Page 1

Quick Start Guide

00825-0100-8782, Rev AA

November 2019

Rosemount™ 8782 Slurry Magnetic Flow

Meter Transmitter

Page 2

Quick Start Guide November 2019

1 Safety

WARNING

• Failure to follow these installation guidelines could result in serious injury

or death.

• Installation and servicing instructions are for use by qualified personnel

only. Do not perform any servicing other than that contained in the

operating instructions, unless qualified.

• Potential electrostatic charging hazard: Rosemount Magnetic flow

meters ordered with non-standard paint options or non-metallic labels

may be subject to electrostatic discharge. To avoid electrostatic charge

build-up, do not rub the flow meter with a dry cloth or clean with

solvents.

• Verify that the operating environment of the sensor and transmitter is

consistent with the appropriate Agency Approval.

• If installed in an explosive atmosphere, verify that the device certification

and installation techniques are suitable for that particular environment.

• To prevent ignition of flammable or combustible atmosphere,

disconnect power before servicing circuits.

• Explosion hazard: Do not disconnect equipment when a flammable or

combustible atmosphere is present.

• Follow national, local, and plant standards to properly earth ground the

transmitter and sensor. The earth ground must be separate from the

process reference ground.

• Shock hazard: Shut off power before servicing. Do not operate without

power compartment cover.

CAUTION

• In cases where high voltage/high current are present near the meter

installation, ensure proper protection methods are followed to prevent

stray voltage/current from passing through the meter. Failure to

adequately protect the meter could result in damage to the transmitter

and lead to meter failure.

• Completely remove all electrical connections from both sensor and

transmitter prior to welding on the pipe. For maximum protection of the

sensor, consider removing it from the pipeline.

2 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 3

November 2019 Quick Start Guide

2 Introduction

This document provides basic installation guidelines for the Rosemount

8782 Magnetic Slurry wall-mount transmitter.

• For sensor installation refer to the Rosemount™ MS Magnetic Slurry Flow

Meter Sensor Quick Installation Guide

• For additional installation information, configuration, maintenance, and

troubleshooting, refer to the Rosemount™ 8782 Magnetic Slurry Flow

Meter with HART Protocol Reference Manual

All user documentation can be found at www.emerson.com. For more

contact information see Emerson Flow customer service.

2.1 Return policy

Emerson procedures must be followed when returning equipment. These

procedures ensure legal compliance with government transportation

agencies and help provide a safe working environment for Emerson

employees. Failure to follow Emerson procedures will result in your

equipment being refused delivery.

