Page 1

EH Pro Range

Installation and Maintenance Instructions

This manual contains important safety

information. Please ensure it is thoroughly

read and understood before installing,

operating or maintaining the equipment.

PUB021-034-00

Date of issue 05/12

Page 2

The Rotork Setting Tool and Setting Tool Pro allows actuator control,

indication and protection functions to be configured to suit site requirements.

In addition, the new Rotork Bluetooth

downloading of Datalogger and uploading/downloading of configuration

files. Files are transferred to and from the Bluetooth

®

Setting Tool Pro also allows

®

Setting Tool Pro via

Insight II.

It is essential that all the actuator settings are checked for compatibility with

the valve, process and control system requirements before the actuator is put

into service. Please read this publication before proceeding.

When Rotork personnel or nominated agents are contracted to carry out site

commissioning and/or acceptance, documentation of commissioned actuator

configuration can be made available for customer records.

Rotork Setting Tool Pro

2

I

Rotork Setting Tool

Bluetooth® Setting Tool Pro

Rotork

Page 3

3

II

This manual provides instruction on:

• Electrical(localandremote)andoptionalmanualoperation.

• Preparationandinstallationoftheactuatorontothevalve.

• SubsequentcommissioningandadjustmentoftheBasicSettings

for correct valve operation.

• CommissioningandadjustmentoftheConfigurationSettingsto

suit site-specific control and indication requirements.

• MaintenanceandTroubleshooting.

• SalesandService.

THE ROTORK FLUID SYSTEMS EH Pro RANGE – A RELIABLE

SOLUTION FOR ELECTRIC FAILSAFE AND MODULATING VALVE

CONTROL THAT YOU CAN COMMISSION AND INTERROGATE

WITHOUT REMOVING ELECTRICAL COVERS.

Using the supplied infrared / Bluetooth setting sool to access the actuator

set up procedures, non-intrusive setting of internal hydraulic pressure levels,

position limits and all other control and indication functions can be made

safely, quickly and conveniently, even in hazardous locations

Standard diagnostics information about the control system, valve and

actuator status in the form of display icons and help screens.

Setup,AlarmandstatustextisavailableinEnglish(default).

Other languages are available upon request.

Instantaneous internal hydraulic pressure and position can be monitored on

the actuator with a single key press of the Setting Tool.

The on board Datalogger captures operational and valve data enabling

informedmaintenancechoicestobemade.InsightIIsoftwareforPCallows

the Datalogger to be interrogated, as well as the complete actuator set up

to be configured and recorded.

Visitourwebsiteatwww.rotork.comformoreinformationontheEHPro,

Insight II and other Rotork actuator ranges.

Page 4

TheRotorkEHPro Range of self-contained, electro-hydraulic actuators

include an integrated control module; a hydraulic manifold; and a power

unitconsistingofamotor,hydraulicpumpandreservoir.EHactuatorsare

available in double-acting or spring-return configurations for both quarterturn and linear applications.

They can be configured to mount in any position, including remote

mountingofthecontrolmoduleand/orhydraulicpowerunit(HPU).Torque

requirementsupto600,000Nm(5.3millionlbf-in)andthrustsupto

5,500,000N(1.2millionlbs)canbeaccommodated.

All electronics are protected in a watertight or explosion-proof enclosure.

Other features include local manual control, indication feedback via

dry contacts and 4-20 mA signal; or optional digital control via Modbus,

Foundation Fieldbus, Profibus, DeviceNet or Rotork Pakscan communication

systems.TheEHRangecanbesuppliedforoperationwithvirtuallyany

singlephase,threephase,or24VDCpowersupply.

Visit our web site at www.rotork.comformoreinformationontheEH,

Insight II and other Rotork actuator ranges.

4III

Page 5

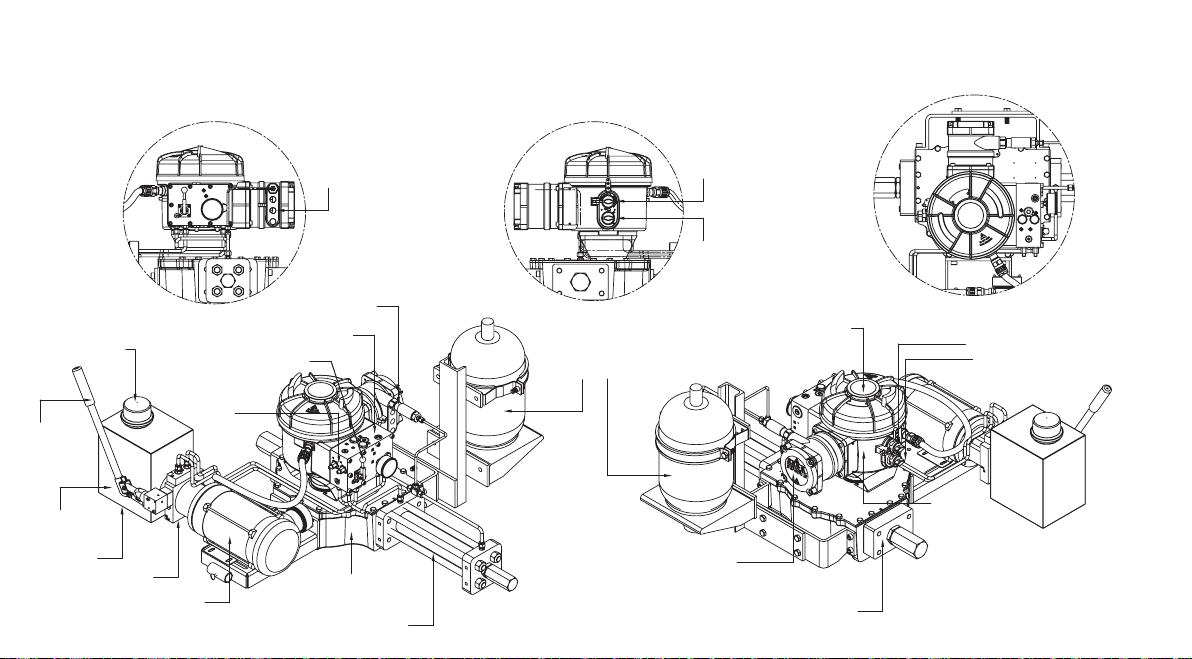

Identifying Actuator Parts

IV

5

Filler/Breather

Manual

Override

Pump

Hydraulic

Reservoir

Oil Drain

Plug

Pump

Motor

Manual Override Lever

SpeedControl

Valves

1/2" NPT

CableEntries

1/2" NPT

CableEntries

Manifold

Actuator

CenterBody

HydraulicCylinder

Accumulator

(Ifapplicable)

TerminalCompartment

Local/Remote

Switch

Open/Close

Switch

Display Window

SpringCanister

(Ifapplicable)

Local/Remote Switch

Open/Close

Switch

Control

Module

Page 6

CONTENTS

Section Page

1 Health and Safety 1

2 Storage 3

3 Operating your EH Pro Actuator 4

3.1 ElectricalOperation 4

3.2 Display – Local Indication 4

3.3 Display Status Indication – Travel 5

3.4 DisplayStatusIndication –Control 5

3.5 Display Alarm Indication 6

3.6 ESDSignal 7

3.7 PartialStroke 7

3.8 LimitSwitches 7

3.9 SpeedControl 7

4 Optional Manual Operation 8

5 Mounting the Actuator 9

5.1 Lifting 9

5.2 Mounting Orientation 9

5.3 Fitting to Valve 9

5.4 MechanicalTravelAdjustment 9

5.5 HydraulicFluid 9

5.6 Power Accumulators 9

6 Cable Connections 10

6.1 Earth/GroundConnections 10

6.2 RemovingTerminalCover 10

6.3 CableEntry 10

6.4 ConnectingtoTerminals 11

Section Page

6.5 ReplacingTerminalCover 11

7Commissioning 12

7.1 SettingProcedure 12

7.2 RotorkSettingTool (oldversion) 13

7.3 RotorkSettingTool Pro 14

7.4 RotorkBluetooth

7.5

7.6 SettingMode– Password 17

7.7 NewPassword[PC] 17

7.8 CheckingMode 17

7.9 BluetoothDiagnostics& Configuration 18

7.10 PartialStrokeTest 18

7.11 FullStrokeTest 19

7.12 Crossroad[Cr] 19

7.13

7.14 ReturningtoValvePositionDisplay 20

EnteringtheActuatorSettingProcedure

ActuatorDisplay–Setting/CheckingMode

8 Commissioning – Basic Functions 21

Viewing the Basic Settings 21

8.1 Menu Structure 28

9 Configuration Settings 29

ConfigurationSettingsContents 29

9.1 AccessingConfigurationSettings 29

9.2 IndicationContactsr1 30

9.3 GeneralSettings 31

9.4 DigitalControl 33

9.5 ESD/Partial StrokeSettings 35

®

Setting Tool Pro 15

17

19

Section Page

9.6 AnalogueControl1 39

9.7 AnalogueControl2 41

9.8 Interrupter Timer 43

9.9 Service 46

9.10 Bus System Option – Pakscan 48

9.11 BusSystemOption–Modbus[OP] 51

9.12 BusSystemOption–ProfibusDP[OP] 54

9.13 BusSystemOption–DeviceNet 57

9.14

10 Maintenance, Monitoring

and Troubleshooting

10.1 Maintenance, Monitoring 64

and Troubleshooting

10.2 Environmental 65

11 Help Screens 66

12 Weights and Measures 71

12.1 Binary,Hexadecimaland 71

DecimalConversionTable

13 Actuator Nameplate 72

14 Hazardous Area Approvals 73

14.1 ApprovedFuses 73

15 Special Conditions of Safe Use 74

Appendix A

Accumulator Precharge and Removal

BusSystemPositioningControlSettings

64

60

V

Page 7

1

Health and Safety

1

This manual is produced to enable a

competent user to install, operate,

adjust and inspect Rotork EH range of

actuators. Rotork EH range of actuators

may have features not covered in

this manual; always refer to order

specific operating documentation. Only

persons competent by virtue of their

training or experience should install,

maintain and repair Rotork actuators.

Work undertaken must be carried out

in accordance with the instructions

in this and other relevant manuals.

The user and those persons working

on this equipment should be familiar

with their responsibilities under any

statutory provisions relating to the

Health and Safety of their workplace.

Due consideration of additional

hazards should be taken when using

the EH range of actuators with other

equipment. Should further information

and guidance relating to the safe use

of the Rotork EH range of actuators be

required, it will be provided on request.

The electrical installation, maintenance

and use of these actuators should be

carried out in accordance with the

National Legislation and Statutory

Provisions relating to the safe use of

this equipment, applicable to the site of

installation.

