Page 1

Reference Manual

00809-0100-4697, Rev GA

November 2014

Rosemount 848T High Density Temperature

Transmitter with FOUNDATION™ fieldbus

Device Revision 8

Page 2

Page 3

Reference Manual

00809-0100-4697, Rev GA

Rosemount 848T High Density Temperature

Transmitter with F

Title Page

November 2014

OUNDATION

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one international number

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 p.m. CST)

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

International

1-(952) 906-8888

™

fieldbus

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an Emerson Process

Management Sales Representative.]

i

Page 4

Title Page

November 2014

Reference Manual

00809-0100-4697, Rev GA

ii

Page 5

Reference Manual

00809-0100-4697, Rev GA

1Section 1: Introduction

2Section 2: Installation

Contents

November 2014

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2.1 Mounting to a DIN rail without an enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.2 Mounting to a panel with a junction box . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.2.3 Mounting to a 2-in. pipe stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.3.3 Surges/transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5 Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6 Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.7 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.7.1 Using cable glands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.7.2 Using conduit entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3Section 3: Configuration

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.1 Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.2 Transmitter configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.3 Custom configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.4 Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2.6 Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Contents

3.2.7 Configure the differential sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2.8 Configure measurement validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

iii

Page 6

Contents

November 2014

Reference Manual

00809-0100-4697, Rev GA

3.3 Common configurations for high density applications. . . . . . . . . . . . . . . . . . . . . .22

3.3.1 Interfacing analog transmitters to Foundation fieldbus . . . . . . . . . . . . . . .25

3.4 Block configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.4.1 Resource block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.4.2 Field Diagnostics & PlantWeb Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.4.3 PlantWeb alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.4.4 Recommended actions for PlantWeb alerts . . . . . . . . . . . . . . . . . . . . . . . . .35

3.4.5 Field Diagnostics Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.4.6 Recommended actions for field diagnostics alerts. . . . . . . . . . . . . . . . . . . .40

3.4.7 Transducer blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.4.8 Transducer block sub-parameter tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4Section 4: Operation and Maintenance

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.2 Foundation™ fieldbus information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.2.1 Commissioning (addressing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.3 Hardware maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.3.1 Sensor check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.3.2 Communication/power check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.3.3 Resetting the configuration (RESTART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.4 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.4.1 Foundation fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.4.2 Resource block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.4.3 Transducer block troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

AAppendix A: Reference Data

A.1 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.1 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.2 Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.3 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.4 Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.5 Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.6 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.7 Transient protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

A.1.8 Update time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.1.9 Humidity limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.1.10Turn-on time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

iv

Contents

Page 7

Reference Manual

00809-0100-4697, Rev GA

Contents

November 2014

A.1.11Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.1.12Backup Link Active Scheduler (LAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.2 Physical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.2.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.2.2 Entries for optional junction box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A.2.3 Environmental ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A.3 Function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A.3.1 Analog input (AI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A.3.2 Input selector (ISEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A.3.3 Multiple analog input block (MAI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A.4 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

A.4.1 Stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

A.4.2 Self calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

A.4.3 Vibration effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

A.4.4 Electromagnetic compatibility compliance testing . . . . . . . . . . . . . . . . . . .60

A.4.5 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

A.4.6 Differential configuration notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

A.4.7 Accuracy for differential configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

A.4.8 Analog sensors 4–20mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

A.4.9 Ambient temperature effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

A.4.10Ambient temperature effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

A.4.11Ambient temperature notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

A.5 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

A.5.1 Mounting options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

A.6 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

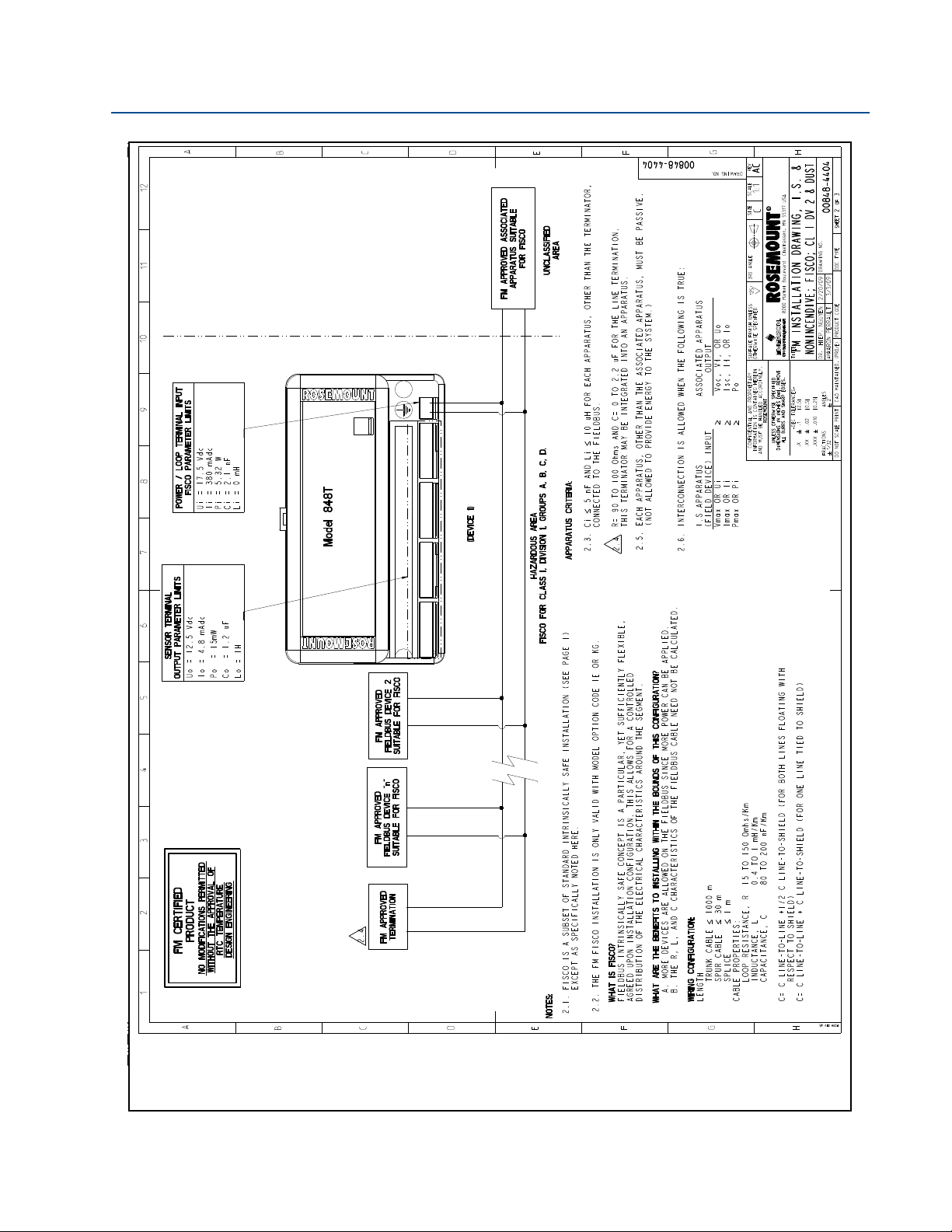

BAppendix B: Product Certificates

B.1 North American Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

B.1.1 European Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

B.2 Intrinsically Safe and Non-Incendive installations . . . . . . . . . . . . . . . . . . . . . . . . . .78

B.3 Installation drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Contents

CAppendix C: Foundation™ fieldbus Technology

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

C.2 Function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

C.3 Device descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

C.4 Block operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

C.4.1 Instrument- specific function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

v

Page 8

Contents

November 2014

Reference Manual

00809-0100-4697, Rev GA

C.4.2 Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

C.5 Network communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

C.5.1 LAS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

C.5.2 Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

C.5.3 Scheduled transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

C.5.4 Unscheduled transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

C.5.5 Function block scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

DAppendix D: Function Blocks

D.1 Analog Input (AI) function block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

D.1.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

D.1.2 AI block troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

D.2 Multiple analog input (MAI) function block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

D.2.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

D.2.2 MAI block troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

D.3 Input selector function block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

D.3.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

D.3.2 ISEL block troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

vi

Contents

Page 9

Reference Manual

00809-0100-4697, Rev GA

Section 1 Introduction

1.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

1.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Process leaks could result in death or serious injury.

Do not remove the thermowell while in operation. Removing while in operation may

cause process fluid leaks.

Install and tighten thermowells and sensors before applying pressure, or process

leakage may result.

Electrical shock could cause death or serious injury.

If the sensor is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on transmitter leads and

terminals.

Use extreme caution when making contact with the leads and terminals.

Section 1: Introduction

November 2014

1.2 Overview

1.2.1 Transmitter

The Rosemount 848T is optimal for process temperature measurement because of its ability to

simultaneously measure eight separate and independent temperature points with one

transmitter. Multiple temperature sensor types may be connected to each transmitter. In

addition, the 848T can accept 4-20 mA inputs. The enhanced measurement capability of the

848T allows it to communicate these variables to any F

configuration tool.

1.2.2 Manual

This manual is designed to assist in the installation, operation, and maintenance of the

Rosemount 848T Temperature Transmitter.

Introduction

OUNDATION

™

fieldbus host or

1

Page 10

Section 1: Introduction

November 2014

Section 1: Introduction

Overview

Considerations

Return of Materials

Section 2: Installation

Mounting

Installation

Wiring

Power Supply

Commissioning

Section 3: Configuration

FOUNDATION fieldbus Technology

Configuration

Function Block Configuration

Reference Manual

00809-0100-4697, Rev GA

Section 4: Operation and Maintenance

Hardware Maintenance

Tro u bl esh o oti ng

Appendix A: Reference Data

Specifications

Dimensional Drawings

Ordering Information

Appendix B: Product Certificates

Hazardous Locations Certificates

Intrinsically Safe and Non-Incendive Installations

Installation Drawings

Appendix C: Foundation™ fieldbus Technology

Device Descriptions

Block Operation

Appendix D: Function Blocks

Analog Input (AI) Function Block

Multiple Analog Input (MAI) Function Block

Input Selector Function Block

2

Introduction

Page 11

Reference Manual

00809-0100-4697, Rev GA

1.3 Service support

To expedite the return process in North America, call the Emerson Process Management

National Response Center toll-free at 800-654-7768. This center, available 24 hours a day, will

assist with any needed information or materials.

The center will ask for the following information:

Product model

Serial numbers

The last process material to which the product was exposed

The center will provide the following:

A Return Material Authorization (RMA) number

Instructions and procedures that are necessary to return goods that were exposed to

hazardous substances

For other locations, contact an Emerson Process Management sales representative.

Section 1: Introduction

November 2014

Note

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS), required by law to be

available to people exposed to specific hazardous substances, must be included with the

returned materials.

Introduction

3

Page 12

Section 1: Introduction

November 2014

Reference Manual

00809-0100-4697, Rev GA

4

Introduction

Page 13

Reference Manual

00809-0100-4697, Rev GA

Section 2 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Section 2: Installation

November 2014

2.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Process leaks could result in death or serious injury.

Do not remove the thermowell while in operation. Removing while in operation may

cause process fluid leaks.

Install and tighten thermowells and sensors before applying pressure, or process

leakage may result.

Electrical shock could cause death or serious injury.

If the sensor is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on transmitter leads and

terminals.

Use extreme caution when making contact with the leads and terminals.

2.2 Mounting

The 848T is always mounted remote from the sensor assembly. There are three mounting

configurations.

