Page 1

PUB033-005-00_0219

MANUAL

FOR

INSTALLATION

AND

OPERATING

For gearbox models AB, 242, and 232

Page 2

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

2

Table of contents

1 PREFACE .................................................................................................................................................... 3

1.1 Introduction 3

2 TECHNICAL DATA SPECIFICATIONS .................................................................................................. 3

2.1 Maximum allowable input- and output torque 3

3 HANDLING AND SAFETY PRECAUTIONS .......................................................................................... 4

3.1 Qualification of staff 4

3.2 Commissioning 4

3.3 Operation 4

3.4 Protective measures 4

3.5 Maintenance 4

3.6 Storage 5

3.7 Long-term storage 5

3.8 Packing 5

3.9 Handling 5

3.10 IP rating and environmental conditions 5

3.11 Stem shaft water ingress 5

3.12 Paint 6

3.13 Primer 6

3.14 Seals 6

3.15 Grease 6

3.16 Gearboxes for – 60°C operation 6

3.17 Correct use 6

3.18 Installation and operating 6

3.19 Disposal 7

3.20 Identification 7

3.21 Orientation options of gearboxes. 7

3.22 Keyway and drive positions 7

4 INSTALLATION: MOUNTING TO THE VALVE ................................................................................... 8

4.1 Mounting instructions chainwheel 8

4.2 Adjustment of set screws 11

4.3 Operating instruction 12

4.4 Number of turns opening or closing 13

4.5 Handwheel type 14

STANDARD CONDITIONS .............................................................................................................................. 15

5 IP RATING................................................................................................................................................ 17

5.1 Solid Particle protection 17

5.2 Liquid ingress protection 17

6 CERTIFICATES ....................................................................................................................................... 18

6.1 Atex 18

6.2 Certificates of conformity 18

6.3 Other certificates 18

6.4 Reach 19

Page 3

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

3

1 PREFACE

1.1 Introduction

The gearbox of the AB, 232, and 242 series is a quarter turn gearbox designed to use for the manual operation

of valves (e.g. butterfly/ball valves) in pipelines.

NB. This manual is valid only for the standard AB, 232 and 242 series gearboxes of Rotork. For special

versions, specifications and model can differ. Rotork is not responsible for any damage caused by incorrect use

of the gearbox.

