Page 1

CK Range

Safe Use and Installation Manual

Modular Design Electric Valve Actuators

Page 2

2

CK Range Safe Use and Installation Manual

Page 3

Table of Contents

1 Introduction 4

2 Safety 5

2.1 Standards and Directives 5

2.2 Competency 5

2.3 Commissioning 5

2.4 Warnings 5

3 Transport and Storage 6

4 Actuator Identification 7

4.1 CK Standard 7

4.2 CK A Atronik 8

4.3 CKc Centronik 9

5 Preparing the Drive Bush 10

5.1 Drive Bush - Type A Coupling: 10

5.1.1 Disassembly of bearing assembly 10

5.1.2 Reassembly of bearing assembly 10

5.2 Drive Bush - Type B Coupling: 11

5.2.1 Disassembly 11

5.2.2 Reassembly 11

6 Mounting the Actuator 12

6.1 Weights and Measures 12

6.2 Mounting the Actuator - Rising Stem Valves 13

6.2.1 Fitting the actuator and base

as a combined unit - all sizes 13

6.2.2 Fitting thrust base to valve - all sizes 13

6.3 Mounting the Actuator -

Non Rising Stem Valves - Top Mounted 13

6.4 Mounting the Actuator -

Valve with Gearbox - Side Mounted 13

6.5 Actuator Sealing 13

9 Commissioning 16

9.1 Atronik Interface 16

9.2 Centronik Interface 17

9.3 Centronik Navigation 18

9.3.1 Local Selector input 18

9.3.2 Setting Tool Input 18

9.4 Centronik Feedback 19

9.4.1 Arrow Identification 19

9.4.2 Confirmation Feedback 19

9.4.3 Torque/Limit Setting 19

9.5 Basic Mechanical Switch Mechanism Setting 20

9.5.1 Instructions 20

9.5.2 Set Position Limits 21

9.6 End of Travel Action 23

9.6.1 Atronik 23

9.6.2 DIP switch functions 23

9.6.3 Centronik 24

9.7 Digital Switch Mechanism Setting 25

9.7.1 Entering Configuration mode 25

9.7.2 Entering the User Password 25

9.7.3 Menu Navigation 26

9.8 Secondar y Function Setting 28

10 Maintenance, Monitoring and Troubleshooting 28

11 Disposal / Recycling 29

12 Environmental 29

13 Components of The Modular CK Actuator Design 30

7 Cable Connections 14

7.1 Terminal block layout 14

7.2 Earth/Ground Connections 15

7.3 Removing the plug and socket 15

7.4 Cable entr y 15

8 Operating Your Actuator 15

8.1 Operating by Hand 15

8.2 Operating Electrically 15

Keeping the World Flowing

3

Page 4

1 Introduction

This manual contains important information to

prevent damage in their handling, setting and use. It

is essential to follow and observe all the points. Please

observe all National Legislation for health and safety

regulations, standards and directives applicable.

This works and the information it contains are the

property of Rotork. The information it contains shall not

be reproduced or disclosed, in whole or in part without

the prior written consent of Rotork.

Instructions included in this document are applicable for

all variants of the CK Range - including but not limited to;

CK Standard, CKr, CKa, CKra, CKc and CKrc.

This manual is produced to enable a competent user to install,

operate, adjust and inspect the CK Range of valve actuators.

These user instructions are provided subject to the following

conditions and restrictions:

This document contains information of a proprietary nature

belonging to Rotork. Such information is supplied solely

for the purpose of assisting users of the CK Range of valve

actuators in its installation and maintenance.

The text and the graphics included in this document are

for the purpose of illustration and reference only. The

specifications on which they are based are subject to change

without notice.

Information in this document is subject to change without

notice.

This manual provides instruction on:

• Manual and electrical operation

• Preparation and installation of the actuator onto the valve

• Basic commissioning

• Maintenance

Refer to Publication PUB111-008 for repair, overhaul and

spare part instructions.

4

CK Range Safe Use and Installation Manual

Page 5

2 Safety

All users working with this product must be familiar with

and observe the safety and warning instructions given in

this manual. To avoid personal injury or property damage

safety instructions and warning signs on the product must be

observed.

Due consideration of additional hazards should be taken

when using the product with other equipment. Further

information and guidance relating to the safe use of the

product is provided on request.

These instructions must be observed otherwise safe use and

operation cannot be guaranteed.

2.1 Standards and Directives

Rotork products are designed and manufactured in

compliance with internationally recognised standards and

directives. EC Declaration of Conformity and Incorporation are

available on request. It is the responsibility of the end user or

contractor to ensure that the legal requirements, directives,

guidelines, national regulations and recommendations

applicable to the site of installation are met with respect to

assembly, electrical connections and operation.

2.2 Competency

The user and those persons working on the equipment should

be familiar with and observe their responsibilities under any

statutory provisions relating to occupational health and safety

regulations. Before working on this product users should have

thoroughly read and understood these instructions.

Only persons competent by virtue of their training and

experience should install, maintain and repair Rotork

actuators.

2.3 Commissioning

It is important to check that all settings meet the requirements

of the application before commissioning the product. Incorrect

settings might cause damage to valves or other property.

Rotork will not be held liable for any consequential damage.

2.4 Warnings

This information is needed to avoid a safety hazard,

which might cause bodily injury

This information is necessary to prevent damage to

the product or other equipment

WARNING: Motor Thermostat / Motor Temperature

Under normal operation the surface temperature of the

actuator’s motor cover can exceed 60 °C above ambient.

Failure to correctly connect the thermostat may lead to

electrical hazards and invalidate the electrical safety case

and any safety approvals. Surface temperatures of motor

enclosures may reach temperatures which can cause

discomfort or injury to personnel accidentally coming

into contact with hot surfaces. Protection should be

provided by the user to protect against accidental contact

with hot surfaces. Failure to observe this precaution

could result in bodily injury.

WARNING: Surface Temperature

The installer/user must ensure that the actuator’s surface

temperature rating is not influenced by external heating/

cooling effect (e.g. valve/pipeline process temperatures).

CAUTION: Enclosure Materials

The CK Range of valve actuators are manufactured

from aluminum alloy with stainless steel fasteners.

