Page 1

GT Range

Pneumatic Actuator

Single-Acting and Double-Acting Configuration

Keeping the World Flowing

Installation, Commissioning and

Maintenance Manual

Page 2

Contents

Section Page Section Page

1.0 Introduction 3

2.0 Standards & Regulations 3

3.0 General Information 4

4.0 Health & Safety 4

4.1 Residual Risks 4

4.2 Thermal Risks 4

4.3 Noise 4

4.4 Health Risks 4

4.5 Mechanical Risks 4

4.6 Magnetic Risks 5

5.0 Labels & Nameplates 5

6.0 Operating Limits 6

6.1 Allowed Fluid Types 6

6.2 Expected Lifetime 6

6.3 Tightening Torque Chart 6

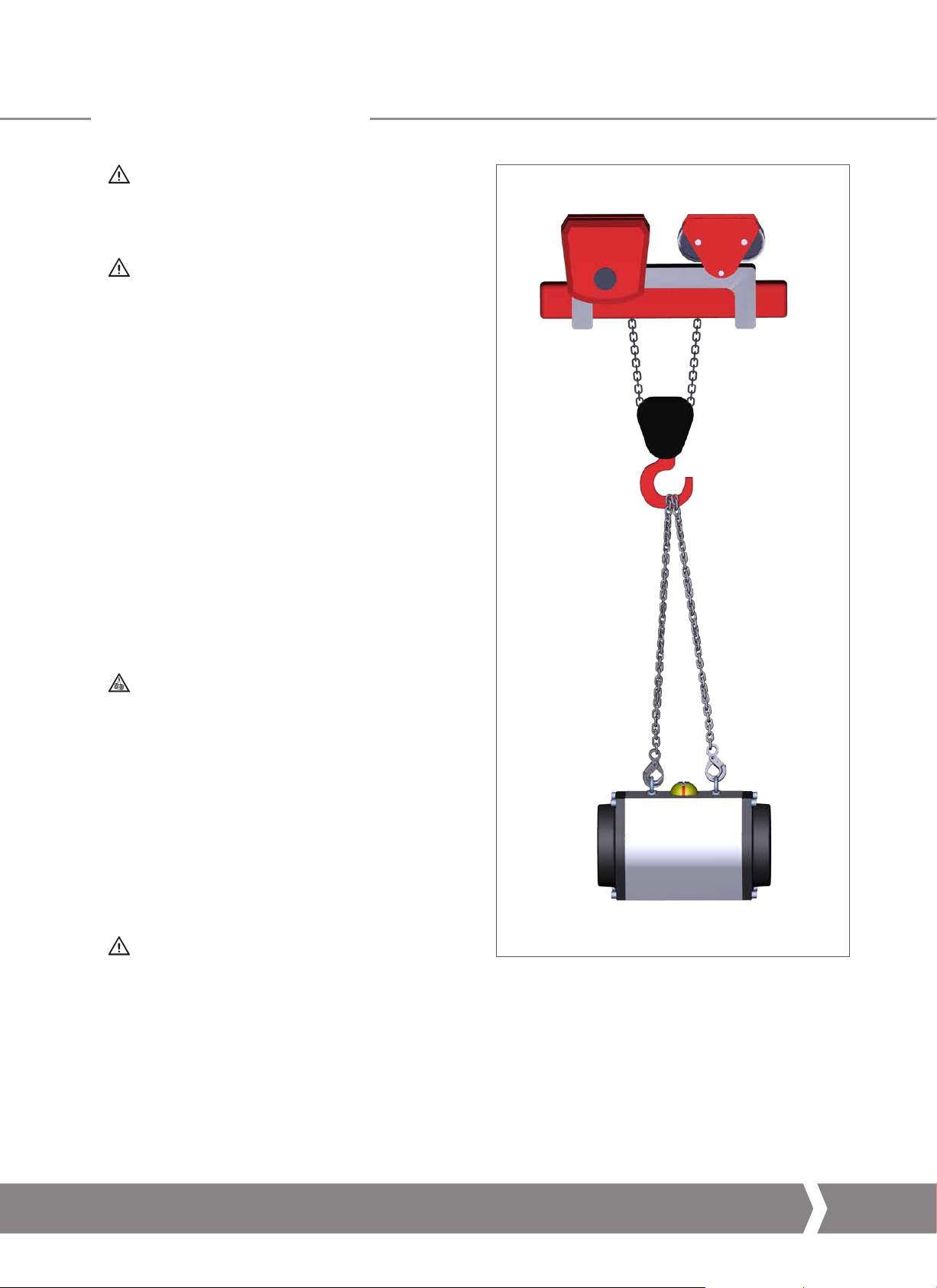

7.0 Handling & Lifting 7

7.1 Lifting Recommendations 7

7.2 Lifting Instructions 7

8.0 Storage 8

9.0 Long Term Storage 8

10.0 Installation on Valve 9

10.1 Preliminary Actions 9

10.2 Instructions 9

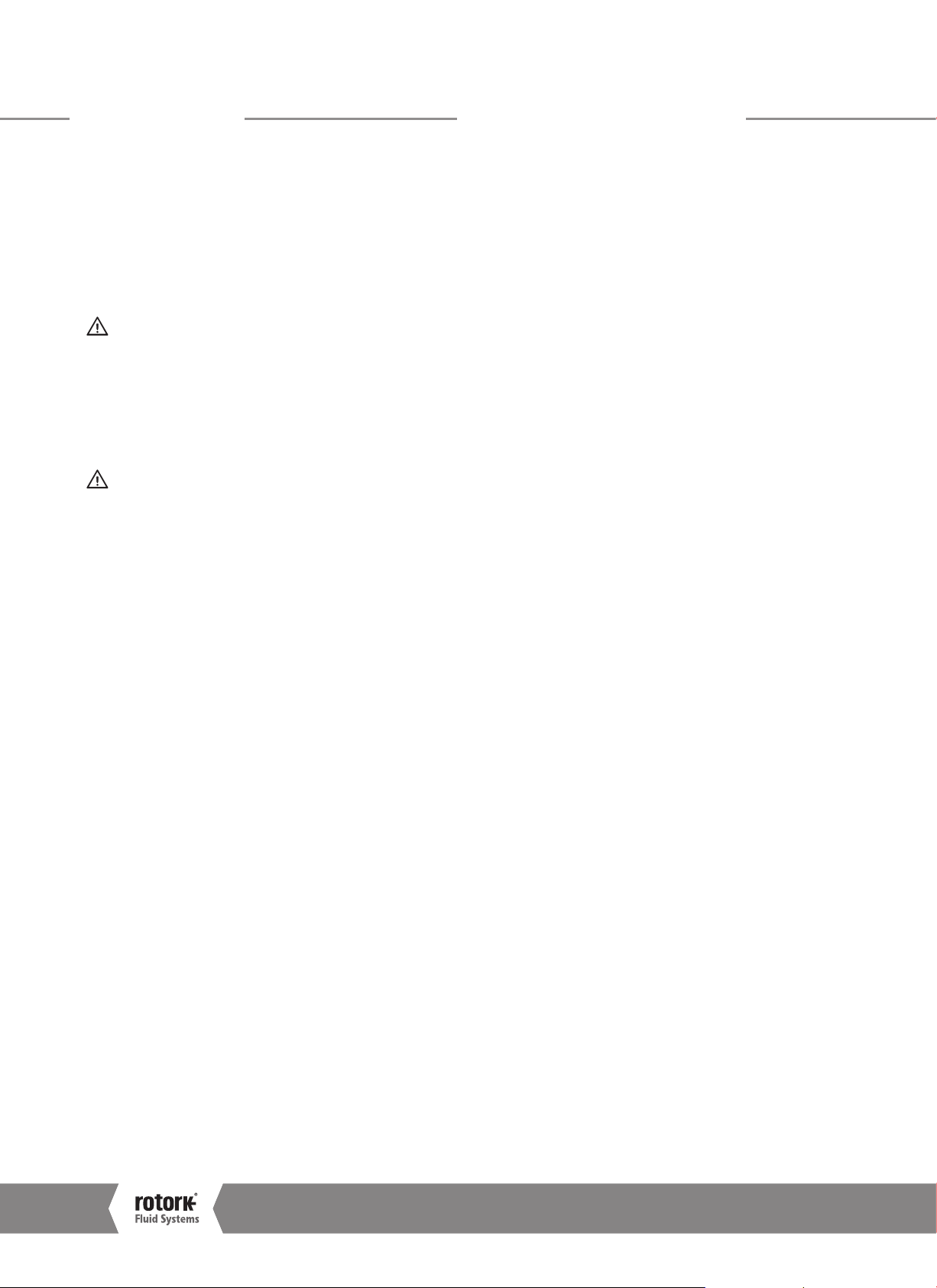

10.3 Assembly Configurations 10

11.0 Removal from Valve 10

12.0 Operation 11

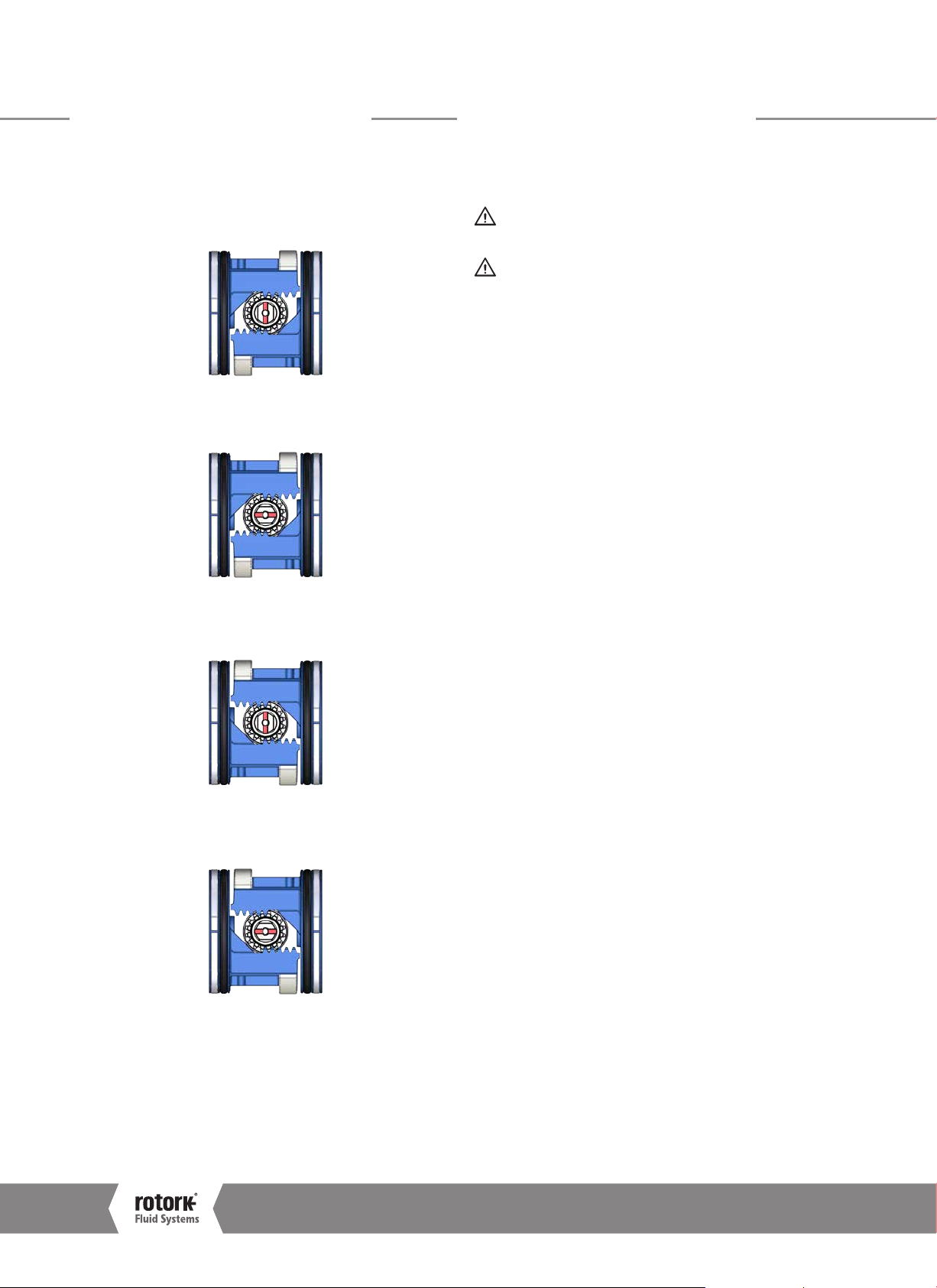

12.1 Description 11

12.2 Single and Double Limit Stop 12

12.3 Angular Stroke Setting 13

12.4 Pneumatic Power Supply 14

12.5 Pneumatic Connections 14

12.6 Electrical Connections 15

12.7 Start Up 15

13.0 Dismantling & Disposal 16

14.0 Rotork Sales and Service 16

15.0 Troubleshooting 17

16.0 Periodic Maintenance 18

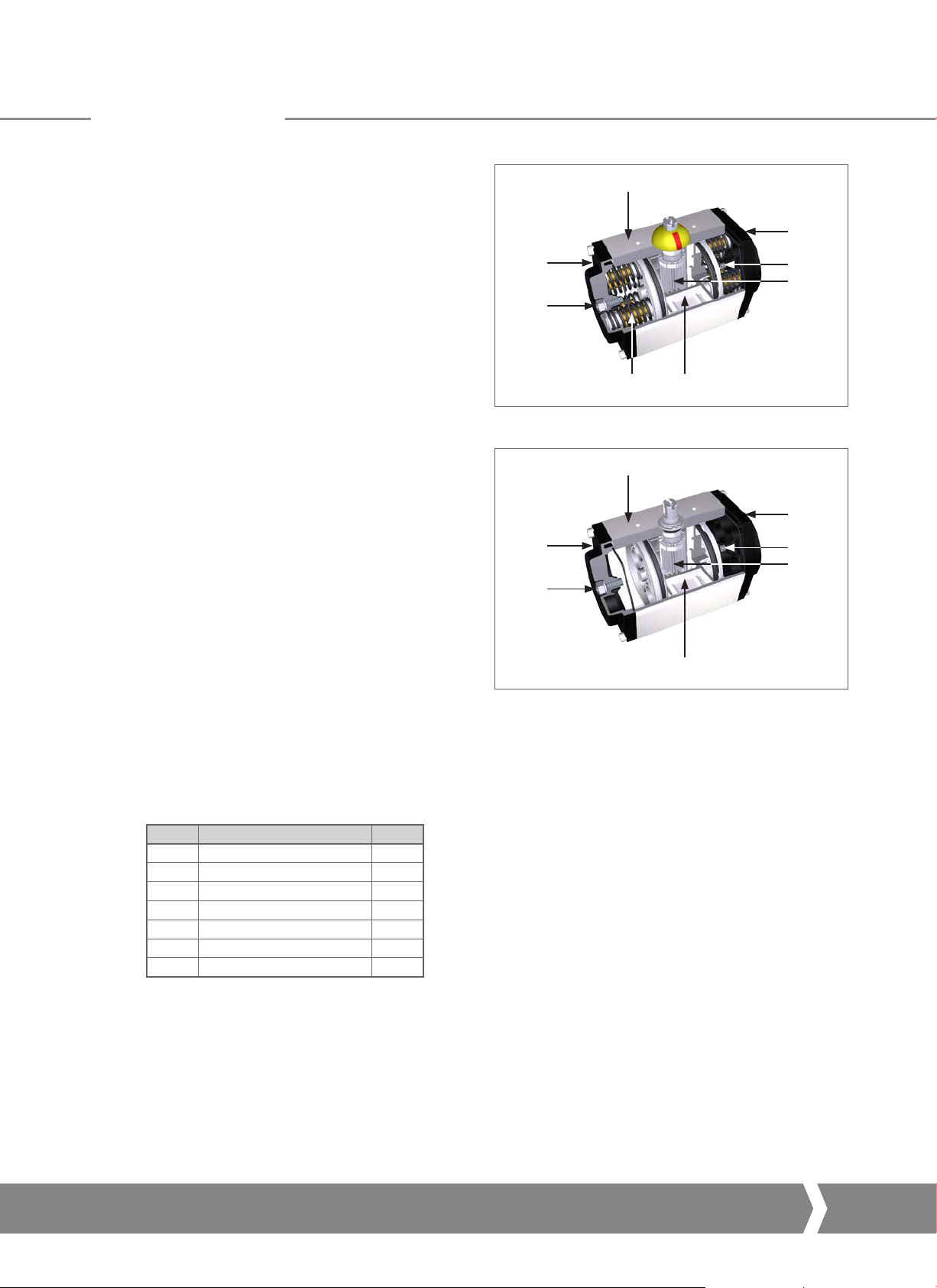

17.0 Part List 32

18.0 Grease Specification 34

18.1 Grease 34

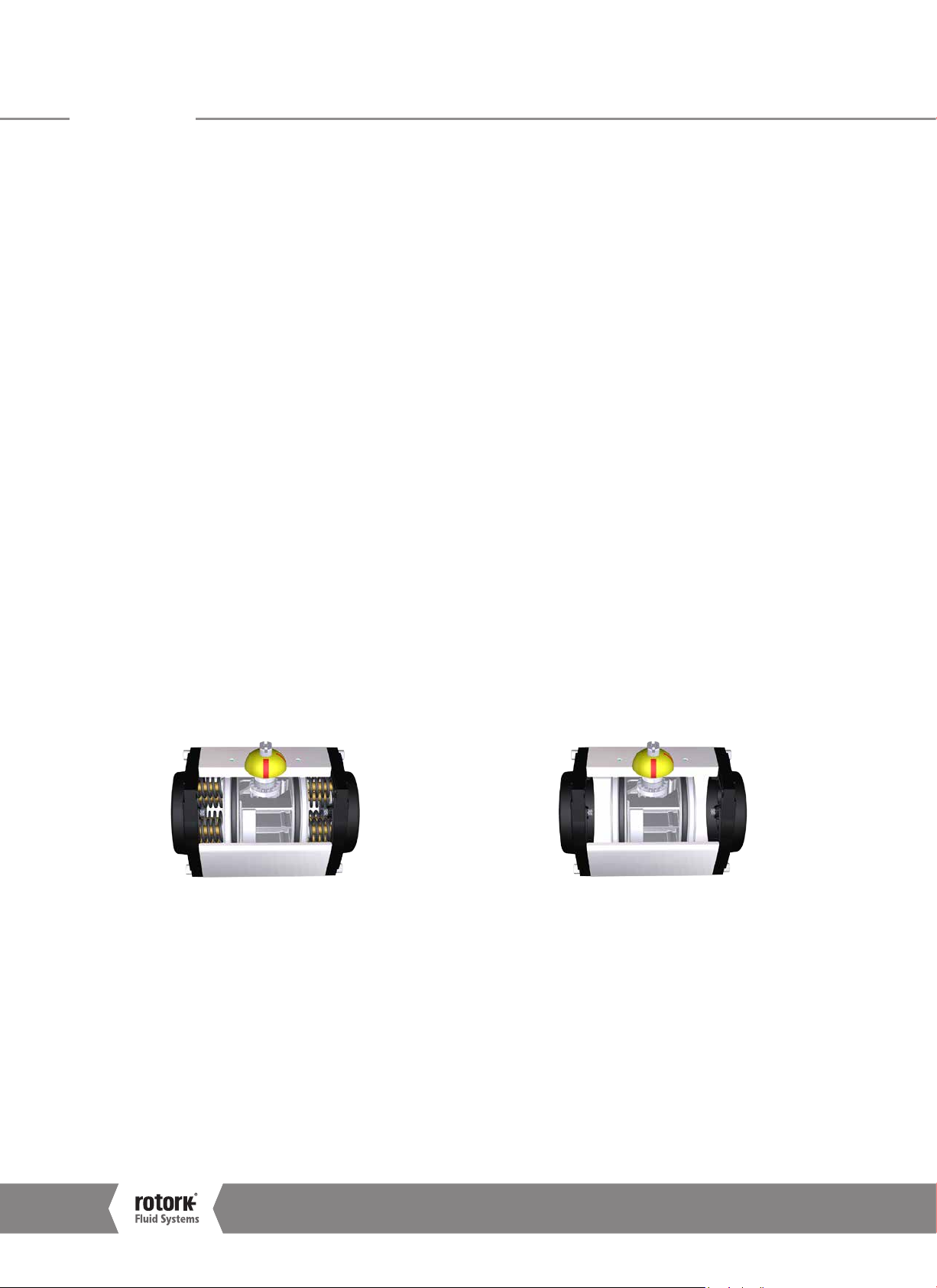

Single-acting actuator Double-acting actuator

This manual contains important safety information.

Please ensure it is throughly read and understood

before installing, operating or maintaining the

equipment.

Rotork Fluid Systems reserves the right to modify,

amend and improve this manual without notice.

2

Installation, Commissioning and Maintenance Manual

Due to wide variation in the terminal numbering of

actuator products, actual wiring of this device should

follow the print supplied with the unit.

Page 3

1.0 Introduction 2.0 Standards & Regulations

This manual covers maintenance aspects and instructions

specific to the GT range actuators. General information on

Rotork Fluid Systems actuators are described in the User

Manual, delivered separately.

In this manual, warning indications are represented by icons,

according to ISO 7010 Safety Signs:

Generic danger

Hand crush / pinch point

Electrocution

Explosive material

