I

IMPORTANT

N

N

S

S

T

T

I

SL210i/SL212i

Compact Inbay Control

(800 Series) (1Ø & 3Ø 208V-240V) (3Ø 480V)

SL210i Moveable Pad Capacity 8,000 lbs.

SL210i Capacity 10,000 lbs.

SL212i Capacity 12,000 lbs.

A

A

L

L

L

L

A

A

T

T

I

O

O

N

N

I

I

I

Attention!!!

These Instructions Contain General Data. Any Deviation From Customers Prints Or Specifications Should Be

Clarified Before Proceeding With Lift Installation.

Check the containment tube for holes due to shipping damage. Do not install a damaged

containment tube. Contact Rotary Lift Customer Service. If the lift has a chance to be exposed to the

elements, protect the lift.

*PLP20447 *

IN20481

Rev. C 2/4/2010

© February 2010 by Rotary Lift. All rights reserved. CO7473.1

LP20447

N

N

S

S

T

T

R

R

U

U

C

C

T

T

I

O

O

N

N

S

S

I

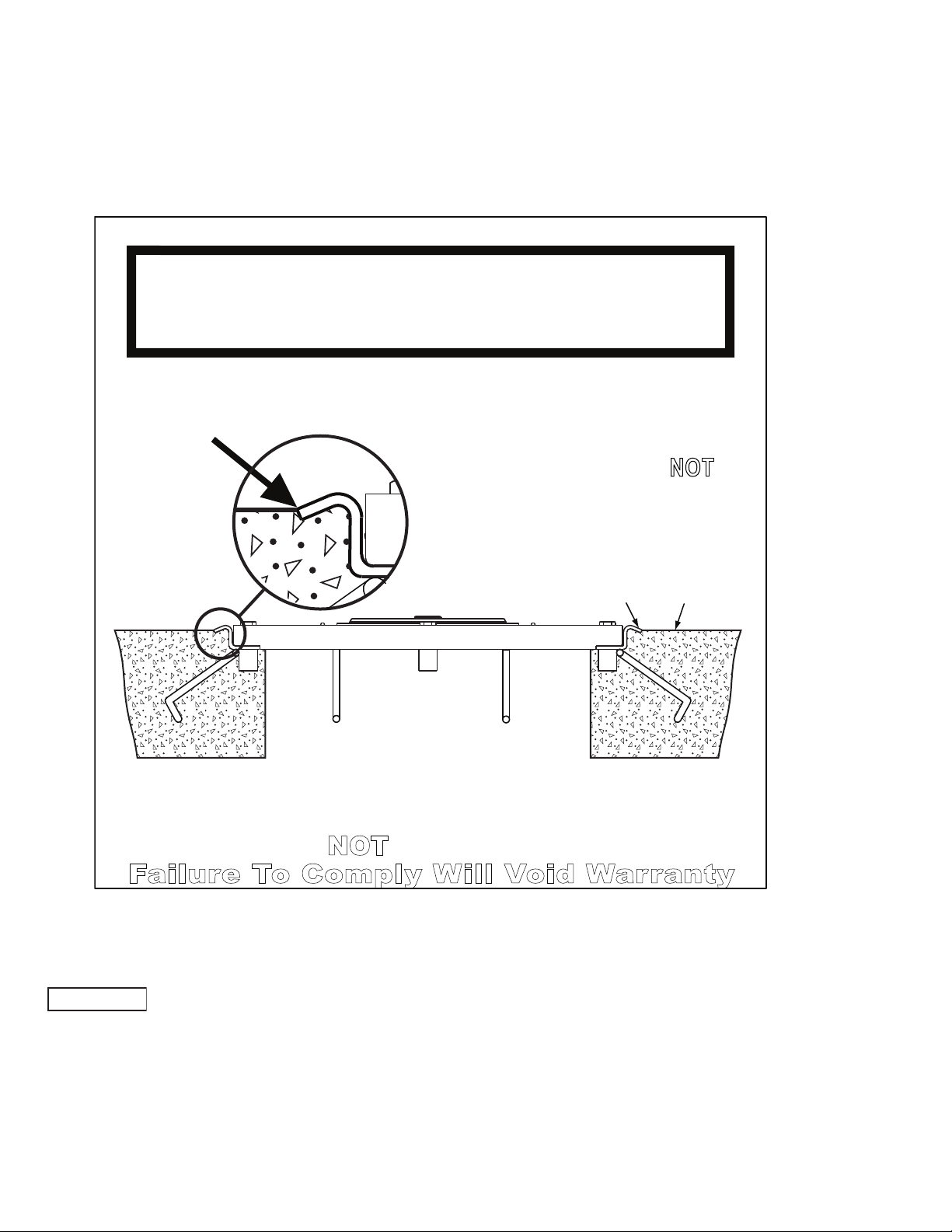

IMPORTANT

Owner: Your Installer Is Responsible For

The Concrete Floor Being Finished To

Grade Angle, NOT

To The Top Of The Lift.

Failure To Comply Will Void Warranty

Failure To Comply Will Void Warranty

Edge Of

Grade

Indicator

Concrete MUST BE Finished To

Edge Of Grade Indicator, NOT

The Top Of The Lift. Finished

Floor Level Must Be 1/4” Below

Top Of Lift On All Sides.

Concrete

Grade Indicator

IMPORTANT

Contact with the electrical heating coils could cause electrolysis and damage the lift and/or its

components. Make sure the lift frame concrete anchors do not contact electrical heating coils, or re-bar that may be

in contact with other embedded electrical sources. The lift being physically connected to any source which promotes

electrolysis will void the warranty.