2 TECHNICAL DATA SPECIFICATIONS

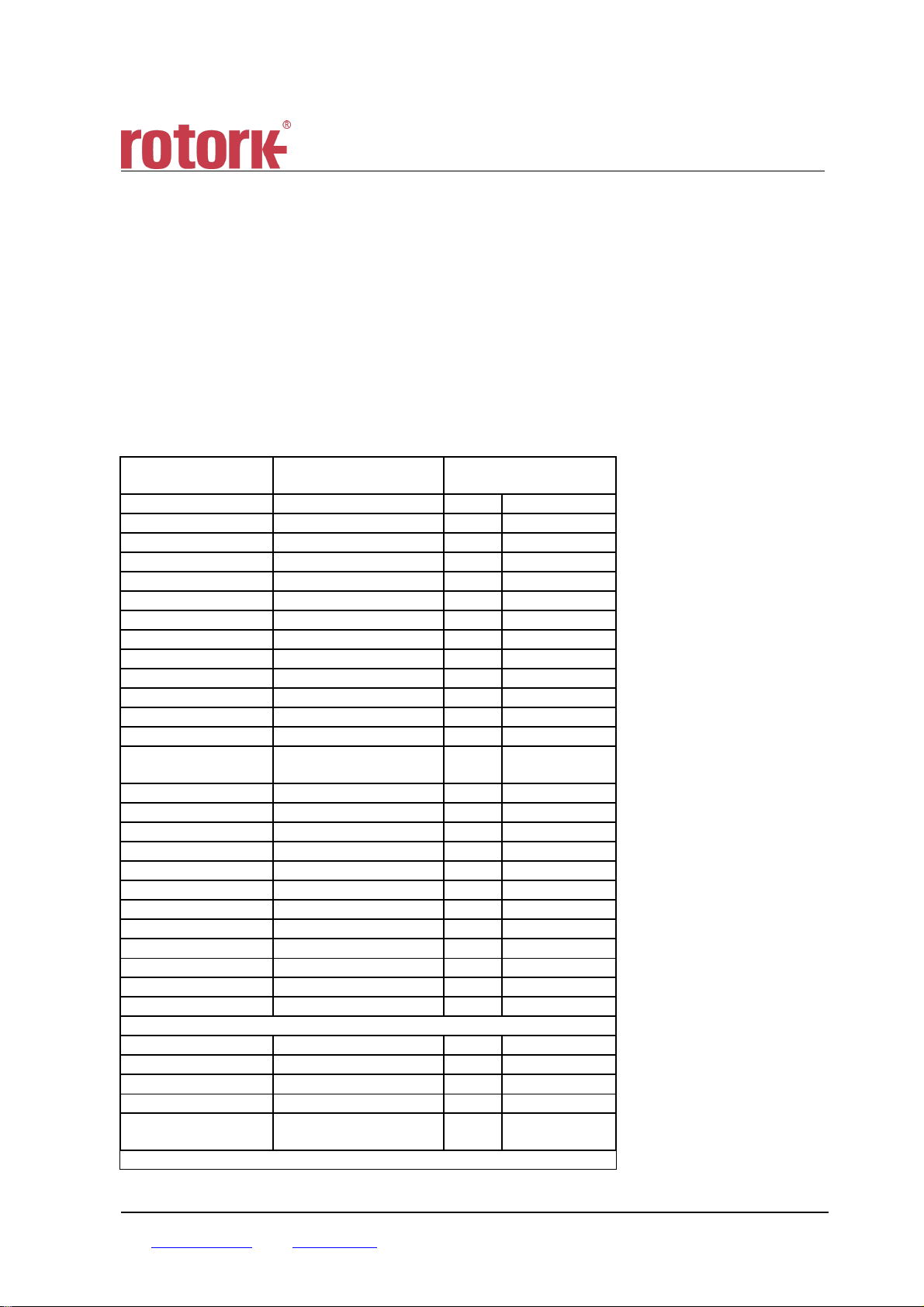

2.1 Maximum allowable input- and output torque

Gearbox

Connection Valve

Max. Manual operating

Torque in [Nm]

type

ISO 5211/1

Input

Output

AB 150

F05-F07

16

150

AB 210(LB)

F05-F07-F10(-F12)

28.5

330

AB 215 (LB)

F05-F07-F10(-F12)

43

500

AB 550 (LB)

F07-F10-F12-F14(-F16)

83

1000

AB 880 (LB)

F10-F12-F14-F16

152

2000

AB 1250 (LB)

F10-F12-F14-F16(-F25)

171

3250

AB 1950(LB)

F12-F14-F16-F25(-F30)

289

5500

AB 1950(LB) HR

F12-F14-F16-F25(-F30)

159

4500

AB 1950(LB)/SP4

F12-F14-F16-F25(-F30)

125

6800

AB 1950(LB/PR4)

F12-F14-F16-F25(-F30)

106

7000

AB2000 (LB)

F12-F14-F16-(F25)

136

4500

AB 3000(LB)

F16-F25(-F30)

305

7000

AB 3000(LB/PR4)

AB 3000(LB/PR6)

F16-F25(-F30)

F16-F25(-F30)

111

104

9000

11000

AB 6800(LB)

F16-F25-F30(-F35)

305

8400

AB 6800(LB)LT/SP4

F16-F25-F30(-F35)

96

9000

AB 6800(LB)/SP4

F16-F25-F30(-F35)

134

12500

AB 6800(LB)/PR4

F16-F25-F30(-F35)

130

12500

AB 6800(LB)/SP6

F16-F25-F30(-F35)

121

17000

AB 6800(LB)/PR6

F16-F25-F30(-F35)

121

17000

AB 6800(LB)/SP9

F16-F25-F30(-F35)

92

17000

A 200/SP9

F25-F30-F35

166

26000

A 200/PR10

F25-F30-F35

124

26000

A 250LT/SP9

F25-F30-F35-F40

116

26000

A 250/SP9

F25-F30-F35-F40

142

32000

A 250/PR10

F25-F30-F35-F40

142

32000

242-10

F05-F07

15

150

242-20

F07-F10-F12

30

300

242-30

F07-F10-F12-F14

65

650

242-40

F10-F12-F14-F16

120

1200

242-50LT

F14-F16-F25

F14-F16-F25

120

140

1800

2100

Page 4

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

4

232-05O

F05-F07

13

125

232-05N

F05-F07

12,5

125

232-06

F05-F07

25

250

232-07

F05-F07

21

250

232-08

F07-F10

41,7

500

232-10

F07-F10-F12

39

500

232-11

F10-F12

75

900

232-12

F10-F12-F14

100

1000

232-13

F10-F12-F14

83

1000

232-14

F10-F12-F14

125

1500

232-15

*per application

125

1500

Table 1 : Connection data of the gearbox

For more specified information, you can contact our sales department.

3 HANDLING AND SAFETY PRECAUTIONS

Be sure to read and understand this manual before installation and use of our gearboxes. All personnel working

with this gearbox must be familiar with the instructions in this manual and observe the instructions given.