Customer Service

For technical assistance, please contact the

Rotork Fluid Systems Customer Service:

E-mail: rfs.internationalservice@rotork.com

Rotork Fluid Systems, Via Padre Jaques Hamel 138B,

Porcari, Lucca, IT. Tel: +39 0583-222-1

Rotork plc, Brassmill Lane, Bath, UK. Tel +44 (0)1225 733200

Actuators destined for European member states have been

designed, built and tested according to the Quality Control

System, in compliance with the EN ISO 9001:2015 standard

and with the following regulations/directives.

•

2006/42/EC: Machinery Directive

•

2014/34/EU: Directive for safety equipment and systems

to be used in potentially explosive atmospheres (ATEX)

•

ISO 80079-36: Non-electrical equipment for explosive

atmospheres – Basic method and requirements

•

ISO 80079-37: Non-electrical equipment for explosive

atmospheres – Non-electrical type of protection

construction safety "c", control of ignition sources "b",

liquid immersion "k".

Keeping the World Flowing

3

Page 4

3.0 General Information 4.0 Health & Safety

This manual is produced to enable a competent user to install,

operate and maintain the Rotork Fluid Systems GT Actuator

Single- and Double-Acting.

The mechanical installation should be carried out as outlined

in this manual and also in accordance with any relevant

national standard codes of practice.

Maintenance and operation should be carried out in

accordance with National Legislation and Statutory Provisions

relating to the safe use of this equipment, applicable to the

site of installation.

Any inspection or repair in a Hazardous Area should not be

undertaken unless it conforms to National Legislation and

Statutory Provisions relating to the specific Hazardous Area.

Only Rotork approved replacement parts should be used.

Under no circumstances should any modification or alteration

be carried out on the equipment, as this could invalidate the

conditions under which its certification was granted.

Only trained and experienced operators should be allowed

to install, maintain and repair Rotork Actuators. Work

undertaken must be carried out in accordance with

instructions in this manual. The user and those persons

working on this equipment should be familiar with their

responsibilities under any statutory provisions relating to the

Health and Safety of their workplace.

Operators should always wear appropriate Personal