2

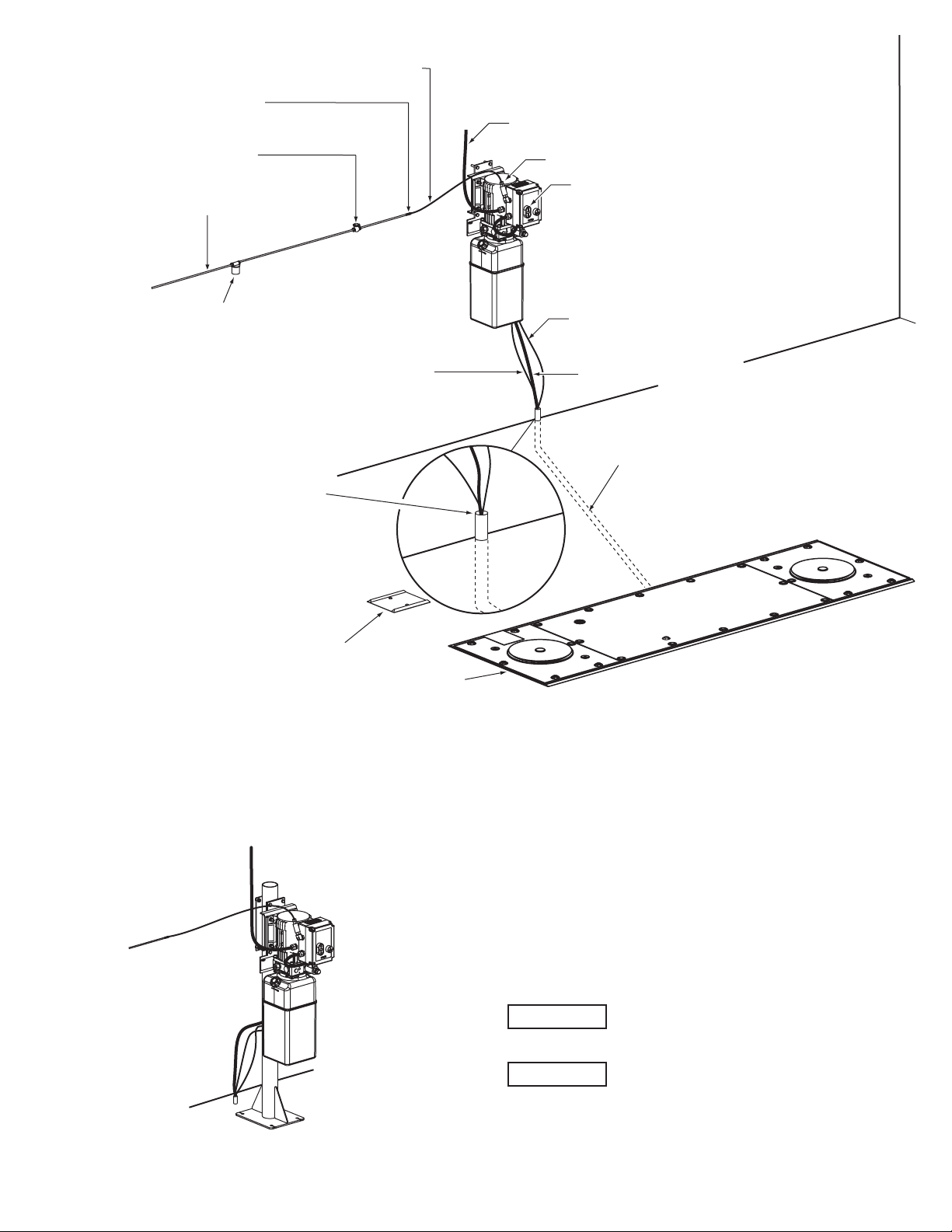

Power Unit

&

Master Control Panel

Mounted On Optional Pedestal

PVC Conduit for Air and Hydraulic

Hose (by Installing Contractor)

Hydraulic Hose to Lift

(by Installing Contractor)

Lift (by Rotary)

Wheel Spotting

Dish (by Rotary)

1/4" Air Line to Locking Latch

And LDS Sensor (by Rotary)

1/4" Air Line to

LDS Sensor (by Rotary)

Electrical Power Supply

(by Instaliing Contractor)

Power Unit (by Rotary)

Master Control Panel (by Rotary)

In-line Air Filter (by Rotary)

1/2" Air Line to Compressor or

Air Main (by Installing Contractor)

Shut Off Valve And Female Fitting

(by Installing Contractor)

In-Line Pressure Regulator/Water

Separator (by Installing Contractor)

1/4" Airline

To In-line Regulator (Inside Master Control Panel)

IMPORTANT!!!:

After Routing The

Air Lines & Hydraulic Hose

Do Not Cap Either End

Of Pipe Chase. Air

Must Vent Out

In Order For

LDS To Work Properly.

IMPORTANT

IMPORTANT

Please follow these instructions to ensure a good installation

and satisfactory operation of the lift. Check your shipment

against the product load list and shipping papers. Enter claims for

damage or shortage with the delivering carrier at once.

• Afterinstallation,pleasereturnthisbooklettotheliterature

package and give to lift owner/operator.

• Literaturepackageshouldbekeptattachedtopowerunitfor

easy access.

• Reviewentireinstallationinstructionsbeforebeginning

excavation.

The center cover is designed for foot traffic

only.

Restrict all unauthorized persons from going

near excavation. OSHA standard restricts anyone from getting in

excavated hole, unless OSHA guidelines are followed. See OSHA

Excavating Standard CFR 1926.

