.3.1 Tight Shut Off

5.3.2 Obstruction Action Active

5.3.3 Obstruction Values Setup

5.3.4 Manual Test Knob Setup

5.3.5 CVA Status Relay Setup

5.4 Advanced Settings 2

5.4.1 Travel Alarm Thresholds

5.4.2 Bumpless Transfer Setup

5.4.3 Manual Test Knob Setup

5.4.4 CVA Status Relay Setup

5.4.5 Travel Alarm Thresholds

5.4.6 Bumpless Transfer Setup

5.5 UPS Configuration and Status

5.5.1 UPS Configuration

5.5.2 UPS Status Information

5.6 CVA Status

5.6.1 Actuator Position (%)

5.6.2 Actuator Torque/Thrust (%)

5.6.3 Analogue Demand Input (mA)

5.6.4 Analogue Position Feedback (mA)

5.6.5 ESD Input Status

24

5.7 CVA Data logger

Page 25

5.7.1 Event Log

5.7.2 Dwell Log

5.7.3 Torque/Thrust Logs

5.7.4 Movement Log

5.1 CVQ/CVL Device Information

Please note that CVA actuators should be configured using dedicated Enlight support software. This is

available to download free of charge from www.rotork.com.

5.1.1 Valve Tag

This is a user defined name for the actuator consisting of up to 32 alpha-numeric or symbolic characters.

It is normally used by operators to specify a unique tag based on location or a description of the

actuator. This setting is linked directly to the MOVTag in the CVA Valve Setup Menu (See Section 5.2.2).

5.1.2 CVA/CVQ Type

This displays the size of the actuator, along with any options fitted. Rotork Service Engineer use only.

5.1.3 CVA Main PCB Software Version

Shows the current Main PCB software version in the actuator. Rotork Service Engineer use only.

5.1.4 Manufacturing Data

Shows the manufacturing data for the actuator. Rotork Service Engineer use only.

5.1.5 Service Notes

This is where service notes can be entered and stored for future reference. This field accepts up to 64

characters. Rotork Service Engineer use only.

5.1.6 Date of Manufacture

Shows the date of manufacture in the format YYYY/MM/DD. Rotork Service Engineer use only.

5.1.7 CVA Hardware

Shows the current CVA Hardware Number. Rotork Service Engineer use only.

5.1.8 Main Controller Serial No.

This is where the Main Controller serial number can be entered and viewed. Rotork Service Engineer use

only.

5.1.9 UPS Controller Serial No.

This is where the UPS Controller serial number can be entered and viewed. Rotork Service Engineer use

only.

5.1.10 Position Sensor Serial No.

This is where the Position Sensor serial number can be entered and viewed. Rotork Service Engineer use

only.

5.1.11 Motor Sensor Serial No.

This is where the Motor Sensor serial number can be entered and viewed. Rotork Service Engineer use

only.

25

Page 26

5.1.12 Force Sensor Serial No.

This is where the Force Sensor serial number can be entered and viewed. Rotork Service Engineer use

only.

5.1.13 User Interface Serial No.

This is where the User Interface serial number can be entered and viewed. Rotork Service Engineer use

only.

5.2 Actuator Configuration - CVA Valve Setup

5.2.1 Valve Action Settings

Valve Open Torque/Thrust Setting (%)

The slider sets the percentage of rated torque/thrust the actuator will be limited to during operation in

the open direction. This is adjustable between 40% and 100%.

Valve Close Torque/Thrust Setting (%)

The slider sets the percentage of rated torque/thrust the actuator will be limited to during operation in

the closed direction. This is adjustable between 40% and 100%.

5.2.2 MOVTag

Valve Tag

This is a user defined name for the actuator consisting of up to 32 alpha-numeric or symbolic characters.

It is normally used by operators to specify a unique tag based on location or a description of the

actuator. This setting is linked directly to the Valve Tag in the CVQ/CVL Device Information Menu (See

Section 5.1.1).

