Rosen ROAIMS for Pipelines User Manual

ROSEN INTEGRITY SOLUTIONS

MANAGING THE INTEGRITY OF

PIPELINE ASSETS

PIPELINE INTEGRITY SERVICES

ROSEN: LEADING THE WAY IN INTEGRITY

MANAGEMENT

The safe and ecient operation of major transmission

pipe lines is an important issue for many stakeholders,

including pipeline operators, landowners, regulatory

bodies, national and local governments, and the general

public.

At ROSEN, we provide specialized engineering, integrity

assessment and data management services that support

operational decision-making.

The key aims for pipeline operators are to

•reduce downtime due to unforeseen events

•define cost-eective inspection plans and

inspection intervals

•avoid unnecessary repairs and interventions during

standard operation

•extend asset life without compromising the principles

of safe operation

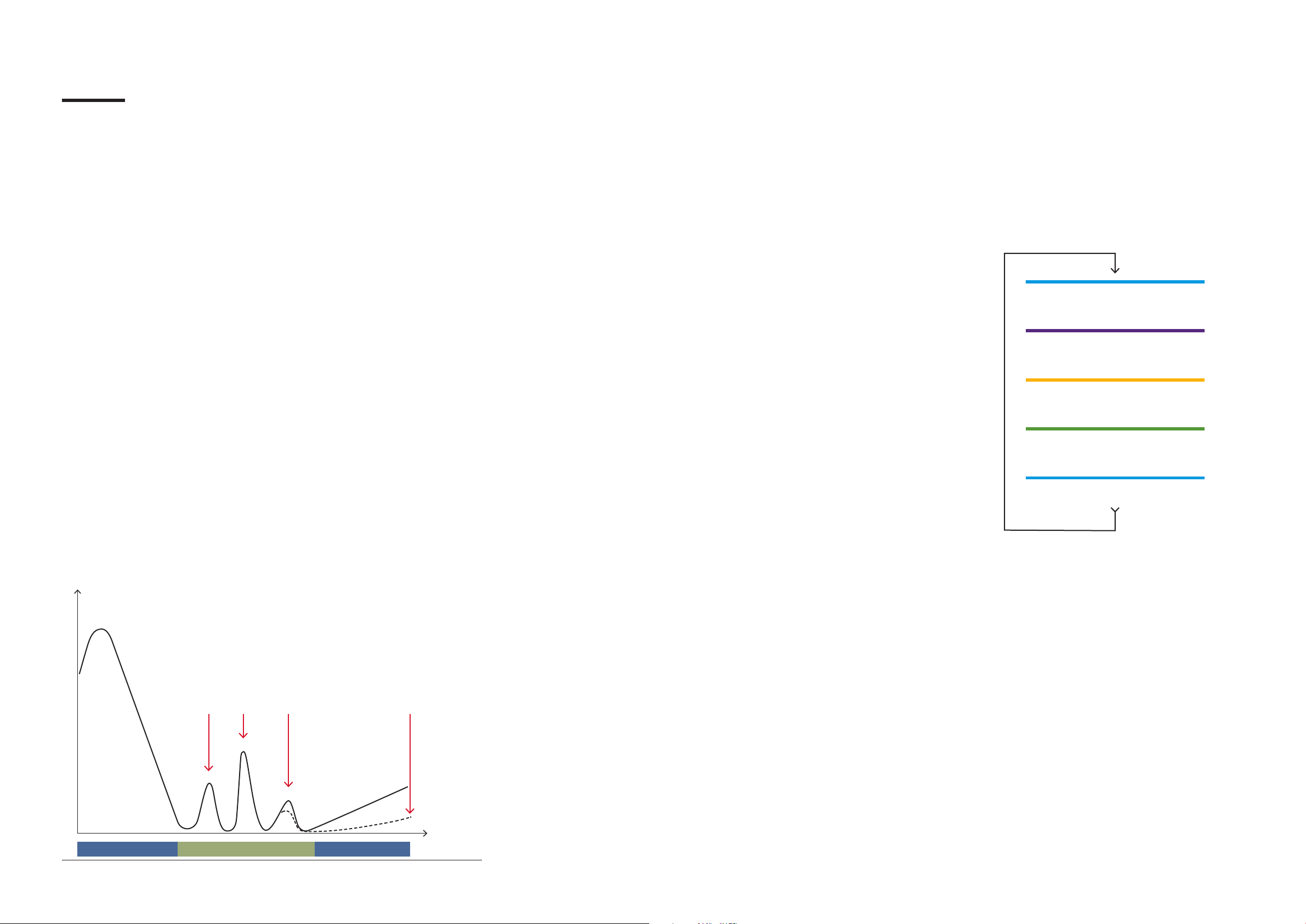

Cost

Inspection Interval

Inspection

Avoid Repairs/Interventions

Repair

Reduction of Downtime

Downtime

These objectives are influenced by a range of legal and

financial factors, including

•compliance with legislation and company policies

•maximizing asset value and production targets

•operational life extension

•centralized approach for integrity management

The ultimate driver for us is to help our customers

balance these factors and make informed decisions to

ensure that they meet their business targets

while maintaining a safe and reliable asset base that

does not harm the environment.