Protection Devices (PPDs) in line with the existing plant

regulations.

Appropriate Usage

Rotork Fluid Systems GT actuators have been specifically

developed to motorize part turn valves, such as ball valves,

butterfly valves or plug valves installed on pipelines for oil &

gas transport and distribution.

Improper use can damage the equipment or cause

dangerous situations for health and safety. Rotork

Fluid Systems declines any responsibility for damage

to people and/or objects resulting from the use of

the equipment for applications different from those

described in the manual.

Before installing the equipment, verify it is suitable for the

intended application. If unsure consult Rotork Fluid Systems.

4.1 Residual Risks

Residual risks resulting from equipment risk evaluation

performed by Rotork Fluid Systems.

4.2 Thermal Risks

Risk Hot/Cold surface during normal

operation (RES_01).

Preventive measures

Operators should wear protective gloves.

4.3 Noise

Risk

Preventive measures Operators should wear ear protections.

Noise >85 dB during operation (RES_05).

Operators should not stand near the

equipment during operation.

4.4 Health Risks

Risk Pressurized fluid ejection during

normal operation (RES_02).

Preventive measures All fittings must be properly sealed.

All fixing clamps must be correctly

tightened and sealed.

Risk Risk of intoxication (according to the

type of medium utilized) (RES_06).

Preventive measures Operators must use P.P.Ds and any

other equipment (breathing apparatus)

based on the type of supply medium.

4.5 Mechanical Risks

Risk Uncontrolled movement (remote

operation) (RES_03) (This risk is

applicable only for actuators provided

with control panel).

Preventive measures Assure that the actuator cannot be

operated remotely. Prior to starting,

remove pneumatic supply, vent all

pressure vessels, and remove

electrical power.

Risk Presence of moving parts (center body,

valve adapter) (RES_04).

Preventive measures Do not perform start-up or test

the actuator if the cylinder tube is

removed.

4

Installation, Commissioning and Maintenance Manual

Page 5

4.0 Health & Safety

5.0 Labels & Nameplates

Risk Loss of stability with possible parts

projection (RES_08).

Preventive measures Do not disassemble the actuator

in case of malfunctioning. Follow

instructions in the manual and contact

Rotork Fluid Systems.

