Safety Manual

00809-0200-4004, Rev AC

August 2020

Rosemount™ 8800D Series Vortex Flowmeter

Safety Manual for Safety Instrumented

Systems (SIS)

2

Safety Manual Contents

00809-0200-4004 August 2020

Contents

Chapter 1 Before you begin........................................................................................................5

1.1 Emerson Flow customer service................................................................................................... 5

1.2 About this document...................................................................................................................5

1.3 Related documents......................................................................................................................6

1.4 Terms and definitions.................................................................................................................. 6

1.5 Skill level requirement................................................................................................................. 8

1.6 Documentation and standards.....................................................................................................8

Chapter 2 Installation and commissioning..................................................................................9

2.1 Identification of SIS certified transmitter......................................................................................9

2.2 Set up the flowmeter................................................................................................................. 11

2.3 Enable transmitter write protection........................................................................................... 12

2.4 Set failure mode........................................................................................................................ 13

2.5 Flow simulation diagnostic........................................................................................................ 15

2.6 Replace equipment....................................................................................................................16

Chapter 3 Proof tests................................................................................................................17

3.1 Proof test requirement.............................................................................................................. 17

3.2 Repair and replacement.............................................................................................................17

3.3 Notification of failures............................................................................................................... 17

3.4 Proof test interval...................................................................................................................... 17

3.5 Tools required............................................................................................................................17

3.6 Proof test options...................................................................................................................... 18

3.7 Partial proof test........................................................................................................................ 18

3.8 Comprehensive proof test......................................................................................................... 19

3.9 SIS example............................................................................................................................... 20

Chapter 4 Operating Constraints..............................................................................................25

4.1 Reverse flow.............................................................................................................................. 25

4.2 Reliability data........................................................................................................................... 25

4.3 Report failures........................................................................................................................... 25

Safety Manual 3

Contents Safety Manual

August 2020 00809-0200-4004

4 Rosemount™ 8800D Safety Manual

Safety Manual Before you begin

00809-0200-4004 August 2020

1 Before you begin

1.1 Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800 522 6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303 527 5200 The Netherlands +31 (0) 704 136

666

Mexico +41 (0) 41 7686

111

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern

France 0800 917 901 India 800 440 1468

+41 (0) 41 7686

Europe

Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

111

New Zealand 099 128 804

Japan +81 3 5769 6803

1.2 About this document

This document provides information about how to install, commission, and proof test the

Rosemount 8800D Series SIL 2/3 Capable Vortex Flowmeter to comply with Safety

Instrumented Systems (SIS) requirements.

The information in this document assumes that users understand:

• Basic flowmeter installation, configuration, and maintenance concepts and procedures

• Safety Instrumented System (SIS) operations, including bypass procedures, flowmeter

maintenance, and company Management of Change procedures

• All corporate, local government, and national government safety standards and

requirements that guard against injuries or death

Safety Manual 5

Before you begin Safety Manual

August 2020 00809-0200-4004

1.3 Related documents

You can find all product documentation via the Rosemount product documentation DVD

shipped with the product or at www.emerson.com/vortex. For more information, see any

of the following documents:

• Rosemount™ 8800D Series Vortex Flow Meter Product Data Sheet

• Rosemount™ 8800D Series Vortex Flow Meter Quick Start Guide

• Rosemount™ 8800D Series Vortex Flow Meter Reference Manual

• Report No. ROS 06/03-34 R001; FMEDA report for Rosemount 8800D Vortex Flow

Meter Prepared for Emerson by exida.com LLC

1.4 Terms and definitions

BPCS

λ

DU

λ

DD

λ

SU

λ

SD

CPT

Diagnostic

Coverage

Diagnostic Test

Interval

Fail-safe state

Fail dangerous

FIT

Fail Dangerous

Detected

Basic Process Control System

Dangerous Undetected

Dangerous Detected

Safe Undetected

Safe Detected

Comprehensive Proof Test

[DC] Percentage of detectable faults

Time during which all internal diagnostics are carried out at least

once.

Failure that causes the device to go to the defined fail-safe state

without a demand from the process.

Failure that deviates the process signal or the actual output by

more than the safety deviation specification, drifts away from the

user defined threshold (Trip Point) and that leaves the output

within the active scale.

Failure In Time per billion hours

Failure that is dangerous but is detected.

Fail Dangerous

Undetected

Fail No Effect

Fail Safe

FMEDA

6 Rosemount™ 8800D Safety Manual

Failure that is dangerous and that is not detected.

Failure of a component that is part of the safety function but that

has no effect on the safety function.

Failure that causes the output to go to the defined fail-safe state

without an input from the process.