The thrust bases are manufactured in SG iron. The user

must ensure that the operating environment and any

materials surrounding the actuator cannot lead to a

reduction in the safe use of, or the protection afforded

by, the actuator. Where appropriate the user must ensure

the actuator is suitably protected against its operating

environment.

WARNING: Unexpected Start up

Actuator may start and operate at any time when power

is applied. This will be dependent on remote control

signal status and actuator configuration.

WARNING: Unit Weight

The actuator weight is shown on the nameplate.

Care must be taken to transport, move or lift the actuator

safely. Lifting information is available in section 6.

Keeping the World Flowing

5

Page 6

3 Transport and Storage

During transportation, care should be taken to ensure that

your actuator is protected from impact. In the unfortunate

event of your actuator receiving an impact, the actuator

should be inspected by a Rotork trained technician (for

transportation purposes, handwheels are supplied separately).

If your actuator cannot be installed immediately, store it in a

clean, dry ventilated location that is off the floor and protect it

from dust and dirt.

CK Range valve actuators are supplied with temporary plastic

transit cable entry plugs. These are for short term use and if

the unit is likely to be stored for a period of time, these must

be replaced with metal plugs which have been sealed with

PTFE tape.

If the actuator has to be installed but cannot be cabled, it is

recommended that the plastic transit cable entry plugs are

replaced with metal plugs which are sealed with PTFE tape

until you are ready to connect the incoming cables.

The CK plug and socket assembly will preserve internal

electrical components perfectly if left undisturbed. Rotork

cannot accept responsibility for deterioration caused on-site

once the covers are removed. Every CK Range actuator is fully

tested before leaving the factory to give years of trouble free

operation, providing it is correctly commissioned, installed and

sealed. Technical documentation that is supplied with each

unit must be kept safe for future reference.

6

CK Range Safe Use and Installation Manual

Page 7

4 Actuator Identification

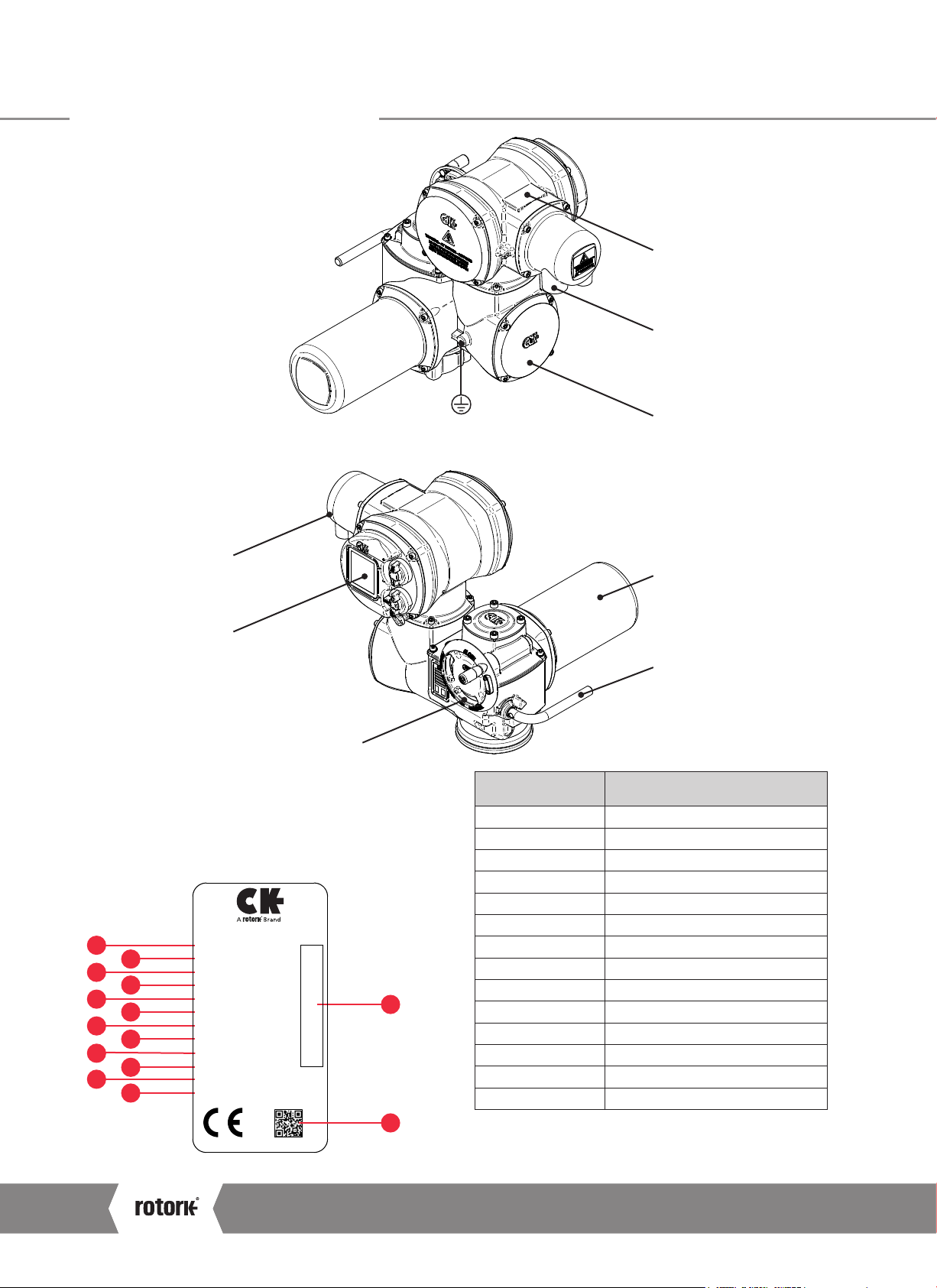

4.1 CK Standard

Hand Wheel

Conduit Entries

Switch Mechanism Cover

Protective Earth Connection

(M6x1p x 10 Deep)

Plug and socket housing

Motor

Name Plate

Electric Actuator Nameplate

The actuator name plate will enable you to identify your unit.