Safety instructions must be observed to avoid personal injury or property damage.

3.1 Qualification of staff

Assembly, commissioning, operation, and maintenance must be carried out exclusively by suitably qualified

personnel authorised by the end user or contractor. Prior to working on this product, the staff must have

thoroughly read and understood these instructions and, furthermore, know and observe officially recognised

rules regarding occupational health and safety. Work performed in explosive atmospheres is subject to special

regulations which have to be observed. The end user or contractor is responsible for respect and control of

these regulations, standards, and laws.

3.2 Commissioning

Prior to commissioning, it is important to check that all settings are in compliance with the requirements of the

application. Incorrect settings might present a danger to the application, e.g. cause damage to the valve or the

installation. The manufacturer will not be held liable for any consequential damage. Such risk lies entirely with

the user.

3.3 Operation

Prerequisites for safe and smooth operation:

• Correct transport, proper storage, mounting and installation, as well as careful commissioning.

• Only operate the gearbox if it is in perfect condition while observing these instructions.

• Immediately notify Rotork about any faults and damage and allow for corrective measures.

• Observe recognised rules for occupational health and safety. Observe the national regulations.

3.4 Protective measures

The end user or the contractor is responsible for implementing the required protective measures on site, such as

enclosures, barriers or personal safety equipment for the staff.

3.5 Maintenance

To ensure reliable gearbox operation, the maintenance instructions included in this manual must be observed.

Any gearbox modification requires the consent of the manufacturer. A Rotork gearbox requires only little

maintenance. To ensure that the gearbox is always ready to operate, we recommend for gearboxes the

following measures. Three (3) months after commissioning and each year:

Page 5

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

5

- Check the bolts on top of the gearbox;

- Check the bolts on the valve flange;

- Perform a test run every six months;

- Check the gearbox for leakage of grease;

- For gearboxes with permanently vibration and exposure above 60ºC, checks should be performed at

shorter intervals.

3.6 Storage

The gearboxes need to be stored inside in a safe way to avoid accidents. Also avoid storage in areas subjected

to high temperature extremes and /or areas subjected to large amounts of humidity and dust. Protect against

floor dampness by storage on a shelf or on a wooden pallet. Apply suitable corrosion protection agent to bare

surfaces.

3.7 Long-term storage

If the Gearbox must be stored for a long period (more than 6 months) the following points must be observed.

Prior to storage:

• Protect uncoated surfaces, in particular the output drive parts and mounting surface, with long-term

corrosion protection agent.

At an interval of approximately 6 months:

• Check for corrosion. If first signs of corrosion show, apply new corrosion protection.

3.8 Packing

Our products are protected and packed by special packaging for the transport ex works. The packaging consists

of environmentally friendly materials which can easily be separated and recycled. We use the following

packaging material: wood, cardboard, paper, and PE foil. For the disposal of the packaging material, we

recommend recycling and collection centres.

3.9 Handling

Never drop the gearbox or otherwise subject it to strong impact. Standard gearboxes are delivered without

eyebolts. On request assembled eyebolts are available for the AB gearboxes these need to be ordered in the

preliminary stages of the order. Eyebolts should only be used to lift the gearbox horizontal on the valve. The

input shaft or hand wheel cannot be used for lifting the gearbox. Do not lift the gearbox when it is assembled to

the valve with eyebolts, input shaft or handwheel.

3.10 IP rating and environmental conditions

The enclosure protection IP65, 67 and 68 only refers to the interior of the gearboxes and not to the stem shaft

coupling compartment. (See table. 6 - IP rating)

Suitability for any specific application is not claimed. IP rating is done in accordance to a standard test

protocol. It is recommended that users carry out tailor made tests to prove the product is fit for purpose for the

specific environmental conditions. For example marine environment, tropical conditions, cold or very hot

conditions, chemical sites with acids or salty conditions requires the end user to assess the fit for purpose.

When the product is used in areas with high temperature fluctuations it is recommended to use pressure

compensators to prevent pressure differences between the outside environment and the interior of the gearbox.

3.11 Stem shaft water ingress

Water can enter into the coupling compartment along the valve shaft, this would lead to corrosion. Therefore a

suitable anticorrosive (or sticky grease) must be applied on the inside bore hole of the gearbox and coupling

before mounting. When water ingress protection towards the stem shaft and rotating quadrant in the coverplate

is required, aluminium position indicators with NBR O-ring is needed, which should be mentioned during

order process. Our G and W gearbox type are suitable. A condition that can occur in some areas is snow on top

of the gearbox with melting water on top of the gearbox, in that case the position indicator with O-ring is

recommended. For horizontal outdoor installation also a sealed aluminium position indicator is recommended.

