Rosemount Analytical

M

ODEL

O

XYGEN ANALYZER

I

NSTRUCTION MANUAL

748213-R

755R

OTICE

N

The information contained in this document is subject to change without notice.

Paliney No. 7™ is a trademark of J.M. Ney Co., Hartford, CT.

Viton-A

Teflon

®

is registered a trademark of E.I. duPont de Nemours and Co. Inc.

®

is a registered trademark of E.I. duPont de Nemours and Co., Inc.

Manual Part Number 748213-R

April 2000

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

C

ONTENTS

PREFACE

INTENDED USE STATEMENT..........................................................................P-1

SAFETY SUMMARY ..........................................................................................P-1

SPECIFICATIONS - PERFORMANCE...............................................................P-3

SPECIFICATIONS - SAMPLE............................................................................P-3

SPECIFICATIONS - ELECTRICAL ....................................................................P-4

SPECIFICATIONS - PHYSICAL.........................................................................P-4

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE....P-5

RETURNING PARTS TO THE FACTORY.........................................................P-5

TRAINING ......................................................................................................P-5

DOCUMENTATION............................................................................................P-5

COMPLIANCES .................................................................................................P-6

SECTION 1. INTRODUCTION

1.1 DESCRIPTION..........................................................................................1-1

1.2 RECORDER OUTPUT RANGE ................................................................1-2

1.3 MOUNTING ..............................................................................................1-2

1.4 ISOLATED CURRENT OUTPUT ..............................................................1-2

1.5 ALARM OPTION .......................................................................................1-2

1.6 ELECTRICAL OPTIONS ...........................................................................1-2

1.7 REMOTE RANGE CHANGE OPTION ......................................................1-2

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

i

ONTENTS

C

SECTION 2. INSTALLATION

2.1 FACILITY PREPARATION........................................................................ 2-1

2.1.1 Installation Drawings..................................................................... 2-1

2.1.2 Electrical Interconnection Diagram................................................ 2-1

2.1.3 Flow Diagram................................................................................ 2-1

2.1.4 Location and Mounting.................................................................. 2-1

2.2 CALIBRATION GAS REQUIREMENTS.................................................... 2-2

2.2.1 Zero Standard Gas........................................................................ 2-3

2.2.2 Span Standard Gas....................................................................... 2-3

2.3 SAMPLE HANDLING ............................................................................... 2-3

2.3.1 Sample Temperature Requirements.......................................... 2-4

2.3.2 Sample Pressure Requirements: General.................................. 2-4

2.3.3 Normal Operation at Positive Gauge Pressures......................... 2-4

2.3.4 Operation at Negative Gauge Pressures....................................2-5

2.3.5 Sample Flow Rate...................................................................... 2-5

2.3.6 Materials in Contact with Sample............................................... 2-6

2.3.7 Corrosive Gases......................................................................... 2-6

2.3.8 Leak Test ................................................................................... 2-6

2.4 ELECTRICAL CONNECTIONS ................................................................ 2-7

2.4.1 Line Power Connections ............................................................ 2-7

2.4.2 Recorder Output Selection and Cable Connections................... 2-8

2.4.2.1 Potentiometric Output................................................. 2-8

2.4.2.2 Isolated Current Output (Optional)............................. 2-9

2.4.3 Output Connections and Initial Setup for Dual Alarm Option..... 2-10

2.5 REMOTE RANGE CHANGE OPTION...................................................... 2-14

SECTION 3. STARTUP AND CALIBRATION

3.1 OVERVIEW .............................................................................................. 3-1

3.2 OPERATING RANGE SELECTION.......................................................... 3-1

3.3 STARTUP PROCEDURE ......................................................................... 3-1

3.4 CALIBRATION.......................................................................................... 3-1

3.4.1 Calibration with Zero and Span Standard Gases....................... 3-2

3.5 COMPENSATION FOR COMPOSITION OF BACKGROUND GAS........ 3-2

3.5.1 Oxygen Equivalent Value of Gases............................................ 3-4

3.5.2 Computing Adjusted Settings for Zero and Span Controls......... 3-5

3.6 SELECTION OF SETPOINTS AND DEADBAND ON ALARM OPTION . 3-7

3.7 CURRENT OUTPUT BOARD (OPTION)................................................. 3-7

ii

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

SECTION 4. OPERATION

4.1 ROUTINE OPERATION ............................................................................4-1

4.2 EFFECT OF BAROMETRIC PRESSURE CHANGES ON INSTRUMENT

READOUT.....................................................................................4-1

4.3 CALIBRATION FREQUENCY...................................................................4-2

ONTENTS

C

S

ECTION

5.1 PRINCIPLES OF OPERATION.................................................................5-1

5.2 VARIABLES INFLUENCING PARAMAGNETIC OXYGEN

5.3 ELECTRONIC CIRCUITRY.......................................................................5-4

S

ECTION

6.1 CIRCUIT OPERATION..............................................................................6-1

6.2 ±15 VDC POWER SUPPLY .....................................................................6-1

6.3 CASE HEATER CONTROL CIRCUIT ......................................................6-1

6.4 DETECTOR HEATER CONTROL CIRCUIT ............................................6-6

5. T

5.2.1 Pressure Effects .........................................................................5-2

5.3.1 Detector/Magnet Assembly.........................................................5-4

5.3.2 Control Board and Associated Circuitry......................................5-6

5.3.3 Power Supply Board Assembly...................................................5-7

5.3.4 Isolated Current Output Board (Optional)...................................5-8

6. C

HEORY

MEASUREMENTS........................................................................5-2

IRCUIT ANALYSIS

6.5 DETECTOR LIGHT SOURCE CONTROL CIRCUIT................................6-7

6.6 DETECTOR WITH FIRST STAGE AMPLIFIER.......................................6-8

6.7 BUFFER AMPLIFIERS U8, U10 WITH ASSOCIATED ANTICIPATION

FUNCTION....................................................................................6-11

6.8 DIGITAL OUTPUT CIRCUIT ....................................................................6-11

6.9 ANALOG OUTPUT CIRCUITS FOR RECORDER ALARMS ...................6-12

6.9.1 First Stage Amplifier....................................................................6-12

6.9.2 Second Stage Amplifier..............................................................6-12

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

iii

ONTENTS

C

SECTION 7. SERVICE AND MAINTENANCE

7.1 INITIAL CHECKOUT WITH STANDARD GASES ................................... 7-1

7.1.1 Control Board Checkout............................................................. 7-2

7.2 HEATING CIRCUITS............................................................................... 7-3

7.2.1 Case Heater Control Circuit ....................................................... 7-3

7.2.2 Detector/Magnet Heating Circuit................................................ 7-3

7.3 DETECTOR CHECK................................................................................ 7-4

7.3.1 Source Lamp.............................................................................. 7-5

7.3.2 Photocells................................................................................... 7-6

7.3.3 Suspension ................................................................................ 7-6

7.4 REPLACEMENT OF DETECTOR/MAGNET ASSEMBLY

COMPONENTS............................................................................ 7-6

7.4.1 Source Lamp.............................................................................. 7-6

7.4.2 Photocell .................................................................................... 7-6

7.4.3 Detector ..................................................................................... 7-8

7.5 CONTROL BOARD SETUP..................................................................... 7-9

SECTION

8.1 CIRCUIT BOARD REPLACEMENT POLICY........................................... 8-1

8.2 SELECTED REPLACEMENT PARTS..................................................... 8-1

ENERAL PRECAUTIONS FOR HANDLING

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

8.