For the UK: Electricity at Work

Regulations 1989 and the guidance

given in the applicable edition of the

“IEE Wiring Regulations’’ should be

applied. Also the user should be fully

aware of his duties under the Health

and Safety Act 1974.

For the USA: NFPA70, National

Electrical Code ® is applicable.

The mechanical installation should be

carried out as outlined in the manual

and also in accordance with relevant

standards. Since Rotork EH range

actuators may include features not

covered in this manual, always refer

to order specific documentation,

including operating instruction,

hydraulic schematic (HS) and wiring

diagram (WD). If the actuator has

nameplates indicating that it is suitable

for installation in hazardous areas then

the actuator may be installed in Zone

1 and Zone 2 classified hazardous area

locations only. It should not be installed

in hazardous area locations with an

ignition temperature less than 135 °C

unless suitability for lower ignition

temperatures has been indicated on the

actuator nameplate.

,

It should only be installed in hazardous

area locations compatible with the gas

groups stated on the nameplate.

The electrical installation, maintenance

and the use of the actuator should be

carried out in accordance with the code

of practice relevant for that particular

hazardous area certification.

No inspection or repair should be

undertaken unless it conforms to the

specific hazardous area certification

requirements. Under no circumstances

should any modification or alteration be

carried out on the actuator as this could

invalidate the actuators hazardous area

approval certification.

Access to live electrical conductors is

forbidden in the hazardous area unless

this is done under a special permit

to work, otherwise all power should

be isolated and the actuator moved

to a non-hazardous area for repair or

attention.

Trained service technicians are

available to assist with or perform

commissioning and maintenance. If

you have any questions or concerns

regarding installation, commissioning,

maintenance, or operation, contact your

local Rotork office for assistance.

EH actuators utilise hydraulic fluid.

Refer to applicable specification for type

required.

Always wear safety glasses and

appropriate protective clothing

including gloves when working with

hydraulic fluid. Also remove any jewelry

or other objects that might conduct

electricity.

Prior to performing any maintenance,

make sure that electric power to the

actuator is removed and that hydraulic

system pressure is released.

Hydraulic fluid is a hazardous material.

Consult the material safety data sheet

(MSDS) for detailed health and safety

information. Fluids should be contained

and disposed of properly in accordance

with applicable regulations.

Page 8

2

NING: Compressed Springs

WAR

All springs within the EH range of

actuators are pre-compressed. Springs

must not be removed from the actuator.

WARNING: Hydraulic Fluid

EH actuators are filled with hydraulic

fluid. See actuator data label for type of

oil supplied.

Should there be a requirement to

change the fluid, then the appropriate

protective clothing including gloves

and safety glasses must be worn. Used

hydraulic fluid must be disposed of

safely (see environmental section).

Note: the PRODUCT SAFETY DATA

SHEETS covering the type of

hydraulic oil supplied by Rotork

Fluid Systems for use within the

supplied power units are available

on request.

WARNING: Operating by Hand

With respect to optional manual

operation of Rotork Fluid Systems

actuators, see warnings in Section 4.

WARNING:

and operate when remote is selected.

This will be dependent on remote

control signal status and actuator

configuration.

WARNING:

only be located in areas where the risk

of impact to the viewing window is low.

Actuator may start

This actuator must

Page 9

2

3

Storage

Actuator Materials

EH

EH enclosure: Aluminium,

Carbon steel

fasteners,

Stainless steel

Actuator body: Carbon steel

Power unit: Aluminium, Steel

Motor: Steel

Copper winding

Piston rod: Plated steel

Switchbox: Aluminium

Piping: Stainless steel

(hard piped)

External fasteners: Stainless steel

Paint finish: Standard 2-pack

epoxy brown red

(158 microns thick)

The user must ensure that the operating

environment and any materials

surrounding the actuator cannot lead

to a reduction in the safe use of, or the

protection afforded by, the actuator.

Where appropriate the user must

ensure the actuator is suitably protected

against its operating environment.

Products manufactured by Rotork

Fluid Systems do not present a hazard

to health under normal conditions of

storage, distribution and use, provided

that good industrial and hygiene

procedures are followed.

If your actuator cannot be installed

immediately, store it in a dry place until

you are ready to connect incoming

cables.

If the actuator is to be installed, but not

immediately cabled, it is recommended

that any plastic cable entry transit plugs

be replaced with a suitable metal plug.

The double-sealed construction of the

terminal compartment will preserve

internal electrical components perfectly

if left undisturbed.

It is not necessary to remove the

electrical compartment covers in order

to commission the EH actuator.

Plug any open hydraulic ports or

electrical entries.

Fill the reservoir with the proper

hydraulic oil to protect the interior from

corrosion.

Visually inspect the equipment

periodically to identify any potential

corrosion. Repair as required.

Do not store in direct sunlight to avoid

premature weathering.

Rotork Fluid Systems will not accept

responsibility for deterioration caused

on site once the covers are removed.

Every Rotork Fluid Systems actuator

has been fully tested before leaving

the factory to give years of trouble

free operation, providing it is correctly

commissioned, installed and sealed.

Do not store in temperatures beyond

the normal operating range as stated

on data label.

Page 10

3

Operating your EH Actuator

4

3.1 Electrical Operation

Check that the power supply voltage

agrees with that on the actuator

nameplate. Switch on power supply. It

is necessary to check phase rotation (on

3-phase units). Proper lead connections

can be verified by viewing the pump/

motor fan while in operation. It should

rotate clockwise. If rotation is anticlockwise, reverse leads.

WARNING:

actuator electrically without first

checking, using the setting tool that

at least the Basic Settings have been

made.

Refer to Section 8.

Do not operate the

Selecting Local/Stop/Remote

Operation

The selector enables either Local or

Remote control, lockable in each position

using a padlock with a 6.5mm hasp.

When the selector is locked in the Local

or Remote positions the Stop facility is

still available. The selector can also be

locked in the Stop position to prevent

electrical operation by Local or Remote

control.

Local Control

With the selector positioned at Local

(clockwise) the lower black knob can

be turned to select Open or Close. For

Stop, turn upper knob anti-clockwise.

Fig. 3.1.

Local/Remote

Switch

Open/Close

Switch

Fig. 3.1.

Remote Control

Rotate the selector to the Remote

position (anti-clockwise), this allows

remote control signals to operate the

actuator. Local Stop can still be used by

turning the upper knob clockwise.

3.2 Display–Local Indication

Fig. 3.2 The Actuator Display

The display consists of:

1. Position Display – This is the main

7-segment position display with icons.

2. Text Display – This is a 2 line, 16

characters dot matrix display which

allows text to be used to compliment

the position display and icons.

3. Infrared LED's.

4. 2 x LED's for position indication.

Alarm Icon – This will be displayed

5.

for Valve, Control, and Actuator alarms.

Alarm indication is supported by fault

description text in the lower display.

6. IR Icon – This icon flashes during

infrared communication activity.

7. Percentage Open Icon – This icon will

be displayed when a percentage

Open value is in the upper display.

8. System Pressure – Hydraulic system

pressure is indicated by a gauge

on the manifold. The pump will

run automatically as required to

maintain adequate system pressure.

For actuators with accumulators, the

motor is controlled by an internal or

external pressure switch.

On power up the actuator’s liquid

crystal display screen is back-lit with an

amber light and one of the indicator

LED's will be on, dependent on

position. The display screen will show

percentage open or an end of travel

symbol. (See Figs 3.3, 3.4 and 3.5)

As standard, the red LED signifies valve

open, amber intermediate, and green

valve closed. Open and closed colour

functions can be reversed on request.

Page 11

3

Operating your EH Actuator continued

5

Open

The Red LED will be lit, the open symbol

and "Open Limit" will be displayed.

Open Limit

Fig. 3.3

Mid Travel

The Amber LED will be lit, percentage

open value will be shown and "Stopped"

will be displayed when there is no

actuator movement.

Stopped

Fig. 3.4

Closed

The Green

and "Closed Limit" will be displayed.

LED will be lit

, closed symbol

Closed Limit

Fig. 3.5

LED Indicators

WARNING: Mid Travel LED

colour may be affected by viewing

angle and lighting level.

The Close LED colour can be changed

to red if required. Refer to section 9.3.

3.3 Display Status Indication

– Travel

The EH display provides real time

status indication. The top line of the

text display is reserved for travel status

indication. Fig 3.6 shows the travel

status example

Closed Limit

.

Closed Limit

Fig. 3.6

Available travel status conditions displayed:

•

Closed Limit

set closed limit position.

Open Limit

•

set open limit position.

Moving Open

•

the open direction.

Moving Closed

•

the closed direction.

Stopped

•

mid travel position, indicated in the

top display (%open).

Actuator has reached the

Actuator has reached the

Actuator is traveling in

Actuator is traveling in

Actuator has stopped in a

•

Timer Active

enabled only. Interrupter Timer has

stopped the actuator mid travel for a

period equal to the set Timer Off

time. Refer to section 9.8.

3.4 Display Status Indication

– Control

The bottom line of the text display is

reserved for control status indication

and is displayed for approximately 2

seconds after the control mode or

signal is applied. Fig 3.7 shows the

control status example

Interrupter Timer option

Remote Control

.

Closed Limit

Remote Control

Fig. 3.7

Available control status conditions displayed:

•

Local Control

Local Stop

•

Remote Control

•

selected.

Local control selected.

Local stop selected.

Remote control

Page 12

3

Operating your EH Actuator continued

6

•

Local Close

Local close signal applied.

Local Open

•

•

or analogue) signal applied.

•

or analogue) signal applied.

•

emergency shut down signal applied.

•

signal applied.

•

signal applied.

•

emergency shut down signal applied.

•

via Bluetooth to either a setting tool

or PC.

* Bus Control option fitted may be Pakscan,

Local open signal applied.

Remote Close

Remote Open

Remote ESD

Remote Bus Open

Remote Bus Close

Remote Bus ESD

BT Connected

Profibus, Modbus, DeviceNet or Foundation

Fieldbus. Refer to actuator wiring diagram.

Remote close

Remote open

Remote hardwired

Remote Bus * open

Remote Bus* close

Remote Bus*

The actuator is connected

(hardwired

(hardwired

3.5 Display Alarm Indication

The EH display provides alarm indication

in the form of text and alarm icons.

General Alarm:

The general alarm icon will be

supported with text in the bottom line

indicating the particular alarm, or if

more than one is present, each alarm

will be displayed in sequence.

Fig 3.8 shows the status example

TRAVEL OP

(Mid Travel Over Pressure).

Stopped

MID TRAVEL OP

Fig. 3.8

Available alarm conditions displayed:

Valve Alarms

•OP IN MID POS - Tripped off on pressure

while moving in either direction between

electrical limits after a signal to move.

•OP AT LIMIT - Tripped off on pressure

while moving in either direction between

the electrical limit and the mechanical

end stop after a signal to move.