Preventive measures Foresee periodic maintenance

procedure to verify tightening.

Risk Presence of potential energy (RES_10)

during dismantling.

Preventive measures Do not disassemble the actuator

during dismantling. Follow instructions

in the manual and contact Rotork

Fluid Systems.

4.6 Magnetic Risks

Risk Risk of magnetic field/disturbance and

exothermic reactions.

Preventive measure The End User shall assure that actuator

and its components are installed

far from magnetic field, electromagnetic field, radioactive source,

electroacoustic transducer which could

modify its behaviour.

(This mitigation is applicable only for

actuators provided with control panel).

Avoid maintenance operations with

acid/basic solutions.

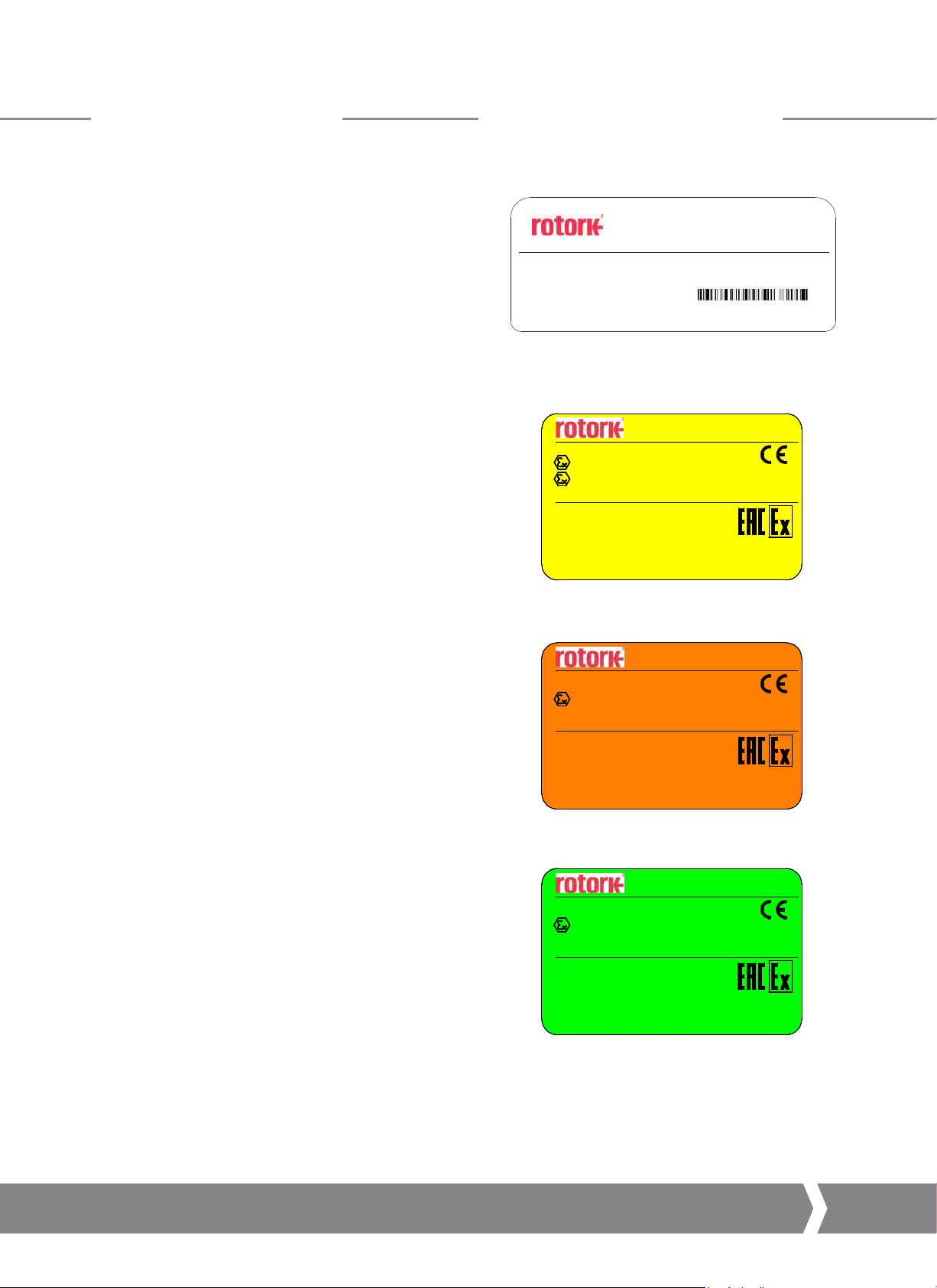

The following label is applied externally to the each Actuator:

Via Padre jacques Hamel, 138B

PORCARI, LUCCA 55016 - ITALY

Fluid Systems

PRODUCT

MAX PRESSURE : 1,0MPa/10bar/150Psi

MAX VOLUME dm :

Serial Number

Product of Italy

3

Tel: +00 (039) 0583 2221

MANUFACTURED 10/2017

Information: sales.lu cca@rotork.com

Fig 5.1 Actuator label

In case of ATEX and/or EAC certifications the following labels

with be also applied:

MODEL: GT / RCR - PNEUMATIC ACTUATOR

II 2 G Ex h IIC T5 Gb

II 2D Ex h IIIC T100°C Db

T. amb. -50 °C +70 °C

Модель: GT / RCR - пневматический привод

№ TC RU C-IT.ME92.B.00889

Серийный номер привода указан на корпусе привода

IIGb IIC T5 X

IIIDb IIIC T100°C X

Темп. окр. среды: -50 °C +70 °C

Fig 5.2 Actuator ATEX/EAC label for standard

MODEL: GT / RCR - PNEUMATIC ACTUATOR

T. amb. -15 °C +160 °C

Модель: GT / RCR - пневматический привод

№ TC RU C-IT.ME92.B.00889

Серийный номер привода указан на корпусе привода

IIGb IIC T3 X

Темп. окр. среды: -15 °C +160 °C

Fluid Systems

Tech-File--TR563-X/2017

Deposited in Cesi

0722

Тех. пакет: R563-X/2017

Депозитарий в

г. Чези, Италия:

temperature (-50°C<T<+70°C)

Fluid Systems

II 2G Ex h IIC T3 Gb

Tech-File--TR563-X/2017

Deposited in Cesi

0722

Тех. пакет: R563-X/2017

Депозитарий в

г. Чези, Италия:

0722

0722

Fig 5.3 Actuator ATEX/EAC label for high

temperature (-15°C<T<+160°C)

Fluid Systems

MODEL: GT / RCR - PNEUMATIC ACTUATOR

II 2G Ex h IIC T2 Gb

T. amb. -60 °C +200 °C

Модель: GT / RCR - пневматический привод

№ TC RU C-IT.ME92.B.00889

Серийный номер привода указан на корпусе привода

IIGb IIC T2 X

Темп. окр. среды: -60 °C +200 °C

Fig 5.4 Actuator ATEX/EAC label for low

temperature (-60°C<T<+200°C)

Label removal is not allowed.

Keeping the World Flowing

Tech-File--TR563-X/2017

Deposited in Cesi

0722

Тех. пакет: R563-X/2017

Депозитарий в

г. Чези, Италия:

0722

5

Page 6

6.0 Operating Limits

Temperature: -50 °C to +70 °C (-58 °F to +158 °F)

NBR o-ring, Delrin Guide

-15 °C to +160 °C (+5 °F to +320 °F)

Viton o-ring, IXEF Guide

-60 °C to +200 °C (-76 °F to +352 °F)

Silicon o-ring, PTFE Guide

Operating pressure: 2 to 10 bar (compressed air)

Operating pressure: 2 to 5 bar (methane, ethane,

propane, butane)

Do not use the equipment outside its operating limits.

It is critical that external surface temperature does not reach

or exceed the ignition temperature of potentially explosive

atmospheres when installed in these locations.

The actuator surface temperature is strictly dependent

on the temperature of the process fluid used and by the

irradiation’s conditions. The end-user has to check the surface

temperature of the assembly, so that this cannot exceed the

minimum gas ignition’s temperature, which classifies the area

with the explosion’s risk.

Dust and debris accumulated on the actuator will slow down

its cooling and contribute to the increase of its external

temperature.

6.3 Tightening Torque Chart

Actuator size

52 - 63 M5 8 2

75 - 83 - 92 M6 12 3

110 - 118 M8 15 4.5

127 M8 15 8

143 - 160 M10 20 8

190 - 210 M12 28 13

254 - 255 M14 40 20

300 M14 40 30

Screw

size

Torque

(Nm)

Stop nut

(Nm)

6.1 Allowed Fluid Types

GT pneumatic actuators are designed to be operated with

Gas, Instrument air filtered PNEUROP/ISO class 4; if not

differently specified in specific project documentation.