Quick Start Guide 3

Page 4

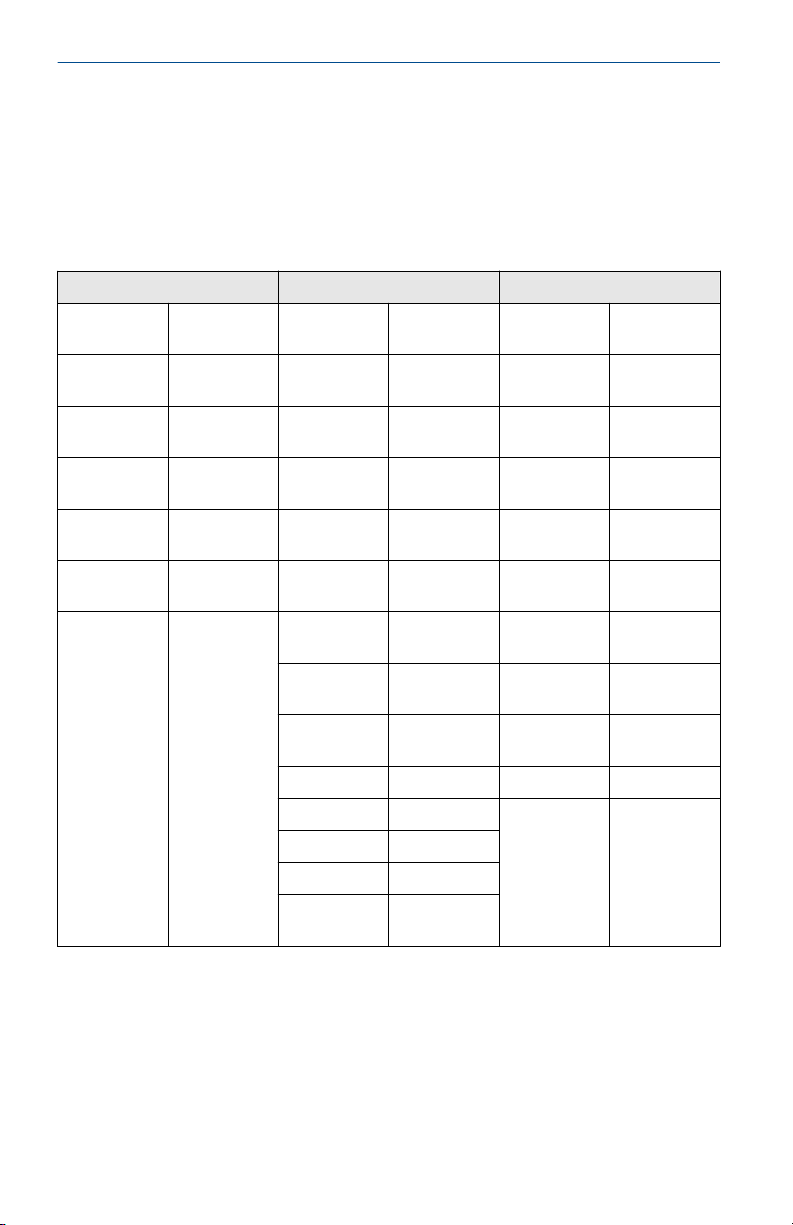

Quick Start Guide November 2019

2.2 Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800 522 6277 U.K. 0870 240

Canada +1 303 527

5200

Mexico +41 (0) 41

7686 111

Argentina +54 11 4837

7000

Brazil +55 15 3413

8000

Venezuela +58 26 1731

3446

The

Netherlands

France 0800 917 901 India 800 440 1468

Germany 0800 182

Italy 8008 77334 China +86 21 2892

Central &

Eastern

Russia/CIS +7 495 995

Egypt 0800 000

Oman 800 70101 Thailand 001 800 441

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444

1978

+31 (0) 704

136 666

5347

+41 (0) 41

7686 111

9559

0015

0684

Australia 800 158 727

New Zealand 099 128 804

Pakistan 888 550 2682

9000

Japan +81 3 5769

6803

South Korea +82 2 3438

4600

Singapore +65 6 777

8211

6426

4 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 5

November 2019 Quick Start Guide

3 Pre-installation

Before installing the transmitter, there are several pre-installation steps that

should be completed to make the installation process easier:

• Identify options and configurations that apply to your application

• Set the hardware switches if necessary

• Consider mechanical, electrical, and environmental requirements

Note

Refer to the product reference manual for more detailed requirements.

Identify options and configurations

The typical transmitter installation includes a device power connection, a

4-20mA output connection, and sensor coil and electrode connections.

Other applications may require one or more of the following configurations

or options:

• Pulse output

• Discrete input/discrete output

• HART multidrop configuration

The transmitter may have up to four user-selectable hardware switches.

These switches set the alarm mode, internal/external analog power,

internal/external pulse power, and transmitter security. The standard

configuration for these switches when shipped from the factory is as follows:

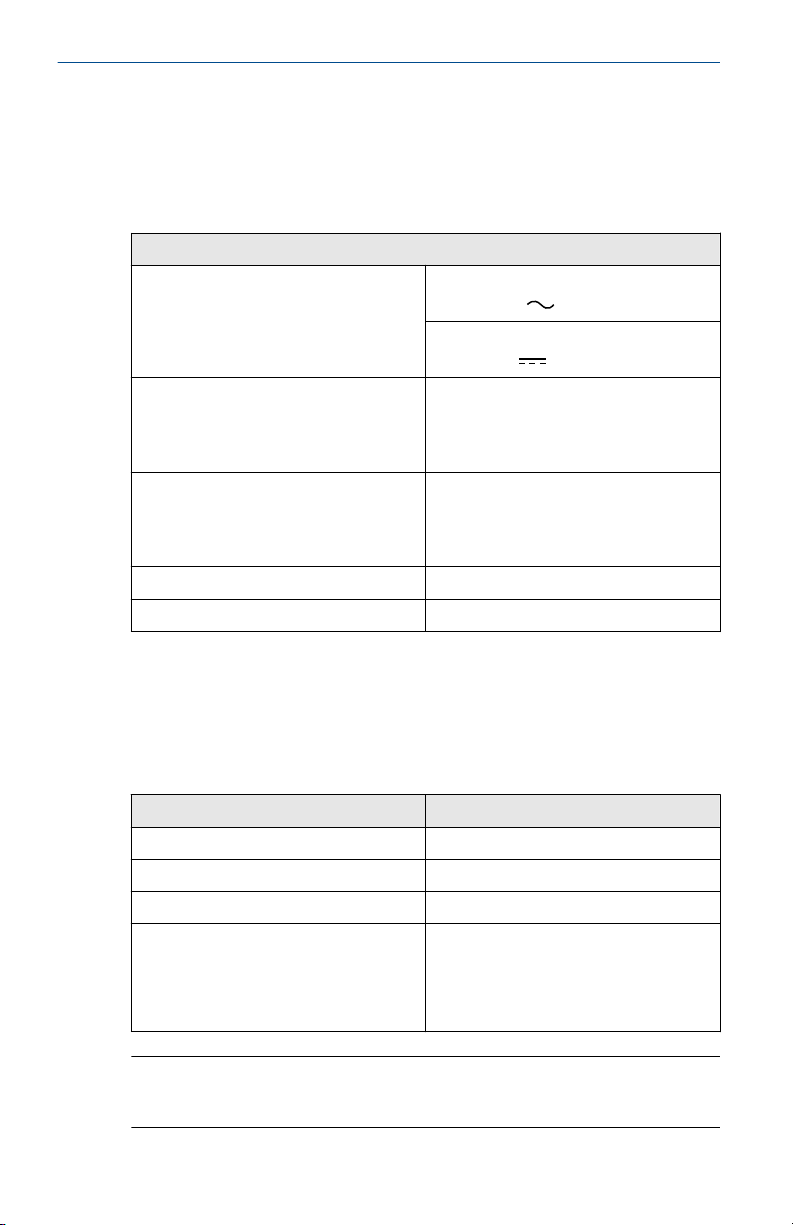

Table 3-1: Hardware switch default settings

Setting Factory configuration

Alarm mode High

Internal/external analog power Internal

Internal/external pulse power External

Transmitter security Off

The analog power switch and pulse power switches are not available when

ordered with intrinsically safe output, ordering code B.

In most cases, it is not necessary to change the setting of the hardware

switches. If the switch settings need to be changed, refer to the product

reference manual.

Be sure to identify any additional options and configurations that apply to

the installation. Keep a list of these options for consideration during the

installation and configuration procedures.

Quick Start Guide 5

Page 6

Quick Start Guide November 2019

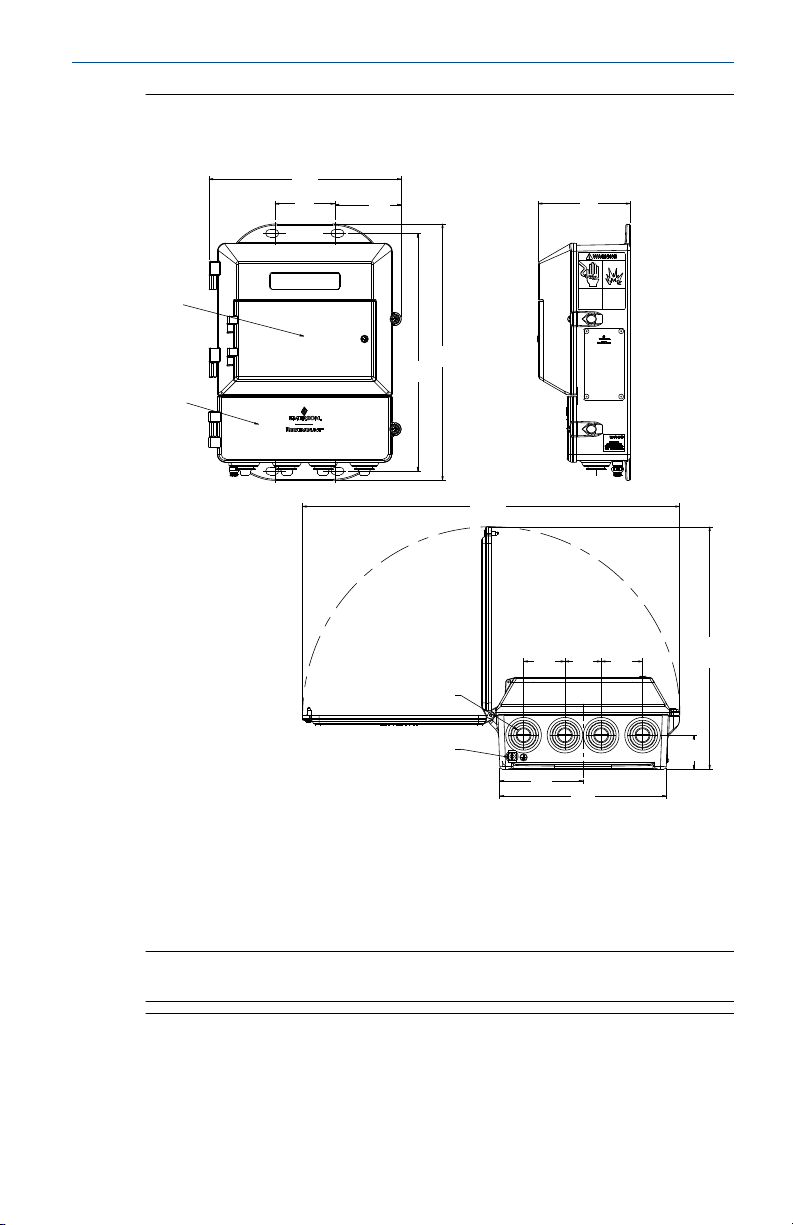

Mechanical considerations

The mounting site for the transmitter should provide enough room for

secure mounting, easy access to conduit entries, full opening of the

transmitter covers, and easy readability of the Local Operator Interface (LOI)

screen (if equipped).