To a DIN rail without an enclosure

To a panel with an enclosure

To a 2-in pipe stand with an enclosure using a pipe mounting kit

5Installation

Page 14

Section 2: Installation

A

B

C

A

D

C

B

E

D

C

November 2014

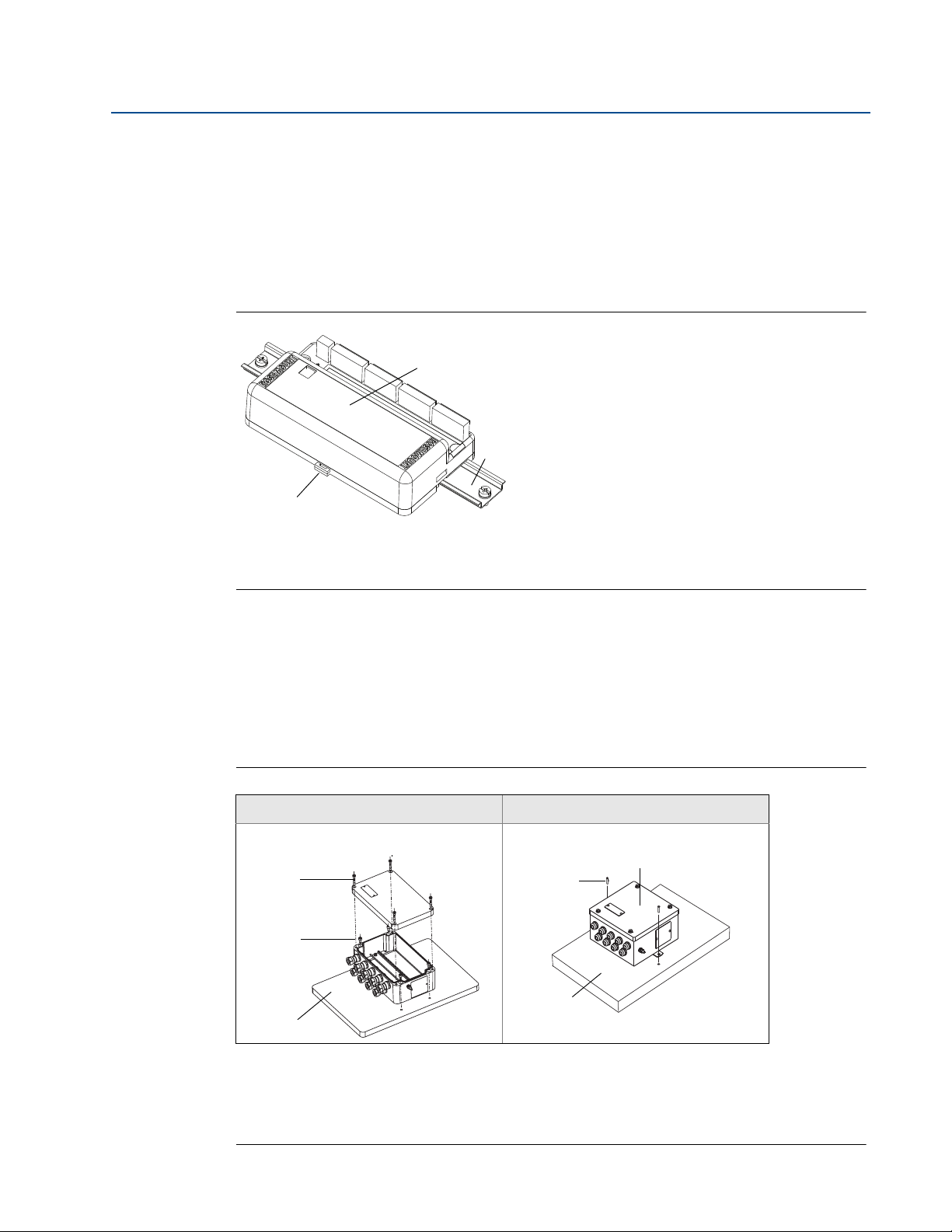

2.2.1 Mounting to a DIN rail without an enclosure

To mount the 848T to a DIN rail without an enclosure, follow these steps:

1. Pull up the DIN rail mounting clip located on the top back side of the transmitter.

2. Hinge the DIN rail into the slots on the bottom of the transmitter.

3. Tilt the 848T and place onto the DIN rail. Release the mounting clip. The transmitter

should be securely fastened to the DIN rail.

Figure 2-1. Mounting the 848T to a DIN Rail

Reference Manual

00809-0100-4697, Rev GA

A. DIN Rail Mounting Clip

B. 848T without installed enclosure

C. DIN Rail

2.2.2 Mounting to a panel with a junction box

When inside of a plastic or aluminum junction box, the 848T mounts to a panel using four 1/4-20

x 1.25-in. screws.

When inside of a stainless steel junction box, the 848T mounts to a panel using two

1

/2-in. screws.

Figure 2-2. Mounting the 848T Junction Box to a Panel

Aluminum/plastic Stainless steel

1

/4-20 x

6

A. 848T with aluminum or plastic box

B. Cover screws (4)

C. Mounting screws (4 for aluminum/plastic mounting, 2 for stainless steel mounting)

D. Panel

E. 848T with a stainless steel box

Installation

Page 15

Reference Manual

A

B

C

D

E

00809-0100-4697, Rev GA

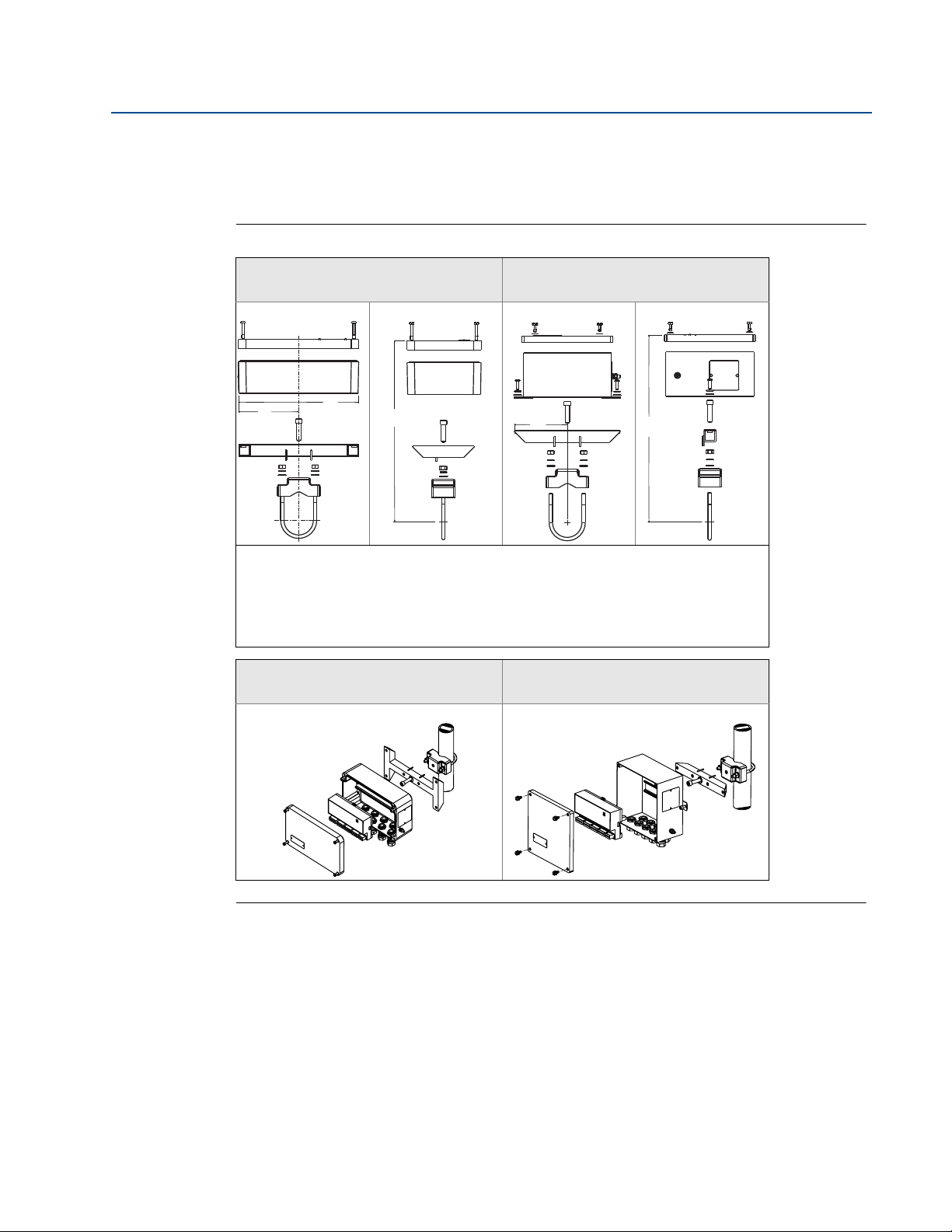

2.2.3 Mounting to a 2-in. pipe stand

Use the optional mounting bracket (option code B6) to mount the 848T to a 2-in. pipe stand

when using a junction box.

Figure 2-3. Mounting the 848T to a 2-in. Pipe Stand Using a Junction Box

Section 2: Installation

November 2014

Aluminum/plastic junction box

(styles JA and JP)

Front view Side view Front view Side view

Dimensions are in inches (millimeters).

A. 5.1 (130)

B. 10.2 (260)

C. 6.6 (167) fully assembled

D. 4.7 (119)

E. 7.5 (190) fully assembled

Aluminum/plastic junction box

mounted on a vertical pipe

Stainless steel junction box

(style JS)

Stainless steel junction box

mounted on a vertical pipe

Installation

7

Page 16

Section 2: Installation

C

E

A

F

H

D

F

November 2014

2.3 Wiring

If the sensor is installed in a high-voltage environment and a fault condition or installation error

occurs, the sensor leads and transmitter terminals could carry lethal voltages. Use extreme

caution when making contact with the leads and terminals.

Note

Do not apply high voltage (e.g. AC line voltage) to the transmitter terminals. Abnormally high

voltage can damage the unit (bus terminals are rated to 42.4 VDC).