Do not use the actuator in presence of naked flames.

6.2 Expected Lifetime

Expected Lifetime greater than 25 years, in normal service

conditions and with planned maintenance.

6

Installation, Commissioning and Maintenance Manual

Page 7

7.0 Handling & Lifting

Only trained and experienced personnel should

handle/lift the actuator.

GT actuators are supplied packed in cardboard boxes suitable

for normal handling.

Handle the actuator with care.

7.1 Lifting Recommendations

•

The lifting device and the sling must be suitably rated for

the actuator weight and dimensions

•

Do not use damaged sling(s)

•

The sling must not be shortened with knots or bolts or

any other makeshift device

•

For lifting purposes, use only suitable lifting tools

•

Do not drill holes, weld eye bolts or add any other type of

lifting device on the actuator external surface

•

Do not lift the actuator and valve combination with the

actuator lifting lugs

•

Every assembly must be estimated separately for a safe

and correct lifting

•

Avoid pulls or abrupt movements during lifting. Avoid

pushing the load

•

During lifting operations, do not handle the slings and/or

the actuator

Do not step underneath suspended load.

7.2 Lifting Instructions

NOTE: Indication of weight, center of gravity,

lifting points are reported within project specific

documentation.

Consult project specific documentation before lifting.

•

Prior to lifting the actuator, remove electrical power and

vent all pressure vessels (if present)

•

Actuators up to size 160 can be manually lifted

•

Actuators sizes from 190 to 302 must be lifted using the

lifting lugs to be installed on the top side of the actuator

The actuator must remain horizontal; balance the load.

•

Angle β must between 0° and 45° as shown opposite

β

Fig 7.1 Lifting (size 190)

Keeping the World Flowing

7

Page 8

8.0 Storage

9.0 Long Term Storage

Rotork Fluid Systems actuators have been fully tested before

leaving the factory.

In order to keep the actuator in good condition

until installation, at least the following measures are

recommended:

•

Check presence and assembling of dust plugs

•

Keep the actuator on shipping pallet until installation

Never put the actuator directly on the ground.

•

Actuator must be positioned upwards

•

Protect against adverse weather conditions, covering the

actuators with appropriate polyethylene sheets

•

Check the actuator condition every 6 months and verify

the above protection measures remain in place

Remove package only when required for

installation.

If long term storage is necessary, further operations must

be carried out to maintain the actuator in a good working

condition:

•

Storage should be indoors and the units should be

protected against humidity and other harmful elements

•

Replace the plastic plugs with metal plugs

•

Stroke the actuator every 12-months

•

Cycle the actuator (using filtered, dehydrated air) to the

working pressure indicated on the name plate

•

Cycle the actuator with all the existing controls

(i.e. two complete strokes - one open, one closed)

at least 5 times

•

Cycle the actuator fitted with the mechanical manual

override or hydraulic manual override by means of the

override for 4 complete strokes

•

Disconnect the pneumatic and electric (if present)

supply from the actuator, and carefully close all the

threaded connections of the actuator

•

Remove electrical component covers (if present) to ensure

control terminals are clean and free from oxidation and

humidity. Reassemble the covers

•

In case of storage for over 12 months prior to installation,

it is recommended to operate the actuator to verify

correct operation

8

Installation, Commissioning and Maintenance Manual

Page 9

10.0 Installation on Valve

Before proceeding, read and understand the Health and

Safety information.

Note: The valve should be properly secured prior to

performing the following operations according to

instructions provided by the Valve Manufacturer.

Prior to performing any operations check the

operating drawings and TAG numbers.

Consult Rotork Fluid Systems for any additional information.

10 .1 Preliminary Actions

Verify the Hazardous Area classification of the

actuator is compatible with the plant zoning. Refer to

actuator nameplate.

•

The centreline of the cylinder is usually aligned to the

centreline of the associated pipe work

•

Ensure all fasteners are adequately tightened to avoid

loosening during operation, taking into account the

vibrations induced by the dynamics of the pipeline

•

Piping used to provide power to the actuator must be

free from contaminants and debris. Ensure tubing runs

are adequately fastened and supported to minimize

repetitive stress induced by the dynamics of the pipeline.

Ensure there are no leaks from any gas connections.

Tighten as required

10.2 Instructions

Actuator to valve attachment can be performed by:

•

Mounting directly using the actuator housing bottom

flange drilling

•

Using an adapter and a coupling joint between the

actuator and the valve

Actuator bottom flange drilling is in accordance to ISO 5211

(DIN 3337) standard.

The assembly position of the actuator must be in accordance

with the actuator design, plant requirements and the valve

model. In order to assemble the actuator onto the valve,

proceed as follows:

•

Verify the coupling dimensions of the valve flange and

stem; they must meet the actuator coupling dimensions

(refer to PUB110-001 for metric and PUB110-002 for

imperial)

•

Actuator is supplied in the fail position (for single-acting).

Set the valve in the right position according to the

actuator fail position. Check the position of the actuator

by means of the position indicator on the body or on the

limit switch box (if present)

•

Clean the coupling flange of the valve and remove

anything that might prevent adherence to the actuator

flange. Grease shall be completely removed

•

Inspect, clean and apply grease on the coupling hole

(valve side of coupling joint)

•

Lubricate the valve stem with oil or grease, to facilitate

assembling

Lift the actuator according to instructions in section 7.0.

•

If possible, place the valve stem in a vertical position

to facilitate assembly – in this case the actuator must

be lifted while the coupling flange is kept in the

horizontal position

•

If a direct mounting is applied, insert the valve stem

directly into the actuator pinion

•

If the assembly uses an adapter and a coupling joint,

assemble the coupling joint onto the valve stem before

proceeding with mounting of the actuator

•

Do not exert any force while lowering the actuator

onto the valve

Installation must be performed by qualified personnel.

Hands must be kept away from the coupling area.

Fig 10.1 Actuator bottom connections

Each pinion, as standard, is provided with a female key ISO

5211 double square, allowing direct mating to the valve stem,

or coupling.

Optional valve interfaces are ISO 5211 single square parallel,

ISO 5211 single square diagonal and double D.

•

Fix the actuator to the valve by means of threaded

connections (bolts, stud bolts and nuts)

•

Tighten bolts or nuts of the connecting stud bolts to the

correct torque, in accordance with the size and material

characteristics of the bolts installed by the Customer,

please refer to the Tightening Torque Chart, section 6.3

Support the actuator until fully installed and fixing

bolts are correctly tightened.

Attention: Do not pressurize the actuator/

valve adapter.

Keeping the World Flowing

9

Page 10

10.0 Installation on Valve 11.0 Removal from Valve

10.3 Assembly Configurations

Different orientations of pinion and pistons are identified

as follows:

Fig 10.2 A ssembly A – Clock wise to close actuators,

upper shaft perpendicular to body

Fig 10.3 A ssembly B – Clock wise to close actuators,

upper shaft parallel to body

The end user is in charge of removing the actuator

from the valve.

Removal shall be performed only by qualified staff,

wearing/using appropriate personal protection devices.

Do not remove the actuator if the valve is blocked in

the intermediate position. Contact Rotork Fluid Systems

Customer Service.

In order to disassemble the actuator from the valve, proceed

as follows:

•

Isolate electrical power supply

•

Isolate pneumatic /hydraulic supply

•

Release any pressure from the control group

•

Remove the supply pipes from the actuator

•

Remove control and signal lines from electric components

(if any)

•

Sling the actuator in line with the instructions given in

section 7.0

•

Unscrew bolts or nuts from the stud bolts fixing the

actuator to the valve

•

Lift and remove the actuator from the valve

Fig 10.4 A ssembly C – Counter-clockwise to close

Fig 10.5 A ssembly D – Counter-clockwise to close

10

actuators, upper shaft perpendicular to body

actuators, upper shaf t parallel to body

Installation, Commissioning and Maintenance Manual

Page 11

12.0 Operation

The following instructions must be followed and integrated

into end user safety program when installing and using

Rotork products. Read and save all instructions prior to

installing, operating and servicing this product.

Follow all warnings, cautions and instructions marked on and

supplied with the product.

Install equipment as specified in Rotork installation

instructions and as per applicable local and national

codes of practice. Connect all products to the proper

pipeline gas sources.

Ensure that the qualified service technician uses only

replacement parts specified by Rotork.

Substitutions will invalidate any hazardous area certification

and may result in fire, electrical shock, other hazards or

improper operation.

12 .1 Description

GT range actuators are a rack and pinion design, available

in both double-acting and single-acting (spring-return)

configurations.