6 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 7

November 2019 Quick Start Guide

Figure 3-1: Rosemount 8782 Dimensional Drawing

9.0

(229)

(71)

2.8

(79)

3.1

C

12.0

(306)

11.2

(283)

D

17.7

(449)

(89)

3.5

11.4

(49)

1.9

1.7

1.9

(43)

(49)

(289)

A

B

3.9

(99)

7.8

(198)

(40)

1.6

A. Conduit entry, ½–14 NPT (4 places)

B. Ground lug

C. LOI keypad cover

D. Lower cover opens for electrical connections

Note

Dimensions are in inches (Millimeters)

Electrical considerations

Before making any electrical connections to the transmitter, consider

national, local, and plant electrical installation requirements. Be sure to have

Quick Start Guide 7

Page 8

Quick Start Guide November 2019

the proper power supply, conduit, and other accessories necessary to

comply with these standards.

The transmitter requires external power. Ensure access to a suitable power

source.

Table 3-2: Electrical Data

Electrical data

Power input AC power:

90–250 VAC ( ), 1.5A, 120 VA

Standard DC power:

12–42 VDC ( ), 8.6 A, 120 W

Pulsed circuit Internally powered (Active): Outputs up

4-20mA output circuit Internally Powered (Active): Outputs up

Um 250 V

Coil excitation output 2.0 A, 85 V max, 80 W max

to 12 VDC, 12.1 mA, 73 mW

Externally powered (Passive): Input up to

28 VDC, 100 mA, 1 W

to 25 mA, 24 VDC, 600 mW

Externally Powered (Passive): Input up to

25 mA, 30 VDC, 750 mW

Environmental considerations

Remote mounted transmitters may be installed in the control room to

protect the electronics from the harsh environment and to provide easy

access for configuration or service.

Table 3-3: Transmitter housing environmental ratings

Type Rating

Ingress protection IP66, IP69

NEMA 4X

Pollution Degree 2

Maximum altitude rating • 13,123 ft (4000 m) at rated input

power voltage (90–250 VAC)

• 16,404 ft (5000 m) at maximum

input power voltage of 150 VAC

Note

For complete environmental and other specifications, refer to the product

reference manual.