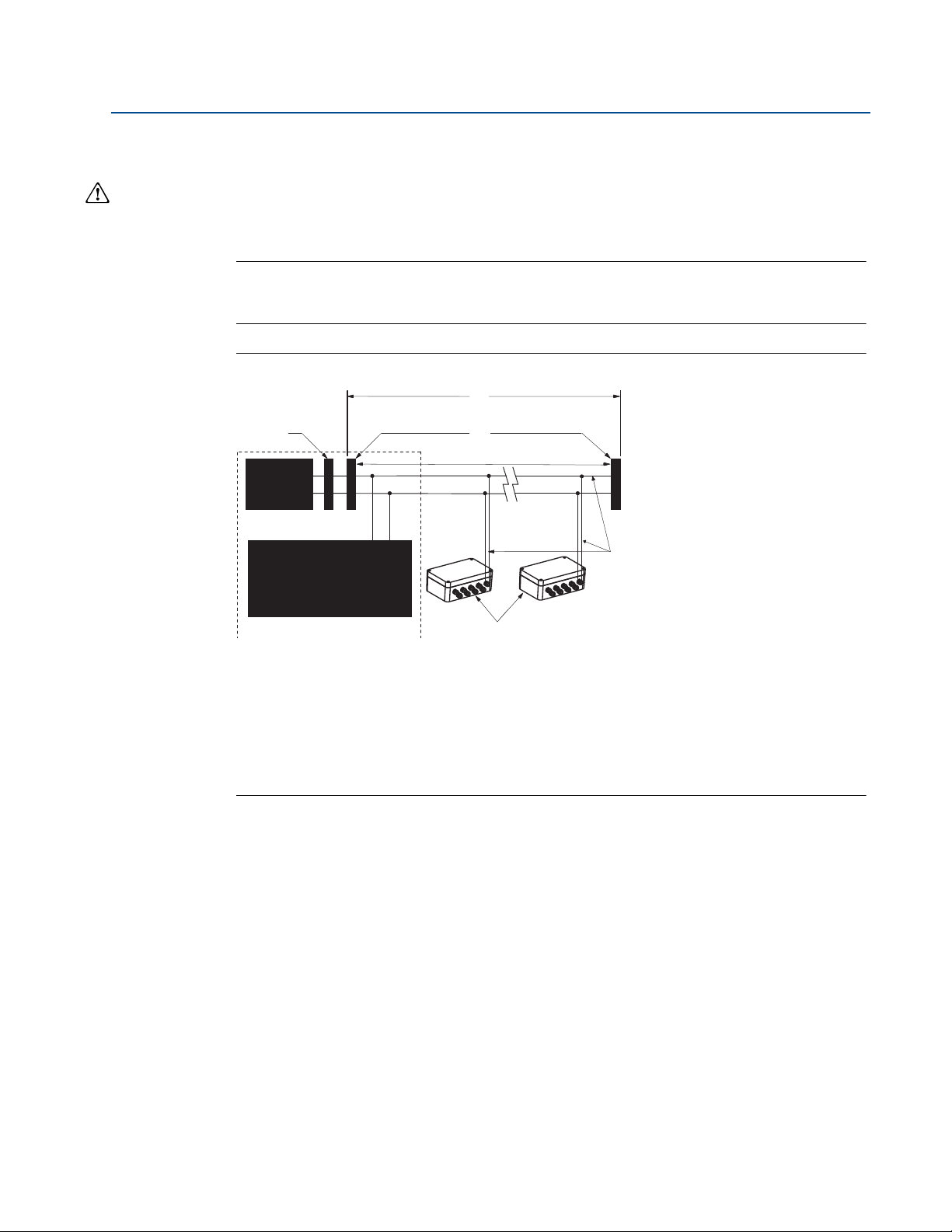

Figure 2-4. 848T Transmitter Field Wiring

Reference Manual

00809-0100-4697, Rev GA

B

A. Integrated Power Conditioner and Filter

B. 6234 ft (1900 m) max (depending on cable characteristics)

C. Terminators (Trunk)

D. Power supply

E. F

OUNDATION

F. S pu r

G. Signal wiring

H. Devices 1-16 (Intrinsically safe installations may allow fewer devices per I.S. barrier)

™

fieldbus host or configuration tool

2.3.1 Connections

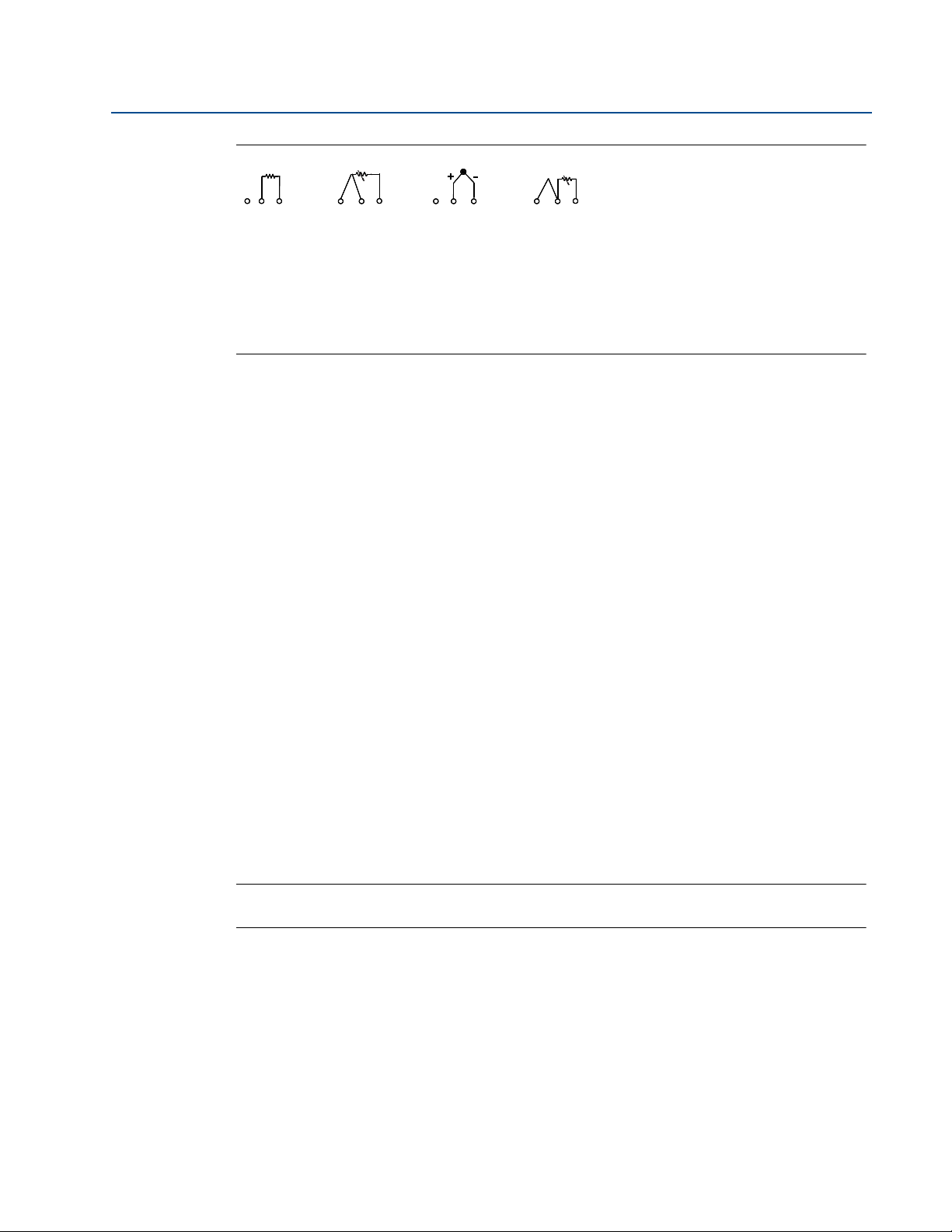

The 848T transmitter is compatible with 2 or 3-wire RTD, thermocouple, ohm, and millivolt

sensor types. Figure 2-5 shows the correct input connections to the sensor terminals on the

transmitter. The 848T can also accept inputs from analog devices using the optional analog

input connector. Figure 2-6 shows the correct input connections to the analog input connector

when installed on the transmitter. Tighten the terminal screws to ensure proper connection.

G

8

Installation

Page 17

Reference Manual

12 3

A

B

C

123 123

D

123

00809-0100-4697, Rev GA

Figure 2-5. Sensor Wiring Diagram

A. 2-wire RTD and ohms

B. 3-wire RTD and ohms (Emerson provides 4-wire sensors for all single-element RTDs; use these RTDs in 3-wire

C. Thermocouples/ohms and Millivolts

D. 2-wire RTD with compensation loop (transmitter must be configured for a 3-wire RTD in order to recognize an RTD

RTD or ohm inputs

Various RTD configurations, including 2-wire and 3-wire are used in industrial applications. If the

transmitter is mounted remotely from a 3-wire RTD, it will operate within specifications,

without recalibration, for lead wire resistances of up to 60 ohms per lead (equivalent to 6,000

feet of 20 AWG wire). If using a 2-wire RTD, both RTD leads are in series with the sensor element,

so errors can occur if the lead lengths exceed one foot of 20 AWG wire. Compensation for this

error is provided when using 3-wire RTDs.

Section 2: Installation

November 2014

configurations by clipping the fourth lead or leaving it disconnected and insulated with electrical tape.)

with a compensation loop)

Thermocouple or millivolt inputs

Use appropriate thermocouple extension wire to connect the thermocouple to the transmitter.

Make connections for millivolt inputs using copper wire. Use shielding for long runs of wire.

Analog inputs

The analog connector converts the 4–20 mA signal to a 20–100 mV signal that can be read by

the 848T and transmitted using F

Use the following steps when installing the 848T with the analog connector:

1. The 848T, when ordered with option code S002, comes with four analog connectors.

Replace the standard connector with the analog connector on the desired channels.

2. Wire one or two analog transmitters to the analog connector according to Figure 2-6.

There is space available on the analog connector label for identification of the analog

inputs.

Note

Power supply should be rated to support the connected transmitter(s).

3. If the analog transmitters can communicate using HART

connectors are supplied with the ability to switch in a 250 ohm resistor for HART

communication (see Figure 2-7).

OUNDATION fieldbus.

®

protocol, the analog

Installation

One switch is supplied for each input (top switch for “A” inputs and bottom switch for

“B” inputs). Setting the switch in the “ON” position (to the right) bypasses the 250 ohm

resistor. Terminals are provided for each analog input to connect a field communicator

for local configuration.