Example below:

www.rotork.com

2

4

6

8

13

14

10

15

12

11

Hand / Auto lever

Mark Description

1 Facility Address

2 Actuator Model

3 Serial Number

4 Maximum Torque

1

3

5

7

9

5 Minimum Torque

6 Output Speed (RPM)

7 Lubricant

8 Temperature Range

9 Manufacturing Date

10 Enclosure Rating

11 Unit Barcode (Factory Use)

12 QR Code

13 Flange Size

14 Maximum Unit Weight

15 Spare Line (Tag Information)

Keeping the World Flowing

7

Page 8

4 Actuator Identification

4.2 CKa Atronik

Atronik Name Plate

Conduit Entries

Protective Earth Connection

(M6x1p x 10 Deep)

Plug and socket housing

Atronik Interface

Hand Wheel

Atronik Module Nameplate

The Atronik name plate will enable you to identify your unit.

Example below:

13

Supplied and Tested by Rotork

1

2

3

4

5

6

7

8

9

Model

Serial nº

Power supply

Cust. supply

Bkp supply

P max. kW

Wiring diag.

Internal diag.

Temp. range

10

14

: ATRONIK

: S0000000102

: 3~380V/50Hz

: 24VDC/5W

: --

: 3,5

: K00000000

: D0000000

: -30ºC/+70ºC

: 06.2018Year

IP 68

Pol.Ind.110, 20100 (Spain)

11

12

Switch Mechanism Cover

Motor

Hand / Auto lever

Mark Description

1 Model

2 Serial Number

3 Power Supply

4 Customer Supply

5 Backup Supply

6 P max

7 Wiring Diagram

8 Internal Diagram

9 Temperature Range

10 Manufacturing Year

11 Serial No. Code Bar

12 QR Code

13 IP Degree

14 Address

8

CK Range Safe Use and Installation Manual

Page 9

4 Actuator Identification

4.3 CKc Centronik

Centronik Name Plate

Conduit Entries

Protective Earth Connection

(M6x1p x 10 Deep)

Plug and socket housing

Centronik Interface

Hand Wheel

Centronik Module Nameplate

The Centronik name plate will enable you to identify your unit.

Example below:

1

2

3

4

5

6

7

8

9

10

15

16

11

12

13

14

Switch Mechanism Cover

Motor

Hand / Auto lever

Mark Description

1 Model

2 Serial Number

3 Main Power Supply

4 Remote Control Supply

5 Internal Customer Supply

6 Backup Supply

7 Maximum Power Rating

8 Customer Wiring Diagram

9 Internal Unit Diagram

10 Temperature Range

11 Enclosure Rating

12 Manufacturing Date

13 Unit Barcode (Factory Use)

14 QR Code

15 Capacitor Value (1ph only)

16 Spare Line (Tag Information)

Keeping the World Flowing

9

Page 10

5 Preparing the Drive Bush

5.1 Drive Bush - Type A Coupling:

Please see Publication PUB111-001 for thrust/torque

allowances.

(Note: CK30/60 actuators may be fitted with a F07/FA07

flange adaptor, in which case this will need to be removed

before the below procedure is carried out).

Turn the actuator onto its side, removing the hex head screws

holding the thrust base (1) onto the actuator.

Remove the two M3 cap screws retaining the spigot ring (2)

Pull out the drive bush (3) complete with the bearing

assembly (4)

1

5

6

CAUTION: Failure to remove the bearing assembly

and the o-rings prior to machining may result in damage

to the bearing.

5.1.1 Disassembly of bearing assembly

Locate and remove the snap ring (5) using a suitable tool

Remove the split collar (6)

If fitted, remove the spacer ring (7)

Slide the bearing (4) off the drive bush (3)

Keep the bearing and the drive bush components clean.

The split collar keys (6) must be kept as a machined pair.

Machine the drive bush, after removing the o-rings, allowing

clearance for rising spindle applications.

5.1. 2 Reassembly of bearing assembly

Ensure the drive bush (3) is clean and free from swarf. Ensure

the o-rings are clean and greased (see Section 11 for typical

grease). Slide the bearing assembly (4) onto the drive bush (3)

and ensure that it is fitted down to the shoulder. Grease and

refit the split collar keys (6) and spacer ring (7) if fitted and

secure with the snap ring (5).

Grease and refit the drive bush bearing assembly into the

thrust base.

Refit the thrust base (1) ensuring that the drive dogs on the

bush align with the slots in the hollow center column and

secure with the hex head screws to the following torque

values: See Table A on page 13.

7

4

3

2

10

CK Range Safe Use and Installation Manual

Page 11

5 Preparing the Drive Bush

5.2 Drive Bush - Type B Coupling:

Please note: Type B couplings are NOT suitable for axial

loads/forces

5.2.1 Disassembly

Turn the actuator onto its side.

Type B3 and B4:

Using a suitable tool, remove the circlip (1) whilst pulling the

drive bush (2) out. The drive bush will detach from the centre

column, leaving circlip (3) behind.

Type B1:

This drive bush is supplied as an integral part of the actuator.

5.2.2 Reassembly

Refitting is the reverse of removal, ensuring that the drive

bush is greased and the bolts are tightened to the correct

torque. See Table A on page 13.

3

2

1

Keeping the World Flowing

11

Page 12

6 Mounting the Actuator

CAUTION: Do not lift the actuator/valve combination

via the actuator. Always lift the combination via the

valve. Each lift must be assessed on an individual basis.

WARNING: Always ensure that the actuator weight is

supported from the actuator body and not the Atronik or

Centronik control module.

WARNING: Ensure the actuator is fully supported

until full valve/gearbox engagement is achieved and the

actuator is secured onto the flange.

Ensure the valve is secure before fitting the actuator as the

combination may become unstable.

If it is necessary to lift the actuator using mechanical

equipment, certified slings should be used. Lifting and slinging

should always be carried out by competent trained personnel.

The actuator base dimensions/couplings conform to ISO 5210

or MSS SP - 102.

Actuator to valve fixing must confirm to material specification

ISO Class 12.9, yield strength 1,080 N/mm2.

6.1 Weights and Measures

Weight - kg (lbs)

CK Standard actuator being lifted in a sling.

Frame Size Gross

30/60 33 (73)

120 39.5 (87)

250/500 79 (174)

Note: Weight stated are the maximum possible within that

model range.

Oil Capacity

Frame Size Litres Pt-US

30/60 0.8 1.69

120 1 2.1

250/500 1.15 2.43

CK Atronik actuator being lifted in a sling.