8 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 9

November 2019 Quick Start Guide

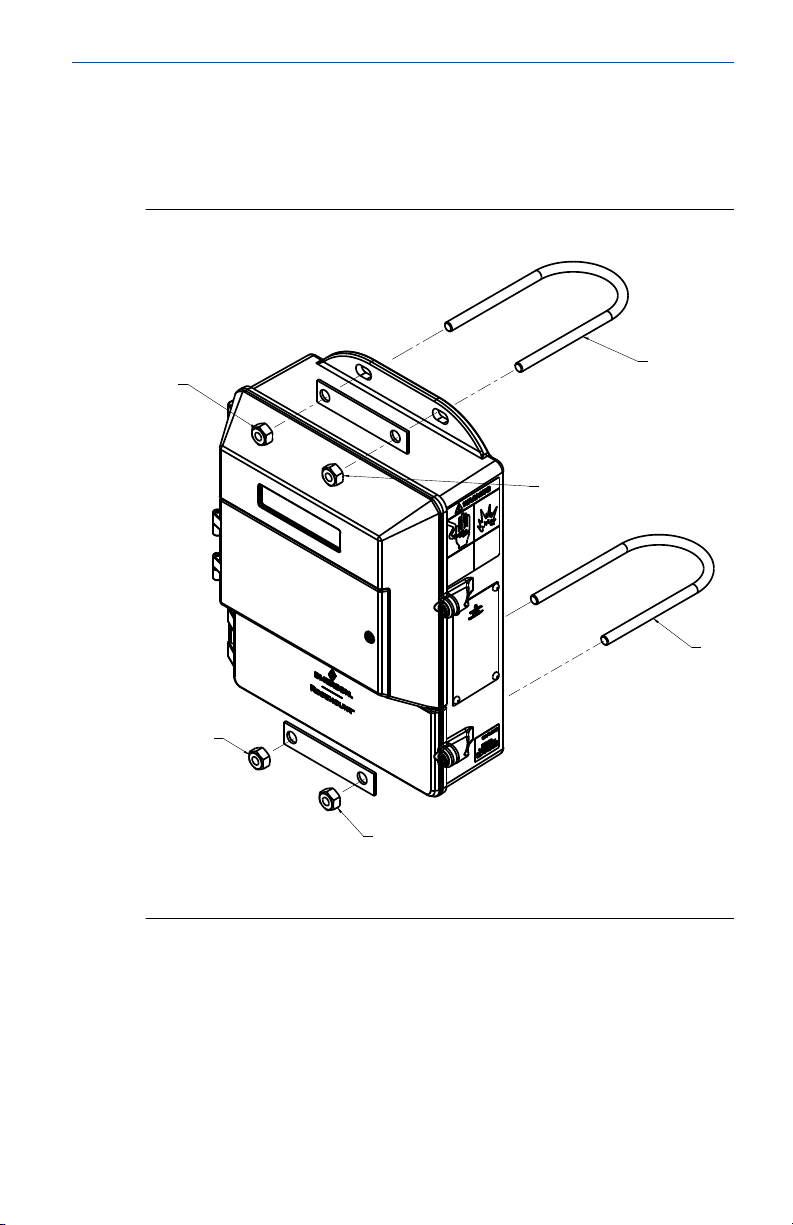

4 Mounting

Wall mount transmitters are shipped with mounting hardware for use on a

2 inch (50 mm) pipe or flat surface.

Figure 4-1: Mounting bracket

A

B

B

A

B

B

A. U-bolt

B. Fasteners

4.1

Quick Start Guide 9

Pipe mounting

1. Assemble the hardware and transmitter housing on the pole as

shown in Figure 4-1.

2. Tighten the nuts to ensure a snug fit.

Page 10

Quick Start Guide November 2019

4.2 Surface mounting

Attach the transmitter to the mounting location using customer supplied

mounting screws. The installation of the transmitter shall be rated for four

(4) times the weight of the transmitter or 44lbs (20kgs).

10 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 11

November 2019 Quick Start Guide

5 Wiring

5.1 Conduit entries and connections

Transmitter conduit entries ports are ½"-14NPT as standard, M20 conduit

connections will use an adapter. Conduit connections should be made in

accordance with national, local, and plant electrical codes. Unused conduit

entries should be sealed with the appropriate certified plugs. The plastic

shipping plugs do not provide ingress protection.

5.2 Conduit requirements

• For installations with an intrinsically safe electrode circuit, a separate

conduit for the coil cable and the electrode cable may be required.

• For installations with non-intrinsically safe electrode circuit, a single

dedicated conduit run for the coil drive and electrode cable between the

sensor and the remote transmitter may be acceptable. Removal of the

barriers for intrinsic safety isolation is permitted for non-intrinsically safe

electrode installations.

• Bundled cables from other equipment in a single conduit are likely to

create interference and noise in the system. See Figure 5-1.

• Electrode cables should not be run together in the same cable tray with

power cables.

• Output cables should not be run together with power cables.

• Select conduit size appropriate to feed cables through to the flowmeter.

Quick Start Guide 11

Page 12

Quick Start Guide November 2019

Figure 5-1: Best practice conduit preparation

5.3

A

B

A. Safety ground

B. Power

C. Coil

D. Output

E. Electrode

C D E

A

A

Sensor to transmitter wiring

Remote cable kits can be ordered directly using the kit numbers shown in

Table 5-1 and Table 5-2. Equivalent Alpha cable part numbers are also

provided as an alternative. To order cable, specify length as quantity desired.

Equal length of component cables is required.

Examples:

• 25 feet = Qty (25) 08732-0065-0001

• 25 meters = Qty (25) 08732-0065-0002

12 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 13

November 2019 Quick Start Guide

Table 5-1: Component cable kits - standard temperature (-20°C to 75°C)

Cable kit # Description Individual

08732-0065-0001 (feet) Kit, component cables, Std

temp (includes Coil and

Electrode)

08732-0065-0002 (meters) Kit, component cables, Std

temp (includes Coil and

Electrode)

08732-0065-0003 (feet) Kit, component cables, Std

temp (includes Coil and I.S.

Electrode)

08732-0065-0004 (meters) Kit, component cables, Std

temp (includes Coil and I.S.

Electrode)

cable

Coil

Electrode

Coil

Electrode

Coil

Instrinsically

Safe Blue

Electrode

Coil

Instrinsically

Safe Blue

Electrode

Alpha p/n

2442C

2413C

2442C

2413C

2442C

Not available

2442C

Not available

Table 5-2: Component cable kits - extended temperature (-50°C to 125°C)

Cable kit # Description Individual

08732-0065-1001 (feet) Kit, Component Cables, Ext

Temp. (includes Coil and

Electrode)

08732-0065-1002 (meters) Kit, Component Cables, Ext

Temp. (includes Coil and

Electrode)

08732-0065-1003 (feet) Kit, Component Cables, Ext

Temp. (includes Coil and I.S.

Electrode)

08732-0065-1004 (meters) Kit, Component Cables, Ext

Temp. (includes Coil and I.S.