5.2.3 Valve Action Settings

Shaft Action

Specify the output direction of the actuator. CVL actuators can be configured for extend to close or

extend to open operation. CVQ actuators can be configured for clockwise to close or anti-clockwise to

close.

26

Page 27

Open Stop Action

The actuator can be set to stop in the open direction when it reaches the open position limit or when it

reaches the defined open torque/thrust setting value (see section 5.2.1).

Close Stop Action

The actuator can be set to stop in the close direction when it reaches the close position limit or when it

reaches the defined close torque/thrust setting value (see section 5.2.1).

5.2.4 Input / Output Setup

Demand Deadband (%)

The demand deadband sets the expected positioning accuracy of the actuator and is dependent on

various factors including actuator output speed, number of turns and valve torque. The actuator will run

until it reaches a position within the demanded deadband. The actuator will not restart until the

demanded position exceeds the extent of the deadband.

Demand Damping Clockwise (secs)

Setting a value greater than 0 will apply a delay in the clockwise direction, temporarily inhibiting

movement when a change to the set point signal occurs.

Demand Damping Anti-Clockwise (secs)

Setting a value greater than 0 will apply a delay in the anti-clockwise direction, temporarily inhibiting

movement when a change to the set point signal occurs.

4-20mA Output

Specify whether the 4-20mA output provides feedback for Valve Position or Valve Torque/Thrust.

5.3 Advanced Settings 1

5.3.1 Tight Shut Off

Valve tight shut off Open position (%)

This is the minimum position required to fully open (tight shut off) the valve.

Valve tight shut off Closed position (%)

This is the maximum position required to fully close (tight shut off) the valve.

5.3.2 Obstruction Action Active

If enabled, the actuator will back off movement if the maximum torque/thrust is exceeded during

travel. The actuator will make 3 attempts to back off and return to the set point. If disabled, the

27

Page 28

actuator will remain stationary until a request to move in the opposite direction is received or the

obstruction is removed. To set up obstruction settings see section 5.3.3.

5.3.3 Obstruction Values Setup

Backoff Distance (%)

The distance the actuator will back off as a percentage of total travel.

Backoff Time (Sec)

The time in seconds before a back off command is executed.

5.3.4 Manual Test Knob Setup

Manual Test Knob Active

Enables or disables the Manual Test knob option provided it is fitted to the actuator.

