Page 1

Quick Start Guide

00825-0100-4004, Rev FD

Rosemount® 8800D Series Vortex

Flowmeter

April 2018

Page 2

Quick Start Guide

1 About this guide

This guide provides basic guidelines for the Rosemount™ 8800D Series

Vortex Flowmeter. It does not provide instructions for detailed configuration,

diagnostics, maintenance, service, troubleshooting, Explosion-proof,

Flameproof, or Intrinsically Safe (I.S.) installations. Refer to the reference

manual for more instruction. The manuals and this quick start guide are also

available electronically on EmersonProcess.com/Rosemount.

WARNING!

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in

accordance with the appropriate local, national, and international standards,

codes, and practices. Review the approvals section of thereference manual

for any restrictions associated with a safe installation.

• Before connecting a handheld communicator in an explosive

atmosphere, make sure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

• Verify the operating atmosphere of the flowmeter is consistent with the

appropriate product certifications.

• In an Explosion-proof/Flameproof installation, do not remove the

flowmeter covers when power is applied to the unit. Electrical shock can

result in death or serious injury.

April 2018

WARNING!

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

1.1

2 Rosemount 8800D Series Vortex Flowmeter

Return policy

Emerson procedures must be followed when returning equipment. These

procedures ensure legal compliance with government transportation

agencies and help provide a safe working environment for Emerson

employees. Failure to follow Emerson procedures will result in your

equipment being refused delivery.

Page 3

April 2018 Quick Start Guide

1.2 Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800 522 6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303 527

Mexico +41 (0) 41 7686

Argentina +54 11 4837

Brazil +55 15 3413

Venezuela +58 26 1731

5200

111

7000

8000

3446

The Netherlands

France 0800 917 901 India 800 440 1468

Germany 0800 182 5347 Pakistan 888 550 2682

Italy 8008 77334 China +86 21 2892

Central & Eastern

Russia/CIS +7 495 981

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

+31 (0) 704 136

666

+41 (0) 41 7686

111

9811

New Zealand 099 128 804

9000

Japan +81 3 5769

South Korea +82 2 3438

6803

4600

6426

Quick Start Guide 3

Page 4

Quick Start Guide

2 Installation

2.1 Mount the flowmeter

Design process piping so the meter body will remain full, with no entrapped

air. The vortex flowmeter can be installed in any orientation without affecting

accuracy. However, the following are guidelines for certain installations.

2.1.1 Vertical mounting

If the vortex flowmeter will be installed in a vertical orientation:

• Install upward or downward flow for gas or steam.

• Install upward flow for liquids.

Vertical installationFigure 2-1:

April 2018

BA

A. Gas flow

B. Liquid or gas flow

4 Rosemount 8800D Series Vortex Flowmeter

Page 5

April 2018

2.1.2 Horizontal mounting

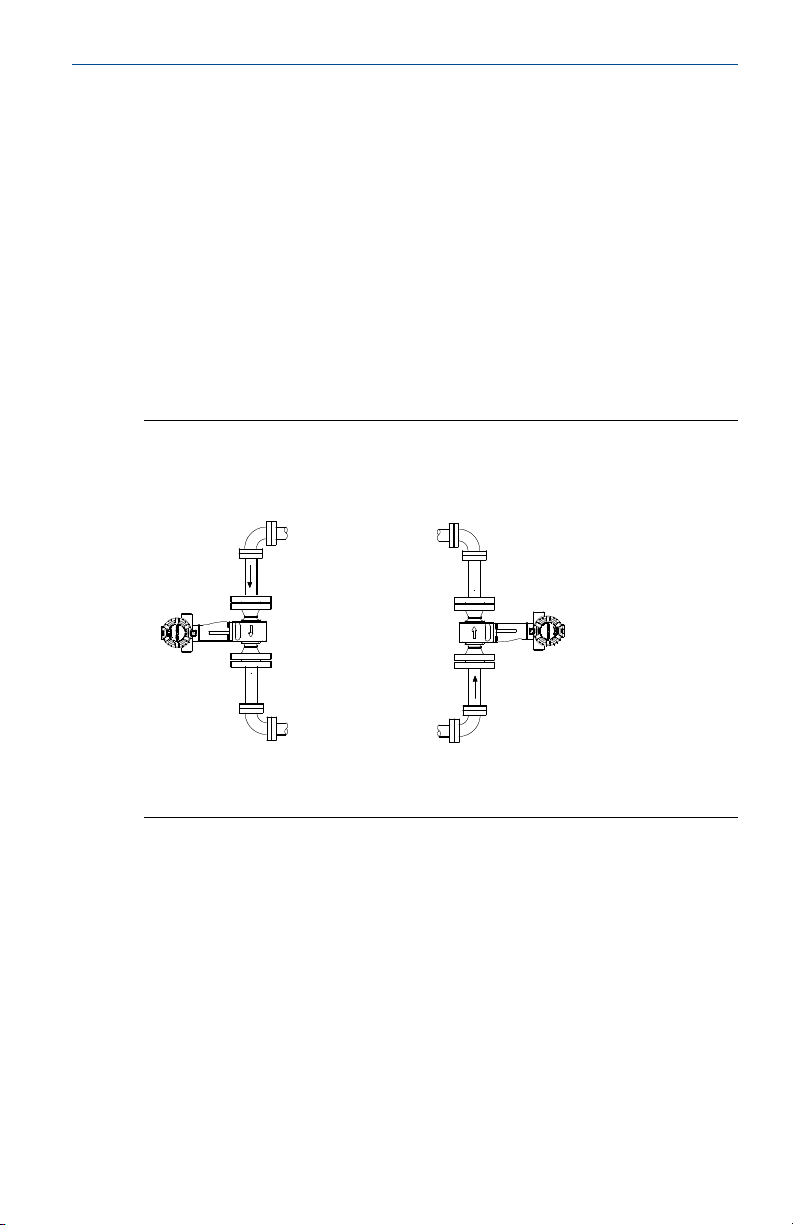

Horizontal installationFigure 2-2:

Quick Start Guide

A

A. Preferred installation—meter body installed with electronics to side of pipe

B. Acceptable installation—meter body installed with electronics above pipe

For steam and fluids with small solids content, it is recommended to have the

flowmeter installed with the electronics to the side of the pipe. This will

minimize potential measurement errors by allowing the condensate or solids

to flow under the shedder bar without interrupting the vortex shedding.

2.1.3 High temperature mounting

The maximum temperature for integral electronics is dependent on the

ambient temperature where the flowmeter is installed. The electronics must

not exceed 185 °F (85 °C).

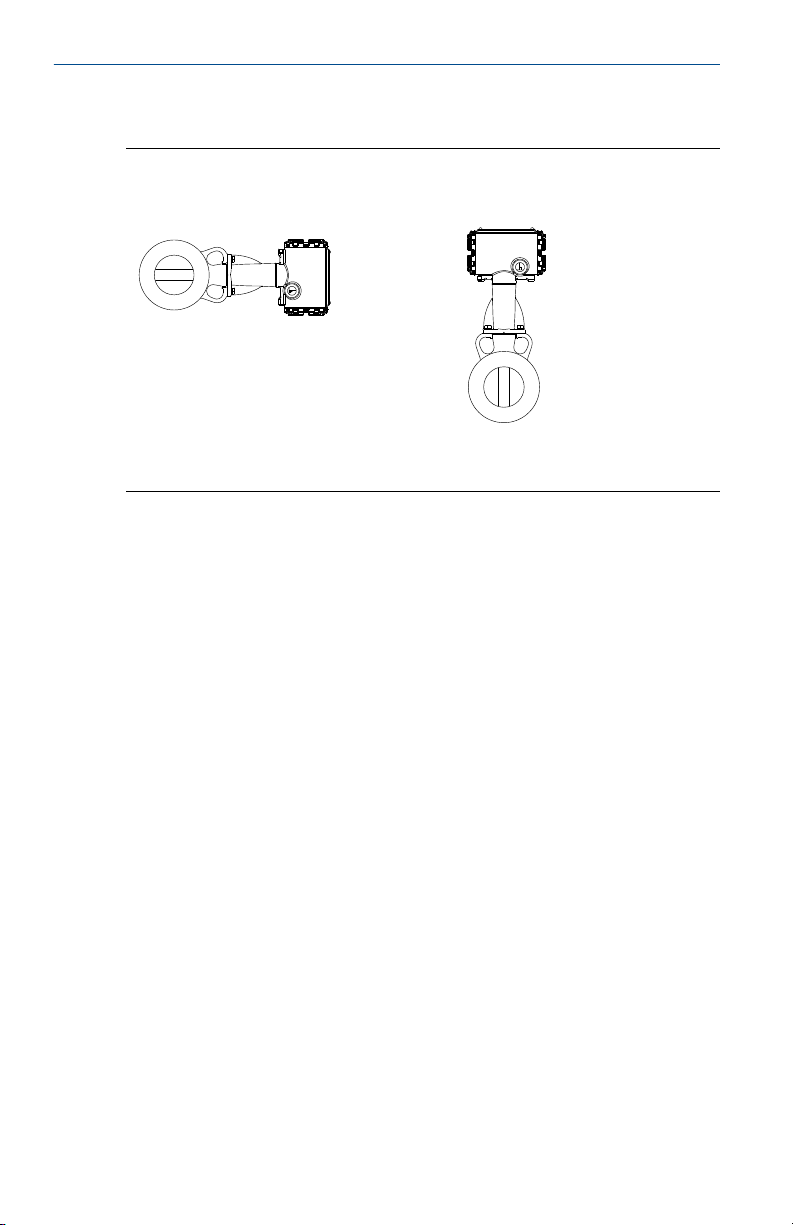

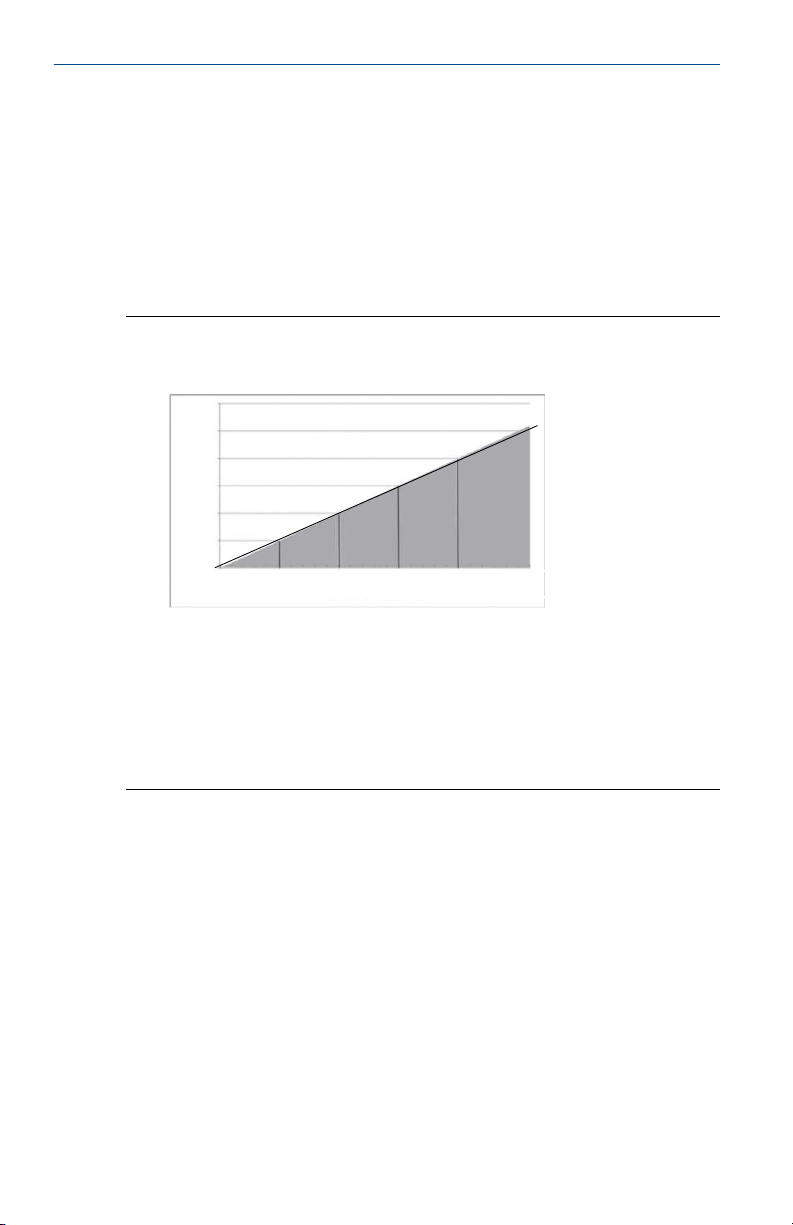

Figure 2-3 shows combinations of ambient and process temperatures needed

to maintain a housing temperature of less than 185 °F (85 °C).

B

Quick Start Guide 5

Page 6

Quick Start Guide

A

A. Ambient temperature °F (°C)

B. Process temperature °F (°C)

C. 185 °F (85 °C) Housing temperature limit.

Note

The indicated limits are for horizontal pipe and vertical meter position, with meter

and pipe insulated with 3 in. (77 mm) of ceramic fiber insulation.

200 (93)

180(82)

160 (71)

140 (60)

120 (49)

100 (38)

80 (27)

60 (16)

April 2018

Ambient/Process temperature limitsFigure 2-3:

C

0

100 (38)

200 (93)

300 (149)

400 (204)

500 (260)

600 (316)

700 (371)

800 (427)

900 (482)

1000 (538)

B

The following orientations are recommended for applications with high

process temperatures.

• Install with electronics head beside or below process pipe.

• Insulation around pipe may be necessary to maintain ambient

temperature below 185 °F (85 °C).

Note

Insulate pipe and meter body only. Do not insulate support tube bracket or

transmitter so heat can be dissipated.