Electrode)

cable

Coil

Electrode

Coil

Electrode

Coil

Intrinsically

Safe Blue

Electrode

Coil

Intrinsically

Safe Blue

Electrode

Alpha p/n

Not available

Not available

Not available

Not available

Not available

Not available

Not available

Not available

Cable requirements

Shielded twisted pairs or triads must be used. See Figure 5-2. Cable lengths

should be limited to less than 300 feet (100 m).

Quick Start Guide 13

Page 14

Quick Start Guide November 2019

Figure 5-2: Individual component cables

A B

1 2

C

3

D

E

F

A. Coil drive

B. Electrode

C. Twisted, stranded, insulated 14 AWG conductors

D. Drain

E. Overlapping foil shield

F. Outer jacket

G. Twisted, stranded, insulated 20 AWG conductors

• 1 = Red

• 2 = Blue

• 3 = Drain

• 17 = Black

• 18 = Yellow

• 19 = White

3

17 18 19

G

Cable preparation

Prepare the ends of the coil drive and electrode cables as shown in Figure

5-3. Remove only enough insulation so that the exposed conductor fits

completely under the terminal connection. Best practice is to limit the

unshielded length (D) of each conductor to less than one inch. Excessive

removal of insulation may result in an unwanted electrical short to the

transmitter housing or other terminal connections. Excessive unshielded

14 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 15

B

C

A

November 2019 Quick Start Guide

length, or failure to connect cable shields properly, may also expose the unit

to electrical noise, resulting in an unstable meter reading.

Figure 5-3: Cable ends

A. Unshielded length

B. Coil

C. Electrode

WARNING

Shock hazard! Potential shock hazard across remote junction box terminals 1

and 2 (85V).

WARNING

Explosion hazard! Electrodes exposed to process. Use only compatible

transmitter and approved installation practices. For process temperatures

greater than 284°F (140°C), use a wire rated for 257°F (125°C).

Quick Start Guide 15

Page 16

Quick Start Guide November 2019

Remote junction box terminal blocks

Figure 5-4: Remote junction box views

B

A

A. Sensor

B. Transmitter

Note

Junction box appearance and configuration may vary, but terminal

numbering is consistent for all junction box types.

Table 5-3: Sensor/transmitter wiring

Wire color Sensor terminal Transmitter terminal

Red 1 1

Blue 2 2

Coil drain 3 or float 3

Black 17 17

Yellow 18 18

White 19 19

Electrode drain

16 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

or float

Page 17

November 2019 Quick Start Guide

5.4 Wiring sensor to transmitter

Figure 5-5: Wiring using component cable

Quick Start Guide 17

Page 18

Quick Start Guide November 2019

5.5 Power and I/O terminal blocks

Open the bottom cover of the transmitter to access the terminal block.

Note

To connect pulse output and/or discrete input/output, and for installations

with intrinsically safe outputs, refer to the product reference manual.

Figure 5-6: Terminal blocks

N 1 2 9 10 5 6 19 18

L1 3 11 12 7 8 17

Table 5-4: Power and I/O terminals

Terminal number AC version DC version

1 Coil Positive Coil Positive

2 Coil Negative Coil Negative

3 Coil Shield Coil Shield

5 + Pulse + Pulse

6 – Pulse – Pulse

(1)

7

(1)

8

(2)

9

(2)

10

(2)

11

(2)

12

17 Electrode Reference Electrode Reference

18 Electrode Negative Electrode Negative

19 Electrode Positive Electrode Positive

N AC (Neutral) DC (–)

Analog HART Analog HART

Analog HART Analog HART

+ Discrete In/Out 2 + Discrete In/Out 2

– Discrete In/Out 2 – Discrete In/Out 2

+ Discrete In/Out 1 + Discrete In/Out 1

– Discrete In/Out 1 – Discrete In/Out 1

18 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 19

November 2019 Quick Start Guide

Table 5-4: Power and I/O terminals (continued)

Terminal number AC version DC version

L1 AC L1 DC (+)

(1) Note Polarity: Internally Powered, Terminal 7 (–) Analog HART, Terminal 8 (+)

Analog HART. Externally Powered, Terminal 7 (+) Analog HART, Terminal 8 (–)

Analog HART

(2) Only available with ordering code AX.

Quick Start Guide 19

Page 20

Quick Start Guide November 2019

5.6 Powering the transmitter

Before connecting power to the transmitter, be sure to have the necessary

electrical supplies and required power source:

Wire the transmitter according to national, local, and plant electrical

requirements.

If installing in a hazardous location, verify that the meter has the appropriate

hazardous area approval. The hazardous area ratings are located on the main

nameplate tag attached to the side of the transmitter.

Supply wire requirements

Use 10–18 AWG wire rated for the proper temperature of the application.