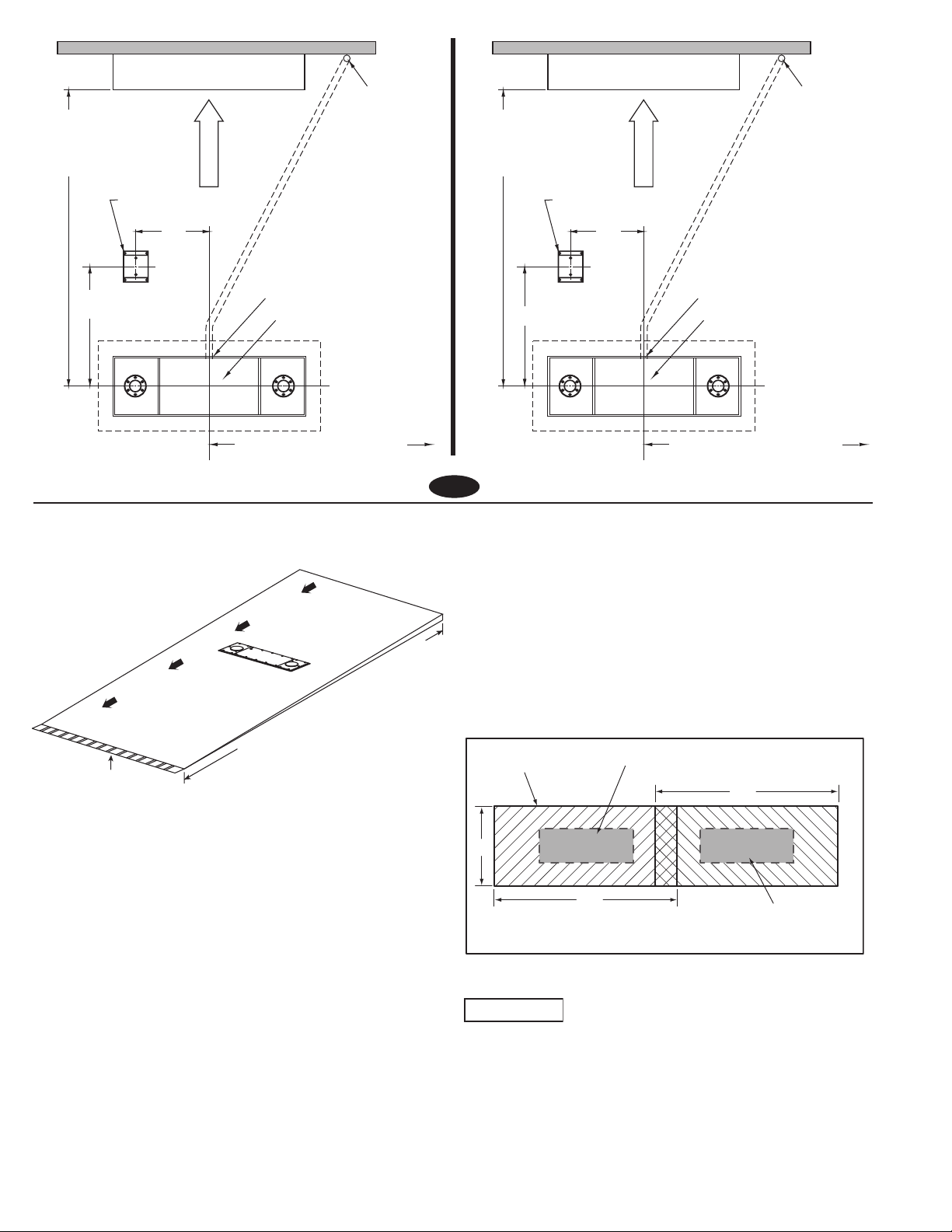

3

Wheel

Spotting Dish

2' 5"

APPROACH

PVC Conduit

Entrance for Air

& Hydraulic Hose

NOTE: Adjust Entrance

For Pedestal Mounting

Installation See Fig. 8a

4' 9" Swing Arm Lifts

5' 0" Moveable Pad Lifts

WORK BENCH (TYPICAL)

12'-0" Min. to

Nearest

Obstruction

or Per

Section 1c

5'-6" Min. to nearest obstruction

Foot traffic only on center cover

SL210i Series

Wheel

Spotting Dish

2' 5"

APPROACH

PVC Conduit

Entrance for Air

& Hydraulic Hose

NOTE: Adjust Entrance

For Pedestal Mounting

Installation See Fig. 8a

4' 9"

WORK BENCH (TYPICAL)

13'-0" Min. to

Nearest

Obstruction

or Per

Section 1c

5'-6" Min. to nearest obstruction

SL212i Series

PVC Inlet Into Containment Tube

Foot traffic only on center cover

PVC Inlet Into Containment Tube

1. Lift Location:

IMPORTANT

Recommended Floor Slope 0-1/16" Per Ft.

Drainage Direction

Drainage Directio

n

Drain

Continuous Trench

Lift Location

5'

Concrete Floor

10'

10'

Lift Location

A. Check architect’s layout if available. Lay out lift as shown in

Fig. 1. Recommended floor slope is 1/16" per foot.

Fig. 1

3. Concrete Preparation:

A. Run 2" PVC from Control Area to Containment Tube. PVC will

enter the Containment Tube 9-1/2" below finished floor grade.

Hole is centered horizontally in Containment Tube, Fig. 1.