Failure Modes, Effects and Diagnostic Analysis

Safety Manual Before you begin

00809-0200-4004 August 2020

®

HART

Highway Addressable Remote Transducer

HFT

High demand

mode

Low demand mode

PFD

AVG

PFH

PPT

Random Integrity

Safety Demand

Interval

Systematic

Capability

Hardware Fault Tolerance as defined by 61508-2 7.4.4.1.1

The safety function is only performed on demand, in order to

transfer the EUC (Equipment Under Control) into a specified safe

state, and where the frequency of demands is greater than one per

year (IEC 61508-4).

The safety function is only performed on demand, in order to

transfer the EUC into a specified safe state, and where the

frequency of demands is no greater than one per year (IEC

61508-4).

Average Probability of Failure on Demand

Probability of dangerous failure per hour.

Partial Proof Test

The SIL limit imposed by the architectural constraints that must be

met for each element.

The expected time between safety demands.

A measure (expressed on a scale of SC 1 to SC 4) of the confidence

that the systematic safety integrity of an element meets the

requirements of the specified SIL, in respect of the specified

element safety function, when the element is applied in

accordance with the instructions specified in the compliant item

safety manual for the element as per 61508-4

SFF

SIF

SIL

SIS

Type B device

Safe Failure Fraction

Safety Instrumented Function

Safety Integrity Level - a discrete level (one out of four) for

specifying the safety integrity requirements of the safety

instrumented functions to be allocated to the safety instrumented

systems. SIL 4 has the highest level of safety integrity, and SIL 1 has

the lowest level.

Safety Instrumented System (SIS) - an instrumented system used

to implement one or more safety instrumented functions. An SIS is

composed of any combination of sensors, logic solvers, and final

elements.

Complex device using controllers or programmable logic, as

defined by the standard IEC 61508.

Safety Manual 7

Before you begin Safety Manual

August 2020 00809-0200-4004

1.5 Skill level requirement

System design, installation and commissioning, and repair and maintenance shall be

carried out by suitably qualified personnel.

1.6 Documentation and standards

This section lists the documentation and standards referred to by this safety manual.

Documents Purpose of documents

IEC 61508-2: 2010

IEC 61511 (ANSI/ISA 84.00.01-2004)

ROS 06/03-34 R001

00813-0100-4004

00809-0100-4004

00825-0100-4004

Functional Safety of Electrical/Electronic/

Programmable Electronic Safety-Related Systems

Functional safety - Safety instrumented systems for

the process industry sector

FMEDA Report Version V1, Revision R1, or later, for

the Rosemount 8800D Series Vortex Flowmeter

Rosemount™ 8800D Series Vortex Flow Meter

Product Data Sheet

Rosemount™ 8800D Series Vortex Flow Meter

Reference Manual

Rosemount™ 8800D Series Vortex Flow Meter Quick

Start Guide

8 Rosemount™ 8800D Safety Manual

Safety Manual Installation and commissioning

00809-0200-4004 August 2020

2 Installation and commissioning

Use this chapter to install and commission the Rosemount 8800D Series SIL 2/3 Capable

Vortex Flowmeter. The safety certified output of the Rosemount 8800D is the 4–20 mA

output. This output provides a signal proportional to process flow, between low flow

cutoff and the Upper Range Value (URV). Detected faults are indicated by an offscale

output (see Set failure mode). The safety logic solver should be configured to detect

offscale output levels. While the pulse output may be used, it is not a safety certified

output. Devices ordered without SI option may not be certified per IEC 61508.

2.1 Identification of SIS certified transmitter

IEC 61508 relevant requirements

The Rosemount 8800D is certified per the relevant requirements of IEC 61508.

Systematic capability

Random capability Low Demand:

Safety Integrity Level (SIL) 3 capable

• Type B element

• SIL 2 capable @ HFT≥0 (single transmitter)

• SIL 3 capable @ HFT≥1 (multiple single transmitters i.e. dual,

2 single or quad flow meter minimum)

High Demand:

• Type B element

• SIL 2 or 3 capable @ HFT≥1 (multiple single transmitters i.e.

dual, 2 single or quad flow meter minimum)