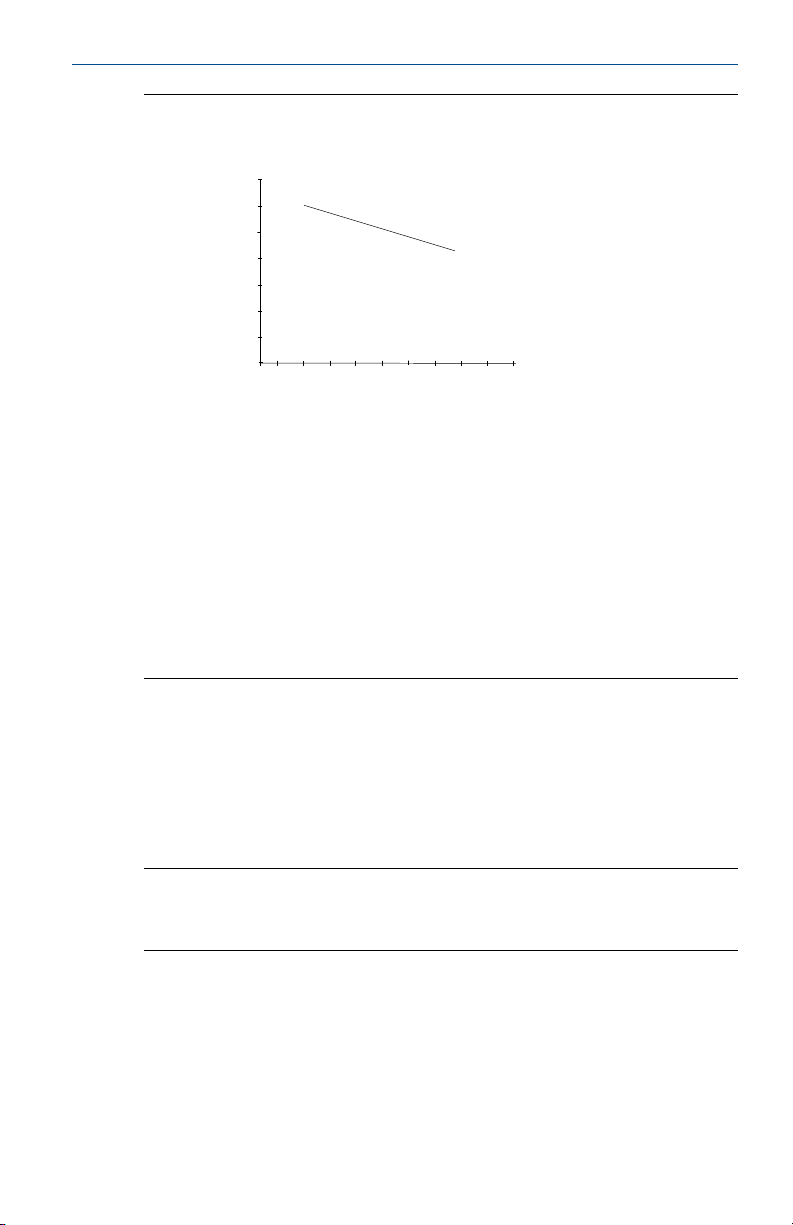

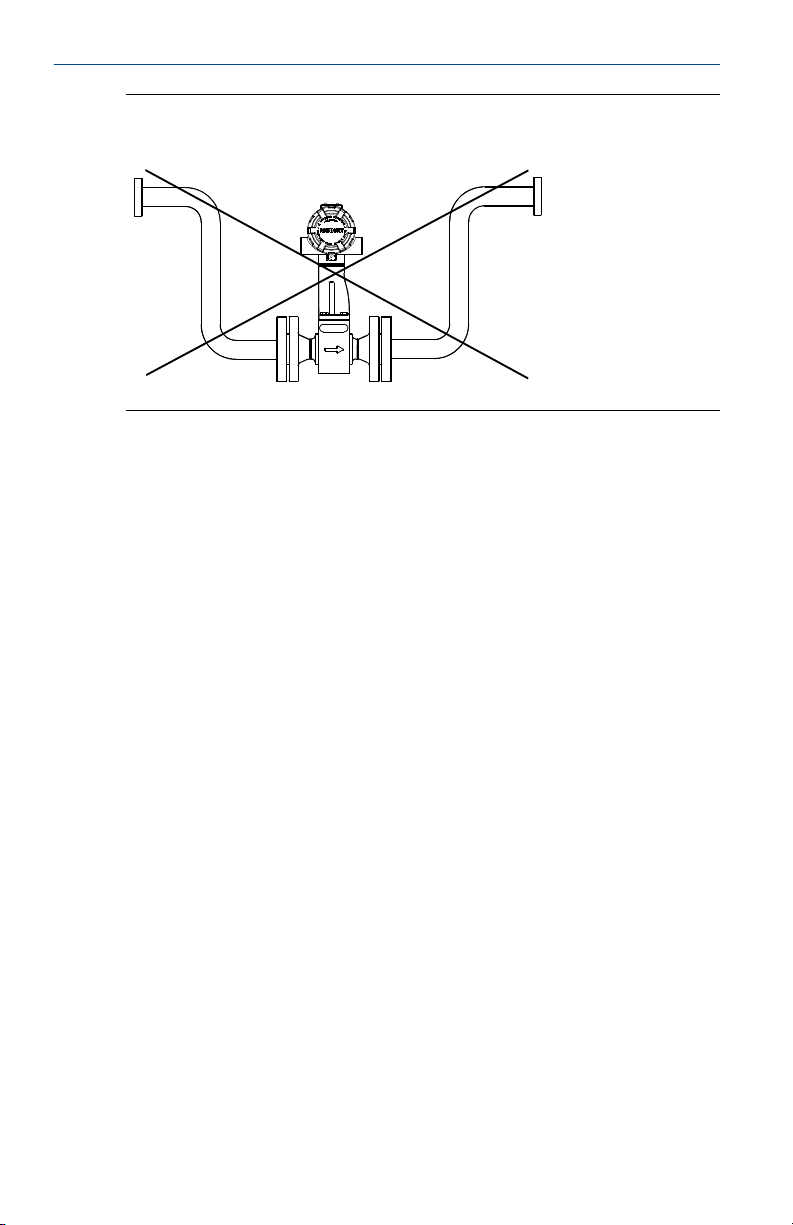

2.1.4 Steam installations

Avoid installation shown in Figure 2-4. Such conditions may cause a waterhammer condition at start-up due to trapped condensation.

6 Rosemount 8800D Series Vortex Flowmeter

Page 7

April 2018

Improper installationFigure 2-4:

2.1.5 Upstream/downstream requirements

The flowmeter may be installed with a minimum of ten straight pipe

diameters (D) upstream and five straight pipe diameters (D) downstream by

following the K-factor corrections as described in the 8800 Installation Effects

Technical Data Sheet (00816-0100-3250). No K-factor correction is required

if 35 straight pipe diameters upstream (35D) and 10 straight pipe diameters

downstream (10D) are present.

Quick Start Guide

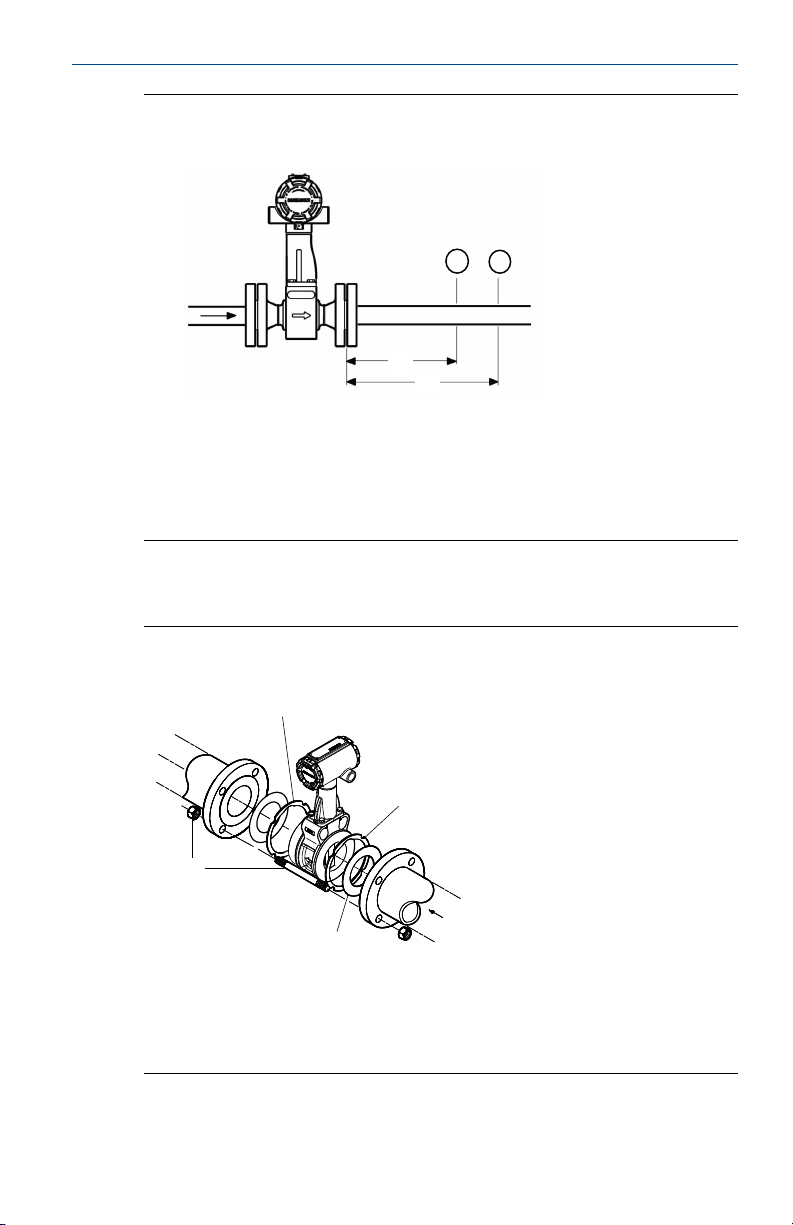

2.1.6 External pressure/temperature transmitters

When using pressure and temperature transmitters in conjunction with the

flowmeter for compensated mass flows, install the transmitters downstream

of the flowmeter as shown in Figure 2-5.

Quick Start Guide 7

Page 8

Quick Start Guide

Upstream/Downstream pipingFigure 2-5:

A. Pressure transmitter

B. Four straight pipe diameters downstream

C. Temperature transmitter

D. Six straight pipe diameters downstream

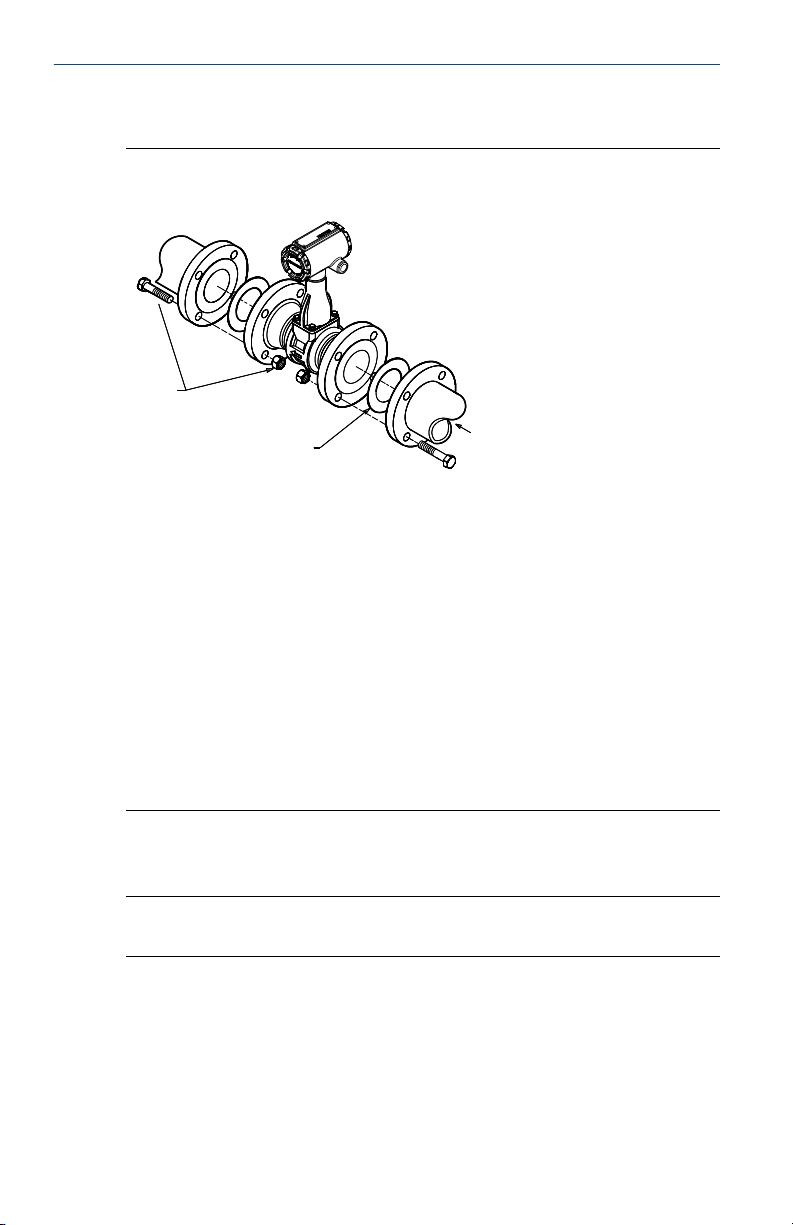

2.1.7 Wafer style installation

April 2018

C

A

B

D

Wafer style installationFigure 2-6:

B

B

A

D

C

A. Installation studs and nuts (supplied by customer)

B. Alignment ring

C. Gaskets (supplied by customer)

D. Flow direction

8 Rosemount 8800D Series Vortex Flowmeter

Page 9

April 2018

2.1.8 Flanged style installation

Flanged style installationFigure 2-7:

A

Quick Start Guide

B

C

A. Installation bolts and nuts (supplied by customer)

B. Gaskets (supplied by customer)

C. Flow direction

Note

The required bolt load for sealing the gasket joint is affected by several factors,

including operating pressure, gasket material, width, and condition. A number of

factors also affect the actual bolt load resulting from a measured torque,

including condition of bolt threads, friction between the nut head and the flange,

and parallelism of the flanges. Due to these application-dependent factors, the

required torque for each application may be different. Follow the guidelines

outlined in ASME PCC-1 for proper bolt tightening. Make sure the flowmeter is

centered between flanges of the same nominal size as the flowmeter.