12

CK Centronik actuator being lifted in a sling.

CK Range Safe Use and Installation Manual

Page 13

6 Mounting the Actuator

6.2 Mounting the Actuator - Rising Stem Valves

6.2.1 Fitting the actuator and base as a combined unit

- all sizes

Fit the machine drive bush as described in Section 5.1 into the

thrust base assembly.

Lower the actuator onto the thxreaded valve stem, engage

HAND operation and wind the handwheel in the open

direction to engage the drive bush onto the valve stem.

Continue winding the handwheel until the actuator is firmly

down on the valve flange. Continue winding for a further

two turns and secure with bolts, tightening down to the listed

torques - Table A.

6.2.2 Fitting thrust base to valve - all sizes

Fit the machine drive bush as described in Section 5.1 into the

thrust base assembly.

Remove the thrust base as described in Section 5.1 and place

it on the threaded valve spindle with the drive keys pointing

uppermost and turn the thrust base in the open direction to

engage it on the spindle. Continue turning until the thrust

base is on the valve flange but do not tighten at this stage.

Lower the actuator onto the thrust base and rotate the

complete actuator until the drive keys on the drive bush align

with the slots on the base of the center column. Continue to

turn the actuator until the fixings holes align with the thrust

base. Replace the base bolts and tighten to the required

torque - Table A.

Open the valve by two turns and secure the thrust base to the

valve flange and tighten to the required torque - Table A.

6.5 Actuator Sealing

Ensure that the sealing cap and o-ring assembly is securely fitted

to prevent moisture ingress into the centre column of the actuator.

For valves with rising spindles, a cover tube may be fitted.

Ensure that the o-ring is correctly fitted and that the cover

tube is secured with the supplied fasteners.

6.3 Mounting the Actuator - Non Rising Stem Valves - Top Mounted

Ensuring that that the drive bush fits the input shaft/key and

has adequate axial engagement then fit into the actuator as

described in Section 5.1/5.2

Engage HAND, offer up the actuator to the valve, turning

the handwheel to align the drive bush. Tighten the mounting

bolts to the required torque - Table A.

Note: When the thrust is being taken in the actuator, a

thrust nut must be fitted above the drive bush and securely

tightened.

6.4 Mounting the Actuator - Valve with Gearbox - Side Mounted

Follow the instructions in Section 6.3 as for top mounted

instructions, checking that the mounting flange is at right

angles to the shaft before installation.

Table A: Required Torque

Metric Tor que

Flange Fixing Nm lbf.f t

F07 M8 26 .1 19.3

F10 M10 51.6 38

F14 M16 219.8 162.1

Imperial Tor que

Flange Fixing Nm lbf.f t

FA07 5/16 24.3 17.9

FA10 3/8 42.3 31.2

FA14 5/8 205.3 151.4

Keeping the World Flowing

13

Page 14

7 Cable Connections

7.1 Terminal block layout

WARNING: Ensure all power supplies are isolated

before removing any covers.

Do NOT run the actuator to limits with incorrect phase

rotation.

Safety Instructions in Section 2 of this document must

be observed and only persons competent by virtue of

their training and experience should carry out electrical

connection.

For unit specific wiring, please refer to the provided

wiring diagram. These can also be downloaded from

www.rotork.com

WARNING: For units including an internal heater.

It is important to isolate the heater supply when heating

is not required.

Electric motor nameplate

The current, mains voltage and mains frequency must match

the data on the motor name plate

7

8

9

10

11

12

:

1

2

3

4

5

6

Mark Description

1 Motor QR Code

2 Enclosure Rating

3 Motor Insulation Class

4 Cos ф Power Factor

5 Duty Rating

6 Capacitor Value

7 Serial Number

8 Supply Voltage

9 Nominal Power

10 Nominal Current

11 Temperature Range

12 Unit Barcode (Factory Use)

14

CK Range Safe Use and Installation Manual

Page 15

7 Cable Connections 8 Operating Your Actuator

7.1 Terminal block layout contd.

A switch or circuit breaker must be included in the wiring

installation to the actuator. The switch or crcuit breaker must

meet the relevant requirements of IEC60947-1 and IEC60947-3

and be suitable for the application. The switch or circuit breaker

must not disconnect the protective earth conductor. The switch

or circuit breaker must be mounted as close to the actuator as

possible and shall be marked to indicate that it is the disconnect

device for that particular actuator.

WARNING: The actuator must be protected with

overcurrent protection devices, see relevant Motor

Performance data sheet.

CAUTION: Power supply cables must have sufficient

mechanical protection properties to meet installation

requirements and be screened to comply with EMC

requirements of the installed actuator. Suitable methods

include armoured and/or screened cables or cables

contained within conduit.

IP68 sealing protection can only be achieved by ensuring that

the correct cable glands are fitted and any remaining entries

are correctly sealed up.

7.2 Earth/Ground Connections

WARNING: Risk of Electric Shock - Do not operate

the actuator with the Protective Earth (PE) conductor

disconnected

The actuator is supplied with two earthing points. A 6 mm

diameter hole is tapped adjacent to the conduit entries on the

main casting for attachment of an external protective earthing

strap. An internal 6 mm earth connection is also provided

however it must not be used alone as the protective earth

connection.

7.3 Removing the plug and socket

Using a 5 mm Allen (Hex) key, loosen the four captive screws

evenly and remove the cover. Do not attempt to lever off the

cover as you may damage the o-ring seal.

8.1 Operating by Hand

CAUTION: Under no circumstances should any

additional lever device such as a wheel-key or wrench be

applied to the handwheel in order to develop more force

when closing or opening the valve as this may cause

damage to the valve and/or actuator or may cause the

valve to become stuck in the seated/backseated position.

Keep clear of the handwheel when engaging hand operation.

Actuators driving valves via extension shafts may be subject

to retained shaft torsion which can cause the handwheel to

rotate when hand operation is engaged.

To engage handwheel drive depress the Hand/Auto lever

into “Hand” position and turn the handwheel to engage

the clutch. The lever can now be released, it will return to its

original position. The handwheel will remain engaged until

the actuator is operated electrically when it will automatically

disengage and return to motor drive.