•STALL IN MID POS - No movement

detected between electrical limits after a

signal to move.

•STALL AT LIMIT - No movement detected

MID

between the electrical limit and the

mechanical end stop after a signal to

move.

Control Alarms

•DEMAND FAULT - This fault indicates

that the analogue demand signal has

dropped below half the minimum set

demand signal. In a 4-20 mA system the

demand signal has dropped below 2

mA, or it goes above 22mA.

•PS UNABLE TO RUN - The actuator may

not be at the correct limit to start the

test or a new command was issued

before the test was complete.

•MANUAL RESET ON - The actuator needs

to be manually reset after either a ESD

command or mains failure. Refer to 9.5

ESD Manual Reset.

•ESD ACTIVE - When present the ESD

signal overrides all local and remote

control signals. Once the ESD action is

carried out operation is inhibited while

the ESD signal is maintained. Refer to

9.5 ESD Action.

Actuator Alarms

• CONFIG ERROR - There may be an error

in the configuration (set up) of the

actuator. Check and reset basic setting

and check configuration settings.

•ELECTRONIC FAULT - A hardware fault is

caused by an internal fault on the Main

PCBA which prevents it from reading

its inputs. This is critical and inhibits

operation. This fault may be cleared by

removing the mains power from the

actuator and waiting for 20 seconds.

•LOCAL CONTROL FAIL - This indicates a

fault caused by a either a Main Board

failure, local control switch failure or

conflicting signals from the switches.

For example, both Local and Remote or

Open and Close selected simultaneously.

•SOL DRIVE FAULT - Contact Rotork.

• POS SENSOR FAULT - Detected failure in

the position sensing system – contact

Rotork.

•PRES SENSE FAULT - Detected failure in

the pressure sensing system – contact

Rotork.

•WRONG DIRECTION - This indicates

that the actuator has started to move

in the opposite direction to the given

command. When this occurs the

actuator is stopped.

• PS ERROR - This indicates that a fault

occurred while the actuator was

attempting a partial stroke.

•OPTION CH 1 FAULT - Contact Rotork.

•OPTION CH 2 FAULT - Contact Rotork.

•EEPROM MISSING - Contact Rotork.

Page 13

3

Operating your EH Actuator continued

7

3.6 ESD Signal

A dedicated ESD digital input is

provided with all standard actuators.

The actuator may be configured to Failin- Position, Fail Close or Fail Open. The

ESD signal can also be configured to

override the Local Stop command.

Double -acting units without an

optional accumulator require power

to the motor in order to stroke the

actuator to the ESD position.

Refer to the wiring diagram for input

terminals. Refer to Section 9.5 for

settings.

3.7 Partial Stroke

A dedicated Partial Stroke input is

provided as a standard feature for

Open/Close applications. Its purpose is

to verify valve and actuator operation

without significant effect on valve flow.

Refer to the wiring diagram for input

terminals. Refer to Section 9.5 for

settings.

3.8 Limit Switches

When fitted, open and close limit

switches are pre-set at the factory to

correspond to the actuator mechanical

travel stops. Pre-set positions should

be checked to ensure full opening and

closing of the valve.

Should adjustment be required, they

must be manually set and are accessed

by removal of the control module cover.

The upper-most switch is the open

switch; the lower is the close switch.

Switch cam adjustment is by fingertip

rotation in either direction. Cams are

compression spring loaded and are held

in position by tapered centers.

Open and Close position limits must

also be set via controller configuration.

Refer to Section 8.

3.8.1 Open Switch Adjustment

Move the valve/actuator to the fully

open position. Locate the proper switch

cam. Push the cam down and rotate

anti-clockwise until the switch operates

and release the cam. The switch is now

set.

3.8. 2 Closed Swtch Ad justment

Move the valve/actuator to the fully

closed position. Locate the proper

switch cam. Lift and turn the cam

clockwise until the switch operates and

release the cam. The switch is now set.

3.8.3 Four SPDT Option

Refer to DOC 1613.

3.9 Speed Control

Speed control is a standard feature only

on the spring stroke of spring return

actuators. For the hydraulic stroke of

spring-return actuators and for doubleacting actuators, it is an available option

requiring the addition of a hydraulic

power storage accumulator.

The speed of the hydraulic stroke is not

adjustable by the Extend speed control.

This is due to the nature of fixed

displacement pumps. The Extend speed

control should be fully anti-clockwise.

3.9.1 Sprin g-Return Adjustment

(No Accumulator)

Only the stroke time for the spring

stroke is adjustable. This is done with

the needle valve labeled Retract on the

hydraulic manifold. Loosen the jam nut

and turn the needle valve clockwise

to decrease the stroke time or anticlockwise to increase stroke time.

The speed of the hydraulic stroke is not

adjustable by the Extend speed control.

This is due to the nature of fixed

displacement pumps. The Extend speed

control should be fully anti-clockwise.

Page 14

3

Operating your EH Actuator continued

4

Optional Manual Operation

8

3.9.2 Spring-Return Adjustment

(Accumulator Fitted)

Speed Control of the spring stroke

is adjusted as outlined in Section

3.9.1.The hydraulic stroke is adjusted

by the Extend needle valve. Loosen the

jam nut and turn the valve clockwise to

decrease stroke time and anti-clockwise

to increase stroke time.

3.9.3 Spring-Return Units for

Positioning Applications

Positioning units will have an additional

speed control labeled Retract Slow.

This is used to slow the spring stroke

as the actuator approaches its demand

position. This will be factory set to

maximize positioning accuracy and

should not need adjusting.

3.9.4 Double-Acting Adjustment

(Accumulator Fitted)

Speed control of double-acting units

is not possible unless a hydraulic

accumulator is supplied.

The speed control labeled NV-EXT and

NV-RET are used to adjust the stroke

time. Loosen the jam nut and turn the

appropriate valve clockwise to decrease

and anti-clockwise to increase.

3.9.5 Double-Acting Adjustment

(No Accumulator)

Speed control is not available on

double-acting units without an

accumulator. This is due to the nature

of fixed displacement pumps.

Optional manual operation may have

been specified for your EH actuator.

For all EH actuators, optional manual

operation is provided with a hydraulic

hand pump. When supplied, a pump

with a removable handle is located on

or near the power unit.

WARNING:

Manual override operation should

only be carried out when there is no

power supplied to the actuator.

Hand pump Operation

In most cases, a two-position lever

on the side of the manifold selects

the direction of travel. Some special

actuators have a ball valve(s) to control

hand pump operation. Consult your

job specific hydraulic schematic for

operation details..

WARNING:

See specific manual override label

as supplied with actuator, for

manual override procedure.

For units fitted with an external

solenoid valve, an extra isolating

valve is fitted inline with the valve,

this must be set to ‘Manual’ to

operate the manual override.

An isolation valve is also fitted for

fail in position actuators, this must

be set to ‘Manual’ to operate the

manual override.

There is also a locking mechanism

fitted to each ball valve to allow it

to be locked in position by means of

a padlock. It is recommended that a

padlock is fitted for actuators being

used in an ESD application.

Page 15

5

Mounting the Actuator

9

5.1 Lifting

WARNING:

Refer to weights and measures

from job specific EH information for

actuator weight.

Ensure the valve is secure before fitting

the actuator as the combination may be

top heavy and therefore unstable.

In no circumstances should hydraulic

piping or electrical cabling be used for

lifting purposes.

If it is necessary to lift the actuator

using mechanical lifting equipment,

certified slings should be attached.

At all times trained and experienced

personnel should ensure safe lifting,

particularly when mounting actuators.

WARNING: The actuator should

be fully supported until complete

valve shaft engagement is achieved

and the actuator is secured to the

valve mounting flange.

Actuator to valve fixing must conform

to material specification ISO Class 8.8,

yield strength 628 N/sq mm.

WARNING: Do not lift the

actuator and valve combination via

the actuator. Always lift the valve/

actuator assembly via

the valve.

Each assembly must be assessed on an

individual basis for safe lifting.

5.2 Mounting Orientation

Refer to order specific installation

drawing for proper mounting

orientation.

5.3 Fitting to Valve

Refer to order specific installation

drawing for proper fitup and mounting

pattern to valve.

5.4 Mechanical Travel

Adjustment

When the actuator has been bolted

to the valve flange or adaptor and

keys inserted; the position of the stop

bolts should be checked to ensure full

opening and closing of the valve.

If the preset end positions are not

suitable, the stop bolts may be adjusted

by first loosening the jam nut and

screwing the bolts in or out until the

desired position is obtained. Stroke the

yoke away from the stop bolt when

adjusting then return to check position.

When the correct position is obtained,

re-tighten the jam nut.

Certain valves incorporate their own

stops. In these cases, it is recommended

that the actuator stop bolt positions

coincide with the valve stop positions.

5.5 Hydraulic Fluid

EH actuators are supplied without

hydraulic fluid and must be filled prior

to operation. See Section 10.1 for the

oil specification.

WARNING:

If the actuator is fitted with an

accumulator it must be drained to

the reservoir before adding oil.

With the spring, or for double-acting

actuators the piston, fully extended,

fill the reservoir to approximately 50

mm (2 inches) below the top. Stroke

the actuator two times and re-check

the reservoir level. Add additional oil as

required. Refer to Section 10.1 for the

oil specification.

5.6 Power Accumulators

Some EH Range actuator configurations

are equipped with hydraulic

accumulators to store energy for

stroking the actuator.

Accumulators must be pre-charged with

dry nitrogen prior to operation. See

Appendix A.

Page 16

6

Cable Connections

10

WARNING:

Ensure all power supplies are

isolated before removing actuator

covers.

Check that the supply voltage is the

same as that stated on the actuator

nameplate.

A switch or circuit breaker must be

included in the wiring installation to

the actuator. The switch or circuit

breaker shall be mounted as close

to the actuator as possible and

shall be marked to indicate that it

is the disconnecting device for that

particular actuator. The actuator must

be protected with a suitably rated

overcurrent protection device as defined

on the applicable wiring diagram.

6.1 Earth/Ground Connections

An M8 X 1.0 earth stud is located

adjacent to the conduit entries for

attachment of an external protective

earthing strap. An internal earth terminal

is also provided on the terminal bung,

however it must not be used alone as

the protective Earth Connection.

6.2 Removing Terminal Cover

Using a 6mm hexagon key loosen the

four captive screws evenly. Do not

attempt to lever off the cover with

a screwdriver as this will damage

the o-ring seal and may damage the

flamepath on a certified unit.