REPLACEMENT PARTS

TORING HIGH PRESSURE CYLINDERS

& S

iv

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

FIGURES

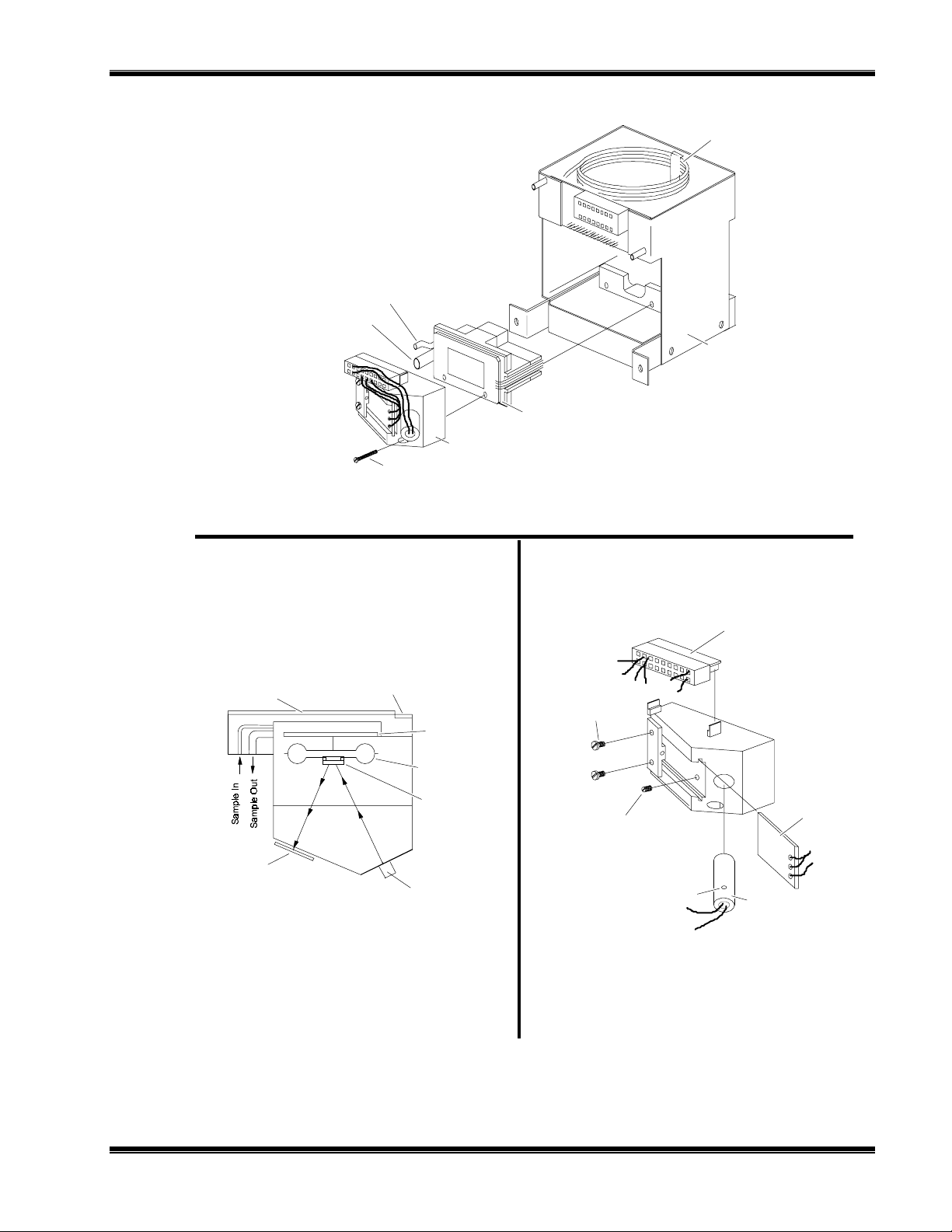

1-1 Model 755R Oxygen Analyzer..................................................................1-1

2-1 Interconnection of Typical Gas Manifold to Model 755R..........................2-3

2-2 Model 755R Rear Panel...........................................................................2-7

2-3 Connections for Potentiometric Recorder with Non-Standard Span.........2-8

2-4 Model 755R Connected to Several Current Activated Output Devices ....2-9

2-5 Relay Terminal Connections for Typical Fail Safe Applications ...............2-10

2-6 Typical Alarm Settings..............................................................................2-13

2-7 Alarm Relay Assembly Schematic Diagram.............................................2-13

3-1 Control Board Adjustments ......................................................................3-3

3-2 Dial Settings for Alarm Setpoint Adjustments...........................................3-8

5-1 Functional Diagram of 755R Paramagnetic O2 Measurement System.....5-3

5-2 Spherical Body in Non-Uniform Magnetic Field........................................5-4

5-3 Detector/Magnet Assembly......................................................................5-5

6-1 Two-Comparator OR Circuit.....................................................................6-3

6-2 Case Heater Control Circuit......................................................................6-3

6-3 Ramp Generator Circuit............................................................................6-4

6-4 Detector Heater Control Circuit ................................................................6-7

6-5 Detector Light Source Control Circuit.......................................................6-8

6-6 Detector with First Stage Amplifier...........................................................6-10

6-7 Buffer, Anticipation, and Digital Output Circuits........................................6-11

6-8 Simplified Analog Recorder Output Circuit...............................................6-13

7-1 Detector/Magnet Assembly......................................................................7-4

7-2 Pin/Lead Removal....................................................................................7-5

7-3 Detector Optical Bench ............................................................................7-5

7-4 Lamp Replacement..................................................................................7-7

ONTENTS

C

TABLES

3-1 Calibration Range for Various Zero-Based Operating Ranges.................3-4

3-2 Oxygen Equivalents of Common Gases...................................................3-6

D

RAWINGS (LOCATED IN REAR OF MANUAL

617186 Schematic Diagram, Power Supply Board

620434 Schematic Diagram, Isolated V/I Board

646090 Schematic Diagram, Remote Range Board

652826 Schematic Diagram, Control Board

654014 Pictorial Wiring Diagram, Model 755R

654015 Installation Drawing, Model 755R

656081 Instructions, Remote Range Selection

748213-R Rosemount Analytical April 2000

)

Model 755R Oxygen Analyzer

v

ONTENTS

C

NOTES

vi

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

P

REFACE

INTENDED USE STATEMENT

The Model 755R is intended for use as an industrial process measurement device

only. It is not intended for use in medical, diagnostic, or life support applications, and

no independent agency certifications or approvals are to be implied as covering such

applications.

S

AFETY SUMMARY

To avoid explosion, loss of life, personal injury and damage to this equipment and

on-site property, all personnel authorized to install, operate and service the Model

755R Analyzer should be thoroughly familiar with and strictly follow the instructions in

this manual. Save these instructions.

DANGER is used to indicate the presence of a hazard which will cause severe

personal injury, death, or substantial property damage if the warning is ignored

WARNING is used to indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION is used to indicate the presence of a hazard which will or can cause minor

personal injury or property damage if the warning is ignored.

NOTE is used to indicate installation, operation, or maintenance information which is

important but not hazard-related.

WARNING: ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to

live parts which can cause death or serious injury. Refer servicing to qualified

personnel.

For safety and proper performance this instrument must be connected to a

properly grounded three-wire source of power.

Optional alarm switching relay contacts wired to separate power sources must

be disconnected before servicing.

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

P-1

REFACE

P

WARNING: POSSIBLE EXPLOSION HAZARD

This analyzer is of a type capable of analysis of sample gases which may be

flammable. If used for analysis of such gases, internal leakage of sample could

result in an explosion causing death, personal injury, or property damage. Do

not use this analyzer on flammable samples. Use explosion-proof version

instruments for analysis of flammable samples.

WARNING: PARTS INTEGRITY

Tampering or unauthorized substitution of components may adversely affect

safety of this product. Use only factory documented components for repair

CAUTION: HIGH PRESSURE GAS CYLINDERS

This analyzer requires periodic calibration with known zero and standard gases.

Refer to Sections 2.2 and 2.3. See also General Precautions for Handling and

Storing High Pressure Cylinders, following Section 7.

This instrument’s internal pullout chassis is equipped with a safety stop latch

located on the left side of the chassis.

When extracting the chassis, verify that the safety latch is in its proper (counterclockwise) orientation.

If access to the rear of the chassis is required, the safety stop may be

overridden by lifting the latch; however, further extraction must be done very

carefully to insure the chassis does not fall out of its enclosure.

CAUTION: TOPPLI N G HA ZARD

If the instrument is located on top of a table or bench near the edge, and the

chassis is extracted, it must be supported to prevent toppling.

P-2

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

REFACE

P

SPECIFICATIONS

OPERATING RANGE (STANDARD)

0 to 5, 0 to 10, 0 to 25, 0 to 50, and 0 to 100% oxygen

OPERATING RANGE (OPTIONAL)

0 to 1, 0 to 2.5, 0 to 5, 0 to 10, 0 to 25, 0 to 50, and 0 to 100% oxygen

R

ESPONSE TIME

90% of fullscale, 20 seconds

R

EPRODUCIBILITY

0.01% oxygen or ±1% of fullscale, whichever is greater

A

MBIENT TEMPERATURE LIMITS

32°F (0°C) to 113°F (45°C)

Z

ERO DRIFT

±1% fullscale per 24 hours, provided that ambient temperature does not

change by more than 20°F (11.1°C)

±2.5% of fullscale per 24 hours with ambient temperature change over

entire range

S

PAN DRIFT

±1% fullscale per 24 hours, provided that ambient temperature does not

change by more than 20°F (11.1°C)

±2.5% of fullscale per 24 hours with ambient temperature change over

entire range

1

- PERFORMANCE

SPECIFICATIONS – SAMPLE

D

RYNESS

Sample dewpoint below 110°F (43°C), sample free of entrained liquids.