For gas applications with sealed position indicators an air vent in the indicator could be required. In case of

permanent submersion of the gearboxes or for buried service, a protection cover must be fitted instead of a

Page 6

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

6

position indicator and should be mentioned in the order. Exchange of the position indicator for the protection

cover is possible.

3.12 Paint

We deliver our gearboxes in different RAL colours, our standard average paint thickness is 60 microns for AB

and 242 gearboxes and 40 microns for the 232 gearboxes, suitable for installation in a clean and dry industrial

indoor environment. Our process consists of a phosphating pre-treatment followed by our standard DTM

(direct to metal) paint system (Polyaspartic) or primer paint. Other paint systems are on customer request. For

submersed, marine conditions, use for buried service or exposed to corrosive outside environment and other

non-standard environments, paint system are to be advised by the customer including IP rating. On request we

can deliver paint systems and thicknesses (see table 4 standard conditions and options)

3.13 Primer

On request we deliver gearboxes in primer. Standard primer is a 1K industry primer which has a maximal

lifetime of 1, 5 month and must be stored only in indoor, clean and dry conditions. On request zinc primer can

be supplied which has a maximal lifetime of 3 months when free from zinc salts and free from contamination

and stored in a clean exterior. In industrial or marine conditions this should be reduced to the practical

minimum.

3.14 Seals

Rotork is using a silicone low volatile liquid seal between cover lid and body. Loosening the top bolts of the

cover plate from the gearbox can break the seal resulting to leakage. Rotork will not be held liable when the

top bolts are opened without notification. Once opened a new liquid sealing must be applied. Liquid seals kits

may be obtained from Rotork. During the order process it should be mentioned when gearboxes are exposed to

high- or low temperatures. Seals made of elastomeric materials are subject to ageing. All NBR seals subject to

rotating parts are lubricated with MI-setral 9-M. Gearboxes up to minus 60 degrees Celsius are built with

special O-rings and an aluminium indicator will be used to prevent water increase into the bore of the gearbox.

3.15 Grease

Rotork is applying grease that is non-self-igniting and do not present an explosion hazard. Dependent on the

environmental conditions different greases can be used such as high temperature grease, silicone free grease,

foodgrade grease or oxygen free grease. Gearboxes for minus 60 degrees Celsius are built with 75% filling

level of grease. Gearboxes are filled for life but on customer request grease nipples are an option to be

mentioned during order process.

3.16 Gearboxes for – 60°C operation

Gearboxes for – 60°C have special O-rings and seals. The AB range has a position indicator with O-ring and

have special closed stainless nuts on the stud bolts with a copper ring and an additional O-ring around the input

shaft. Gearboxes are filled for life with 75% grease. Up to AB1250 the housing is made of cast iron and tested

up to minus 60 degrees Celsius. On request ductile iron is available. For the AB1950 up to the A250 we supply

ductile iron housing for – 60°C as standard. On request the gearboxes will be supplied with stainless steel

name plate.

3.17 Correct use

Prior to installation, be sure the gearbox will NOT be overloaded during normal use. For this, verify that valve

size and required opening torque do not exceed the values given for the gearbox. For the maximum allowable

torque on the gearbox, (see table 1). AB, 232 and 242 gearboxes can only be used for manual operation.

3.18 Installation and operating

Not observing the rules as stated in this manual, can lead to damage and/or personal injuries. Qualified

personnel must be fully aware of the instructions as described in this manual. Only when the instructions are

observed, correct operation of the gearboxes can be guaranteed.

Page 7

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

7

3.19 Disposal

Never dispose a gearbox at a general disposal site/depot. The gearbox has to be offered to a disposal depot for

recycling. The iron parts can be used for recycling. The seals are of nitrile and can be used for plastic

recycling. The grease may not be discharged to sewer- or surface water. It has to be disposed according to local

regulations.

3.20 Identification

Each gearbox has a nameplate. On this nameplate you find the following standard information:

• Model type – Rotork order.no with line.no – Production date and other customer information, when

required.

N.B. Information on the name plate is important and is required in case of non-conformities or requests. In case

of non-conformity, please send a description of the complaint, details from the nameplate with clear

photograph(s) to sales.gearsbv@rotork.com.

3.21 Orientation options of gearboxes.

To determine whether a gearbox is left or right handed, the gearbox is observed from above (top view) with set

screws pointing downwards. The shaft is than at the top either pointing to the left (left handed gearbox) or to

the right (right handed gearbox).

Standard we deliver our gearboxes in A2 orientation. Other options are available (see Figure 1).

A1 = LH input shaft – anticlockwise in, clockwise out. A2 = LH input shaft – clockwise in, clockwise

out.