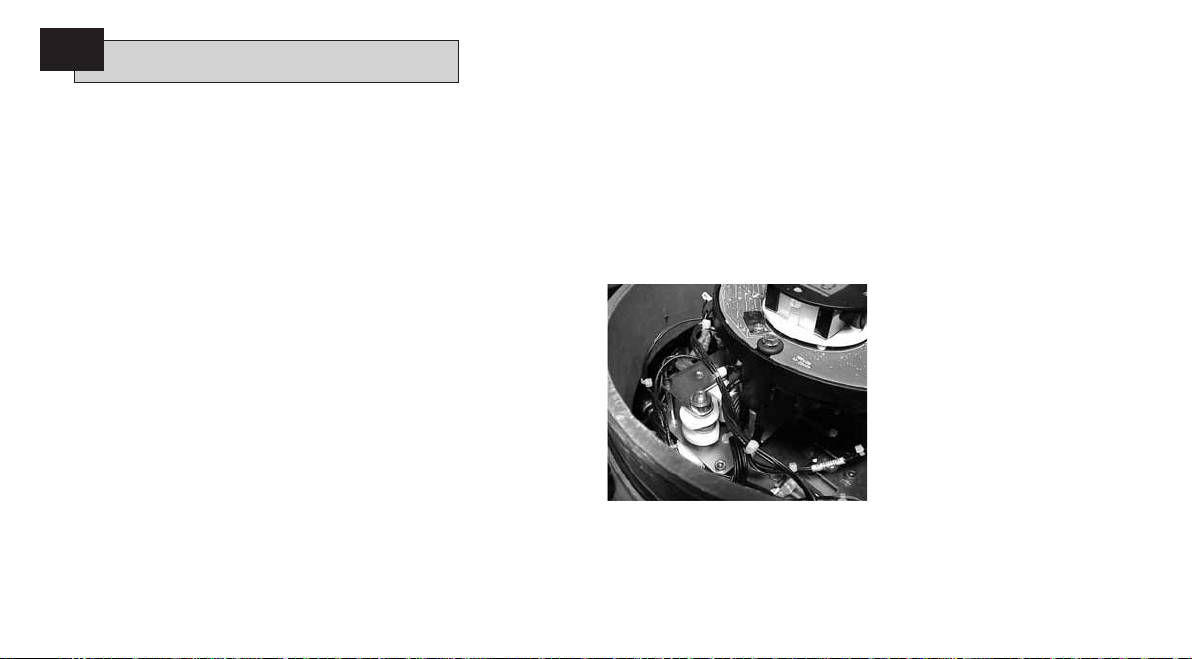

Fig. 6.1.

A plastic bag with the actuator contains

the following:

• Terminalscrewsandwashers.

• Sparecovero-ringseal.

• Wiringdiagram.

• Instructionbook.

Fig. 6.2.

6.3 Cable Entry

The four cable entries on the actuator

terminal housing are tapped ½” NPT.

Only appropriate certified ExplosionProof entry reducers, glands or conduit

may be used in hazardous locations.

Remove any red plastic transit plugs.

Make cable entries appropriate to

the cable type and size. Ensure that

threaded adaptors, cable glands or

conduit are tight and fully waterproof.

Seal unused cable entries with a steel or

brass threaded plug. In hazardous areas

an appropriately certified threaded

blanking plug must be used.

Page 17

6

Cable Connections continued

11

6.4 Connecting to Terminals

On EExde enclosure units

connections to the power and

control terminals must be made

using AMP type 160292 ring tabs for

power and earth terminals and AMP

type 34148 ring tabs for the control

terminals.

Refer to the wiring diagram inside the

terminal cover to identify functions of

terminals. Check that supply voltage

is the same as that marked on the

actuator nameplate.

Remove the red power terminal screen.

Begin by connecting these cables and

replace the red power terminal screen.

When all connections are made, ensure

wiring diagram is replaced in the

terminal compartment.

6.5 Replacing Terminal Cover

Ensure cover o-ring seal and spigot

joint are in good condition and lightly

greased before re-fitting cover.

WARNING:

plug is always tight before stroking

the actuator in either direction.

Ensure the oil fill

Heading

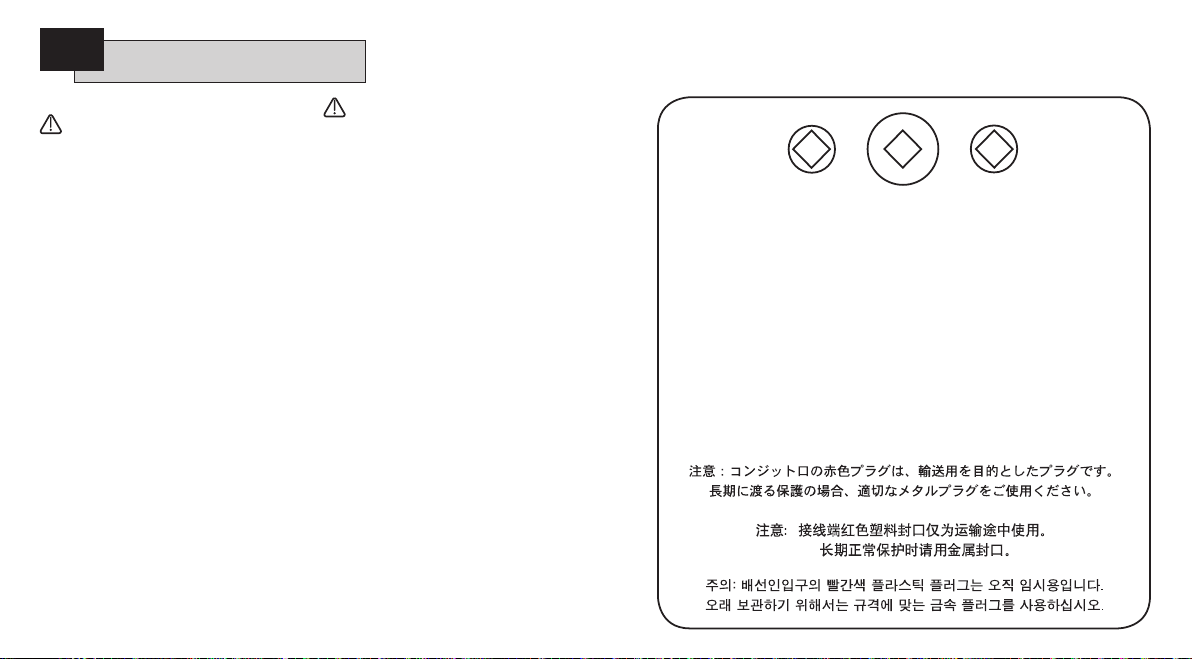

ATTENTION: RED PLASTIC PLUGS IN CONDUIT ENTRIES ARE FOR TRANSIT ONLY.

FOR LONG TERM PROTECTION FIT SUITABLE METAL PLUGS.

ATTENZIONE: I TAPPI IN PLASTICA ROSSA PER L'ENTRATA CAVI SONO SOLO

TEMPORANEI. PER UNA PROTEZIONE PERMANENTE PREGO SOSTITUIRLI CON

ATENCION: LOS TAPONES ROJOS DE PLASTICO EN LAS ENTRADAS DE CABLE

SON UNICAMENTE PARA TRANSPORTE. PARA PROTECCION PERMANENTE

ACHTUNG: DIE ROTEN PLASTIKSTOPFEN SIND NUR FÜR DEN TRANSPORT GEEIGNET.

FÜR DAVERHAFTEN SCHUTZ SIND DIESE GEGEN GEEIGNETE BLINDSTOPFEN

ATTENTION: LES BOUCHONS PLASTIQUES ASSURENT UNE PROTECTION

TEMPORAIRE. POUR UNE PROTECTION DEFINITIVE UTILISER DES BOUCHONS

APPOSITI TAPPI METALLICI.

COLOCAR TAPONES METALICOS APROPIADOS.

AUSZÜTAUSCHEN.

METALLIQUES.

Page 18

7

Commissioning

12

7.1 The Setting Procedure

The Rotork Fluid Systems EH actuators

are designed so that commissioning

may be carried out without removing

any electrical covers.

Setting the internal hydraulic pressure,

limit and other functions is achieved

by using the Infrared Setting Tool. The

Setting Tool is certified Intrinsically Safe

to allow commissioning in hazardous

areas.

All the commissioning functions are

stored in non-volatile memory in the

actuator. The Setting Tool enables the

user to view all the functions in turn

via the actuator display window. As

each function is viewed its setting can

be checked and, if required, changed

within the bounds of that function.

The power supply must be connected

and energised for commissioning

purposes. The setting procedure is

divided into two stages:

1. Basic Settings

Setting end of travel limit actions,

pressure values and limit

positions.

2. Configuration Settings

Settings covering the control,

indication and optional

equipment functions.

All EH actuator functions are

configured before despatch

to Rotork Fluid Systems

standard default settings

unless alternatives have been

specified with the order. Should

difficulty be encountered during

commissioning the default

settings can be reinstated,

returning the actuator

configuration to its original

manufactured state. Site

commissioning can then begin

again.

The default function should be used

with caution as settings selected after

manufacture may be essential for

the safe operation of the valve and/

or plant.

Actuator Display

Position Display

or a percentage open value.

Pressure and Position

Password P?

Crossroad cr

Basic Settings Configuration Settings

Limit Actions Indication Contacts

Pressure Values Control Mode

Limit Positions Options

Help Screens

Defaults

Note: The Basic Settings must be commissioned first.

50

This may be an open or closed symbol

m

50

Refer to Section 10.