Failure rates per IEC 61508 in FIT

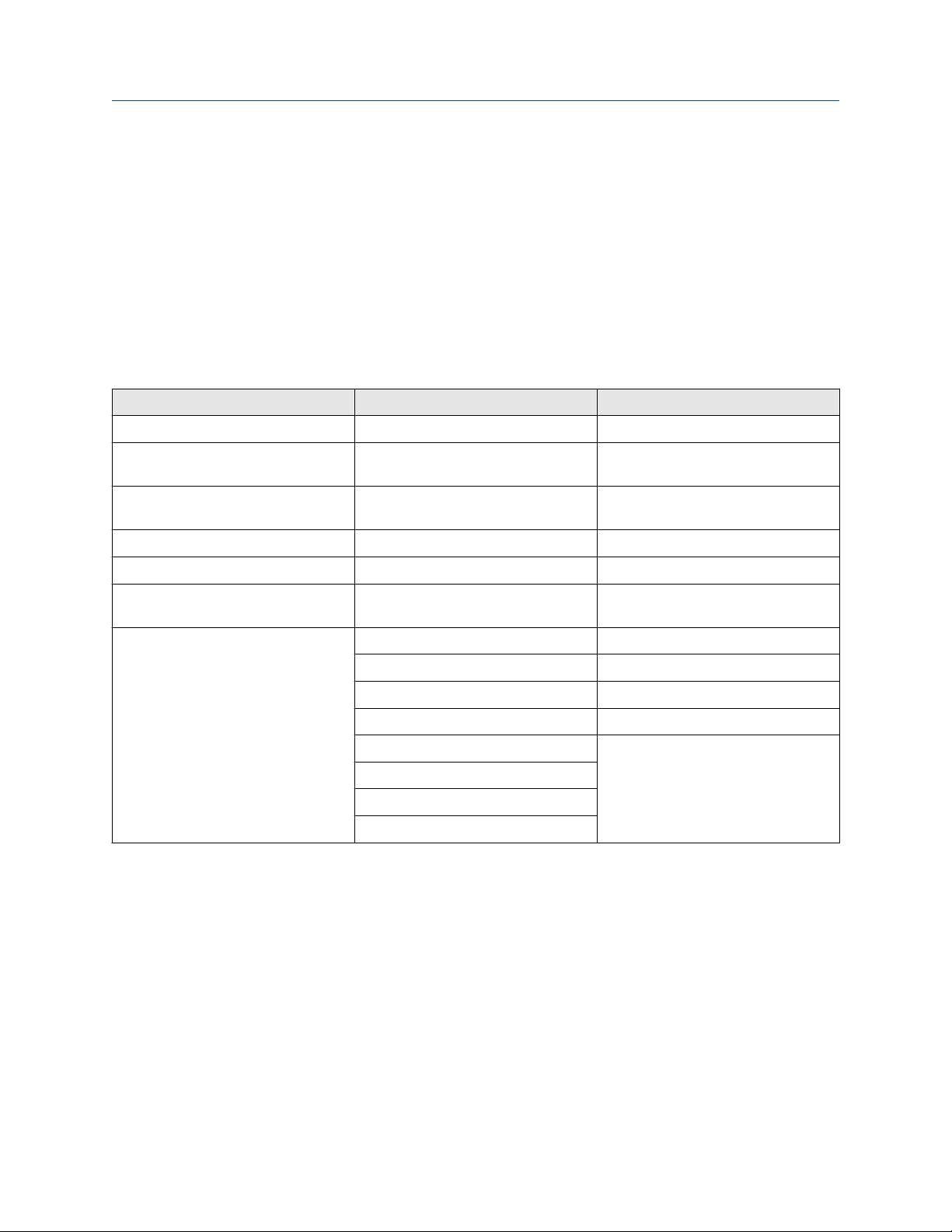

Table 2-1: Rosemount 8800D Series SIL 2/3 Capable Vortex Flowmeter

Failure categories λ

Low Flow Trip 0 76 387 74

High Flow Trip 0 32 387 119

SD

λ

SU

λ

DD

λ

DU

SIS-certified versions

All Rosemount 8800D Vortex Flowmeters must be identified as safety certified before

installing into SIS systems.

To identify a safety certified Rosemount 8800D Vortex with single or dual flow meter,

requirements 1 and 2, or requirements 2 and 3 must be satisfied. The requirements are:

8800 Single and Dual meters

1. Verify the option code "SI" in the model code. The SI code will appear somewhere

after the 16th character of the model code (after the required fields.) Note that the

Safety Manual 9

Installation and commissioning Safety Manual

August 2020 00809-0200-4004

optional options, including SI, can appear in any order and be valid. Please refer to A

of Figure 2-1.

• For example: 8800D................SI

2. Verify 4-20mA marking on the transmitter housing nameplate. Please refer to B of

Figure 2-1.

3. Confirm firmware revision is one of the revisions listed in Table 2-2.

Note

Software version information may be verified in the device from the Field Communicator:

Overview → Device Information → Revision Number.