B1 = RH input shaft – clockwise in, clockwise out. B2 = RH input shaft – Anticlockwise in,

Clockwise out.

Figure 1: Orientation of gearboxes

3.22 Keyway and drive positions

Figure 2 shows the different options of key positions. Figure 3 is the top view of our standard left handed

gearbox in closed position. Figure 4 shows the different drive options. Special drive requirements on request.

Figure 2: keyway in closed position Figure 3: AB left handed gearbox Figure 4: drive options

Top view top view with setscrews bottom side

Page 8

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

8

4 INSTALLATION: MOUNTING TO THE VALVE

Following description applies to standard type gearbox.

1. The gearbox is standard delivered in the closed position, setscrews are loosely tightened.

2. It is recommended to mount a hand wheel on the input shaft before assembling the gearbox to the

valve (see figure 5).

Figure 5: mounting handwheel

3. Check if the bolt circle of the flanges (of gearbox and valve) coincide. Also check if the valve stem

and the bore of the gearbox match.

4. Make sure the valve is in the closed position. If not, close the valve before continuing.

5. Check if the gearbox is in fully closed position by turning the handwheel clockwise.

6. When stud bolts are used for fixing the gearbox to the valve, it is recommended to screw them into the

bottom flange of the gearbox before mounting the gearbox on top of the valve.

7. The use of a gasket or liquid seal between the flange of the valve and gearbox is recommended to

prevent water ingress.

8. Mount the gearbox perpendicular to the valve (see figure 6)

9. Fix the gearbox to the valve appropriate studs and nuts with washers or bolts. Take into account Table

2 for maximum screw dept. For tightening, refer to standard VDI 2230.

10. The assembly is now ready for adjustment.

Figure 6: left handed gearbox perpendicular to the valve

4.1 Mounting instructions chainwheel

Following instructions need to be followed for mounting the chainwheel on the shaft. It is advised to use a

suitable anticorrosive (or sticky grease) on the inside bore hole of the chainwheel and guide sleeve. When used

outside or in a wet or humid environment then we recommended the use of a stainless steel shaft for which we

have different classifications to suit several environmental specifications and not a protected or painted C45

steel shaft. Corrosion between the shaft and the chain guide can cause the combination of the chainwheel and

the guide to fail. When ordering chain please order 2x the necessary operation distance + full diameter of

chainwheel. The chainwheel needs to be sized on the maximum rimpull of 700N. The use of chainwheel is not

applicable to the aluminium 232 range. It is not advised to apply more force than the 700N downward force

Page 9

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

9

towards the chainwheel as this gives the risk of damaging the input shaft of the gearbox. For the AB range the

smallest gearbox with chainwheel is AB210 and for the 242 range is this 242-30. For the AB150 and 242-10

and 20 chainwheel is not applicable.

1. The gearbox is standard delivered in the closed position, setscrews are loosely tightened.

2. It is recommended to mount the chainwheel on the input shaft before assembling the gearbox to the

valve (see figure 7).

3. Mount item 1, 2, 3, 4 and 5 on the input shaft (see figure 7)

4. Locate the holes of the chainwheel and shaft opposite each other, insert item 6 (slotted springtype

straightpin) by hammering.

5. Mount item 7b (set screw with cone point) in front of the chainwheel. Optional item 7a (hexagon

head bolt) can be mounted, this for additional locking of the chain wheel. This extra option need to be

ordered in the preliminary stages of the order.

6. Slide item 4, 3, 2 and 1 together and mount item 8 (hexagon head bolt) in tapped hole of item 1 (Axial

disc)

7. Mount the chain after you have fixed the gearbox to the valve. Connect the loose ends of the chain

with the supplied splitlink (see figure 8)

Figure 7: Mounting chainwheel kit

Figure 8: Chain splitlink

Page 10

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

10

PCD

F05

F07 F10

F12

F14

F16

F25

F30

F35

F40

Max. screw depth

8

11 13

14

16

18

18

18

30

36

Maximum screw depth per pitch circle diameter (PCD) for the AB range

PCD

F05

F07

F10

F12

F14

F16

F25

Max. screw depth

6 8 10

12

16

20

16

Maximum screw depth per pitch circle diameter (PCD) for the 242 range

PCD

F05

F07

F10

F12

F14

F16

F25

Max. screw depth

8

11

13

14

16

18

18

Maximum screw depth per pitch circle diameter (PCD) for the 232 range

Table 2. Maximum screw depth

Figure 9: Standard delivery off-center. On request we can deliver on-center with reduced tapping depths

and dowel pin holes

Figure 10: left handed gearbox setscrew adjustment

Page 11

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

11

4.2 Adjustment of set screws

The gearbox is now mounted on top of valve (see installation chapter 4).