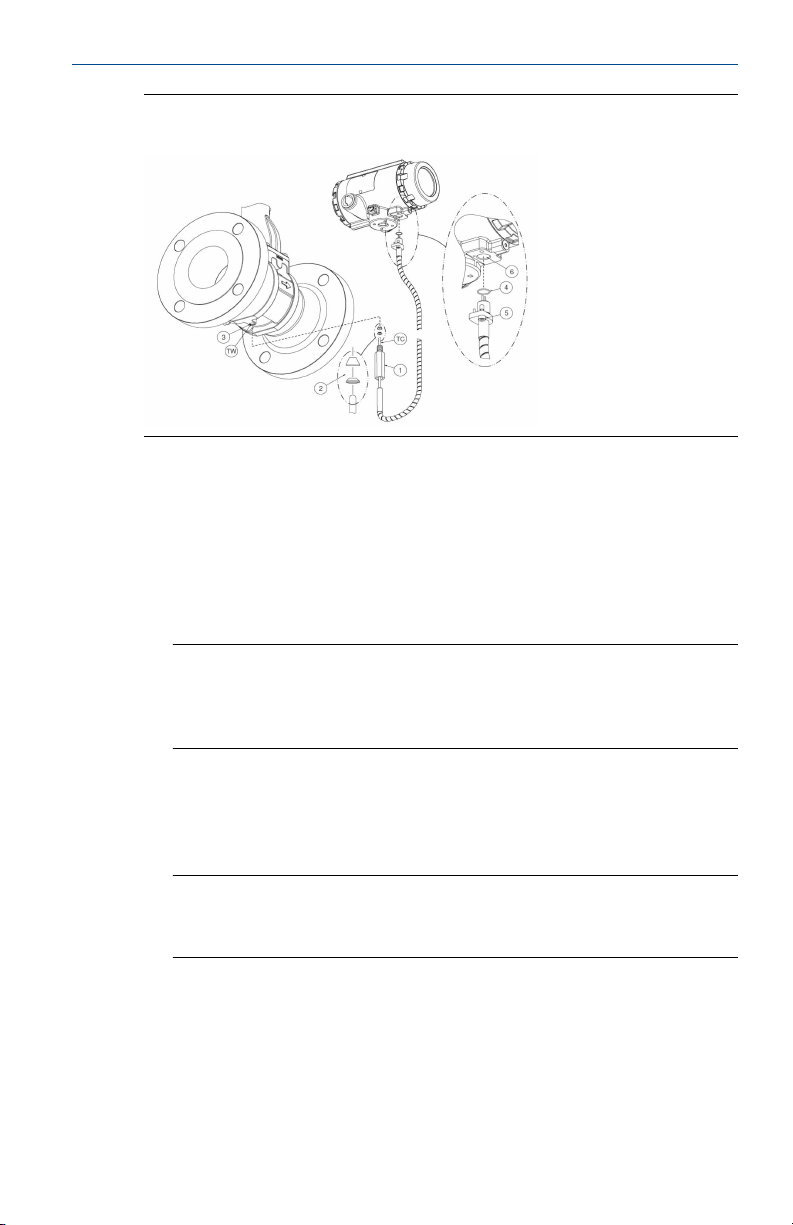

2.1.9 Insert integral temperature sensor (MTA option only)

Note

Step number of procedure corresponds with number in Figure 2-8.

Quick Start Guide 9

Page 10

Quick Start Guide

Procedure

1. Slide the thermocouple bolt (1) over the thermocouple (TC).

2. Place the 2-part ferrule (2) over the end tip of the thermocouple (TC).

3. Insert the thermocouple in to the thermowell hole (TW) on the bottom

side of the meter body.

April 2018

Thermocouple assemblyFigure 2-8:

Important

Carefully push the thermocouple in to the thermowell completely. This is

critical to get the proper insertion depth. Then thread the thermocouple

bolt in to the hole.

4. When the thermocouple bolt is hand tight, mark the position of the bolt

in relation to the meter body (the mark will help determine rotations).

Using a ½-in. wrench turn the bolt clockwise ¾ turn to seat the ferrule.

Note

After completing Step 4, the ferrule and thermocouple bolt will be

permanently installed on the thermocouple.

5. Verify the rubber O-ring is installed on the electronics connection end of

the thermocouple.

6. Verify the 2.5 mm hex head screw is installed.

7. Insert the electronics end connector in to the transmitter housing.

Tighten the screw with a 2.5 mm hex bit to secure the connection.

10 Rosemount 8800D Series Vortex Flowmeter

Page 11

April 2018

Important

Do not over tighten hex screw.

2.2 Install remote electronics

If you order one of the remote electronics options (options R10, R20, R30, or

RXX), the flowmeter assembly ships in two parts:

1. The meter body with an adapter installed in the support tube and an

interconnecting coaxial cable attached to it.

2. The electronics housing installed on a mounting bracket.

If you ordered the armored remote electronics options, follow the same

instructions as for the standard remote cable connection with the exception

that the cable may not need to be run through conduit. Armored includes the

glands.

Refer to Figure 2-9 and these steps to connect the loose end of the coaxial

cable to the electronics housing.

Quick Start Guide

Quick Start Guide 11

Page 12

Quick Start Guide

April 2018

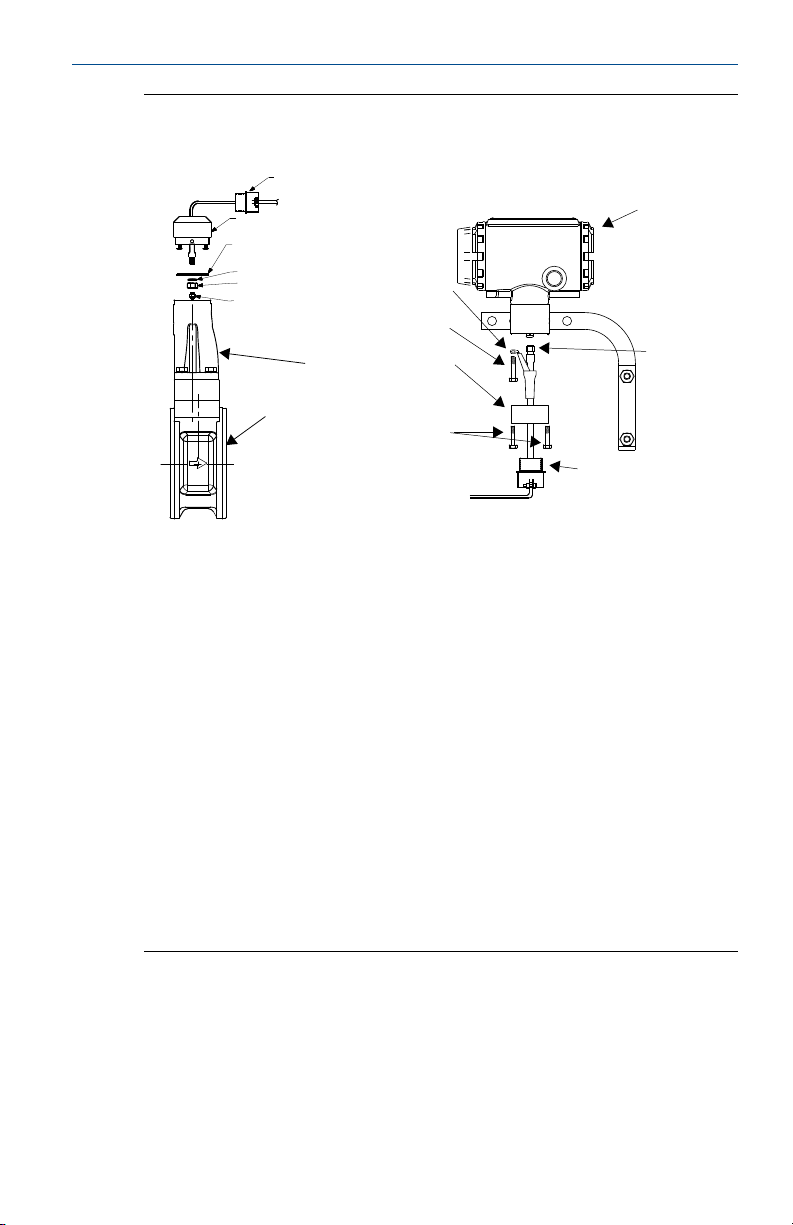

Remote electronics installationFigure 2-9:

A

B

C

J

D

E

F

P

G

O

H

N

K

I

M

L

A. 1/2 NPT conduit adapter or cable gland (supplied by customer)

B. Coaxial cable

C. Meter adapter

D. Union

E. Washer

F. Nut

G. Sensor cable nut

H. Support tube

I. Meter body

J. Electronics housing

K. Coaxial cable nut

L. Conduit adapter (optional-supplied by customer)

M. Housing adapter screws

N. Housing adapter

O. Housing base screw

P. Ground connection

Prerequisites

1. Mount the meter body in the process flow line as described in Section 2.1.

2. Mount the bracket and electronics housing in the desired location. The

housing can be repositioned on the bracket to facilitate field wiring and

conduit routing.

12 Rosemount 8800D Series Vortex Flowmeter

Page 13

April 2018

Quick Start Guide

Procedure

1. If you plan to run the coaxial cable in conduit, carefully cut the conduit to

the desired length to provide for proper assembly at the housing. A

junction box may be placed in the conduit run to provide a space for extra

coaxial cable length.

CAUTION!

The coaxial remote cable cannot be field terminated or cut to length. Coil

any extra coaxial cable with no less than a 2-in. (51 mm) radius.

2. Slide the conduit adapter or cable gland over the loose end of the coaxial

cable and fasten it to the adapter on the meter body support tube.

3. If using conduit, route the coaxial cable through the conduit.

4. Place a conduit adapter or cable gland over the end of the coaxial cable.

5. Remove the housing adapter from the electronics housing.

6. Slide the housing adapter over the coaxial cable.

7. Remove one of the four housing base screws.

8. Attach and securely tighten the coaxial cable nut to the connection on

the electronics housing.

9. Attach the coaxial cable ground wire to the housing via the housing base

ground screw.

10. Align the housing adapter with the housing and attach with two screws.

11. Tighten the conduit adapter or cable gland to the housing adapter.

CAUTION!

To prevent moisture from entering the coaxial cable connections, install

the interconnecting coaxial cable in a single dedicated conduit run or use

sealed cable glands at both ends of the cable.

Note

Refer to the reference manual for details for the CPA option.

Quick Start Guide 13

Page 14

Quick Start Guide

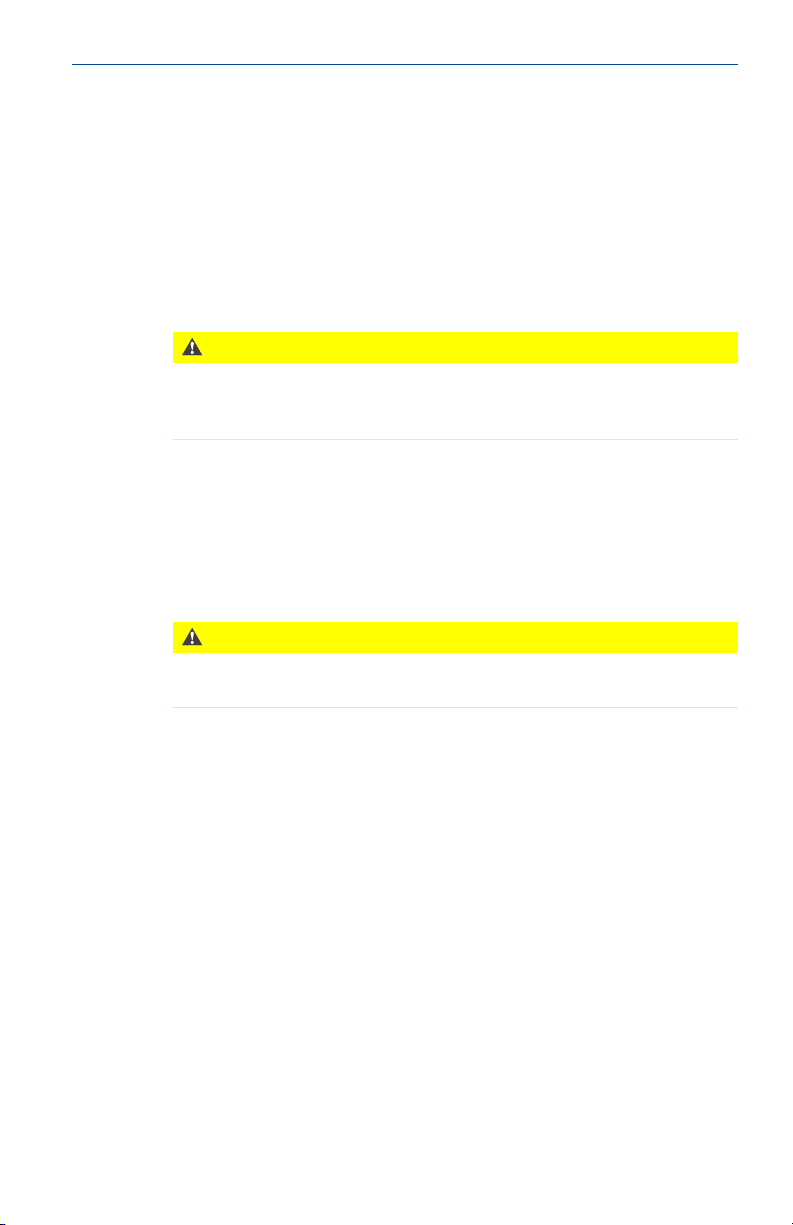

3 Consider housing rotation

The entire electronics housing may be rotated in 90° increments for easy

viewing. Use the following steps to change the housing orientation,

1. Loosen the three housing rotation set screws at the base of the

electronics housing with a 5/32” hex wrench by turning the screws

clockwise (inward) until they clear the support tube.