Figure 2-1: Example of transmitter nameplate for Single or Dual meters

A. SI option code

B. 4–20mA Output

To identify a safety certified transmitters with in an 88800D Quad Vortex Flowmeter,

requirements 1 and 2, or requirements 2 and 3 must be satisfied. The requirements are:

8800 Quad meters

1. SI[X] option code to be present in respects to the transmitter in question. Please

refer to A of Figure 2-2 for location of transmitter number. Confirm model string

contains SI[X], where X is the transmitter number, option code for the indicated

transmitter. Please refer to B of Figure 2-2 for location of SI[X] option code(s). The

SI[X] code will appear somewhere after the 26th character of the model code (after

the required fields). Note that the optional options, including SI[X], can appear in

any order and be valid

• For example: 8800DQ................SI1SI2SI3

Note

In this example, Transmitter 4 may not be safety certified.

2. Verify 4–20mA marking on the transmitter housing nameplate. Please refer to C of

Figure 2-2.

3. Confirm firmware revision is one of the revisions listed in Table 2-2.

10 Rosemount™ 8800D Safety Manual

Safety Manual Installation and commissioning

00809-0200-4004 August 2020

Figure 2-2: Example of Quad transmitter nameplate

A. Transmitter number

B. SI option code

C. 4–20mA Output

Table 2-2: Rosemount 8800D SIS revisions and versions

Device Display tag Safety certified version combinations

8800D firmware Universal revision 5 5 7

Transmitter revision 2 3 2

Software revision 8 4 4

8800D hardware Hardware revision 1 2 2

Safety precautions

Prior to making any changes to the flowmeter,such as changing the configuration or

replacing the transmitter hardware or sensor:

• Take appropriate action to avoid a false trip by electronically bypassing the safety logic

solver.

• Prior to placing the meter online and removing the bypass from the safety logic solver,

verify the transmitter configuration and all safety parameters per Set up the flowmeter.

Important

Ensure alternate means are in place to maintain the process in a safe state.

2.2 Set up the flowmeter

1 2 3

Use the following procedure to make sure the flowmeter is installed and configured for SIS

applications.

You can use ProLinkIII software, AMS Device Manager,or the Field Communicator to verify,

or configure these settings. For more information, see the product reference manual.

The flowmeter does not require special installation other than the standard installation

procedures in the reference manual.

Safety Manual 11

Installation and commissioning Safety Manual

August 2020 00809-0200-4004

Note

Transmitter output is not safety-rated during the following: Configuration changes, loop

test mode, simulation mode, multidrop operation, temperature compensation of the

process fluid, SMART fluid diagnostics, saturated steam or mass flow with temperature

and/or pressure compensation. Alternative means should be used to ensure process safety

during configuration and maintenance activities.

1. Verify that the software revision running is one of the revisions listed in Table 2-2.

ProLink III Software Device Tools → Device Information → Software Revision

2. Verify all safety parameters.

a. Verify that all appropriate flow calibration parameters are set (Reference K-

Factor, Process Fluid, Fixed Process Temperature, Fixed Process Density).

b. Verify that the Lower Range Value (LRV) and the Upper Range Value (URV)

for the 4-20 mA output is configured

2.3 Enable transmitter write protection

Write-protection helps protect the transmitter against accidental changes to

configuration. When the transmitter is write-protected, no changes to the transmitter

configuration will be accepted.

Tip

Write protecting the transmitter prevents accidental changes to configuration. It does not

prevent normal operational use. You can always disable write protection, perform any

required configuration changes, then re-enable write protection.

The SECURITY jumper enables write protection.

• If the jumper is in the ON position, write protection is enabled.

• If the jumper is in the OFF position, write protection is disabled.

1. If you are in a hazardous area, power down the transmitter.

2. WARNING

Never remove the transmitter housing cover in a hazardous area when the

transmitter is powered up. Failure to follow these instructions may result in an

explosion.

Remove the transmitter housing cover (opposite of the terminal block).

3. Move the two-pin SECURITY jumper to the ON position.

The location of the security switch depends upon whether or not the transmitter

has the (M5) optional display.

12 Rosemount™ 8800D Safety Manual

Safety Manual Installation and commissioning

00809-0200-4004 August 2020

Figure 2-3: SECURITY jumper location without M5 optional display

Figure 2-4: SECURITY jumper location with M5 optional display

4. Replace the transmitter housing cover.

5. Power up the transmitter.

2.4 Set failure mode

As part of normal operations, the flowmeter continuously runs a self-diagnostic routine. If

the routine detects an internal failure, the failure mode setting determines whether the

flowmeter output is driven to a low or high alarm level.

The failure mode setting is controlled by the ALARM jumper, which is set at the factory per

the CDS (Configuration Data Sheet); the default setting is HI.

