Page 1

Product Data Sheet

00813-0100-4004, Rev KG

Rosemount™ 8800D Vortex Flowmeter

August 2019

Industry Leading Vortex

■

HART™ and FOUNDATION™ Fieldbus Protocols

■

All welded, non-clog design provides maximum performance, reliability and enhanced safety by eliminating ports and gaskets.

■

CriticalProcess™ increases process availability and enhances overall safety.

■

SIL 2/3 Capable: IEC 61508 certified by an accredited 3rd party agency for use in safety instrumented systems up to SIL 3.

■

Available with optional multivariable output. Internal temperature compensation provides cost-effective saturated steam and

liquid mass flow measurement.

■

Adaptive Digital Signal Processing (ADSP) provides vibration immunity and flow range optimization.

■

Reducer™ Vortex extends the measurable flow range, reduces installation costs, and minimizes project risk.

■

Simplified troubleshooting through device diagnostics and meter verification.

■

Available in wafer, flanged, dual, weld end, and reducer and high pressure designs.

Page 2

Product Overview

The Rosemount 8800D delivers reliability, safety, and maximum process availability

August 2019

■

Rosemount Reliability—The Rosemount 8800D Vortex eliminates impulse lines, ports, and gaskets to improve reliability.

■

Non-clog Design—Unique all welded, gasket-free construction which has no ports or crevices that can clog.

■

SIL 2/3 Capable - The Rosemount 8800D Vortex is certified by an accredited 3rd party agency for use in safety instrumented

systems up to SIL 3 (minimum requirement of single use [1oo1] for SIL 2 and redundant use [1oo2] for SIL 3).

■

Vibration Immunity—Mass balancing of the sensor system, and Adaptive Digital Signal Processing (ADSP) provide vibration

immunity.

■

Replaceable Sensor—The sensor is isolated from the process and can be replaced without breaking the process seal. All line sizes

use the same sensor design allowing a single spare to serve every meter.

■

Simplified Troubleshooting—Device Diagnostics enable field verification of meter electronics and sensor without process

shutdown.

Contents

Product Overview.............................................................................................................................................................................. 2

Flow rate sizing..................................................................................................................................................................................7

Ordering Information........................................................................................................................................................................ 8

Product Specifications..................................................................................................................................................................... 16

Product certifications...................................................................................................................................................................... 30

Dimensional drawings..................................................................................................................................................................... 30

2 www.emerson.com/vortex

Page 3

August 2019

The Rosemount 8800D Critical Process Vortex increases process availability and enhances overall safety

Eliminate bypass piping for critical process installations

Traditional vortex installations in critical applications include a bypass line to allow process fluid to be re-directed around the vortex

flow meter during routine sensor maintenance. Rosemount's unique non-wetted sensor can be installed without bypass piping,

even in the most difficult process environments.

Improve process availability

Eliminate the need to shut down the process during routine maintenance and meter verification.

Enhances safety in hazardous process fluid applications

A Critical Process Valve (CPA option) enables access to the sensor cavity to verify that no process fluid is present.

www.emerson.com/vortex 3

Page 4

August 2019

Reduce installed costs, simplify installation and improve performance in liquid

and steam flow applications with the Rosemount 8800D MultiVariable

™

Multivariable vortex design

Incorporates temperature sensor into the vortex meter using the shedder bar as a thermowell, which keeps the vortex and

temperature sensors isolated from process for easy verification and replacement.

Temperature compensated capability for saturated steam

Calculates density from measured process temperature and uses the calculated density to provide a temperature compensated

mass flow. Compensated mass flow using integrated ASME steam tables.

Temperature compensated liquids allows for precision measurement of high temperature liquids by correcting

the liquid density as the process temperature changes

■

Select from water or enter up to five temperature and density pairs to accommodate any liquid type.

■

Water density calculations consistent with IAPWS IF-97.

■

New units of measure such as standard barrels, SBBL, are selectable in the corrected volumetric flow measurement mode.

Reduces installation costs

MultiVariable Vortex eliminates the need for an external thermowell and temperature sensor.

Available with integrated thermowell for flanged (1½ inch through 12 inch) and Reducer Vortex (2 inch

through 12 inch) meter body sizes

To order meter with temperature compensated liquids or temperature compensated steam, include MTA in the model string. For

smaller line sizes, consult your Emerson Flow representative.

4 www.emerson.com/vortex

Page 5

August 2019

Available with flow computer for additional functionality

Integrating the Multivariable vortex flow meter with a pressure transmitter for full pressure and temperature compensation of

superheated steam and various gases provides the following additional functionality:

■

Remote communications

■

Heat flow calculations

■

Remote totalization

■

Peak demand calculation

■

Data logging capabilities

Contact an Emerson Flow representative for more information (see back page).

Maximum reliability and reduced installation complexity with the armored remote cable

■

Improved protection against abrasion, impact, and moisture.

■

Available in 10, 20, 33, 50, and 75 foot (3, 6, 10, 15, and 23 m) lengths.

■

Two cable glands are provided to securely connect the remote cable to transmitter and meter body.

■

The cable gland material will match the material of construction of the mating parts at both the meter body end and

transmitter end. The cable gland that connects to the meter body will utilize a stainless steel gland and the cable gland material

www.emerson.com/vortex 5

Page 6

at the electronics end will be either aluminum or stainless steel depending on the material of the electronics housing that is

ordered.

Detect process fluid changes with SMART Fluid Diagnostics

August 2019

Oil and gas separators

■

Remotely detect when your separator dump valve allows gas to pass through your water dump leg.

■

Selectable alert modes (digital, analog or pulse) signal when gas flow is detected.

Steam, nitrogen, or air blow down

■

Control your clean in place (CIP) or blow down cycles with a single meter that measures the flow rate of your primary process

fluid as well as the change from liquid to gas flow.

■

Set your control system to control down cycle based on alert from in-line vortex meter.

■

Selectable alert modes (digital, analog or pulse) signal when gas flow is detected.

6 www.emerson.com/vortex

Page 7

August 2019

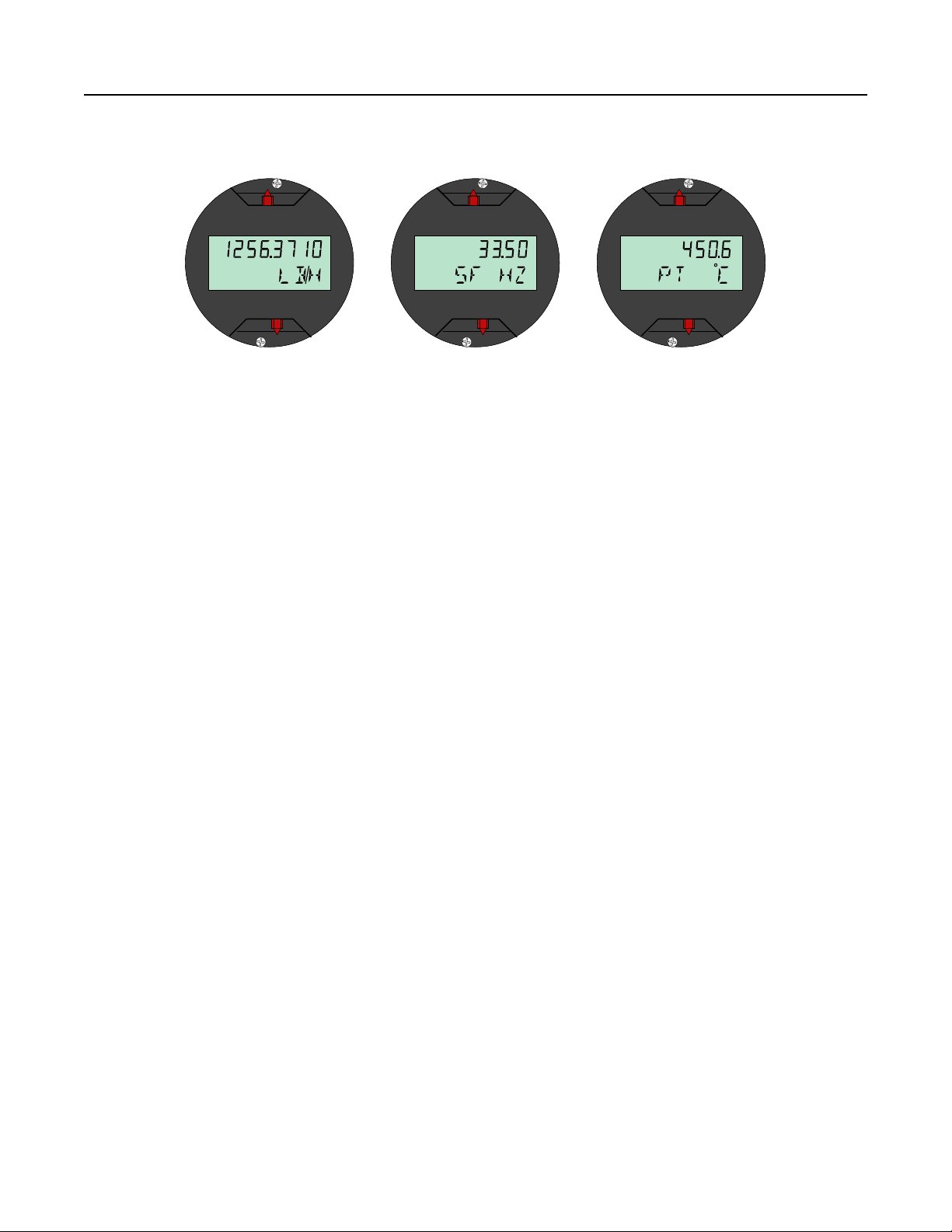

Access process variables and diagnostics locally with the optional LCD Display

HI LO

HI LO

ALARM

ALARM

HI LO

HI LO

ALARM

ALARM

HI LO

HI LO

ALARM

ALARM

SECURITY

SECURITY

TEMP

FLOW

SECURITY

SECURITY

ON OFF

ON OFF

SECURITY

SECURITY

ON OFF

ON OFF

ON OFF

ON OFF

The optional 11 digit, two-line integral LCD display can be configured to alternate between selected display options (e.g., flow,

totalizer, mA output, and (MTA) temperature. Diagnostics and fault conditions, when present, will also appear on the display for

local troubleshooting.

Flow rate sizing

Sizing is critical to select the correct Vortex meter for each application is critical to the performance of the Vortex meter.

■

Refer to the product reference manual for typical flow rates for common applications.

■

Go to the Rosemount 8800D Product Page, and select Size for detailed sizing on most applications, or complete a

Configuration Data Sheet and contact an Emerson Flow representative (see back page).

www.emerson.com/vortex 7

Page 8

August 2019

Ordering Information

Model code structure

In conjunction with a complete model code string, we strongly recommend every meter be configured at the factory for your

application. Use the Configuration Data Sheet (00806-0100-4004) to convey your configuration information to the factory.

Example model code with one selection out of each required category:

8800D F 020 S A1 N 1 D 1 M5 MTA Q4 Q8

The starred (★) offerings represent the best delivery options.