2. Slowly pull the electronics housing out of the support tube.

CAUTION!

Do not pull the housing more than 1.5 in. (40 mm) from the top of the

support tube until the sensor cable is disconnected. Damage to the

sensor may occur if this sensor cable is stressed.

3. Unscrew the sensor cable from the housing with a 5/16” open end

wrench.

4. Rotate the housing to the desired orientation.

5. Hold it in this orientation while you screw the sensor cable onto the base

of the housing.

April 2018

CAUTION!

Do not rotate the housing while the sensor cable is attached to the base

of the housing. This will stress the cable and may damage the sensor.

6. Place the electronics housing into the top of the support tube.

7. Use a hex wrench to turn the three housing rotation screws counterclockwise (outward) to engage the support tube.

14 Rosemount 8800D Series Vortex Flowmeter

Page 15

April 2018

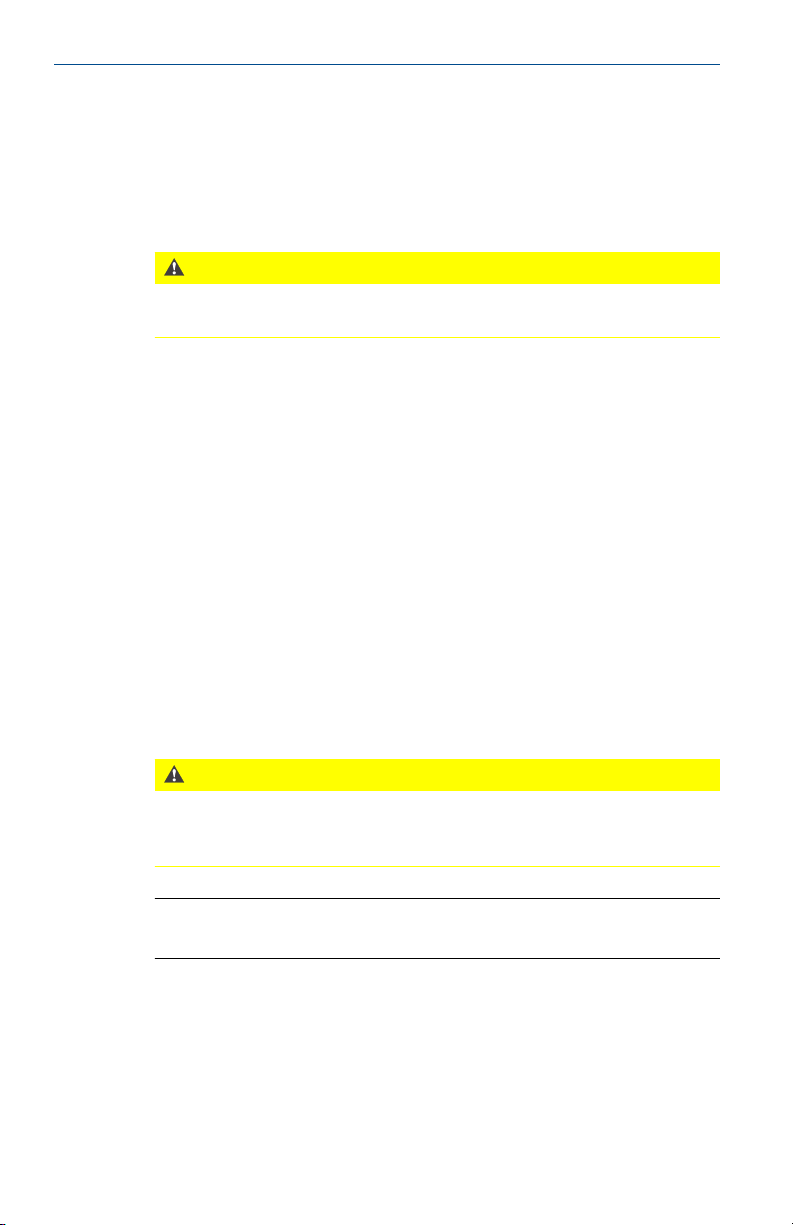

4 Set jumpers

Adjust jumpers to desired settings.

4.1 HART jumpers

If alarm and security jumpers are not installed, the flowmeter will operate

normally with the default alarm condition alarm high and the security off.

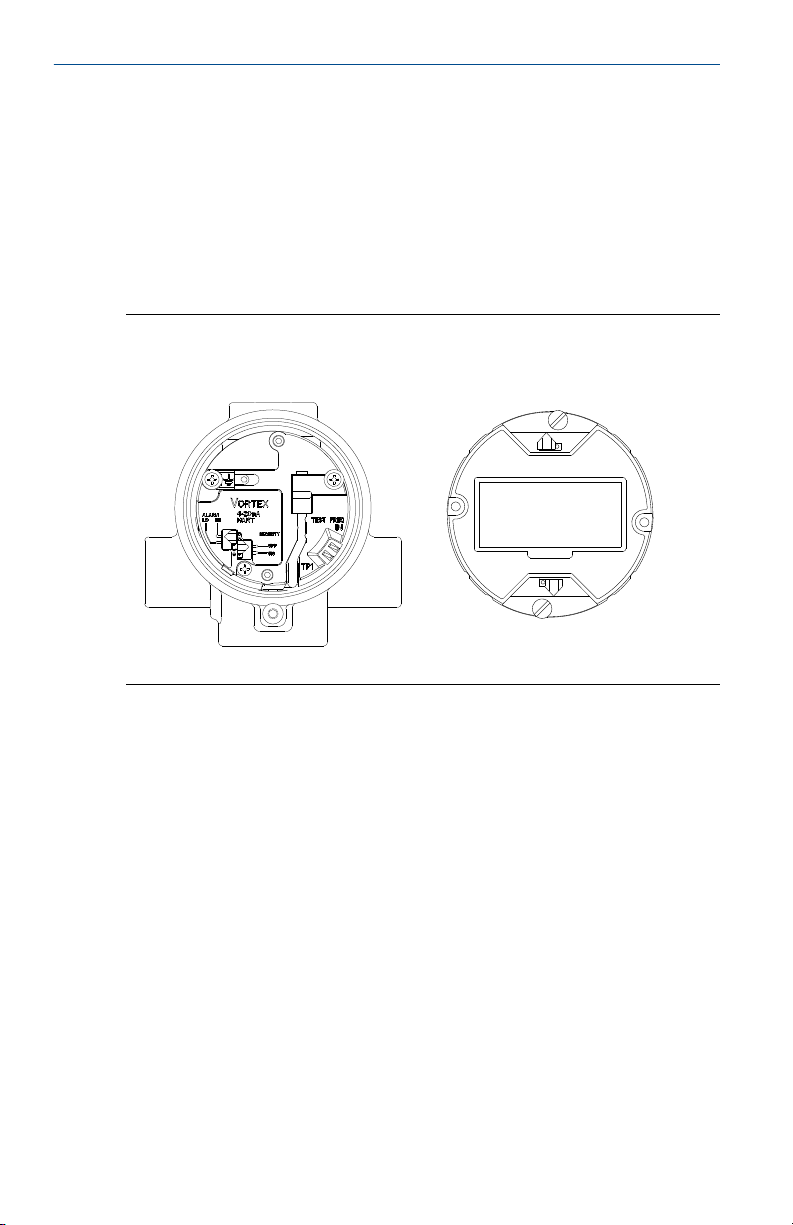

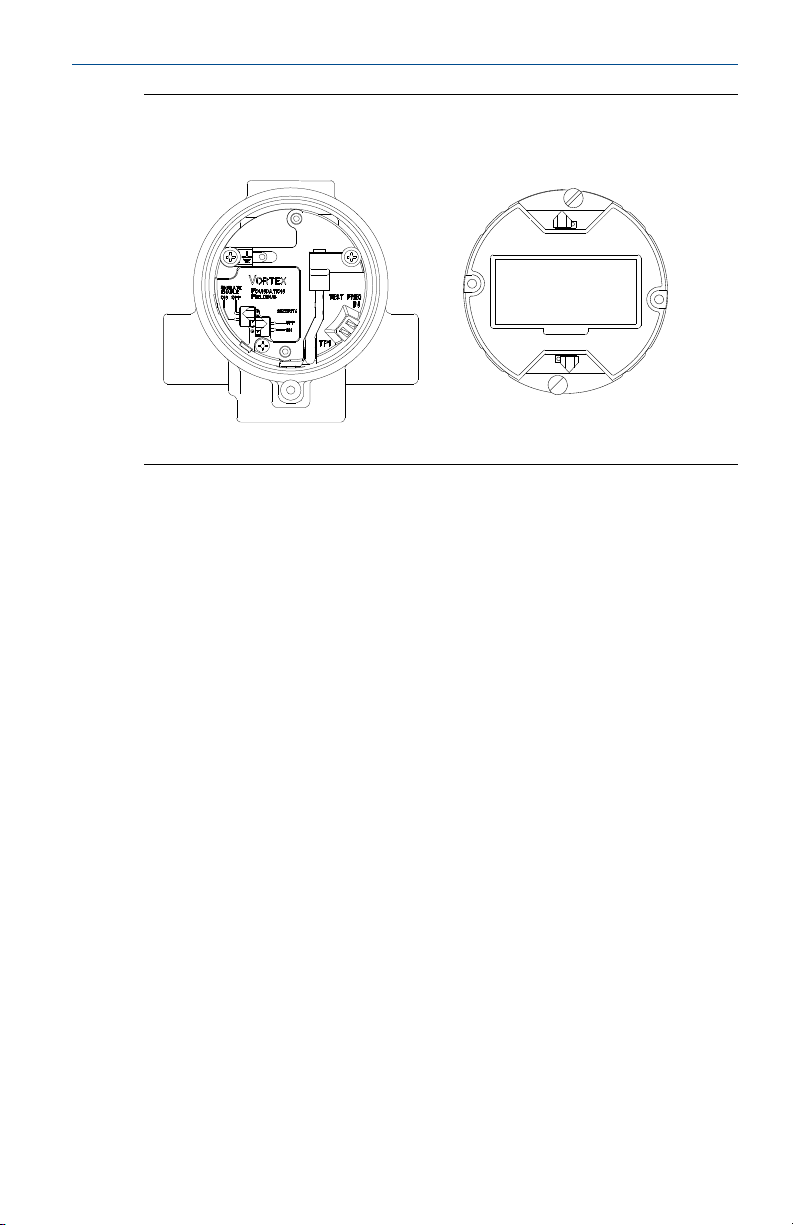

HART jumpers and LCD displayFigure 4-1:

Quick Start Guide

4.2 Foundation fieldbus

If security and simulate enable jumpers are not installed, the flowmeter will

operate normally with the default security “OFF” and simulate enable “OFF”.

HI

SECURITY

ON

LO

ALARM

OFF

Quick Start Guide 15

Page 16

Quick Start Guide April 2018

Foundation fieldbus jumpers and LCD displayFigure 4-2:

OFF

SIMULATE ENABLE

SECURITY

ON

OFF

ON

16 Rosemount 8800D Series Vortex Flowmeter

Page 17

April 2018

5 Connect wiring and power up

5.1 Power supply (HART)

The dc power supply should provide power with less than two percent ripple.

The total resistance load is the sum of the resistance of the signal leads and

the load resistance of the controller, indicator, and related pieces. Note that

the resistance of intrinsic safety barriers, if used, must be included.

Load limitationFigure 5-1:

1500

1250

1000

750

A

500

250

0

10.8 16.8 22.8 28.8 34.8 42

B

Quick Start Guide

A. Rloop in ohms

B. Power supply voltage

Maximum Loop Resistance = 41.7 (Power Supply Voltage - 10.8) The Field

Communicator requires a minimum loop resistance of 250 ohms.

5.2

5.3

Quick Start Guide 17

Power supply (Foundation fieldbus)

The flowmeter requires 9-32 Vdc at the power terminals. Each fieldbus power

supply requires a power conditioner to decouple the power supply output

from the fieldbus wiring segment.

Conduit installation

Prevent condensation in any conduit from flowing into the housing by

mounting the flowmeter at a high point in the conduit run. If the flowmeter is

mounted at a low point in the conduit run, the terminal compartment could

fill with fluid.

If the conduit originates above the flowmeter, route conduit below the

flowmeter before entry. In some cases a drain seal may need to be installed.

Page 18

Quick Start Guide

A. Conduit line

April 2018

Proper conduit installationFigure 5-2:

A A

5.4

Wire the flowmeter

Use the following figures and steps to wire the flowmeter:

4–20 mA wiringFigure 5-3:

RL ≥ 250 Ω

+

A

-

A. Power supply

18 Rosemount 8800D Series Vortex Flowmeter

Page 19

April 2018

4–20 mA and pulse wiring with electronic totalizer/counterFigure 5-4:

RL ≥250 Ω

+

A

-

A. Power supply

B. Power supply with counter

100 Ω ≤ R

-

+

≤ 100 kΩ

L

Quick Start Guide

B

Quick Start Guide 19

Page 20

Quick Start Guide April 2018

Flowmeter field wiring for Foundation fieldbus protocolFigure 5-5:

A

B

C

D

F

E

G G

H

A. 6234 ft (1900 m) max, depending upon cable characterisitcs

B. Integrated power conditioner and filter

C. Terminators

D. Fieldbus segment

E. Power supply

F. (Trunk)

G. (Spur)

H. Devices 1 through 16

(1)

Note

The power supply, filter, first terminator, and configuration tool are typically

located in the control room.