1. Close the valve completely, by turning the handwheel clockwise (standard gearbox).

2. The valve position is indicated by the arrow on the position indicator.

3. Remove carefully the plastic caps from the setscrews.

4. When the fully closed position cannot be achieved, loosen the setscrew-close (see figure 10) by turning

them counterclockwise. Continue turning the hand wheel until valve is totally closed.

5. Screw the set-screw back into the gearbox (by turning clockwise) until tight (blocked). Secure the

setscrew–close with the nut.

6. Open the valve by turning the handwheel counterclockwise.

7. When opening the valve completely (90°) is not possible, loosen the setscrew-open (see figure 3) by

turning it counter clockwise. Continue turning the handwheel until the valve is completely opened.

8. Screw the set-screw back into the gearbox (by turning clockwise) until tight (blocked). Secure the

setscrew–open with the nut.

9. Close the valve with the handwheel.

10. Put the plastic caps back on the setscrews.

11. Adjustment completed

For the AB, 242 and 232, the set screws contain bonded seals. This is to prevent oil leakage from inside the

gearbox when the gearboxes are mounted on the valve with the studbolts pointing downwards. When adjusting

the set screws more than once it may result in a loss of the bonded seal and it is advised to apply Loctite

Threadlock 242. It is also important to lock the screws properly with a torque according to the table below.

TYPE

SCREW SIZE

TORQUE

TIGHTNESS lbs ft

TORQUE TIGHTNESS Nm

SOCKET HEAD

M4

2 - 3

3 - 4

M5

4 - 6

5 - 8

M6

7 - 10

9 - 13

M8

16 - 24

21 - 32

M10

32 - 47

42 - 63

M12

55 - 82

74 - 110

M16

136 - 204

182 - 247

M20

266 - 400

357 - 535

M24

460 - 690

616 - 924

HEXAGON

HEAD

M6

4 - 6

5 - 8

M8

10 - 15

13 - 20

M10

19 - 29

26 - 39

M12

34 - 51

46 - 68

M16

84 - 126

113 - 169

M20

170 -255

231-364

M24

294 - 441

399 - 598

DURLOK

M8

30 - 45

40 - 60

M10

57 - 86

77 - 115

Page 12

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

12

M12

101 - 151

135 - 203

M16

246 - 370

330 - 496

M20

476 - 713

638 - 956

SOCKET CAP

w / NORDLOCK

WASHER

M8

18 - 27

24 – 36

M10

35 - 52

47 – 71

M12

60 - 91

82 – 124

M16

148 - 221

200 – 300

M20

289 - 434

392 – 588

M24

502 - 752

680 – 1020

Table 3: Tighten force in Nm

4.3 Operating instruction

The AB and 242 models are manually operated quarter turn gearboxes made of cast iron. The 232 models are

made of aluminium. All mentioned gearboxes can only be used for manual operating.

The maximum allowable input- and output torques are listed in (table 1).

1. The gearbox is manually operated by handwheel.

2. For opening the valve, the handwheel is turned counterclockwise. For closing turn the handwheel

clockwise1.

3. Stop turning when the required valve position is achieved. The number of turns needed to completely

open or close the valve is stated in table 3. (Changed to table 3)

4. The valve position is indicated by the position indicator on top of the gearbox. In case of buried

service remote position indicators can be used.

5. When the valve cannot be completely opened (or closed), first detect and solve the cause of

malfunction.

6. In case of malfunction of the gearbox ask directly assistance from Rotork and explain the malfunction

of the complaint with details from the nameplate with clear photograph(s). Send your mail to

sales.gearsbv@rotork.com.

7. When it is decided to do the repair in house, all replacement parts must be obtained from Rotork to

assure proper operation of the gearbox.

8. The gearbox is self-braking. Therefore no fixation needs to be installed to retain the valve position2.

9. Turn the handwheel until blocked to open or closed position.

10. The system is ready for us.

1

As special we can deliver clockwise = opening, counter clockwise=closing.

2

Option is the possibility to fix the inputshaft to prevent (not allowed) turning.