Torque

m

PC k Bt k Pt k FT

k

m

k

m

Page 19

7

Commissioning continued

13

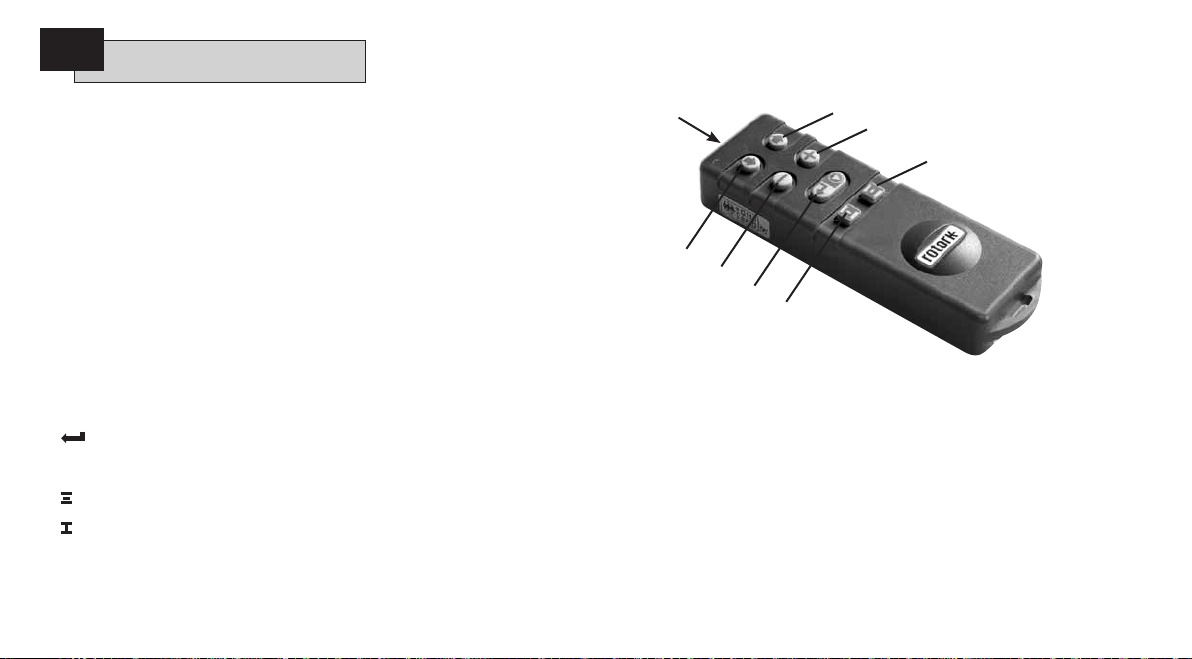

7.2 Rotork Setting Tool (old version)

Specification

Enclosure IP67

Certification EEx ia IIC T4 (intrinsically safe)

FM, INT SAFE, Class I & II Div 1 Groups A B C D E F G, T4A

CSA, Exia, Class I, II Div 1 Groups A B C D

Power supply 9V Battery (supplied and fitted)

Operating range 0.75m (from actuator display window)

Name Instruction

1. m Key* Display next function down

Key* Display next function across

2.

k

-

Key Decrease/change displayed function’s value or option setting

3.

+

Key Increase/change displayed function’s value or option setting

4.

Key Enter displayed value or option setting

5.

Infrared local operation (when enabled)

Key Non-functional on EH actuators

6.

Key Non-functional on EH actuators

7.

8. Infrared Transmitter Window

* Pressing the two arrow keys together returns the actuator display to the position

indication mode

8

1

3

5

7

Fig. 7.1 Rotork Setting Tool

2

4

6

Page 20

7

Commissioning continued

14

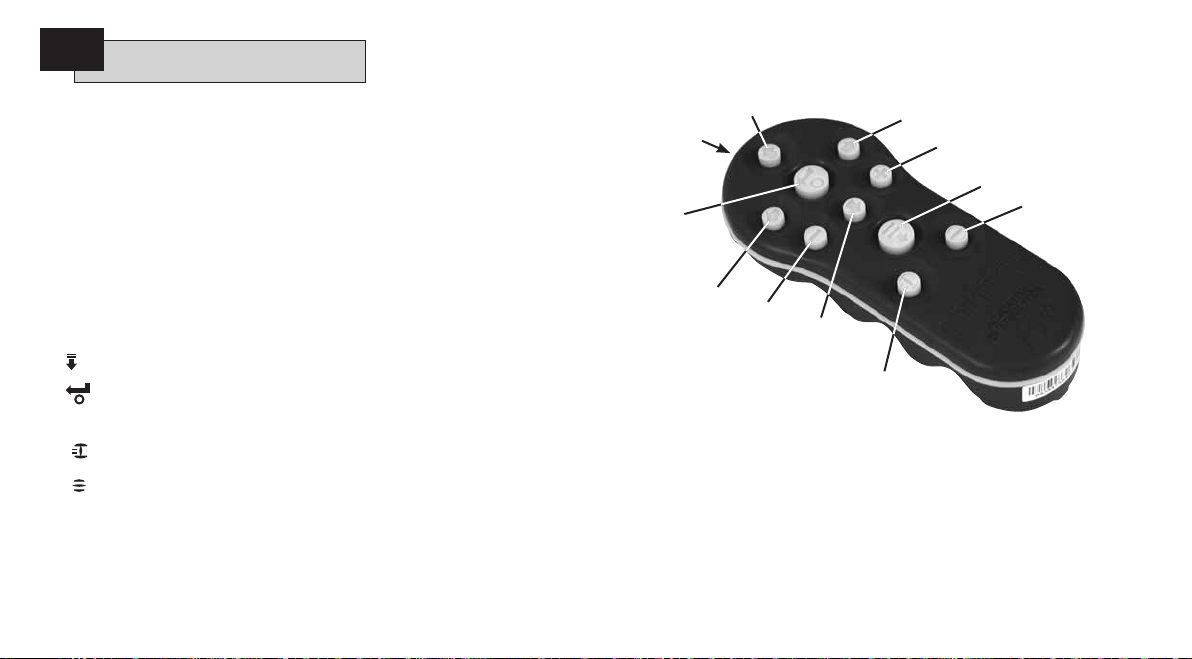

7.3 Rotork Setting Tool Pro

Name Instruction

1. m Key* Display next function down.

i Key Display previous function up.

2.

Key* Display next function across right.

3.

k

o

Key Display previous function across left.

4.

-

Key Decrease/change displayed function’s value or option setting.

5.

+

Key Increase/change displayed function’s value or option setting.

6.

Key Non-functional on EH actuators.

7.

Key Enter displayed value or option setting.

8.

9. Infrared transmitter window.

Key Non-functional on EH actuators.

10.

Key Non-functional on EH actuators.

11.

* Pressing these two arrow keys together exits setting mode and returns the

actuator display to the pressure/position indication mode.

2

9

8

3

6

7

11

4

5

1

Fig. 7.3. Rotork Setting Tool Pro

Specification

Enclosure: IP54

Certification: ATEX CE 0518 Ex II 1G

FM, INT SAFE, Class I, Div 1, Groups A, B, C & D, T4.

CSA, Exia, Class I, Div 1, Groups A, B, C & D, T4.

Temperature: Tamb = -30 ºC to 50 ºC

Power supply: 2x 1.5V AA Batteries (supplied and fitted)

Operating range: 0.75m (from actuator display window)

10

Page 21

7

Commissioning continued

15

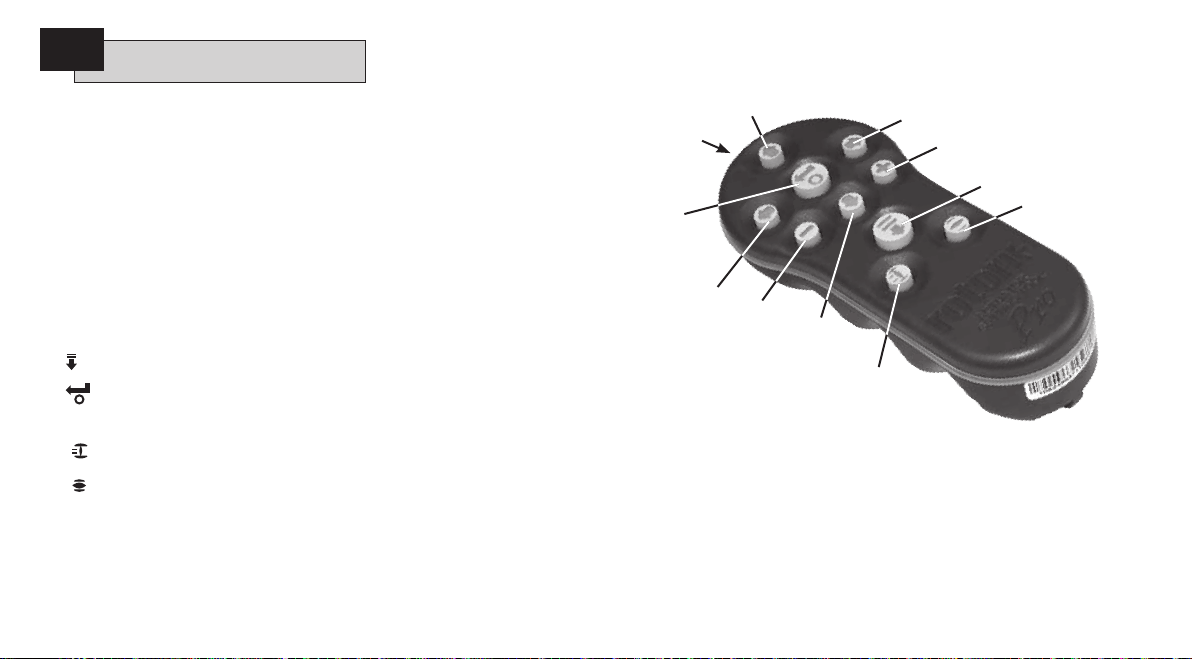

7.4 Rotork Bluetooth® Setting Tool Pro

Name Instruction

1. m Key* Display next function down.

i Key Display previous function up.

2.

Key* Display next function across right.

3.

k

o

Key Display previous function across left.

4.

-

Key Decrease/change displayed function’s value or option setting.

5.

+

Key Increase/change displayed function’s value or option setting.

6.

Key Initiate download/upload via Bluetooth.

7.

Key Enter displayed value or option setting.

8.

9. Infrared transmitter window.

Key Non-functional on EH actuators.

10.

Key Non-functional on EH actuators.

11.

* Pressing these two arrow keys together exits setting mode and returns the

actuator display to the pressure/position indication mode.

2

9

8

4

5

3

6

7

11

1

10

®

Fig. 7.4. Rotork Bluetooth

Specification

Enclosure: IP54

Certification: ATEX CE 0518 Ex II 1G

FM, INT SAFE, Class I, Div 1, Groups A, B, C & D, T4.

CSA, Exia, Class I, Div 1, Groups A, B, C & D, T4.

Temperature: Tamb = -30 ºC to 50 ºC

Power supply: 4 x 1.5V AAA Batteries (supplied and fitted)

Operating range: Infrared: 0.75m (from actuator display window)

Bluetooth: 3m (from actuator display window)

Setting Tool Pro

Page 22

7

Commissioning continued

16

Setting Tool Battery Replacement

Battery status can be checked by

looking at the Infrared transmitter

window while depressing any Setting

Tool button. A flashing red indicator

should be seen.

Battery replacement must be

carried out in a safe area. To replace

the battery remove the six caphead

screws in the back of the Setting

Tool. Remove the back cover to

expose the battery.

The Setting Tool (old version):

In order to maintain hazardous

area certification fit only Duracell

mN1604 or Rayovac Alkaline

maximum NoAL-9V battery types.

The Setting Tool Pro:

In order to maintain hazardous

area certification fit only with

the following AA size, AlkalineManganese, approved battery types:

Duracell, Coppertop, type MN1500

Duracell, Procell, type MN1500

GP, Super Alkaline, type GP15A

Other types of AA size batteries,

including Duracell, Ultra, type

MN1500, must not be fitted.