• If the ALARM jumper is in the HI position, the flowmeter output will be driven to a high

alarm level in the event of a failure.

• If the ALARM jumper is in the LOW position, the flowmeter output will be driven to a

low alarm level in the event of a failure.

Safety Manual 13

Installation and commissioning Safety Manual

August 2020 00809-0200-4004

Note

For exact alarm values, see the product reference manual.

1. If you are in a hazardous area, power down the transmitter.

2. WARNING

Never remove the transmitter housing cover in a hazardous area when the

transmitter is powered up. Failure to follow these instructions may result in an

explosion.

Remove the transmitter housing cover (opposite of the terminal block).

3. Move the two-pin ALARM jumper to the HI or LOW position, as desired.

The location of the ALARM jumper depends upon whether or not the transmitter

has the (M5) optional display.

Figure 2-5: ALARM jumper location without (M5) optional display

Figure 2-6: ALARM jumper location with (M5) optional display

4. Replace the transmitter housing cover.

5. Power up the transmitter.

14 Rosemount™ 8800D Safety Manual

Safety Manual Installation and commissioning

00809-0200-4004 August 2020

2.5 Flow simulation diagnostic

Performing an internal flow simulation ensures the current calibration state of the

transmitter by carrying out a verification of the electronics board stack to indicate the

health of the various components on the board stack. Failure may indicate a need to

replace the electronics. Every transmitter comes with internal flow simulation capabilities.

Note

For the Flow Simulation Function to operate, Primary Variable must be set to Velocity

Flow, Volume Flow, or Mass Flow and the write protection must be disabled (see Enable

transmitter write protection).

1. Ensure that the write protection is disabled (see Enable transmitter write

protection).

2. Read the calculated Shedding Frequency at URV.

ProLink III Software

3. Navigate to Flow Simulation.

ProLink III Software

4. Select Internal Flow Simulation, Fixed Flow, Percent of Range and enter 50%

flow.

5. Verify that flow rate output is 50% of full scale and Frequency is 1/2 of calculated

Frequency at URV.

a. If the flow rate output is 50% of full scale, the electronics are working

properly.

b. If the flow rate output is not 50% of full scale, see the troubleshooting

information in the product reference manual.

Note

(Optional): Verify shedding frequency from internal signal generator is the same as

displayed on handheld communicator, Prolink III, or AMS Device Manager. This can

be accomplished by connecting a device such as a Fluke multi-meter with frequency

measurement capability to the test points behind the display labeled "TP1" and

Ground (using the universal ground symbol). Connect the positive lead of the

digital multi-meter to TP1 and the negative lead to the Ground lug. The frequencies

should match to a plant specified tolerance that is no less than the tolerance of the

device used to read the frequency.

• If the shedding frequency is 50% of full scale, the electronics are working

properly.

Device Tools → Configuration → Process Measurement →

Signal Processing

Device Tools → Diagnostics → Testing → Flow Simulation

• If the shedding frequency is not 50% of full scale, see the troubleshooting

information in the product reference manual.

6. Exit simulation by selecting Normal Flow Measurement or Exit.

7. Enable write protection (see Enable transmitter write protection).

Safety Manual 15

Installation and commissioning Safety Manual

August 2020 00809-0200-4004

2.6 Replace equipment

If you need to replace hardware, purchase all spare parts from Emerson. You cannot use

user-supplied components on any Rosemount printed circuit assemblies.

1. Replace the hardware by contacting your local Emerson or Emerson affiliated sales

representative to obtain the correct part number.

Use the product reference manual or quick start guide for proper maintenance

guidelines.

2. Verify the transmitter configuration and all safety parameters (see Set up the

flowmeter).

3. Enable write protection (see Enable transmitter write protection).

4. Set the failure mode (see Set failure mode.)

16 Rosemount™ 8800D Safety Manual

Safety Manual

00809-0200-4004 August 2020

Proof tests

3 Proof tests

3.1 Proof test requirement

During operation, an SIF must be proof tested. The objective of proof testing is to detect

failures within the equipment in the SIF that are not detected by any automatic

diagnostics of the system. Undetected failures that prevent the SIF from performing its

function are the main concern.

Periodic proof tests shall take place at the frequency (or interval) defined by the SIL

verification calculation. The proof-tests must be performed more frequently than or as

frequently as specified in the SIL verification calculation in order to maintain the required

safety integrity of the overall SIF.

Results from periodic proof tests shall be recorded and periodically reviewed.

3.2 Repair and replacement

Repair procedures in the product reference manual must be followed.