T

EMPERATURE LIMITS

50°F (10°C) to 150°F (65°C)

O

PERATING PRESSURE

Maximum: 10 psig (68.9 kPa)

Minimum: 5 psig vacuum (34.5 kPa vacuum)

F

LOW RATE

50 cc/min. to 500 cc/min.

Recommended 250 ±20 cc/min.

M

ATERIALS IN CONTACT WITH SAMPLE

Glass, 316 stainless steel, titanium, Paliney No. 7, epoxy resin, Viton-A,

platinum, nickel, and MgF2

1

Performance specifications are measured at recorder output and are based on constant sample pressure and deviation

from set flow held to within 10% or 20 cc/min., whichever is smaller.

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

P-3

REFACE

P

SPECIFICATIONS - ELECTRICAL

SUPPLY VOLTAGE AND FREQUENCY

STANDARD:

115 VAC ±10%, 50/60 Hz

OPTIONAL:

230 VAC ±10%, 50/60 Hz

POWER CONSUMPTION

300 watts maximum, 75 watts nominal

O

UTPUTS STANDARD

Field selectable voltage output of 0 to 10 mV, 0 to 100 mV, 0 to 1 V, or 0 to

5 VDC

O

UTPUTS OPTIONAL

Isolated current output of 0 to 20 mA or 4 to 20 mA is obtainable through

plug-in of optional circuit board

O

PTIONAL ALARMS

High and low, independently adjustable alarms. Form C contact ratings.

A

LARM CONTACT RATINGS

5 A, 240 VAC resistive

5 A, 120 VAC resistive

5 A, 28 VDC resistive

S

ETPOINT

Adjustable from 1% to 100% fullscale

D

EADBAND

Adjustable from 1% to 20% fullscale. Factory set to 10% of fullscale.

S

PECIFICATIONS

M

OUNTING

19 inch rack (IEC 297-1, 1986)

C

ASE CLASSIFICATION

General Purpose

W

EIGHT

46 lbs. (21 kg)

- P

HYSICAL

P-4

D

IMENSIONS

19.0 x 8.7 x 19.2 inches (482.2 x 221 x 487 mm) W x H x D

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

REFACE

P

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

RETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call: Model Number, Serial Number, and Purchase Order Number or Sales Order

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returning any product or component that has been exposed to a toxic, corrosive

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

TRAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the Current Operator and Service Training Schedule contact

the Technical Services Department at:

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

D

OCUMENTATION

The following Model 755R Oxygen Analyzer instruction materials are available.

Contact Customer Service or the local representative to order.

748213 Instruction Manual (this document)

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

P-5

REFACE

P

COMPLIANCES

This product satisfies all obligations of all relevant standards of the EMC framework in

Australia and New Zealand.

9

N

6

P-6

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

I

NTRODUCTION

1

1.1 DESCRIPTION

The Model 755R Oxygen Analyzer provides continuous readout of the oxyg en content of

a flowing gas sample. The determination is based on measurement of the magnetic

susceptibility of the sample gas. Oxygen is strongly paramagnetic while most other

common gases are weakly diamagnetic.

The instrument provides direct readout of 0 to 100% oxygen concentration on a front

panel digital display. In addition, a field-selectable voltage output is provided as

standard. An isolated current output of 0 to 20 mA or 4 to 20 mA is obtainable through

plug-in of an optional circuit board. Current and voltage outputs may be utilized

simultaneously if desired. An alarm option is also available by way of a relay assembly

that mounts at the rear of the case with a cable that plugs into the Control Board.

Customer connections are available on thi s assembl y .

The basic electronic circuitry is incorporated into two master boards designated the

Control Board assembly and the Power Supply Board assembly. The Control Board has

receptacles that accept optional plug-in curr ent output boar d and alar m features.

F

IGURE

1-1. M

ODEL

Digita l Di s play

%

O

2

SPANZERO

Rosemount Analytical

Zero Control Span Control

755R O

XYGEN ANALYZER

Model 755R

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

1-1

NTRODUCTION

I

1.2 RECORDER OUTPUT RANGES

Seven zero-based ranges are available with the Model 755R: 0 to 1%, 0 to 2.5%, 0 to

5%, 0 to 10%, 0 to 25%, 0 to 50%, and 0 to 100%. Each range is jumper selectable.

1.3 MOUNTING

The Model 755R is a rack-mounted instrument, standard for a 19-inch relay rack (Refer

to IEC Standard, Publication 297-1, 1986).

1.4 ISOLATED CURRENT OUTPUT OPTION

An isolated current output is obtainable by using an optional current output board, either

during factory assembly or subsequently in the field. The board provides ranges of 0 to

20 or 4 to 20 mA into a maximum resistiv e l oad of 1000 ohms.

1.5 ALARM OPTION

The alarm option contains:

• An alarm circuit incorporating two comparator amplifiers, one each for the

ALARM 1 and ALARM 2 functions. Each amplifier has associated setpoint and

deadband adjustments. Setpoint is adjustable from 1% to 100% of fullscale.

Deadband is adjustable from 1% to 20% of fullscale.

• An alarm relay assembly, containing two single-pole, double-throw relays (one

each for the ALARM 1 and ALARM 2 contacts). These relays may be used to

drive external, customer-supplied alarm and/or control devices.

1.6 ELECTRICAL OPTIONS

The analyzer is supplied, as ordered, for operation on either 115 VAC, 50/60 Hz or 230

VAC, 50/60 Hz.

1.7 REMOTE RANGE CHANGE OPTION

This option allows the customer to remotely control the recorder scaling. It disables

the internal recorder fullscale range select without affecting the front panel display.

1-2

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

I

NSTALLATION

2.1 FACILITY PREPARATION

Observe all precautions given in this section when installing the instrument.

2

2.1.1 I

2.1.2 E

2.1.3 F

2.1.4 L

NSTALLATION DRAWINGS

For outline and mounting dimensions, gas connections, and other installation

information, refer to Installation Drawing 654015 at the back of this manual.

LECTRICAL INTERCONNECTION DIAGRAM

Electrical interconnection is also shown in drawing 654015. Refer also to Section 2.4.

LOW DIAGRAM

The flow diagram of Figure 2-1 shows connection of a typical gas selector manifold to

the Model 755R.

OCATION AND MOUNTING

Install the Model 755R only in a non-hazardous, weather-protected area. Permissible

ambient temperature range is 32°F to 113°F (0°C to 45°C). Avoid mounting where

ambient temperature may exceed the allowable maximum.

Magnetic susceptibilities and partial pressures of gases vary with temperature. In the

Model 755R, temperature-induced readout error is avoided by control of temperatures

in the following areas:

1. Interior of the analyzer is maintained at 140°F (60°C) by an electrically controlled

heater and associated fan.

2. Immediately downstream from the inlet port, prior to entry into the detector, the

sample is preheated by passage through a coil maintained at approximately the

same temperature as the detector (See Figure 5-3, A).

3. The detector is maintained at a controlled temperature of 150°F (66°C).

Also, avoid excessive vibration. To minimize vibration effects, the detector/magnet

assembly is contained in a shock-mounted compartment.

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

2-1

M

ODEL

755R O

XYGEN ANALYZER

WARNING: POSSIBLE EXPLOSION HAZARD

This analyzer is of a type capable of analysis of sample gases which may be

flammable. If used for analysis of such gases, internal leakage of sample could

result in an explosion causing death, personal injury, or property damage. Do

not use this analyzer on flammable samples. Use explosion-proof version

instruments for analysis of flammable samples.

Use reasonable precautions to avoid excessive vibration. In making electrical

connections, do not allow any cable to touch the shock-mounted detector assembly or

the associated internal sample inlet and outlet tubing. This precaution ensures against

possible transmission of mechanical vibration through the cable to the detector, which

could cause noisy readout.

2.2 CALIBRATION GAS REQUIREMENTS

WARNING: HIGH PRESSURE GAS CYLINDERS

Calibration gas cylinders are under pressure. Mishandling of gas cylinders

could result in death, injury, or property damage. Handle and store cylinders

with extreme caution and in accordance with the manufacturer’s instructions.

Refer to GENERAL PRECAUTIONS FOR HANDLING & STORING HIGH

PRESSURE CYLINDERS at the rear of this manual.