9

Page 18

Section 2: Installation

A

B

C

A

C

D

B

November 2014

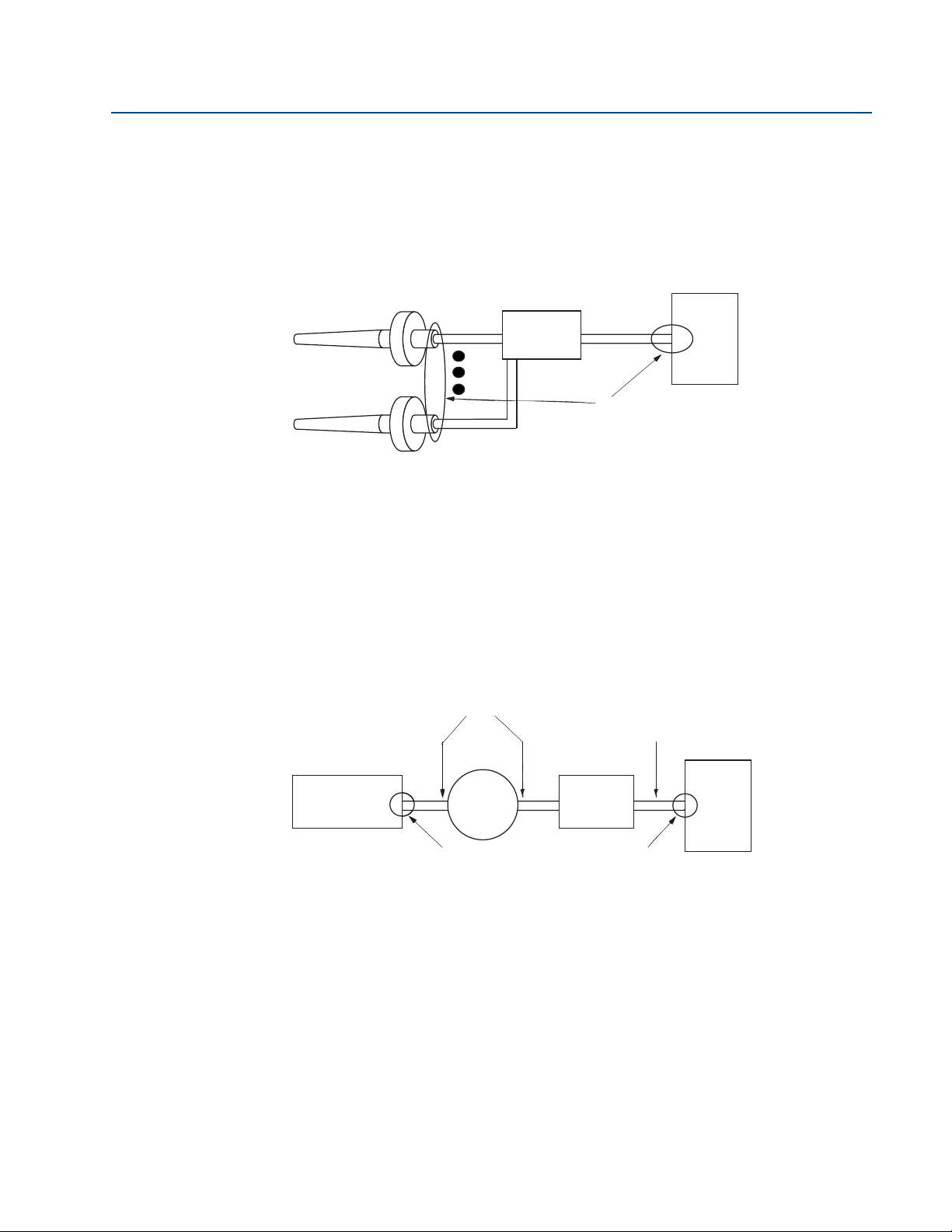

Figure 2-6. 848T Analog Input Wiring Diagram

Reference Manual

00809-0100-4697, Rev GA

A. Analog input connectors

B. Analog transmitters

C. Power supply

Figure 2-7. 848T Analog Connector

A. HART Channel A

B. 250 ohm resistor in the loop when switched to the left

C. HART Channel B

D. Space available for identification of inputs

10

Installation

Page 19

Reference Manual

NOT USED

SECURITY

SIMULA

TE ENABLE

A

B

00809-0100-4697, Rev GA

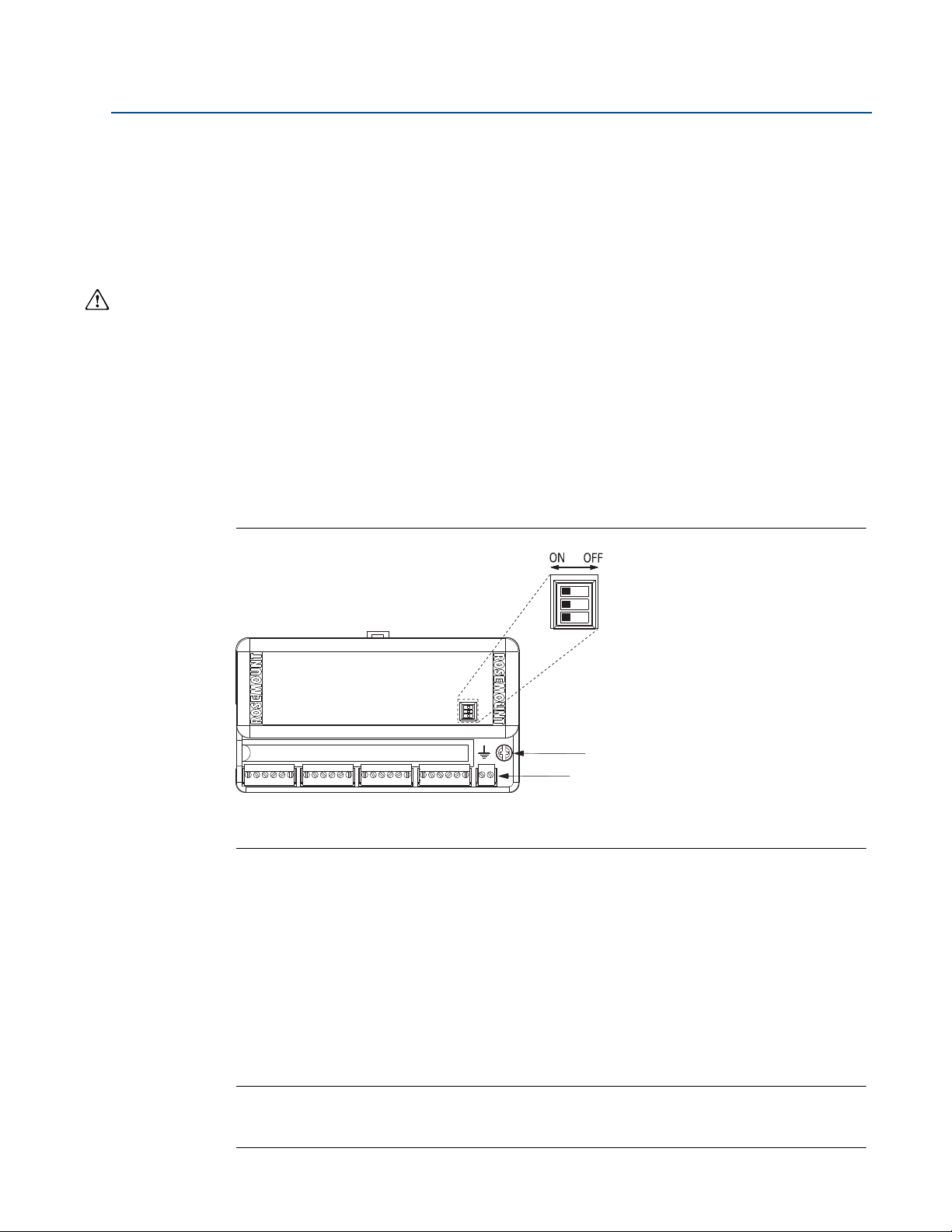

2.3.2 Power supply

Connections

The transmitter requires between 9 and 32 VDC to operate and provide complete functionality.

The DC power supply should provide power with less than 2% ripple. A fieldbus segment

requires a power conditioner to isolate the power supply filter and decouple the segment from

other segments attached to the same power supply.

All power to the transmitter is supplied over the signal wiring. Signal wiring should be shielded,

twisted pair for best results in electrically noisy environments. Do not use unshielded signal

wiring in open trays with power wiring or near heavy electrical equipment.

Use ordinary copper wire of sufficient size to ensure the voltage across the transmitter power

terminals does not go below 9 VDC. The power terminals are polarity insensitive. To power the

transmitter:

1. Connect the power leads to the terminals marked “Bus,” as shown in Figure 2-8.

2. Tighten the terminal screws to ensure adequate contact. No additional power wiring is

necessary.

Section 2: Installation

November 2014

Figure 2-8. Transmitter Label

A. Ground (required with T1 option)

B. Connect power leads here

2.3.3 Surges/transients

The transmitter will withstand electrical transients encountered through static discharges or

induced switching transients. However, a transient protection option (option code T1) is

available to protect the 848T against high-energy transients. The device must be properly

grounded using the ground terminal (see Figure 2-8).

2.4 Grounding

The 848T transmitter provides input/output isolation up to 620 V rms.

Note

Neither conductor of the fieldbus segment can be grounded. Grounding out one of the signal

wires will shut down the entire fieldbus segment.

Installation

11

Page 20

Section 2: Installation

A

B

C

D

A

B

C

D

November 2014

Shielded wire

Each process installation has different requirements for grounding. Use the grounding options

recommended by the facility for the specific sensor type or begin with grounding option 1

(most common).

Ungrounded thermocouple, mV, and RTD/ohm inputs

Option 1:

1. Connect signal wiring shield to the sensor wiring shield(s).

2. Ensure shields are tied together and electrically isolated from transmitter enclosure.

3. Only ground shield at the power supply end.

4. Ensure sensor shield(s) is electrically isolated from the surrounding grounded fixtures.

Reference Manual

00809-0100-4697, Rev GA

A. Sensor wires

B. 848T

C. Power supply

D. Shield ground point

Option 2:

1. Connect sensor wiring shield(s) to the transmitter enclosure (only if enclosure is

grounded).

2. Ensure sensor shield(s) is electrically isolated from surrounding fixtures that may be

grounded.

3. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. 848T

C. Power supply

D. Shield ground points

12

Installation

Page 21

Reference Manual

A

B

C

D

C

D

EF

B

00809-0100-4697, Rev GA

Grounded thermocouple inputs

1. Ground sensor wiring shield(s) at the sensor.

2. Ensure that the sensor wiring and signal wiring shields are electrically isolated from the

3. Do not connect the signal wiring shield to the sensor wiring shield(s).

4. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. 848T

C. Power supply

D. Shield ground points

Section 2: Installation

November 2014

transmitter enclosure.

Analog device inputs

1. Ground analog signal wire at the power supply of the analog devices.

2. Ensure the analog signal wire and the fieldbus signal wire shields are electrically isolated

from the transmitter enclosure.

3. Do not connect the analog signal wire shield to the fieldbus signal wire shield.

4. Ground fieldbus signal wire shield at the power supply end.

A

A. 4-20 mA loop

B. F

OUNDATION fieldbus bus

C. Analog device power supply

D. Analog device

E. 848T

F. Power supply

G. Shield ground points

G

G

Transmitter enclosure (optional)

Ground the transmitter in accordance with local electrical requirements.

Installation

13

Page 22

Section 2: Installation

NOT USED

SECURITY

SIMULATE ENABLE

November 2014

2.5 Switches

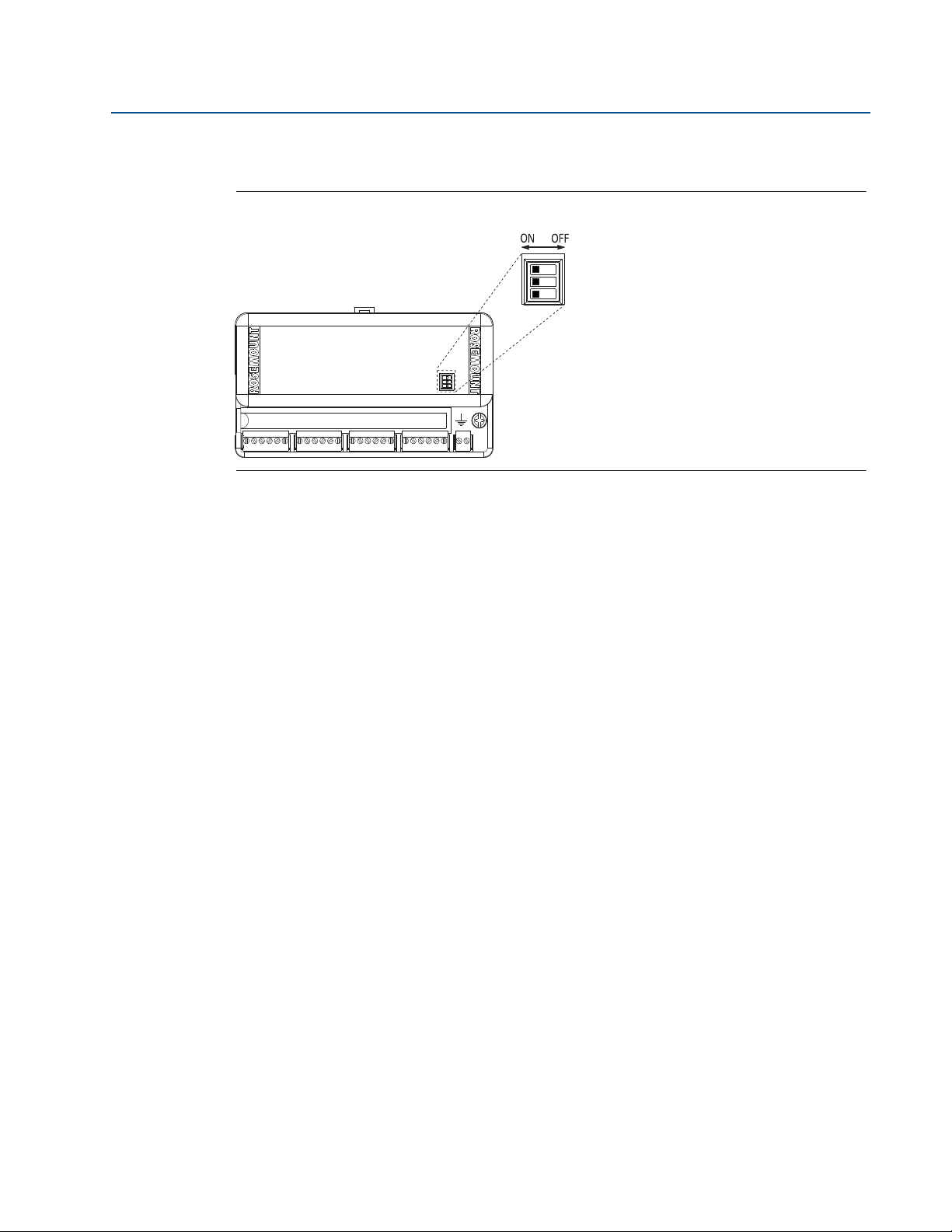

Figure 2-9. Switch Location on the Rosemount 848T

Security

Reference Manual

00809-0100-4697, Rev GA

After configuring the transmitter, the data can be protected from unwarranted changes. Each

848T is equipped with a security switch that can be positioned “ON” to prevent the accidental

or deliberate change of configuration data. This switch is located on the front side of the

electronics module and is labeled SECURITY.

See Figure 2-9 for switch location on the transmitter label.

Simulate enable

The switch labeled SIMULATE ENABLE is used in conjunction with the Analog Input (AI) and

Multiple Analog Input (MAI) function blocks. This switch is used to simulate temperature

measurement.

Not used

The switch is not functional.

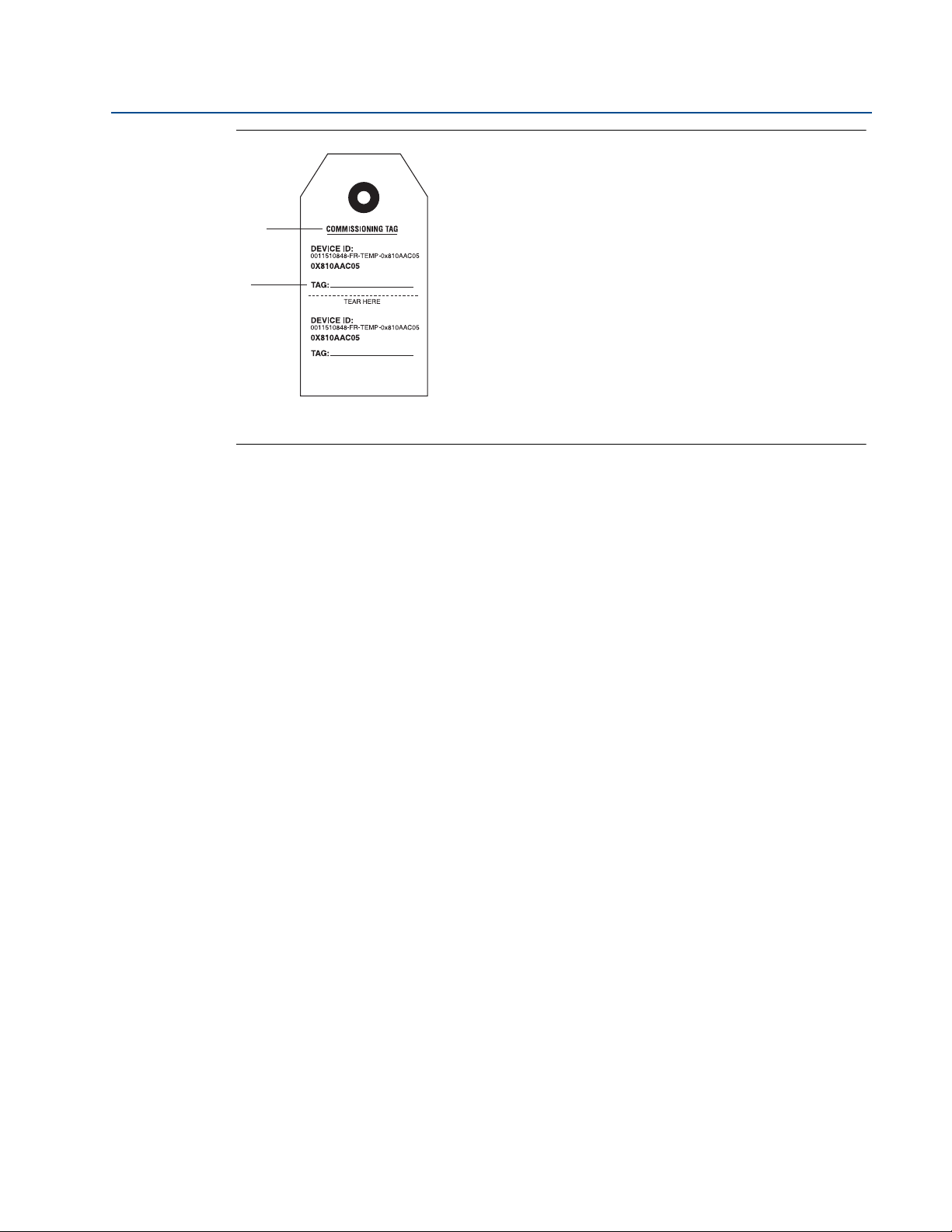

2.6 Tagging

Commissioning tag

The 848T has been supplied with a removable commissioning tag that contains both the Device

ID (the unique code that identifies a particular device in the absence of a device tag) and a space

to record the device tag [the operational identification for the device as defined by the Piping

and Instrumentation Diagram (P&ID)].