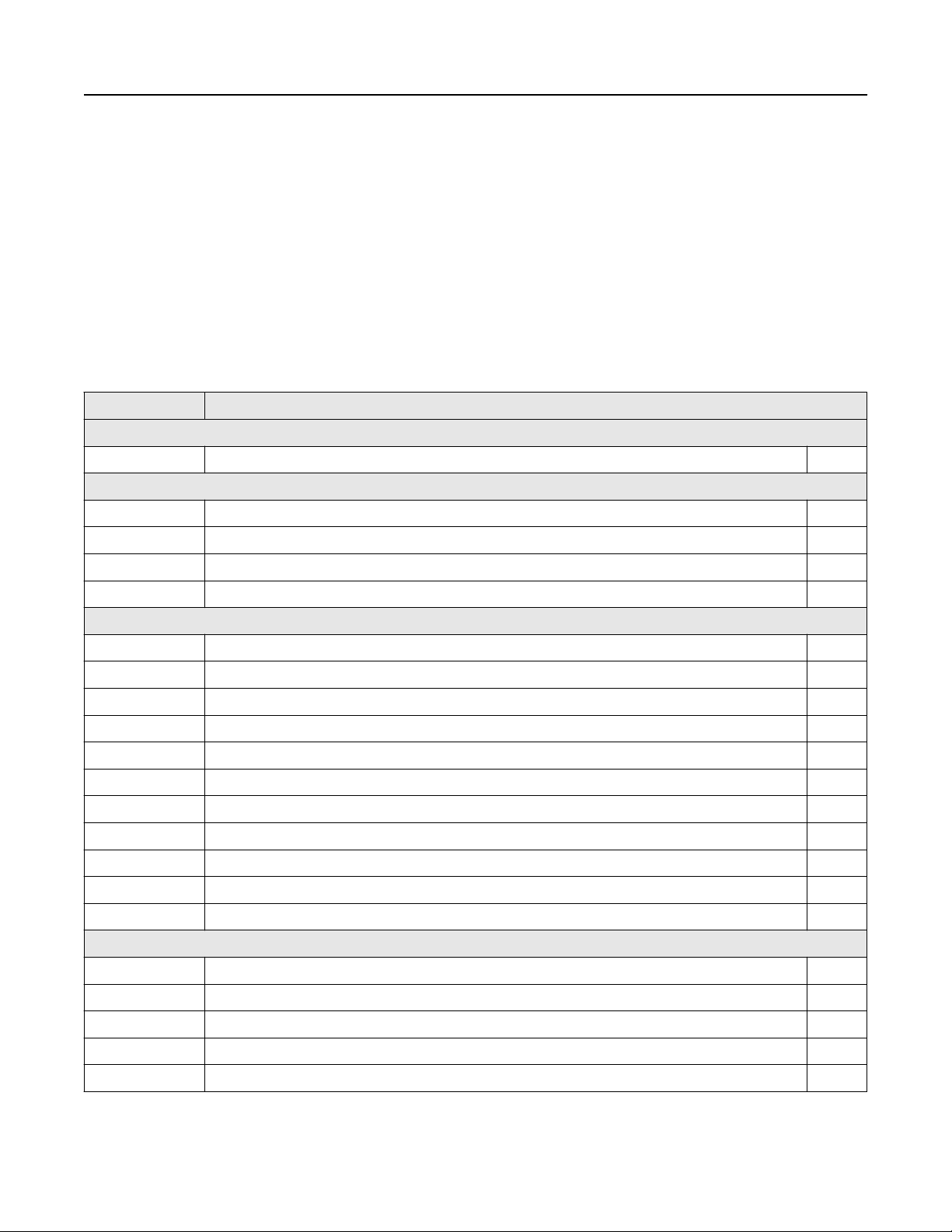

Requirements

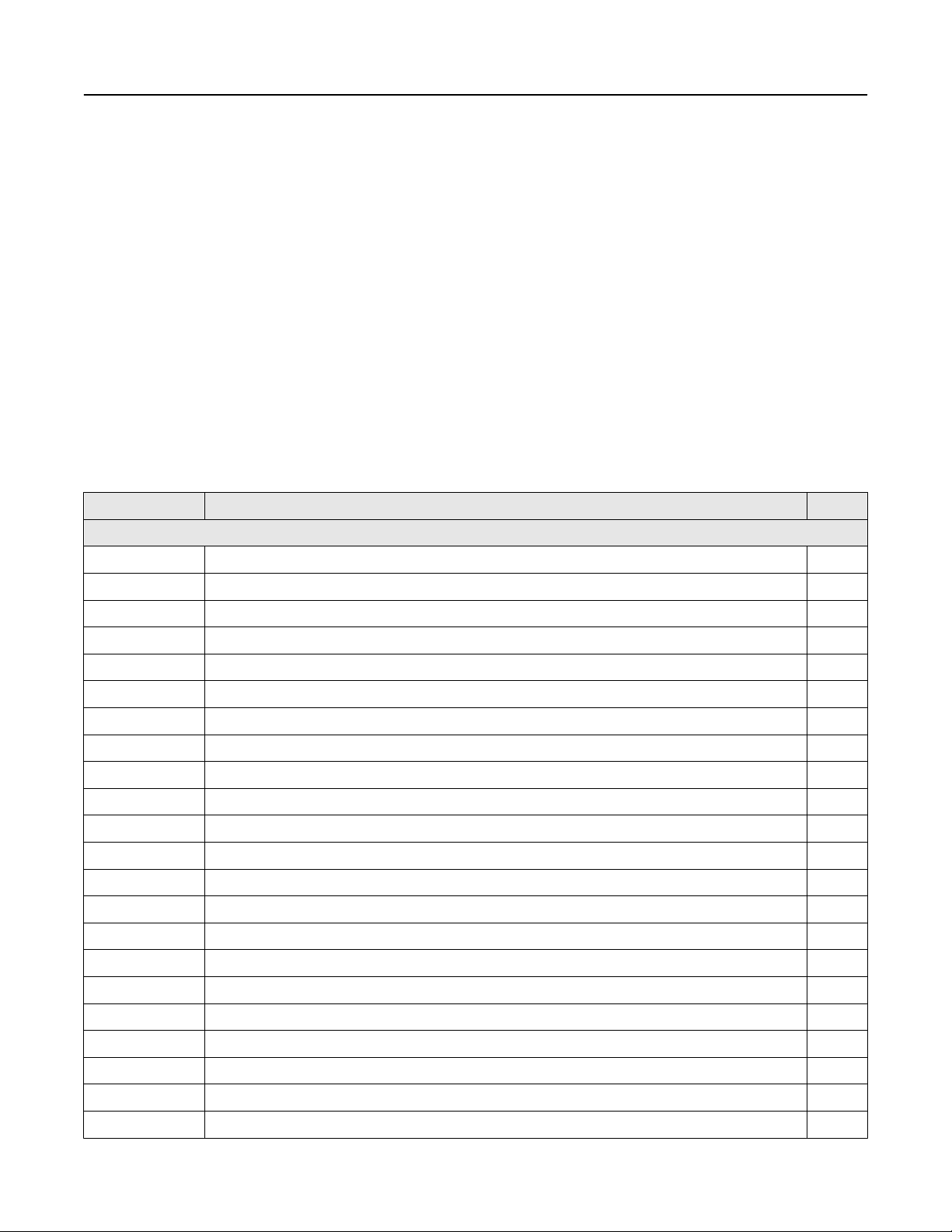

Table 1: Requirements - select one from each available choice

Code Description

Base model

8800D Vortex Flow Meter ★

Meter style

F Flanged ★

W Wafer ★

R Reducer – Meter body is one nominal size smaller than line size selection ★

D Dual-sensor (flanged-style only)

Line size

(1)

005

010 1 inch (25 mm) ★

015 1½ inch (40 mm) ★

020 2 inch (50 mm) ★

030 3 inch (80 mm) ★

040 4 inch (100 mm) ★

060 6 inch (150 mm) ★

080 8 inch (200 mm) ★

100 10 inch (250 mm)

120 12 inch (300 mm)

(2)

140

Wetted materials

S 316 wrought stainless and CF-3M cast stainless; Material of construction is 316/316L. ★

(3)

H

½ inch (15 mm) ★

14 inch (350 mm)

UNS N06022 wrought nickel alloy; CW2M cast nickel alloy.

C A105 forged carbon steel and WCB cast carbon steel

L LF2 forged carbon steel and LCC cast carbon steel

(4)

D

UNS S32760 wrought duplex stainless steel and 6A cast duplex stainless steel

8 www.emerson.com/vortex

Page 9

August 2019

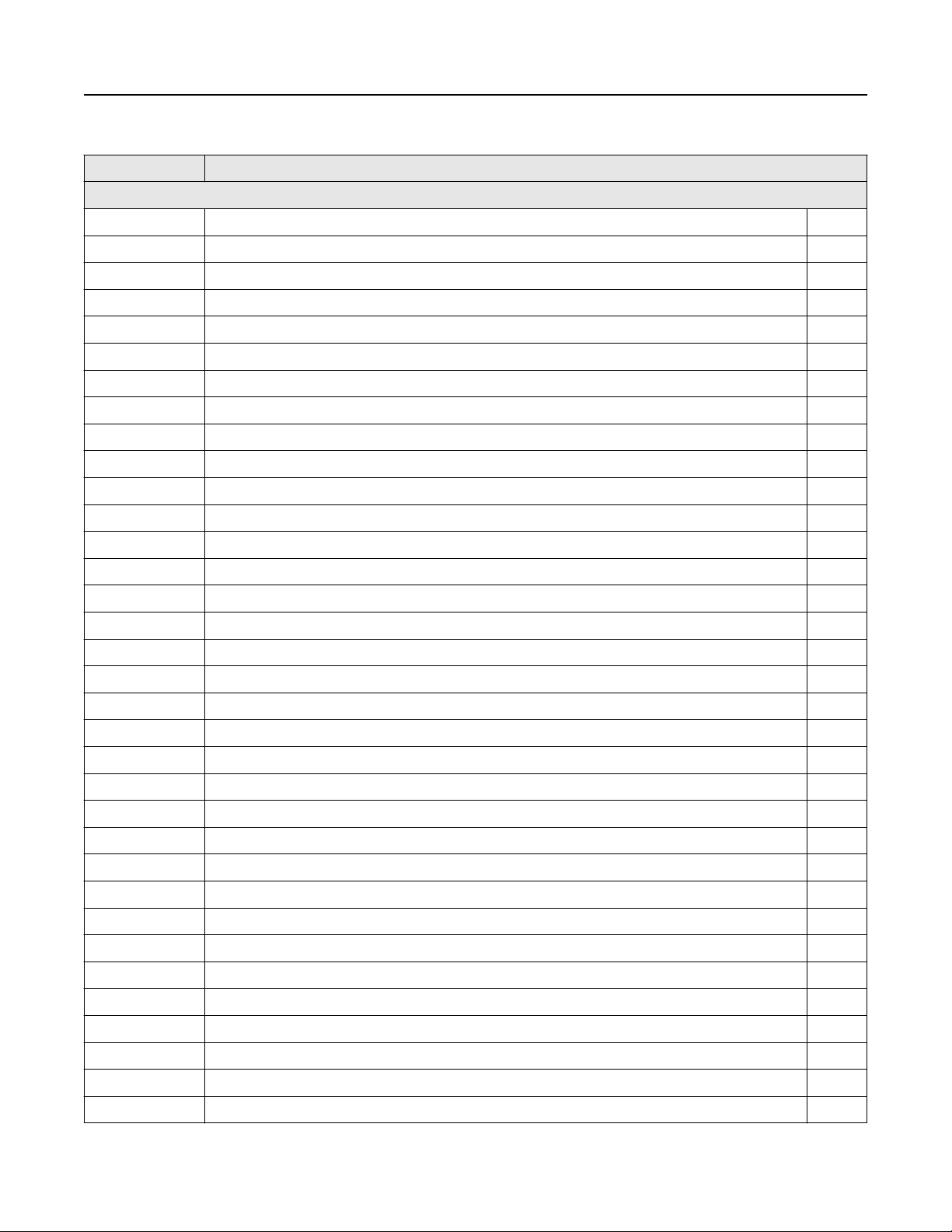

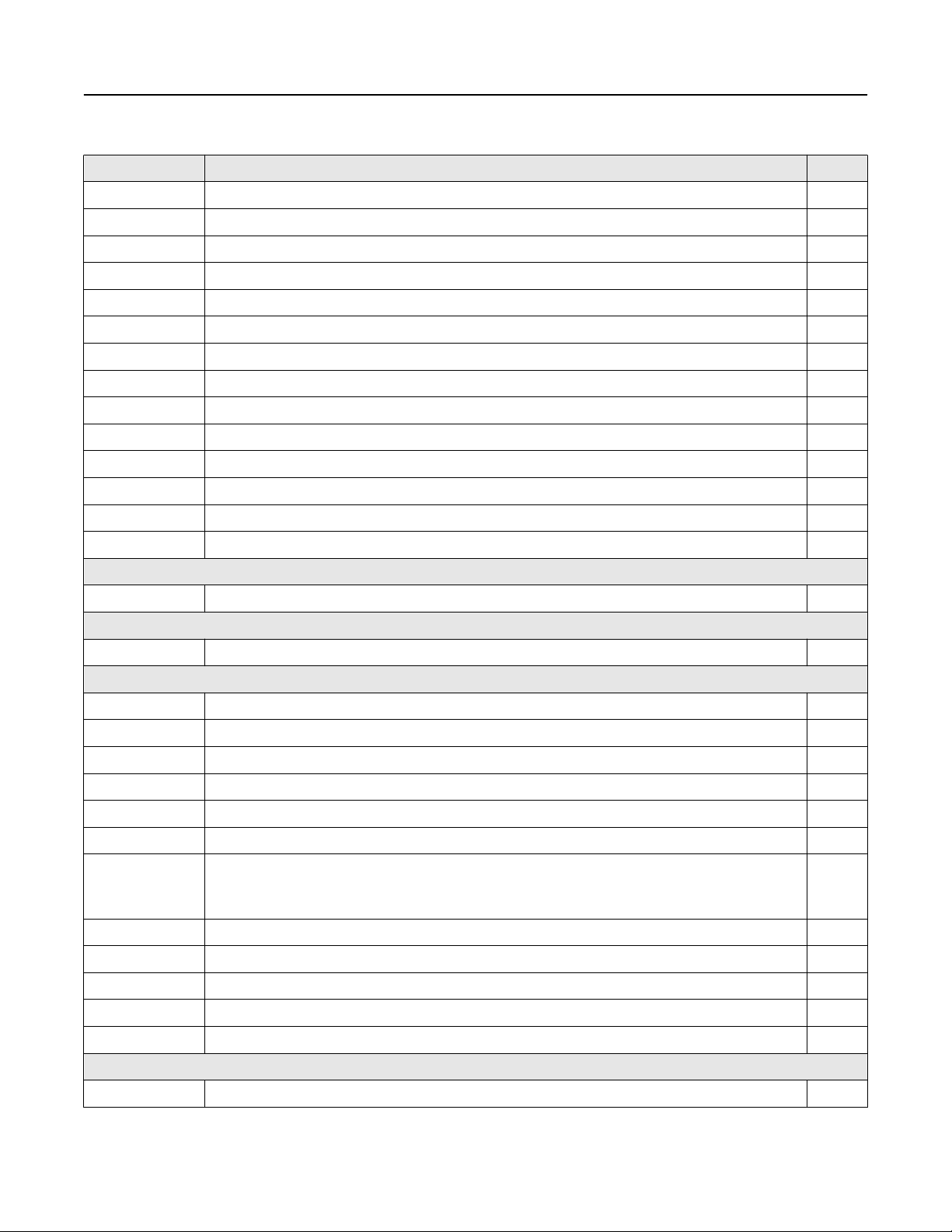

Table 1: Requirements - select one from each available choice (continued)

Code Description

Process connection style and pressure rating

A1 ASME B16.5 (ANSI) RF Class 150 ★

A3 ASME B16.5 RF Class 300 ★

A6 ASME B16.5 RF Class 600

(5)

A7

A8

B1

(6)

(7)

ASME B16.5 RF Class 900

ASME B16.5 RF Class 1500

ASME B16.5 RTJ Class 150 for flange-style only

B3 ASME B16.5 RTJ Class 300 for flange-style only

B6 ASME B16.5 RTJ Class 600 for flange-style only

(5)

B7

B8

(6)

ASME B16.5 RTJ Class 900 for flange-style only

ASME B16.5 RTJ Class 1500 for flange-style only

C1 ASME B16.5 RF Class 150, smooth finish

C3 ASME B16.5 RF Class 300, smooth finish

C6 ASME B16.5 RF Class 600, smooth finish

(5)