Analyzer calibration consists of establishing a zero calibration point and a span

calibration point.

Zero calibration is performed on the range that will be used during sample analysis. In

some applications, however, it may be desirable to perform span calibration on a

range of higher sensitivity (i.e., more narrow span) and then jumper to the desired

operating range. For example, if the operating range is to be 0 to 50% oxygen, span

calibration may be performed on the 0 to 25% range to permit use of air as the span

standard gas.

Recommendations on calibration gases for various operating ranges are tabulated in

Table 3-1 and are explained in Sections 2.2.1 and 2.2.2.

Each standard gas should be supplied from a cylinder equipped with dual-stage, metal

diaphragm type pressure regulator, with output pressure adjustable from 0 to 50 psig

(0 to 345 kPa).

Instrument response to most non-oxygen sample components is comparatively slight,

but is not in all cases negligible. During initial installation of an instrument in a given

application, effects of the background gas should be calculated to determine if any

correction is required (See Section 3.4).

2-2

Rosemount Analytical

April 2000

748213-R

NSTALLATION

I

2.2.1 Z

ERO STANDA RD GAS

In the preferred calibration method, described in Section 3.4.1, a suitable zero

standard gas is used to establish a calibration point at or near the lower range limit.

Composition of the zero standard normally requires an oxygen-free zero gas, typically

nitrogen.

2.2.2 S

PAN STANDA RD GAS

A suitable span standard gas is required to establish a calibration point at or near the

upper range limit. If this range limit is 21% or 25% oxygen, the usual span standard

gas is air (20.93% oxygen).

2.3 SAMPLE HANDLING

Basic requirements for sample handling are:

1. A 2-micron particulate filter, inserted into the sample line immediately upstream

from the analyzer inlet.

2. Provision for pressurizing the sample gas to provide flow through the analyzer.

3. Provision for selecting sample, zero standard, or span standard gas for admission

to the analyzer, and for measuring the flow of the selected gas.

Sample In

Zero

Standard

Gas

Span

Standard

Gas

Needle

Valves

Two Micron

Flowmeter

Filter

Model 755R

Oxygen Analyzer

To Vent

F

IGURE

748213-R Rosemount Analytical April 2000

2-1. I

NTERCONNECTION OF TYPICAL GAS MANIFOLD TO MODEL

755R

Model 755R Oxygen Analyzer

2-3

NSTALLATION

I

2.3.1 S

AMPLE TEMPERATURE REQUIREMENTS

Sample temperature at the analyzer inlet should be in the range of 50°F to 150°F

(10°C to 66°C).

Normally, however, a maximum entry temperature of 110°F (43°C) is recommended

so that the sample temperature will rise during passage of the sample through the

analyzer. This precaution prevents cooling of the sample and possible

analyzer-damaging condensation. With a thoroughly dry sample, entry temperature

can be as high as 150°F (66°C) without affecting readout accuracy.

2.3.2 S

AMPLE PRESSURE REQUIREMENTS

: G

ENERAL

Operating pressure limits are as follows: maximum, 10 psig (68.9 kPa); minimum, 5

psig vacuum (34.5 kPa vacuum).

CAUTION: RANGE LIMITATIONS

Operation outside the specified pressure limits may damage the detector, and

will void the warranty.

The basic rule for pressure of sample and standard gases supplied to the inlet is to

calibrate the analyzer at the same pressure that will be used during subsequent

operation, and to maintain this pressure during operation. The arrangement required

to obtain appropriate pressure control will depend on the application. When inputting

sample or calibration gases, use the same pressure that will be used during

subsequent operation. Refer to Section 2.3.3, Normal Operation at Positive Gauge

Pressures, or Section 2.3.4, Operation at Negative Gauge Pressures.

2.3.3 N

ORMAL OPERATION AT POSITIVE GAUGE PRESSURES

Normally, the sample is supplied to the analyzer inlet at a positive gauge pressure in

the range of 0 to 10 psig (0 to 68.9 kPa).

CAUTION: HIGH PRESSURE GAS

Pressure surges in excess of 10 psig during admission of sample or standard

gases can damage the detector.

Maximum permissible operating pressure is 10 psig (68.9 kPa). To ensure against

over-pressurization, insert a pressure relief valve into the sample inlet line. In addition,

2-4

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

NSTALLATION

I

a check valve should be placed in the vent line if the analyzer is connected to a

manifold associated with a flare or other outlet that is not at atmospheric pressure. If

the detector is over-pressurized, damage will result.

The analyzer exhaust port is commonly vented directly to the atmosphere. Any

change in barometric pressure results in a directly proportional change in the indicated

percentage of oxygen.

Example:

Range, 0% to 5% O2.

Barometric pressure change after calibration, 1%.

Instrument reading, 5% O2.

Readout error = 0.01 x 5% O2 = 0.05% O2.

Fullscale span is 5% O

2.

Therefore, the 0.05% O2 error is equal to 1% of fullscale.

Thus, if the exhaust is vented to the atmosphere, the pressure effect must be taken

into consideration. This may be accomplished in various ways, including manual

computation and computer correction of data.

2.3.4 O

PERATION AT NEGATIVE GAUGE PRESSURES

Operation at negative gauge pressures is not normally recommended, but may be

used in certain special applications. A suction pump is connected to the analyzer

exhaust port to draw sample into the inlet and through the analyzer. Such operation

necessitates special precautions to ensure accurate readout. First is the basic

consideration of supplying the standard gases to the analyzer at the same pressure

that will be used for the sample during subsequent operation. In addition, any leakage

in the sample handling system will result in decreased readout accuracy as compared

with operation at atmospheric pressure.

The minimum permissible operating pressure is 5 psig vacuum (34.5 kPa vacuum).

Operation of the analyzer below this limit may damage the detector, and will void the

warranty.

2.3.5 S

AMPLE FLOW RATE

Operating limits for sample flow rate are as follows: minimum, 50 cc/min; maximum,

500 cc/min. A flow rate of less than 50 cc/min is too weak to sweep out the detector

and associated flow system efficiently. Incoming sample may mix with earlier sample,

causing an averaging or damping effect. Too rapid a flow will cause back pressure

that will affect the readout accuracy. The optimum flow rate is between 200 and 300

cc/min.

Deviation from the set flow should be held to within 10% or 20 cc/min, whichever is

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

2-5

NSTALLATION

I

smaller. If deviation is held to within these parameters and operating pressure remains

constant, zero and span drift will remain within specification limits.

The analyzer should be installed near the sample source to minimize transport time.

Otherwise, time lag may be appreciable. For example, assume that sample is supplied

to the analyzer via a 100-foot (30.5 m) length of 1/4-inch (6.35 mm) tubing. With a flow

rate of 100 cc/min, sample transport time is approximately 6 minutes.

Sample transport time may be reduced by piping a greater flow than is required to the

analyzer, and then routing only the appropriate portion of the total flow through the

analyzer. The unused portion of the sample may be returned to the stream or

discarded.

2.3.6 M

ATERIALS IN CONTACT WITH SAMPLE

Within the Model 755R, the following materials are exposed to the sample: 316

stainless steel, glass, titanium, Paliney No.7, epoxy resin, Viton-A, platinum, nickel

and MgF2 coating on mirror.

2.3.7 C

ORROSIVE GASES

In applications where the sample stream contains corrosive gases, a complete drying

of the sample is desirable, as most of these gases are practically inert when totally

dry. For corrosive applications consult the factory.

2.3.8 L

EAK TEST

WARNING: POSSIBLE TOXIC OR CORROSIVE HAZARD

The sample containment system must be carefully leak checked upon

installation and before initial start-up, during routine maintenance and any time

the integrity of the sample containment system is broken, to ensure the system

is in leak proof condition.

2-6

Internal leaks resulting from failure to observe these precautions could result in

personal injury or property damage.

For proper operation and safety, system leakage must be corrected, particularly

before introduction of toxic or corrosive samples and/or application of electrical power.

To check system for leaks, liberally cover all fittings, seals, and other possible sources

of leakage with suitable leak test liquid such as SNOOP (P/N 837801). Check for

leak-indicative bubbling or foaming. Leaks that are inaccessible to SNOOP application

could evade detection by this method.

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

A B I C D E

L1/HOT

L2/NEUT

CUR VOLT

OUTPUT OUTPU T

+ - G + -

GND

NSTALLATION

I

F

IGURE

(Rear terminal cover remo ved f o r clarity)

A. Sample outlet. 1/4” O.D. tube fitting.

B. Sample Inlet. 1/4” O.D. tube fitting.

C. 5/8” diameter hole for opti onal Dual Alarm Cable. Cable suppli ed by customer, mi ni mum 24 AWG.

D. 5/8” diameter hole fit ted with liquid-tight gland for Recorder Out put Cable. Cable supplied by customer, 2

conductor, minimum 24 AWG.