When commissioning more than one device on a fieldbus segment, it can be difficult to identify

which device is at a particular location. The removable tag, provided with the transmitter, can

aid in this process by linking the Device ID to its physical location. The installer should note the

physical location of the transmitter on both the upper and lower location of the commissioning

tag. The bottom portion should be torn off for each device on the segment and used for

commissioning the segment in the control system.

14

Installation

Page 23

Reference Manual

A

B

00809-0100-4697, Rev GA

Figure 2-10. Commissioning Tag

A. Device ID

B. Device Tag to denote physical location

Transmitter tag

Section 2: Installation

November 2014

Hardware

Tagged in accordance with customer requirements

Permanently attached to the transmitter

Software

The transmitter can store up to 32 characters.

If no characters are specified, the first 30 characters of the hardware tag will be used.

Sensor tag

Hardware

A plastic tag is provided to record identification of eight sensors.

This information can be printed at the factory upon request.

In the field, the tag can be removed, printed onto, and reattached to the transmitter.

Software

If sensor tagging is requested, the Transducer Block SERIAL_NUMBER parameters will

be set at the factory.

The SERIAL_NUMBER parameters can be updated in the field.

Installation

15

Page 24

Section 2: Installation

I

F

A

B

E

D

G

H

J

K

C

November 2014

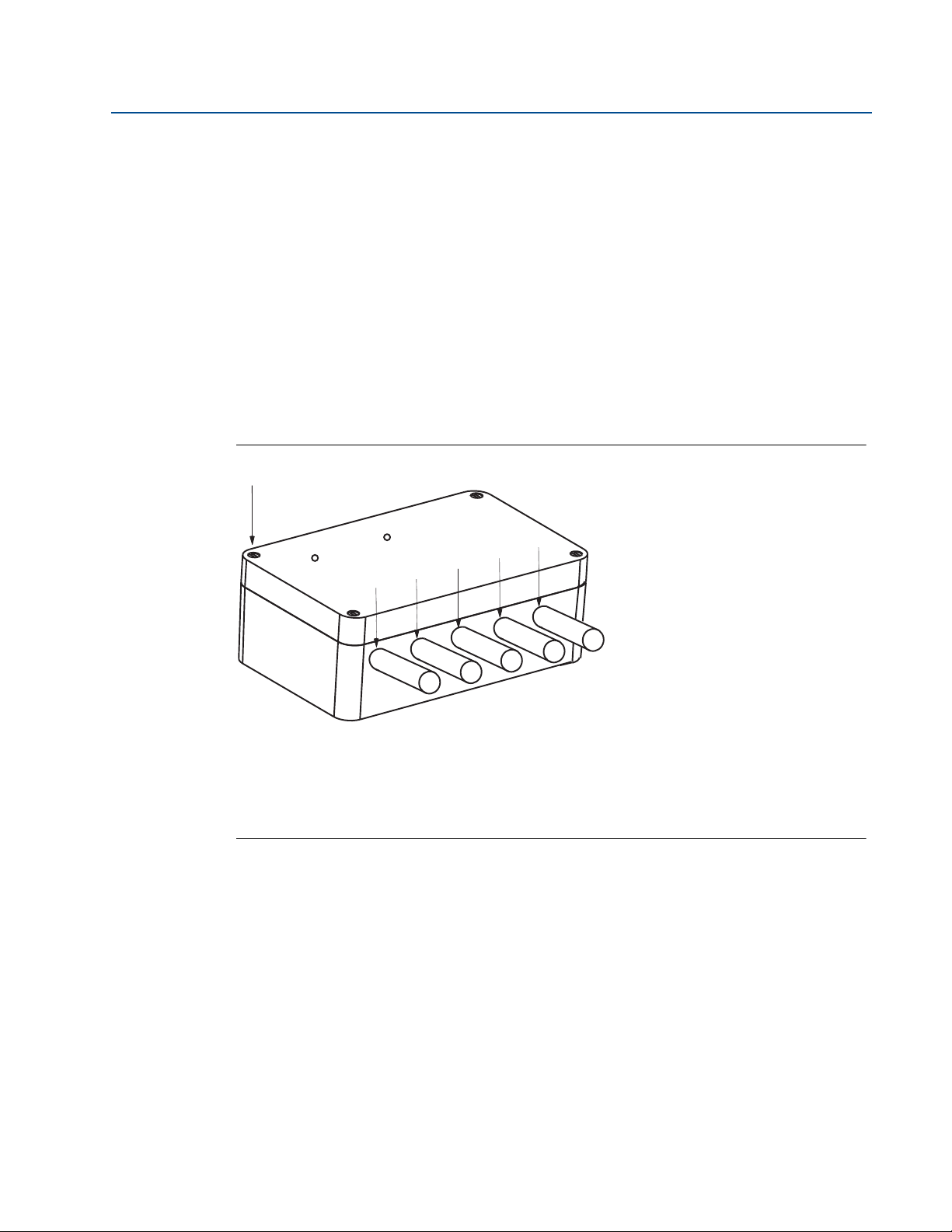

2.7 Installation

2.7.1 Using cable glands

Use the following steps to install the 848T with cable glands:

1. Remove the junction box cover by unscrewing the four cover screws.

2. Run the sensor and power/signal wires through the appropriate cable glands using the

pre-installed cable glands (see Figure 2-11).

3. Install the sensor wires into the correct screw terminals (follow the label on the

electronics module).

4. Install the power/signal wires onto the correct screw terminals. Power is polarity

insensitive, allowing the user to connect positive (+) or negative (–) to either fieldbus

wiring terminal labeled “Bus.”

5. Replace the enclosure cover and securely tighten all cover screws.

Figure 2-11. Installing the 848T with Cable Glands

Reference Manual

00809-0100-4697, Rev GA

A. Enclosure cover screw (4)

B. Cable gland

C. Sensor 1

D. Sensor 3

E. Sensor 5

F. S en sor 7

G. Power/signal

H. Sensor 2

I. Sensor 4

J. Sensor 6

K. Sensor 8

16

Installation

Page 25

Reference Manual

B

C

D

E

F

00809-0100-4697, Rev GA

2.7.2 Using conduit entries

Use the following steps to install the 848T with conduit entries.

1. Remove the junction box cover by unscrewing the four cover screws.

2. Remove the five conduit plugs and install five conduit fittings (supplied by the installer).

3. Run pairs of sensor wires through each conduit fitting.

4. Install the sensor wires into the correct screw terminals (follow the label on the

electronics module).

5. Install the power/signal wires into the correct screw terminals. Power is polarity

insensitive, allowing the user to connect positive (+) or negative (–) to either fieldbus

wiring terminal labeled “Bus.”

6. Replace the junction box cover and securely tighten all cover screws.

Figure 2-12. Installing the 848T with Conduit Entries

A

Section 2: Installation

November 2014

Installation

A. Enclosure cover screw

B. Sensors 1 and 2 conduit

C. Sensors 3 and 4 conduit

D. Sensors 5 and 6 conduit

E. Sensors 7 and 8 conduit

F. P ower/s ig nal

17

Page 26

Section 2: Installation

November 2014

Reference Manual

00809-0100-4697, Rev GA

18

Installation

Page 27

Reference Manual

00809-0100-4697, Rev GA

Section 3 Configuration

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Common configurations for high density applications . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Block configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

3.1.1 Warnings

Section 3: Configuration

November 2014

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Process leaks could result in death or serious injury.

Do not remove the thermowell while in operation. Removing while in operation may

cause process fluid leaks.

Install and tighten thermowells and sensors before applying pressure, or process

leakage may result.

Electrical shock could cause death or serious injury.

If the sensor is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on transmitter leads and

terminals.

Use extreme caution when making contact with the leads and terminals.

19Configuration

Page 28

Section 3: Configuration

November 2014

3.2 Configuration

3.2.1 Standard

Each FOUNDATION™ fieldbus configuration tool or host system has a different way of displaying

and performing configurations. Some will use Device Descriptions (DDs) and DD Methods to

make configuration and displaying of data consistent across host platforms.

Unless otherwise specified, the 848T will be shipped with the following configuration (default):

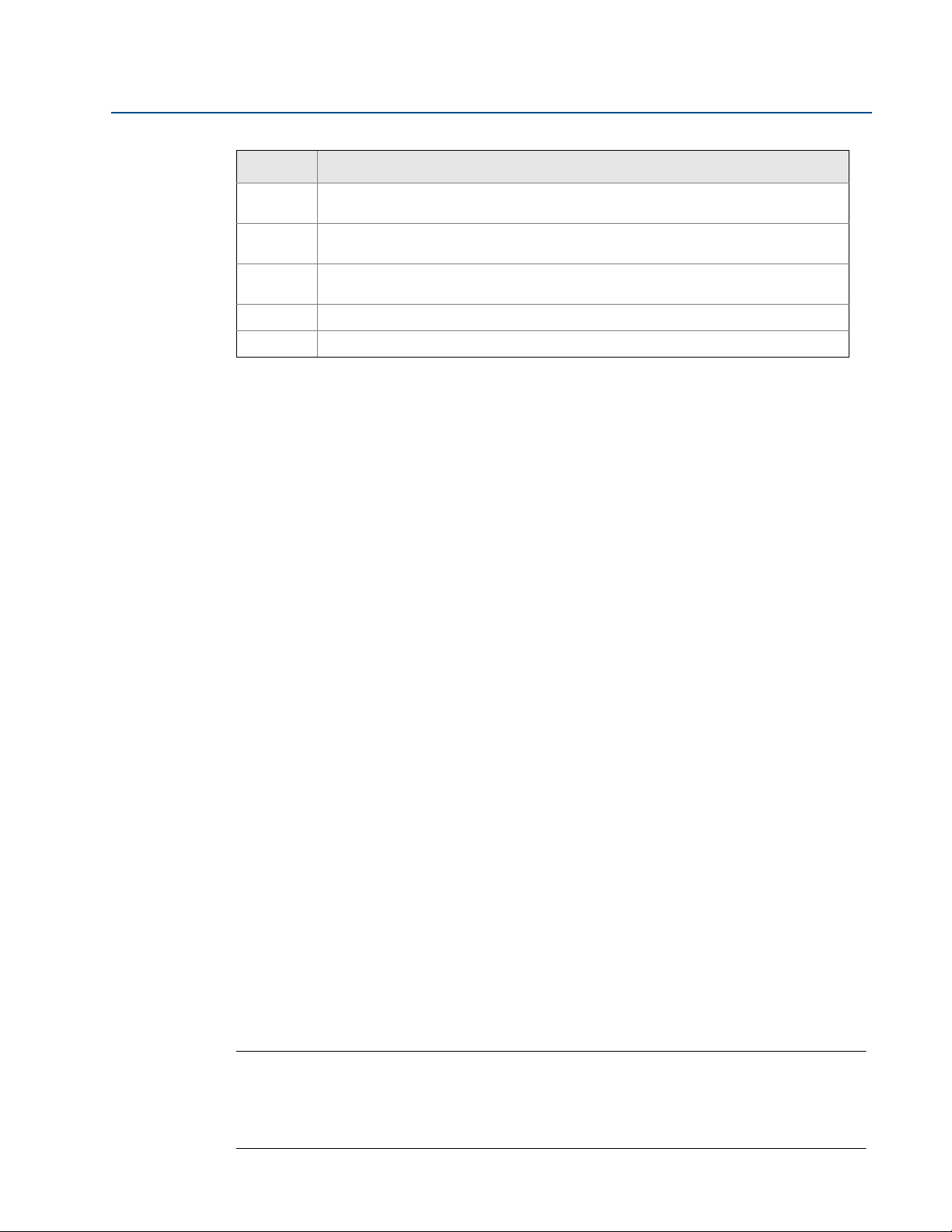

Table 3-1. Standard Configuration Settings

Sensor Type

Damping

Measurement Units

Output

Line Voltage Filter

(1)

(1)

(1)

(1)

(1)

Reference Manual

00809-0100-4697, Rev GA

Type J Thermocouple

5 seconds

°C

Linear with Temperature

60 Hz

Temperature Specific Blocks

FOUNDATION fieldbus Function Blocks

(1) For all eight sensors

Refer to that systems documentation to perform configuration changes using a F

fieldbus host or configuration tool.