C7

C8

(6)

ASME B16.5 RF Class 900, smooth finish

ASME B16.5 RF Class 1500, smooth finish

K0 EN 1092-1 PN 10 Type B1

K1 EN 1092-1 PN 16 (PN 10/16 for wafer style) Type B1 ★

K2 EN 1092-1 PN 25 Type B1

K3 EN 1092-1 PN 40 (PN 25/40 for wafer style) Type B1 ★

K4 EN 1092-1 PN 63 Type B1

K6 EN 1092-1 PN 100 Type B1

(5)

K7

EN 1092-1 PN 160 Type B1

L0 EN 1092-1 PN 10 Type B2

L1 EN 1092-1 PN 16 (PN 10/16 for wafer style) Type B2

L2 EN 1092-1 PN 25 Type B2

L3 EN 1092-1 PN 40 (PN 25/40 for wafer style) Type B2

L4 EN 1092-1 PN 63 Type B2

L6 EN 1092-1 PN 100 Type B2

(5)

L7

EN 1092-1 PN 160 Type B2

M0 EN 1092-1 PN 10 Type D for flange style only

M1 EN 1092-1 PN 16 Type D for flange style only

M2 EN 1092-1 PN 25 Type D for flange style only

M3 EN 1092-1 PN 40 Type D for flange style only

M4 EN 1092-1 PN 63 Type D for flange style only

www.emerson.com/vortex 9

Page 10

Table 1: Requirements - select one from each available choice (continued)

Code Description

M6 EN 1092-1 PN 100 Type D for flange style only

(5)

M7

EN 1092-1 PN 160 Type D for flange style only

N0 EN 1092-1 PN 10 Type F

N1 EN 1092-1 PN 16 Type F

N2 EN 1092-1 PN 25 Type F

N3 EN 1092-1 PN 40Type F

N4 EN 1092-1 PN 63 Type F

N6 EN 1092-1 PN 100 Type F

N7 EN 1092-1 PN 160 Type F

J1 JIS 10K

J2 JIS 20K

J4 JIS 40K

(8)

W1

W4

W8

W9

(8)

(7)(8)

(8)

Weld-end, Schedule 10S

Weld-end, Schedule 40S

Weld-end, Schedule 80S

Weld-end, Schedule 160S

August 2019

Sensor process temperature range

N Standard: –40 to +450 °F (–40 to +232 °C) ★

(9)

E

(9)

S

Extended: –330 to +800 °F (–200 to +427 °C) ★

Severe service: –330 to +800 °F (–200 to +427 °C) and nickel alloy construction for increased

corrosion resistance

Housing material and conduit entries

1 Aluminum housing, two ½–14 NPT conduit entries ★

(10)

2

(10)

3

Aluminum housing, two M20 x 1.5 conduit entries ★

Aluminum housing, two PG 13.5 conduit adapters ★

4 Aluminum housing, one G1/2 conduit adapter (one conduit entry) ★

5 Aluminum housing, two G1/2 conduit adapters (two conduit entries) ★

6 Stainless steel housing, two ½–14 NPT conduit entries

(10)

7

Stainless steel housing, two M20 x 1.5 conduit entries

Outputs

D 4–20 mA digital electronics (HART protocol) ★

P 4–20 mA digital electronics (HART protocol) with scaled pulse ★

(11)

F

FOUNDATION Fieldbus digital signal ★

Calibration

1 Flow calibration ★

10 www.emerson.com/vortex

Page 11

August 2019

Not available for Rosemount 8800DR.

(1)

Code 140 (14 inch [350 mm]) size is only available with reducer.

(2)

See Table 3 for collared vs. weld neck flange configuration.

(3)

Available in Flanged and Dual from 6 inch through 12 inch and Reducer from 8 inch through 12 inch Class 1500 in 6 inch and 8 inch meter body

(4)

sizes and Class 900 in 10 inch through 12 inch meter body sizes.

Available on flanged and dual style meters from 1/2- through 8-in. (15–200 mm) and reducer style meters from 1– 8-in. (25–200 mm). Also

(5)

available in 10- through12-in. (250-300 mm) flanged and dual meters along with 12-in. (300 mm) reducers when using Super Duplex material of

construction.

Only available for flange and dual style meters from 1 inch through 8 inch (25–200 mm).

(6)

Not available with ½ inch line size.

(7)

Only available with Meter Style F.

(8)

The meter body and sensor, in remote mount configurations, is functionally rated to +842 °F process temperature. Process temperature may be

(9)

further restricted depending on hazardous area options and PED certificates. Consult applicable certificates for particular installation limits. –320

°F to 800 °F (–196 to +427 °C) for European Pressure Equipment Directive (PED), consult factory for lower temperature requirements. The Super

Duplex material of construction is limited to use in applications with process temperatures from –40 to +450 °F (–40 to +232 °C).

No Japan (E4) approval.

(10)

The Safety Certifications SI option code is not available with this option.

(11)

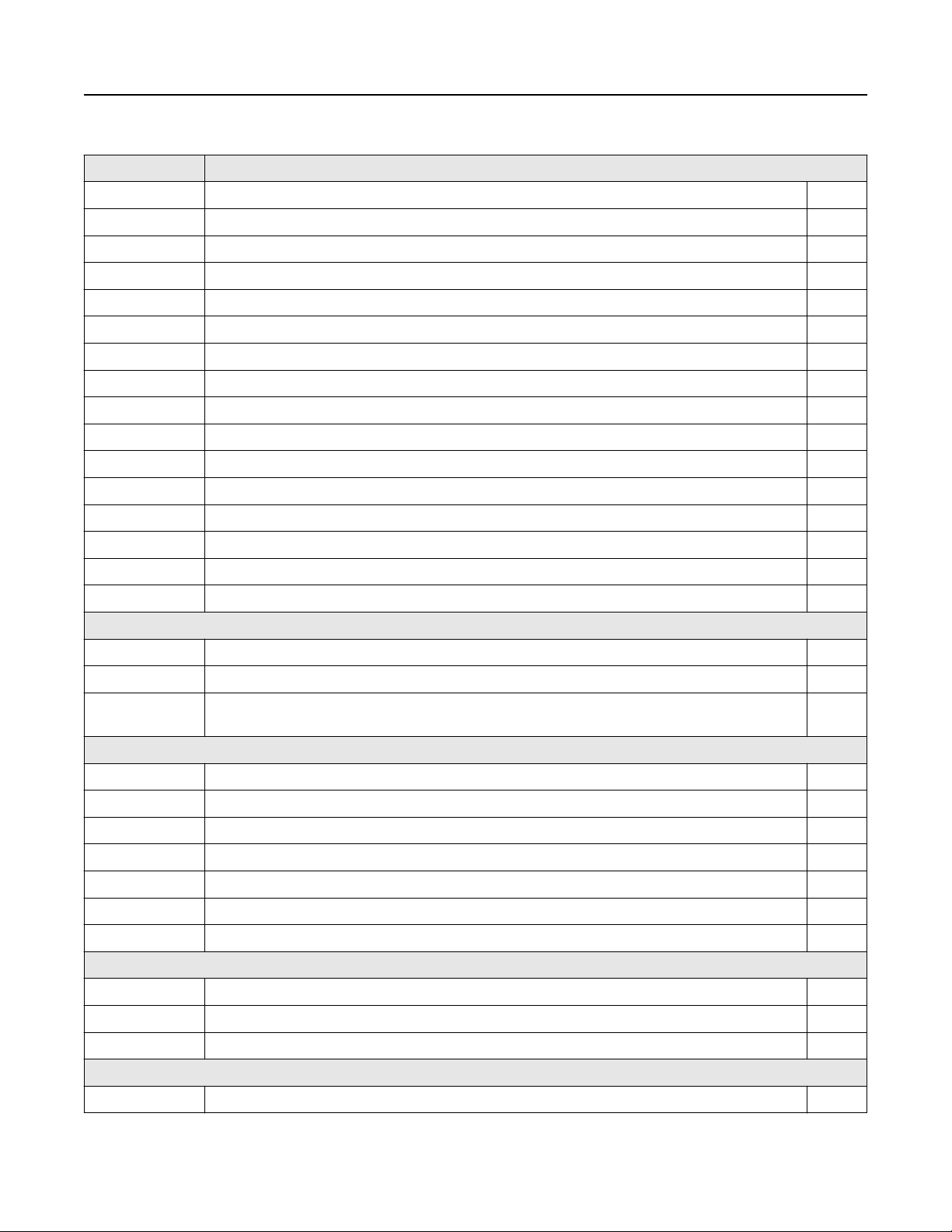

Options

Select only as needed.

Table 2: Options

Code Description

Hazardous area approvals

E5 US Approvals Explosion-proof and Dust Ignition-proof ★

I5 US Approvals Intrinsically Safe and Non-Incendive ★

(1)

IE

US Approvals FISCO Intrinsically Safe and Non-Incendive ★

K5 US Approvals Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Non-Incendive ★

E6 US/Canadian Approvals Explosion-proof and Dust Ignition-proof ★

I6 US/Canadian Approvals Intrinsically Safe and Division 2 ★

(1)

IF

US/Canadian Approvals FISCO Intrinsically Safe and Division 2 ★

K6 US/Canadian Approvals Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

KB US/Canadian Approvals Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ia; Intrinsic Safety ic ★

(1)

IA

ATEX FISCO Intrinsic Safety ★

N1 ATEX Type n ★

ND ATEX Dust ★

K1 ATEX Flameproof; Intrinsic Safety; Type n; Dust ★

E7 IECEx Flameproof ★

I7 IECEx Intrinsic Safety ★

(1)

IG

IECEx FISCO Intrinsic Safety ★

N7 IECEx Type n ★

NF IECEx Dust ★

K7 IECEx Flameproof; Intrinsic Safety; Type n; Dust ★

E2 INMETRO Flameproof ★

www.emerson.com/vortex 11

Page 12

August 2019

Table 2: Options (continued)

Code Description

I2 INMETRO Intrinsic Safety ★

(1)

IB

INMETRO FISCO Intrinsic Safety ★

K2 INMETRO Flameproof; Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

(1)

IH

China FISCO/FNICO Intrinsic Safety ★

K3 China Flameproof; Dust; Intrinsic Safety; Type n ★

E4 Japan Flameproof ★

E8 Technical Regulations Customs Union (EAC) Flameproof ★

I8 Technical Regulations Customs Union (EAC) Intrinsic Safety ★

N8 Technical Regulations Customs Union (EAC) Type n ★

K8 Technical Regulations Customs Union (EAC) Flameproof; Intrinsic Safety; Type n ★

G8 Technical Regulations Customs Union (EAC) FISCO Intrinsic Safety ★

MultiVariable

(2)(3)

MTA

MultiVariable output with temperature compensation and integral temperature sensor ★

Display type

M5 LCD indicator ★

Remote electronics

R10 Remote electronics with 10 ft (3,0 m) cable ★

R20 Remote electronics with 20 ft (6,1 m) cable ★

R30 Remote electronics with 30 ft (9,1 m) cable ★

R33 Remote electronics with 33 ft (10,1m) cable ★

R50 Remote electronics with 50 ft (15,2 m) cable ★

R75 Remote electronics with 75 ft (22,9 m) cable ★

Rxx Remote Electronics with customer-specified cable length (xx ft., 1 ft to 75 ft cable in 1 ft

increments)

Example: R15 = 15 ft, R34 = 34 ft

A10 Armored remote electronics with 10 ft (3,0 m) cable

A20 Armored remote electronics with 20 ft (6,1 m) cable

A33 Armored remote electronics with 33 ft (10,1 m) cable

A50 Armored remote electronics with 50 ft (15,2 m) cable

A75 Armored remote electronics with 75 ft (22,9 m) cable

Transient protection

T1 Transient Protection terminal block

12 www.emerson.com/vortex

Page 13

August 2019

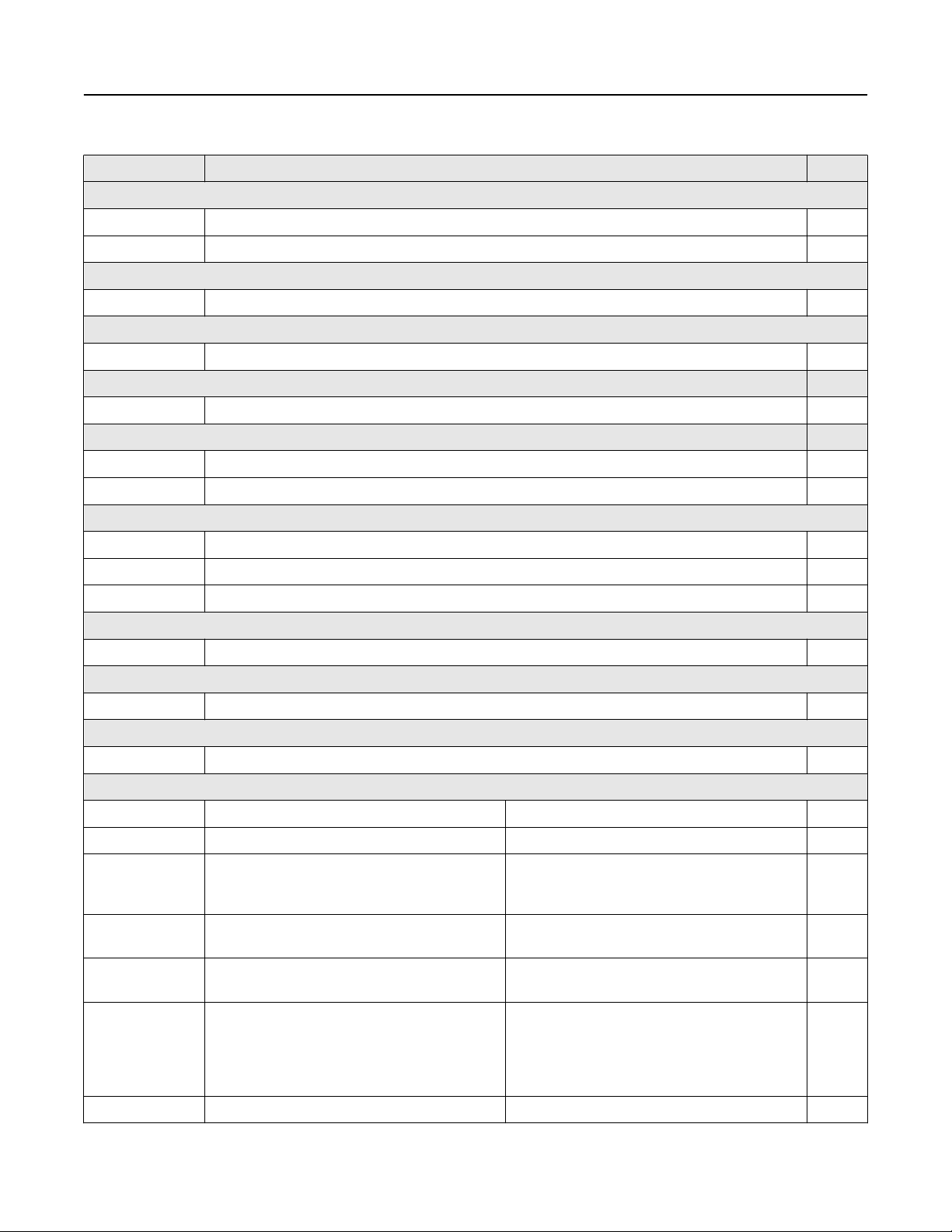

Table 2: Options (continued)