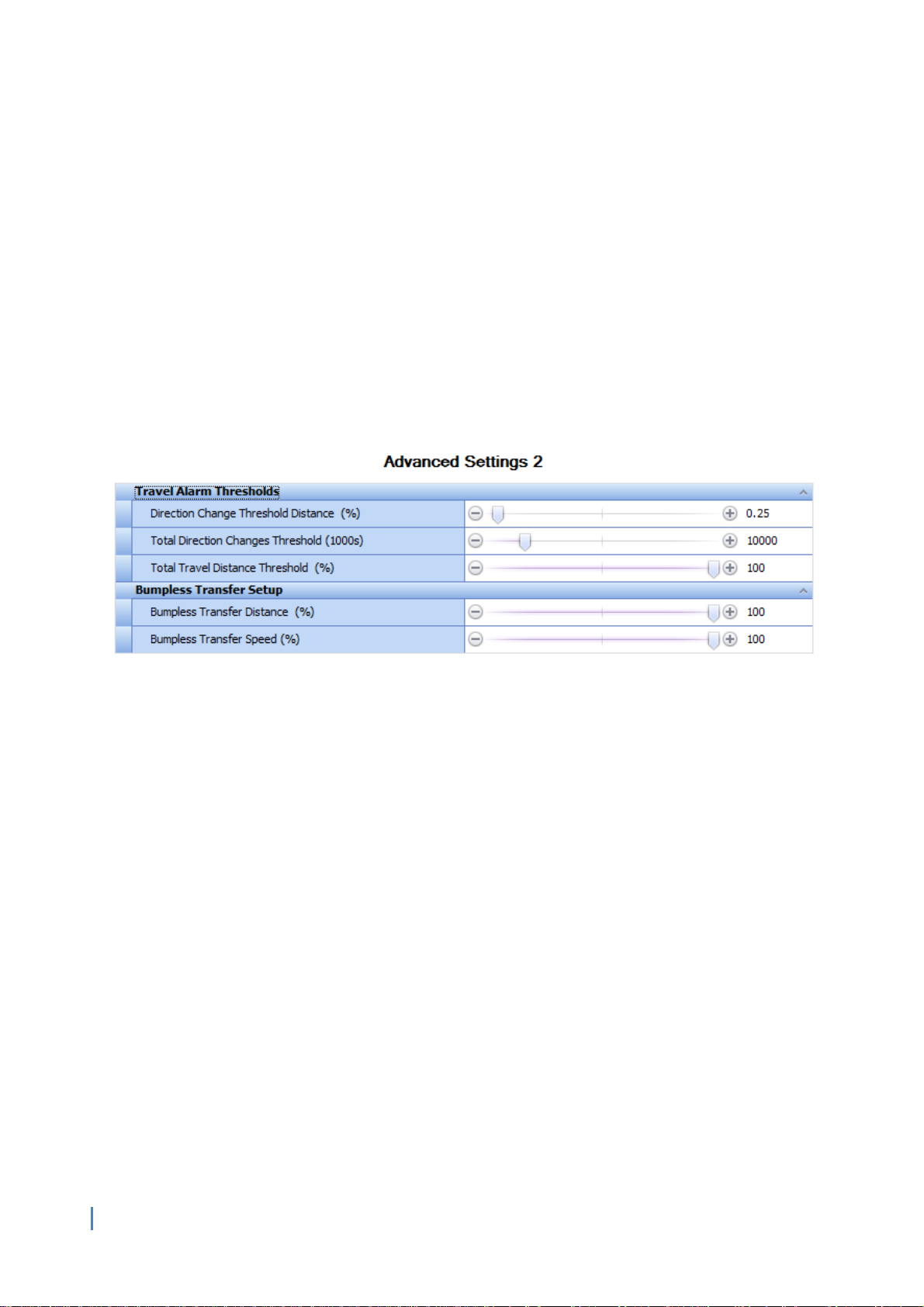

5.4 Advanced Settings 2

5.4.1 Travel Alarm Thresholds

Direction Change Threshold Distance (%)

The distance the actuator must move (as a percentage of full travel) before a direction change is

registered by the data logger as a start. The default setting is 0.25%.

Total Direction Changes Threshold (1000s)

This can be used to generate a Travel Alarm when a set number of direction changes have been

performed by the actuator.

Total Travel Distance Threshold (%)

This can be used to generate a Travel Alarm when a set distance has been travelled by the actuator.

5.4.2 Bumpless Transfer Setup

Bumpless Transfer Distance (%)

This is the percentage of position error that will reduce the actuator speed to the Bumpless Transfer

Speed.

Bumpless Transfer Speed (%)

This is the speed that the actuator will revert to if the bumpless transfer distance is exceeded. It is

measured as a percentage of rated maximum speed and the default setting is 40%.

28

Page 29

5.5 UPS Configuration and Status

5.5.1 UPS Configuration

Action on Loss of Power

The actuator can be configured to perform four different actions on loss of power. These are:

Closed Limit: The actuator will move to the closed limit.

Open Limit: The actuator will move to the open limit.

Stayput: The actuator will remain at the current position (Default Setting).

Go To Position: The actuator will move to a pre-determined position.

Position CVA travels to on Loss of Power (%)

The position the actuator will travel to on Loss of power, provided the Power Loss Action is set for Go To

Position. The position is a percentage of the full stroke and can be configured in increments of 0.1%.

Powerloss Action Delay timeout (sec)

The delay in seconds before the Power Loss Action is executed. The maximum allowable delay to

guarantee a failsafe action will perform is 10 seconds.