For local lockout purposes the Hand/Auto lever can be locked

in either position using a padlock with a 6.5 mm hasp.

Locking the lever in the "hand" position prevents electrical

movement.

8.2 Operating Electrically

CAUTION: Electrical operation is only permitted

once the actuator is fully commissioned to the valve.

Operating electrically before commissioning could result

in damage to the actuator and/or valve.

Electrical motor operation has priority over hand operation.

The motor drive will automatically re-engage after hand

operation has occurred unless the hand/auto lever is held in

theengagedposition.

Electrical operation is possible with external controls or using

the local controls included with the Atronik or Centronik

control module (if fitted).

7.4 Cable entry

The cable entries into the plug and socket are M20 x 1.5p,

M25 x 1.5p and M32 x 1.5p. Remove the plastic transit plugs

and make cable entries appropriate to the cable type and size.

Ensure that threaded adaptors, cable glands or conduit are

tight and fully waterproof. Seal unused cable entries with steel

or brass threaded plugs.

Ensure that the cables are of the appropriate rating for

the required duty and are fastened to the correct terminal.

Connection details can be found on the wiring diagram.

Cable Size: Power Terminals 1,2 and 3: Max 6 mm²

PE connection: Max 6 mm²

Control contacts: (4 - 50) Max 2.5 mm²

Keeping the World Flowing

15

Page 16

9 Commissioning

9.1 Atronik Interface

A Status Indication

B Open

C Close

D Remote

E Stop

F Local

A Open Limit

B Close Limit

C Intermediate Travel

D Fault Condition

B

C

A

D

E

F

A

B

C

D

16

CK Range Safe Use and Installation Manual

Page 17

9 Commissioning

OPEN LIM

DEMO

9.2 Centronik Interface

A IrCK Transmitter / Receiver

B Open

C Close

D Remote

E Stop

F Local

A Bluetooth® Connection

B Infrared Connection

C Configuration Mode

D Communication Feedback

E Valve Position

F Current Menu

G Sub Menu / Setting Value

B

A

C

D

E

F

CB

A

F

IrCK

SETTINGS

LIMITS

D

E

G

Keeping the World Flowing

17

Page 18

9 Commissioning

9.3 Centronik Navigation

The Centronik Control Module can be configured using two

different input methods. An optional Bluetooth Setting Tool

provides a handheld solution compatible with Infrared or optional

Bluetooth communication. Alternatively the local selector knobs

can be used to navigate in the same way. Be sure to read and

understand the equivalent input commands. Instructions included

in this manual are provided as shorthand symbols shown below.

9. 3.1 Local Selector input

9.3.2 Setting Tool Input

Navigate to previous item within

the current menu / decrease

value / toggle setting

Exit to previous menu /

exit setting change

18

Navigate to next item within the

current menu / increase value /

toggle setting

Enter menu / confirm selection /

edit setting / save setting value

CK Range Safe Use and Installation Manual

Page 19

9 Commissioning

9.4 Centronik Feedback

The Centronik display interface includes various features that

provide feedback to the operator. This ensures that changes

to the configuration of the actuator can be confirmed and

validated during the commissioning process.

9. 4 .1 Arrow Identification

During general menu navigation, each submenu/setting will

have a set of behaviour arrows associated with it. This lets the

operator know what can be achieved on the current screen.

Solid blocks on the setting indicate you are in viewing

mode.

Arrows on the setting/menu indicate navigation is

possible - both directions.

Current Value

Both Directions

This indicates you are presently at the first menu choice

or lowest setting value.

This indicates you are presently at the last menu choice

or highest setting value.

This indicates the setting is read only or only has one

possible value.

9.4.2 Confirmation Feedback

Whilst modifying settings or navigating through the various

Centronik interface menus, it is important to recognise that a

change has been accepted or saved.

A small confirmation dot will be shown in the top right corner

of the display if a valid input command has been recognised by

the Centronik interface.

For each movement, the confirmation dot will only

be shown once the Open/Close selector returns to the

default rest position.

First Menu

Last Menu

Read Only

CLOSELIM

DEMO

9.4.3 Torque/Limit Setting

Refer to valve manufacturer for recommended setting. In the

absence of valve manufacturer instruction refer to the table below.

Valve Type Close Action Open Action

Wedge Gate Tor qu e Limit

Globe Torqu e Limit

Butterfly Limit Limit

Through Conduit Limit Limit

Ball Limit Limit

Plug Limit Limit

Sluice Limit Limit

Penstock Limit Limit

Parallel Slide Limit Limit

Keeping the World Flowing

19

Page 20

9 Commissioning

9.5 Basic Mechanical Switch Mechanism Setting

9. 5 .1 Instructions

WARNING: Isolate all power to the actuator unless

explicitly instructed otherwise.

Remove the four M6 cap screws retaining the switch

mechanism cover.

Note: Consult wiring to determine specification of switches

fitted.

A 5mm Allen (Hex.) key and 0.8 x 4mm flat screwdriver are

required to perform commissioning of the CK Mechanical

Switch Mechanism.

CAUTION: For CK Standard and CKr actuators,

the required end of travel action (torque or position)

is determined by the set of switches cabled to the

controlling switch gear - refer to actuator terminal plan

and site field wiring.

CAUTION: For CKa, CKra, CKc and CKrc actuators,

the required end of travel action (torque or position) is

determined by settings detailed in Section 9.6.

A

B

C D

Set Torque Limits

A Indicator/Adjustment Point

B Torque Cam Clutch Screw

C Open Torque Adjustment Point

D Close Torque Adjustment Point

E Factory Calibration Fixings

CAUTION: Do not adjust the factory calibration

fixings or position of the yellow torque indicator plates.

These are factory configured and should not be removed

under anycircumstance.

1) Move the valve to a mid-travel position and loosen the

Torque Cam Clutch 1.5 turns using a flat screwdriver.

2) Adjust each Torque Cam to the desired value - between

min. (40%) & max. (100%) - by moving the cam using a

screwdriver on the adjustment point.

CAUTION: To avoid introducing an offset to the set

value when adjusting the torque trip limits. Ensure

the screwdriver remains perpendicular to the switch

mechanism faceplate.

3) Tighten the Torque Cam Clutch Screw once both torque

trip limits have been set.