Code Description

Alarm mode

(4)

C4

CN

(4)

NAMUR alarm and saturation values, high alarm ★

NAMUR alarm and saturation values, low alarm ★

Special cleaning

P2 Cleaning for special services ★

Ground screw assembly

V5 External ground screw assembly ★

Plantweb™ control functionality

(5)

A01

Basic Control: One Proportional/Integral/Derivative (PID) Function Block★ ★

ASME B31.1 code compliance

J2 ASME B31.1 General compliance

J7 ASME B31.1 Boiler External Piping (BEP) code stamp

Conduit electrical connectors

(6)

GE

GM

(6)

M12, 4-pin, Male Connector (eurofast™)

A size Mini, 4-pin, Male Connector (minifast™)

GN ATEX Flameproof A size, Mini 4-pin male connector (minifast)

HART communication

(7)

HR7

HART Revision 7 ★

Process diagnostics

(7)

DS3

Smart Fluid Diagnostics ★

Safety certifications

SI Safety Certification of 4–20 mA Output per IEC 61508 ★

Quality certificate

Q4 Calibration Certification Certificate of calibration ★

Q5 Hydrostatic Certification Certificate verifying structural quality ★

Q8 Material Certification Certificate of material conformance and

traceability in accordance with ISO 10474 3.1B

and EN 10204 3.1

QP Calibration Certification and Tamper Evident

Seal

Certificate of calibration with tamper evident

seal

Q25 NACE Certification Certificate verifying MR0175 / ISO15156 and

MR0103 requirements

Q66 Welding Certification Package Includes Welding Qualification Record

Documentation (PQR), Certificate for Welder

Performance Qualification Records (WPQ), and

Certification for Welding Procedure

Specifications (WPS)

★

★

★

★

Q70 Radiographic, Dye Pen, and Helium Certification Certificate verifying weld joint integrity

www.emerson.com/vortex 13

Page 14

Table 2: Options (continued)

Code Description

August 2019

Q71 Radiographic, Dye Pen, and Helium Certification

with Images

Certificate verifying weld joint integrity with Xray images

Q76 PMI Certification Certificate verifying chemical composition of

material

Q77 PMI Certification with Carbon Content Certificate verifying chemical composition of

material and carbon content

Sensor completion

WG Witness General

Pressure Equipment Directive (PED)

PD Pressure Equipment Directive (PED) ★

Shipboard approvals

SBS American Bureau of Shipping (ABS) type approval ★

SBV Bureau Veritas (BV) type approval ★

SDN Det Norske Veritas (DNV) type approval ★

SLL Lloyd’s Register (LR) type approval ★

Critical process vortex

(8)

CPA

Critical Process Online Sensor Replacement

Quick Start Guide language (default is English)

★

★

YF French ★

YG German ★

YI Italian ★

YJ Japanese ★

YK Korean ★

YM Chinese (Mandarin) ★

YP Portuguese ★

YR Russian ★

YS Spanish ★

Fieldbus Intrinsic Safe Concept (FISCO) available with output code F (Foundation Fieldbus digital signal) only.

(1)

The Safety Certifications SI option code is not available with this option.

(2)

Available with Rosemount 8800DF from 1½ inch through 12 inch (40 mm through 300 mm). Available with 8800DR from 2 inch through 12 inch

(3)

(50 mm through 300 mm). Not available with 8800DW or 8800DD.

NAMUR compliant operation and the alarm latch options are preset at the factory and can be changed to standard operation in the field.

(4)

Requires output code F.

(5)

Not available with certain hazardous location certifications. Contact an Emerson Flow representative for details (see back page).

(6)

The Safety Certifications SI option code is not available with this option.

(7)

The CPA option is not available on wafer, ½ inch flange, or 1 inch reducer units. In addition it is not available on 1 inch flanged and 1½ inch

(8)

reducer JIS 10K, EN PN40, or EN PN16. Not available with Super Duplex or B31.1 line sizes greater than 6 inch.

14 www.emerson.com/vortex

Page 15

August 2019

Table 3: Material of construction details for wetted material code H

Flange rating code

Line size in. (mm) A1 A3 A6 A7 K1 K3 K4 K6 K7

½ (15) C C C W W W NA W W

1 (25) C C C W W W NA W W

1½ (40) C C C W W W NA W W

2 (50) C C C W C C W W W

3 (80) C C C W C C W W W

4 (100) C C C W C C W W W

6 (150) C C C * W W W W *

8 (200) C C C * W W W W *

10 (250) W W W NA W W W W NA

12 (300) W W W NA W W W W NA

14 (350) Reducer only W W W W W W W W W

C

Nickel alloy collar and 316 SST lap flange (Table 4). If weld neck flange is required, please consult factory.

W

Nickel alloy weld neck flange (Table 4).

*

Contact an Emerson Flow representative (see back page).

NA

Not Available.

All Rosemount 8800DR Reducer Vortex Meters with nickel alloy materials of construction use weld neck flanges.

All other listed flange rating codes use weld neck flanges.

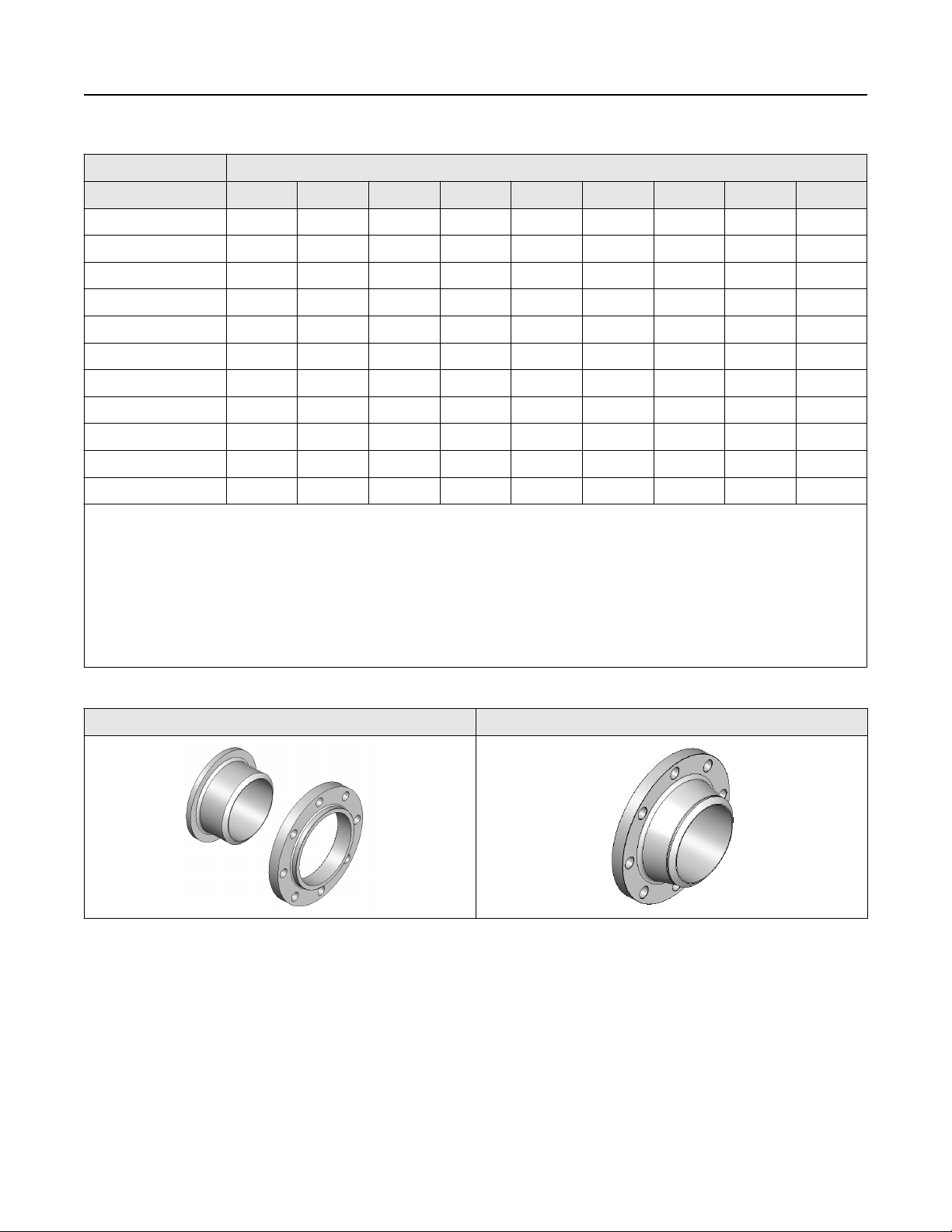

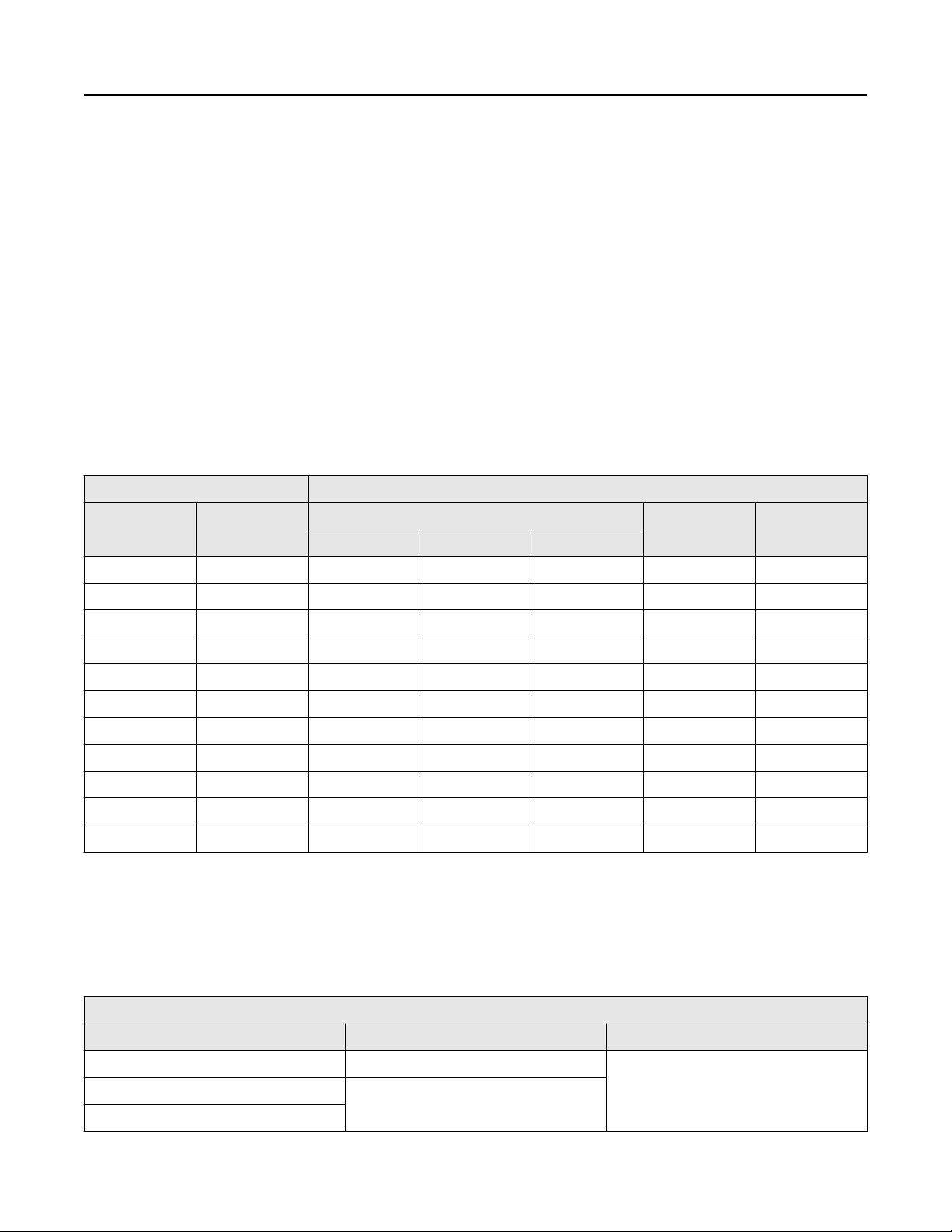

Table 4: Flange illustrations

Collar/lap Weld neck

www.emerson.com/vortex 15

Page 16

August 2019

Product Specifications

Physical specifications

Process fluids

Liquid, Gas, and Steam applications. Fluids must be homogeneous and single-phase.