3.3 Notification of failures

In case of malfunction of the system or SIF, the Rosemount 8800D Series SIL 2/3 Capable

Vortex Flowmeter shall be put out of operation and the process shall be kept in a safe state

by other measures.

Emerson must be informed when the Rosemount 8800D Series SIL 2/3 Capable Vortex

Flowmeter is required to be replaced due to failure. The occurred failure shall be

documented and reported to Emerson using the contact details on the back page of this

functional safety manual. This is an important part of Emerson SIS management process.

3.4 Proof test interval

The time intervals for proof testing are defined by the SIL verification calculation (subject

to the PFDAVG). The proof tests must be performed more frequently than or as frequently

as specified in the SIL verification calculation in order to maintain the required safety

integrity of the overall SIF.

Results from periodic proof tests shall be recorded and periodically reviewed. For the

specification of customer requirements required to fulfil this SIS requirement, please see

IEC-61511.

3.5 Tools required

• HART host or Field Communicator

• mA meter

Safety Manual 17

Proof tests

Safety Manual

August 2020 00809-0200-4004

3.6 Proof test options

The flowmeter has two proof tests you can use to detect failures. Proof tests can be

performed using ProLink III software or the Field Communicator.

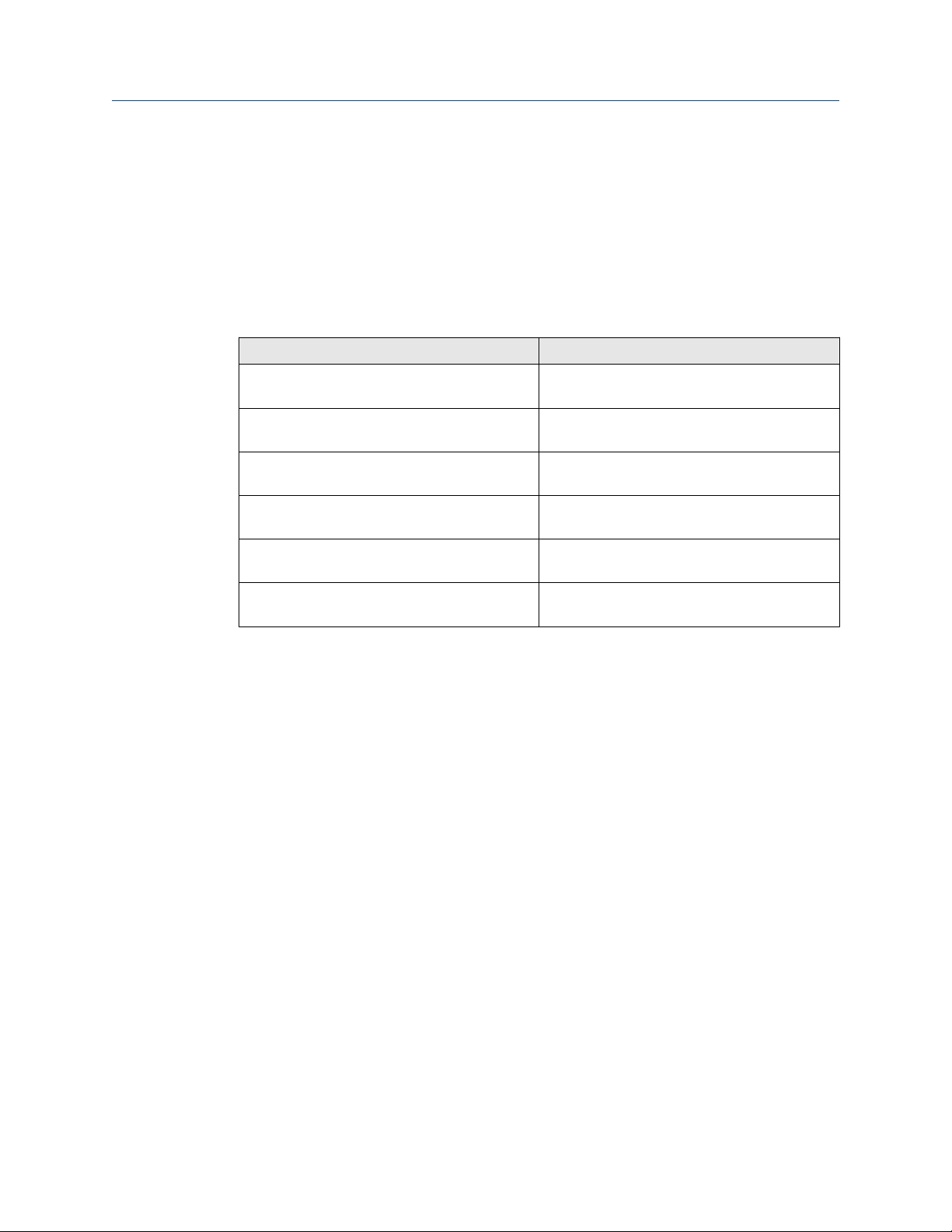

Table 3-1: Proof test options

Device Proof test Description DU failure

detection

8800D Partial • Low/High alarm checks

• Visual inspection of flow meter

• Single point reasonability check or internal

• Checking for alarms

• Checking configuration

Comprehensive• Low/High alarm checks

• Visual inspection of flow meter

• 3 to 5-point calibration check using reference

• Checking for alarms

• Checking configuration

3.7 Partial proof test

The partial proof test is recommended for all Rosemount 8800D Series SIL 2/3 Capable

Vortex Flowmeters.

This procedure assumes that you are familiar with plant procedures. For details on how to

do any of the following steps, see the product reference manual.

High flow trip:

85%

Low flow trip:

77%

flow simulation at 2 points

High flow trip:

94%

Low flow trip:

92%

standard

1. Take appropriate action to avoid a false trip by electronically bypassing the safety

Programmable Logic Controller (PLC).

2. Inspect flowmeter for any leaks, visible damage or contamination.

3. Verify that the transmitter does not indicate alarms or warnings using HART host or

LCD.

4. Cycle power and use HART communications to retrieve any diagnostics and take

appropriate action.

5. Disable write protection (see Enable transmitter write protection).

6. Using the Loop Test function, send a HART command to the transmitter to go to the

high alarm current output and verify that the analog current reaches that value.

• Loop Test can be found at Service Tools → Simulate → Analog Output → Loop

Test.

• High alarm and low alarm levels can be found in the product reference manual.

18 Rosemount™ 8800D Safety Manual

Safety Manual

00809-0200-4004 August 2020

This step tests for compliance voltage problems, such as low voltage on the loop