The Rotork Bluetooth® Setting

Tool Pro:

In order to maintain hazardous

area certification fit only with

the following AAA size, AlkalineManganese or Zinc-Manganese

approved battery types:

Duracell, Procell, type MN2400

Energizer, type E92.

Refit cover ensuring red indicator

LED faces the transmitter window in

the back cover.

When a button is depressed the Setting

Tool transmits the relevant instruction

to the actuator by infrared pulses and

must therefore be directly in front of

the actuator indicator window and at a

distance no greater than 0.75m.

The enclosure of the Rotork Setting Tool

Pro, and Rotork Bluetooth

Pro, is manufactured from the following

materials:

Polycarbonate, ABS blend

Polycarbonate

Silicon Rubber

If the Rotork Setting Tool Pro and Rotork

Bluetooth® Setting Tool

to come into contact with aggressive

substances (e.g. solvents that may affect

®

Setting Tool

Pro

are likely

polymetric materials), then it is the

responsibility

precautions (e.g. regular checks as part

of the routine inspections or establishing

that the materials are resistant to the

specific chemical) that prevent it from

being adversely affected, thus ensuring

that the type of protection is not too

compromised.

No form of repair must be

attempted on any of the actuator

Setting Tools.

of the user to take suitable

Download / Upload Function

This new feature has been introduced

with the new Rotork Bluetooth® Setting

Tool Pro. It allows the user to download

datalogger files and download/upload

configuration files. The new tool is

weatherproof and intrinsically safe and

so it can be used safely in all environments.

Refer to Bluetooth® Setting Tool Pro

publication PUB095-001.

Display Set-Up Mode

The Setting Tool and Setting Tool arrow

keys are used to access and navigate

through the actuator set-up procedure

using the actuator display. Each actuator

function with it's current setting is

represented on screen by a combination

Function

Code

Close Action

Function

Function

Code

Stop on Pressure

Open Pressure

Function

of code and text.

The Setting Tool change keys (+ and

–) allow the user to view the available

setting options.

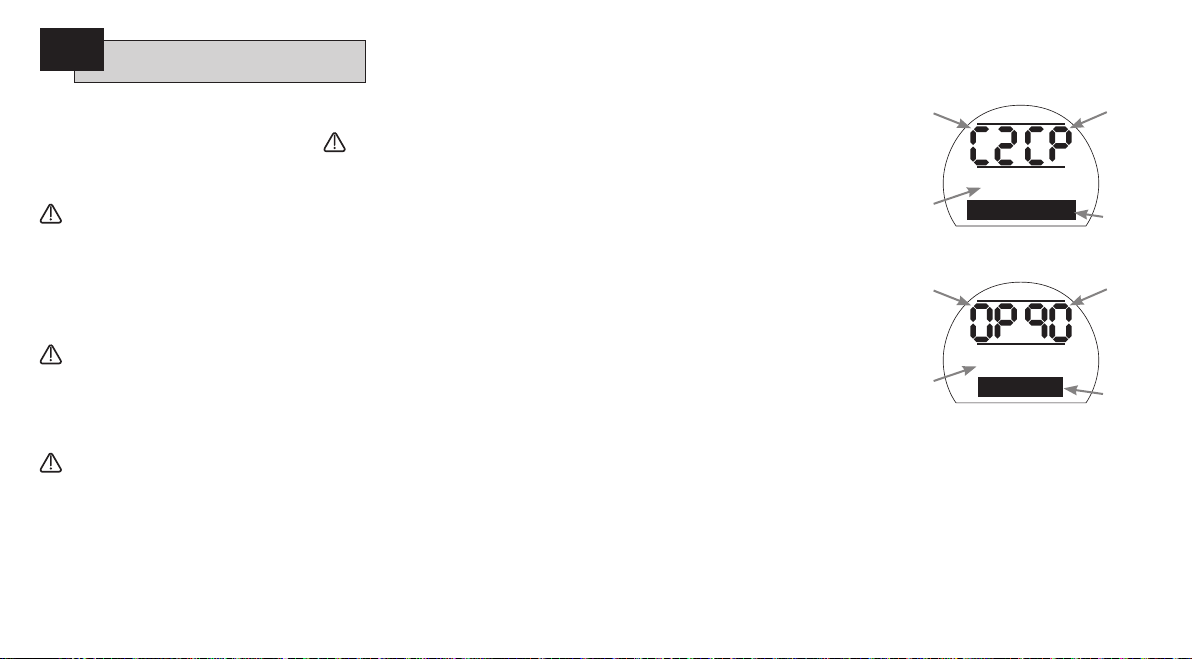

The examples of displayed functions

Close Action, [C2] and Open

Pressure

Note that a setting option or value is

highligh

This instruction manual uses both code

and text for description.

at Limit 90%

, [OP] are shown above.

ted.

Setting

Code

Setting

Option

Setting

Value

Setting

Value

Page 23

7

Commissioning continued

17

7.5 Entering the Actuator

Setting Procedure

With the actuator securely mounted

on the valve, the mains supply on and

Local control or Stop selected.

PRESS THE m KEY.

The actuator upper display will remain

the same and the lower display will

change to Pressure value. This will be

represented by Pressure = XX%,XXBAR

or XXPSI and a bar graph.

PRESS THE m KEY.

The actuator display will change and

the password protection display will be

seen.

Enter Password

1D Hex

The Actuator Function Settings

can be protected by the Use

of a Password

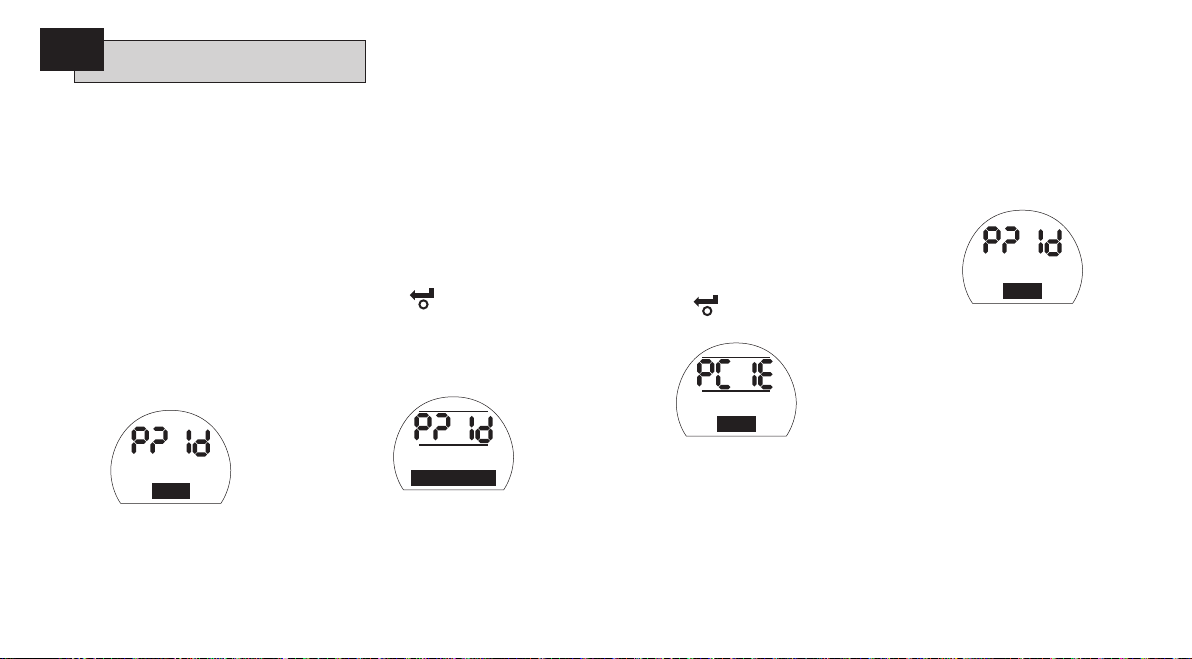

7.6 Setting Mode – Password

To enable setting and adjustment of the

actuator functions the correct password

must be entered. The factory set (default)

password is [ld]. If the actuator has

previously been set with a site password

this must be entered.

+

-

or

Use the

available passwords 00–FF (hexadecimal).

With the correct password displayed press

the enter key.

keys to scroll through the

PRESS THE KEY.

Two “setting” bars will appear and will

remain visible on every function display

screen. In addition, "Password Correct"

will be displayed for 3 seconds.

Enter Password

Password Correct

Default Password,

Setting Mode Enabled

7.7 New Password [PC]

To configure a new password, the

actuator must be in setting mode with the

password display – setting mode enabled

– showing,

PRESS THE

The display will change to [PC].

Using the

available passwords until the desired

password is displayed.

KEY.

k

+

or - key scroll through the

PRESS THE KEY.

Change Password

1E Hex

Password Changed to [IE]

NOTE: The new password becomes

effective the next time setting mode is

entered.

7.8 Checking Mode

The actuator function settings can be

checked without entering the correct

password. The settings can only be

viewed and not altered. The setting bars

will not be seen.

Enter Password

1D Hex

Password Display, Checking Mode

Once the procedure has been completed

in the required mode

PRESS THE m KEY.

The procedure branch [Cr] (crossroad)

display can now be seen.

Page 24

7

Commissioning continued

18

7.9 Bluetooth Diagnostic and

Configuration

EH Pro actuators include a Bluetooth

interface as standard, allowing nonintrusive diagnostics, analysis and

configuration.

Insight II software for PC has been

developed to enable the actuator

configuration and onboard Datalogger

to be reconfigured and analysed. A PC

running Insight II software can be used

to interrogate the actuator via nonintrusive Bluetooth communication. Visit

www.rotork.com for information.

Alternatively, the intrinsically safe Rotork

Bluetooth® Setting Tool

user to extract and store EH actuator

configuration and Datalogger files

within the tool. Stored files can then be

uploaded via Bluetooth to a PC running

Insight II where they can be viewed,

analysed and stored in a safe, clean

environment.

Using the Rotork

Tool

Pro

, actuator setup can be

configured on the PC, stored in the

tool, transported to the actuator

and uploaded. The tool can transfer

the same configuration to multiple

actuators where actuator setup is the

same.

Pro

allows the

Bluetooth® Setting

Refer to PUB095-001-00 for full

instructions on the use of the Rotork

Bluetooth® Setting Tool

To enable communication with Insight

II, the actuators Bluetooth interface

must be enabled.

The default setting for the Bluetooth

interface is [OF] disabling Bluetooth.

[OF] Off (Default): Bluetooth is disabled

[ON] On: Bluetooth is permanently

enabled.

[LS] Local Stop Only: Bluetooth is only

enabled when the actuator is in Local

Stop.

To change this setting press the +

or – key until the required setting is

displayed.

Bluetooth Comms

Pro

.

Off

PRESS THE KEY.

The displayed option will flash (stored)

indicating that it has been set.