Procedure

1. Remove the housing cover on the side marked FIELD TERMINALS.

2. Connect the positive lead to the “+” terminal and the negative lead to the

“−” terminal as shown in Figure 5-3 for HART installations and Figure 5-5

for Foundation fieldbus installations.

(1) Intrinsically safe installations may allow fewer devices per I.S. barrier.

20 Rosemount 8800D Series Vortex Flowmeter

Page 21

April 2018

Quick Start Guide

Note

Foundation fieldbus terminals are not polarity sensitive.

3. For HART installations utilizing the pulse output, connect the positive

lead to the “+” terminal of the pulse output and the negative lead to the

“−” terminal of the pulse output as shown in Figure 5-4. A separate 5 to 30

Vdc power supply is required for the pulse output. Maximum switching

current for the pulse output is 120 mA.

CAUTION!

Do not connect the powered signal wiring to the test terminals. Power

could damage the test diode in the test connection. Twisted pairs are

required to minimize noise pick up in the 4–20 mA signal and digital

communication signal. For high EMI/RFI environments, shielded signal

wire is required and preferred in all other installations. Use 24 AWG or

larger wire and do not exceed 5,000 feet (1,500 meters). For ambient

temperatures above 140 °F (60 °C) use wire rated to 176 °F (80 °C) or

higher.

Figure 5-3 and Figure 5-4 show wiring connections necessary to power a

transmitter and enable communications with a hand-held Field

Communicator.

Figure 5-5 shows wiring connections necessary to power a transmitter

with Foundation fieldbus.

4. Plug and seal unused conduit connections. Use pipe sealing tape or paste

on threads to ensure a moisture-tight seal. Housing conduit entries

marked with M20 will require M20 x 1.5 blanking plug thread. Unmarked

conduit entries will require a ½–14 NPT blanking plug thread.

Note

Straight threads require a minimum of three wraps of tape to obtain a

tight seal.

5. If applicable, install wiring with a drip loop. Arrange the drip loop so the

bottom is lower than the conduit connections and the flowmeter

housing.

Note

Installation of the transient protection terminal block does not provide

transient protection unless the transmitter case is properly grounded.

Quick Start Guide 21

Page 22

Quick Start Guide

CAUTION!

Flowmeters ordered with painted meter body may be subject to

electrostatic discharge. To avoid electrostatic charge build-up, do not rub

the meter body with a dry cloth or clean with solvents.

5.5 Secure cover jam screw

For transmitter housings shipped with a cover jam screw, the screw should be

properly installed once the transmitter has been wired and powered up. The

cover jam screw is intended to disallow the removal of the transmitter cover

in flameproof environments without the use of tooling.

1. Verify the cover jam screw is completely threaded into the housing.

2. Install the transmitter housing cover and verify that the cover is tight

against the housing.

3. Using an M4 hex wrench, loosen the jam screw until it contacts the

transmitter cover.

4. Turn the jam screw an additional ½ turn counterclockwise to secure the

cover.

CAUTION!

Application of excessive torque may strip the threads.

April 2018

5. Verify that the cover cannot be removed.

22 Rosemount 8800D Series Vortex Flowmeter

Page 23

April 2018

6 Verify configuration

Before operating the flowmeter in an installation, you should review the

configuration data to ensure that it reflects the current application. In most

cases, all of these variables are pre-configured at the factory. Configuration

may be required if your flowmeter is not configured or if the configuration

variables need revision. Rosemount recommends the following variables are

reviewed before startup.

HART

• Tag

• Transmitter Mode

• Process Fluid

• Reference K-Factor

• Flange Type

• Mating Pipe ID

• PV Units

• PV Damping

• Process Temperature Damping

• Fixed Process Temperature

• Auto Adjust Filter

• LCD Display Configuration (For units with a display only)

• Density Ratio (For Standard or Normal flow units only)

• Process Density and Density Units (For mass flow units only)

• Variable Mapping

• Range Values

• Pulse Output Configuration (For units with a pulse output only)

Quick Start Guide

Foundation fieldbus configuration

• Tag

• Transmitter Mode

• Process Fluid

• Reference K-Factor

• Flange Type

• Mating Pipe ID

• PV Units (configured in the AI block)

Quick Start Guide 23

Page 24

Quick Start Guide April 2018

• Flow Damping

• Process Temperature Damping

• Fixed Process Temperature

• Auto Adjust Filter

• LCD Display Configuration (for units with a display only)

• Density Ratio (for Standard or Normal flow units only)

• Process Density and Density Units (for mass flow units only)

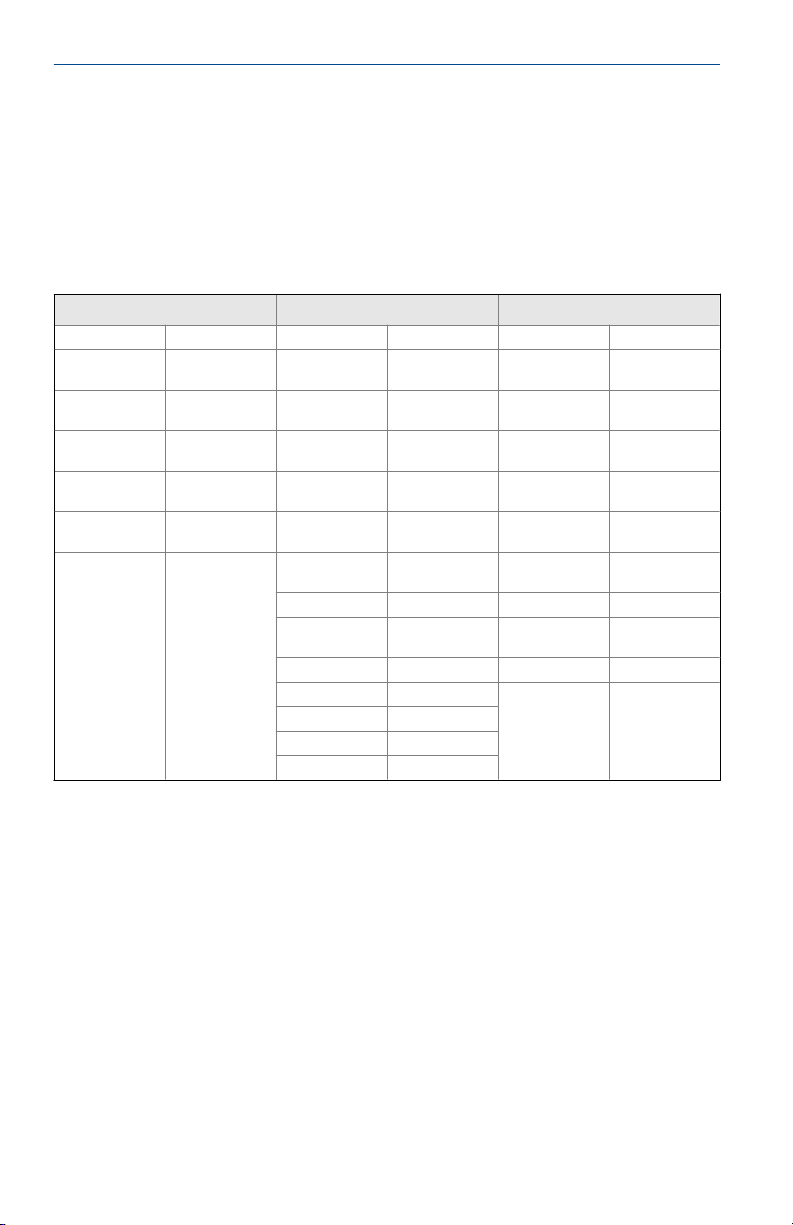

Table 6-1:

Fast Keys for Rosemount 8800D Device Revision 1 DD

Revision 2 and Device Revision 2 DD Revision 1

Function HART Fast Keys Function HART Fast Keys

Alarm Jumpers 1, 4, 2, 1, 3 Meter Body Number 1, 4, 1, 5

Analog Output 1, 4, 2, 1 Minimum Span 1, 3, 8, 3

Auto Adjust Filter 1, 4, 3, 1, 4 Num Req Preams 1, 4, 2, 3, 2

Base Time Unit 1, 1, 4, 1, 3, 2 Poll Address 1, 4, 2, 3, 1

Base Volume Unit 1, 1, 4, 1, 3, 1 Process Fluid Type 1, 3, 2, 2

Burst Mode 1, 4, 2, 3, 4 Process Variables 1, 1

Burst Option 1, 4, 2, 3, 5 Pulse Output 1, 4, 2, 2, 1

Burst Variable 1 1, 4, 2, 3, 6, 1 Pulse Output Test 1, 4, 2, 2, 2

Burst Variable 2 1, 4, 2, 3, 6, 2 PV Damping 1, 3, 9

Burst Variable 3 1, 4, 2, 3, 6, 3 PV Mapping 1, 3, 6, 1

Burst Variable 4 1, 4, 2, 3, 6, 4 PV Percent Range 1, 1, 2

Burst Xmtr Variables 1, 4, 2, 3, 6 QV Mapping 1, 3, 6, 4

Conversion Number 1, 1, 4, 1, 3, 4 Range Values 1, 3, 8

D/A Trim 1, 2, 5 Review 1, 5

Date 1, 4, 4, 5 Revision Numbers 1, 4, 4, 7

Descriptor 1, 4, 4, 3 Scaled D/A Trim 1, 2, 6

Density Ratio 1, 3, 2, 4, 1, 1 Self Test 1, 2, 1, 5

Device ID 1, 4, 4, 7, 6 Signal to Trigger Ratio 1, 4, 3, 2, 2

Electronics Temp 1, 1, 4, 7, 1 STD/ Nor Flow Units 1, 1, 4, 1, 2

Electronics Temp

Units

Filter Restore 1, 4, 3, 3 Status 1, 2, 1, 1

Final Assembly Num-

ber

Fixed Process Density 1, 3, 2, 4, 2 Tag 1, 3, 1

Fixed Process Tem-

perature

Flange Type 1, 3, 4 Totalizer Control 1, 1, 4, 4

Flow Simulation 1, 2, 4 Transmitter Mode 1, 3, 2, 1

Installation Effects 1, 4, 1, 6 TV Mapping 1, 3, 6, 3

K-factor (Reference) 1, 3, 3 Trigger Level 1, 4, 3, 2, 5

1, 1, 4, 7, 2 Special Units 1, 1, 4, 1, 3

1, 4, 4, 7, 5 SV Mapping 1, 3, 6, 2

1, 3, 2, 3 Total 1, 1, 4, 4, 1

24 Rosemount 8800D Series Vortex Flowmeter

Page 25

April 2018 Quick Start Guide

Table 6-1:

Fast Keys for Rosemount 8800D Device Revision 1 DD

Revision 2 and Device Revision 2 DD Revision 1 (continued)

Function HART Fast Keys Function HART Fast Keys

Local Display 1, 4, 2, 4 URV 1, 3, 8, 1

Loop Test 1, 2, 2 User Defined Units 1, 1, 4, 1, 3, 3

Low Flow Cutoff 1, 4, 3, 2, 3 USL 1, 3, 8, 4

Low Pass Filter 1, 4, 3, 2, 4 Shedding Frequency 1, 1, 4, 6

LRV 1, 3, 8, 2 Variable Mapping 1, 3, 6

LSL 1, 3, 8, 5 Velocity Flow 1, 1, 4, 3

Manufacturer 1, 4, 4, 1 Velocity Flow Base 1, 1, 4, 3, 3

Mass Flow 1, 1, 4, 2, 1 Volumetric Flow 1, 1, 4, 1

Mass Flow Units 1, 1, 4, 2, 2 Wetted Material 1, 4, 1, 4

Mating Pipe ID (Inside

Diameter)

Message 1, 4, 4, 4

Table 6-2:

Fast Keys for Rosemount 8800D Device Revision 2 DD

1, 3, 5 Write Protect 1, 4, 4, 6

Revision 3

Function HART Fast Keys Function HART Fast Keys

Alarm Direction 1, 3, 1, 3, 2 Percent of Range 3, 4, 3, 2

Analog Output 3, 4, 3, 1 Polling Address 2, 2, 7, 1

Analog Trim 3, 4, 3, 6 Primary Variable

Base Time Unit 2, 2, 2, 3, 2 Primary Variable 2, 2, 2, 1, 1

Base Volume Unit 2, 2, 2, 3, 1 Process Density Units 2, 2, 2, 2, 6

Burst Mode 2, 2, 7, 2 Process Fluid Type 2, 2, 1, 1, 2

Burst Option 2, 2, 7, 3 Process Temp Units 2, 2, 3, 1, 2

Burst Slot 0 2, 2, 7, 4, 1 Process Variables 3, 2, 1

Burst Slot 1 2, 2, 7, 4, 2 Pulse Output 3, 2, 4, 4

Burst Slot 2 2, 2, 7, 4, 3 Pulse Output Test 3, 5, 3, 4

Burst Slot 3 2, 2, 7, 4, 4 Recall Factory Calibra-

Burst Variable Mapping

Compensated K-Factor

Conversion Number 2, 2, 2, 3, 4 Restore Default Filters 2, 1, 4, 6

Date 2, 2, 8, 2, 1 Revision Numbers 2, 2, 8, 3

Descriptor 2, 2, 8, 2, 2 Scaled Analog Trim 3, 4, 3, 7

Density Ratio 2, 2, 3, 3, 2 2nd Variable 2, 2, 2, 1, 2

Device ID 2, 2, 8, 1, 5 Self Test 3, 4, 1, 1

Display 2, 1, 1, 2 Set Variable Mapping 2, 2, 2, 1, 5

Electronics Temp 3, 2, 5, 4 Shedding Frequency 3, 2, 4, 2

2, 2, 7, 4, 5 Reference K-Factor 2, 2, 1, 2, 1

2, 2, 1, 2, 2 Reset Transmitter 3, 4, 1, 2

Damping

tion

2, 1, 4, 1

3, 4, 3, 8

Quick Start Guide 25

Page 26

Quick Start Guide April 2018

Table 6-2:

Fast Keys for Rosemount 8800D Device Revision 2 DD

Revision 3 (continued)