Flow calibration

Every Emerson Vortex flowmeter is water calibrated and given a unique calibration number called a reference K-factor. Emerson

flow labs use traceable calibrations that reference internationally recognized standards such as NIST in the United States and

Mexico, National Institute of Standards in China, and ISO 10725 in Europe.

Theoretical and experimental data have shown that the K-factor is independent of fluid density and viscosity, proving the K-factor is

applicable in all types of fluid—liquid, gas and steam. The K-factor is a function of the shedder bar and meter geometry.

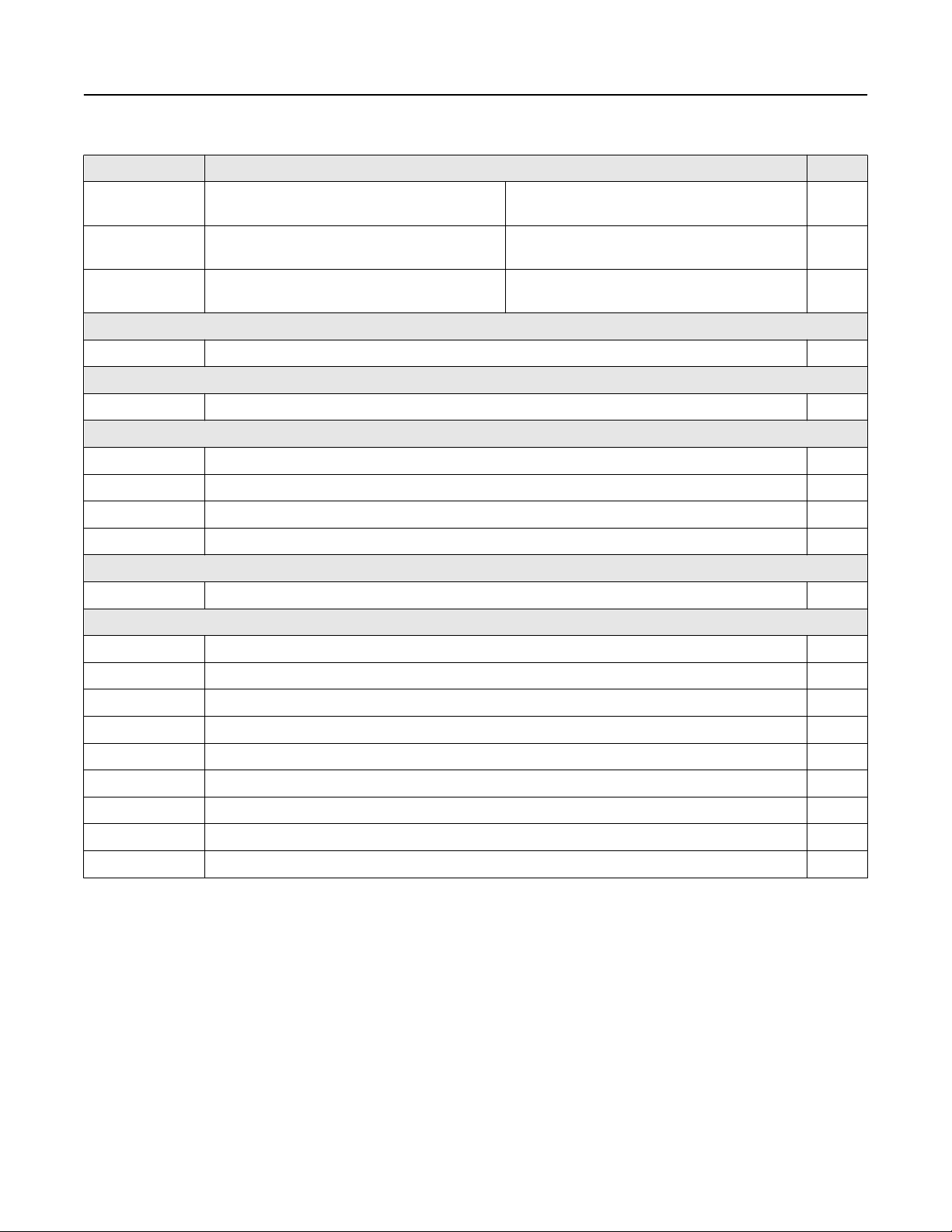

Line sizes and pipe schedules

Table 5: Line sizes by process connection type

Line size Process connection type (✓ indicates availability)

Inches DIN Flanged Wafer Weld-end

Standard Dual Reducer

0.5 15 ✓ ✓ ✓ ✓

1 25 ✓ ✓ ✓ ✓ ✓

1.5 40 ✓ ✓ ✓ ✓ ✓

2 50 ✓ ✓ ✓ ✓ ✓

3 80 ✓ ✓ ✓ ✓ ✓

4 100 ✓ ✓ ✓ ✓ ✓

6 150 ✓ ✓ ✓ ✓ ✓

8 200 ✓ ✓ ✓ ✓ ✓

10 250 ✓ ✓ ✓ ✓

12 300 ✓ ✓ ✓ ✓

14 350 ✓

Process pipe schedules

Meters will be shipped from the factory at the Schedule 40 default value unless otherwise specified. The value can be changed in

the field if necessary.

For a weld-end style meter, see Table 11.

Table 6: Wetted materials by component

Process wetted materials

Meter body Flanges Collar

CF–3M cast stainless steel 316 / 316 L stainless steel N06022 nickel alloy

CW2M cast nickel alloy N06022 nickel alloy weld neck

N06022 wrought nickel alloy

(2)

(1)

16 www.emerson.com/vortex

Page 17

August 2019

Table 6: Wetted materials by component (continued)

Process wetted materials

Meter body Flanges Collar

WBB cast carbon steel A105 forged carbon steel

LCC cast carbon steel LF2 forged carbon steel

6A duplex stainless steel UNS S32760 wrought duplex stainless

steel

Mated with 316/316L stainless steel lap flange.

(1)

Applicable to 10 inch and 12 inch meters only.

(2)

Surface finish

■

Standard surface facing finish meets the requirements of the applicable flange standard.

■

Optional smooth facing finish (flange option codes Cx) is 63 to 125 μ inches (1.6 to 3.1 μ meters) Ra roughness.

NACE compliance

■

Materials of Construction meet NACE material recommendations per MR0175 / ISO15156 for use in H₂S containing

environments in oil field production.

■

Materials of Construction also meet NACE recommendations per MR0103-2003 for corrosive petroleum refining environments.

■

MR0103/MR0103 compliance requires Q25 option in model code.

Table 7: Non-wetted materials by component

Non-wetted Materials

Sensor 316 SST or Monel / Iconel

Lap Flange 316 / 316 L SST

Type N Thermocouple 304 Stainless Steel

Transmitter support tube 316 Stainless Steel

Transmitter housing Aluminum or 316 Stainless Steel

Pressure limits

Table 8: Flanged/Dual style meter

ASME 16.5 EN1092-1 JIS

Class 150 PN 10 10K

Class 300 PN 16 20K

Class 600 PN 25 40K

Class 900 PN 40

Class 1500 PN 63

PN 100

PN 160

www.emerson.com/vortex 17

Page 18

Table 9: Reducer style meter

ASME 16.5 EN1092-1

Class 1500 PN 63

Table 10: Wafer style meter

ASME 16.5 EN1092-1 JIS

Class 150 PN 10 10K

Class 300 PN 16 20K

Class 600 PN 25 40K

August 2019

Class 150 PN 10

Class 300 PN 16

Class 600 PN 25

Class 900 PN 40

PN 100

PN 160

PN 40

PN 63

PN 100

Table 11: Weld-end style meter

W1 W4 W8 W9

Mating pipe schedule: Schedule 10 Schedule 40 Schedule 80 Schedule 160

Pressure rating for 1

720 psig (4.96 MPa-g) 1440 psig (9.93 MPa-g) 2160 psig (14.9 MPa-g) 3600 psig (24.8 MPa-g)

inch to 4 inch sizes:

Pressure rating for 6

N/A 720 psig (4.96 MPa-g) 1440 psig (9.93 MPa-g) 2160 psig (14.9 MPa-g)

inch to 12 inch sizes:

Temperature limits

Table 12: Vortex sensor temperature limits

Vortex sensor Temperature limit

Standard –40 °F to +450 °F (–40 °C to +232 °C)

Extended –330 °F to +800 °F (–201 °C to +427 °C)

(1)

Severe

(1) The meter body and sensor, in remote mount configurations, is functionally rated to +842 °F process temperature. Process

temperature may be further restricted depending on hazardous area options and PED certificates. Consult applicable certificates

for particular installation limits.

–320 °F to 800 °F (–196 to +427 °C) for European Pressure Equipment Directive (PED), Contact an Emerson Flow representative

(see back page).

The Super Duplex material of construction is limited to use in applications with process temperatures from –40 to +450 °F (–40 to

+232 °C). Contact an Emerson Flow representative (see back page).

–330 °F to +800 °F (–201 °C to +427 °C)

18 www.emerson.com/vortex

Page 19

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

br)

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

br)br&

$PELHQWWHPSHUDWXUH

3URFHVVWHPSHUDWXUH

7HPSHUDWXUH

OLPLWIRUKRXVLQJ

August 2019

Table 13: Temperature sensor (MTA option) temperature limits

Temperature sensor Temperature limit

Type N thermocouple –40 °F to +800 °F (–40 °C to +427 °C)

Meets ASTM E230/E230M-17 Special Tolerance Standard.

(1)

Table 14: Electronics temperature limits (remotely-mounted transmitter)

Ambient operating temperature range –58 °F to +185 °F (–50 °C to +85 ° C)

(1)

Ambient operating temperature range

with LCD—Local Indicator

(1)

–40 °F to +185 °F (–40 °C to +85 ° C)

Storage temperature range –58 °F to +250 °F (–50 °C to +121 ° C)

Storage temperature range with LCD –50 °F to +185 °F (–46 °C to +85 ° C)

LCD contrast may be affected below –4 °F (–20 °C).

(1)

Table 15: Electronics temperature limits (integrally-mounted transmitter)

Operating and storage temperature

range, with and without LCD

Same as remotely-mounted transmitter. See Table 14. However, high process

temperature lowers the maximum allowable ambient temperature. See Figure 1.

Maximum process temperature Interdependent with ambient temperature. Figure 1 indicates the combined ambient

and process temperature limits under which the electronics temperature can be

maintained below the maximum +185 °F (+85 ° C).

Note

The indicated limit is with the integral transmitter directly above a horizontal pipe,

and the pipe insulated with three inches of ceramic fiber. Other configurations may

affect the actual electronics temperature.

Figure 1: Maximum ambient/process temperature limit

EMI/RFI effect

■

Meets EMC requirements to Directive 2014/30/EU.

■

Output error less than ±0.025% of span with twisted pair from 80-1000 MHz for radiated field strength of 10 V/m.

■

1.4 - 2.0 GHz for radiated field strength of 3 V/m.

www.emerson.com/vortex 19

Page 20

■

2.0 - 2.7 GHz for radiated field strength of 1 V/m.

■

No affect on the values that are being given if using HART digital signal.

■

Tested per EN61326.

Humidity limits

Operates in 0–95% relative humidity under noncondensing conditions (tested to IEC 60770, Section 6.2.11).

Transmitter housing details

Table 16: Transmitter housing (enclosure) physical details

Material of construction Low-copper aluminum is standard. 316 SST is optional.

Enclosure rating CSA Type 4X; IP66.

Conduit entry ½–14 NPT or M20 x 1.5 threads

Paint Polyurethane

Cover O-rings Buna -N

Remote transmitter mounting hardware and cables

■

Mounting hardware is provided.

■

The transmitter and meter body are interconnected by a standard or armored signal cable assembly.

— Cable length is specified when ordered (see Ordering Information), and it cannot be altered in the field.

— Standard cable is non-armored and is intended to be run through rigid metal conduit.

— Armored cable includes glands/adapters to connect the cable to the meter body and transmitter.

— Both types of cable are flame resistant in accordance with IEC 60322-3.

August 2019

Tagging

■

Standard tags are stainless steel.

■

The standard tag is permanently attached to the flowmeter.

■

Character height is 1/16 inch (1,6 mm).

■

A wired-on tag is available on request.

■

Character height on the wire-on tag is 0.236 inch (6 mm).

■

Wire on tags can contain five lines with an average of 19 characters per line at standard character height.

Performance specifications

The following performance specifications are for all Rosemount models except where noted. Digital performance specifications

applicable to both Digital HART and FOUNDATION Fieldbus output. Unless stated otherwise, all accuracy specifications include

linearity, hysteresis, and repeatability.

Volume flow accuracy

Table 17: Volume flow accuracy

Process fluid

Liquids with Reynolds number over 20,000 ±0.65% of rate

Gas and steam with Reynolds number over 15,000 ±1.0% of rate

Digital and pulse output

(1)(2)

(3)(2)

20 www.emerson.com/vortex

Page 21

August 2019

Table 17: Volume flow accuracy (continued)

Process fluid

For all process fluids from stated limit to a Reynolds number of

Digital and pulse output

From process limit specification to ±2% linear increase

10,000

For Reynolds numbers less than 10,000 to 5,000 ±2% to ±6%, linear

6 inch to 12 inch reducer (150 mm to 300 mm) ±1.0% of rate.

(1)

Analog ±0.025% of span

(2)

6 inch to 12 inch reducer (150 mm to 300 mm): ±1.35% of rate.