Page 13

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

13

4.4 Number of turns opening or closing

Table 4 . Number of turns for complete opening /closing

Model

Number of turns

AB Range

AB 150

10

AB 210/215

9,25

AB 550

8,5

AB 880

9,5

AB 1250

13,75

AB 1950(LB)

13

AB 1950(LB) HR

21

AB 1950(LB)/SP4

52

AB 1950(LB)/PR4

54,25

AB2000 (LB)

27,25

AB3000 (LB)

14,5

AB3000 PR4 (LB)

60,75

AB3000 PR6

87

AB 6800(LB)

19,5

AB 6800(LB)LT/SP4

79

AB 6800(LB)/PR4

81,5

AB 6800(LB)/SP6

117

AB 6800(LB)/PR6

162,56

AB 6800(LB)/SP9

160,25

A 200/SP9

148

A200/PR10

182,25

AB 250LT/SP9

176

AB 250LT/PR10

182,25

AB 250/SP9

176

AB 250/PR10

182,25

242 Range

242-10

10

242-20

10

242-30

10

242-40

10

242-50LT

15

242-50

15

232 Range

232-05

10

232-06

10

232-07

9,25

232-08

9,25

232-10

11,25

232-11

11,25

232-12

10

232-13

10

232-14

10

232-15

10

Page 14

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

14

4.5 Handwheel

type

Handwheel Type - weight Kgs (lbs)

Size in mm

CD

(casted)

PS

(pressed steel)

SG

(Steel welded)

S

(Stainless steel)

F

(Steel welded)

50

0.11 (0.24) - - - -

75

0.21 (0.46) - - - -

100

0.32 (0.71)

0.15 (0.33)

- - -

125

0.54 (1.19)

0.2 (0.44)

- - -

150

- - 1 (2.20)

0.4 (0.88)

-

160

-

0.35 (0.77)

- - -

200

1 (2.20)

0.75 (1.65)

1.35 (2.98)

1 (2.20)

1 (2.20)

250

-

1.5 (3.31)

1.4 (3.09)

- - 300

- - 1.8 (3.97)

-

1.5 (3.31)

315

-

2 (4.41) - - - 350

- - 2.3 (5.07)

1.5 (3.31)

-

400

-

3.5 (7.72)

2.8 (6.17)

-

2.2 (4.85)

450

- - 3 (6.61) - -

500

- - 3.5 (7.72)

-

3 (6.61)

600

- - 4.5 (9.92)

-

3.2 (7.05)

700

- - 5 (11.02)

-

5.5 (12.13)

800

- - 5.5 (12.13)

-

6.6 (14.55)

900

- - 6 (13.23)

-

7.2 (15.87)

Table 5. Handwheel type – weight Kgs (lbs)

Page 15

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

15

STANDARD CONDITIONS

Conditions

Enclosure protection

(See table 4: IP

rating)

Standard: 232 range IP65

Standard: 242 range IP67

Option: AB range N type IP67

Option: AB range G type IP68

Option: AB range W type IP68-1 (tested 1mtr under water, 72 hours)

Option: AB range CS type IP68-10 (tested 10 meter under clean water continuously)

Option: Special requirements on request

Paint protection

Standard:

• AB range 60 microns. Suitable for installation in clean and dry industrial indoor

units.

• 232 range 40 microns. Suitable for installation in clean and dry industrial indoor

units.

• 242 range 60 microns. Suitable for installation in clean and dry industrial indoor

units

Options:

• 120 microns. Suitable for installation in industrial outdoor units water, gas or power

plants with a low pollutant concentration

• Higher thickness on request. Suitable for installation in occasionally or permanently

outdoor atmosphere with a moderate pollutant concentration (e.g. in waste water

treatment plants, chemical/oil/gas industry)

• Other paint systems on request

Pre treatment

Standard: Chemical treatment (phosphating)

Option: Sandblasting SA 2.5

Option: Other pre-treatments on request

Paint

Paint

Primer

Zinc primer

Standard: QD polyaspartic direct to metal paint

Options: Epoxy coat, other paint systems on request

Standard: 1K industry primer (maximum lifetime 1,5 month stored only in indoor,

clean and dry conditions)

Options: Zinc primer (maximum lifetime 3 months when free from zinc salts and free

from contamination and stored in clean exterior conditions. In industrial or

marine conditions this interval should be reduced to the practical minimum.

Colour

Paint thickness

Paint thickness

Paint thickness

Paint thickness

Standard: different RAL colours on request

Standard: 40 microns 232 serie (Gloss paint)

Standard: 60 microns AB and 242 serie (QD polyaspartic)

Options: 120 microns higher thickness on request (Epoxy coat or QD polyaspartic)

Standard: 40 microns (1K industry primer)

Options: 40 – 60 microns (zinc primer)

Grease

Ambient temperature

Standard: Renolit CLX 2 grease

Standard: – 20°C to + 120°C

Options: – 40°C to + 120°C

Options: – 60°C to + 120°C

Options: Other types of grease (low temperature, food, silicone free or high

temperature) on request

Page 16

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

16

Set screws cover

Position indicator

Shafts

Handwheels

Padlock system

Standard: Plastic nutcaps with dubo ring (N type)

Option: W-nuts with dubo ring (W gearbox type)

Option: W-nuts with washer for – 60°C specification

Option: W-nuts with cupper ring (G and CS gearbox type)

Standard: Plastic indicator with zinc plated bolt screws (N type)

Option: Aluminium indicators without NBR O-rings (N gearbox type)

Option: Aluminium indicators with NBR O-rings (protected for water ingress at

stem shaft) (G, W, gearbox type)

Option: Aluminium or GG25 indicators with Special O-rings for – 60°C

specification.