Note

To make configuration changes, ensure that the block is Out of Service (OOS) by setting the

MODE_BLK.TARGET to OOS, or set the SENSOR_MODE to Configuration.

3.2.2 Transmitter configuration

The transmitter is available with the standard configuration setting. The configuration settings

and block configuration may be changed in the field with the Emerson Process Management

Systems DeltaV

™

, with AMS®inside, or other FOUNDATION fieldbus host or configuration tool.

3.2.3 Custom configuration

Custom configurations are to be specified when ordering.

3.2.4 Methods

For FOUNDATION fieldbus hosts or configuration tools that support device description (DD)

methods, there are two configuration methods available in the transducer block. These

methods are included with the DD software.

• Transducer Block (1)

• Analog Input (8)

•Multiple Analog Input (2)

• Input Selector (4)

OUNDATION

20

Sensor Configuration

Sensor Input Trim (user input trim)

See the host system documentation for information on running DD methods from the host

system. If the F

OUNDATION fieldbus host or configuration tool does not support DD methods,

refer to “Block configuration” on page 25 for information on how to modify sensor

configuration parameters.

Configuration

Page 29

Reference Manual

00809-0100-4697, Rev GA

3.2.5 Alarms

Use the following steps to configure the alarms, which are located in the Resource Function

Block:

1. Set the resource block to OOS.

2. Set WRITE_PRI to the appropriate alarm level (WRITE_PRI has a selectable range of

priorities from 0 to 15, see “Alarm Priority Levels” on page 31. Set the other block alarm

parameters at this time.

3. Set CONFIRM_TIME to the time, in

confirmation of receiving a report before trying again (the device does not retry if

CONFIRM_TIME is 0).

4. Set LIM_NOTIFY to a value between zero and MAX_NOTIFY. LIM_NOTIFY is the

maximum number of alert reports allowed before the operator needs to acknowledge

an alarm condition.

5. Enable the reports bit in FEATURES_SEL. (When Multi-bit alerts is enabled, every active

alarm is visible for any of the eight sensors, generated by a PlantWeb

Diagnostics alert. This is different than only viewing the highest priority alarm.)

6. Set the resource block to AUTO.

Section 3: Configuration

November 2014

1

/32 of a millisecond, that the device will wait for

®

and Field

For modifying alarms on individual function blocks (AI or ISEL blocks), refer to Appendix D:

Function Blocks.

3.2.6 Damping

Use the following steps to configure the damping, which is located in the transducer function

block:

1. Set Sensor Mode to Out of Service.

2. Change DAMPING to the desired filter rate (0.0 to 32.0 seconds).

3. Set Sensor Mode to In Service.

3.2.7 Configure the differential sensors

Use the following steps to configure the differential sensors:

1. Set Dual Sensor Mode to Out of Service.

2. Set Input A and Input B to the sensor values that are to be used in the differential

equation diff = A–B. (Note: Unit types must be the same.)

3. Set the DUAL_SENSOR_CALC to either Not Used, Absolute, or INPUT A minus INPUT B.

4. Set Dual Sensor Mode to In Service.

Configuration

21

Page 30

Section 3: Configuration

November 2014

3.2.8 Configure measurement validation

Use the following steps to configure measurement validation:

1. Set mode to Disabled for specific sensor.

2. Select sample rate. 1-10 sec/sample is available. 1 second/sample is preferred for

sensor degradation. The higher the number of seconds between samples, the more

emphasis put on process variation.

3. Select Deviation Limit from 0 to 10 units. If deviation limit is exceeded, a status event

will be triggered.

4. Select Increasing Limit. Sets the limit for increasing rate of change. If limit is exceeded, a

status event will be triggered.

5. Select Decreasing Limit. Sets the limit for decreasing rate of change. If li mit is exceeded,

a status event will be triggered.

Note

The decreasing limit selected is required to be a negative value.

Reference Manual

00809-0100-4697, Rev GA

6. Set the Deadband from 0 to 90%. This threshold is used to clear the PV status.

7. Set Status Priority. This determines what happens when the specific limit has been

exceeded. No Alert - Ignores limit settings. Advisory - Sets Advisory Plant Web Alert,

but does not do anything with PV status. Warning - Sets a Maintenance Plant Web Alert

and sets PV status to uncertain. Failure - Sets A Failure Plant Web Alert and sets PV

status to Bad.

8. Set mode to Enabled for specific sensor.

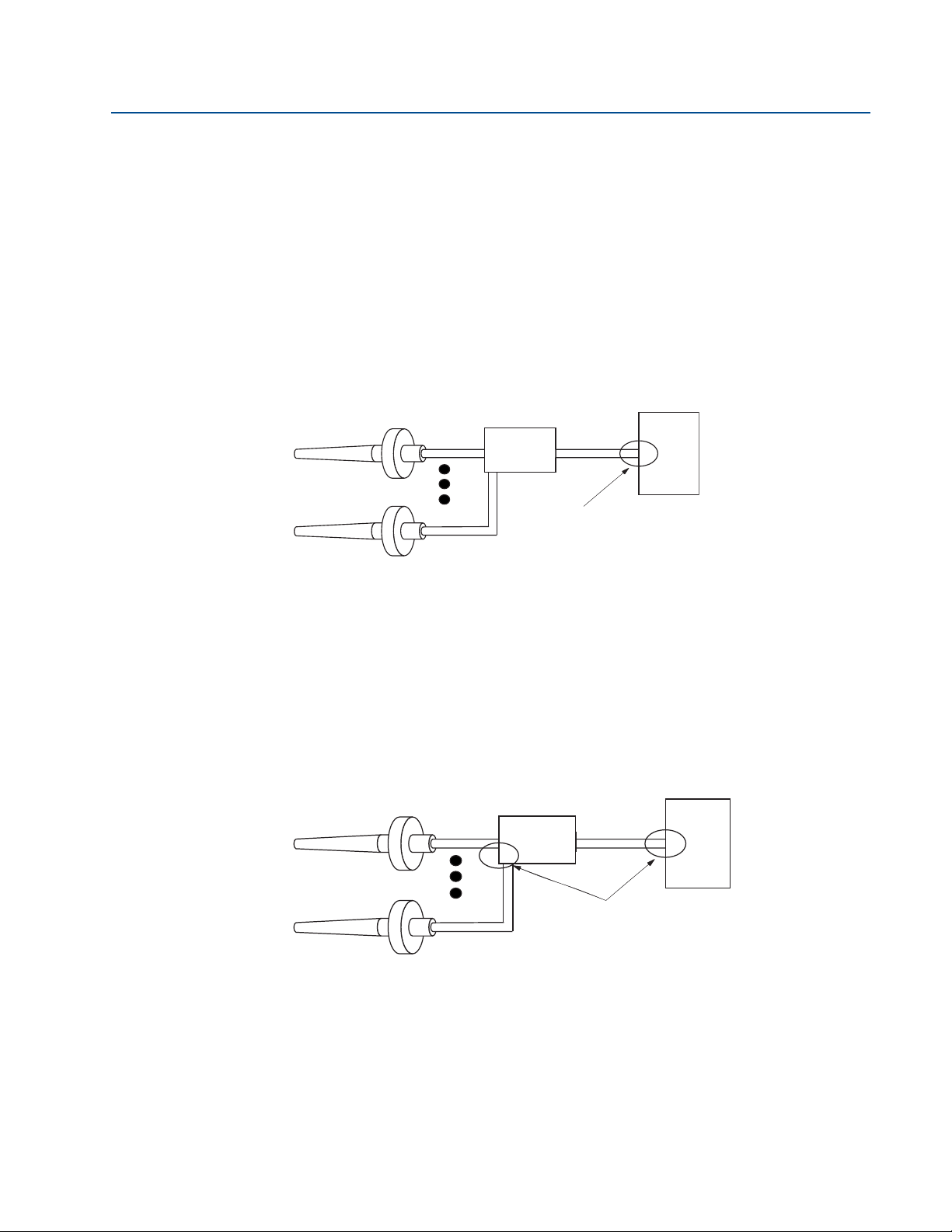

3.3 Common configurations for high density applications

For the application to work properly, configure the links between the function blocks and

schedule the order of their execution. The Graphical User Interface (GUI) provided by the

F

OUNDATION fieldbus host or configuration tool will allow easy configuration.

The measurement strategies shown in this section represent some of the common types of

configurations available in the 848T. Although the appearance of the GUI screens will vary from

host to host, the configuration logic is the same.

Note

Ensure the host system or configuration tool is properly configured before downloading the

transmitter configuration. If configured improperly, the F

configuration tool could overwrite the default transmitter configuration.

OUNDATION fieldbus host or

22

Configuration

Page 31

Reference Manual

MAI

Function

Block

Out_1

Out_2

Out_3

Out_4

Out_5

Out_6

Out_7

Out_8

MAI

Function

Block

Out_1

Out_2

Out_3

Out_4

Out_5

Out_6

Out_7

Out_8

ISEL

Function

Block

IN_1

IN_2

IN_3

IN_4

IN_5

IN_6

IN_7

IN_8

Out

Out_D

00809-0100-4697, Rev GA

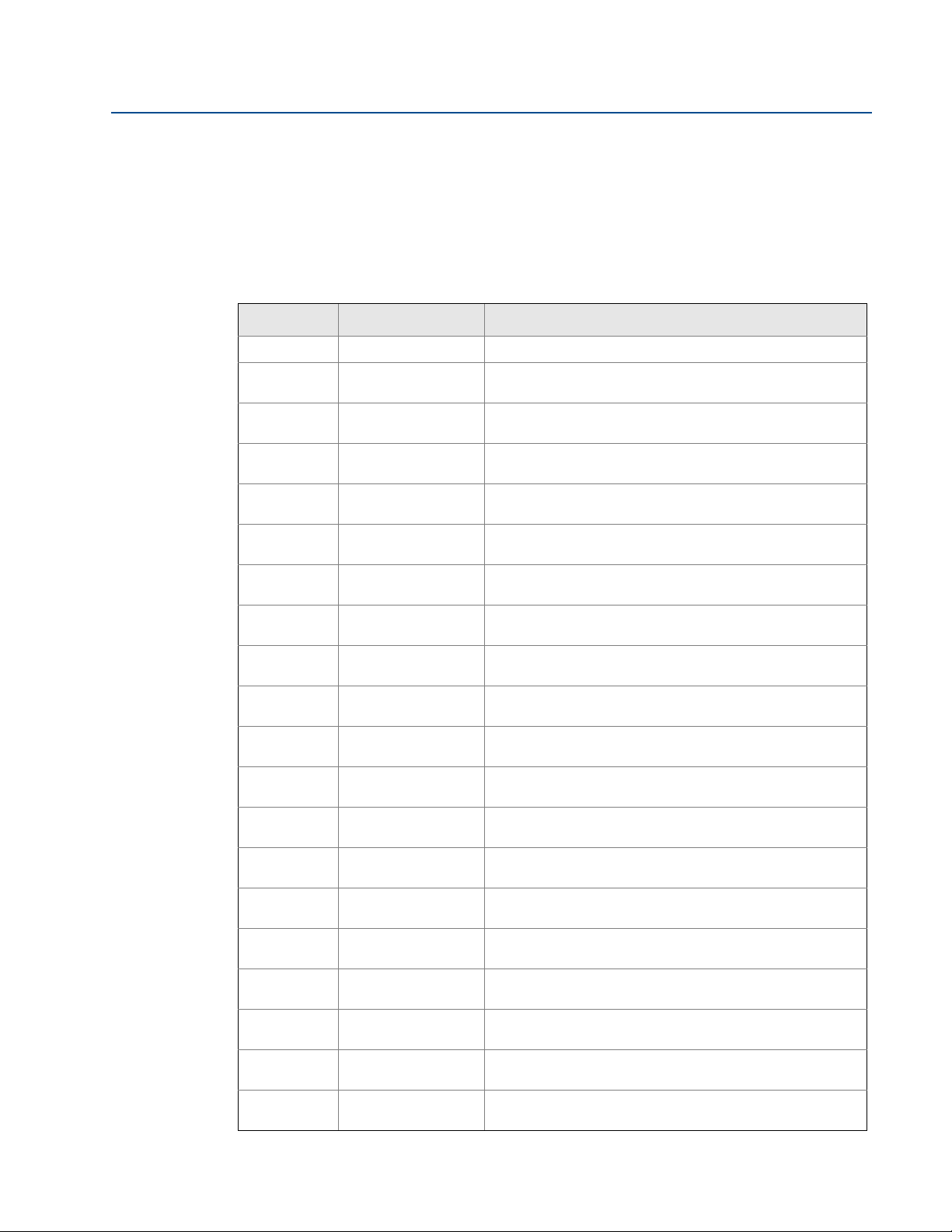

Typical profiling application

Example: Distillation column temperature profile where all channels have the same sensor units

(°C, °F, etc.).