(3)

Accuracy limitations for gas and steam:

■

For ½ inch and 1 inch (DN 15 and DN 25); max velocity of 220 ft/s (67.06 m/s)

■

For all dual shedder bar design meters: max velocity of 100 ft/s (30.5 m/s)

■

For dual shedder bar design meters above 100 ft/s (30.5 m/s) contact an Emerson Flow representative (see back page).

Volume flow repeatability

±0.1 percent of actual flow rate.

Process temperature accuracy

Table 18: Process temperature accuracy by installation type

Installation type Process temperature accuracy

Integral mount 2.2 °F (1.2 °C) or 0.4% of reading, whichever is greater

Remote mount Add ±0.018 °F/ft (±0.03 °C/m) of uncertainty to measurement

Temperature sensor accuracy meets ASTM E230/E230M-17 Special Tolerance Standard.

Mass flow accuracy

Table 19: Mass flow accuracy by process fluid type

Process fluid type Accuracy

Temperature compensated Steam ±2.0% of rate (typical)

Temperature compensated Liquid (water) ±0.70 % of rate up to 500 °F (260 °C)

(1)

Temperature compensated liquid (user defined) Dependent on user inputs

±0.85% of rate between 500 °F to 600 °F (260 °C to 316 °C)

(1)

Process temperature effect on K-factor

The compensated K-factor is based on the reference K-factor as compensated for the given process temperature and wetted

materials. Compensated K-factor is calculated by the electronics.

The percentage change in K-factor for all materials is no greater than ±0.3 per 100 °F (56 °C).

Table 20: Ambient temperature effect

Output type Ambient temperature effect

Digital and pulse output No effect

Analog output ±0.1% of span from –58 °F to 185 °F (–50 to 85 °C)

www.emerson.com/vortex 21

Page 22

August 2019

Measurable flow rates

Capable of processing signals from flow applications which meet the Reynolds number and velocity limitations listed in Table 21,

Table 22, and Table 23.

Table 21: Minimum Measurable Meter Reynolds Numbers

Meter sizes Reynolds number limitations

½ – 4 inch (DN 15 – DN100) 5000 minimum

6 – 12 inch (DN150 – DN300)

Table 22: Minimum measurable meter velocities

Process Feet per second

(2)

Liquids

(2)

Gases

(1)

36/ρ 54/ρ

36/ρ 54/ρ

ρ is the process fluid density at flowing conditions in lb/ft³ for ft/s and kg/m³ for m/s.

Referenced to schedule 40 pipe.

(1)

This minimum measurable meter velocity is based on default filter settings.

(2)

Table 23: Maximum Measurable Meter Velocities (use the smaller of the two values)

Process Feet per second

(1)

Meters per second

Meters per second

(1)

(1)

Liquids

Gases

(2)

90,000/ρ

90,000/ρ

or 25

or 300

134,000/ρ

134,000/ρ

or 7.6

or 91.4

ρ is the process fluid density at flowing conditions in lb/ft³ for ft/s and kg/m³ for m/s.

Referenced to schedule 40 pipe.

(1)

Accuracy limitations for gas and steam for dual-style meters (½ to 4 inch): max velocity of 100 ft/s (30.5 m/s).

(2)

Note

Go to the Rosemount 8800D Product Page, and select Size for detailed sizing on most applications, or complete a Configuration

Data Sheet and contact an Emerson Flow representative (see back page).

Permanent pressure loss

The approximate permanent pressure loss (PPL) from the flowmeter is calculated for each application in the Vortex sizing software.

Go to the Rosemount 8800D Product Page, and select Size for detailed sizing on most applications, or complete a Configuration

Data Sheet and contact an Emerson Flow representative (see back page).

The PPL is determined using the equation:

22 www.emerson.com/vortex

Page 23

August 2019

2

4

D

PPL

Permanent pressure loss (psi or kPa)

ρ

Density at operating conditions (lb/ft³ or kg/m³)

ƒ

Q

Actual volumetric flow rate (Gas = ft³/min or m³/hr; Liquid = gal/min or l/min)

D

Flowmeter bore diameter (in. or mm)

A

Constant depending on meter style, fluid type, and flow units. Determined

PPL =

A × ρƒ× Q

per :

Meter style English units SI units

8800DF/W 3.4 × 10

8800DR 3.91 × 10

8800DD

(1)

For all 6- through 12-in. line sizes, A is the same for 8800DD and 8800DF

(1)

A

liquid

(1)

6.12 × 10

For all 6- through 12-in. line sizes, A is the same for 8800DD and 8800DF

A

gas

–5

1.9 × 10

–5

2.19 × 10

–5

3.42 × 10

A

liquid

–3

0.425 118

–3

0.489 136

–3

0.765 212

A

gas

Minimum upstream pressure (liquids)

Flow metering conditions that would allow cavitation, the release of vapor from a liquid, should be avoided. This flow condition can

be avoided by remaining within the proper flow range of the meter and by following appropriate system design.

For some liquid applications, incorporation of a back pressure valve should be considered. To prevent cavitation, the minimum

upstream pressure should be the smaller result of these two equations:

■

2.9 × ΔP + 1.3 × p

■

2.9 × ΔP + pv + 0.5 psia (3.45 kPa)

Where:

v

P

Line pressure five pipe diameters downstream of the meter (psia or kPa abs)

ΔP

Pressure loss across the meter (psi or kPa)

p

Liquid vapor pressure at operating conditions (psia or kPa abs)

v

Vibration effect

High vibration may cause a false flow measurement when there is no flow. The meter design will minimize this effect, and the

factory settings for signal processing are selected to eliminate these errors for most applications. If an output error at zero flow is

still detected, it can be eliminated by adjusting the low flow cutoff, trigger level, or low-pass filter. As the process begins to flow

through the meter, most vibration effects are quickly overcome by the flow signal.

Vibration specifications

■

Integral aluminum housings, remote aluminum housings, and remote SST housings: At or near the minimum liquid flow rate in

a normal pipe mounted installation, the maximum vibration should be 0.087 inch (2,21 mm) double amplitude displacement or

1 g acceleration, whichever is smaller. At or near the minimum gas flow rate in a normal pipe mounted installation, the

maximum vibration should be 0.043 inch (1,09 mm) double amplitude displacement or ½ g acceleration, whichever is smaller.

■

Integral SST housing: At or near the minimum liquid flow rate in a normal pipe mounted installation, the maximum vibration

should be 0.044 inch (1,11 mm) double amplitude displacement or ⅓ g acceleration, whichever is smaller. At or near the

minimum gas flow rate in a normal pipe mounted installation, the maximum vibration should be 0.022 inch (0,55 mm) double

amplitude displacement or ⅙ g acceleration, whichever is smaller.

www.emerson.com/vortex 23

Page 24

August 2019

Mounting position effect

Meter will meet accuracy specifications when mounted in horizontal, vertical, or inclined pipelines. Best practice for mounting in a

horizontal pipe is to orient the shedder bar in the horizontal plane. This will prevent solids in liquid applications and liquid in gas/

steam applications from disrupting the shedding frequency.

Pipe length requirements

Rated accuracy is based on the number of pipe diameters from an upstream disturbance. No K-factor correction is required if the

meter is installed with 35D upstream and 5D downstream. The value of the K-factor may shift up to 0.5% when the upstream

straight pipe length is reduced down to the minimum recommended 10D. Refer to the Rosemount 8800 Vortex Installation Effects

Technical Data Sheet for detailed information on K-factor correction.

Flow calibration information

Flowmeter calibration and configuration information is provided with every flowmeter. For a certified copy of flow calibration data,

the Q4 option code must be ordered in the model number.

HART specifications

Output signals

Digital HART signal

Optional scalable pulse

output

Bell 202 superimposed on 4–20 mA signal

0 to 10000 Hz; transistor switch closure with adjustable scaling via HART communications; capable

of switching from 5 to 30 Vdc, 120 mA maximum

Analog output adjustment

Engineering units and lower and upper range values are user-selected. Output is automatically scaled to provide 4 mA at the

selected lower range value, 20 mA at the selected upper range value. No frequency input is required to adjust the range values.

Scalable frequency adjustment

The scalable pulse output can be set to a specific velocity, volume, or mass (i.e. 1 pulse = 1 lb). The scalable pulse output can also be

scaled to a specific rate of volume, mass, or velocity (i.e. 100 Hz = 500 lb/hr).

Analog 4–20 mA Power supply

External power supply required. Flowmeter operates on 10.8 VDC to 42 VDC terminal voltage. See Figure 2.

Power consumption

One watt maximum

24 www.emerson.com/vortex

Page 25

5വ

9SV

August 2019

HART communication

Figure 2: HART communication voltage/resistance requirement

Maximum loop resistance is determined by the voltage level of the external power supply, as described in the graph.

Note that HART Communication requires a minimum loop resistance of 250 ohms up to a maximum of 1100 ohms.

R(Ω)

V

ps

R(Ω)max = 41.7 (Vps – 10.8 V).

Load resistor value.

Minimum power supply voltage required

Failure mode alarm levels

If transmitter self-diagnostics detect a fault condition, the analog signal will be driven to the values in Table 24.

Table 24: mA outputs for low and high alarm

Alarm jumper position mA output by Alarm Type setting

Rosemount standard NAMUR-compliant

Low 3.75 3.60

Hi 21.75 22.6

The Alarm and Saturation Type settings can be pre-configured at the factory (Options C4 and CN for NAMUR-compliance) or user-configured.

(1)

Saturation output values

When the operating flow is outside the range points, the analog output continues to track the operating flow until reaching the

saturation values in Table 25. The output does not exceed the listed saturation value regardless of the operating flow.

(1)

www.emerson.com/vortex 25

Page 26

August 2019

Table 25: mA output saturation values

mA output saturation value by type

Rosemount standard NAMUR-Compliant

Low 3.9 3.8

Hi 20.8 20.5

The Alarm and Saturation Type settings can be pre-configured at the factory (Options C4 and CN for NAMUR-compliance) or user-specified.

(1)

(1)

Damping

Flow Damping adjustable between 0.2 and 255 seconds.

Process temperature damping adjustable between 0.4 and 32.0 seconds (MTA Option only).

Response time

Three vortex shedding cycles or 300 ms, whichever is greater, maximum required to reach 63.2% of actual input with the minimum

damping (0.2 seconds).

Turn-on time

Less than six seconds plus the response time to rated accuracy from power up (less than eight seconds with the MTA Option).

Transient protection

The optional transient terminal block prevents damage to the flowmeter from transients induced by lightning, welding, heavy

electrical equipment, or switch gears. The transient protection electronics are located in the terminal block.

The transient terminal block meets the following specifications:

■

IEEE C62.41 - 2002 Category B

■

3 kA crest (8 3 20 ms)

■

6 kV crest (1.2 3 50 ms)

■

6 kV/0.5 kA (0.5 ms, 100 kHz, ring wave)

Security lockout

When the security lockout jumper is enabled, the electronics will not allow you to modify parameters that affect flowmeter output.

Output testing

Analog output

Pulse output

Flow meter may be commanded to set the analog output to a specified value between 3.6 mA and 22.6 mA.

Flow meter may be commanded to set the pulse output frequency to a specified value between 0 Hz and

10000 Hz.

Low flow cutoff

Adjustable over entire flow range. Below selected value, output is driven to 4 mA and zero pulse output frequency.

Overrange capability

Analog signal output continues to 105 percent of span, then remains constant with increasing flow. The digital and pulse outputs

will continue to indicate flow up to the upper sensor limit of the flowmeter and a maximum pulse output frequency of 10400 Hz.

Magnetic-field interference

■

Output error less than ±0.025% of span at 30 A/m (rms).

■

Tested per EN 61326.

26 www.emerson.com/vortex

Page 27

August 2019

Series mode noise rejection

Output error less than ±0.025% of span at 1 V rms, 60 Hz.

Common mode noise rejection

Output error less than ±0.025% of span at 30 V rms, 60 Hz.

Power supply effect

Less than 0.005% of span per volt

Transmitter electrical connections

Model Terminal type

Analog 4–20 mA/HART Compression screw terminal permanently fixed to the terminal

Analog 4–20 mA/HART + Pulse

block.

Field Communicator connections

Communication Terminals

All models Clips permanently fixed to the terminal block.

FOUNDATION™ Fieldbus specifications

Transducer block

The transducer block calculates flow from sensor frequency. The calculation includes information about damping, shedding

frequency, K-factor, process fluid, pipe ID, and diagnostics.

Resource block

The resource block contains physical transmitter information, including available memory, manufacturer identification, device

type, software tag, and unique identification.

Backup Link Active Scheduler (LAS)

The transmitter is classified as a device link master. A device link master can function as an LAS if the current link master device fails

or is removed from the segment.

The host or other configuration tool is used to download the schedule for the application to the link master device. In the absence

of a primary link master, the transmitter will claim the LAS and provide permanent control for the H1 segment.

Diagnostics

The transmitter automatically performs continuous self-diagnostics. The user can perform on-line testing of the transmitter digital

signal. Advanced simulation diagnostics are available. This enables remote verification of the electronics via a flow signal generator

built into the electronics. The sensor strength value can be used to view the process flow signal and provide information regarding

filter settings.

FOUNDATION Fieldbus function blocks

Analog input

The AI function block processes the measurement and makes it available to other function blocks. The AI

function block also allows filtering, alarming, and engineering unit changes.

The Rosemount 8800D Flowmeter with Foundation Fieldbus comes with five AI function blocks. Two of the

AI function blocks, flow and signal strength, come as standard. Three additional AI function blocks are

available when the MTA option is selected: electronics temperature, process temperature, and process

density. Note that process density is only available when the process fluid is configured as temperature

compensated saturated steam, shown as TComp Sat Steam in the device.

www.emerson.com/vortex 27

Page 28

August 2019

Proportional/

Integral/

Derivative

Integrator

Arithmetic

The optional PID function block provides a sophisticated implementation of the universal PID algorithm. The

PID function block features input for feed forward control, alarms on the process variable, and control

deviation. The PID type (series or Instrument Society of America [ISA]) is user-selectable on the derivative

filter.