For wire 10–14 AWG use lugs or other appropriate connectors. For

connections in ambient temperatures above 122 °F (50 °C), use a wire rated

for 194 °F (90 °C). For DC powered transmitters with extended cable lengths,

verify that there is a minimum of 12VDC at the terminals of the transmitter

with the device under load.

Electrical disconnect requirements

Connect the device through an external disconnect or circuit breaker per

national and local electrical code.

Overcurrent protection

The transmitter requires overcurrent protection of the supply lines. Fuse

rating and compatible fuses are shown in Line power fuses.

Installation category

The installation category for the transmitter is OVERVOLTAGE CAT II.

AC power system installation requirements

Neutral-earth power requirements

• The power system must have a neutral that is locally bonded to earth, or

provide both line to earth and neutral to earth voltage limitation of no

more than 250 VAC.

Power line impedance

• Sources of inductance on the AC power system, such as isolation

transformers, must be limited to less than 1 mH at 120 VAC, and 2 mH at

240 VAC.

Power terminals

For AC powered transmitter (90–250VAC, 50/60 Hz):

• Connect AC Neutral to Terminal N and AC Line to Terminal L1.

20 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 21

November 2019 Quick Start Guide

For DC powered transmitter:

• Connect negative to Terminal N and positive to Terminal L1.

• DC powered units may draw up to 8.6 A.

Power supply

• 90 VAC to 250 VAC @ 50/60Hz.

— Overvoltage Category II

— Single Phase Earthed Neutral System

• 12 VDC to 42 VDC.

Note

For applications with sensors greater than 14 inch (350 mm) and process

temperature greater than 212 °F (100 °C), consult an Emerson Flow

representative (see back page) when applying less than 18 VDC to power

terminals.

Line power fuses

Power supply type Rating Manufacturer part number

90–250 VAC 2.5 A, 250 VAC Bel Fuse 3AG 2.5-R, Littlefuse

12–42 VDC 12 A, 250 VAC Bel Fuse 3AB 12-R, Littlefuse

312025, or equivalent

314012, or equivalent

Power consumption

• 90 VAC to 250 VAC: 120 VA maximum

• 12 VDC to 42 VDC: 120 W maximum

Inrush/Start-up current

The power system must be capable of supporting inrush/start-up currents

of:

• AC supply: Maximum 7 A (<5 ms)

• DC supply: Maximum 13 A (<5 ms)

Quick Start Guide 21

Page 22

&XUUHQW$PSV

9$&506

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

1.40

90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250

Quick Start Guide November 2019

AC power supply requirements

Units powered by 90 VAC to 250 VAC have the following power

requirements. Peak inrush is 7 A at 250 VAC supply, lasting approximately

1 ms.

Figure 5-7: AC current requirements

22 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 23

2

3

4

5

6

7

8

9

10

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

&XUUHQW$PSV

9ROWV

November 2019 Quick Start Guide

DC power supply requirements

Units powered by 12 VDC power supply may draw up to 8.6 A of current

steady state. Peak inrush is 13 A at 12 VDC supply, lasting approximately

1 ms.

Figure 5-8: DC current requirements

A. Supply current (amps)

B. Power supply (VDC)

Covers

Use the transmitter lower door screw to secure the terminal compartment

after the instrument has been wired. Follow these steps to ensure the

housing is properly sealed to meet ingress protection requirements:

1. Ensure all wiring is complete and close the lower door.

2. Tighten the lower door screw until the lower door is tight against the

housing. Metal to metal contact of the screw bosses is required to

ensure a proper seal.

Note

Application of excessive torque may strip the threads or break the

screw.

Quick Start Guide 23

3. Verify the lower door is secure.

Page 24

Quick Start Guide November 2019

5.7 Analog output

The analog output signal is a 4-20 mA current loop. Depending on the IS

output option, the loop can be powered internally or externally via a

hardware switch located on the front of the electronics stack. The switch is

set to internal power when shipped from the factory. Intrinsically safe analog

output requires a shielded twisted pair cable. For HART communication, a

minimum resistance of 250 ohms is required. It is recommended to use

individually shielded twisted pair cable. The minimum conductor size is

24 AWG (0.51 mm) diameter for cable runs less than 5,000 feet (1,500 m)

and 20 AWG (0.81 mm) diameter for longer distances.

Note

For more information about the analog output characteristics, refer to the

product reference manual.

Figure 5-9: Analog output wiring

A B

A. Terminal #7

B. Terminal #8

Note

Terminal polarity for the analog output is reversed between internally and

externally powered.