1. Place the Multiple Analog Input (MAI) function block in OOS mode (set

2. Set CHANNEL= “channels 1 to 8.” Although the CHANNEL_X parameters remain

3. Set L_TYPE to direct or indirect.

Section 3: Configuration

November 2014

MODE_BLK.TARGET to OOS).

writable, CHANNEL_X can only be set = X when CHANNEL=1.

4. Set XD_SCALE (transducer measurement scaling) to the appropriate upper and lower

range values, the appropriate sensor units, and display decimal point.

5. Set OUT_SCALE (MAI output scaling) to the appropriate upper and lower range values,

the appropriate sensor units, and display decimal point.

6. Place the MAI Function Block in auto mode.

7. Verify that the function blocks are scheduled.

Monitoring application with a single selection

Example: Average exhaust temperature of gas and turbine where there is a single alarm level for

all inputs.

1. Link the MAI outputs to the ISEL inputs.

2. Place the Multiple Analog Input (MAI) function block in OOS mode (set

MODE_BLK.TARGET to OOS).

Configuration

3. Set CHANNEL= “channels 1 to 8.” Although the CHANNEL_X parameters remain

writable, CHANNEL_X can only be set = X when CHANNEL=1.

4. Set L_TYPE to direct or indirect.

5. Set XD_SCALE (transducer measurement scaling) to the appropriate upper and lower

range values, the appropriate sensor units, and display decimal point.

23

Page 32

Section 3: Configuration

AI

Function

Block 1

Out

AI

Function

Block 8

Out

Out_D

Out_D

November 2014

6. Set OUT_SCALE (MAI output scaling) to the appropriate upper and lower range values,

7. Place the MAI function block in auto mode.

8. Place the Input Selector (ISEL) function block in OOS mode by setting

9. Set OUT_RANGE to match the OUT_SCALE in the MAI block.

10. Set SELECT_TYPE to the desired function (Maximum Value, Minimum Value, First Good

11. Set the alarm limits and parameters if necessary.

12. Place the ISEL function block in auto mode.

13. Verify that the function blocks are scheduled.

Measuring temperature points individually

Example: Miscellaneous monitoring of temperature in a “close proximity” where each channel

can have different sensor inputs with different units and there are independent alarm levels for

each input.

Reference Manual

00809-0100-4697, Rev GA

the appropriate sensor units, and display decimal point.

MODE_BLK.TARGET to OOS.

Value, Midpoint Value, or Average Value).

24

1. Place the first Analog Input (AI) function block in OOS mode (set MODE_BLK.TARGET to

OOS).

2. Set CHANNEL to the appropriate channel value. Refer to “Alarm Priority Levels” on

page 31 for a listing of channel definitions.

3. Set L_TYPE to direct.

4. Set XD_SCALE (transducer measurement scaling) to the appropriate upper and lower

range values, the appropriate sensor units, and display decimal point.

5. Set OUT_SCALE (AI output scaling) to the appropriate upper and lower range values,

the appropriate sensor units, and display decimal point.

6. Set the alarm limits and parameters if necessary.

7. Place the AI function block in auto mode.

8. Repeat steps 1 through 7 for each AI function block.

9. Verify that the function blocks are scheduled.

Configuration

Page 33

Reference Manual

00809-0100-4697, Rev GA

Section 3: Configuration

November 2014

3.3.1 Interfacing analog transmitters to FOUNDATION fieldbus

Transducer block configuration

Use the sensor configuration method to set the sensor type to mV – 2-wire for the applicable

transducer block or follow these steps.

1. Set the MODE_BLK.TARGET to OOS mode, or set the SENSOR_MODE to configuration.

2. Set the SENSOR to mV.

3. Set the MODE_BLK.TARGET to AUTO, or set the SENSOR_MODE to operation.

Multiple analog input or analog input block configuration

Follow these steps to configure the applicable block.

1. Set the MODE_BLK.TARGET to OOS mode, or set the SENSOR_MODE to configuration.

2. Set CHANNEL to the transducer block configured for the analog input.

3. Set XD_SCALE.EU_0 to 20

Set XD_SCALE.EU_100 to 100

Set XD_SCALE.ENGUNITS to mV

4. SET OUT_SCALE to match the desired scale and units for the connected analog

transmitter.

Flow Example: 0 – 200 gpm

OUT_SCALE.EU_0 = 0

OUT_SCALE.EU_100 = 200

OUT_SCALE.ENGUNITS = gpm

5. Set L_TYPE to INDIRECT.

6. Set the MODE_BLK.TARGET to AUTO, or set the SENSOR_MODE to operation.

3.4 Block configuration

3.4.1 Resource block

The resource block defines the physical resources of the device including type of measurement,

memory, etc. The resource block also defines functionality, such as shed times, that is common

across multiple blocks. The block has no linkable inputs or outputs and it performs

memory-level diagnostics.

Table 3-2. Resource Block Parameters

Number Parameter Description

01 ST_REV The revision level of the static data associated with the function block.

02 TA G_D ES C The user description of the intended application of the block.

03 STRATEGY The strategy field can be used to identify grouping of blocks.

04 ALERT_KEY The identification number of the plant unit.

05 MODE_BLK The actual, target, permitted, and normal modes of the block. For further

06 BLOCK_ERR This parameter reflects the error status associated with the hardware or software

description, see the Mode parameter formal model in FF-890.

components associated with a block. Multiple errors may be shown. For a list of

enumeration values, see FF-890, Block_Err formal model.

Configuration

25

Page 34

Section 3: Configuration

November 2014

Reference Manual

00809-0100-4697, Rev GA

Table 3-2. Resource Block Parameters

Number Parameter Description

07 RS_STATE State of the function block application state machine. For a list of enumeration

08 TEST_RW Read/write test parameter - used only for conformance testing.

09 DD_RESOURCE String identifying the tag of the resource which contains the Device Description for

10 MANUFAC_ID Manufacturer identification number - used by an interface device to locate the DD

11 DEV_TYPE Manufacturer's model number associated with the resource - used by interface

12 DEV_REV Manufacturer revision number associated with the resource - used by an interface

13 DD_REV Revision of the DD associated with the resource - used by the interface device to

14 GRANT_DENY Options for controlling access of host computer and local control panels to

15 HARD_TYPES The types of hardware available as channel numbers. The supported hardware

16 RESTART Allows a manual restart to be initiated.

17 FEATURES Used to show supported resource block options. The supported features are:

18 FEATURE_SEL Used to select resource block options.

19 CYCLE_TYPE Identifies the block execution methods available for this resource. The supported

20 CYCLE_SEL Used to select the block execution method for this resource.

21 MIN_CYCLE_T Time duration of the shortest cycle interval of which the resource is capable.

22 MEMORY_SIZE Available configuration memory in the empty resource. To be checked before

23 NV_CYCLE_T Minimum time interval specified by the manufacturer for writing copies of NV

24 FREE_SPACE Percent of memory available for further configuration. Zero in preconfigured

25 FREE_TIME Percent of the block processing time that is free to process additional blocks.

26 SHED_RCAS Time duration at which to give up on computer writes to function block RCas

27 SHED_ROUT Time duration at which to give up on computer writes to function block ROut

28 FAULT _STAT E Condition set by loss of communication to an output block, fault promoted to an

29 SET_FSTATE Allows the FAIL_SAFE condition to be manually initiated by selecting Set.

30 CLR_FSTATE Writing a Clear to this parameter will clear the device FAIL_SAFE if the field

31 MAX_NOTIFY Maximum number of unconfirmed notify messages possible.

values, see FF-890.

the resource.

file for the resource.

devices to locate the DD file for the resource.

device to locate the DD file for the resource.

locate the DD file for the resource.

operating, tuning and alarm parameters of the block.

type is: SCALAR_INPUT

1) Run: This is passive state of this parameter.

2) Restart resource: To clear up the problems like garbage collection.

3) Restart with defaults: reset all configurable function block application objects to

their initial value i.e. their value before any configuration was done by the user.

This will also remove appended serial numbers of function block tags

4) Restart processor: provides a way to hit the reset button on the processor

associated with the resource.

5) Restart to append serial number: Appends serial number to function block tags.

11) Restart default blocks: defaults manufacturer pre-instantiated blocks.

SOFT_WRITE_LOCK_SUPPORT, HARD_WRITE_LOCK_SUPPORT, REPORTS,

UNICODE, MULTI_BIT_ALARM_SUPPORT and FB_ACTION_RESTART_RELINK

cycle types are: SCHEDULED, and COMPLETION_OF_BLOCK_EXECUTION

attempting a download.

parameters to non-volatile memory. Zero means it will never be automatically

copied. At the end of NV_CYCLE_T, only those parameters which have changed

need to be updated in NVRAM.

resource.

locations. Shed from RCas will never happen when SHED_RCAS = 0.

locations. Shed from ROut will never happen when SHED_ROUT = 0.

output block or physical contact. When FAIL_SAFE condition is set, then output

function blocks will perform their FAIL_SAFE actions.

condition has cleared.

26

Configuration

Page 35

Reference Manual

00809-0100-4697, Rev GA

Section 3: Configuration

November 2014

Table 3-2. Resource Block Parameters

Number Parameter Description

32 LIM_NOTIFY Maximum number of unconfirmed alert notify messages allowed.

33 CONFIRM_TIME The time the resource will wait for confirmation of receipt of a report before trying

34 WRITE_LOCK If set, all writes to static and non-volatile parameters are prohibited, except to clear

35 UPDATE_EVT This alert is generated by any change to the static data.

36 BLOCK_ALM The BLOCK_ALM is used for all configuration, hardware, connection failure or

37 ALARM_SUM The current alert status, unacknowledged states, unreported states, and disabled

38 ACK_OPTION Selection of whether alarms associated with the block will be automatically

39 WRITE_PRI Priority of the alarm generated by clearing the write lock.

40 WRITE_ALM This alert is generated if the write lock parameter is cleared.

41 ITK_VER Major revision number of the interoperability test case used in certifying this

42 FD_VER This parameter's value equals the value of the major version of the Field

43 FD_FAIL_ACTIVE Reflects the error conditions that are being detected as active as selected for this

44 FD_OFFSPEC_ACTIVE Reflects the error conditions that are being detected as active as selected for this

45 FD_MAINT_ACTIVE Reflects the error conditions that are being detected as active as selected for this

46 FD_CHECK_ACTIVE Reflects the error conditions that are being detected as active as selected for this

47 FD_FAIL_MAP Maps conditions to be detected as active for this alarm category. Thus the same

48 FD_OFFSPEC_MAP Maps conditions to be detected as active for this alarm category. Thus the same

49 FD_MAINT_MAP Maps conditions to be detected as active for this alarm category. Thus the same

50 FD_CHECK_MAP Maps conditions to be detected as active for this alarm category. Thus the same

51 FD_FAIL_MASK Allows the user to suppress any single or multiple conditions that are active, in this

52 FD_OFFSPEC_MASK Allows the user to suppress any single or multiple conditions that are active, in this

53 FD_MAINT_MASK Allows the user to suppress any single or multiple conditions that are active, in this

54 FD_CHECK_MASK Allows the user to suppress any single or multiple conditions that are active, in this

again. Retry will not happen when CONFIRM_TIME=0.

WRITE_LOCK. Block inputs will continue to be updated.

system problems in the block. The cause of the alert is entered in the subcode field.

The first alert to become active will set the Active status in the Status attribute. As

soon as the Unreported status is cleared by the alert reporting task, another block

alert may be reported without clearing the Active status, if the subcode has

changed.

states of the alarms associated with the function block.

acknowledged.

device as interoperable. The format and range are controlled by the fieldbus

FOUNDATION.