The rack and pinion design assures constant torque, strength

and reduced overall dimensions. All double-acting actuators

can be easily field converted to spring-return type by inserting

the correct number of spring cartridges to the double-acting

unit without changing the existing end caps. This eliminates

bulky housing extensions and saves weight and space.

For 90° execution, specially designed and patented preloaded

self-containing spring cartridges are completely contained

assuring safe installation and removal. For 120°-180° action

the springs are free.

Standard action is 90°, 120°, 135°, 180° and 240°.

Customised angles are available, as well as three position

versions.

2

3

1

56

Fig 12.1 GT spring-return main components

2

3

1

5

Fig 12.2 GT double-acting main components

3

7

4

3

7

4

Table 1: GT double-ac ting main components

IT DESCRIPTION QTY

1 Mechanical stop bolt 1

2 Body 1

3 End cap 2

4 Pinion 1

5 Rack 2

6 Spring cartridge *

7 Mechanical stop bolt 1

(*) Model dependant

Keeping the World Flowing

11

Page 12

12.0 Operation

12.2 Single and Double Limit Stop

GT Actuators can be provided in 2 versions: single and double

limit stop.

The

single limit stop

stop bolts installed in the end caps and allows adjustment

of the open stroke of a clockwise to close (close stroke of an

anti-clockwise to close) actuator. Adjustability is ±5°.

The

double limit stop

mechanical stop bolts installed in the end caps and allows

the adjustment of both travel directions. Adjustability is

±5° on the open stroke of a clockwise to close (close stroke

of an anticlockwise to close) actuator and -25°/+5° on the

close stroke of a clockwise to close (open stroke of an

anticlockwise to close) actuator.

is provided with 2 identical mechanical

is provided with 2 different

Fig 12.3 Single limit stop

Fig 12.4 Double limit stop

12

Installation, Commissioning and Maintenance Manual

Page 13

12.0 Operation

12.3 Angular Stroke Setting

Single and double-acting actuator, cylinder stop

bolt setting

Perform the following operations as first setting.

Adjust the stop bolt located in the end flange of the

cylinder as follows:

1

A. Verify the absence of pressure

B. Loosen stop nut (1) with a suitable spanner

2

C. With the help of a suitable size Allen (hex.) Key, rotate

the stop bolt (2) clockwise to increase (counter-clockwise

to decrease) the angular stoke

Verify the newly obtained angular position with one stroke

D. Repeat operations A to D, until the desired angle

is obtained

1

2

E. Hold the stop bolt (2) with a Allen (hex.) key and carefully

tighten the stop nut (1)

G: Repeat the operation for the other stop bolt

The above procedure applies to both single limit stop

and double limit stop.

In case of double limit stop, before starting

the procedure to adjust the stop bolt for -25°/+5°

(identifiable from the bronze colour stop nut), make

sure the stop bolt is not against the pinion to avoid a

stick slip movement.

Keeping the World Flowing

13

Page 14

12.0 Operation

12.4 Pneumatic Supply

Verify allowed supply pressure range on actuator label.

Verify medium composition. Contact Rotork Fluid

Systems to check the compatibility with the supply

medium.

12.5 Pneumatic Connections

Preliminary Operations

A. Verify sizes of pipes and fittings according to applicable

plant specifications

B. Clean the inside of the connection pipes by washing them

with a suitable detergent and by blowing air into them

C. The connecting pipes must be properly shaped and fixed

to prevent stress or loosening of threaded connections

Connect the pneumatic source in accordance to the

applicable operating diagram, please refer to specific

job for details.

Depending upon the control circuit design,

pneumatic actuators may exhaust the supply gas into

the atmosphere during normal operation. This may

present an unacceptable hazard.

Port 2 is connected to the inboard side of the pistons.

Port 4 is connected to the outboard side of the pistons.

Port 4

Port 2

Fig 12.5 Inlet port for Single-Acting actuator

Port 4

Port 2

Fig 12.6 Inlet / Exhaust port for Double-Acting actuator

Single-Acting actuators

Pressurising port 2 will move the pistons out. When port 2 is

depressurised, spring force will move the pistons in. Venting

is through port 2. Port 4 is not to be pressurised on springreturn actuators.

Double-Acting actuators

Pressurising port 2 will force the pistons out until they reach

the travel stops. Venting is through port 4.

Pressurising port 4 will force the pistons in until they reach

the travel stops (if fitted). Venting is through port 2.

The direction of pinion rotation is determined by the

assembly configuration described in section 10.3.

14

Installation, Commissioning and Maintenance Manual

Page 15

12.0 Operation

12.6 Electrical Connections

Check electrical component supply voltage,

before start-up.

Access to live electrical conductors is forbidden in

hazardous areas unless done under a special permit.

Otherwise, all power should be isolated and the unit

moved to a non-hazardous area for repair.

Prevent electrostatic charges in potentially

explosive areas.

Electrical connection can be performed as follows:

•

Remove power supply

•

Remove the plastic protection plugs from the cable

entries

•

Use only appropriately certified reduction fittings, cable

glands, fittings and explosion-proof cables

•

The cable glands must be tightened in the threaded

inlets, to guarantee the waterproof and explosion proof

protection

•

Cable gland sealing should be installed correctly to

prevent water or debris ingress to the electrical enclosure

•

The size of the electric supply cable must be suitable for

the electrical power required

•

Insert the connection cables through cable glands

and perform assembly according to the cable gland

manufacturer’s instructions

•

Connect the cable wires to the terminal blocks in

accordance with the applicable wiring diagram

•

Electric connections must be made by using rigid conduits

and trailing cables to prevent mechanical stresses in the

cable entries

•

Unused entries must have metal blanking plugs installed

in order to guarantee sealing and to comply with

explosion safety protection codes

•

Assemble the covers of the electric components, paying

attention to seals

•

Once connections have been completed, check electrical

components functionality

12.7 Start Up

During start-up of the actuator, it is necessary to check if:

•

Medium supply pressure is as prescribed

•

The power supply to electrical components (solenoid

valves coils, limit switches, pressure switches, etc.) are

within specification

•

Actuator controls such as remote control, local control,

emergency control, etc. work properly

•

Input remote signals are correct

•

The setting of control unit components is according to the

plant requirements

•

Pneumatic connections show no leakage. If necessary,

tighten fittings or adjust sealing

•

The painted parts have not been damaged during

transport, assembly or storage operations. Otherwise

adequately repair the damaged parts following the

applicable painting specifications

•

Actuator and all additional equipment work as expected

•

Operating time is in accordance with requirements

The end user must guarantee equal voltage

potential between the valve and the actuator and

provide appropriate grounding. End user shall

indicate and maintain the grounding connections

on the actuator.

Actuator and electrical components must be

protected from electrical sparks, lightning, magnetic or

electro-magnetic fields.

Keeping the World Flowing

15

Page 16

13.0 Dismantling & Disposal 14.0 Rotork Sales and Service

Prior to dismounting the actuator, ensure no parts are still

under pressure.

For Single-Acting Actuator

The spring cartridge module contains potential

energy due to compressed elastic elements.

After removing the spring cartridge from the center body,

the spring cartridge must be returned to the manufacturer’s

plant, upon agreement with Rotork Fluid System.

Grease and oil must be disposed of safely in

accordance with the local environmental laws and

regulations.

•

Dismount the actuator, separate and divide the various

components according to the type of material

•

Dispose steel, cast iron and aluminium alloy components

as metal scraps

•

Dispose rubber, PVC, resins, etc. separately, in accordance

with national and regional regulations

•

Electrical components are to be separately disposed of on

specialized disposal sites

If your Rotork actuator has been correctly installed and

sealed, it will give years of trouble-free service. Should you

require technical assistance or spares, Rotork guarantees

the best service in the world. Contact your local Rotork

representative or the factory direct at the address on the

nameplate, quoting the actuator type and serial number.

Some actuators have a special spare parts list. Refer to the

project specific documentation for further details.