B. Box out a 5' x 10' area around where lift is to be located.

NOTE: For multiple lift installations, boxed out areas will

overlap. Dig continuous trench, see illustration below.

C. Pour concrete floor ensuring not to get concrete in boxed out

area.

NOTE: By using this installation method, the RAI can more

accurately set lift to proper grade relative to finished floor.

Reference Page 2.

B. SL210i: The 5' 6" centerline to side and 12' 0" centerline

to front and rear dimensions should be maintained to provide

adequate working space. The minimum overhead clearance

should be 85" plus height of highest vehicle to be raised. 24' 0"

length bay recommended. Other lengths may be used, provided

ample clearance is maintained at each end of lift.

SL212i: The 5' 6" centerline to side and 13' 0" centerline to front

and rear dimensions should be maintained to provide adequate

working space. The minimum overhead clearance should be

88" plus height of highest vehicle to be raised. 26' 0" length bay

recommended. Other lengths may be used, provided ample

clearance is maintained at each end of lift.

C. Base Unit Lifts: If you are planning to install roll-on/

wheel alignment runways, locate lift per instructions from

superstructure manufacturer. Use superstructure manufacturer's

instructions for fore and aft, side to side, and ceiling clearances.

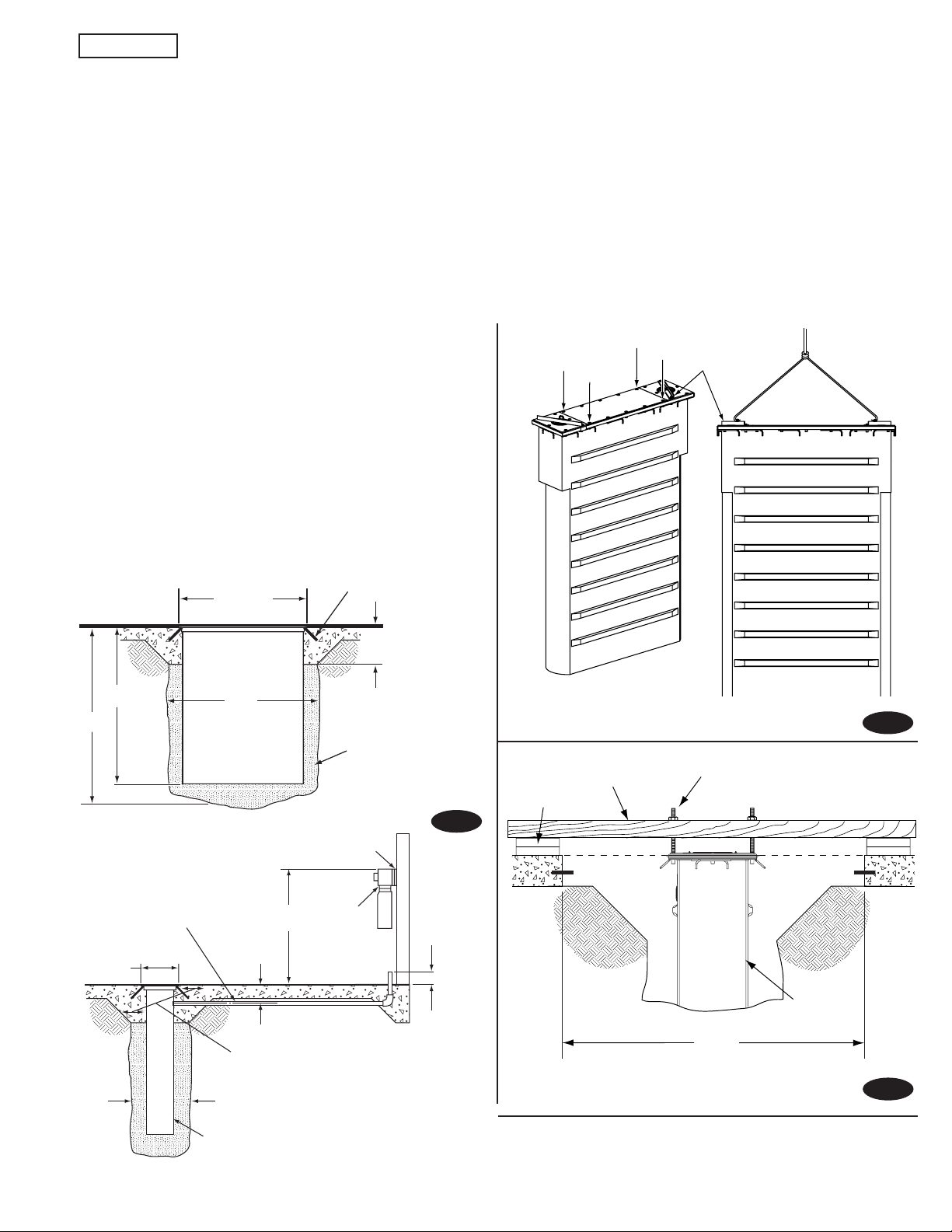

2. Excavation: Excavate hole to dimensions shown in Fig. 2.

Dig trench for 2" PVC pipe between lift and power unit location.

Trench should be dug 11" below finished floor grade. Air line and

hydraulic hose to be contained in this 2" PVC pipe.

4. Lift Setting:

Check the containment tube for holes due to

shipping damage. Do not install a damaged containment tube.

Contact Rotary Lift Customer Service.

A. Chain hoist must have capacity of 2,500 lbs. with a clear

swing of 9' 0". Rig sling for unit, attaching to the shipping strap,

Fig. 3, and lower assembly into hole. Center lift and be sure lift

containment inlet is located as shown in Fig. 1.