Speed of Operation during UPS action rated (%)

The speed of operation during the UPS action can be adjusted as a percentage of normal operating

speed.

29

Page 30

5.5.2 UPS Status Information

UPS Status Data (Raw Decimal Value)

For indication only, shows the raw decimal value that the UPS supplies to the actuator.

UPS Supply Voltage (V)

For indication only, shows the UPS supply voltage received by the actuator.

UPS Capacitor Voltages (V)

For indication only, shows the charge stored by each capacitor.

UPS Temperature Sensor Value (°C)

For indication only, shows the temperature measured at the UPS.

UPS Capacitor Values (Farads)

For indication only, shows the UPS capacitor values for all fitted capacitors.

UPS Capacitor Discharge Voltages (V)

For indication only, shows the separate discharge voltage for all fitted capacitors.

UPS End Discharge Voltage (V)

For indication only, shows the separate end discharge voltage for all fitted capacitors.

UPS Discharge Time (sec)

For indication only, shows the separate discharge time for each of the fitted capacitors.

5.6 CVA Status

5.6.1 Actuator Position (%)

For indication only, shows the position of the actuator as a percentage of full travel.

5.6.2 Actuator Torque (%)

For indication only, shows the percentage of rated torque currently measured through the actuator

drive train.

5.6.3 Analogue Demand Input (mA)

For indication only, shows the analogue input signal being received by the actuator.

5.6.4 Analogue Position Feedback (mA)

For indication only, shows the output signal being transmitted by the actuator with reference to

position or force (see 5.2.4).

5.6.5 ESD Input Status

For indication only, denotes whether the actuator ESD input is presently active or not.

30

Page 31

5.7 CVA Main Datalogger

The size of the Insight 2 window can be adjusted to expand or retract the visible range on graphical

screens for increased or decreased detail.

5.7.1 Event Logger

The Event Logger will store information related to actuator actions and condition changes. All events

are date and time stamped to accurately assess the actuator operations.

The top scroll bar can be used to navigate from the first recorded event (far left) to the most recent

event (far right). The recorded event number is shown with the event date and event time above the

navigation bar.

Time Line

The Time Line display style provides the user with a visual indication of active conditions for the specific

event selected with the top scroll bar. An active condition is indicated by a checked box. The dropdown

menu is included to apply a filter. The Prev and Next actions buttons chronologically skip to the next

recorded event for the chosen condition.

31

Page 32

Trace View

The trace view provides a comparison between various event triggers during each period between

events. The Position (%) trace is an analogue recorded value whilst other event conditions can be

configured as Digital Traces.

The top scroll bar can be used to navigate through various events. There is

also an additional scroll bar within the Trace view window. This can be

used to adjust the scaling of both traces for more detailed analysis.

Each digital trace can be allocated a different function by opening the

associated drop down menu and selecting the required condition.

32

Page 33

List View

This type of display depicts the Data Log of the CVA in tabular format as a chronological series of events.

The top slider bar can be used to navigate through all available events currently in the data log.

Alternatively the scroll bar on the right side of the event information can be used to navigate events in

the same fashion.

33

Page 34

5.7.2 CVA Dwell Log

The Dwell Log Graph indicates the amount of time spent at each position between the limits of travel.

The graph range extends 25% beyond both limits to account for any actions closing or opening on

torque/thrust beyond the set limits.

Graph detail can be enhanced by dragging a selection area over a section of the graph. This will adjust

the axis to zoom into a full sized graph of that area.

5.7.3 CVA Torque Logs

The torque profile graphs show various traces of torque experienced by the actuator across a full stroke.

The torque reference is a saved stroke trace that is configured during the auto-setup stage when

commissioning the unit. These graphs will display thrust profiles for CVL actuators.

Graph detail can be enhanced by dragging a selection area over a section of the graph. This will adjust

the axis to zoom into a full sized representation of that area. All traces can be selected/deselected to

provide bespoke comparisons.