E. 13/16” diameter hole for Power Cable. Cable supplied by custom er, 3 conductor, minimum 18 AWG.

F. TB1: Customer hook-up f or P ower.

G. TB2: Customer hook-up for Recorder Output.

H. Optional Dual Alarm c onnections.

I. Connections for Opti onal Remote Range Change.

2-2. M

ODEL

755R R

EAR PANEL

H G H

2.4 ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL SHOCK HAZARD

For safety and proper performance, this instrument must be connected to a

properly grounded three-wire source of supply.

Cable connections for AC power, recorder output, and alarm output are shown in

Installation Drawing, 654015, and are explained in the following sections.

2.4.1 L

INE POWER CONNECTION

The analyzer is supplied, as ordered, for operation on 115 VAC or 230 VAC, 50/60 Hz.

Ensure that the power source conforms to the requirements of the individual

instrument, as noted on the name-rating plate.

Electrical power is supplied to the analyzer via a customer-supplied three-conductor

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

2-7

NSTALLATION

I

(Verif

I

cable, type SJT, minimum wire size 18 AWG. Route power cable through conduit and

into appropriate opening in the instrument case. Connect power leads to HOT, NEUT,

and GND terminals on the I/O board. Connect analyzer to power source via an

external fuse or breaker, in accordance with local codes. Do not draw power for

associated equipment from the analyzer power cable (Refer to Figure 2-3).

F

IGURE

2-3. C

S

755R

Analyzer

Voltage Divider

(Customer Supplied)

Position of Recorder Output

Selector Plug

10 mV 1K

100 mV 10K

1 V 100K

5 V 2K

Minimum Permissible

Resistance for R1 + R2

ONNECTIONS FOR POTENTIOMETRIC RECORDER WITH NON-STANDARD

PAN

Potentiometric

Recorder

nput

Terminals

y polarity

is correct)

(ohms)

If the analyzer is mounted in a protected rack or cabinet or on a bench, an accessory

kit (P/N 654008) is available which provides a 10-foot North American power cord set

and a liquid-tight feed through gland for the power cable hole. The kit also contains

four enclosure support feet for bench top use.

2.4.2 R

ECORDER OUTPUT SELECTION AND CABLE CONNECTIONS

If a recorder, controller, or other output device is used, connect it to the analyzer via a

number 22 or number 24 AWG two-conductor shielded cable. Route the cable into the

case through the liquid-tight feed through gland in the Recorder Output opening (See

Installation Drawing, 654015). Connect the shield only at the recorder end or the

analyzer end, not to both at the same time because a ground loop may occur.

Note:

Route recorder cable through a separate cable gland (P/N 899329) or conduit not

with power cable or alarm output cable. Cable connections and output selection

for potentiometric and current-actuated devices are explained below.

2.4.2.1 P

OTENTIOMETRIC OUTPUT

1. Insert RECORDER OUTPUT Selector Plug (See Figure 3-1) in position appropriate

to the desired output: 10 mV, 100 mV, 1V or 5V.

2. Connect leads of shielded recorder cable to “REC OUT +” and “-” terminals on the

2-8

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

NSTALLATION

N

1000 oh

R

C

R

I

I/O board.

3. Connect the output cable to the appropriate terminals of the recorder or other

potentiometric device:

a. For device with span of 0 to 10 mV, 0 to 100 mV, 0 to 1V, or 0 to 5V, connect

cable directly to input terminals of the device, ensuring correct polarity and

range selection.

b. For a device with intermediate span (i.e., between the specified values),

connect the cable to the device via a suitable external voltage divider (See

Figure 2-3).

2.4.2.2 I

SOLATED CURRENT OUTPUT (OPTIONAL

)

1. Verify that the optional current output board appropriate to desired output is

properly in place in its connector. See Figure 3-1. If originally ordered with the

analyzer, the board is factory installed.

2. On I/O board, connect leads of shielded recorder cable to “CURRENT OUT+” and

“-” terminals.

3. Connect free end of output cable to input terminals of recorder or other

current-actuated device, making sure that polarity is correct. If two or more

current-actuated devices are to be used, they must be connected in series (See

Figure 2-4). Do not exceed the maximum load resistance of 1000 ohms.

Current and voltage outputs may be utilized simultaneously if desired.

+

755R

Analyzer

mA

-

+

-

+

-

ecorder

ontroller

+

emote

Indicator

ote: Total series resistance of all devices is not to exceed

F

IGURE

748213-R Rosemount Analytical April 2000

2-4. M

O

ODEL

755R C

UTPUT DEVICES

ONNECTED TO DRIVE SEVERAL CURRENT-ACTUATED

ms.

-

Model 755R Oxygen Analyzer

2-9

NSTALLATION

I

2.4.3 O

UTPUT CONNECTIONS AND INITIAL SETUP FOR DUAL ALARM OPTION

If so ordered, the analyzer is factory equipped with alarm output. Alternatively, the

alarm feature is obtainable by subsequent installation of the 654019 Alarm Kit.

The alarm output provides two sets of relay contacts for actuation of alarm and/or

process-control functions. Leads from the customer-supplied external alarm system

connect to terminals on the 654019 Alarm Assembly (See Figure 2-5 and Interconnect

Drawing 654014).

REQUIREMENT TYPICAL CONNECTIONSREQUIREMENT TYPICAL CONNECTIONS

Solenoid

Valve

Alarm Bell

or Lamp

Solenoid

Valve

Solenoid

Valve

Alarm Bell

or Lamp

Low Alarm,

Fail-Safe

High Alarm,

Fail-Safe

Low Control

Limit,

Fail-Safe

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

Alarm Bell

or Lamp

Alarm Bell

or Lamp

Solenoid

Valve

115 VAC

115 VAC

115 VAC

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

N

H

Low Control

Limit,

Fail-Safe

Lower

Low Alarm

Indicator,

Fail-Safe

N

H

H

N

Low Control,

Fail-Safe

High Control,

Fail-Safe

Higher

High Alarm

Indicator,

Fail-Safe

115 VAC

115 VAC

115 VAC

115 VAC

115 VAC

H

N

N

H

H

N

H

N

N

H

F

IGURE

2-10

2-5. R

ELAY TERMINAL CONNECTIONS FOR TYPICAL FAIL-SAFE

A

PPLICATIONS

Note the following recommendations:

1. A fuse should be inserted into the line between the customer-supplied power

supply and the alarm relay terminals on the Alarm Relay Assembly.

2. If the alarm contacts are connected to any device that produces radio frequency

interference (RFI), it should be arc suppressed. The 858728 Arc Suppressor is

recommended.

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

NSTALLATION

I

3. If at all possible, the analyzer should operate on a different AC power source, to

avoid RFI.

Alarm 1 and Alarm 2 output through the 654019 Alarm Relay Assembly is provided by

two identical single-pole, double-throw relays. These relay contacts are rated at the

following values:

5 amperes 240 VAC resistive

1 ampere 240 VAC inductive

5 amperes 120 VAC resistive

3 amperes 120 VAC inductive

5 amperes 30 VDC resistive

3 amperes 30 VDC inductive

Removal of AC power from the analyzer (such as power failure) de-energizes both

relays, placing them in alarm condition. Switching characteristics of the Alarm 1 and

Alarm 2 relays are as follows:

The Alarm 1 relay coil is de-energized when the display moves downscale through the

value that corresponds to setpoint minus deadband. This relay coil is energized when

the display moves upscale through the value that corresponds to setpoint plus

deadband.

The Alarm 2 relay coil is de-energized when the display moves upscale through the

value that corresponds to the setpoint plus deadband. This relay coil is energized

when the display moves downscale through the value that corresponds to setpoint

minus deadband.

Both the ALARM 1 and ALARM 2 functions generally incorporate automatic rest.

When the display goes beyond the pre-selected limits, the corresponding relay is

de-energized. When the display returns within the acceptable range, the relay is

turned on.

The ALARM 1 and/or ALARM 2 alarm functions may be converted to manual reset.

The conversion requires the substitution of an external pushbutton or other

momentary contact switch for the jumper that connects the RESET terminals on the

Alarm Relay Assembly. If the corresponding relay is now de-energized (i.e., in alarm

condition), the relay remains de-energized until the operator momentarily closes the

switch.