4

Frame Anchor

105"

110"

18"

73-5/8"

Frame Width

96"

Clean Pea

Gravel Fill

36"

Lift & Containment Tube

7,200 lbs. maximum reaction

longitudinal and transverse

direction due to eccentric loads

15,000 lbs. maximum vertical loads

23-3/8"

Frame

2" PVC Pipe

9-1/2"

56"

Power

Unit

Wall Bracket

6"-8"

IMPORTANT

Owner: Your Installer Is Responsible For The

Lift and

Containment Tube

6 x 6's

Blocks

(2) 1/2"-13NC x 18" lg. Threaded Rod,

Flat Washers, & Nuts

60"

X

X

X

X

Shipping

Straps

Concrete Floor Being Finished To The Leading Edge Of The Grade

Angle (1/4" Below Top Of Lift), NOT To The Top Of The Lift, Fig. 5.

Failure To Comply Will Void Warranty.

B. Bend frame anchors out perpendicular to concrete frame and

downward approximately 45° to floor level, Fig. 2.

C. Remove and retain (4) 1/2"-13NC HHCS (marked with X, Fig.

3). Insert 1/2" Threaded Rods x 18" lg. into the holes and secure in

place using 1/2" flat washers and nuts, Fig. 4.

D. Attach 6 x 6’s to support unit on existing floor and secure in

place with 1/2" flat washers and nuts, Fig. 4. Remove shipping

straps and install guide barrel bolts in open holes and torque to 60

ft-lbs. Remove protective covers from top of jacks.

E. Plumb and level by placing machinist level on top of jack. Do

Not plumb or level off unit frame. See Fig 5.

F. Shore Lift Securely!

G. Connect 2" PVC to containment tube, chamfer PVC entering

containment tube seal and lubricate I.D. of seal with grease or

oil to ease entry of PVC into seal. PVC pipe should extend into

containment tube 1" maximum.

NOTE: If your PVC pipe and containment inlet do not align, you

may have to cut back PVC pipe, and attach 2" Flexible PVC to

make connection. All PVC joints MUST be leak proof.