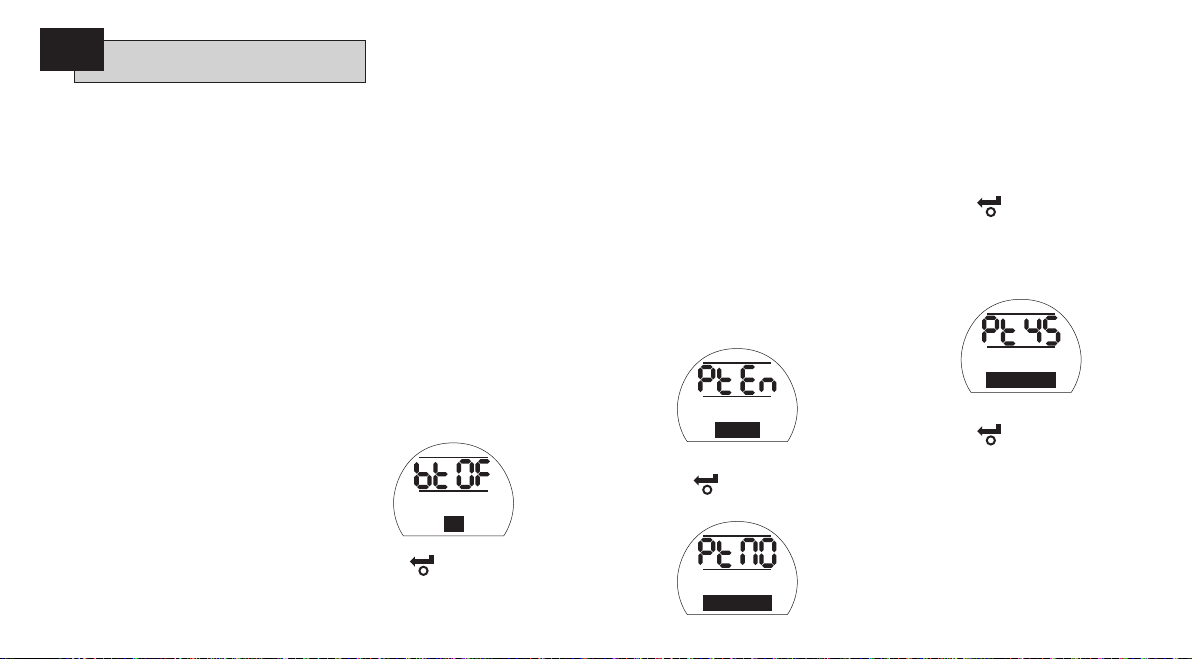

7.10 Partial Stroke Test

This function performs a partial stroke

test based on the parameters set in

[PP] and a setup test being completed

in [SP]. Insight II can then be used to

compare subsequent partial stroke

tests against the original test when the

actuator was first commissioned.

The actuator must be in Local to

perform a test.

The actuator needs to be moved to the

correct limit prior to initiating the test

[Pt] Perform the partial stroke test.

P-Stroke Te st

Confirm?

PRESS THE KEY.

P-Stroke Te st

- No +

This brings up an option to either

cancel or confirm that the partial stroke

test should be completed.

To cancel the test: Ensure that [No] is

displayed on the screen.

PRESS THE KEY.

To confirm that the test should be

completed: Press the + key until the

display changes to [Ys]

P-Stroke Te st

- Yes +

PRESS THE KEY.

Page 25

7

Commissioning continued

19

7.11 Full Stroke Test

This function performs a full stroke test

based on a setup test being completed

in [SF]. Insight II can then be used to

compare subsequent full stroke tests

against the original test when the

actuator was first commissioned.

The actuator must be in Local to

perform a test.

The actuator needs to be moved to

either the closed or open limit prior to

initiating the test.

[Ft] Perform the partial stroke test.

Full Stroke Test

Confirm?

PRESS THE KEY.

Full Stroke Test

- No +

This brings up an option to either

cancel or confirm that the full stroke

test should be completed.

To cancel the test: Ensure that [No] is

displayed on the screen.

PRESS THE KEY.

To confirm that the test should be

completed: Press the + key until the

display changes to [yS]

Full Stroke Test

- Yes +

PRESS THE KEY.

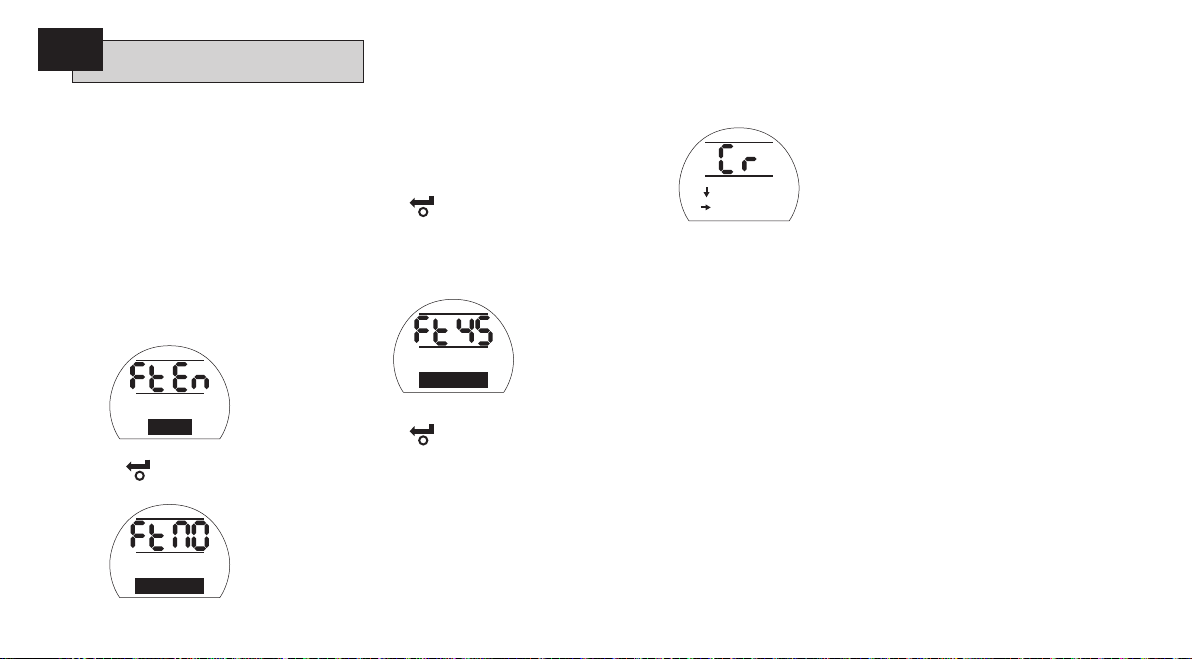

7.12 Crossroad [Cr]

Basic Setup

Config Setup

To access the Basic Settings press the

arrowm key. Refer to 8.

To access the Configuration Settings

press the arrow

Section 9.

key. Refer to

k

7.13 The Actuator Display –

Setting/Checking Mode

Actuator functions as laid out in the

Basic and Configuration commissioning

stages, can be individually displayed by

using the Setting Tool arrow keys.

m

arrow key will always display the

The

FIRST function on the next level DOWN

within the procedure.

arrow key will always display

The

k

the NEXT function on the SAME level

and will wrap around the functions on

the same level.

Actuator functions are displayed in code

form in the top left portion of the liquid

crystal display screen.

The setting for the displayed function is

shown in the top right hand portion of

the screen. Depending on the actuator

function displayed, its setting may be

an option or a value.

Text relating to the function and setting

values will be displayed in the lower

display.

Page 26

7

Commissioning continued

20

key.

Stored

+

"

In setting mode the Setting Tool

-

or

keys will cause the setting to be

changed. In checking mode the settings

cannot be altered.

In setting mode, once displayed, a new

setting can be entered into the actuator

memory by pressing the

The setting will flash off and back on,

confirming its selection, and "

will be displayed for 2 seconds in the

text display.

TOP LEFT

PORTION

Function e.g.

Open Pressure

at Limit 90%

OP = Open Pressure

TOP RIGHT

PORTION

Function Setting

e.g. Value = 90%

LOWER DISPLAY

Function: Open Pressure

Setting Value: 90%

7.14 Returning to Valve

Position Display

There are five ways of returning to valve

position display:

1. Approximately 5 minutes after the

last Setting Tool operation the

display will automatically return to

position display.

2. Press the

together.

3. Press the

display returns to position.

4. Press the

to position display.

5. Select Remote control using the

Local/Stop/Remote selector.

m

m

iarrow key to return

and

arrow keys

k

arrow key until the

Page 27

8

Commissioning – Basic Functions

21

Fig. 8

ELECTRICAL OPERATION MUST

NOT TAKE PLACE UNTIL THE BASIC

SETTINGS HAVE BEEN MADE AND

CHECKED.

The actuator’s Basic Settings affect

the correct operation of the valve by

the actuator. If the actuator has been

supplied with the valve, the valve maker

or supplier may have already made

these settings.

This instruction assumes setting mode

has been entered. Refer to section 7.6.

Viewing the Basic Settings

With the actuator mounted on the

valve, the power supply on and Local

or Stop control selected, point the

setting tool at the actuator indicator

window from a distance of no more

than 0.75m. By pressing the m key

and, when appropriate, the

it is possible to move through the

procedure, displaying the various

functions and their settings as shown in

Fig. 8.1.The right-hand side of Fig.8.1

explains the function of each LCD

display.

k

key,

Settings and operation must

be verified by electric operation

and function test of the actuator

to ensure correct operation.

Page 28

8

Commissioning – Basic Functions continued

Viewing the Basic Settings

Function Description

50

m

50

Position and Internal Hydraulic Pressure Display

Torque

m

P? k PC k bt k Pt k Ft Password k Password Change k Bluetooth k Partial Stroke Test k Full Stroke Test

m

Cr k Configuration Crossroad k Configuration Settings, refer to section 7.1

Position Display

(This may be an open or closed symbol or % open value)

m

m

m

22

REFER TO SECTION 7,

COMMISSIONING

C2

C3 Close Action k Open Action

k

m

CP k cP k OP k oP

m

LC k LO Set Close Limit k Set Open Limit

m

50

Position Display

Fig. 8.1 Basic Setting Displays

m

Close Pressure (Limit)

m

m

Close Pressure (Mid) k Open Pressure (Limit) k Open Pressure (Mid)

k

BASIC SETTINGS CONTENTS

page

C2 Close Action 26

C3 Open Action 27

CP Close Pressure (Limit) 27

cP Close Pressure (Mid) 28

OP Open Pressure (Limit) 28

oP Open Pressure (Mid) 29

LC Set Close Limit 30

LO Set open Limit 30

Page 29

8

Commissioning – Basic Functions continued

C2

Close Action

23

Each actuator is built in the factory to

be either Normally Closed, Normally

Open or Stay-put depending on what

configuration was ordered.