The standard integrator block is available for totalization of flow.

The standard arithmetic block is available for various computations.

Output signal

Completely digital output with Foundation Fieldbus communication (ITK 6.0 compliant).

Power supply

External power supply required. Flowmeter operates on 9 to 32 Vdc, 18 mA maximum.

Power consumption

600 mW maximum

Failure mode alarm

The AI block allows the user to configure the alarm to HI-HI, HI, LO, or LO-LO with a variety of priority levels.

Damping

Flow Damping adjustable between 0.2 and 255 seconds.

Process temperature damping adjustable between 0.4 and 32.0 seconds (MTA Option only).

Response time

Three vortex shedding cycles or 300 ms, whichever is greater, maximum required to reach 63.2% of actual input with the minimum

damping (0.2 seconds).

Turn-on time

Performance within specifications no greater than 10.0 seconds after power is applied.

Overrange capability

■

For liquid process fluid type, the transducer block digital output will continue to a nominal value of 25 ft/s. After that, the status

associated with the transducer block output will go to UNCERTAIN. Above a nominal value of 30 ft/s, the status will go to BAD.

■

For gas/steam service, the transducer block digital output will continue to a nominal value of 220 ft/s for 0.5 and 1.0-in. line

sizes and a nominal value of 250 ft/s for 1.5–12-in. line sizes. After that, the status associated with the transducer block output

will go to UNCERTAIN. Above a nominal value of 300 ft/s for all line sizes, the status will go to BAD.

Status

If self-diagnostics detect a transmitter failure, the status of the measurement will inform the control system. Status may also set

the PID output to a safe value.

Schedule entries

Six (6)

Links

Twelve (12)

Virtual communications relationships (VCRs)

■

Maximum VCRs: 20

■

Number of Permanent Entries: 1

28 www.emerson.com/vortex

Page 29

August 2019

Table 26: Block Information

Block Base index Execution time (milliseconds)

Resource (RB) 1000 N/A

Transducer (TB) 1200 N/A

Analog Input 1 (AI 1) 1400 15

Analog Input 2 (AI 2) 1600 15

Proportional/ Integral/ Derivative (PID) 1800 20

Integrator (INTEG) 2000 25

Arithmetic (ARITH) 2200 20

Analog Input 3 (AI 3) 2400 15

Analog Input 4 (AI 4) 2600 15

Analog Input 5 (AI 5) 2800 15

Magnetic-field interference

■

No effect on digital output accuracy at 30 A/m (rms).

■

Tested per EN 61326.

Series mode noise rejection

No effect on digital output accuracy at 1 V rms, 60 Hz.

Common mode noise rejection

No effect on digital output accuracy at 250 V rms, 60 Hz.

Power supply effect

No effect on accuracy.

Electrical connections

Model

FOUNDATION fieldbus Compression screw terminal permanently fixed to the terminal

Power terminals

block.

LCD indicator functional specifications

Optional LCD indicator

The optional 11 digit, two-decimal, two-line integral LCD display can be configured to alternate between selected display options,

which differ depending upon the output type selected.

www.emerson.com/vortex 29

Page 30

Table 27: Indicator options

HART FOUNDATION fieldbus Examples

■

Primary Variable

■

Velocity Flow

■

Volumetric Flow

■

Corrected Volumetric Flow

■

Mass Flow

■

Signal Strength

■

Percent of Range

■

Analog Output

■

Totalizer

■

Shedding Frequency

■

Pulse Output Frequency

■

Electronics Temperature

■

Process Temperature (MTA only)

■

Calculated Process Density (MTA only)

■

Primary Variable

■

Percent of Range

■

Shedding Frequency

■

Electronics Temperature (MTA only)

■

Process Temperature (MTA only)

■

Calculated Process Density (MTA only)

■

Totalizer (via Integrator block)

HI LO

HI LO

ALARM

ALARM

FLOW

SECURITY

SECURITY

ON OFF

ON OFF

HI LO

HI LO

ALARM

ALARM

SECURITY

SECURITY

ON OFF

ON OFF

HI LO

HI LO

ALARM

ALARM

August 2019

TEMP

SECURITY

SECURITY

ON OFF

ON OFF

When more than one item is selected, the display will scroll through all items selected. In the event of a fault, the display shows

the applicable fault code.

Product certifications

For information about product certifications, refer to Rosemount™ 8800D Series Vortex Flowmeter Approval Document (00825VA00-0001). You can find it at emerson.com or contact an Emerson Flow representative (see back page).

Dimensional drawings

Flanged style flowmeter (½- inch through 12-inch/15 mm through 300 mm line sizes)

Dimensions are in inches (millimeters).

30 www.emerson.com/vortex

Page 31

August 2019

Figure 3: Side view

3.40

(86.4)

2.56

(65)

1.10

(28)

C

2.85

(72)

Ø 3.06 (78)

A

ØB

C

Display option

Diameter B

Terminal cover

Note

See Table 28 and Table 29 for dimensions.

Figure 4: Front view – without MTA option

1.00 (25.4)

A

B Ø

2.00

(51)

C

A

A

C

Dimension A

Dimension C

Note

See Table 28 and Table 29 for dimensions.

www.emerson.com/vortex 31

Page 32

Figure 5: Front view – with MTA option

August 2019

2.00

(51)

С

D

A

A

C

D

Dimension A

Dimension C

Dimension D

Note

See Table 28 and Table 29 for dimensions.

Table 28: Dimensions and weights for flanged-style flowmeter (

Nominal size

inch (mm)

½ (15) Class 150

1 (25) Class 150

Flange rating Face-to-face A

inch (mm)

6.8 (173)

Class 300

Class 600

Class 900

PN 16/40

PN 100

JIS 10K/20K

JIS 40K

7.2 (183)

7.7 (196)

8.3 (211)

6.1 (155)

6.6 (168)

6.3 (160)

7.3 (185)

7.5 (191)

Class 300

Class 600

Class 900

Class 1500

8.0 (203)

8.5 (216)

9.4 (239)

9.4 (239)

A-ANSI RTJ inch

(mm)

N/A

7.6 (193)

7.6 (193)

8.3 (211)

N/A

N/A

N/A

N/A

8.0 (203)

8.5 (216)

8.5 (216)

9.4 (239)

9.4 (239)

½ - inch through 2-inch/15 mm through 50 mm line size)

Diameter B inch

(mm)

0.54 (13,7)

0.54 (13,7)

0.54 (13,7)

0.54 (13,7)

0.54 (13,7)

0.54 (13,7)

0.54 (13,7)

0.54 (13,7)

0.95 (24,1)

0.95 (24,1)

0.95 (24,1)

0.95 (24,1)

0.95 (24,1)

Dimension C

inch (mm)

7.6 (193)

7.6 (193)

7.6 (193)

7.6 (193)

7.6 (193)

7.6 (193)

7.6 (193)

7.6 (193)

7.7 (196)

7.7 (196)

7.7 (196)

7.7 (196)

7.7 (196)

Weight lb (kg)

9.1 (4,1)

10.4 (4,7)

10.8 (4,9)

15.3 (6,9)

10.4 (4,7)

12.4 (5,6)

10.2 (4,6)

13.7 (6,2)

12.3 (5,6)

15.0 (6,8)

15.8 (7,2)

24.1 (11,1)

24.4 (11,1)

PN 16/40

PN 100

PN 160

6.2 (157)

7.7 (196)

7.7 (196)

N/A

N/A

N/A

0.95 (24,1)

0.95 (24,1)

0.95 (24,1)

7.7 (196)

7.7 (196)

7.7 (196)

13.6 (6,2)

19.6 (8,9)

19.6 (8,9)

32 www.emerson.com/vortex

Page 33

August 2019

Table 28: Dimensions and weights for flanged-style flowmeter (½ - inch through 2-inch/15 mm through 50 mm line size)

(continued)

Nominal size

inch (mm)

1½ (40) Class 150

2 (50) Class 150

Flange rating Face-to-face A

JIS 10K/20K

JIS 40K

Class 300

Class 600

Class 900

Class 1500

PN 16/40

PN 100

PN 160

JIS 10K/20K

JIS 40K

Class 300

Class 600

Class 900

Class 1500

PN 16/40

PN 63/64

PN 100

PN 160

inch (mm)

6.5 (165)

7.8 (198)

8.2 (208)

8.7 (221)

9.3 (236)

10.3 (262)

10.3 (262)

6.9 (175)

8.2 (208)

8.4 (213)

7.3 (185)

8.4 (213)

9.2 (234)

9.7 (246)

10.5 (267)

12.7 (323)

12.7 (323)

8.0 (203)

9.1 (231)

9.6 (244)

10.2 (259)

A-ANSI RTJ inch

(mm)

N/A

N/A

8.7 (221)

9.2 (234)

9.3 (236)

10.3 (262)

10. 3(262)

N/A

N/A

N/A

N/A

N/A

9.7(246)

10.4 (264)

10.6 (269)

12.9 (328)

12.9 (328)

N/A

N/A

N/A

N/A

Diameter B inch

(mm)

0.95 (24,1)

0.95 (24,1)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.49 (37,8)

1.92 (48,8)

1.92 (48,8)

1.92 (48,8)

1.92 (48,8)

1.79 (45,5)

1.92 (48,8)

1.92 (48,8)

1.92 (48,8)

1.92 (48,8)

Dimension C

inch (mm)

7.7 (196)

7.7 (196)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.1 (206)

8.5 (216)

8.5 (216)

8.5 (216)

8.5 (216)

8.5 (216)

8.5 (216)

8.5 (216)

8.5 (216)

8.5 (216)

Weight lb (kg)

14.0 (6,3)

17.7 (7,9)

17.6 (8,0)

23.0 (10,4)

25.5 (11,6)

36.6 (16,6)

36.6 (16,6)

19.4 (8,8)

28.0 (12,7)

29.5 (13,4)

18.6 (8,4)

25.5 (11,6)

22.0 (10,0)

26.1 (11,8)

29.8 (13,5)

59.5 (27,0)

59.5 (27,0)

23.2 (10,5)

30.8 (13,9)

36.5 (16,6)

38.8 (17,6)

JIS 10K

JIS 20K

JIS 40K

Table 29: Flanged-Style Flowmeter (3- through 6-in./80 mm through 150 mm Line Sizes)

Nominal size

inch (mm)

3 (80) Class 150

Flange rating Face-to-face A

Class 300

Class 600

Class 900

Class 1500

PN 16/40

PN 63/64

PN 100

PN 160

JIS 10K

JIS 20K

JIS 40K

7.7 (195)

8.3 (210)

9.8 (249)

inch (mm)

9.9 (251)

10.6 (269)

11.4 (290)

12.9 (328)

14.1 (358)

8.9 (226)

10.0 (254)

10.5 (267)

11.1 (282)

7.9 (201)

9.3 (236)

11.0 (279)

N/A

N/A

N/A

A-ANSI RTJ inch

(mm)

10.4 (264)

11.2 (284)

11.5 (292)

13.0 (330)

14.2 (361)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

1.92 (48,8)

1.92 (48,8)

1.92 (48,8)

Diameter B inch

(mm)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

2.60 (66)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

2.87 (72,9)

8.5 (216)

8.5 (216)

8.5 (216)

Dimension C

inch (mm)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

9.1 (231)

19.5 (8,8)

20.4 (9,3)

28.5 (12,9)

Weight lb (kg)

37.2 (16,9)

46.5 (21,1)

52.6 (23,8)

76.1 (34,5)

108.9 (49,4)

36.6 (16,6)

45.3 (20,6)

54.7 (24,8)

59.6 (27,0)

28.0 (12,7)

35.4 (16,1)

50.3 (22,8)

www.emerson.com/vortex 33

Page 34

Table 29: Flanged-Style Flowmeter (3- through 6-in./80 mm through 150 mm Line Sizes) (continued)

August 2019

Nominal size

inch (mm)

4 (100) Class 150

6 (150) Class 150

Flange rating Face-to-face A

Class 300

Class 600

Class 900

Class 1500

PN 16

PN 40

PN 63/64

PN 100

PN 160

JIS 10K

JIS 20K

JIS 40K

Class 300

Class 600

Class 900

Class 1500

PN 16

PN 40

PN 63/64

PN 100

inch (mm)

10.3 (262)

11.0 (279)

12.8 (325)

13.8 (351)

14.5 (368)

8.4 (213)

9.4 (239)

10.4 (264)

11.3 (287)

12.1 (307)

8.7 (220)

8.7 (220)

11.8 (300)

11.6 (295)

12.3 (312)

14.3 (363)

16.1 (409)

18.6 (472)

8.9 (226)

10.5 (267)

12.1 (307)

13.6 (345)

A-ANSI RTJ inch

(mm)

10.8 (274)

11.6 (295)

12.9 (328)

13.9 (353)

14.6 (371)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

12.1 (307)

13.0 (330)

14.4 (366) 16.2

(411)

18.8 (478)

N/A

N/A

N/A

N/A

Diameter B inch

(mm)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.40 (86,4)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

3.79 (96,3)

5.7 (144,8)

5.7 (144,8)

5.7 (144,8)

5.14 (130,6)

5.14 (130,6)

5.7 (144,8)

5.7 (144,8)

5.7 (144,8)

5.7 (144,8)

Dimension C

inch (mm)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

9.6 (244)

10.8 (274)

10.8 (274)

10.8 (274)

10.8 (274)

10.8 (274)

10.8 (274)

10.8 (274)

10.8 (274)

10.8 (274)

Weight lb (kg)

51.3 (23,3)

71.5 (32,4)

97.5 (44,2)

120.8 (54,8)

162.6 (73,8)

40.4 (18,3)

49.5 (22,4)

62.5 (28,3)

78.9 (35,8)

86.2 (39,1)

37.5 (17,0)

45.4 (20,6)

75.8 (34,4)

81 (37)

120 (55)

187 (55)

277.9 (126,0)

375.8 (170.4)