Diagnostics specification that this device was designed to.

category. It is a bit string, so that multiple conditions may be shown.

category. It is a bit string, so that multiple conditions may be shown.

category. It is a bit string, so that multiple conditions may be shown.

category. It is a bit string, so that multiple conditions may be shown.

condition may be active in all, some, or none of the 4 alarm categories.

condition may be active in all, some, or none of the 4 alarm categories.

condition may be active in all, some, or none of the 4 alarm categories.

condition may be active in all, some, or none of the 4 alarm categories.

category, from being broadcast to the host through the alarm parameter. A bit

equal to ‘1’ will mask i.e. inhibit the broadcast of a condition, and a bit equal to ‘0’

will unmask i.e. allow broadcast of a condition.

category, from being broadcast to the host through the alarm parameter. A bit

equal to ‘1’ will mask i.e. inhibit the broadcast of a condition, and a bit equal to ‘0’

will unmask i.e. allow broadcast of a condition.

category, from being broadcast to the host through the alarm parameter. A bit

equal to ‘1’ will mask i.e. inhibit the broadcast of a condition, and a bit equal to ‘0’

will unmask i.e. allow broadcast of a condition.

category, from being broadcast to the host through the alarm parameter. A bit

equal to ‘1’ will mask i.e. inhibit the broadcast of a condition, and a bit equal to ‘0’

will unmask i.e. allow broadcast of a condition.

Configuration

27

Page 36

Section 3: Configuration

November 2014

Reference Manual

00809-0100-4697, Rev GA

Table 3-2. Resource Block Parameters

Number Parameter Description

55 FD_FAIL_ALM Used primarily to broadcast a change in the associated active conditions, which are

56 FD_OFFSPEC_ALM Used primarily to broadcast a change in the associated active conditions, which are

57 FD_MAINT_ALM Used primarily to broadcast a change in the associated active conditions, which are

58 FD_CHECK_ALM Used primarily to broadcast a change in the associated active conditions, which are

59 FD_FAIL_PRI Allows the user to specify the priority of this alarm category.

60 FD_OFFSPEC_PRI Allows the user to specify the priority of this alarm category.

61 FD_MAINT_PRI Allows the user to specify the priority of this alarm category.

62 FD_CHECK_PRI Allows the user to specify the priority of this alarm category.

63 FD_SIMULATE Allows the conditions to be manually supplied when simulation is enabled. When

64 FD_RECOMMEN_ACT A device enumerated summarization of the most severe condition or conditions

65 FD_EXTENDED_ACTIVE_1 An optional parameter or parameters to allow the user finer detail on conditions

66 FD_EXTENDED_MAP_1 An optional parameter or parameters to allow the user finer control on enabling

67 COMPATIBILITY_REV Optionally used when replacing field devices. The correct usage of this parameter

68 HARDWARE_REVISION Manufacturer hardware revision

69 SOFTWARE_REV Manufacturer hardware revision

70 PD_TAG PD tag description of device

71 DEV_STRING Used to load new licensing into the device. The value can be written but will always

72 DEV_OPTIONS Indicates which miscellaneous and diagnostic device licensing options are enabled.

73 OUTPUT_BOARD_SN Output board serial number

74 FINAL_ASSY_NUM Same final assembly number placed on the neck label

75 DOWNLOAD_MODE Gives access to the boot block code for over the wire downloads

76 HEALTH_INDEX Parameter shall be set based on the active FD alarms or PWA alarms.

77 FAI LE D_P RI Designates the alarming priority of the FAILED_ALM and also used as switch b/w FD

78 RECOMMENDED_ACTION Enumerated list of recommended actions displayed with a device alert

79 FA ILE D_A LM Alarm indicating a failure within a device which makes the device non-operational

80 MAINT _ALM Alarm indicating the device needs maintenance soon. If the condition is ignored,

81 ADVISE _ALM Alarm indicating advisory alarms. These conditions do not have a direct impact on

not masked, for this alarm category to a Host System.

not masked, for this alarm category to a Host System.

not masked, for this alarm category to a Host System.

not masked, for this alarm category to a Host System.

simulation is disabled both the diagnostic simulate value and the diagnostic value

track the actual conditions. The simulate jumper is required for simulation to be

enabled and while simulation is enabled the recommended action will show that

simulation is active.

detected. The DD help should describe by enumerated action, what should be

done to alleviate the condition or conditions. 0 is defined as Not Initialized, 1 is

defined as No Action Required, all others defined by manufacturer.

causing an active condition in the FD_*_ACTIVE parameters.

conditions contributing to the conditions in FD_*_ACTIVE parameters.

presumes the COMPATIBILIT Y_REV value of the replacing device should be equal or

lower than the DEV_REV value of the replaced device.

read back with a value of 0.

It also indicates Transducer options.

HEALTH_INDEX will show 100 if target mode of block is OOS or there are no active

alarms in device. The table below represents HEALTH_INDEX value when FD or

PWA alarms are active in a device.

and legacy PWA. If value is greater than or equal to 1 then PWA alerts will be active

in device else device will have FD alerts.

the device will eventually fail.

the process or device integrity.

28

Configuration

Page 37

Reference Manual

00809-0100-4697, Rev GA

Section 3: Configuration

November 2014

Table 3-2. Resource Block Parameters

Number Parameter Description

82 FAI LE D_E NA BLE Enabled FAILED_ALM alarm conditions. Corresponds bit for bit to the

83 FA ILE D_M AS K Mask of Failure Alarm. Corresponds bit for bit to the FAILED_ACTIVE. A bit on

84 FAI LED _AC TI VE Enumerated list of failure conditions within a device. All open bits are free to be

85 MAINT_PRI Designates the alarming priority of the MAINT_ALM

86 MAINT_ENABLE Enabled MAINT_ALM alarm conditions. Corresponds bit for bit to the

87 MAINT_MASK Mask of Maintenance Alarm. Corresponds bit for bit to the MAINT_ACTIVE. A bit on

88 MAINT_ACTIVE Enumerated list of maintenance conditions within a device. All open bits are free to

89 ADVISE_PRI Designates the alarming priority of the ADVISE_ALM

90 ADVISE_ENABLE Enabled ADVISE_ALM alarm conditions. Corresponds bit for bit to the

91 ADVISE_MASK Mask of Advisory Alarm. Corresponds bit for bit to the ADVISE_ACTIVE. A bit on

92 ADVISE_ACTIVE Enumerated list of advisory conditions within a device. All open bits are free to be

FAILED_ACTIVE. A bit on means that the corresponding alarm condition is enabled

and will be detected. A bit off means the corresponding alarm condition is disabled

and will not be detected. This parameter is the Read Only copy of FD_FAIL_MAP.

means that the failure is masked out from alarming. This parameter is the Read

Only copy of FD_FAIL_MASK.

used as appropriate for each specific device.This parameter is the Read Only copy

of FD_FAIL_ACTIVE.

MAINT_ACTIVE. A bit on means that the corresponding alarm condition is enabled

and will be detected. A bit off means the corresponding alarm condition is disabled

and will not be detected.This parameter is the Read Only copy of

FD_OFFSPEC_MAP.

means that the failure is masked out from alarming.This parameter is the Read

Only copy of FD_OFFSPEC_MASK.

be used as appropriate for each specific device. This parameter is the Read Only

copy of FD_OFFSPEC_ACTIVE.

ADVISE_ACTIVE. A bit on means that the corresponding alarm condition is enabled

and will be detected. A bit off means the corresponding alarm condition is disabled

and will not be detected.This parameter is the Read Only copy of FD_MAINT_MAP

& FD_CHECK_MAP.

means that the failure is masked out from alarming.This parameter is the Read

Only copy of FD_MAINT_MASK & FD_CHECK_MASK.

used as appropriate for each specific device. This parameter is the Read Only copy

of FD_MAINT_ACTIVE & FD_CHECK_ACTIVE.

Configuration

29

Page 38

Section 3: Configuration

November 2014

Block errors

The table below lists conditions reported in the BLOCK_ERR parameter.

Table 3-3. BLOCK_ERR Conditions

Number

0 Other

1 Block Configuration Error: A feature in CYCLE_SEL is set that is not supported by

Reference Manual

00809-0100-4697, Rev GA

Name and description

CYCLE_TYPE.

3 Simulate Active: This indicates that the simulation jumper is in place. This is not an

6 Device needs maintenance soon

7 Input failure/process variable has bad status

9 Memory Failure: A memory failure has occurred in FLASH, RAM, or EEPROM memory.

10 Lost Static Data: Static data that is stored in non-volatile memory

11 Lost NV Data: Non-volatile data that is stored in non-volatile memory

13 Device Needs Maintenance Now

14 Power Up: The device was just powered-up.

15 OOS: The actual mode is out of service.

indication that the I/O blocks are using simulated data.

has been lost.

has been lost.

Modes

The resource block supports two modes of operation as defined by the MODE_BLK parameter:

Automatic (Auto)

The block is processing its normal background memory checks.

Out of service (OOS)

30

The block is not processing its tasks. When the resource block is in OOS, all blocks within

the resource (device) are forced into OOS. The BLOCK_ERR parameter shows Out of

Service. In this mode, changes can be made to all configurable parameters. The target

mode of a block may be restricted to one or more of the supported modes.

Alarm detection

A block alarm will be generated whenever the BLOCK_ERR has an error bit set. The types of

block error for the resource block are defined above. A write alarm is generated whenever the

WRITE_LOCK parameter is cleared. The priority of the write alarm is set in the following

parameter:

WRITE_PRI

Configuration

Page 39

Reference Manual

00809-0100-4697, Rev GA

Table 3-4. Alarm Priority Levels

Section 3: Configuration

November 2014

Number Description

0 The priority of an alarm condition changes to 0 after the condition that caused the

1 An alarm condition with a priority of 1 is recognized by the system, but is not reported

2 An alarm condition with a priority of 2 is reported to the operator, but does not require

3-7 Alarm conditions of priority 3 to 7 are advisory alarms of increasing priority.

8-15 Alarm conditions of priority 8 to 15 are critical alarms of increasing priority.

alarm is corrected.

to the operator.

operator attention (such as diagnostics and system alerts).

Status handling

There are no status parameters associated with the resource block.

3.4.2 Field Diagnostics & PlantWeb Alerts

The 848T ITK6 has two mechanisms for alarms, one is Field Diagnostics (FD) and other is

PlantWeb Alerts (PWA) for backward compatibility only.

The flexible capability has been added to allow user to select any alarm to be in the PWA

FAILED/FD FAILED group or PWA MAINTENANCE/FD OFFSPEC group or PWA ADVISE/FD

MAINTENANCE group or PWA ADVISE/FD CHECK group.

In PlantWeb Alerts, the alarms can be represented in three groups i.e. FAILED, MAINT & ADVISE.

In Field Diagnostic, the alarms can be represented in four groups i.e. FAILED, OFFSPEC, MAINT &

CHECK.

Parameter FAILED_PRI is used as a switch for using Field Diagnostic and PlantWeb Alerts.

How to use Field Diagnostic Alarm

If FAILED_PRI is equal to 0, Field Diagnostic alarms are supported and PlantWeb alarms are not.

Field Diagnostic functionality includes four different Field Diagnostic Alarms such as

FD_FAIL_ALM, FD_OFFSPEC_ALM, FD_MAINT_ALM and FD_CHECK_ALM. For these alarms,

there are corresponding alarm priority parameter, masking parameter alarm active and alarm

mapping parameter such as FD_*_PRI, FD_*_MASK & FD_*_ACTIVE & FD_*_MAP.

How to use PlantWeb Alarm

If FAILED_PRI is greater than 0, PlantWeb alarms are supported and Field Diagnostic are not.

PlantWeb functionality includes three different PlantWeb Alarms FAILED_ALM, MAINT_ ALM

and ADVISE_ ALM. For PlantWeb Alerts, there are corresponding alarm masking parameter,

alarm active parameter and alarm mapping parameter such as *_MASK, *_ACTIVE & *_ENABLE.

These parameters have Read only access and are duplicated from corresponding FD parameters.

So for example, in case of PWA alarms, if user wishes to change the mapping of any PlantWeb

Alerts then the new value is written to the corresponding FD_*_MAP parameter. *_ENABLE shall

reflect whatever is being written to FD_*_MAP parameter. The same applies for *_MASK

parameters.

Note

Here * implies all 4 categories of FD alerts for e.g. FD_*_ACTIVE resembles FD_FAIL_ACTIVE,

FD_OFFSPEC_ACTIVE, FD_MAINT_ACTIVE & FD_CHECK ACTIVE.

The similar notation is also applicable for PWA alarms for e.g. FD_*_ACTIVE resembles

FAIL_ACTIVE, MAINT_ACTIVE & ADVISE ACTIVE.

Configuration

31

Page 40

Section 3: Configuration

November 2014

3.4.3 PlantWeb alerts

The alerts and recommended actions should be used in conjunction with “Operation and

Maintenance” on page 53.

The Resource Block will act as a coordinator for PlantWeb alerts. There will be three alarm

parameters (FAILED_ALARM, MAINT_ALARM, and ADVISE_ALARM) which will contain