CAUTION: Tighten the Torque Cam Clutch Screw until

the spring washer is fully deformed under the screw

head.

E

Torque cam clutch screw adjustment.

Close torque setting adjustment.

20

CK Range Safe Use and Installation Manual

Page 21

DEMO

9 Commissioning

9.5.2 Set Position Limits

F OLS Indicator Window

G OLS Adjustment Screw

H Drive Clutch Shaft

I CLS Indicator Window

J CLS Adjustment Screw

F

G

I

CAUTION: The main power supply must be

maintained during the commissioning process for CKa,

CKra, CKc and CKrcactuators.

1) Move the actuator to the valve CLOSED position using the

handwheel.

2) Using a flat screwdriver, depress the Drive Clutch Shaft

and rotate to the “Set” position as shown on the switch

mechanism faceplate.

3) The CLS Adjustment Screw must now be rotated

to engage the closed limit switch inside the switch

mechanism. The CLS Indicator Window will show one of

four possible symbols. Refer to Figure 1 on page 22.

4) Depending on where the mechanism is in the cycle,

it is possible that the switch will be approached from

the wrong direction, in this case it is necessary to move

through the limit and approach it from the correct

direction. This avoids the need to wind through the

whole mechanism to reach the limit position. The correct

direction to approach the limit is shown by the arrow next

to the Adjustment Screw input.

5) It is necessary to confirm the switch has engaged correctly.

a. For CK Standard or CKR units, measure across the

appropriate terminals using a continuity meter –

12 and 13

indication feedback.

b. For CKA or CKRA units fitted with an Atronik control

module, confirm the closed limit status indicator

isilluminated.

c. For CKC or CKRC units fitted with a Centronik control

Module, confirm the position display shows the closed

limit symbol.

6) Using a flat screwdriver, depress the Drive Clutch Shaft

and rotate to the “Run” position as shown on the switch

mechanism faceplate.

7) Rotate the CLS and OLS Adjustment Screws a small

amount in both directions to re-engage the mechanism

drive. A click will be heard as the drive drops back into

engagement and the adjustment screws will no longer

move in either direction.

CAUTION: This must be done or the limit will be lost

when the actuator is moved.

for motor control and 14 and 15 for

J

H

CLSOLS

Atronik close limit indication.

CLOSELIM

Centronik close limit indication.

Keeping the World Flowing

21

Page 22

9 Commissioning

8) Move the actuator to the valve OPEN position using the

handwheel.

9) Using a flat screwdriver, depress the Drive Clutch Shaft

and rotate to the “Set” position as shown on the switch

mechanism faceplate.

10) The OLS Adjustment Screw must now be rotated to engage

the open limit switch inside the switch mechanism. The OLS

Indicator Window will show one of four possible symbols.

Please refer to Figure 1 below for direction input.

11) Depending on where the mechanism is in the cycle, it is

possible that the switch will be approached from the wrong

direction, in this case it is necessary to move through the limit

and approach it from the correct direction. This avoids the

need to wind through the whole mechanism to reach the

limit position. The correct direction to approach the limit is

shown by the arrow next to the Adjustment Screw input.

12) It is necessary to confirm the switch has engaged correctly.

a. For CK Standard or CKR units, measure across the

appropriate terminals using a continuity meter - 16 and 17

for motor control and 18 and 19 for indication feedback.

b.

For CKa or CKra units fitted with an Atronik control module,

confirm the open limit status indicator is illuminated.

c.

For CKc or CKrc units fitted with a Centronik control module,

confirm the position display shows the open limit symbol.

13) Using a flat screwdriver, depress the Drive Clutch Shaft

and rotate to the “Run” position as shown on the switch

mechanism faceplate.

14) Rotate the OLS and CLS Adjustment Screws a small amount

in both directions to re-engage the mechanism drive. A click

will be heard as the drive drops back into engagement and

the adjustment screws will no longer move in either direction.

CAUTION: This must be done or the limit will be lost

when the actuator is moved.

CLSOLS

Atronik open limit indication.

OPEN LIM

DEMO

Centronik open limit indication.

CLSOLS CLSOLS

Rotate the OLS/CLS Adjustment Shaft Clockwise. Rotate the OLS/CLS Adjustment Shaft Anti-Clockwise.

CLSOLS CLSOLS

Rotate the OLS/CLS Adjustment Shaft in the direction shown

next to the shaft input.

Figure 1.

22

CK Range Safe Use and Installation Manual

The limit switching point is near or made.

Page 23

9 Commissioning

9.6 End of Travel Action

9. 6 .1 Atronik

For CKa or CKra actuators, the required end of travel action

(torque or position) is determined by 'OPEN ACTION' and

'CLOSE ACTION' DIP switch settings as shown below.

9.6.2 DIP switch functions

Label Function OFF ON

ESD FUNCTION A

ESD FUNCTION B

ESD NC/NO ESD Contact Form

PTR LOCAL Local Control Local control is push-to-run Local control is maintained

CLOSE DIRECTION Direction Clockwise to close Anti-clockwise to close

PRIORITY A

PRIORITY B

OPEN ACTION Open Action Stop on position limit Stop on torque limit

CLOSE ACTION Close Action Stop on position limit Stop on torque limit

LED LED

STD/OPT CONTROL Control Source Hardwired control only Option control only

POWER Power 3-phase power supply 1-phase power supply

RE L AY A

RE L AY B

RE L AY C

ESD Action

2-Wire Priority

Relay Conditions

A OFF and B OFF = Disabled

A ON and B OFF = Open

ESD active when signal applied

(normally open)

A OFF and B OFF = Close Priority

A ON and B OFF = No Priority

Green = Close

Red = Open

Relay settings are determine by a combination of A, B and C.

Refer to PUB111-110 for relay setting information.

A ON and B ON = Stay put

A OFF and B ON = Close

ESD active when signal removed

(normally closed)

A ON and B ON = Open Priority

A OFF and B ON = No Priority

Red = Close

Green = Open

SERVICE Service For Rotork Service use only. Do not adjust switch position.

Keeping the World Flowing

23

Page 24

9 Commissioning

9.6.3 Centronik

For CKc or CKrc actuators fitted with a Mechanical Switch

Mechanism, the required end of travel action (torque or

position) is determined by the [ACTION] setting within the

Centronik configuration. All other limit functions will not be

available as they need to be intrusively set on the mechanism.