power supply, or increased wiring resistance.

7. Send a HART command to the transmitter to go to the low alarm current output

and verify that the analog current reaches that value.

This step tests for possible failures related to quiescent current.

8. Exit fixed current mode.

9. Compare the process flow with the Low Flow Cutoff, and do one of the following:

Option Description

Proof tests

Process flow greater than

Low Flow Cutoff

Process flow less than Low

Flow Cutoff

10. Verify all safety-critical configuration parameters (see Set up the flowmeter).

11. Enable write-protection (see Enable transmitter write protection).

12. Remove the bypass and otherwise restore normal operation.

13. Document the results of this proof test as part of your plant safety management

procedures.

Confirm measured flow compares reasonably to an

independent measurement.

Check output at 2 points using internal flow

simulation, with at least one point between LFC and

URV.

3.8 Comprehensive proof test

The comprehensive proof test is recommended for all Rosemount 8800D Series SIL 2/3

Capable Vortex Flowmeters.

This procedure assumes that you are familiar with plant procedures. For details on how to

do any of the following steps, see the product reference manual.

1. Take appropriate action to avoid a false trip by electronically bypassing the safety

Programmable Logic Controller (PLC).

2. Inspect flow meter for any leaks, visible damage or contamination.

3. Verify that the transmitter does not indicate alarms or warnings using HART host or

LCD.

4. Cycle power and use HART communications to retrieve any diagnostics and take

appropriate action.

5. Disable write protection (see Enable transmitter write protection).

6. Using the Loop Test function, send a HART command to the transmitter to go to the

high alarm current output and verify that the analog current reaches that value.

• Loop Test can be found at Service Tools → Simulate → Analog Output → Loop

Test.

• High alarm and low alarm levels can be found in the product reference manual.

Safety Manual 19

Proof tests Safety Manual

August 2020 00809-0200-4004

This step tests for compliance voltage problems, such as low voltage on the loop

power supply, or increased wiring resistance.

7. Send a HART command to the transmitter to go to the low alarm current output

and verify that the analog current reaches that value.

This step tests for possible failures related to quiescent current.

8. Exit fixed current mode.

9. Perform a 3 to 5-point calibration check of the transmitter and flowmeter against a

reference standard.

10. Verify all safety-critical configuration parameters (see Set up the flowmeter).

11. Enable write-protection (see Enable transmitter write protection).

12. Remove the bypass and otherwise restore normal operation.

13. Document the results of this proof test as part of your plant safety management

procedures.

3.9 SIS example

The following figures illustrate the indicative benefits of using a combination of

comprehensive and partial proof tests to manage the level of risk associated with a

particular SIS Installation. Figure 3-1 shows a typical 1oo1 safety system configuration.