34

Page 35

5.7.4 CVA Movement Log

The movement profile graph displays the actuator position and the demanded position of the CVA. This

will include all controlling actions and any failsafe action under UPS power.

35

Page 36

6.0 IQ3 Settings

6.1 Actuator Information

6.1.1 Actuator User Information

6.1.2 Actuator Serial Numbers

6.1.3 Actuator Manufacturing Information

6.1.4 Actuator Software Information

6.2 Actuator Name Plate

6.2.1 Actuator Name Plate Info

6.2.2 Valve Manufacturing Information

6.2.3 Gearbox Manufacturing Information

6.3 Actuator Settings

6.3.1 Basic Settings

6.3.2 ESD Configuration

6.3.3 Remote Configuration

6.3.4 Local Configuration

6.3.5 Special Mode Configuration

6.4 Torque Settings

6.4.1 Current Torque Readings

6.4.2 Actuator Torque Settings

6.4.3 Torque Engineering Settings

6.4.4 Torque Advanced Settings

6.4.5 Torque Profile Settings

6.5 Power Settings

6.5.1 Power Type

6.5.2 Battery Settings

6.6 Digital Input Settings

6.6.1 DI Function

6.6.2 DI Input Type

6.7 Partial Stroke Settings

6.7.1 Partial Stroke Enable

6.7.2 Partial Stroke Initial Position

6.7.3 Partial Stroke Position (%)

6.7.4 Partial Stroke Time to Position (sec)

6.7.5 Partial Stroke Time to Limit (sec)

6.8 Relay Settings

36

6.8.1 Monitor Relay Function

6.8.2 Relay Settings

Page 37

6.9 Option Control

6.9.1 Option Source Selection

6.9.2 Auxiliary Mask Configuration

6.9.3 Option 1-4 Configuration

6.10 Control Settings

6.10.1 Position Calibration

6.10.2 Position Settings

6.10.3 Movement Settings

6.10.4 Interrupter Timer

6.11 UI Settings

6.11.1 Indication Configuration

6.11.2 Communication Configuration

6.12 Language Settings

6.12.1 Display Language

6.12.2 Language Option Details

6.13 AMS Encoder

6.13.1 Position Encoder Absolute Position

6.13.2 Position Encoder Status

37

Page 38

6.1 Actuator Information

The Actuator Information comprises of technical information about the actuator that will help to

identify spare parts and important test dates.

6.1.1 Actuator User Information

Valve Label

This is a user defined description of up to 32 Characters long. It is normally used to denote the function

or location of the actuator or valve.

6.1.2 Actuator Serial Numbers

Actuator

Shows the serial number of the connected actuator.

Main Controller

For indication only, shows the serial number of the main controller board.

Position Sensor

For indication only, shows the serial number of the Position Sensor.

Torque Sensor

For indication only, shows the serial number of the Torque Sensor.

User Interface

For indication only, shows the serial number of the User Interface.

Option 1

For indication only, shows the serial number of Option card 1 (if fitted).

Option 2

For indication only, shows the serial number of Option card 2 (if fitted).

38

Page 39

Option 3

For indication only, shows the serial number of Option card 3 (if fitted).

Option 4

For indication only, shows the serial number of Option card 4 (if fitted).

DC Power board

For indication only, shows the serial number of the DC power board (for DC only).

Power Board

For indication only, shows the serial number of the power board (for AC only).

Solid State Starter board

For indication only, shows the serial number for the Solid State Starter board (if fitted).

6.1.3 Actuator Manufacturing Information

Date of Manufacture

For indication only, shows the manufacture date of the actuator.

Service Commission Date

Shows the date the actuator was commissioned by a Rotork Engineer.

For indication only, shows Inspection Date

For indication only, shows when the actuator is due its next inspection.

Factory Acceptance Test Date

For indication only, shows when the actuator was factory tested by Rotork.