By appropriate connection to the double-throw relay contacts, it is possible to obtain

either a contact closure or a contact opening for an energized relay. Also, either a

contact closure or a contact opening may be obtained for a de-energized relay. It is

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

2-11

NSTALLATION

I

important, for fail-safe applications, that the user understands what circuit conditions

are desired in event of power failure and the resultant relay de-energization. Relay

contacts should then be connected accordingly (See Figure 2-5).

The ALARM 1 and ALARM 2 circuits have independent setpoint and deadband

adjustments (See Figure 3-1). Initially, the ALARM 1 and ALARM 2 Setpoint

Adjustments must be calibrated by means of the ALARM 1 and ALARM 2 Calibration

Adjustments by the following procedure:

1. Set RANGE Select in a position appropriate to the span standard gas.

2. Inject span standard gas through analyzer at 50 to 500 cc/min.

3. Verify that ALARM 1 and ALARM 2 Deadband Adjustments (See Figure 3-1) are

set for minimum value (turned fully counterclockwise). These potentiometers

should be factory-set for minimum deadband. Both potentiometers MUST REMAIN

at this setting throughout calibration of the alarm setpoint adjustments.

4. Adjust ALARM 1 control function as follows:

a. With ALARM 1 Setpoint Adjustment at 100% (i.e., position 10 on dial), adjust

front panel SPAN Control so that the display or recorder reads exactly fullscale.

b. Set ALARM 1 Calibrate A djustment (R63) to its clockwise limit. Carefully rotate

R63 counterclockwise the minimum amount required to obtain energization of

ALARM 1 Relay K1 (See Figures 2-6 and 3-1). Energization may be verified by

connecting an ohmmeter to relay terminals on 654019 Alarm Relay Assembly.

c. To verify correct adjustment of R63, adjust front panel SPAN Control so that

the display or recorder reads 99% of fullscale. Relay K1 should now be

DE-ENERGIZED.

5. Adjust ALARM 2 control function as follows:

a. With ALARM 2 Setpoint Adjustment at 100% (i.e., Position 10 on the dial),

adjust front panel SPAN Control so that

b. the display or recorder reads exactly fullscale.

c. Set ALARM 2 Calibrate Adjustmen t (R67) to its clockwise limit. Carefu lly rotate

R67 counterclockwise the minimum amount required to obtain energization of

ALARM 2 Relay K2 (See Figure 2-5).

d. To verify correct adjustment of R67, adjust front panel SPAN Control so that

the display or recorder reads 99% of fullscale. Relay K2 should now be

DE-ENERGIZED.

2-12

The ALARM 1 and ALARM 2 Setpoint Adjustments are now properly calibrated and

may be used to select the desired alarm setpoints, as described in Section 3.6.

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

A. Typical ALARM 1 Setting

DEADBAND SET FOR

20% OF FULLSCALE

B. Typical ALARM 2 Setting

DEADBAND SET FOR

10% OF FULLSCALE

F

IGURE

2-6. T

40

INPUT SIGNAL

Percent of Fullscale

30

20

55

INPUT SIGNAL

Percent of Fullscale

50

45

YPICAL ALARM SETTINGS

NSTALLATION

I

When input signal moves upscale through this point, the

coil of ALARM 1 relay (K1) is energized, providing

continuity between the common and normally-closed

contacts of the relay.

ALARM 1 Setpoint

When input signal moves downscale through this point, the

coil of ALARM 1 relay (K1) is de-energized, providing

continuity between the common and normally-open

contacts of the relay.

When input signal moves upscale through this point, the

coil of ALARM 2 relay (K2) is de-energized, providing

continuity between the common and normally-open

contacts of the relay.

ALARM 2 Setpoint

When input signal moves upscale through this point, the

coil of ALARM 2 relay (K2) is energized, providing

continuity between the common and normally-closed

contacts of the relay.

F

IGURE

J5

+15V

-15V

Alarm

No. 1

Command

Alarm

No. 2

Command

1

2

4

6

2. CR! AND CR2 ARE ANY 600V, 1 AMP DIODE.

1. RELAYS SHOWN IN ENERGIZED POSITION.

NOTES:

2-7. A

LARM RELAY ASSEMBLY SCHEMATIC DIAGRAM

CR1

14

K1

CR2

14 13

K2

TB4

1

5

13

12

1

5

12

9

8

9

8

NO

COM

NC

Reset

NO

COM

NC

Reset

Alarm

No. 1

Alarm

No. 2

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

2-13

NSTALLATION

I

2.5 REMOTE RANGE CHANGE OPTION

The power supply circuitry on the Remote Range Board 646004 must be jumpered for

the correct line voltage, either 115 VAC or 230 VAC. See Drawings # 656081 (Table

2) and 646090 for correct jumper locations.

On the Remote Range Board, an additional option exists: for using either the on-board

12 V to drive the range select relays or an external 12 V supply.

To use an external supply:

1. Remove the E to F jumper (DW G 646090).

2. Apply the external 12 V to J3-5.

3. Program the remote controller to pull the range bits, J3-1 through J3-4, low. (See

truth table below.)

To use the internal 12 V supply:

1. Verify the E to F jumper is in place.

2. Connect the controller's common to J3-6 to reference the instrument's common to

the controller's common.

DO NOT connect anything to J3-5.

3. Connect J3-1 to J3-4, as shown in the truth table below, to switch ranges.

Remember that you are dealing with inverse logic and not normal binary addresses.

Also, this process switches the recorder output only, and does not affect the front

panel display.

Remote Range Switching Truth Table

J3-4 J3-3 J3-2 J3-1 Hex

Range 1 1 1 1 0 E

Range 2 1 1 0 1 D

2-14

Range 3 1 0 1 1 B

Range 4 0 1 1 1 7

Note: 1 = 12 V, 0 << 1 V.

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

S

TARTUP AND CALIBRATION

3

3.1 OVERVIEW

Preparatory to startup and calibration, a familiarization with Figure 3-1 is

recommended. This figure gives locations and summarized descriptions of operating

adjustments of the Model 755R Oxygen Analyzer.

3.2 OPERATING RANGE SELECTION

The Model 755R is designed to operate on a single, field-selectable range. A new

range may be selected any time the analyzer application changes or any time

calibration may require a range change.

To select the operating range, reposition the jumper shown in Figure 3-1 to the

desired location. Each position is labeled as to its fullscale range. Only the analog

output (voltage and optional current) is affected by range selection. The digital display

always reads 100% oxygen.

3.3 STARTUP PROCEDURE

Inject a suitable on-scale gas (not actual sample) through the analyzer. Turn power

ON. If digital display gives overrange indication, the probable cause is the suspension

in the detector is hung up. To correct this condition, turn power OFF, tap detector

compartment with fingers, wait 30 seconds, turn power ON.

When on-scale reading is obtained, allow analyzer to warm-up for a minimum of one

hour with gas flowing. This warm-up is necessary because a reliable calibration is

obtainable only after the analyzer reaches temperature stability. Moreover, the

resultant elevated temperature will ensure against condensation within, and possible

damage to the detector assembly. After warm-up, the digital display or recorder

should give stable, drift-free readout. If so, proceed to Section 3.3. Otherwise, refer

to Section 7, Service and Maintenance.

3.4 CALIBRATION

Calibration consists of establishing a zero calibration point and a span calibration point

(see Table 3-1). Zero and span calibration should be performed on the range that will

be used during sample analysis. In some applications, however, it may be desirable

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

3-1

TARTUP AND CALIBRAT ION

S

to perform span calibration on a range of higher sensitivity (i.e., more narrow span)

and then move the jumper to the desired operating range. For example, if the

operating range is to be 0 to 50% oxygen, span calibration may be performed on the 0

to 25% range to permit use of air as the span standard gas.

3.4.1 C

ALIBRATION WITH ZERO AND SPAN STANDA RD GASES

Note:

The same flow rate must be maintained for zero, span, and sample to avoid

measure error. The exhaust is vented to the atmosphere to avoid back

pressure. The following procedure is based on the standards in Table 3-2.

Performance specifications are based on recorder output.

ET ZERO CALIBRATION POINT

S

Inject nitrogen zero standard gas through analyzer at suitable flow rate, preferably 250

cc/min. Allow gas to purge analyzer for a minimum of three minutes.

Adjust ZERO control so that the reading on the digital display or recorder is zero

ET SPAN CALIBRATION POINT

S

Inject span standard gas (see Table 3-1) through the analyzer at the same flow rate as

was used for zero standard gas. Allow gas to purge analyzer for a minimum of three

minutes.

Adjust SPAN control so that reading on display or recorder is appropriate to the span

standard gas.