66 (30)

86 (39)

130 (59)

160 (73)

JIS 10K

JIS 20K

JIS 40K

Table 30: Flanged-Style Flowmeter (8- through 12-in./200 mm through 300 mm Line Sizes)

Nominal size

inch (mm)

8 (200) Class 150

Flange rating Face-to-face A

Class 300

Class 600

Class 900

Class 1500

PN 10

PN 16

PN 25

PN 40

PN 63/64

PN 100

10.6 (270)

10.6 (270)

14.2 (361)

inch (mm)

13.5 (343)

14.3 (363)

16.5 (419)

18.8 (478)

22.8 (579)

10.4 (264)

10.4 (264)

11.8 (300)

12.5 (318)

14.2 (361)

15.8 (401)

N/A

N/A

N/A

A-ANSI RTJ inch

(mm)

14.0 (356)

14.9 (378)

16.7 (424)

18.9 (480)

23.2 (589)

N/A

N/A

N/A

N/A

N/A

N/A

5.7 (144,8)

5.7 (144,8)

5.7 (144,8)

Diameter B inch

(mm)

7.55 (191,8)

7.55 (191,8)

7.55 (191,8)

6.62 (168,1)

6.62 (168,1)

7.55 (191,8)

7.55 (191,8)

7.55 (191,8)

7.55 (191,8)

7.55 (191,8)

7.55 (191,8)

10.8 (274)

10.8 (274)

10.8 (274)

Dimension C

inch (mm)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

11.7 (297)

70 (32)

88 (40)

166 (75)

Weight lb (kg)

141.6 (64,2)

198.7 (90,1)

298.6 (135,4)

479.2 (217,4)

652.4 (295,9)

110.5 (50,1)

109.4 (49,6)

137.7 (62,5)

156.5 (71,0)

217.1 (98,5)

282.7 (128,2)

34 www.emerson.com/vortex

Page 35

August 2019

Table 30: Flanged-Style Flowmeter (8- through 12-in./200 mm through 300 mm Line Sizes) (continued)

Nominal size

inch (mm)

10 (250) Class 150

12 (300) Class 150

Flange rating Face-to-face A

JIS 10K

JIS 20K

JIS 40K

Class 300

Class 600

PN 10

PN 16

PN 25

PN 40

PN 63/64

PN 100

JIS 10K

JIS 20K

JIS 40K

Class 300

Class 600

inch (mm)

12.2 (310)

12.2 (310)

16.5 (419)

14.5 (368)

15.8 (401)

19.0 (483)

11.9 (302)

12.0 (305)

13.5 (343)

14.8 (376)

16.4 (417)

18.9 (480)

14.5 (368)

14.5 (368)

18.1 (460)

16.8 (427)

18.0 (457)

20.5 (521)

A-ANSI RTJ inch

(mm)

N/A

N/A

N/A

15.0 (381)

16.4 (417)

19.2 (488)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

17.3 (439)

18.6 (472)

20.6 (523)

Diameter B inch

(mm)

7.55 (191,8)

7.55 (191,8)

7.55 (191,8)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

9.56 (243)

11.38 (289)

11.38 (289)

11.38 (289)

Dimension C

inch (mm)

11.7 (297)

11.7 (297)

11.7 (297)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

12.8 (325)

13.7 (348)

13.7 (348)

13.7 (348)

Weight lb (kg)

110.1 (49,9)

134.5 (61,0)

255.7 (116)

197.7 (89,7)

286.2 (129,8)

477.9 (219,9)

157.1 (71,3)

161.9 (73,5)

198.6 (90,1)

246.8 (111,9)

308.2 (139,8)

445.2 (201,9)

174.5 (79,1)

221.8 (100,6)

378.5 (171,7)

297.5 (134,9)

415.7 (188,6)

595.4 (270,1)

PN 10

PN 16

PN 25

PN 40

PN 63/64

PN 100

JIS 10K

JIS 20K

JIS 40K

13.1 (333)

13.9 (353)

15.0 (381)

16.8 (427)

18.8 (478)

21.2 (538)

15.7 (399)

15.7 (399)

19.6 (498)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

11.38 (289)

11.38 (289)

11.38 (289)

11.38 (289)

11.38 (289)

11.38 (289)

11.38 (289)

11.38 (289)

11.38 (289)

13.7 (348)

13.7 (348)

13.7 (348)

13.7 (348)

13.7 (348)

13.7 (348)

13.7 (348)

13.7 (348)

13.7 (348)

204.1 (92,6)

224.6 (101,9)

269.4 (122,2)

347.9 (157,8)

431.2 (195,6)

644.1 (292,2)

222.9 (101,1)

284.2 (128,9)

493.8 (224,0)

www.emerson.com/vortex 35

Page 36

Rosemount 8800DR Reducer Flowmeter (1- through 12-in./25 mm through 300 mm Line Sizes)

Figure 6: Side view

3.40

(86.4)

2.56

(65)

2.85

(72)

1.10

(28)

B

August 2019

A

B

ØB

Display option

Terminal cover

Diameter B, see Table 31, Table 32

Figure 7: Front view – without MTA option

3.06 (78)

1.00 (25)

A

Ø B

2.00

(51)

C

A

A

C

Dimension A

Dimension C

Note

See Table 31 and Table 32 for dimensions.

36 www.emerson.com/vortex

Page 37

August 2019

Figure 8: Front view – with MTA option

2.00

(51)

C

D

A

A

C

D

Dimension A

Dimension C

Dimension D

Note

See Table 31 and Table 32 for dimensions.

Table 31: Reducer Flowmeter (1- through 3-in./25 mm through 80 mm Line Sizes)

Nominal size

inch (mm)

Flange rating Face-to-face A

inch (mm)

A-ANSI RTJ inch

(mm)

Diameter B inch

(mm)

Dimension C

inch (mm)

Weight lb (kg)

1 (25) Class 150 7.5 (191) 8.0 (203) 0.54 (13,7) 7.6 (193) 11.56 (5,24)

Class 300 8.0 (203) 8.5 (216) 0.54 (13,7) 7.6 (193) 14.22 (6,45)

Class 600 8.5 (216) 8.5 (216) 0.54 (13,7) 7.6 (193) 15.11 (6,85)

Class 900 9.4 (239) 9.4 (239) 0.54 (13,7) 7.6 (193) 20.70 (9.40)

PN 16/40 6.2 (157) N/A 0.54 (13,7) 7.6 (193) 12.64 (5,73)

PN 100 7.7 (196) N/A 0.54 (13,7) 7.6 (193) 18.44 (8,36)

1 1/2 (40) Class 150 8.2 208 8.7 (221) 0.95 (24,1) 7.7 (196) 15.81 (7,17)

Class 300 8.7 (221) 9.2 (234) 0.95 (24,1) 7.7 (196) 21.20 (9,62)

Class 600 9.3 (236) 9.3 (236) 0.95 (24,1) 7.7 (196) 23.77 (10,78)

Class 900 10.3 (262) 10.3 (262) 0.95 (24,1) 7.7 (196) 34.98 (15,87)

PN 16/40 6.9 (175) N/A 0.95 (24,1) 7.7 (196) 17.50 (7,94)

PN 100 8.2 (208) N/A 0.95 (24,1) 7.7 (196) 26.20 (11,88)

PN 160 8.4 (213) N/A 0.95 (24,1) 7.7 (196) 27.67 (12,55)

2 (50) Class 150 9.2 (234) 9.7 (246) 1.49 (37,8) 8.1 (206) 22.61 (10,26)

Class 300 9.7 (246) 10.4 (264) 1.49 (37,8) 8.1 (206) 26.76 (12,14)

www.emerson.com/vortex 37

Page 38

Table 31: Reducer Flowmeter (1- through 3-in./25 mm through 80 mm Line Sizes) (continued)

August 2019

Nominal size

inch (mm)

3 (80) Class 150 9.9 (251) 10.4 (264) 1.92 (48,8) 8.5 (216) 33.15 (15,04)

Table 32: Reducer Flowmeter (4- through 12-in./100 mm –300 mm Line Sizes)

Flange rating Face-to-face A

inch (mm)

Class 600 10.5 (267) 10.6 (269) 1.49 (37,8) 8.1 (206) 30.59 (13,88)

Class 900 12.7 (323) 12.9 (328) 1.49 (37,8) 8.1 (206) 60.76 (27,56)

PN 16/40 8.0 (203) N/A 1.49 (37,8) 8.1 (206) 23.52 (10,67)

PN 63/64 9.1 (231) N/A 1.49 (37,8) 8.1 (206) 31.28 (14,19)

PN 100 9.6 (244 N/A 1.49 (37,8) 8.1 (206) 37.25 (16,90)

PN 160 10.2 (259) N/A 1.49 (37,8) 8.1 (206) 39.64 (17,98)

Class 300 10.6 (269) 11.2 (284) 1.92 (48,8) 8.5 (216) 42.66 (19,35)

Class 600 11.4 (290) 11.5 (292) 1.92 (48,8) 8.5 (216) 49.46 (22,43)

Class 900 12.9 (328) 13.0 (330) 1.92 (48,8) 8.5 (216) 73.28 (33,24)

PN 16/40 8.9 (226) N/A 1.92 (48,8) 8.5 (216) 33.30 (15,10)

PN 63/64 10.0 (254) N/A 1.92 (48,8) 8.5 (216) 42.45 (19,25)

PN 100 10.5 (267) N/A 1.92 (48,8) 8.5 (216) 52.21 (23,68)

PN 160 11.1 (282) N/A 1.92 (48,8) 8.5 (216) 57.94 (26,28)

A-ANSI RTJ inch

(mm)

Diameter B inch

(mm)

Dimension C

inch (mm)

Weight lb (kg)

Nominal size

inch (mm)

4 (100) Class 150 10.3 (262) 10.8 (274) 2.87 (72,9) 9.1 (231) 46.33 (21,01)

6 (150) Class 150 11.6 (295) 12.1 (307) 3.79 (96,3) 9.6 (244) 70.27 (31,87)

Flange rating Face-to-face A

inch (mm)

Class 300 11.0 (279) 11.6 (295) 2.87 (72,9) 9.1 (231) 67.04 (30,41)

Class 600 12.8 (325) 12.9 (328) 2.87 (72,9) 9.1 (231) 94.26 (42,76)

Class 900 13.8 (351) 13.9 (353) 2.87 (72,9) 9.1 (231) 118.04 (53,54)

PN 16 8.4 (213) N/A 2.87 (72,9) 9.1 (231) 36.36 (16,49)

PN 40 9.4 (239) N/A 2.87 (72,9) 9.1 (231) 45.89 (20,81)

PN 63/64 10.4 (264) N/A 2.87 (72,9) 9.1 (231) 59.72 (27,09)

PN 100 11.3 (287) N/A 2.87 (72,9) 9.1 (231) 76.73 (34,80)

PN 160 12.1 (307) N/A 2.87 (72,9) 9.1 (231) 84.73 (38,43)

Class 300 12.3 (312) 13.0 (330) 3.79 (96,3) 9.6 (244) 113.09 (51,30)

Class 600 14.3 (363) 14.4 (366) 3.79 (96,3) 9.6 (244) 185.13 (83,97)

Class 900 16.1 (409) 16.2 (411) 3.79 (96,3) 9.6 (244) 246.33 (111,73)

PN 16 8.9 (226) N/A 3.79 (96,3) 9.6 (244) 59.20 (26,85)

PN 40 10.5 (267) N/A 3.79 (96,3) 9.6 (244) 81.94 (37,17)

PN 63/64 12.1 (307) N/A 3.79 (96,3) 9.6 (244) 125.36 (56,86)

A-ANSI RTJ inch

(mm)

Diameter B inch

(mm)

Dimension C

inch (mm)

Weight lb (kg)

PN 100 13.6 (345) N/A 3.79 (96,3) 9.6 (244) 162.29 (73,61)

38 www.emerson.com/vortex

Page 39

August 2019

Table 32: Reducer Flowmeter (4- through 12-in./100 mm –300 mm Line Sizes) (continued)

Nominal size

inch (mm)

8 (200) Class 150 13.5 (343) 14.0 (356) 5.70 (144,8) 10.8 (274) 124 (56)

10 (250) Class 150 14.5 (368) 15.0 (381) 7.55 (191,8) 11.7 (297) 182.45 (82,76)

Flange rating Face-to-face A

inch (mm)

PN 160 14.7 (373) N/A 3.79 (96,3) 9.6 (244) 187.91 (85,23)

Class 300 14.3 (363) 14.9 (378) 5.70 (144,8) 10.8 (274) 186 (84)

Class 600 16.5 (419) 16.7 (424) 5.70 (144,8) 10.8 (274) 295 (134)

PN 10 10.4 (264) N/A 5.70 (144,8) 10.8 (274) 91 (41)

PN 16 10.4 (264) N/A 5.70 (144,8) 10.8 (274) 91 (41)

PN 25 11.8 (300) N/A 5.70 (144,8) 10.8 (274) 124 (56)

PN 40 12.5 (318) N/A 5.70 (144,8) 10.8 (274) 145 (66)

PN 63/64 14.2 (361) N/A 5.70 (144,8) 10.8 (274) 211 (96)

PN 100 15.8 (401) N/A 5.70 (144,8) 10.8 (274) 283 (128)

Class 300 15.8 (401) 16.4 (417) 7.55 (191,8) 11.7 (297) 281.66 (127,76)

Class 600 19.0 (483) 19.2 (488) 7.55 (191,8) 11.7 (297) 489.89 (222,21)

PN 10 11.9 (302) N/A 7.55 (191,8) 11.7 (297) 138.63 (62,88)

PN 16 12.0 (305) N/A 7.55 (191,8) 11.7 (297) 148.58 (67,39)

PN 25 13.5 (343) N/A 7.55 (191,8) 11.7 (297) 191.00 (86,64)

A-ANSI RTJ inch

(mm)

Diameter B inch