Wiring Diagram

For indication only, shows the wiring diagram number for the actuator.

39

Page 40

6.2 Actuator Name Plate

This menu replicates the physical name plate information visible on the actuator gear case. Should the

nameplate become damaged, the correct information will still be retained in this section.

6.2.1 Actuator Name Plate Info

Actuator Rated Torque

For indication only, shows the rated output torque of the actuator.

Actuator Voltage

For indication only, shows the supply voltage the actuator is configured to receive.

Actuator Frequency

For indication only, shows the actuator supply voltage frequency (Hz).

Actuator Wiring Diagram

For indication only, shows the actuator wiring diagram number which determines the specific internal

wiring of the actuator.

Actuator Wiring Diagram Issue

For indication only, shows the issue number of the wiring diagram upon installation. This is important as

the wiring diagram may have been superseded at a later date.

Actuator Size

For indication only, shows the actuator size and type. For example an IQS12 is a single phase IQ12.

40

Page 41

Actuator Speed

For indication only, shows the speed of the actuator in revolutions per minute (RPM).

Actuator Base

For indication only, shows what size base flange is fitted to the actuator.

Actuator Coupling

For indication only, shows what size coupling the actuator is fitted with.

Actuator Enclosure

For indication only, shows what enclosure type the actuator has.

Actuator Gearbox

For indication only, shows what gearbox is attached to the actuator. If there is no gearbox is fitted to

the actuator this will be listed as N.

6.2.2 Valve Manufacturing Information

Valve Tag

This is similar to the actuator valve label (see section 6.1.1). A user defined label consisting of 16 alphanumeric or symbolic characters. It is normally used to denote valve location or function.

Valve Serial Number

Input for the serial number of the attached valve. 10 alpha-numeric or symbolic characters are available

to input the valve serial number.

Valve Type

Input for the type of the attached valve. 10 alpha-numeric or symbolic characters are available to input

the valve type.

Valve Size

Input for the size of the attached valve. 10 alpha-numeric or symbolic characters are available to input

the valve size.

Valve Class

Input for the valve classification. 10 alpha-numeric or symbolic characters are available to input the

valve classification.

Valve Manufacturer

Input for detail of the valve manufacturer. 10 alpha-numeric or symbolic characters are available to

input the valve classification.

Valve Service Fluid

Input for the fluid flowing through the valve. 10 alpha-numeric or symbolic characters are available to

input the valve classification.

Valve Service Temperature

Input for the maximum operating temperature of the valve before requiring a service. 5 alpha-numeric

or symbolic characters are available to input the valve classification.

Valve Location

Input for detail of the valve’s location. 10 alpha-numeric or symbolic characters are available to input

the valve location.

41

Page 42

Valve Installation Date

Record for when the valve was installed. 8 alpha-numeric or symbolic characters are available to input

the valve installation date.

6.2.3 Gearbox Manufacturing Information

Gearbox Serial Number

Record for the serial number of the actuator gearbox. If no gearbox is fitted the default value will be

blank or GearSerial.

Gearbox Mechanical Advantage

Record for the mechanical advantage of the gearbox. If no gearbox is fitted the default value will be

blank or MechAdv.

Gearbox Ratio

Record for the internal gear ratio of the gearbox. If no gearbox is fitted the default value will be blank or

GearRati.

42

Page 43

6.3 Actuator Settings

This screen displays the current actuator settings. These settings are all relevant to standard actuator

control functions.

6.3.1 Basic Settings

Close Action

The actuator can be configured to close on torque for seating valve types or limit for non-seating valve

types. Limit means the actuator will stop moving once it reaches the set closed travel limit. Torque

means the actuator will stop when it reaches the set closed torque limit (Default 40% of Rated).

Open Action

The actuator can be configured to open on torque for back-seating valve types or limit for non-backseating valve types. Limit means the actuator will stop moving once it reaches the set open travel limit.