H. Recheck plumb.

Fig. 3

Fig. 2

Fig. 4

5

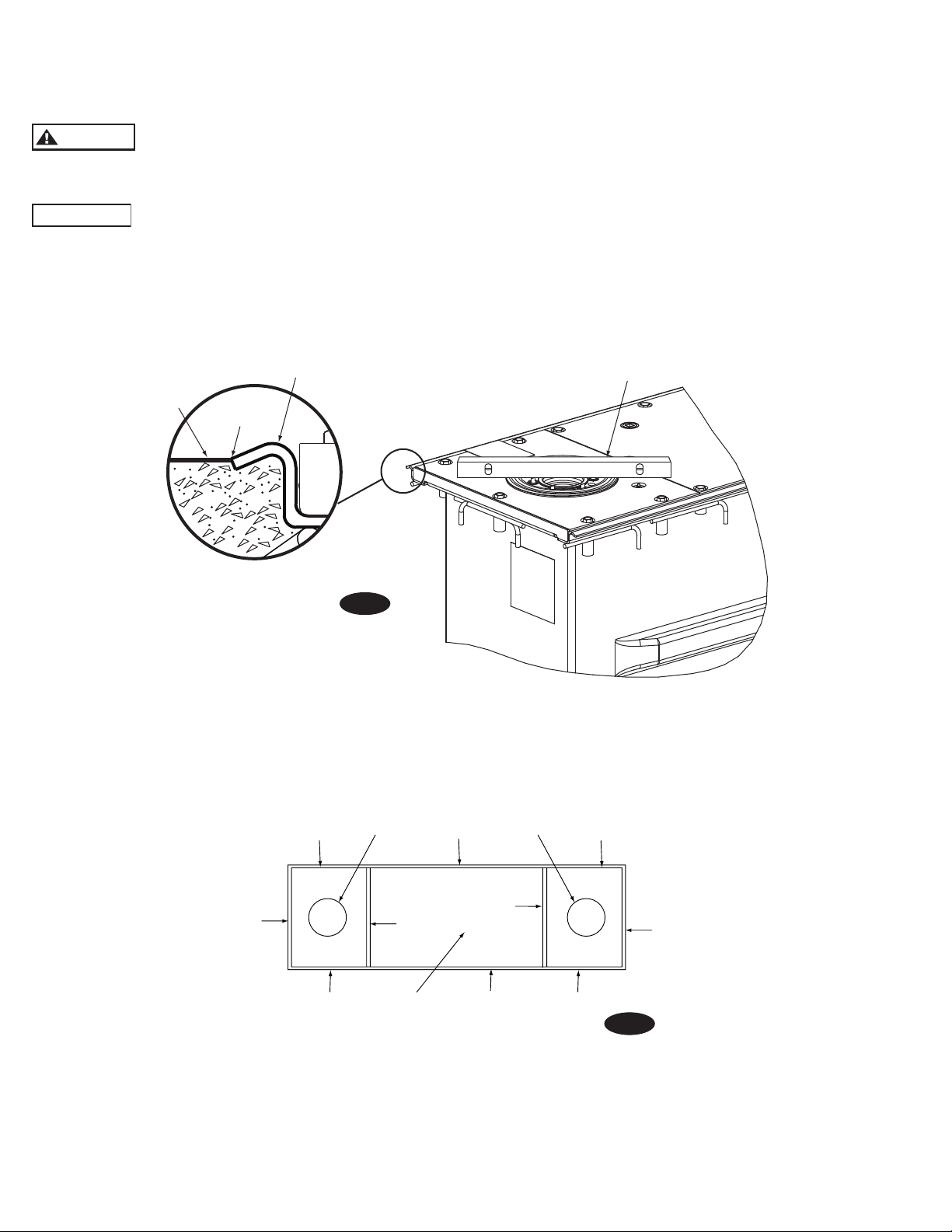

5. Backfill:

CAUTION

IMPORTANT

X

X

XX

X

X

X

X

X

X

Tape Covers

Over Plungers

Tape Covers

Over Plungers

Center Cover

Grade Indicator

Leading

Edge

Concrete

Floor

Machinist Level

A. Duct tape joint areas indicated by X, Fig. 6, to protect these

areas during backfill and concrete work. Backfill around unit

using only pea gravel to within 18" of top of finished floor.

Do not use a mechanical tamper or saturate

the backfill material to achieve compaction. This could cause lift

containment sides to bend inward, HAND TAMP ONLY.

Do Not fill plunger with any ballast material.

B. Complete backfill and tamp pipe trench.

C. After lift is backfilled, make final elevation and plumb checks,

Fig 5.

D. Make sure frame anchors are bent out, Fig. 7.

Fig. 5

Fig. 6

6

Lift and

Containment Tube

Bend Out

Frame Anchors

Rebar or Stud Anchor

Grade Indicator

Leading

Edge

Concrete

Floor

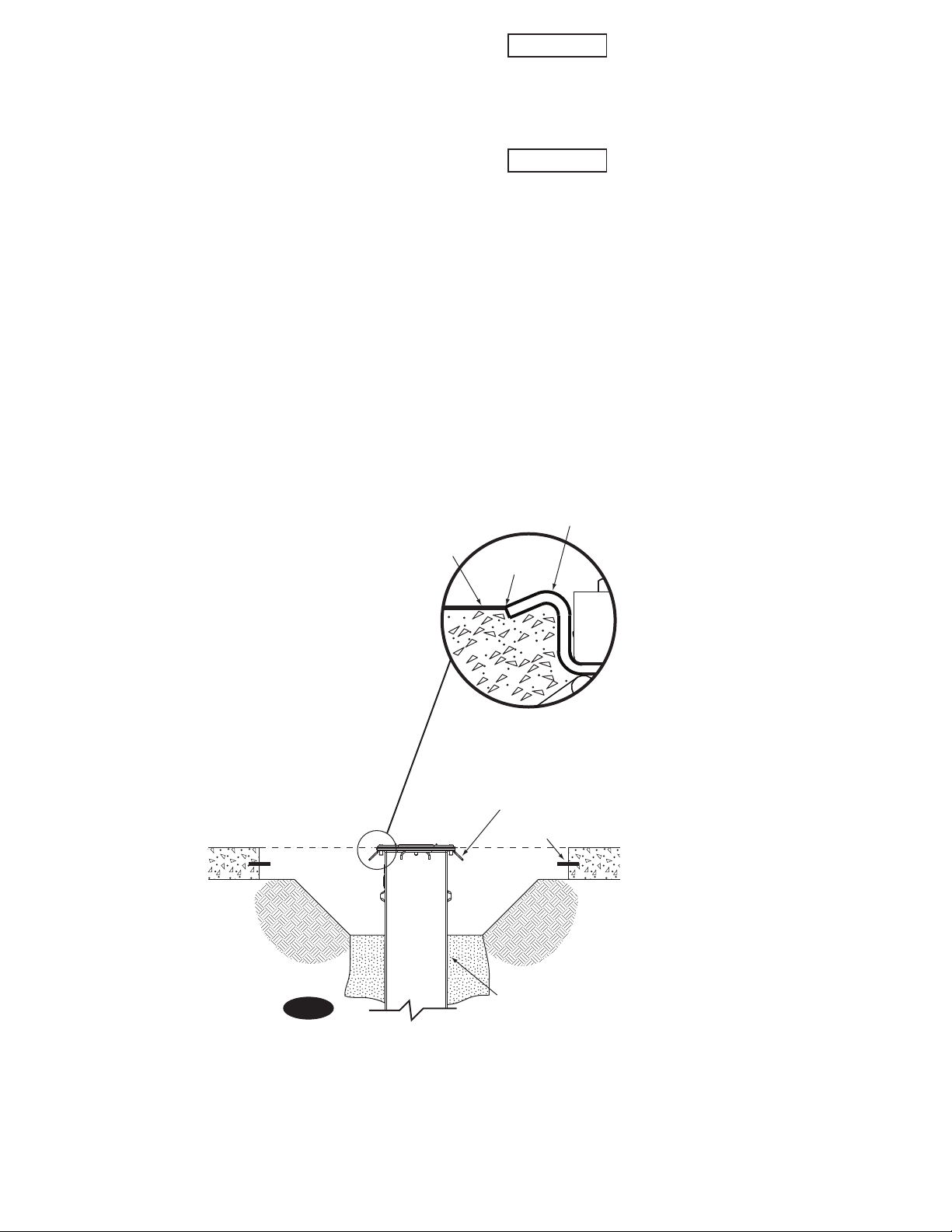

6. Concrete Work:

IMPORTANT

IMPORTANT

A. Leave 6 x 6's in place.

B. New concrete around the lift must be keyed into existing floor

with rebar or stud anchors, Fig. 7.

C. A minimum concrete strength of 3,000 PSI is suggested. DO

NOT use calcium chloride as a curing accelerator. If using a

curing accelerator, we recommend a non-chloride additive such

as High Early* or equivalent.