USER X

MAIN.MENU LANGUAGE

SETTINGS LIMITS

CLOSE.SET ACTION

Password

Entry Process

Main menu Language

Settings Limit settings

OPEN.SETT. ACTION

Close settings

Open settings

Stop on Position

or Torque

Stop on Position

or Torque

24

CK Range Safe Use and Installation Manual

Page 25

9 Commissioning

9.7 Digital Switch Mechanism Setting

9. 7.1 Entering Configuration mode

Access to configuration mode will vary depending on the

navigation method employed. To access configuration mode

with the local selector, ensure the actuator is in Stop mode and

input the following sequence:

Each command input must be completed within one

second of the last and the selector knob must return to

its default rest position between each input.

To access configuration mode with the Bluetooth Setting Tool,

ensure the actuator is in Stop mode and point the setting tool

directly at the IrCK LED.

PASSWORD

ROTORKOO

Press

be shown when an input from the Bluetooth Setting Tool is

registered by the Centronik Control Module.

If the optional Bluetooth module is fitted, the Setting Tool will

begin communication through IrCK until a secure Bluetooth

link has been established. To confirm a Bluetooth connection

has been successful, the top left symbol on the Centronik

display will change from IrCK to

Tool button will illuminate solid blue.

For IrCK communication, the Bluetooth Setting Tool must

be aligned to the IrCK LED at all times.

9. 7. 2 Entering the User Password

The password entry screen will be displayed with the default

password visible. Press

on changing the user password, refer to PUB111-005.

Blank spaces will fill with

Once a valid password has been entered the display will show

the current active permission level with a symbol and text.

Press

to initiate communication. The IrCK symbol will

and the Bluetooth Setting

to confirm this entry or use

to return to the main menu.

to enter a different password. For instruction

whilst modifying the password text.

PASSWORD

USER x

Actuator settings cannot be modified in Remote.

The symbol shown to the left side of the display will reference

the following permission levels:

User level permission to provide basic access to settings

for commissioning and configuration purposes.

Super User level permission to provide access to more

advanced setting features.

Service level permission for engineer access only.

Keeping the World Flowing

25

Page 26

9 Commissioning

9. 7. 3 Menu Navigation

The menu map below provides direction for the basic setting

and commissioning of a CKc or CKrc actuator equipped with a

Digital Switch Mechanism and Centronik Control Module.

USER X

MAIN.MENU LANGUAGE

SETTINGS LIMITS

CLOSE.SET DIRECTION ACTION SEAT.TORQ SET.LIMIT.

OPEN.SETT. ACTION SEAT.TORQ. SET.LIMIT. TURNS

Password

Entry Process

Main menu Language

Settings Limit settings

TRQ.LIM.BP. OPENING OP.BP.POSI. CLOSING CL.BP.POSI.

Close settings

Open settings

Torque

Limit Bypass

Direction

to close

Stop on Position

or Torque

Enable in the

Open Direction

Stop on Position

or Torque

Torque

Limit Value

Opening Bypass

Position Value

Torque Limit

Value

Set End of

Travel Position

Enable in the

Close Direction

Set End of

Travel Position

Total

Travel Turns

Closing Bypass

Position Value

26

CK Range Safe Use and Installation Manual

Page 27

9 Commissioning

Main Menu > Settings > Limits

The Limits menu details all of the appropriate settings to

control the conditions for stopping actuator movement.

Use the menu map on the previous page to follow the menu

structure through to the [LIMITS] sub menu

Limits > Close Settings [CLOSE.SET.]

Direction to Close [DIRECTIO.]

Press to edit, select preferred option using and

clockwise or anti-clockwise operation and press to save

selection.

Action [ACTION]

Press to edit, select preferred option using and

Seat Limit or Seat Torque and press to save selection.

Seating Torque [SE AT.TORQ.]

Press to edit, adjust shown value using and

press to confirm selection (40% - 100%).

CAUTION:

torque limit protection through full valve travel.

The Seating Torque value is used as

.

for

for

and

Limits > Open Settings [OPEN.SETT.]

Action [ACTION]

Press to edit, select preferred option using and

Seat Limit or Seat Torque and press to save selection.

Seating Torque [SE AT.TORQ.]

Press to edit, adjust shown value using and

press to confirm (40% - 100%).

CAUTION:

torque limit protection through full valve travel.

Turns [TURNS]

This setting will show the number of output turns configured

for actuator / valve travel between the open and closed limit

positions. This is a read only function to validate total valve

travel.

Setting the Open Position Limit [SET.LIMI T.]

Move the actuator to the fully open position. Allow for overrun

by winding the manual override handwheel in the close

direction by five turns (10 turns for CK500).

Press to edit.

The Seating Torque value is used as

and

for

Setting the Close Position Limit [SET. LIMI T.]

Move the actuator to the fully closed position . Allow for

overrun by winding the manual override handwheel in the

open direction by five turns (10 turns for CK500).

Press to edit.

[SURE??] will show on the display, press to confirm.

Once these steps are complete, the Centronik display position

should replicate the image below.

CLOSELIM

DEMO

[SURE??] will show on the display, press to confirm.

Once these steps are complete, the Centronik display position

should replicate the image below.

OPEN LIM

DEMO

Keeping the World Flowing

27

Page 28

9 Commissioning

Limits > Torque Limit Bypass [TRQ.LIM.B.P.]

Occasionally applications will require a break to open or break

to close torque that exceeds the standard torque limit. Setting

the torque limit bypass will ignore existing torque limit settings

and apply maximum torque (up to approximately 150% or

rated) across a predetermined portion of travel.

CAUTION: The valvemaker / integrator should be

consulted to confirm the valve structure and

interface components can withstand the additional

torque/thrust

Torque Limit Bypass

The [OPENING] and [CLOSING] settings will enable torque

limit bypass for the relevant direction of travel, use

to enter the setting sub menu.

Press to edit, select [ON] or [OFF] and press to save

selection.

Torque Limit Bypass Position

The [OP.BP.POSI.] value dictates the travel away from the

closed position limit that the torque limit will be bypassed in

the open direction.