Torque means the actuator will stop when it reaches the set open torque limit (Default 40% of Rated).

Direction to Close

This sets the direction of rotation for the actuator to perform a close operation to the valve. There are

two available settings; clockwise and anti-clockwise. A close command will always operate in the set

direction; therefore a reversal of controls is not required when changing the operating direction to suit

the valve.

43

Page 44

6.3.2 ESD Configuration

ESD Action

This function sets the emergency shutdown action. There are four options.

ESD CLOSE: Upon receiving an ESD signal this setting will cause the actuator to close using the action set

in the ‘Close Action’ screen. See section 6.3.1.

ESD Stop: Upon receiving an ESD signal this option will cause the actuator to stop.

ESD Open: Upon receiving an ESD signal this option will cause the actuator open using the action set in

the ‘Open Action’ screen. See section 6.3.1.

ESD OFF: The ESD function has been disabled. Applying an ESD signal will not affect the actuator

operation.

ESD Normally Closed

This setting dictates if the ESD action will be performed when a signal is applied (normally open) or

removed (normally closed).

ESD Override interlock

This setting specifies if the ESD action should override an active interlock. (Default Setting: No)

ESD Override Local stop

This setting specifies if the ESD action should override a local stop command. The local control selector

has to be in the stop position to actively apply a local stop command. (Default Setting: No)

ESD Override Thermostat

This setting specifies if the ESD action should override an active thermostat trip. (Default Setting: No)

ESD Override Interrupter Timer

This setting specifies if the ESD action should override the interrupter timer function. (Default Setting:

No)

ESD Input Function

The function of the ESD input can be configured in two different ways.

ESD: When an ESD signal is received by the actuator it will perform its ESD action taking into account

any override settings.

Network Control Disable: When an ESD signal is received by the actuator it will disable all network

control inputs until the ESD signal is removed. During this period the actuator can only be controlled via

hardwired remote inputs determined by the auxiliary mask setting.

44

Page 45

6.3.3 Remote Configuration

Two Wire Priority

This sets the action the actuator will take when a close and open signal are applied simultaneously.

Open Priority: The actuator will run open if both signals are applied.

Stop Priority: The actuator will stay put or stop moving if both signals are applied.

Close Priority: The actuator will run closed if both signals are applied.

Interlock Mode

This sets the mode for the interlock inputs. Refer to the actuator wiring diagram for installation details.

To operate the actuator when an interlock mode is enabled, an interlock signal must be applied in the

appropriate direction whilst providing a control signal.

Disabled: The interlock inputs are disabled.

Interlocks Enabled: Interlocks are enabled for local and remote operation.

Conditional Control Enabled: Interlocks are enabled in remote control only.

Partial Stroke On Open Interlock Enabled: The open interlock will act as a remote input to initiate a

partial stroke test.

Fast Remotes (DC Only)

For indication only, this setting reduces the minimum required control signal pulse length. (Default

Setting: Disabled) Rotork Service Engineer use only.

Push to run past limit

This function will cause the actuator control signal to be Maintained once the actuator limit setting has

been passed. (Default: Enabled)

6.3.4 Local Configuration

Local Push to Run

When enabled this changes the local open/close control knob function to a push to run operation. The

knob position must be manually maintained for the actuator to run, upon removal of the signal the

actuator will stop.

Local Close Dominant Mode

For indication only, this setting means that when a local close control command is applied it will

override all other types of control. (Default: Disabled) Rotork Service Engineer use only.

Setting Tool Local Control

This setting enables the actuator to be controlled using the open, close and stop commands on the

setting tool.

Vandal Resist Mode

The vandal resist mode is aimed at preventing unauthorised actuator operation. There are four options

available.

Vandal Resist Off: All control knobs are active and the actuator will respond to all inputs, providing the

unit is in the correct control mode. (Default)

Vandal Resist Local: In this mode the local and remote controls are disabled. The actuator can only be

controlled by the open, close and stop commands on the setting tool.