16

Installation, Commissioning and Maintenance Manual

Page 17

15.0 Troubleshooting

ID FAILURE POSSIBLE CAUSES CORRECTIVE MEASURES

1 Incorrect valve position •

2 Incorrect indication of valve position •

3 Incorrect movement

4 Valve stroke not fully completed

5 Leakages

6 Actuator moves too fast

7 Actuator moves too slow

8 Loss of power

Fault of pipeline valve

Incorrect signal from limit switches

•

Irregular supply of operating medium

•

Worn parts

•

Fault in control panel equipment

(if present)

•

Fault of pipeline valve

•

Insufficient gas flow

•

Incorrect assembly between actuator

and valve

•

Valve blocked

•

Stop bolts wrong setting

•

Stop bolts wrong setting

•

Worn seals

•

No pressure on pipeline

•

Supply pressure greater than allowed

range values

•

Fault on pipeline valve (valve hardened)

•

Supply pressure lower than allowed

range values

•

Possible internal undue friction

•

Inadequate supply pressure

•

Leakage from cylinder

•

Consult the valve manufacture’s documentation

•

Check limit switches position (see job

specific documentation and limit switch box

manufacturer’s documentation)

•

Verify the supply pressure and adjust as

necessar y

•

Contact Rotork Fluid Systems

•

Contact Rotork Fluid Systems Customer Service

•

Consult the valve manufacture’s documentation

•

Increase gas supply flow

•

Perform assembly according to section 10.0

•

Consult the valve manufacture’s documentation

•

Adjust stop bolt setting following instructions in

section 12.3

•

Adjust stop bolt setting following instructions in

section 12.3

•

Replace seals according instructions reported in

PM-GT-005/006

•

Restore pipeline pressure

•

Verify the supply pressure and adjust as

necessar y

•

Consult the valve manufacture’s documentation

•

Verify the supply pressure and adjust as

necessar y

•

Contact Rotork Fluid Systems Customer Service

•

Ensure that the supply pressure is above the

minimum operating pressure of the actuator

and that the output torque produced at supply

pressure exceeds the required valve torque

•

Replace seals according instructions reported in

PM-GT-005/006

For other problems, please contact Rotork Fluid Systems Customer Service.

Keeping the World Flowing

17

Page 18

16.0 Periodic Maintenance

Rotork Fluid Systems recommends performing the following checks to help comply with the rules and regulations

of the country of final installation:

Remove pressure before proceeding with maintenance operations, discharge any accumulators

or tanks (if present), except where otherwise indicated.

Periodic Maintenance Schedule

MAINTENANCE ACTIVITY PERIODICITY REFERENCE

Months Years

Visual check of external components and control groups 6* *

Breather cleaning 6* *

Check pneumatic connections for leaks. Tighten pipe fittings as required - 1*

Cleaning - 1* PM-GT-001

Visual check of paint coating. Verify absence of damage. Repair if necessary

according to painting specification

Functional test - 1* PM-GT-002

Functional test by Manual Override - 1*

Check electrical components (if applicable) and grounding connections - 1* PM-GT-004

Check threaded connections (bolts, studs and nuts) with valve. If necessary

tighten to the recommended torque, in accordance with the size and the

characteristics of the fastener material installed by the Customer

Single stop actuator pneumatic cylinder seals replacement

(Spring-Return and Double-Acting Actuator)

Double stop actuator pneumatic cylinder seals replacement

(Spring-Return and Double-Acting Actuator)

(*) The time between maintenance tasks will vary depending on the medium and service conditions. Refer to End User Plant Preventive Maintenance

Program for specific task frequenc y.

- 1*

1*

- 5* PM-GT-005

- 5* PM-GT-006

Corrective Maintenance Task

In case of fault, according to section 15.0, the following operations could be executed by the End User.

MAINTENANCE ACTIVITY REFERENCE

Single limit stop actuator fail mode converting CM-GT-001

Double limit stop actuator fail mode converting CM-GT-002

18

Installation, Commissioning and Maintenance Manual

Page 19

16.0 Periodic Maintenance

Component: Single-Acting actuator

Double-Acting actuator

PM-GT-001 Page:1/1

Task: Cleaning

Equipment, Tools, Materials:

Damp cloth

Project documentation (design and operating pressure values)

Preliminary Operations:

Description:

Remove electric and pneumatic supply before proceeding.

1. Remove dust from actuator external surface with a damp cloth

The tools and cleaning procedures must not produce sparks or create adverse conditions in the environment during maintenance

operations, so as to prevent potential explosion hazards.

Prevent electrostatic charges in potentially explosive areas.

Warnings:

Keeping the World Flowing

19

Page 20

16.0 Periodic Maintenance

Component: Single-Acting actuator

Double-Acting actuator

PM-GT-002 Page:1/1

Task: Functional test

Equipment, Tools, Materials:

Chronometer/timer

Project documentation (required stroke times)

Preliminary Operations:

Description:

NOTE: Actuator must be connected to the pneumatic supply to perform the following test.

1. Operate the actuator

2. Perform the stroke several times by local and remote (if applicable) control

Actuator could exhaust medium supply to the atmosphere during normal operation.

Wear appropriate PPD including breathing device.

3. Verify actuator is correctly working

4. Note the stroke time(s)

5. Verify stroke time(s) are as required

Warnings:

20

Installation, Commissioning and Maintenance Manual

Page 21

16.0 Periodic Maintenance

PM-GT-004 Page:1/1

Component: Electrical components (if present) Task: Check electrical components (if present) and grounding

connections

Equipment, Tools, Materials:

Project documentation

Preliminary Operations:

Description:

Isolate electrical power supply before working on electrical devices.

Read and follow the safety precautions reported in the Manufacturer’s Maintenance Manual.

Risk of temporary modification of the component protection.

Use only antistatic clothes.

1. Remove cover from electric components

2. Check electric device components

3. Verify tightness of terminal blocks

4. Verify absence of humidity and oxidation

5. Check cable gland seals

6. Verify grounding connection and restore if necessary

Warnings:

Keeping the World Flowing

21

Page 22

16.0 Periodic Maintenance

Component: Single limit stop actuator pneumatic cylinder seals

replacement (Spring-Return and Double-Acting Actuator)

PM-GT-005 Page:1/2

Task: Pneumatic cylinder seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

Description:

Note: the following instructions apply both to Single-Acting and Double-Acting actuators unless otherwise specified.

Isolate pneumatic and electrical supply (if present) before performing any operation.

Preliminary actions

1. Remove any pressure

2. Remove electric supply

3. Remove actuator from valve

4. Position the actuator on a workbench (if possible) or in a stable position in a clean and closed area

5. Remove any control equipment (if present). Refer to the project specific documentation

6. Remove pneumatic pipes

7. With an Allen (hex.) key remove the 4 screws (1) from the

end cap (2)

8. Remove end caps (2)

9. Remove springs (3), if present

Warnings:

1

2

10. With the help of a Key-wrench, rotate the pinion shaft (4)

to extrude the 2 pistons (5)

23

45 5

22

Installation, Commissioning and Maintenance Manual

Page 23

16.0 Periodic Maintenance

Component: Single limit stop actuator pneumatic cylinder seals

replacement (Spring-Return and Double-Acting Actuator)

PM-GT-005 Page:2/2

Task: Pneumatic cylinder seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

11. Remove o-ring (7) and guide belt (8)

12. Remove sliding guide (9)

13. Carefully clean piston (5) o-ring grooves and all sealing surfaces

14. Replace o-rings (7) and lubricate with a grease layer

15. Replace guide belt (8) and sliding guide (9)

16. Repeat operations 11 to 15 for the other piston (5)

Warnings:

9

8 7

95

17. Reinstall pistons (5) – be careful to respect 0° position and

fail action

18. Reinstall (3) springs, if present

19. Reinstall end caps (2) and tighten screws (1) – refer to

section 6.3

8 7

45 5

1

2

23

Keeping the World Flowing

23

Page 24

16.0 Periodic Maintenance

Component: Double limit stop actuator pneumatic cylinder seals

replacement (Spring-Return and Double-Acting Actuator)

PM-GT-006 Page:1/4

Task: Pneumatic cylinder seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

Description:

Note: the following instructions apply both to Single-Acting and Double-Acting actuators unless otherwise specified.

Isolate pneumatic and electrical supply (if present) before performing any operation.