Function HART Fast Keys Function HART Fast Keys

Electronics Temp

Units

Final Assembly Number

Fixed Process Density 2, 2, 1, 1, 5 Special Volume Unit 2, 2, 2, 3, 3

Fixed Process Tem-

perature

Flange Type 2, 2, 1, 4, 2 Tag 2, 2, 8, 1, 1

Flow Simulation 3, 5, 1 3rd Variable 2, 2, 2, 1, 3

4th Variable 2, 2, 2, 1, 4 Total 1, 3, 6, 1

Installation Effects 2, 2, 1, 1, 7 Totalizer Configura-

Lower Range Value 2, 2, 4, 1, 4 Totalizer Control 1, 3, 6, 2

Lower Sensor Limit 2, 2, 4, 1, 5, 2 Transmitter Mode 2, 2, 1, 1, 1

Loop Test 3, 5, 2, 6 Trigger Level 2, 1, 4, 5

Low Flow Cutoff 2, 1, 4, 3 Upper Range Value 2, 2, 4, 1, 3

Low-pass Corner Fre-

quency

Manufacturer 2, 2, 8, 1, 2 Velocity Flow 3, 2, 3, 4

Mass Flow 3, 2, 3, 6 Velocity Flow Units 2, 2, 2, 2, 2

Mass Flow Units 2, 2, 2, 2, 4 Velocity Measure-

Mating Pipe ID (Inside

Diameter)

Message 2, 2, 8, 2, 3 Volume Flow Units 2, 2, 2, 2, 1

Meter Body Number 2, 2, 1, 4, 5 Wetted Material 2, 2, 1, 4, 1

Minimum Span 2, 2, 4, 1, 6 Write Protect 2, 2, 8, 1, 6

Optimize DSP 2, 1, 1, 3

2, 2, 2, 2, 5 Signal Strength 3, 2, 5, 2

2, 2, 8, 1, 4 Special Flow Unit 2, 2, 2, 3, 5

2, 2, 1, 1, 4 Status 1, 1, 1

1, 3, 6, 3

tion

2, 1, 4, 4 Upper Sensor Limit 2, 2, 4, 1, 5, 1

2, 2, 2, 2, 3

ment Base

2, 2, 1, 1, 6 Volume Flow 3, 2, 3, 2

Table 6-3:

Fast Keys for Rosemount 8800D HART 7 Device Revision 2 (DD

Revision 1)/ HART 5 Device Revision 3 (DD Revision 1)

Function Fast Key Function Fast Key

Analog Output 3, 4, 3, 1 Polling Address 2, 2, –

Analog Trim 3, 4, 3, 7 Primary Variable 2, 2, 2, 1

Base Mass Unit (MF) 2, 2, 2, 8, 1 Process Fluid Type 2, 2, 1, 1, 3

Base Process Density 2, 2, 3, 2, 1 Process Variables 3, 2, 3

Base Time Unit (CVF) 2, 2, 2, 9, 4 Pulse Output 3, 2, 5, 3

Base Time Unit (MF) 2, 2, 2, 8, 4 Pulse Output Test 3, 5, 3, 4

Base Time Unit (VF) 2, 2, 2, 7, 4 Reference K-Factor 2, 2, 1, 2, 1

Base Volume Unit

(CVF)

2, 2, 2, 9, 1 Reset Transmitter 3, 4, 4, 1, 2

26 Rosemount 8800D Series Vortex Flowmeter

(1)

, 2, 1

Page 27

April 2018 Quick Start Guide

Table 6-3:

Fast Keys for Rosemount 8800D HART 7 Device Revision 2 (DD

Revision 1)/ HART 5 Device Revision 3 (DD Revision 1) (continued)

Function Fast Key Function Fast Key

Base Volume Unit (VF) 2, 2, 2, 7, 1 Restore Default Filters 2, 1, 4, 6

Compensated K-Fac-

tor

Conversion Factor

(CVF)

Conversion Factor

(MF)

Conversion Factor

(VF)

Date 2, 2, –

Corrected Volumetric

Flow

Corrected Volumetric

Flow Units

Density Ratio 2, 2, 3, 4 Set Low-pass Corner

Descriptor 2, 2, –

Device ID 2, 2, –

Device Status 1, 1 Signal Strength 3, 4, 2, 1, 4

Display 2, 1, 1, 2 Special Flow Unit

Electronics Temp 3, 2, 6 Special Flow Unit (MF) 2, 2, 2, 8, 5

Electronics Temp

Units

Final Assembly Num-

ber

Fixed Process Density 2, 2, 1, 1, 5 Tag 2, 2, –

Fixed Process Tem-

perature

Flange Type 2, 2, 1, 4, 2 Total 2, 2, 4, 3, 1

Flow Simulation 3, 5, 1, 2, 1 Totalizer Configura-

Fourth Variable 2, 2, 2, 4 Totalizer Control 2, 2, 4, 3, 2

Loop Test 3, 5, 2, 7 Transmitter Mode 2, 2, 1, 1, 1

Lower Range Value 2, 2, 4, 1, 4 Upper Range Value 2, 2, 4, 1, 3

Lower Sensor Limit 2, 2, 4, 1, 6 Upper Sensor Limit 2, 2, 4, 1, 5

Mass Flow 3, 2, 1 Variable Mapping 2, 2, 2, 5

Mass Flow Units 2, 2, 2, 6, 5 Velocity Flow 3, 2, 1

Message 2, 2, –

Meter Factor 2, 2, 1, 1, 7 Velocity Measure-

Minimum Span 2, 2, 4, 1, 7 Volume Flow 3, 2, 1

Optimize DSP 2, 1, 1, 3 Volume Flow Units 2, 2, 2, 6, 1

Percent of Range 3, 4, 3, 2 Wetted Material 2, 2, 1, 4, 1

2, 2, 1, 2, 2 Restore Factory Cali-

3, 4, 3, 9

bration

2, 2, 2, 9, 2 Revision Numbers 2, 2, –

(1)

2, 2, 2, 8, 2 Scaled Analog Trim 3, 4, 3, 8

2, 2, 2, 7, 2 Second Variable 2, 2, 2, 2

(1)

, 1, 5 Self Test 3, 4, 4, 1, 1

3,2,1 Set Damping 2, 1, 4, 1

2,2,2,6,2 Set Low Flow Cutoff 2, 1, 4, 3

2, 1, 4, 4

Frequency

(1)

, 1, 6 Set Trigger Level 2, 1, 4, 5

(1)

, 1 Shedding Frequency 3, 2, 5, 1

2, 2, 2, 9, 5

(CVF)

2, 2, 2, 6, 7 Special Flow Unit (VF) 2, 2, 2, 7, 5

2, 2, 1, 4, 3 Special Volume Unit 2, 2, 2, 7, 3

(1)

2, 2, 1, 1, 4 Third Variable 2, 2, 2, 3

2, 2, 4, 3, 3

tion

(1)

, 1, 7 Velocity Flow Units 2, 2, 2, 6, 3

2, 2, 2, 6, 4

ment Base

, 2

, 1, 1

Quick Start Guide 27

Page 28

Quick Start Guide April 2018

Table 6-3:

Fast Keys for Rosemount 8800D HART 7 Device Revision 2 (DD

Revision 1)/ HART 5 Device Revision 3 (DD Revision 1) (continued)

Function Fast Key Function Fast Key

Pipe Inside Diameter 2, 2, 1, 1, 6 Write Protect 2, 2, 4, 1

(1) These items are in a list format without numeric labels. To access these features, you must

scroll to this option in the HART Communicator.

Note

For detailed configuration information, refer to the product reference

manual.

28 Rosemount 8800D Series Vortex Flowmeter

Page 29

April 2018 Quick Start Guide

7 Safety instrumented systems installation

For safety certified installations, refer to the Rosemount 8800D Safety

Manual (Document # 00809-0200-4004) for installation procedure and

system requirements.

Quick Start Guide 29

Page 30

Quick Start Guide April 2018

8 Product certifications

Flameproof enclosure Ex d protection type in accordance with IEC

60079-1, EN 60079-1

• Transmitters with Flameproof enclosure type protection shall only be

opened when power is removed.

• Closing of entries in the device must be carried out using the appropriate

Ex d cable gland or blanking plug. Unless otherwise marked on housing,

the standard conduit entry thread forms are 1/2–14 NPT.

Type n protection type in accordance with IEC 60079-15, EN60079-15

Closing of entries in the device must be carried out using the appropriate Ex e

or Ex n cable gland and metal blanking plug or any appropriate ATEX or IECEx

approved cable gland and blanking plug with IP66 rating certified by an EU

approved certification body.

8.1

8.2

8.3

European directive information

The CE Declaration of Conformity for all applicable European directives for

this product can be found on our website at www.emerson.com/rosemount. A

hard copy may be obtained by contacting our local sales office.

ATEX Directive

Emerson Process Management complies with the ATEX Directive.

European Pressure Equipment Directive (PED)

Rosemount 8800D Vortex Flowmeter line size 40 mm to 300 mm

• Certificate Number 4741-2014-CE-HOU-DNV

•

0575 or 0496

• Module H Conformity Assessment

• Mandatory CE-marking for flowmeters in accordance with Article 15 of

the PED can be found on the flowtube body.

• Flowmeter categories I – III use module H for conformity assessment

procedures.

Rosemount 8800D Vortex Flowmeter line size 15 mm and 25 mm

Sound Engineering

Practice (SEP)

Flowmeters that are SEP are outside the scope of

PED and cannot be marked for compliance with

PED.

30 Rosemount 8800D Series Vortex Flowmeter

Page 31

April 2018 Quick Start Guide

9 Hazardous location certifications

9.1 North American Certifications

Factory Mutual (FM)

E5

Explosion proof-Intrinsically Safe for Class I, Division 1, Groups B, C, and

D

Dust-ignition proof for Class II/III, Division 1, Groups E, F, and G

Temperature Code T6 (-50 °C ≤ Ta ≤ 70 °C)

Factory Sealed Enclosure Type 4X, IP66

I5

Intrinsically safe for use in Class I, II, III Division 1, Groups A, B, C, D, E, F,

and G

Non-incendive for Class I, Division 2, Groups A, B, C, and D

NIFW (Non-incendive Field Wiring) when installed per Rosemount

Drawing 08800-0116

Temperature Code T4 (-50 °C ≤ Ta ≤ 70 °C) 4-20 mA HART

Temperature Code T4 (-50 °C ≤ Ta ≤ 60 °C) Fieldbus

Enclosure Type 4X, IP66

IE

FISCO for Class I, II, III, Division 1, Groups A, B, C, D, E, F and G

FNICO for Class I Division 2, Groups A, B, C, and D when installed per

Rosemount control drawing 08800-0116

Temperature Code T4 (-50 °C ≤ Ta ≤ 60 °C)

Enclosure Type 4X, IP66

Combined Factory Mutual (FM) certifications

K5

E5 and I5 Combination

Special conditions for safe use (X):

1. When fitted with 90V transient suppressors (T1 Option),

the equipment is not capable of passing the 500V

insulation test. This must be taken into account upon

installation.

2. The Model 8800D Vortex Flowmeter when ordered with

aluminum electronics housing is considered to constitute

a potential risk of ignition by impact or friction. Care

should be taken into account during installation and use to

prevent impact or friction.

Canadian Standards Association (CSA)

E6

Explosion-Proof for Class I, Division 1, Groups B, C, and D

Quick Start Guide 31

Page 32

Quick Start Guide April 2018

Dust-ignition proof for Class II and Class III, Division 1, Groups E, F, and

G

Class I, Zone 1, AEx d [ia] IIC T6 Gb (-50 °C ≤ Ta ≤ 70 °C)

Factory Sealed; Single Seal

Enclosure Type 4X

Install per drawing 08800-0112;

I6

Intrinsically safe for use in Class I, II, III Division 1, Groups A, B, C, D, E, F,

G

Non-incendive for Class I, Division 2, Groups A, B, C and D

Class I, Zone 0, AEx ia IIC T4 Ga

Temperature Code T4 (-50 °C ≤ Ta ≤ 70 °C) 4-20 mA HART

Temperature Code T4 (-50 °C ≤ Ta ≤ 60 °C) Fieldbus

Single Seal; Enclosure Type 4X

Install per drawing 08800-0112

IF

FISCO for Class I, Division 1, Groups A, B, C, and D

FNICO for Class I Division 2, Groups A, B, C, and D

Class I, Zone 0, AEx ia IIC T4 Ga

Temperature Code T4 (-50 °C ≤ Ta ≤ 60 °C)

Single Seal; Enclosure Type 4X

Install per drawing 08800-0112

Combined Canadian certifications (CSA)

K6

Combined North America certifications (FM and CSA)

KB

E6 and I6 Combination

E5, I5, E6, and I6 Combination

9.2 European certifications (ATEX)

ATEX I.S. certification

• EN 60079-0: 2012 +A11: 2013

• EN 60079-11: 2012

I1

Certification No. Baseefa05ATEX0084X

ATEX marking:

•

II 1 G Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ 70 °C) 4–20 mA HART

•

II 1 G Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ 60 °C) Fieldbus

•

2460

32 Rosemount 8800D Series Vortex Flowmeter

Page 33

April 2018 Quick Start Guide

4–20 mA HART entity parameters

U

I

P

C

L

(1) Total for transmitter.

i

(1)

i

(1)

i

i

i

= 30 VDC U

= 185 mA I

= 1.0 W P

= 0 µF C

= 0.97mH L

Fieldbus entity parameters FISCO input parameters

i

(1)

i

(1)

i

i

i

ATEX FISCO

IA

Certification No. Baseefa05ATEX0084X

ATEX marking:

•

II 1 G Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ 60 °C)

•

2460

Special conditions for safe use (X):

1. When fitted with 90V transient suppressors (T1 option),

the equipment is not capable of passing the 500V isolation

test. This must be taken into account upon installation.

2. The enclosure may be made from aluminum alloy and

given a protective polyurethane paint finish; however, care

should be taken to protect it from impact or abrasion when

located in Zone 0 environment. The polyurethane paint

finish may constitute an electrostatic hazard and must only

be cleaned with a damp cloth.