Option: Buried surface and special requirements on request

Standard: Carbon steel shafts (N type gearbox)

Option: Stainless steel shaft different classifications (G, W and CS type gearbox)

Option: Shaft extensions on request

Standard: Pressed steel RAL9005

Standard: Steel welded RAL9005

Standard: For 242 gearboxes Casted handwheel RAL9005

Option: For 242 Pressed steel or steel welded RAL9005

Option: Stainless steel handwheels

Option: Chainwheel (kit) with zinc plated-, steel zinc plated- or stainless steel chain.

Note: When ordering chain please order 2x the necessary operation distance + full

diameter of chainwheel.

Option: Stainless steel chainwheel on request.

Table 6: Standard conditions and options

Page 17

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

17

5 IP RATING

5.1 Solid Particle protection

The first digit indicates the level of protection that the enclosure provides against access to hazardous parts

(e.g., electrical conductors, moving parts) and the ingress of solid foreign objects.

Level

Object size protected against

Effective against

6

Dust tight

No ingress of dust; complete protection against contact

5.2 Liquid ingress protection

The second digit indicates the level of protection that the enclosure provides against harmful ingress of water.

Level

Protected against

Testing for

Details

5

Water jets

Water projected by a nozzle (6.3 mm)

against enclosure from any direction shall

have no harmful effects.

Test duration: at least 3 minutes

Water volume: 12.5 litres per minute

Pressure: 30 kPa at distance of 3 m

6

Powerful water jets

Water projected in powerful jets (12.5

mm nozzle) against the enclosure from

any direction shall have no harmful

effects.

Test duration: at least 3 minutes.

Water volume: 100 litres per minute.

Pressure: 100 kPa at distance of 3m.

7

Immersion up to 1 m

Ingress of water in harmful quantity shall

not be possible when the enclosure is

immersed in water under defined

conditions of pressure and time (up to 1

m of submersion).

Test duration: 30 minutes

Immersion at depth of at least 1 m

measured at bottom of device, and at least

15 cm measured at top of device

8

Immersion beyond 1 m

The equipment is suitable for continuous

immersion in water under conditions

which shall be specified by the

manufacturer. Normally, this will mean

that the equipment is hermetically sealed.

However, with certain types of

equipment, it can mean that water can

enter but only in such a manner that it

produces no harmful effects.

Test duration: continuous immersion in

water

Depth specified

Table 7. IP rating

Page 18

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

18

6 CERTIFICATES

6.1 Atex

Directive EC 94/9/EG states the directive only applies to equipment which is capable of causing an explosion

through its own potential sources of ignition. The gearboxes from type AB, 242, 232, ILG/S and ILG/D don’t

have their own potential source of ignition, so directive EC 94/9/EG doesn’t apply. Therefore we state that:

Operation of gearboxes type series AB and 232 with the marking:

II 2 G D c 120 C

in areas with explosive gas atmospheres Zone I and II Category 2 (and 3)

and explosive dust atmospheres Zone 21 and 22 Categories 2 (and 3)

: this product meets the requirements for explosion prevention

II : in a potential explosive surrounding, other than in mines,

2 : with a high level of safety, based on normal operation and anticipated risks

G D : suitable for a possible explosive atmosphere caused by gases, vapours, mists of air/dust

mixtures

c : safety obtained by constructive solutions.

120C : indicating the maximum surface temperature in °C

6.2 Certificates of conformity

Rotork certify that the Gearbox models AB, 242 and 232 supplied conforms in all respects to our specifications

and have been subject to our Quality System conforming to BS EN IS09001:2008

6.3 Other certificates

For other certificates please contact our sales department, these are on request an need to be ordered in the

preliminary stages. The following certificates we can provide:

- EUR 1 certificate

- Certificate of origin

- GOST certificate

- Certificate of Conformity

- 2.2 certificate

- Long term supplier declaration

Page 19

model AB, 232, 242 manual

Rotork Gears BV - Nijverheidstraat 25 - 7581 PV Losser The Netherlands - Tel: +31 (0)53 5388677 - Fax: +31 (0)535383939

Mail: info@rotorkgears.nl - Web: www.rotork.com

PUB033-005-00_0219

19

6.4 Reach

Loading...

Loading...