24 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 25

November 2019 Quick Start Guide

Table 5-5: Terminal assignment by power source type

Power source Terminal #7 Terminal #8

Internal 4–20 mA negative (–) 4–20 mA positive (+)

External 4–20 mA positive (+) 4–20 mA negative (–)

Figure 5-10: Analog loop load limitations

600

A

C

0

10.8 30

B

A. Load (ohms)

B. Power supply (volts)

C. Operating region

• R

• Vps = power supply voltage (volts)

• R

= 31.25 (Vps–10.8)

max

= maximum loop resistance (ohms)

max

Quick Start Guide 25

Page 26

Quick Start Guide November 2019

6 Basic Configuration

Once the flow meter is installed and power has been supplied, the

transmitter must be configured using the LOI, if equipped, or a configuration

tool, such as ProLink III Software, AMS Device Manager, or AMS Trex Device

Communicator. Configuration settings are saved in nonvolatile memory

within the transmitter. Descriptions of more advanced functions are

included in the product reference manual.

6.1 Basic Setup

Tag

Tag is the quickest and shortest way of identifying and distinguishing

between transmitters. Transmitters can be tagged according to the

requirements of your application. The tag can be up to 32 characters long.

Calibration number

The sensor calibration number is a 16-digit number generated at the factory

during flow calibration, is unique to each sensor, and is located on the sensor

tag.

Flow units (PV)

The flow units variable specifies the format in which the flow rate will be

displayed. Units should be selected to meet your particular metering

needs. .

Line size

The line size (sensor size) must be set to match the actual sensor connected

to the transmitter. The size must be specified in inches.

Upper range value (URV)

The URV sets the 20 mA point for the analog output. This value is typically

set to full-scale flow. The units that appear will be the same as those selected

under the flow units parameter. The URV may be set between –39.3 ft/s to

39.3 ft/s (–12 m/s to 12m/s). There must be at least 1 ft/s (0.3 m/s) span

between the URV and LRV.

Lower range value (LRV)

The LRV sets the 4 mA point for the analog output. This value is typically set

to zero flow. The units that appear will be the same as those selected under

the flow units parameter. The LRV may be set between –39.3 ft/s to 39.3 ft/s

(–12 m/s to 12m/s). There must be at least 1 ft/s (0.3 m/s) span between the

URV and LRV.

26 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 27

November 2019 Quick Start Guide

Auto zero

The Auto zero is recommended for optimum performance when a flow

meter is initially installed, and it typically does not need to be performed

again. However, if process conditions drastically change, a new Auto zero is

recommended. The sensor must be filled completely with process fluid at

zero flow. For more information, refer to the product reference manual.

6.2 Local operator interface (LOI)

To access the transmitter menu, press the XMTR MENU key. Use the UP,

DOWN, LEFT(E), and RIGHT arrows to navigate the menu structure.

The display can be locked to prevent unintentional configuration changes.

The display lock can be activated through a HART communication device, or

by holding the UP arrow for three seconds and then following the on-screen

instructions.

6.3 Other configuration tools

Table 6-1 shows the approximate category or location of basic setup

parameters for typical configuration tools.

Table 6-1: Approximate setup category/locations for typical

configuration tools

Function Category/Location

Flow Units

PV Upper Range Value

(URV)

PV Lower Range Value

(LRV)

Auto zero

Calibration Number Basic Setup → Setup

Line Size Basic Setup → Setup

Tag Device Info → Identification

Long Tag Device Info → Identification

Basic Setup

Basic Setup → AO

Basic Setup → AO

Diagnostics

Quick Start Guide 27

Page 28

Quick Start Guide November 2019

7 Product Certifications

For detailed approval certification information and installation drawings,

please see the appropriate document listed below:

• Document number 00825-MA00-0009: Rosemount 8782 and MS

Approval Document - Class Division

• Document number 00825-MA00-0010: Rosemount 8782 and MS

Approval Document - IECEx and ATEX

• Document number 00825-MA00-0011: Rosemount 8782 and MS

Approval Document - North America Zone

• Document number 00825-MA00-0012: Rosemount 8785 Approval

Document

• Document number 00825-MA00-0013: Rosemount 8782 and MS

Approval Document - EAC EX

28 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 29

November 2019 Quick Start Guide

Quick Start Guide 29

Page 30

Quick Start Guide November 2019

30 Rosemount™ 8782 Slurry Magnetic Flow Meter Transmitter

Page 31

November 2019 Quick Start Guide

Quick Start Guide 31

Page 32

*00825-0100-8782*

00825-0100-8782, Rev. AA

Quick Start Guide

November 2019

Emerson Automation Solutions USA

7070 Winchester Circle

Boulder, Colorado USA 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.emerson.com

Emerson Automation Solutions Europe

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.micromotion.nl

©

2019 Rosemount, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Rosemount, 8600, 8700, 8800 marks are marks of one of the Emerson

Automation Solutions family of companies. All other marks are property

of their respective owners.

Emerson Automation Solutions Asia

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6363-7766

F +65 6770-8003

Emerson Automation Solutions United

Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Loading...

Loading...