3. When the equipment is installed, particular precautions

must be taken to ensure taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

= 30 VDC U

= 300 mA I

= 1.3 W P

= 0 µF C

< 10 µH L

= 17.5 VDC

i

(1)

= 380 mA

i

(1)

= 5.32 W

i

= 0 µF

i

< 10 µH

i

ATEX Type 'n' certification

• EN 60079-0: 2012 + A11: 2013

• EN 60079-11: 2012

• EN 60079-15: 2010

N1

Certification No. Baseefa05ATEX0085X

ATEX marking:

Quick Start Guide 33

Page 34

Quick Start Guide

ATEX Dust certification

•

II 3 G Ex nA ic IIC T5 Gc (-50 °C ≤ Ta ≤ 70 °C) 4–20 mA

HART

•

II 3 G Ex nA ic IIC T5 Gc (-50 °C ≤ Ta ≤ 60 °C) Fieldbus

Maximum Working Voltage = 42 VDC 4–20 mA HART

Maximum Working Voltage = 32 VDC Fieldbus

Special conditions for safe use (X):

1. When fitted with 90V transient suppressors (T1 Option),

the equipment is not capable of passing the 500V isolation

test. This must be taken into account upon installation.

2. The enclosure may be made from aluminum alloy with a

protective polyurethane paint finish. The polyurethane

paint finish may constitute and electrostatic hazard and

must only be cleaned with a damp cloth.

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

April 2018

• EN 60079-0: 2012 + A11: 2013

• EN 60079-31: 2014

ND

Certificate: BaseefaATEX17.0020X

II 2 D Ex tb IIIC T85°C Db (-20 °C ≤ Ta ≤ 70 °C)

2460

Maximum Working Voltage = 42 VDC 4–20 mA HART

Maximum Working Voltage = 32 VDC Fieldbus

Special conditions for safe use (X):

1. The enclosure may be made from aluminium alloy with a

protective polyurethane paint finish which may constitute

a potential electrostatic ignition risk. Care should be taken

to protect it from external conditions conducive to the

build-up of electrostatic charge on such surfaces. The

enclosure must not be rubbed or cleaned with a dry cloth.

2. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

34 Rosemount 8800D Series Vortex Flowmeter

Page 35

April 2018

ATEX Flameproof certification

• EN 60079-0: 2012 + A11: 2013

• EN 60079-1: 2014

• EN 60079-11: 2012

• EN 60079-26: 2015

E1

Certificate: KEMA99ATEX3852X;

Integral Flowmeter marked:

II 1/2 G Ex db [ia] IIC T6...T1 Ga/Gb (-50 °C ≤ Ta ≤ 70 °C)

Remote Transmitter marked:

II 2(1) G Ex db [ia Ga] IIC T6 Gb (-50 °C ≤ Ta ≤ 70 °C)

with meter body marked:

II 1 G Ex ia IIC T6...T1 Ga (-50 °C ≤ Ta ≤ 70 °C)

EPL Ga piezo sensor and thermocouple connections.

EPL Gb transmitter enclosure.

2460

42 VDC Max 4–20 mA HART

32 VDC Max Fieldbus

Um = 250V

Thermal data:

Quick Start Guide

Ambient temperature

(°C) Process temperature (°C) T-Class sensor (°C)

–50 to +70 –200 to +75 T6

–50 to +70 –200 to +95 T5

–50 to +70 –200 to +130 T4

–50 to +70 –200 to +195 T3

–50 to +70 –200 to +290 T2

–50 to +70 –200 to +427 T1

Installation instructions:

1. The cable and conduit entry devices shall be of a certified

flameproof type Ex d, suitable for the conditions of use and

correctly installed.

2. Unused apertures shall be closed with suitable blanking

elements.

3. When the ambient temperature at the cable or conduit

entries exceed 60 °C, cables suitable for at least 90 °C shall

be used.

Quick Start Guide 35

Page 36

Quick Start Guide

Combined ATEX certifications

April 2018

4. Remote mounted sensor; in type of protection Ex ia IIC,

only to be connected to the associated Model 8800D

Vortex Flowmeter electronics. the maximum allowable

length of the interconnecting cable is 152 m (500 ft).

Special conditions for safe use (X):

1. For information regarding the dimensions of the

flameproof joints, the manufacturer shall be contacted.

2. The Flowmeter shall be provided with special fasteners of

property class A2-70 or A4-70.

3. Units marked with “Warning: Electrostatic Charging

Hazard” may use non-conductive paint thicker that 0.2

mm. Precaution shall be taken to avoid ignition due to

electrostatic charge on the enclosure.

4. When the equipment is installed, precautions shall be

taken to ensure the ambient temperature of the

transmitter lies between –50 °C to +70 °C, taking into

account process fluid effects. If the ambient temperature is

outside this range remote transmitters shall be used.

K1

E1, I1, N1, and ND combination

9.3 International certifications (IECEx)

IECEx I.S. certification

• IEC 60079-0: 2011

• IEC 60079-11: 2011

I7

Certificate No. IECEx BAS05.0028X

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ 70 °C) 4-20 mA HART

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ 60 °C) Fieldbus

4–20 mA HART entity parameters

U

I

P

C

L

(1) Total for transmitter.

= 30 VDC U

i

(1)

= 185 mA I

i

(1)

= 1.0 W P

i

= 0 µF C

i

= 0.97mH L

i

36 Rosemount 8800D Series Vortex Flowmeter

Fieldbus entity parameters FISCO input parameters

= 30 VDC U

i

(1)

= 300 mA I

i

(1)

= 1.3 W P

i

= 0 µF C

i

< 10 µH L

i

= 17.5 VDC

i

(1)

= 380 mA

i

(1)

= 5.32 W

i

= 0 µF

i

< 10 µH

i

Page 37

April 2018

FISCO

IG

Certificate: IECEx BAS 05.0028X

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ 60 °C)

Special conditions for safe use (X):

1. When fitted with 90V transient suppressors (T1 Option),

the equipment is not capable of passing the 500V isolation

test. This must be taken into account upon installation.

2. The enclosure may be made from aluminum alloy and

given a protective polyurethane paint finish; however, care

should be taken to protect it from impact or abrasion when

located in Zone 0 environment. The polyurethane paint

finish may constitute an electrostatic hazard and must only

be cleaned with a damp cloth.

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

Type 'n' certification

• IEC 60079-0: 2011

• IEC 60079-11: 2011

• IEC 60079-15: 2010

Quick Start Guide

N7

Certificate No. IECEx BAS05.0029X

Ex nA ic IIC T5 Gc (-50 °C ≤ Ta ≤ 70 °C) 4-20 mA HART

Ex nA ic IIC T5 Gc (-50 °C ≤ Ta ≤ 60 °C) Fieldbus

Maximum Working Voltage = 42 VDC 4-20 mA HART

Maximum Working Voltage = 32 VDC Fieldbus

Special conditions for safe use (X):

1. When fitted with 90V transient suppressors (T1 Option),

the equipment is not capable of passing the 500V isolation

test. This must be taken into account upon installation.

2. The enclosure may be made from aluminum alloy with a

protective polyurethane paint finish. The polyurethane

paint finish may constitute an electrostatic hazard and

must only be cleaned with a damp cloth.

Quick Start Guide 37

Page 38

Quick Start Guide April 2018

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

IECEx Dust certification

• IEC 60079-0: 2011

• IEC 60079-31: 2013

NF

Certificate: IECEx BAS 17.0019X

Ex tb IIIC T85°C Db (-20 °C ≤ Ta ≤ 70 °C)

Maximum Working Voltage = 42 VDC 4-20 mA HART

Maximum Working Voltage = 32 VDC Fieldbus

Special conditions for safe use (X):

1. The enclosure may be made from aluminium alloy with a

protective polyurethane paint finish which may constitute

a potential electrostatic ignition risk. Care should be taken

to protect it from external conditions conducive to the

build-up of electrostatic charge on such surfaces. The

enclosure must not be rubbed or cleaned with a dry cloth.

2. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

IECEx Flameproof certification

• IEC 60079-0: 2011

• IEC 60079-1: 2014

• IEC 60079-11: 2011

• IEC 60079-26: 2014

E7

Certificate: IECEx KEM05.0017X

Integral Flowmeter marked:

Ex db [ia] IIC T6...T1 Ga/Gb (-50 °C ≤ Ta ≤ 70 °C)

Remote Transmitter marked:

Ex db [ia Ga] IIC T6 Gb (-50 °C ≤ Ta ≤ 70 °C)

with meter body marked: Ex ia IIC T6...T1 Ga (-50 °C ≤ Ta ≤ 70 °C)

EPL Ga piezo sensor and thermocouple connections.

EPL Gb transmitter enclosure.

38 Rosemount 8800D Series Vortex Flowmeter

Page 39

April 2018

Quick Start Guide

42 VDC Max 4-20 mA HART

32 VDC Max Fieldbus

Um = 250V

Thermal data:

Ambient temperature

(°C) Process temperature (°C) T-Class sensor (°C)

–50 to +70 –200 to +75 T6

–50 to +70 –200 to +95 T5

–50 to +70 –200 to +130 T4

–50 to +70 –200 to +195 T3

–50 to +70 –200 to +290 T2

–50 to +70 –200 to +427 T1

Installation instructions:

1. The cable and conduit entry devices shall be of a certified

flameproof type Ex d, suitable for the conditions of use and

correctly installed.

2. Unused apertures shall be closed with suitable blanking

elements.

3. When the ambient temperature at the cable or conduit

entries exceed 60 °C, cables suitable for at least 90 °C shall

be used.

4. The remote mounted sensor may only be connected to the

transmitter with the associated cable, supplied by the

manufacturer.

Special conditions for safe use (X):

1. For information regarding the dimensions of the

flameproof joints, the manufacturer shall be contacted.

2. The Flowmeter shall be provided with special fasteners of

property class A2-70 or A4-70.

3. Units marked with “Warning: Electrostatic Charging

Hazard” may use non-conductive paint thicker that 0.2

mm. Precaution shall be taken to avoid ignition due to

electrostatic charge on the enclosure.

4. When the equipment is installed, precautions shall be

taken to ensure the ambient temperature of the

transmitter lies between –50 °C to +70 °C, taking into

account process fluid effects. If the ambient temperature is

outside this range remote transmitters shall be used.

Quick Start Guide 39

Page 40

Quick Start Guide

Combined IECEx certifications

April 2018

K7

Combination of E7, I7, N7, and NF

9.4 Chinese certifications (NEPSI)

Flameproof certification

• GB3836.1 – 2010

• GB3836.2 – 2010

• GB3836.4 – 2010

• GB3836.20 – 2010

E3

Certification No. GYJ12.1493X

Ex ia / d IIC T6 Ga/Gb (Integral Transmitter)

Ex d [ia Ga] IIC T6 Gb (Remote Transmitter)

Ex ia IIC T6 Ga (Remote Sensor)

Ambient temperature range: -50 °C ≤ Ta ≤ +70 °C

Process temperature range: -202 °C to +427 °C

Power Supply: 42 Vdc Max 4-20 mA HART

Power Supply: 32 Vdc Max Fieldbus

Um = 250V

Special conditions for safe use (X):

1. The maximum allowable length of the interconnecting

cable between transmitter and sensor is 152 m. The cable

shall also be provided by Rosemount Inc., or by Emerson

Process Management Flow Technologies Co., Ltd.

2. Suitable heat-resisting cables rated at least +80 °C shall be

used when the temperature around the cable entry

exceeds +60 °C.

3. Dimensions of flameproof joints are other than the

relevant minimum or maximum specified in Table 3 of

GB3836.2-2010. Contact manufacturer for details.

4. The Flowmeter is provided with special fasteners of

property class A2-70 or A4-70.

5. Any friction should be prevented in order to avoid the risk

of electrostatic charge on the enclosure due to nonconductive paint.

6. The earthing terminal should be connected to the ground

reliably at site.

7. Do not open when energized.

40 Rosemount 8800D Series Vortex Flowmeter

Page 41

April 2018 Quick Start Guide

8. The cable entry holes have to be connected by means of

suitable entry device or stopping plugs with type of

protection of Ex d IIC Gb the cable entry device and

stopping plugs are approved in accordance with

GB3836.1-2010 and GB3836.2-2010, and which are

covered by a separate examination certificate, any unused

entry hole is to be fitted with type of protection of Ex d IIC

Gb flameproof stopping plug.

9. Users are forbidden to change the configuration to ensure

the explosion protection performance of the equipment.

Any faults shall be settled with experts from the

manufacturer.

10. Precautions shall be taken to ensure that the electronic

parts are within permissible ambient temperature

considering the effect of the allowed fluid temperature.

11. During installation, operation and maintenance, users shall

comply with the relevant requirements of the product

instruction manual, GB3836.13-1997 “Electrical apparatus

for explosive gas atmospheres Part 13: Repair and overhaul

for apparatus used in explosive gas atmospheres”,

GB3836.15-2000 “Electrical apparatus for explosive gas

atmospheres Part 15: Electrical installations in hazardous

areas (other than mines)”, GB3836.16-2006 “Electrical

apparatus for explosive gas atmospheres Part 16:

Inspection and maintenance of electrical installation (other

than mines)”, and GB50257-1996 “Code for construction

and acceptance of electrical device for explosion

atmospheres and fire hazard electrical equipment

installation engineering”.

I.S. certification

• GB3836.1 – 2010

• GB3836.4 – 2010

• GB3836.20 – 2010

I3

Certification No. GYJ17.1196X

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ + 70 °C) 4-20 mA HART

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ + 60 °C) Fieldbus

4–20 mA HART entity parameters

U

I

Quick Start Guide 41

= 30 VDC U

i

(1)

= 185 mA I

i

Fieldbus entity parameters FISCO input parameters

= 30 VDC U

i

(1)

= 300 mA I

i

= 17.5 VDC

i

(1)

= 380 mA

i

Page 42

Quick Start Guide

April 2018

4–20 mA HART entity parameters

(1)

P

C

L

(1) Total for transmitter.