Preliminary actions

1. Remove any pressure

2. Remove electric supply

3. Remove actuator from valve

4. Position the actuator on a workbench (if possible) or in a stable position in a clean and closed area

5. Remove any control equipment (if present). Refer to the project specific documentation

6. Remove pneumatic pipes

7. With an Allen (hex.) key remove the 4 screws (1) from the

end cap (2)

8. Remove end cap (2)

9. Remove springs (3), if present

Warnings:

1

2

10. With an Allen (hex.) key remove the 4 screws (1) from the

other end cap (2)

3

1

2

24

Installation, Commissioning and Maintenance Manual

Page 25

16.0 Periodic Maintenance

Component: Double limit stop actuator pneumatic cylinder seals

replacement (Spring-Return and Double-Acting Actuator)

PM-GT-006 Page:2/4

Task: Pneumatic cylinder seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

11. Loosen the nut (10) with a socket wrench, remove washer (12)

and o-ring (11)

12. Using an Allen (hex.) key rotate the stop bolt (13) clockwise

all the way in

13. Remove the end cap (2)

14. Remove the springs (3), if present

Warnings:

111312 10

3 2

15. With the help of a Key-wrench, rotate the pinion shaft (4)

to extrude the 2 pistons (5) and (6)

45 6

Keeping the World Flowing

25

Page 26

16.0 Periodic Maintenance

Component: Double limit stop actuator pneumatic cylinder seals

replacement (Spring-Return and Double-Acting Actuator)

PM-GT-006 Page:3/4

Task: Pneumatic cylinder seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

16. Remove o-ring (7) and guide belt (8)

17. Remove sliding guide (9)

18. Carefully clean pistons (5) o-ring grooves and all sealing surfaces

19. Replace o-rings (7) and lubricate with a grease layer

20. Replace guide belt (8) and sliding guide (9)

21. Repeat operations 11 to 15 for the other piston (6)

Warnings:

9

8 7

95

22. Remove stop bolt (13) from piston (6)

23. Remove o-ring (6)

24. Clean the o-ring (6) groove

25. Replace o-ring (6) and lubricate with a grease layer

26. Pull stop bolt (13) back in place

27. Reinstall pistons (5) and (6) – be careful to respect

0° position and fail action

8 7

13

6

6

45 6

26

Installation, Commissioning and Maintenance Manual

Page 27

16.0 Periodic Maintenance

Component: Double limit stop actuator pneumatic cylinder seals

replacement (Spring-Return and Double-Acting Actuator)

PM-GT-006 Page:4/4

Task: Pneumatic cylinder seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

28. Reinstall (3) springs, if present

29. Reinstall end cap (2) and tighten screws (1) –

refer to section 6.3

30. Reinstall (3) springs, if present

31. Insert the end cap (2)

Warnings:

1

2

3

3 2

32. Using an Allen (hex.) key rotate the stop bolt (13) anti-clockwise

all the way back

33. Replace o-ring (11)

34. Reinstall washer (12)

35. Fasten the nut (10) with a socket wrench

36. With an Allen (hex.) key fasten the 4 screws (1) in the

end cap (2)

111312 10

1

2

Keeping the World Flowing

27

Page 28

16.0 Periodic Maintenance

CM-GT-001 Page:1/1

Component: Single limit stop Spring-Return and Double-Acting actuator Task: Fail mode converting

Equipment, Tools, Materials:

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

1. With an Allen (hex.) key remove the 4 screws (1) from the

end cap (2)

2. Remove end cap (2)

3. Remove springs (3), if present

4. Turn the shaft (4) to help removal of the pistons (5)

5. Rotate pistons 180°

Warnings:

1

2

23

45 5

6. Reinstall pistons, be careful to perfectly match the pinion tooth

to keep the original pinion position

8. Reinstall (3) springs, if present

9. Reinstall end cap (2) and tighten screws (1) –

refer to section 6.3

410 10

1

2

23

28

Installation, Commissioning and Maintenance Manual

Page 29

16.0 Periodic Maintenance

Component: Double limit stop Spring-Return and Double-Acting

actuator

CM-GT-002 Page:1/3

Task: Fail mode converting

Equipment, Tools, Materials:

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

1. With an Allen (hex.) key remove the 4 screws (1) from the

end cap (2)

2. Remove end cap (2)

3. Remove springs (3), if present

4. With an Allen (hex.) key remove the 4 screws (1) from the

other end cap (2)

Warnings:

1

2

23

1

5. Loosen the nut (10) with a socket wrench, remove washer (11)

and o-ring (12)

6. Using an Allen (hex.) key rotate the stop bolt (13) clockwise all

the way in

2

111312 10

Keeping the World Flowing

29

Page 30

16.0 Periodic Maintenance

Component: Double limit stop Spring-Return and Double-Acting

actuator

CM-GT-002 Page:2/3

Task: Fail mode converting

Equipment, Tools, Materials:

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

7. Remove the end cap (2)

8. Remove the springs (3), if present

9. Turn the shaft (4) to help removal of pistons (5)

10. Rotate pistons 180°

Warnings:

3 2

45 5

11. Reinstall pistons, be careful to perfectly match the pinion tooth

to keep the original pinion position.

45 5

30

Installation, Commissioning and Maintenance Manual

Page 31

16.0 Periodic Maintenance

Component: Double limit stop Spring-Return and Double-Acting

actuator

CM-GT-002 Page:3/3

Task: Fail mode converting

Equipment, Tools, Materials:

Wrench

Lifting tools

Project documentation

Preliminary Operations: Removal from Valve

12. Reinstall (3) springs, if present

13. Reinstall end cap (2) and tighten screws (1) –

refer to section 6.3

14. Reinstall (3) springs, if present

15. Insert the end cap (2)

Warnings:

1

2

3

3 2

16. Using an Allen (hex.) key rotate the stop bolt (13) anti-clockwise

all the way back

17. Replace o-ring (12)

18. Reinstall washer (11)

19. Fasten the nut (10) with a socket wrench

20. With an Allen (hex.) key fasten the 4 screws (1) in the

end cap (2)

111312 10

1

2

Keeping the World Flowing

31

Page 32

17.0 Part List

Single Stop Actuator

Fig 17.1 Single Stop Actuator

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1 Piston guide belt

2 Pinion upper washer 1 22 Circlip 1

6 Pinion upper bearing 1 23 Nut 2

8 Pinion bottom washer 2 25 Stop bolt o-ring

9 Piston sliding guide

10 Position indicator 1 28 Bottom pinion o-ring

13 Anti-blow-out ring 1 29 Piston o-ring

15 Pistons 2 30 Washer 2

16 Actuator body 1 31 End cap o-ring

17 Pinion 1 33 Stop bolt 2

20 Body end caps 2 34 Screws 8

● Recommended spare par t

●

●

2 21 Spring cartridge

2 27 Upper pinion o-ring

●

●

●

●

●

2

1

1

2

2

32

Installation, Commissioning and Maintenance Manual

Page 33

17.0 Part List

Double Stop Actuator

Fig 17.2 Double Stop Actuator

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1 Piston Guide Belt

2 Pinion upper washer 1 21 Spring cartridge Model

6 Pinion upper bearing 1 22 Circlip 1

7 Guiding bush 1 23 Nut 2

8 Pinion bottom washer 2 25 Stop bolt o-ring

9 Piston sliding guide

10 Position indicator 1 27 Upper pinion o-ring

13 Anti-blow-out ring 1 28 Bottom pinion o-ring

14 Stop bolt 1 29 Piston o-ring

15 Pistons 2 30 Washer 2

16 Actuator body 1 31 End cap o-ring

17 Pinion 1 33 Stop bolt 2

18 Washer 1 34 Screws 8

● Recommended spare part

●

●

2 20 Body end caps 2

dependant

●

2 26 O-ring

●

●

●

●

●

2

1

1

1

2

2

Keeping the World Flowing

33

Page 34

18.0 Grease Specification

In general, there is no need to lubricate the actuator because

its mechanism is lubricated for life. The standard grease for

Rotork Fluid Systems GT actuators is shown below. If an

alternative was specified and/or supplied, please refer to the

job specific documentation.

18 .1 Grease

Lubricate mechanical components and cylinders of actuators

using the following grease or equivalent for temperature

range -50° < T < +140 °C.

Manufacturer: BECHEM Lubrication Technology

Trade name: BERULUBE FR 16

Colour:

Base OIl

Solid Lubricant

Thickener

Worked penetration (ISO 2137):

Viscosity of oil at 40 °C (104 °F) (DIN 51 562):

Service temperature:

Drop point (IP 396):

Corrosion test on Copper (24h\100 °C) 1 (DIN51 881)

Oxidation stability (100h\99 °C) 0.2 bar (DIN51 805)

Beige

Polyalphaolefin

Microfine PTFE powder

Special lithium soap

265-295 mm/10

32 mm2/s

-50 to 140 °C (-58 to 284 °F)

≥190

34

Installation, Commissioning and Maintenance Manual

Page 35

Keeping the World Flowing

35

Page 36

www.rotork.com

A full listing of our worldwide sales and

service network is available on our website.

Rotork plc

Brassmill Lane, Bath, UK

tel +44 (0)1225 733200

fax +44 (0)1225 333467

email mail@rotork.com

PUB110-009-00

Issue 0 4/18

Rotork is a corporate

member of the Institute

of Asset Management

All Rotork F luid Systems a ctuator s are manufac tured unde r a third par ty accredi ted ISO9 001 qualit y

assurance p rogramme. A s we are contin ually devel oping our pr oducts , their des ign is subjec t to change

without notice.

The name Rot ork is a regis tered trade mark. Rotor k recognis es all regis tered trade marks. Pu blished an d

produced i n the UK by Rotor k Fluid Syste ms. POW TG0518

Loading...

Loading...