Figure 3-2 through Figure 3-5 illustrate the benefit of implementing a combination of

comprehensive and partial proof tests on the system's PFD.

Note

It is assumed that the sensor typically contributes ∼30% to the systems SIL 2 PFD budget,

with the logic solver and actuator the remaining ∼70%.

20 Rosemount™ 8800D Safety Manual

Safety Manual

Proof tests

00809-0200-4004 August 2020

Figure 3-1: Single use 1oo1 (1 out of 1) for SIL 2 low demand (SIL 2@HFT=0)

A. Sensor (Rosemount 8800D)

B. Logic solver

C. Actuator

Figure 3-2: PFD and PFD average of system when no proof testing applied

C

D

A

0 2 4 6 8 10

B

A. PFD (Probability of failure on demand)

B. Mission time (years)

C. PFD

(average probability of failure on demand)

AVG

D. Predicted PFD

Safety Manual 21

Proof tests

Safety Manual

August 2020 00809-0200-4004

Figure 3-3: Unit subjected to either no proof test or a comprehensive proof test every

5 years

D

C

E

A

0 2 4 6 8 10

B

E

E

A. PFD (Probability of failure on demand)

B. Mission time (years)

C. PFD

(average probability of failure on demand)

AVG

D. Predicted PFD

E. Predicted PFD + CPT (comprehensive proof test)

Figure 3-4: Unit subjected to a partial proof test every year and a comprehensive

proof test every 3 years

D

C

D

A

0 2 4 6 8 10

B

A. PFD (Probability of failure on demand)

B. Mission time (years)

C. PFD

(average probability of failure on demand)

AVG

D. Predicted PFD + PPT (partial proof test) + CPT (comprehensive proof test)

22 Rosemount™ 8800D Safety Manual

Safety Manual Proof tests

00809-0200-4004 August 2020

Figure 3-5: Unit subjected to a partial proof-test every year and a comprehensive

proof test every 5 years

D

C

D

A

0 2 4 6 8 10

B

A. PFD (Probability of failure on demand)

B. Mission time (years)

C. PFD

(average probability of failure on demand)

AVG

D. Predicted PFD + PPT (partial proof test) + CPT (comprehensive proof test)

Safety Manual 23

Proof tests Safety Manual

August 2020 00809-0200-4004

24 Rosemount™ 8800D Safety Manual

Safety Manual Operating Constraints

00809-0200-4004 August 2020

4 Operating Constraints

4.1 Reverse flow

Use appropriate means to ensure only zero or forward flow through the meter, as

indicated by the arrow on the meter body. Reverse flow operation may result in erroneous

non-zero flow indication.

4.2 Reliability data

The Rosemount 8800D Series SIL 2/3 Capable Vortex Flowmeter:

• Has a specified safety deviation of 2%. Internal component failures are listed in the

device failure rate if they will cause an on-scale error of 2% or greater.

• Reports an internal failure within 30 minutes of fault occurrence – worst case scenario.

• Generates a valid signal within 6 seconds plus configured damping response of a

power-on startup.

FMEDA report

The Failure Mode, Effects, and Diagnostics Analysis (FMEDA) report is used to calculate the

failure rate. A FMEDA report for a Vortex Flow Meter with a Rosemount 8800D transmitter

contains:

• All failure rates and failure modes

• Common cause factors for applications with redundant devices that should be included

in reliability calculations

• The expected lifetime of your flowmeter and transmitter, as the reliability calculations

are valid only for the lifetime of the equipment

Obtain a FMEDA report at www.emerson.com/vortex.

Environmental and application limits

See the product data sheet for environmental and application limits.

Using the flowmeter or transmitter outside environmental or application limits invalidates

the reliability data in the FMEDA report.

4.3 Report failures

If you have detected any failures that compromise safety, contact the Flow Solutions

Group Product Safety Officer.

Contact the Product Safety Officer through the Flow Solutions Group customer service.

Customer service is available 24 hours a day, seven days a week. Contact information is

located at the front of this manual.

Safety Manual 25

*00809-0200-4004*

00809-0200-4004

Rev. AC

2020

Emerson Automation Solutions USA

7070 Winchester Circle

Boulder, Colorado USA 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.emerson.com

Emerson Automation Solutions Asia

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6363-7766

F +65 6770-8003

©

2020 Rosemount, Inc. All rights reserved.

The Emerson and Rosemount logos are trademarks and service marks of Emerson Electric Co. All

other marks are property of their respective owners.

Emerson Automation Solutions Europe

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.micromotion.nl

Emerson Automation Solutions United

Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Loading...

Loading...