D. Pour concrete floor, being careful not to run concrete in and

around top surface of lift unit.

Owner: Your Installer Is Responsible For The

Concrete Floor Being Finished To The Leading Edge Of The Grade

Angle (1/4" Below Top Of Lift), NOT To The Top Of The Lift, Fig. 7.

Failure To Comply Will Void Warranty.

It is imperative that lift be set level

regardless of floor slope or other factors. Trowel smooth and

allow to harden.

E. After concrete is set-up, remove 6 x 6's and threaded rods.

F. Reinstall the guide barrel bolts, use Loctite 242 (blue) on bolts

and torque to 60 ft.-lbs.

G. Do not use lift until concrete has achieved 3,000 PSI.

Fig. 7

7

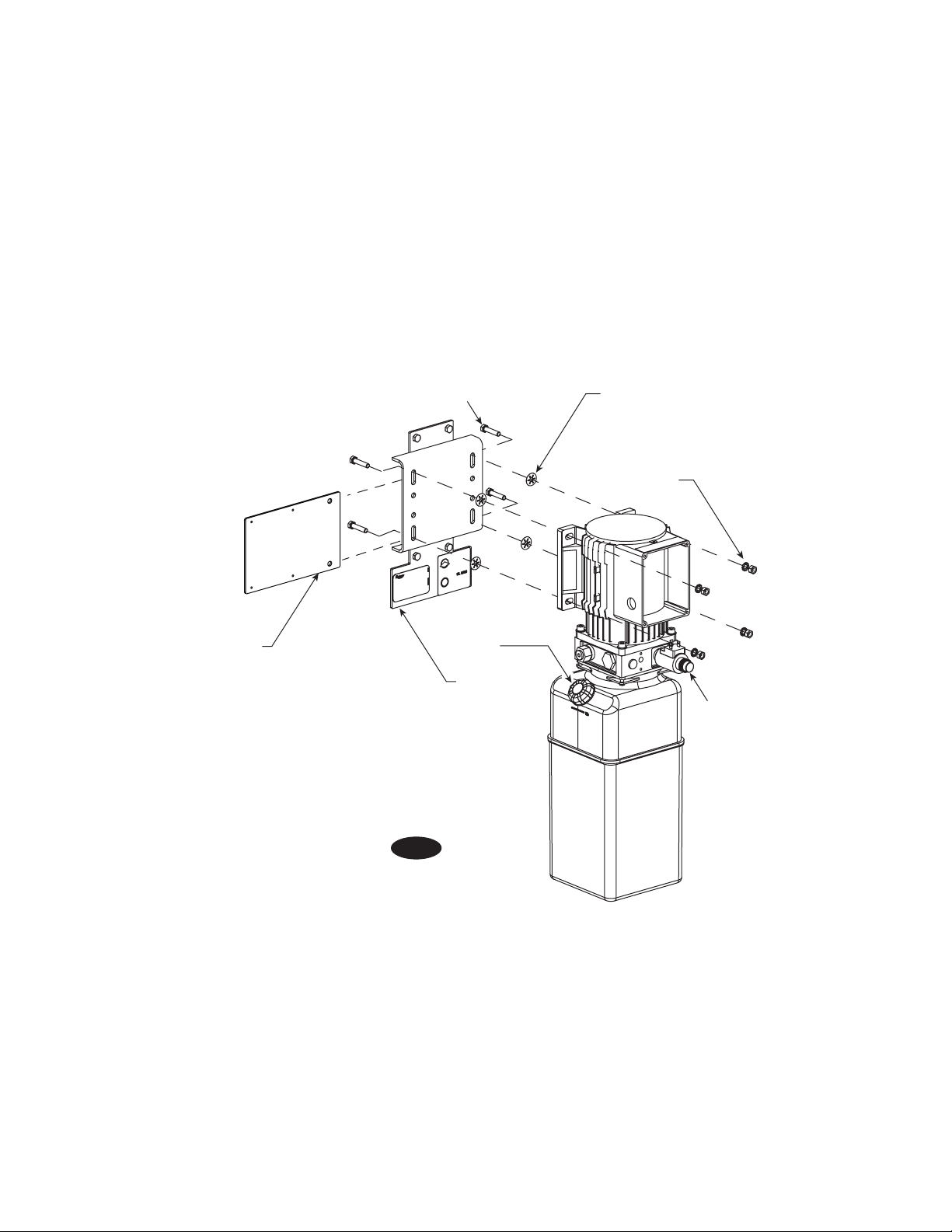

7. Power Unit:

Push nuts hold

bolts to brackets

Lowering

Valve

Fill

Breather

Cap

Power Unit

Bracket

(By Rotary)

Use (4)5/16"-18NC

x 1-1/2" lg. HHCS

Use (4)5/16"-18NC

Nuts and 5/16" Star

Washers

When Required

For Installing

Tr ansformer Box

(Can Be Mounted Left Or Right Side)

*For workbench installations mount transfomer box

behind power unit and on the inside side wall at least

18'' above the floor. Use supplied #10 x 3/8'' tapping

screws. Drill 0.136'' pilot holes.

A. Wall Mounting: For operating convenience, locate Power Unit

bracket so top of bracket will be approximately 56" above floor,

Fig. 2.

B. Locate and mount the power unit bracket, using (4) 3/8" wall

anchors, on the wall, Fig. 8. Anchors must be able to hold 20 lbs.

of shear force.

C. Put (4) 5/16"-18NC x 1-1/2" HHCS through wall bracket using

push-nuts to hold in place, Fig. 8.