.

and

10 Maintenance, Monitoring

and Troubleshooting

Routine Maintenance should include the following :

• Check actuator to valve fixing bolts for tightness

• Ensure valve stems and drive nuts are clean and

properly lubricated

• If the motorised valve is rarely operated, a schedule

of operation should be set up

• Check the actuator for damage, loose or missing fixings

• Ensure that there is not an excessive build up of dust or

contaminate on the actuator

Press to edit, adjust shown value using and

press to save selection. E.g. setting at 5% will bypass the

torque limit between 0% and 5%.

The [CL.BP.POSI.] value dictates the travel away from the

open position limit that the torque limit will be bypassed in the

close direction.

Press to edit, adjust shown value using and

press to save selection. E.g. setting at 95% will bypass the

torque limit between 95% and 100%.

and

and

9.8 Secondary Function Setting

CK Range actuators can be provided with optional add-ons

that provide extra functionality. For instruction on setting

secondary functions, please refer to the following documents

which are available on www.rotork.com

CK Standard and

CKa and CKra - refer to PUB111-110

CKc and CKrc - refer to PUB111-004

CKr - refer to PUB111-003

28

CK Range Safe Use and Installation Manual

Page 29

12 Environmental11 Disposal / Recycling

User advice on disposal of your product at the end of its

life. Please see table below. In all cases check local authority

regulation before disposal.

Oil:

Unless specially ordered for extreme climatic conditions,

Standard CK actuators are suitable for applications where

vibration and shock severity does not exceed the following:

Plant Induced Vibration: 1g rms total for all vibration

within the frequency range of

10 to 1000 Hz

actuators are dispatched with gearcases filled with SAE 80EP oil

suitable for ambient temperatures ranging from -22 to 160 °F

(-30 to 70 °C).

Base assembly:

O-rings grease: Multis EP2 / Lithoshield EP2 or equivalent for

Shock: 5g peak acceleration

Watertight: IP68 EN 60529

(8 metres for 96 hours)

Temperature: -30 to +70 °C (-22 to +158 °F)

all temperature ranges.

The actuator can be removed by reversing the operations

detailed in the mounting and cabling sections. All warnings as

detailed in the mounting and cable connection sections must

be followed. Disposal of the actuator or any of its components

should be done in accordance with the table below.

WARNING: It is essential that the actuator is not

subject to any valve / system loads at the time of removal

as this could cause operator injury due to the actuator

moving unexpectedly.

Subject Definition Remarks / examples Hazardous Recyclable

EU Waste

Code

Disposal

Electrical &

Electronic

Metals

Plastics

Oil /Grease

Rubber Seals & O-rings Cover and shaft sealing Yes No 16 01 99

Printed circuit boards All products Yes Yes 20 01 35

Wire All products Yes Yes 17 04 10

Aluminium Gearcases and covers No Ye s 17 04 02

Copper/Brass Wire, gears, motor windings No Yes 17 04 01

Zinc

Iron/Steel Gears and bases No Yes 17 04 05

Mixed Metals CK motor rotors No Yes 17 04 07

Glass filled nylon Electronics chassis No No 17 02 04

Unfilled Gears, window, blanking plug No Ye s 17 02 03 Use specialist recyclers

Mineral

Food Grade

Grease Handwheel Yes No 13 02 08

CK clutch ring and associated

components

Gearbox lubrication Yes Yes

Gearbox lubrication Yes Yes

No Yes 17 04 04

13 02 04

13 02 08

Use specialist recyclers

Use licensed recyclers

Disposal as general

commercial waste

Will require special treatment

before disposal, use specialist

recyclers or waste disposal

companies

May require special treatment

before disposal, use specialist

waste disposal companies

Keeping the World Flowing

29

Page 30

13 Components of The Modular CK Actuator Design

1 Atronik module

The Atronik control module provides the user with

simple, robust valve control and clear valve status

indication

1a LED status indication display plus non-intrusive

local controls

1b Plug and Socket connection

1c Double-sealing water and dust ingress protection

2 Centronik module

The Centronik control module provides the user with

comprehensive intelligent valve control, detailed data

logging and asset management

2a

Multilingual display plus non-intrusive local controls

2b Plug and Socket connection

2c Double-sealing water and dust ingress protection

2d Up to two extra option cards

Module Compatibility Chart

Symbol Actuator

CK & CKr - no control module

CKa & CKra - Atronik control module

CKc & CKrc - Centronik control module

3 Standardised motor module

Motor modules utilise the same connection method

across all speeds for each size CK

4 Manual handwheel

Independent manual override for emergency operation

5 Double-sealing water and dust ingress protection

Proven double sealing arrangement to maintain IP68

(8m for 96 hours) protection

6 Mechanical switch mechanism (MSM)

Cam engaged position and torque switches with

reduction gearing for extended travel

7 Digital switch mechanism (DSM)

Absolute encoder device for fully digital position and

torque measurement

8 Additional Indication Drive

Increases functionality beyond the switch mechanism to

include local position indication, intermediate switches,

potentiometer or loop powered 4-20 mA CPT

9 Local indication cover

Rotate through 360º in 90º increments to suit

installation in any orientation

10 Detachable thrust bases

Separate the base from the actuator for faster

maintenance

11 Rotork Bluetooth® Setting Tool Pro

View, adjust and extract data from Centronik control

modules

30

CK Range Safe Use and Installation Manual

Page 31

1

2

1b

1c

Modular Actuator Design

1a

2b

2c

3

5

2d

2a

4

6

8

9

7

10

11

Keeping the World Flowing

31

Page 32

www.rotork.com

A full listing of our worldwide sales and

service network is available on our website.

Rotork plc

Brassmill Lane, Bath, UK

tel +44 (0)1225 733200

fax +44 (0)1225 333467

email mail@rotork.com

PUB111-007-00

Issue 05/19

Rotork is a corporate

member of the Institute

of Asset Management

As part of a process of on-going product development, Rotork reserves the right to amend and change

specifications without prior notice. Published data may be subject to change. For the very latest version

release, visit our website at www.rotork.com

The name Rotork is a registered trademark. Rotork recognises all registered trademarks. Published and

produced in the UK by Rotork. POWJB0 419

Loading...

Loading...