3.5 COMPENSATION FOR COMPOSITION OF BACKGROUND GA S

Any gas having a composition other than 100% oxygen contains background gas.

The background gas comprises all non-oxygen constituents. Although instrument

response to most gases other than oxygen is comparatively slight, it is not in all cases

negligible. The contribution of these components to instrument response is a function

of the span and range used, and can be computed for each individual case.

If the zero and span standard gases contain the same background gas as the sample,

the routine standardization procedure automatically compensates for the background

components. Therefore, the zero and span standard gases would introduce no error.

If the background gas in the sample is different from that in the zero and/or span

standard gas(es), background effects must be taken into consideration to ensure

correct readout. During adjustment of the front panel ZERO and SPAN controls (see

Figure 1-1), the instrument is not set to indicate the true oxygen content of the zero

and span standard gases. It is set to indicate a slightly different value, relative to

background gas, calculated to provide correct readout during subsequent analysis of

the sample gas.

3-2

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

TARTUP AND CALIBRATION

S

16

15

SPAN

E10

100% 50% 25% 10% 2.5%

R8

R9

CR2

U6

I G O

1

2

3

4

I

G

O

U5

C5

I G O

U3

C4

U4

1

C59

E21 E1 E3 E5 E7

C60

C56

U18

C58

U16

E22 E2 E4 E6 E8

C49

C57

8

E11 E13 E15

E23E9

E12 E14 E16 E20

E24

R3

R4

R5

R6

U2

C2

C3 CR1 C1

5V 1V .1V .01V

U13

5% 1%

R2 R1

U1

J1

R57

R58

R59

R60

C14

7

E17

E19

TP5 TP6

TP7 TP8 TP9 TP10 TP11 TP16 TP17 TP18

E18

R52

R87

R53

R82

U17

R47

R84

R85

R86

R102

C48

R43

CR5

R49

T1

R40

U12

C61

C13

C12

U4

J2

C55

U15

C65

R50

SPAN

SPAN

C53

R20

CW

CW

S

S

CCW

CCW

R21

R22

R23

R24

U14

R56

R55

R42

CR4

C45

TP19

U21

C68

TP20

R89

R89

+

T1

U11

U11

C51

C44

C31

C31

5 4

3

2

R90

R90

R88 R30 R29 R100

R88 R30 R29 R100

C64

C64

R68

R25

R25

C29

C29

C26

C26

R13

R13

U20

U20

C38 C41

C38 C41

C17

C17

C16

C16

C18

C39

C39

C36

C36

R27

R27

CW

CW

S

S

CCW

CCW

C28 C27

C28 C27

R68

C8

C8

C1

C1

CR1

CR2R1R2R3R4R5R6

CR1

CR2R1R2R3R4R5R6

C30

C30

U8

U8

C63

C63

U19

U19

R11 R66 R77 R80 R82 R72 R70

R11 R66 R77 R80 R82 R72 R70

BL

CR3 R12 R76 R69 R81 R75 R71 R85

CR3 R12 R76 R69 R81 R75 R71 R85

R101

C50

C50

C37

C37

U10

U10

R54

R37

R37

R36

R31

R61

R39

R38

R28

R36

R31

R61

R39

R38

R28

ZERO

ZERO

6 10

R9

R9

R64

R64

Q1

Q1

E

E

R10 C66

R10 C66

R8

R7

R8

R7

C2

C2

C5

C5

J5

J5

13

R79 R74

R79 R74

Q2

Q2

E

E

U1

C4

C4

C7C3

C7C3

J6

J6

C10

C10

C67

C67

R63

R63

R67

R67

R73

R73

R78

R78

U2

U2

C9

C9

12

9

14

11

C6

C6

J4

J4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

652830 SIGNAL CONTROL BOARD

652830 SIGNAL CONTROL BOARD

1. RECORDER OUTPUT selector plug Provides selectable output of 10 mV, 100 mV, 1 V or 5 V for a volt age

recorder.

2. DIGITAL READOUT (R100) Calibration of digital readout.

3. AMPLIFIER U8 ZERO (R29) Initial factory zeroing of amplifier U8.

4. RESPONSE TIME (R30) Adjustment of electronic respons e t ime.

5. FULLSCALE OUTPUT (R88) Setting fullscale for 1 V, 0.1 V and 10 mV output s.

6. DETECTOR COARSE ZERO (R9) Coarse adjustment of det ector zero by shifting the posi t i on of the detector

within the magnetic fiel d. It is adjusted during factory checkout, and does not

require readjustment except if detector is replaced.

7. CURRENT OUTPUT ZERO (R1) Located on Current Output Board, adjus tment for zero-level current out put, i.e.,

4mA or 0mA

8. CURRENT OUTPUT SPAN (R2) Locat ed on Current Output Board, adjustment for fullscale current output:

20mA

9. ALARM 2 CALIBRATION (R67) Initial calibration of ALARM 2 circuit.

10. ALARM 2 SETPOINT (R68) Conti nuously variable adjustment of setpoint for ALARM 2 circuit, for actuation

of external, customer s uppl i ed control device(s). Adjus t ment range is 0 to

100% of fullscale span.

11. ALARM 2 DEADBAND (R78) Adjustm ent of ALARM 2 deadband circuit from 1% to 20% of fullscale.

Deadband is essentially symmetrical with respect to setpoint.

12. ALARM 1 CALIBRATION (R63) Initial calibration of ALARM 1 circuit.

13. ALARM 1 SETPOINT (R64) Conti nuously variable adjustment of setpoint for ALARM 1 circuit, for actuation

of external, customer s uppl i ed control device(s). Adjus t ment range is 0 to

100% of fullscale span.

14. ALARM 1 DEADBAND (R73) Adjustm ent of ALARM 1 deadband circuit from 1% to 20% of fullscale.

Deadband is essentially symmetrical with respect to setpoint.

15. OUTPUT RANGE selector plug Selectable fullscal e output range.

16. DETECTOR ISOLATION plug For servicing and testing of t he Control Board.

DIGITAL DISPLAY Display (viewed on front panel) indicates oxygen content of sample.

ZERO control (R13) Accessible on front panel , use to establish zero-calibration point.

SPAN control (R20) Ac cessible on front panel, us e t o establish span calibrat i on poi nt.

F

IGURE

3-1. C

ONTROL BOARD ADJUSTMENTS

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

3-3

TARTUP AND CALIBRAT ION

S

RANGE % OXYGEN

RECOMMENDED ZERO

STANDARD GAS

RECOMMENDED SPAN

STANDARD GAS

0 to 1 Nitrogen 0.9% O2, balance N

0 to 2.5 Nitrogen 2.3% O2, balance N

0 to 5 Nitrogen 4.5% O2, balance N

0 to 10 Nitrogen 9% O2, balance N

0 to 25 Nitrogen Air (20.93% O

2)

0 to 50 Nitrogen 45% O2, balance N

2

T

ABLE

3-1. C

3.5.1 O

0 to 100 Nitrogen 100% O

ALIBRATION RANGE FOR VARIOUS ZERO-BASED OPERATING RANGES

XYGEN EQUIVALENT VALUE OF GASES

For computation of background corrections, the analyzer response to each component

of the sample must be shown. Table 3-2 lists the percentage oxygen equivalent

values for many common gases.

The percentage oxygen equivalent of a gas is the instrument response to the given

gas compared to the response to oxygen, assuming that both gases are supplied at

the same pressure .

2

2

2

2

2

In equation form:

%O2 Equivalent of Gas =

Analyzer Response to Gas

Analyzer Response to O

X 100%

2

To select a random example from Table 3-2, if analyzer response to oxygen is +100%,

the response to xenon would be -1.34%.

The oxygen equivalent of a gas mixture is the sum of the contribution of the individual

gas components.

Example: Zero Based Range

At lower range limit, i.e., 0% oxygen, composition of sample is 80% CO2, 20%

N2.

From Table 3-1, the % oxygen equivalents are CO2. -0.623 and N2, -0.358%.

% oxygen equivalent of mixture =

0.8 x (-0.623) + 0.2 x ( -0.358) = (-0.4984) + (-0.0716) = - 0.570% Oxygen

3-4

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

TARTUP AND CALIBRATION

(A)

S

3.5.2 C

OMPUTING ADJUSTED SETTINGS FOR ZERO AND SPAN CONTROLS

During instrument calibration, adjusted values may be required in setting the ZERO

and SPAN controls to correct for the magnetic susceptibility of the background gas.