= 1.0 W P

i

= 0 µF C

i

= 0.97mH L

i

FISCO

IH

Certification No. GYJ17.1196X

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ +60 °C)

Special conditions for safe use (X):

1. Cable between transmitter and sensor shall be provided by

the manufacturer.

2. During installation, users shall comply with Clause 12.2.4 in

GB3836.15-2000 “Electrical apparatus for explosive gas

atmospheres Part 15: Electrical installations in hazardous

areas (other than mines).”

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

4. Only be connected to the certified associated apparatus,

the Vortex Flowmeter could be used in the explosive

atmosphere. The connection should be complied with the

requirements of the manual of the associated apparatus

and the Vortex Flowmeter.

5. The enclosure should be taken to protect it from impact.

6. Any friction should be prevented in order to avoid the risk

of electrostatic charge on the enclosure due to nonconductive paint.

7. The cable with shield is suitable for connection, and the

shield should be connected to earth.

8. Users are forbidden to change the configuration to ensure

the explosion protection performance of the equipment.

Any faults shall be settled with experts from the

manufacturer.

Fieldbus entity parameters FISCO input parameters

(1)

= 1.3 W P

i

= 0 µF C

i

< 10 µH L

i

(1)

= 5.32 W

i

= 0 µF

i

< 10 µH

i

42 Rosemount 8800D Series Vortex Flowmeter

Page 43

April 2018

9. During installation, operation and maintenance, users shall

comply with the relevant requirements of the product

instruction manual, GB3836.13- 2013 “Electrical apparatus

for explosive gas atmospheres Part 13: Repair and overhaul

for apparatus used in explosive gas atmospheres”,

GB3836.15-2000 “Electrical apparatus for explosive gas

atmospheres Part 15: Electrical installations in hazardous

areas (other than mines)”, GB3836.16-2006 “Electrical

apparatus for explosive gas atmospheres Part 16:

Inspection and maintenance of electrical installation (other

than mines)”, and GB50257- 2014 “Code for construction

and acceptance of electrical device for explosion

atmospheres and fire hazard electrical equipment

installation engineering”.

Type 'n' certification

• GB3836.1 – 2010

• GB3836.4 – 2010

• GB3836.8 – 2014

N3

Certification No. GYJ17.1197X

Ex nA ic IIC T5 Gc (- 50 °C ≤ Ta ≤ +70 °C) 4-20 mA HART

Ex nA ic IIC T5 Gc (- 50 °C ≤ Ta ≤ +60 °C) Fieldbus

Special conditions for safe use (X):

1. Cable between transmitter and sensor shall be provided

by the manufacturer.

2. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

3. During installation, users shall comply with Clause 12.2.4

in GB3836.15-2000 “Electrical apparatus for explosive gas

atmospheres Part 15: Electrical installations in hazardous

areas (other than mines).”

4. Any friction should be prevented in order to avoid the risk

of electrostatic charge on the enclosure due to nonconductive paint.

5. Do not open when energized.

6. The cable entry holes must be connected by means of

suitable cable entry. The cable entry shall meet Ex d/Ex

e/Ex nA installation requirements according to GB3836

Quick Start Guide

Quick Start Guide 43

Page 44

Quick Start Guide April 2018

and with Ex approval certificate. The installation method

shall ensure the equipment satisfies degree of protection

IP66 according to GB4208-2008.

7. Users are forbidden to change the configuration to ensure

the explosion protection performance of the equipment.

Any faults shall be settled with experts from the

manufacturer.

8. During installation, operation and maintenance, users

shall comply with the relevant requirements of the

product instruction manual, GB3836.13- 2013 “Electrical

apparatus for explosive gas atmospheres Part 13: Repair

and overhaul for apparatus used in explosive gas

atmospheres”, GB3836.15-2000 “Electrical apparatus for

explosive gas atmospheres Part 15: Electrical installations

in hazardous areas (other than mines)”, GB3836.16-2006

“Electrical apparatus for explosive gas atmospheres Part

16: Inspection and maintenance of electrical installation

(other than mines)”, and GB50257- 2014 “Code for

construction and acceptance of electrical device for

explosion atmospheres and fire hazard electrical

equipment installation engineering”.

Combined Chinese certifications (NEPSI)

K3

Combination of E3, I3, N3, and Dust

9.5 Japanese certifications (CML)

Flameproof certification

• JNIOSH-TR-46-1

• JNIOSH-TR-46-2

• JNIOSH-TR-46-6

E4

Certificate: CML17JPN1145X

Ex d [ia] IIC T6 Ga/Gb (integral transmitter and sensor)

Ex d [ia Ga] IIC T6 Gb (remote transmitter)

Ex ia IIC T6 Ga (remote sensor)

Ambient temperature range: -20 °C to +60 °C

Process temperature range: -202 °C to +427 °C

42 VDC Max, 4-20 mA HART

32 VDC Max, Fieldbus

Um = 250V

Special conditions for safe use (X):

44 Rosemount 8800D Series Vortex Flowmeter

Page 45

April 2018

1. For information regarding the dimensions of the

flameproof joints, the manufacturer shall be contacted.

2. The Flowmeter shall be provided with special fasteners of

property class A2-70 or A4-70.

3. Units marked with “Warning: Electrostatic Charging

Hazard” may use non-conductive paint thicker that

0.2mm. Precaution shall be taken to avoid ignition due to

electrostatic charge on the enclosure.

9.6 Brazilian certifications (INMETRO)

I. S. certification

• ABNT NBR IEC 60079-0: 2013

• ABNT NBR IEC 60079-11: 2013

• ABNT NBR IEC 60079-26: 2008 and 2009 correction

• ABNT NBR IEC 60529: 2011

• Portaria INMETRO no. 179: 18 May 2010

I2

Certification Number: TÜV 16.1958 X

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ + 70 °C) 4-20 mA HART

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ + 60 °C) Fieldbus

Quick Start Guide

IB

Certification Number: TÜV 16.1958 X

Ex ia IIC T4 Ga (-60 °C ≤ Ta ≤ + 60 °C)

Special conditions for safe use (X):

1. When fitted with 90V transient suppressors, the equipment

is not capable of passing the 500V insulation test. This

must be taken into account upon installation.

2. The enclosure may be made from aluminum alloy with a

protective polyurethane paint finish; however, care should

be taken to protect it from impact or abrasion when

located in Zone 0. The polyurethane paint finish may

constitute an electrostatic hazard and must only be

cleaned with a damp cloth.

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

Quick Start Guide 45

Page 46

Quick Start Guide

Flameproof certification

• ABNT NBR IEC 60079-0: 2013

• ABNT NBR IEC 60079-1: 2009 and 2011 correction

• ABNT NBR IEC 60079-11: 2013

• ABNT NBR IEC 60079-26: 2008 and 2009 correction

• Portaria INMETRO no. 179: 18 May 2010

E2

Remote mounted sensor

In type of protection Ex ia IIC, only to be connected to the associated Model

8800D Vortex Flowmeter electronics. The maximum length of the

interconnecting cable is 152 m (500 ft).

April 2018

Certification Number: TÜV 16.1959 X

Ex d [ia] IIC T6 Ga/Gb (Integral Transmitter)

Ex d [ia Ga] IIC T6 Gb (Remote Transmitter)

Ex ia IIC T6 Ga (Remote Sensor)

Ambient temperature range: -50 °C ≤ Ta ≤ +70 °C

Process temperature range: -202 °C to +427 °C

Power Supply: 42 Vdc Max 4-20 mA HART

Power Supply: 32 Vdc Max Fieldbus Transmitter

Um = 250 V

Special conditions for safe use (X):

1. For information regarding the dimensions of the flameproof joints, the

manufacturer shall be contacted.

2. The Flowmeter is provided with special fasteners of property class A2-70

of A4-70.

3. Units marked with “Warning: Electrostatic Charging Hazard” may use

non-conductive paint thicker than 0.2 mm. Precautions shall be taken to

avoid ignition due to electrostatic charge of the enclosure.

Combined Brazilian certifications (INMETRO)

K2

Combination of E2 and I2

9.7 EurAsian Conformity (EAC)

This section addresses compliance with the requirements of technical

regulations of the Customs Union.

• TR CU 020/2011—Electromagnetic compatibility of technical means

• TR CU 032/2013—On the safety of equipment operating under excessive

pressure

46 Rosemount 8800D Series Vortex Flowmeter

Page 47

April 2018 Quick Start Guide

• TR CU 012/2011—About the safety of equipment for use in potentially

explosive atmospheres

• GOST R IEC 60079-0-2011

• GOST R IEC 60079-1-2011

• GOST R IEC 60079-11-2010

• GOST R IEC 60079-15-2010

• GOST 31610.26-2002/IEC 60079-26:2006

E8

Type of protection flameproof enclosure «d» with intrinsically safe flow

sensor

Ex marking of the integral installation:

Ga/Gb Ex d [ia] IIC T6 X (-50°C ≤ Ta ≤ 70°C)

Ex marking of the remote installation: electronics module:

1Ex d [ia Ga] IIC T6 Gb X (-50°C ≤ Ta ≤ 70°C) flow sensor:

0Ex ia IIC T6 Ga X (-50°C ≤ Ta ≤ 70°C)

Electrical parameters:

Maximum DC supply voltage (with output signal 4-20 mA HART/pulse)

42 V;

Maximum DC supply voltage (with output signal Foundation Fieldbus

and FISCO) 32 V

Special conditions for safe use (X):

1. For flowmeters with Ex marking 0Ex ia IIC T6 Ga X, Ga / Gb

Ex d [ia] IIC T6 X and transmitter with Ex marking 1Ex d [ia

Ga] IIC T6 Gb X cabling in explosive area must be

conducted according to requirements of IEC

60079-14-2011. Sheath cables must be designed for a

maximum ambient temperature;

2. Remote installation should be made only with special

coaxial cable provided by the manufacturer of flowmeters;

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range;

4. Precautions shall be taken to avoid ignition due to

electrostatic charge on the enclosure

I8,

Type of protection "intrinsically safe circuit" level «ia»

G8

Ex marking: 0Ex ia IIC T4 Ga X

Ambient temperature range:

• (I8) Flowmeters with pulse output signals, 4-20 mA /

HART (-60°C ≤ Ta ≤ 70°C)

Quick Start Guide 47

Page 48

Quick Start Guide April 2018

• Flowmeters with output Fieldbus (I8) and FISCO (G8)

(-60°C ≤ Ta ≤ 60°C)

Input intrinsically safe parametersTable 9-1:

Output signal

Intrinsically safe

parameters

(1)

Ui,

V 30 30 17.5

(1)

Ii,

mA 185 300 380

(1)

Pi,

W 1 1.3 5.32

Li, uH 970 20 10

Ci, nF 0 0 0

(1) Applicable values Ui, Ii are limited by the maximum input power Pi. It is not allowed

to apply max values of Ui, Ii at the same time.

4–20mA/HART

pulse

Foundation fieldbus FISCO

Special conditions for safe use (X):

1. Power supply of flowmeters with Ex marking 0Ex ia IIC T4

Ga X must be implemented through intrinsically safe

barriers having certificate of conformity for appropriate

subgroups of electrical equipment.

2. Inductance and capacitance of intrinsically safe circuits of

flowmeters with Ex marking 0Ex ia IIC T4 Ga X, with given

parameters connecting cables must not exceed

maximum values shown on the intrinsically safe barrier

from the side of explosive zone.

3. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

4. When fitted with the 90V transient suppressors, the

equipment is not capable of passing the 500V insulation

test. This must be taken into account upon installation.

5. The enclosure may be made from aluminium alloy with a

protective polyurethane paint finish; however, care

should be taken to protect it from impact or abrasion

when located in Zone 0.

N8

Type of protection «n» and "intrinsically safe" level «ic»

Ex marking: 2Ex nA ic IIC T5 Gc X (-50°C ≤ Ta ≤ 70°C)

Electrical parameters:

48 Rosemount 8800D Series Vortex Flowmeter

Page 49

April 2018 Quick Start Guide

• The maximum DC voltage (with output 4-20 mA HART/

pulse) 42V;

• Maximum supply DC voltage (with output signal

Foundation Fieldbus and FISCO) 32V

Special conditions for safe use (X):

1. When the equipment is installed, particular precautions

must be taken to ensure, taking into account the effect of

process fluid temperature, that the ambient temperature

of the electrical housing of the equipment meets the

marked protection type temperature range.

2. When fitted with the 90V transient suppressors, the

equipment is not capable of passing the 500V insulation

test. This must be taken into account upon installation.

3. Precautions shall be taken to avoid ignition due to

electrostatic charge on the enclosure.

K8

Combination of E8, I8, N8

Quick Start Guide 49

Page 50

Quick Start Guide April 2018

9.8 Rosemount 8800 Declaration of Conformity

50 Rosemount 8800D Series Vortex Flowmeter

Page 51

April 2018 Quick Start Guide

Quick Start Guide 51

Page 52

Quick Start Guide April 2018

52 Rosemount 8800D Series Vortex Flowmeter

Page 53

April 2018 Quick Start Guide

Quick Start Guide 53

Page 54

Quick Start Guide April 2018

54 Rosemount 8800D Series Vortex Flowmeter

Page 55

April 2018 Quick Start Guide

Quick Start Guide 55

Page 56

*00825-0100-4004*

Emerson Automation Solutions USA

7070 Winchester Circle

Boulder, Colorado USA 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.emerson.com

Emerson Automation Solutions Europe

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.micromotion.nl

Quick Start Guide

00825-0100-4004, rev. FD

April 2018

Emerson Automation Solutions Asia

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Emerson Automation Solutions Japan

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

Emerson Automation Solutions United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

©

2017 Rosemount, Inc. All rights reserved.

The Emerson logo is a trademark and service mark

of Emerson Electric Co. Rosemount, 8600, 8700,

8800 marks are marks of one of the Emerson

Automation Solutions family of companies. All

other marks are property of their respective

owners.

Loading...

Loading...