D. Mount power unit, with motor up, to the power unit bracket

and install (4) 5/16" nuts and lock washers, Fig.8.

8. Hose And Elbow Attachment (Hose Provided By Installer):

A. Hose must meet Dayco EZ Flex 150 or equivalent specs. with

3,000 PSI minimum working pressure, 3/8" I.D. with 9/16-18THD,

JIC fitting, female swivel ends.

B. Hose must be free of debris. Inspect all threads for damage.

C. Install hose onto elbow adapter on power unit, Fig. 9.

D. Do not route hose to lift at this time.

Fig. 8

8

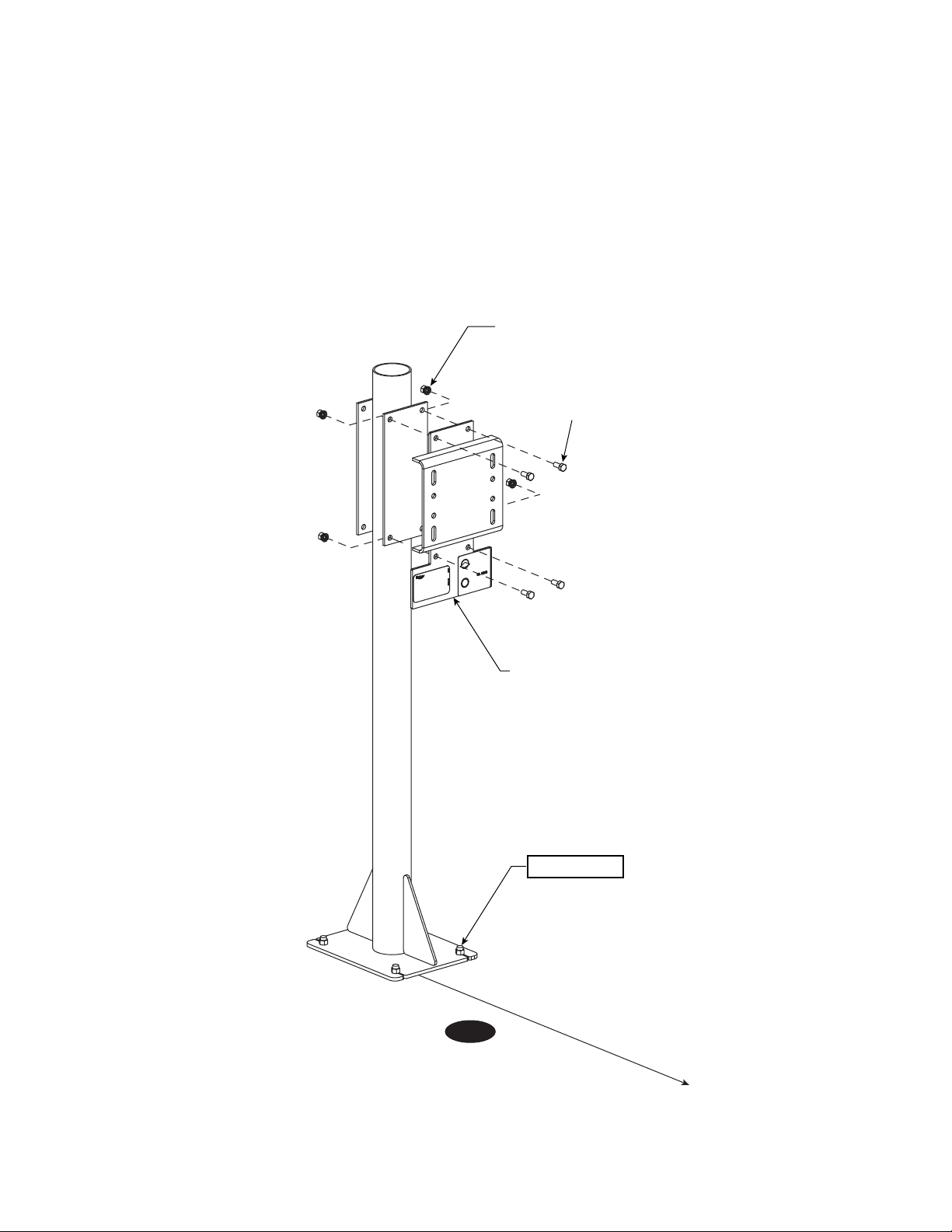

E. Pedestal Mounting: Pedestal must be anchored to the floor

Secure Pedestal

To Floor With 3/8”

Anchor Bolts Before

Attaching Power Unit

Use (4)5/16"-18NC

x 3/4" lg. HHCS

Use (4)5/16"-18NC

Nuts and 5/16" Star

Washers

IMPORTANT

30" From Nearest Obstacle

Power Unit

Bracket

(By Rotary)

with 3/8" anchor bolts before attaching power unit, Fig. 8a.

F. Use base for pattern to mark holes for anchoring. Pedestal

must be anchored at least 30" away from the any obstacle to

allow for wiring and maintenance of the power unit, Fig 8a.

G. Mount power unit bracket to pedestal with (4) 5/16"-18NC x

1-1/2" HHCS, (4) 5/16" nuts and lock washers, Fig. 8a.

H. Put (4) 5/16"-18NC x 1-1/2" HHCS through power unit bracket

using push-nuts to hold in place, Fig. 8b.

I. Mount power unit, with motor up, to the power unit bracket

and install (4) 5/16" nuts and lock washers, Fig.8b.

Fig. 8a

9

Loading...

Loading...