The quantities are defined as follows:

BGGst = Oxygen equivalent of background gas in standard gas (see Table 3-2)

BGGs = Oxygen equivalent of background gas sample (see Table 3-2)

OP = operating pressure. Unless special pressure corrections are to be made,

the zero standard, span standard and sample gases must all be admitted at the

same pressure.

Use the following equation to compute the adjusted settings for the ZERO and SPAN

controls:

Adjusted % O2 for standard gas =

[100 + (B-C)] - 100 [B-C]

Where:

100

A = true % O2 of standard gas

B = BGGs

C = BGGst

Example:

Background gas in sample is CO2, oxygen equivalent = -0.623%

Zero gas is 100% N2

Span standard gas is air: 21% O2, 79% N2

Background gas in zero and span standard gases is N2, oxygen equivalent = -

0.358%

With N2 zero standard gas flowing, ZERO control is adjusted so digital display

reads:

0[100+(-0.623-(-0.358))] - 100[-0.623-(-0.358)]

0.265% O

=

2

100

With air flowing, SPAN control is adjusted so the digital display reads:

21[100 - 0.265) - 100 (-0.265)

100

748213-R Rosemount Analytical April 2000

= 21.209% O2 ≅

Model 755R Oxygen Analyzer

21.21

3-5

TARTUP AND CALIBRAT ION

S

In two limiting cases, the general equation is reduced to simpler forms.

1. If the span standard gas is 100% oxygen, the adjusted oxygen value for setting the

SPAN control is the same as the true value (i.e., 100% oxygen).

2. If the zero standard is an oxygen-free zero gas, the adjusted value for setting the

ZERO control = BGGst - BGGs. (If the oxygen-free zero gas is more diamagnetic

than the background gas in the sample, this difference is negative. The negative

value may be set on the digital display or the recorder if provided with below-zero

capability.)

GAS

Acetylene, C2H

Allene, C3H

4

Ammonia, NH

EQUIV. % AS

2

O

2

-0.612 Hydrogen, H

GAS

2

-0.744 Hydrogen Bromide, Hbr -0.968

3

-0.479 Hydrogen Chloride, HC1 -0.651

EQUIV. % AS

2

O

-0.117

Argon, A -0.569 Hydrogen Fluoride, HF -0.253

Bromine, Br

1,2-Butadiene C4H

1,3-Butadiene C4H

n-Butane, C4H

iso-Butane, C4H

Butene-1, C4H

cis Butene-2, C4H

iso-Butene, C4H

trans butene-2, C4H

2

6

6

10

10

8

8

8

8

-1.83 Hydrogen Iodide, HI -1.403

-1.047 Hydrogen Sulphide, C2S -0.751

-1.944 Kryton, Kr -0.853

-1.481 Methane, CH

4

-0.512

-1.485 Neon, Ne -0.205

-1.205 Nitric Oxide, NO +44.2

-1.252 Nitrogen, N

-1.201 Nitrogen Dioxide, NO

-1.274 n-Octane, C8H

2

2

18

-0.358

+28.7

-2.840

T

ABLE

3-6

Carbon Dioxide CO

2

-0.623 Oxygen, O

2

Carbon Monoxide, CO -0.354 n-Pentane, C5H

Ethane, C2H

Ethylene, C2H

Helium, H

n-Heptane, C7H

n-Hexane, C6H

cyclo-Hexane, C6H

3-2. O

6

4

e

16

12

12

-0.789 iso-Pentane, C5H

-0.553 neo-Pentane, C5H

-0.059 Propane, C3H

-2.508 Propylene, C3H

-2.175 Water, H2O -0.381

-1.915 Xenon, Xe -1.340

XYGEN EQUIVALENT OF COMMON GASES

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

8

+100.0

12

12

12

-1.810

-1.853

-1.853

-1.135

6

-0.903

TARTUP AND CALIBRATION

(

)

S

3.6 SELECTION OF SETPOINTS AND DEADBAND ON ALARM

OPTION

The ALARM 1 and ALARM 2 setpoint adjustments (see Figure 3-1) are adjustable for

any desired value from 1% to 100% of the fullscale analyzer span. The adjustment

screws are graduated from 0 to 10.

Required dial settings for both setpoint adjustments may be determined from either

Figure 3-2 or the appropriate equation that follows:

• Zero-based operating range

• Required control setting =

desired alarm setpoint)(10

fullscale span

Figure 3-2 example:

Operating range, 0 to 5% oxygen

Desired ALARM 1 setpoint = 4% oxygen

Turn potentiometer R64 to 8

Desired ALARM 2 setpoint = 3% oxygen

Turn potentiometer R68 to 6

The desired deadband may be selected via the appropriate trimming potentiometer,

R73, for ALARM 1 deadband adjustment and R78 for ALARM 2 deadband

adjustment. For any setpoint, deadband is adjustable from 1% of fullscale

(counterclockwise limit) to 20% of fullscale (clockwise limit). Deadband is essentially

symmetrical with respect to setpoint.

3.7 CURRENT OUTPUT BOARD (OPTION)

The Current Output is set at the factor for 4 to 20 mA. If a 0 to 20 mA output is

required, readjust both the zero and span potentiometers (R1 and R2) on the Current

Output Board.

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

3-7

TARTUP AND CALIBRAT ION

S

RANGE

%

OXYGEN

0 to 1

0 to 1

0 to 2.5

0 to 5

0 to 10

PERCENTAGE OXYGEN READOUT

versus

ALARM SETPOINT DIAL READING

Percentage Oxygen Readout

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

Percentage Oxygen Readout

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

Percentage Oxygen Readout

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

Percentage Oxygen Readout

0 1 2 3 4 5 6 7 8 9 10

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

F

IGURE

3-2. D

Percentage Oxygen Readout

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

0 to 25

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

Percentage Oxygen Readout

0 5 10 15 20 25 30 35 40 45 50

0 to 50

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

Percentage Oxygen Readout

0 10 20 30 40 50 60 70 80 90 100

0 to 100

0 1 2 3 4 5 6 7 8 9 10

Setpoint Dial Reading

IAL SETTINGS FOR ALARM SETPOINT ADJUSTMENTS

3-8

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

O

PERATION

4

4.1 ROUTINE OPERATION

After the calibration procedure of Section 3.4, admit sample gas to the analyzer at the

same pressure and the same flow rates used for the zero and span gases. The

instrument will now continuously indicate the oxygen content of the sample gas.

4.2 EFFECT OF BAROMETRIC PRESSURE CHANGES ON

INSTRUMENT READOUT

If the analyzer exhaust port is vented through a suitable absolute backpressure

regulator, barometric pressure changes do not affect the percent oxygen readout.

However, if the analyzer exhaust port is vented directly to the atmosphere, any change

in barometric pressure after instrument standardization will result in a directly

proportional change in the indicated percentage of oxygen. This effect may be

compensated in various ways. If desired, correction may be made by the following

equation:

True % Oxygen = (Pst/Pan)(Indicated % Oxygen)

Where:

Pst = Operating pressure during standardization

Pan = Operating pressure sample analysis

Example: U.S. Units

Pst = 760 mm Hg

Pan = 740 mm Hg

Indicated % O

True % O2 = (760/740)(40%) = 41.1% O

Example: S.I. Units

Pst = 101 kPa

Pan = 98.2 kPa

Indicated % O2 = 40%

True % O2 = (101/98.2)(40%) = 41.1% O

2

2

2

748213-R Rosemount Analytical April 2000

Model 755R Oxygen Analyzer

4-1

PERATION

O

4.3 CALIBRATION FREQUENCY

The appropriate calibration interval will depend on the accuracy required in the

particular application, and is best determined by keeping a calibration log. If the

analyzer exhaust port is vented directly to the atmosphere, the greatest source of error

is normally the variation in barometric pressure. If desired, effects of barometric

pressure variation can be minimized by calibrating immediately before taking readings,

for example, at the beginning of each shift.

4-2

April 2000 Rosemount Analytical 748213-RModel 755R Oxygen Analyzer

T

HEORY

5

5.1 PRINCIPLES OF OPERATION

Oxygen is strongly paramagnetic while most other common gases are weakly

diamagnetic. The paramagnetism of oxygen may be regarded as the capability of an

oxygen molecule to become a temporary magnet when placed in a magnetic field.

This is analogous to the magnetization of a piece of soft iron. Diamagnetic gases are

analogous to non-magnetic substances.

With the Model 755R, the volume magnetic susceptibility of the flowing gas sample is

sensed in the detector/magnet assembly. As shown in the functional diagram of Figure

5-1, a dumbbell-shaped, nitrogen-filled, hollow glass test body is suspended on a