Extension of Lifetime

Time

DecommissionOperationNew Construction

Schematical view of

total spendings during

pipeline service life

DRIVERS AND POLICIES: HOW ROSEN CAN

HELP ENSURE COMPLIANCE WITH INDUSTRY

REGULATIONS

Codes and standards issued by regulatory bodies provide

guidance to pipeline operators on how to maintain the

integrity of their assets. ROSEN’s product and service portfolio is aligned with core industry framework documents

and codes.

System definition and data gathering

ROSEN supports its clients in reviewing and implementing

their integrity programs down to the creation of integrityrelevant procedures and processes.

Threat assessment

Adopting both qualitative and quantitative approaches,

we utilize the data and subject matter expertise of our

engineers and our clients to determine the presence of

potential threats along a pipeline route.

Risk analysis and inspection strategy

On the basis of an evaluation of potential threats and the

likely consequences of specific failure events, ROSEN

assists customers in implementing risk-reduction and

mitigation measures. As part of this service, we determine

the most cost-eective inspection strategy including

the most appropriate technology for assessing the

identified threats.

Action plan execution

In addition to our best-in-class in-line inspection services,

ROSEN oers further inspection measures that help

pipeline operators identify and verify threats. Examples

are above-ground survey projects, geotechnical assessments as well as remote sensing projects.

To optimize corrective measures based on inspection

findings, ROSEN provides follow-up analysis such

as fitness-for-service assessment and corrosion

growth studies.

System Definition

Data Gathering

Threat Assessment

Risk Analysis and Evaluation

Action Plan / Inspection Strategy

Action Plan Execution

Response to Findings

Information Analysis

Unified Integrity Management Process

Response to findings

ROSEN integrity specialists have extensive experience

in selecting the most appropriate rehabilitation method

for identified defects. In addition, we ensure that the

right data are collected during field verifications. The

information collected on site provides highly useful input

for assessing the quality and reliability of inspection

data and can additionally be used for further analysis.

Information analysis

ROSEN Business Consultants support the process of

reconciling integrity aspects with commercial

considerations. This reconciliation is achieved, for

example, by connecting our integrity systems to

SAP and Maximo, resulting in a centralized approach

for the Pipeline Integrity Management System (PIMS).

2 3

PIPELINE ENGINEERING AND CONSULTANCY SERVICES

ROSEN INTEGRITY PRODUCTS AND SERVICES

PORTFOLIO: WHAT ROSEN CAN OFFER

Engineering and consultancy services

Based on our strategic partnership with MACAW

Engineering, we provide the following integrity based

services:

•ILI feature review and corrosion mechanism diagnosis

•Fitness For Purpose (FFP) assessment

•Future integrity management planning

•Corrosion Growth Assessment (CGA), including raw

signal data comparison

•Remaining life assessment

•Risk assessments and Risk-Based Inspection (RBI)

implementation

•Pipeline Integrity Management System (PIMS),

including reviews and recommendations

•Materials and welding consultancy

•Failure investigation

(including laboratory based services)

Integrity software implementation services

The ROSEN Asset Integrity Management Software

(ROAIMS) for pipelines is recognized as one of the industry’s best integrity management software suites. Utilizing

ROAIMS, we perform the following activities with the final

goal of creating auditable standards of integrity:

•Client-specific enterprise interfaces

•Client-specific algorithms for defect and risk assessment

•On-site and o-site data gathering and processing

•Dataqualityevaluation(QA/QC)

Data management services

•Data services: from high consequence area evaluation

to comparison of ILI data with as-built information,

ROSEN performs various data analysis services. The

analysis is typically conducted using a structured data

model such as PODS.

•Geo-services: using GIS technology, we perform

geotechnical threat and environmental change

assessments; also pipeline movement is analyzed

combining inertial mapping results from in-line

inspections with satellite and aerial imagery.