Normally Closed:

Quarter-turn

(spring-return clockwise)

Linear

(spring-return to extend)

Normally Open:

Quarter-turn

(spring-return anti-clockwise)

Linear

(spring-return to retract)

Consult factory if this configuration

needs to be changed as it cannot be

done through software alone.

The actuator can be configured to

either close on Pressure (hydraulic or

spring) for seating valves or Limit for

non-seating valves.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Refer to valve manufacturer for

recommended setting.

Close Action

Stop on Pressure

[CP] Stop on Pressure (Default)

[CL] Stop on Limit

+

To change the function press the

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

Page 30

C3

Open Action

CP

Close Pressure at Limit

24

The actuator can be configured to

either open on Pressure (hydraulic or

spring) for back seating valves or Limit

for non-back seating valves.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Refer to valve manufacturer for

recommended setting.

Open Action

Stop on Limit

[OL] Stop on Limit (Default)

[OP] Stop on Pressure

+

To change the function press the

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

This setting allows the maximum cut-off

pressure in a normally open actuator

while travelling from the closed electrical

limit to the closed mechanical end stop

to be set. The value set is a % of the

maximum available pressure, which is

limited by the pressure relief valve.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Close Pressure

at Limit 90%

To change this value press the +

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

Page 31

cP

Close Pressure at Mid

OP

Open Pressure at Limit

25

This setting allows the maximum

cut-off pressure in a normally open

actuator while travelling in mid-travel

between the open and closed electrical

limits while closing to be set. If the

value is set to 00, the pressure-off value

from CP is used.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Close Pressure

at Mid 0%

To change the function press the +

-

key until the required setting is

or

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

This setting allows the maximum cut-off

pressure in a normally closed actuator

while travelling from the open electrical

limit to the open mechanical end stop

to be set. The value set is a % of the

maximum available pressure, which is

limited by the pressure relief valve.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Open Pressure

at Limit 90%

To change the function press the +

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

Page 32

oP

Open Pressure at Mid

Setting the Closed / Open Limit

26

This setting allows the maximum

cut-off pressure in a normally closed

actuator while in mid-travel between

the closed and open electrical limits

while opening to be set. If the value is

set to 00, the pressure-off value from

OP is used.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Open Pressure

at Mid 0%

To c hange the function press the +

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

If the actuator fails to complete

a closed or open valve operation

due to the set pressure being

reached, it may indicate a valve

and/or process problem or change.

It is the responsibility of the user

to ensure the valve and process

conditions are within the specified

operational limits before increasing

the pressure value.

To set the closed and open electrical

limits correctly, the actuator should

be moved to both the closed and

open mechanical limits and the

positions stored. The actuator will then

automatically scale in 2% from each

end to set the electrical limits.

The number shown in the top right of

the display screen when in either LC

or LO, is the percentage of full scale

read directly back from the positional

feedback device.

When at either the closed or open limit,

if the number on the screen is between

00 - 05 or 95 - 99, the actuator will

indicate a PO fault and will not operate,

its assumes that there is a problem

with feedback device. If this is the case

then the feedback device will require

adjustment.

Page 33

LC

Set Closed Limit

LO

Set Open Limit

27

Move the actuator to the closed

position by using the local controls.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Set Close Limit

Move to Close

To change the function press the

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

+

Move the actuator to the open position

by using the local controls.

50

m

50

Torque

m

P? k PC k bt k Pt k Ft

m

Cr

m

C2 k C3

m

CP k cP k OP k oP

m

LC k LO

m

50

Set Open Limit

Move to Open

To change the function press the

or - key until the required setting is

displayed.

PRESS THE KEY.

The displayed option will flash (stored),

indicating that it has been set.

+

Page 34

8.1

Menu Structure

0%

Pressure Display

m

P?

PC

bt

Pt

Password

ChangePassword

m

Cr

Crossroad

m m

CP

Close

Pressure(atLimit)

m m

LC

SetClosed

Limit(Manual)

cP

Close

Pressure(atMid)

LO

Set Open

Limit(Manual)

BluetoothComms

OP

Open

Pressure(atLimit)

Partial

Stroke Test

oP

Open

Pressure(atMid)

Ft

Full Stroke Test

r1

Relay 1 Function

Od

Remote Select

rP

2-wire

Remote Priority

m

EA

ESDAction

m

FI

Analogue

Input Type

m

dC

DeadbandClosing

m

OJ

Interrupter Timer

m

CF

ConfirmFaults

m

H1

Limit Flags

m

Option Card

r1

r1

Relay 1 Value

cL

LocalControls

HP

HoldPosition

EO

ESDOverride

Local Stop

FL

Set

DemandClosed

dO

Deadband Opening

Jd

Interrupter

Timer Direction

tL

Test lights

H2

LocalControl

Option card specific settings to be displayed when an option card is detected.

Menu to be hidden if no card is fitted.

Relay 1 Form

LP

Low Power Mode

PH

PositionHysteresis

Ec

ESDContactType

FH

Set

Demand Open

HC

HysteresisClosing

JC

Interrupter

TimerStart-Close

Un

Firmware Version

H3

Digital Feedback

Ld

Closed

LEDColour

OH

Over

PressureHysteresis

rE

ESDManualReset

Co

CPTOutputType

HO

HysteresisOpening

JO

I.Timer Stop- Open

U1

Option 1 Version

H4

Digital Feedback

UL

ChangeLanguage

UH

Under

PressureHysteresis

Et

TempLossofESD

Sc

SetCPTClosed

JS

I.Timer Interval

U2

Option 2 Version

H5

ControlFlags

SF

Full Stroke Setup

PP

Partial

Stroke Position

SO

(OP)

SetCPTOpen

Jn

I.Timer On Time

Ur

Reset to Factory

H6

Driver Buffer

SP

Partial

Stroke Set-up

FF

Analogue

Fail Action

JF

I.Timer Off Time

H7

ErrorFlags1

JE

Interrupter

TimerOverrideESD

H8

ErrorFlags2

H9

Driver Logic

Contact r1

General

Settings

Digital Control

ESD/Partial

Stroke

Analogue

Control 1

Analogue

Control 2

Interrupter

Timer

Service Mode

Help Screens

Option Card

28

Page 35

9

Configuration Settings

Accessing the

9.1

Configuration Settings

29

CONFIGURATION SETTINGS

page

9.1 Accessing Configuration Settings 29

9.2 Indication Contact r1 30

9.3 General Settings 31

9.4 Digital Control 33

9.5 ESD / Partial Stroke Settings 35

9.6 Analogue Control 1 39

9.7 Analogue Control 2 41

9.8 Interrupter Timer 43

9.9 Service 46

9.10 Bus System Option Pakscan 48

9.11 Bus System Option Modbus 51

9.12 Bus System Option Profibus DP 54

9.13 Bus System Option DeviceNet 57

9.14 Bus System Positioning Control Settings 60

Having established that the Basic

Settings have been correctly set, the

Configuration Settings can now be

configured to suit the site control and

indication requirements.

It is possible to move through the

various Configuration Settings as shown

in Fig. 9.1 using the k and m keys.

The actuator model code will indicate

any options fitted.

In order to display the Configuration

Settings it is necessary to press the

key until [Cr] appears.

If you have chosen to enter

Configuration Settings in the checking

mode the display will be as Fig. 9.1.

If you have chosen to enter

Configuration Settings in the setting

mode the display will be as Fig. 9.2

Refer to Section 7.

Basic Setup

Config Setup

Fig. 9.1 Fig. 9.2

PRESS THE

k

KEY.

Basic Setup

Config Setup

m

Page 36

9.2

Indication Contact r1

r1

Relay 1 Function

r1

30

Relay 1 Value

Indication contact r1 may be set to trip

for any one of the following functions:

Code Function (as displayed)

Closed Limit

[CL]

[OP]

Open Limit

[FA]

Fault Alarm

[Po]

Position % Open

[rr]

Motor Running

[dC]

Closing

[dO]

Opening

[rn]

Moving

[St]

Stall (mid-travel)

[SE]

Stall (end of travel)

[SP]

Stall (any position)

[Pt]

Over pressure (mid-travel)

[PE]

Over pressure (end of travel)

[PP]

Over pressure (any position)

[LS]

Stop Selected

[Lo]

Local Selected

[rE]

Remote Selected

[CA]

Control Alarm

[ES]

ESD Active

[tt]

Temperature (°C)

[HA]

Manual override switch

[AS]

Accumulator pressure switch

[Er]

External manual reset switch

[Ht]

Motor thermostat switch

[PP]

Partial stroke passed

[PF]

Partial stroke failed

[n2]

Monitor 2

[OF]

Off

The r contact form can be set normally

open [nO] or normally closed [nC].

Unless specified with order, the

default setting for indication

contact is the following:

r1 – [CL] Closed Limit [nO]

To change the function press the +

-

key until the required setting is

or

displayed.

PRESS THE KEY.

The displayed function will flash

indicating that it has been set.

Relay 1 Function

Closed Limit

This screen will only be displayed if the

relay function is set to [Po] Position %

Open and [tt] Temperature (°C).

When the relay function is set to either

[Po] or [tt], the required trip value

must be set.

The value can be set from 1% to 99%

in 1% increments for

99 °C in 1 °C increments for [tt].

To change the value press the

or - key until the required setting is

displayed.

[Po] or 60 °C to

+

PRESS THE KEY.

The displayed value will flash (stored)

indicating that it has been set.

Relay 1 Value

Position: 25%

Page 37

r1

Relay 1 Form

9.3

General Settings

Od

Remote Select

31

If function [Po] Position % Open,

is selected and it is configured as a

normally open contact it will make at

the set value with the actuator moving

in the open direction.

+

To change the form press the

or - key until the required setting is

displayed.

[nO] Normally Open (Default):

[nC] Normally Closed:

PRESS THE KEY.

The displayed option will flash (stored)

indicating that it has been set.

Relay 1 Form

Normally Open

This section includes selecting the

remote control source for the actuator

along with configuring the local

controls, changing the colour of the

closed LED, changing the display

language and performing a full stroke

reference test.

The correct setting for remote control

source will be determined by the type

of remote control required and the

option specified and fitted, if any.

There are five options available to

configure the remote control source:

rE]

Digital (Default):

[

for hard-wired pushbutton / relay

contact control.

Analogue:

[AI]

actuator is remotely controlled by an

external analogue signal in the range

0-20 mA or 0-10 Volts, with or without

offset zero.

Option:

[OP]

actuator is fitted with one of the

following Network cards:

Pakscan

Modbus

Profibus

Foundation Fieldbus

DeviceNet

Option ESD

[OE]

if the actuator is fitted with one of

the Network cards listed above and a