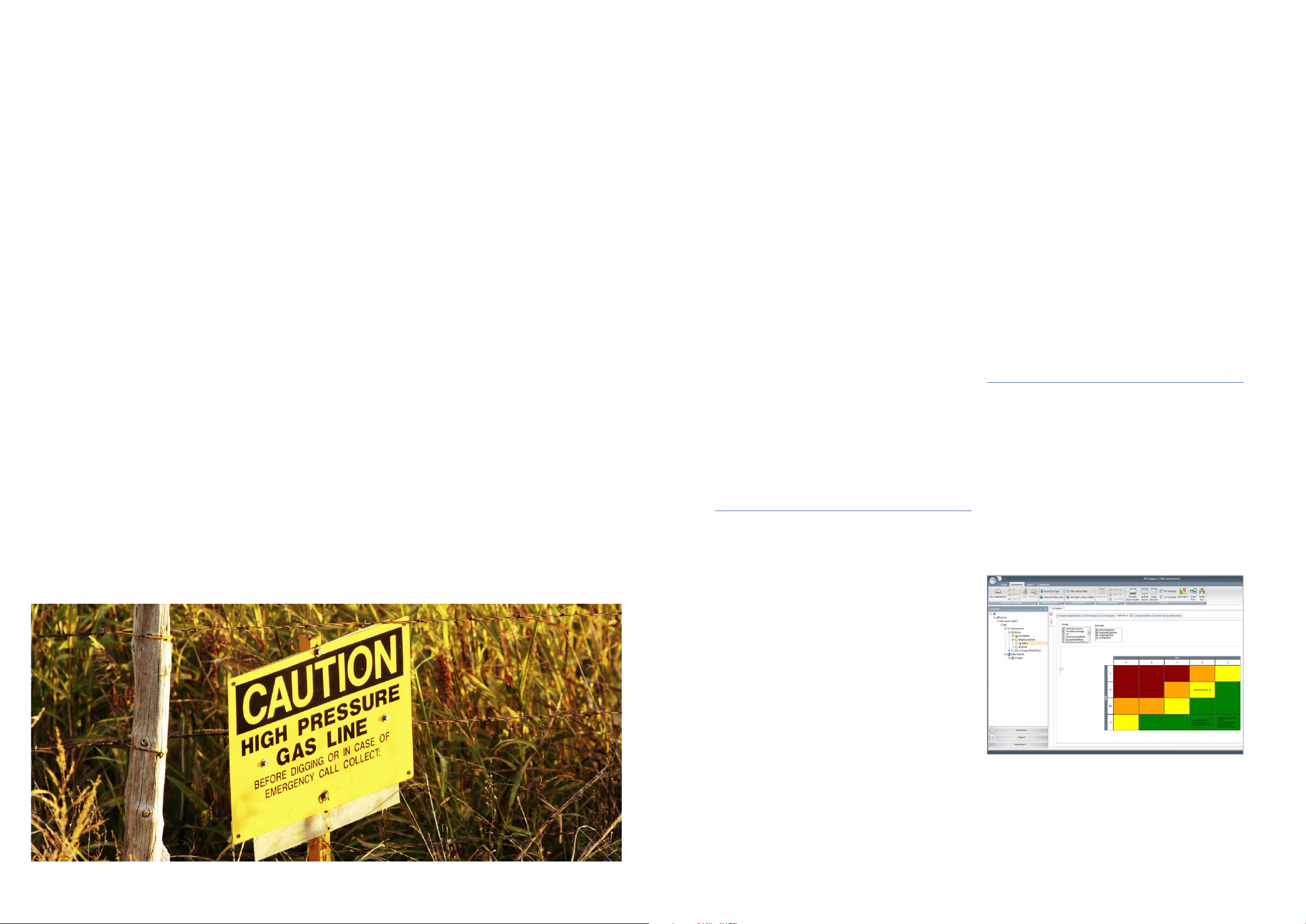

RISK ASSESSMENT

Risk assessment involves identification and evaluation

of threats, failure modes and potential consequences

for pipelines. Based on methodologies customized

to client system requirements, such risk assessment

provides the clear direction and priorities required

for the development and implementation of Integrity

Management Plans (IMP).

Ensuring compliance with the relevant safety, health,

environmental protection and quality regulations, risk

assessment and management aim at improving security

of supply, maintaining safe operations, reducing risk

to human health, and avoiding environmental damage.

KEY STEPS INCLUDE:

•Holding client workshops to determine available data

and risk model customization requirements

•Client system definition and segmentation

•Threat/hazard identification

•Threat susceptibility assessment

•Consequence analysis

•Risk result presentation as per client-specific

requirements

•Prioritization of future integrity actions

IMMEDIATE INTEGRITY ASSESSMENT

Immediate integrity assessment provides expert analysis

of inspection findings and corrosion mechanisms to

determine the current integrity of the pipeline (i.e., at the

time of the last inspection).

KEY STEPS INCLUDE:

•Summarizing feature distributions and identifying

activity hot spots

•Characterization and diagnosis of reported corrosion

•Consideration of High Consequence Areas (HCAs) for

activity prioritization

•Assessment of metal loss features in accordance with

applicable international/regional codes

•Assessment of other features (e.g., dents) reported by

the inspection

•Identification and prioritization of features requiring

repair

Utilizing our product ROAIMS for the analysis execution,

the client decides whether results are provided in analog

report or in a populated version of the software.

Risk matrix is one of the main tools used

to visualize assessment results.

4 5

Loading...

Loading...